Patents

Literature

205 results about "Misch metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Misch metal, alloy consisting of about 50 percent cerium, 25 percent lanthanum, 15 percent neodymium, and 10 percent other rare-earth metals and iron. Misch metal has been produced on a relatively large scale since the early 1900s as the primary commercial form of mixed rare-earth metals.

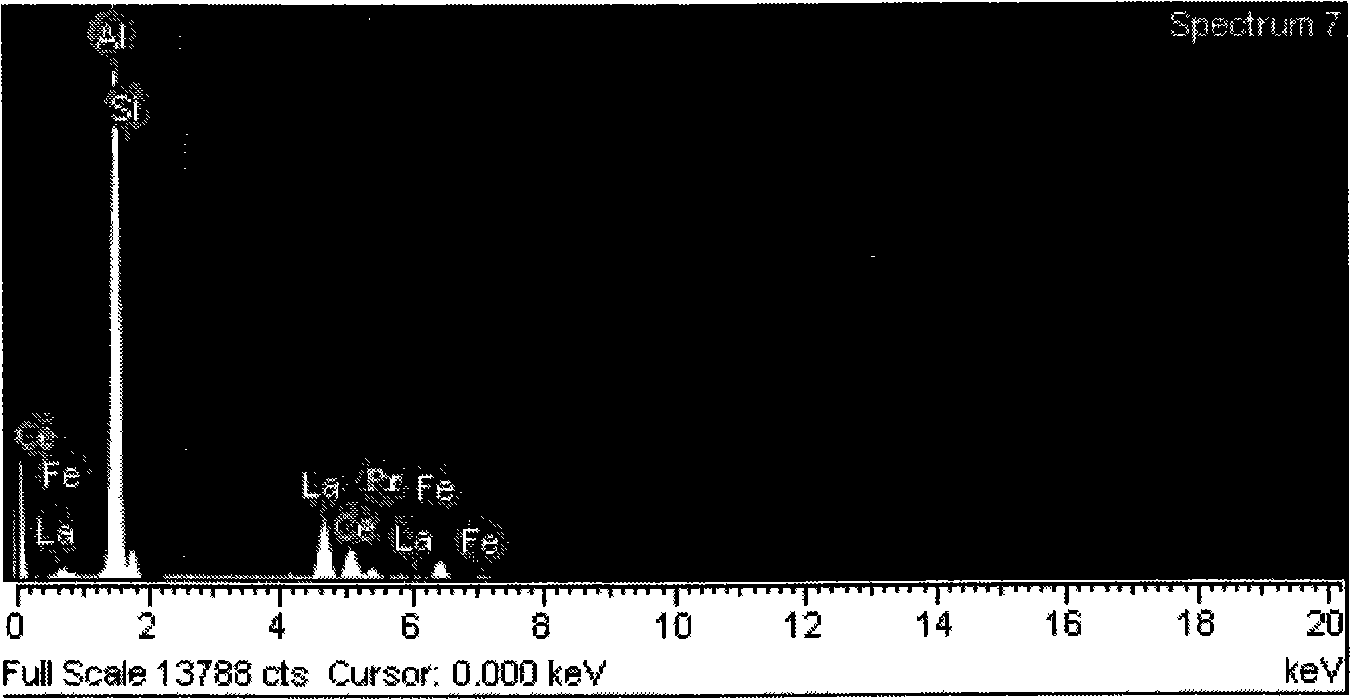

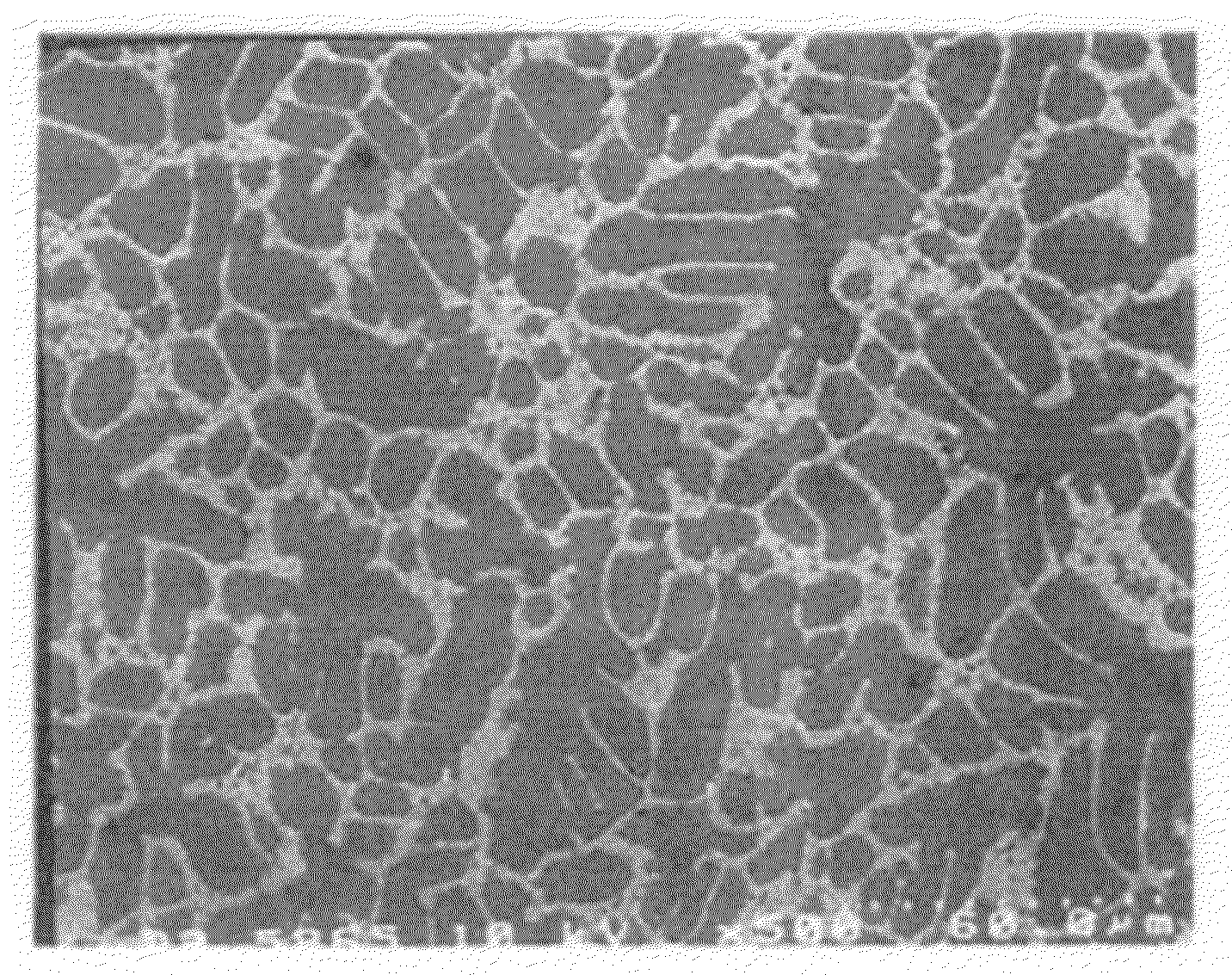

Heat resisting low expansion silumin and preparation thereof

The invention belongs to the field of non-ferrous materials and preparation and formation thereof, and relates to heat-resisting low-expansion high-silicon cast aluminum alloy. The alloy comprises the following compositions in percentage by mass: 18 to 25 percent of silicon, 1.0 to 2.5 percent of copper, 0.2 to 0.8 percent of magnesium, 0.5 to 2.5 percent of nickel, 0.3 to 0.6 percent of manganese, 0.3 to 1.0 percent of misch metal RE (the content of cerium is more than 40 percent), 0.006 to 0.04 percent of phosphorus, and the balance of aluminum. The production method comprises: firstly, melting raw materials of copper, nickel, silicon and aluminum into an aluminum silicon alloy fused mass; secondly, re-superheating the aluminum silicon alloy fused mass to the temperature of between 850 and 870 DEG C, adding manganese raw materials, and obtaining a mixed fused mass after uniform melting; thirdly, adjusting the temperature of the mixed fused mass to between 780 and 800 DEG C and adding the magnesium into the mixed fused mass; fourthly, adding rare earth raw materials into the mixed fused mass, maintaining at the temperature for 10 to 15 minutes, and raising the temperature to between 820 and 840 DEG C; fifthly, performing refining; and sixthly, raising the temperature of the refined mixed fused mass to between 830 and 850 DEG C, adding phosphorus raw materials into the mixed fused mass for modification, maintaining at the temperature for 15 to 20 minutes after modification, and performing casting, wherein the casting temperature is between 790 and 830 DEG C. Castings can well meet the performance requirements of peripheral materials of automobile engines after T6 heat treatment.

