Thick steel board

A thick steel plate and steel plate technology, which is applied in the field of low yield ratio and high toughness thick steel plate, can solve the problems of low yield ratio and high toughness, and achieve the effect of low yield ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

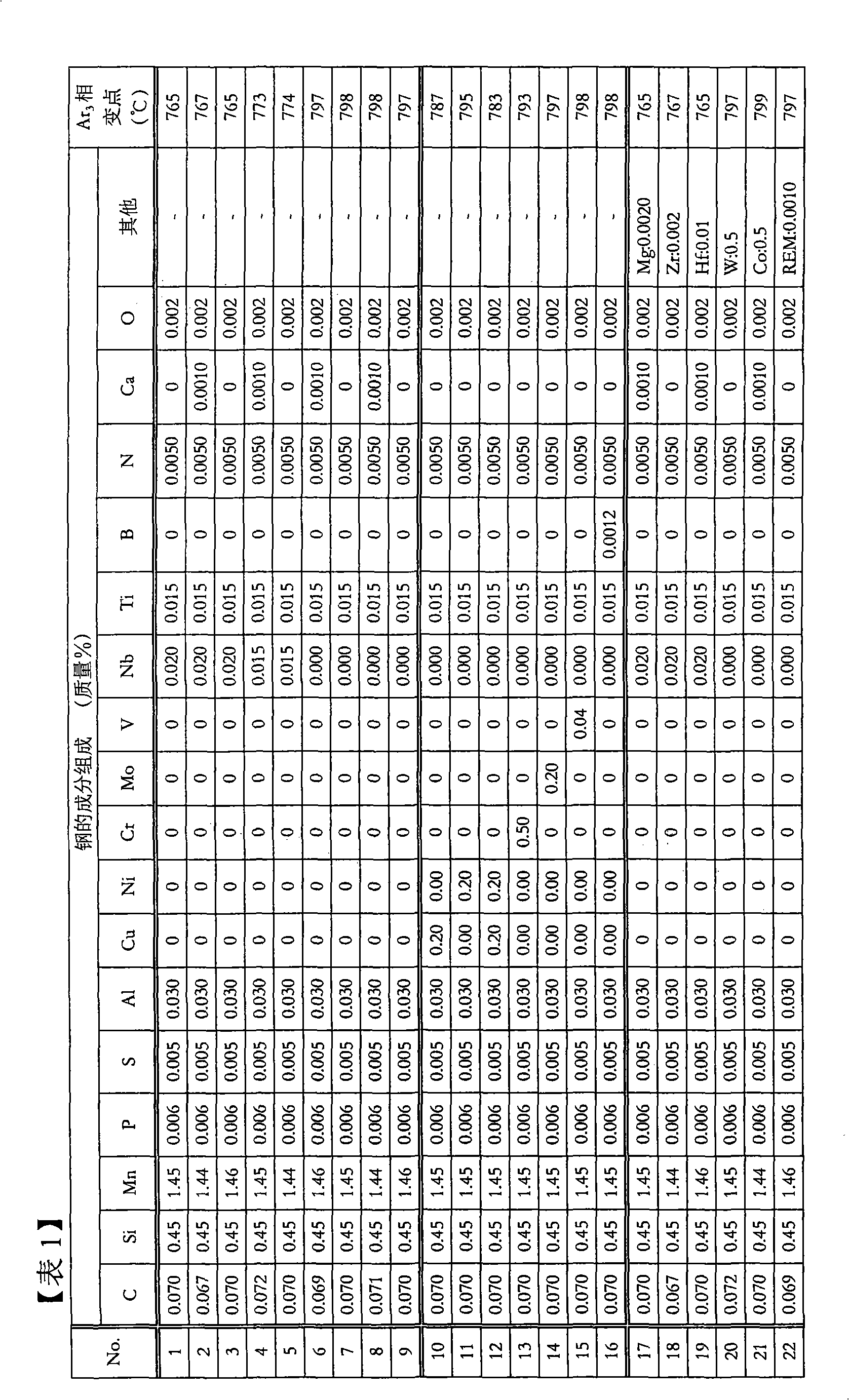

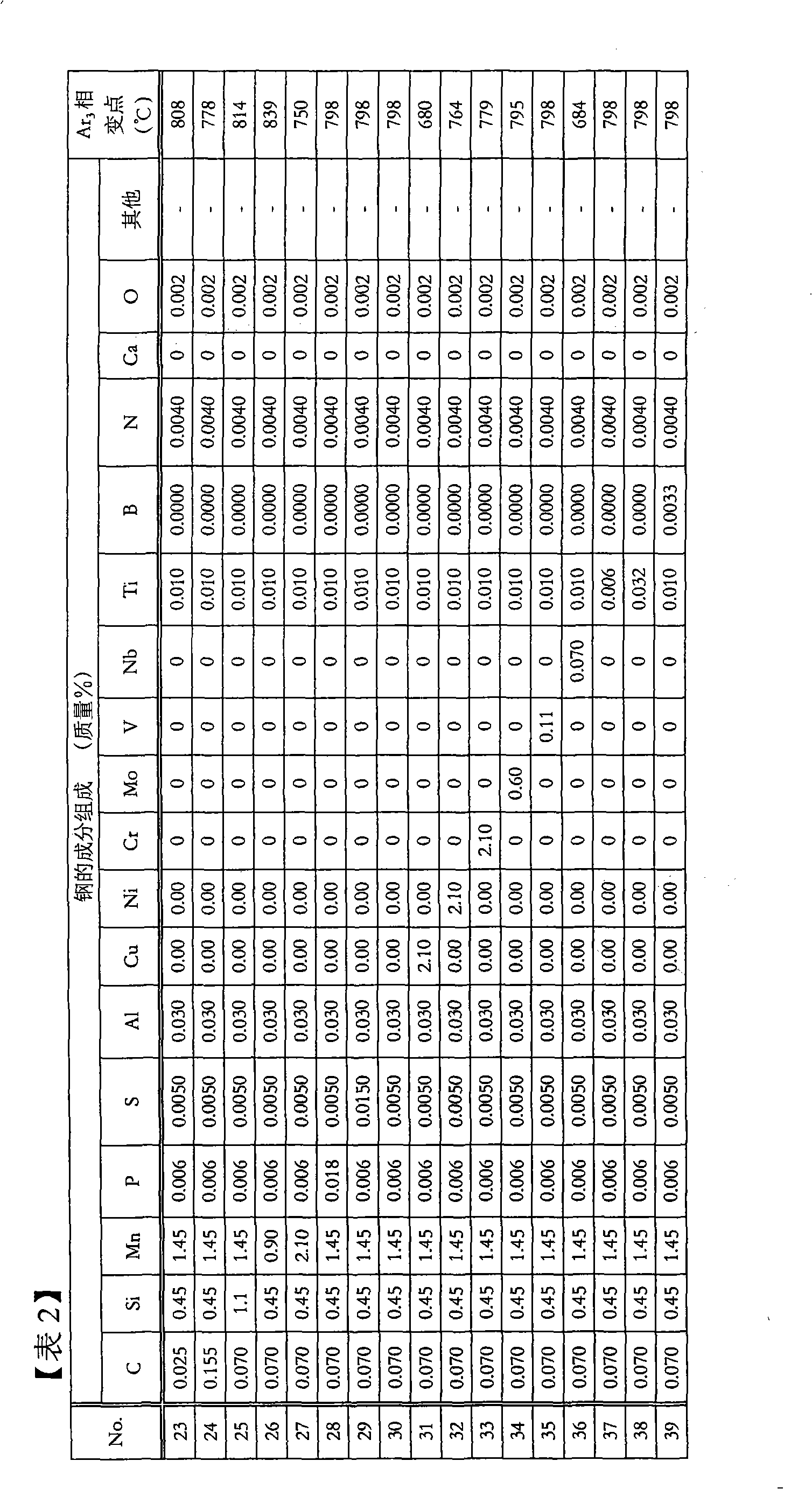

[0074] Various molten steels with the chemical composition shown in the following Tables 1 to 3 are smelted by the usual smelting method, and after cooling the molten steel to form a slab, hot rolling and cooling are performed under the conditions shown in the following Tables 4 and 5. , to obtain various steel plates (thickness: 50mm). In addition, in the following Tables 1 and 3, REM is added in the form of misch metal containing about 50% of La and about 25% of Ce. In addition, "-" in following Tables 1-3 shows that an element was not added.

[0075]

[0076]

[0077]

[0078] 【Table 4】

[0079]

[0080] 【table 5】

[0081]

[0082]

[0083] For each of the obtained steel sheets, the base metal structure (ferrite grain size, MA fraction), mechanical properties (tensile properties of the base material, impact properties of the base material) were measured by the following method, and the HAZ toughness was also measured. evaluate. The measurement results ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com