Owner:HUAZHONG UNIV OF SCI & TECH

Ultra-fine aluminum alloy wire and preparation method thereof

ActiveCN102021442AImprove electrical performanceGood flexibilitySingle bars/rods/wires/strips conductorsMetal/alloy conductorsMisch metalRare earth

The invention discloses a preparation method for an ultra-fine aluminum alloy wire. The aluminum alloy wire comprises the following elements such as Al, Fe, Mg, Cu and Sb, and also comprises 0.1 to 1.2 weight percent of misch metal. The aluminum alloy material has high strength and high stretchability and can be drawn into a 0.1 mm or finer aluminum alloy wires by smelting, line-casting, rolling and drawing; and the aluminum alloy wire can be used for an insulated flexible line, an electrical cable, an electromagnetic line, an electrical equipment line, a vehicle wire, a communication cable line and the like.

Owner:安徽中青欣意铝合金电缆有限公司

Ni-base brazing alloy

InactiveUS6696017B2Influences the melting point of the obtained alloyHigh strengthWelding/cutting media/materialsSoldering mediaMisch metalBraze alloy

The present invention relates to a Ni-base brazing alloy. The alloy has a good wettability toward a material to be brazed when melting, an excellent corrosion resistance and a high strength. The alloy is used for process of joining two pieces of metal such as stainless steel. The alloy contains Cr in an mount of 25 to 35% by weight, P in an amount of 4 to 8% by weight, Si in an amount of 3 to 6% by weight, wherein the total amount of P and Si is 9 to 11.5% by weight, at least one selected from a group consisting of Al, Ca, Y and misch metal in an amount of 0.01 to 0.10% by weight, and the balance of Ni and unavoidable impurities.

Owner:FUKUKA METAL FOIL & POWDER CO LTD

High-strength high-conductivity oxidation-resisting low-silver copper-base alloy and preparation thereof

A copper base alloy, which possesses high-strength, high conductivity, oxidation resistance and contains silver of low content, is characterized in that said high-strength high-conductivity oxidation-resistance low-silver copper base alloy is composed of low-silver copper base alloy powder, diamond powder of 0.2-1.0% and graphitized nanometer carbon fibre and is prepared through a powder metallurgy technological process, wherein said low-silver copper base alloy powder contains Ag of 0.08 -0.12%, Y, La and Ce of 0.05 -0.5% or one of misch metal or mixture of several misch metal. Said alloy in accordance with the present invention possesses higher intensity and hardness, stronger anti-crackle forming and stomatic expandability, and exhibits definite puddle welding resistance and better electroconductive performances at the same time.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Zinc-aluminium alloy silk containing rare earth and producing process thereof

The present invention is RE containing Zn-Al alloy wire and its preparation process, and the RE containing Zn-Al alloy is used as the end spraying material for metallized film capacitor. The RE containing Zn-Al alloy contains Al 4-16 wt%, RE mixture with light RE as main components 0.01-0.12 wt%, and impurity not more than 0.025 wt% except Zn. The preparation process includes pouring Al molt into Zn molt, raising the temperature for melting while stirring, adding intermediate RE alloy, and smelting while stirring to obtain the RE containing Zn-Al alloy. The RE containing Zn-Al alloy wire of the RE containing Zn-Al alloy has compact structure, improved machining performance and use performance, and improved welding condition.

Owner:戴国水

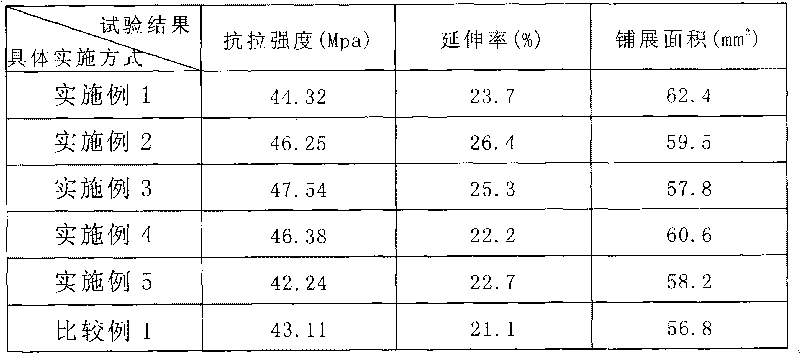

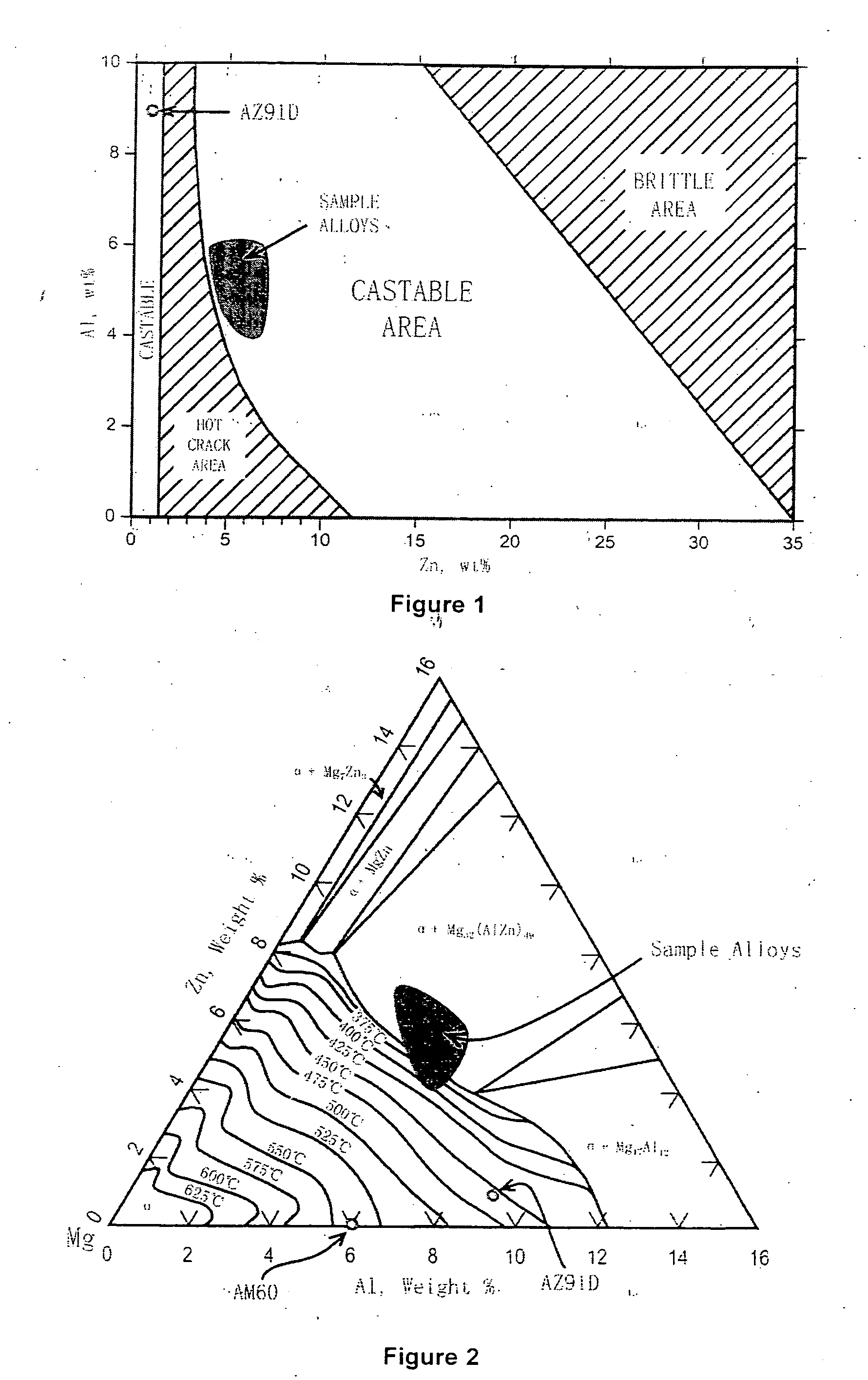

Die casting magnesium alloy and magnesium die casting

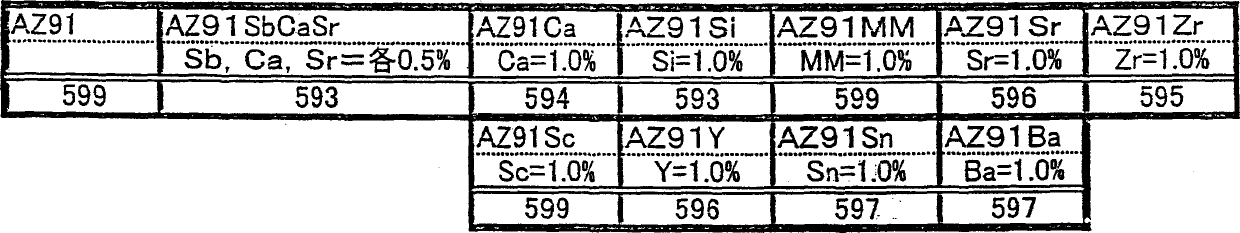

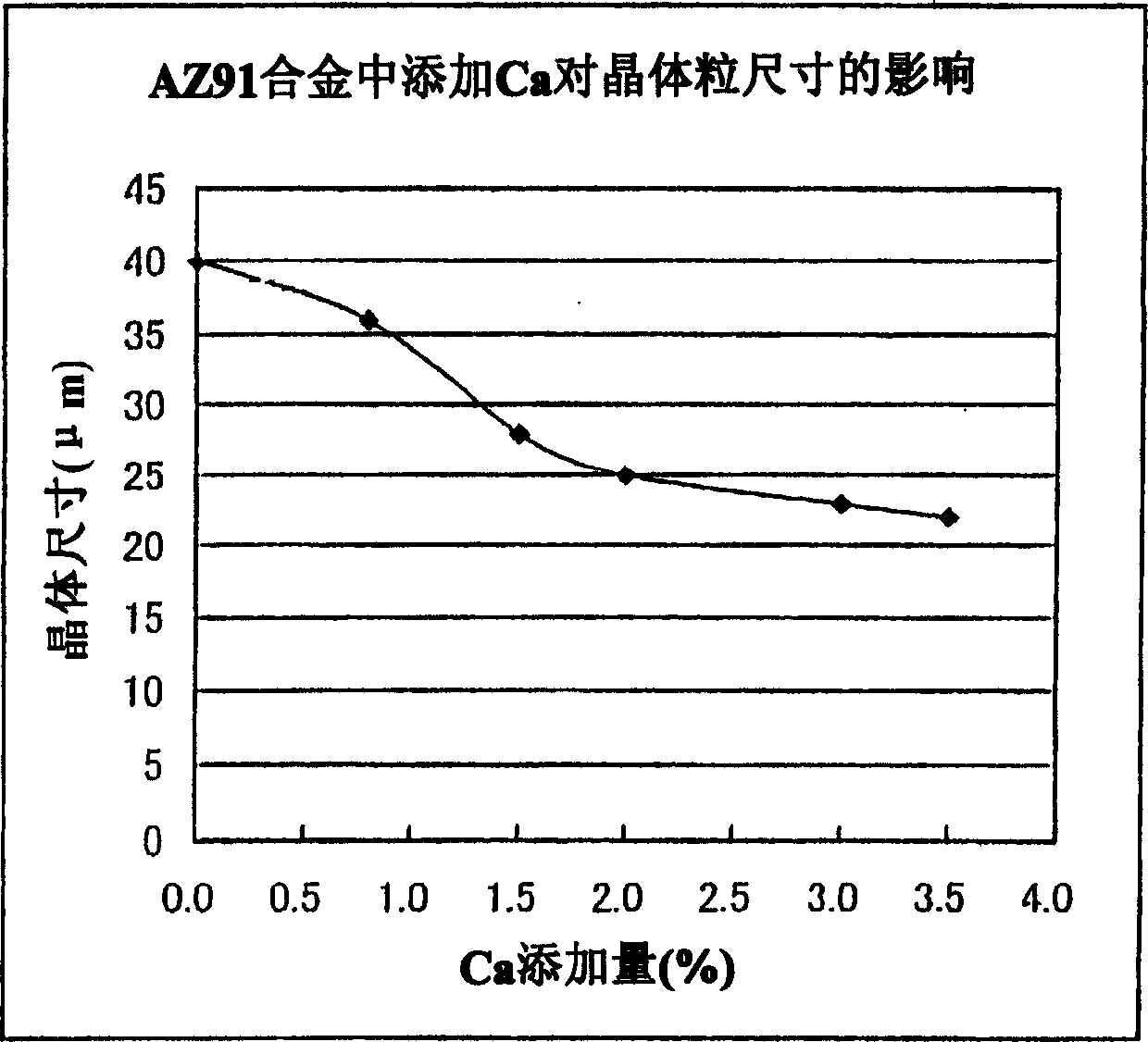

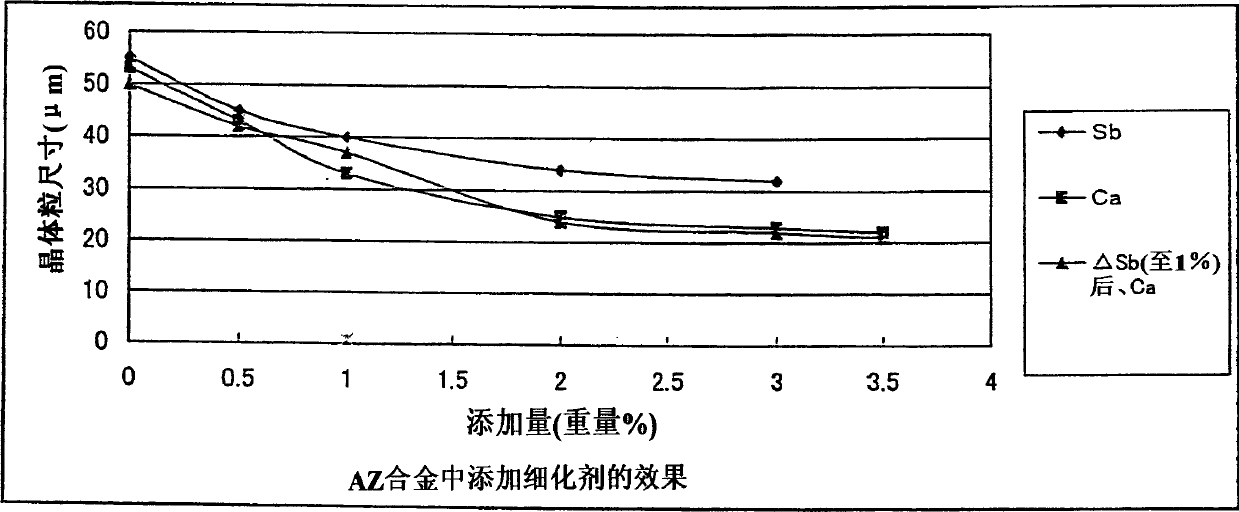

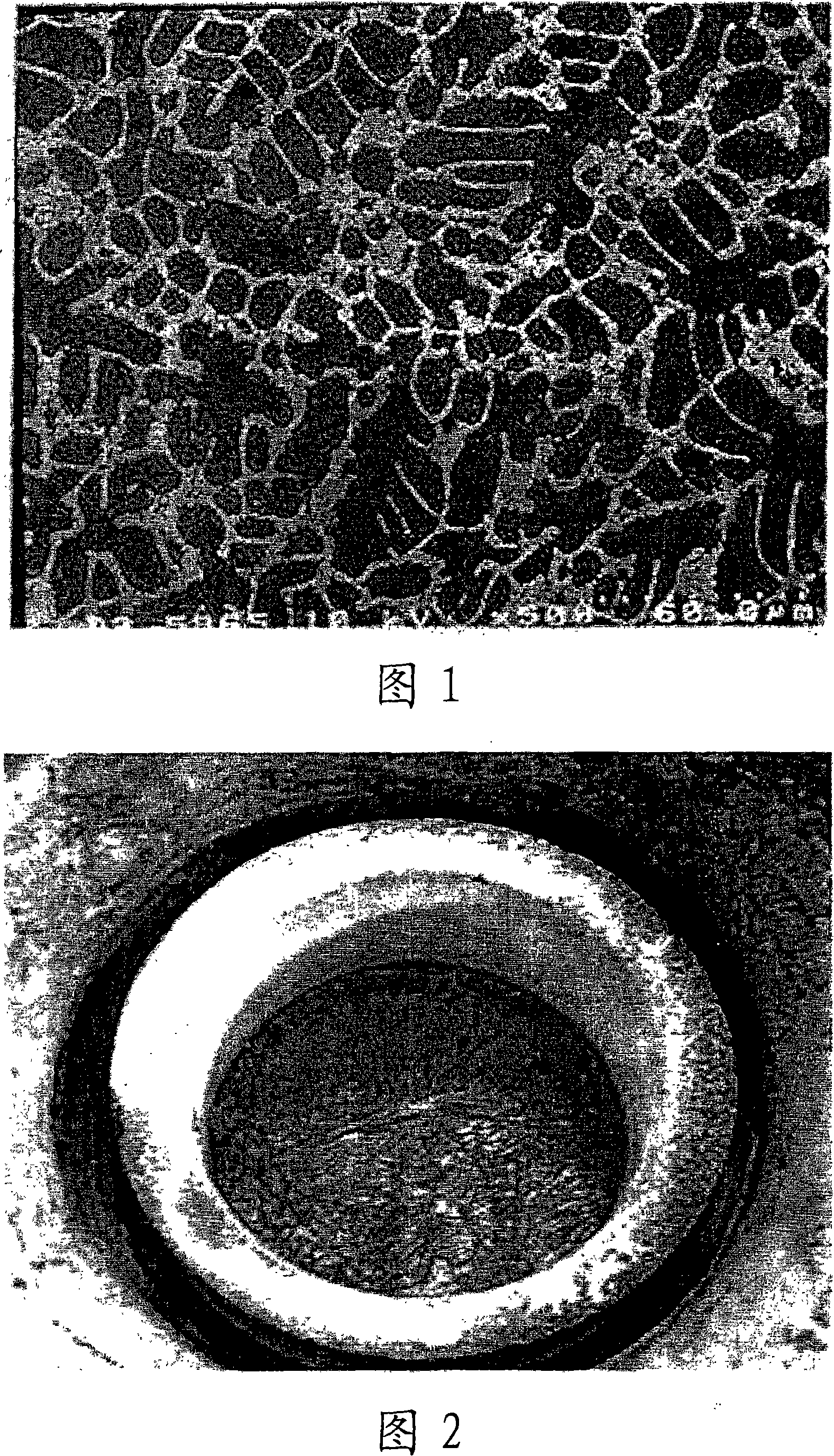

InactiveCN1637160ALarge particle sizePrevention of reduction in strength characteristicsUnderwater structuresReceptacle cultivationRare-earth elementMischmetal

The invention provides a magnesium alloy for die-casting that can improve the high-temperature creep performance without reducing the strength at room temperature, and a magnesium die-cast product using the alloy. Manufacture of magnesium die-casting products using a magnesium alloy for die-casting, wherein the magnesium alloy for die-casting is an AZ91 series alloy of 6.0 to 11.0% by weight of aluminum, 0.1 to 2.5% by weight of zinc, and 0.1 to 0.5% by weight of manganese, and added silicon: 0.1 to 1.5% by weight 1. At least one of misch metal containing rare earth elements: 0.1-1.2% by weight, zirconium: 0.2-0.8% by weight, made into an AZ91-based matrix alloy, and adding 0.1-1.5% by weight of antimony to the AZ91-based matrix alloy and at least one of 0.05 to 3.5% by weight of calcium, and 0.1 to 2.5% by weight of strontium, and other components are unavoidable components.

Owner:ADVANCED TECH +1

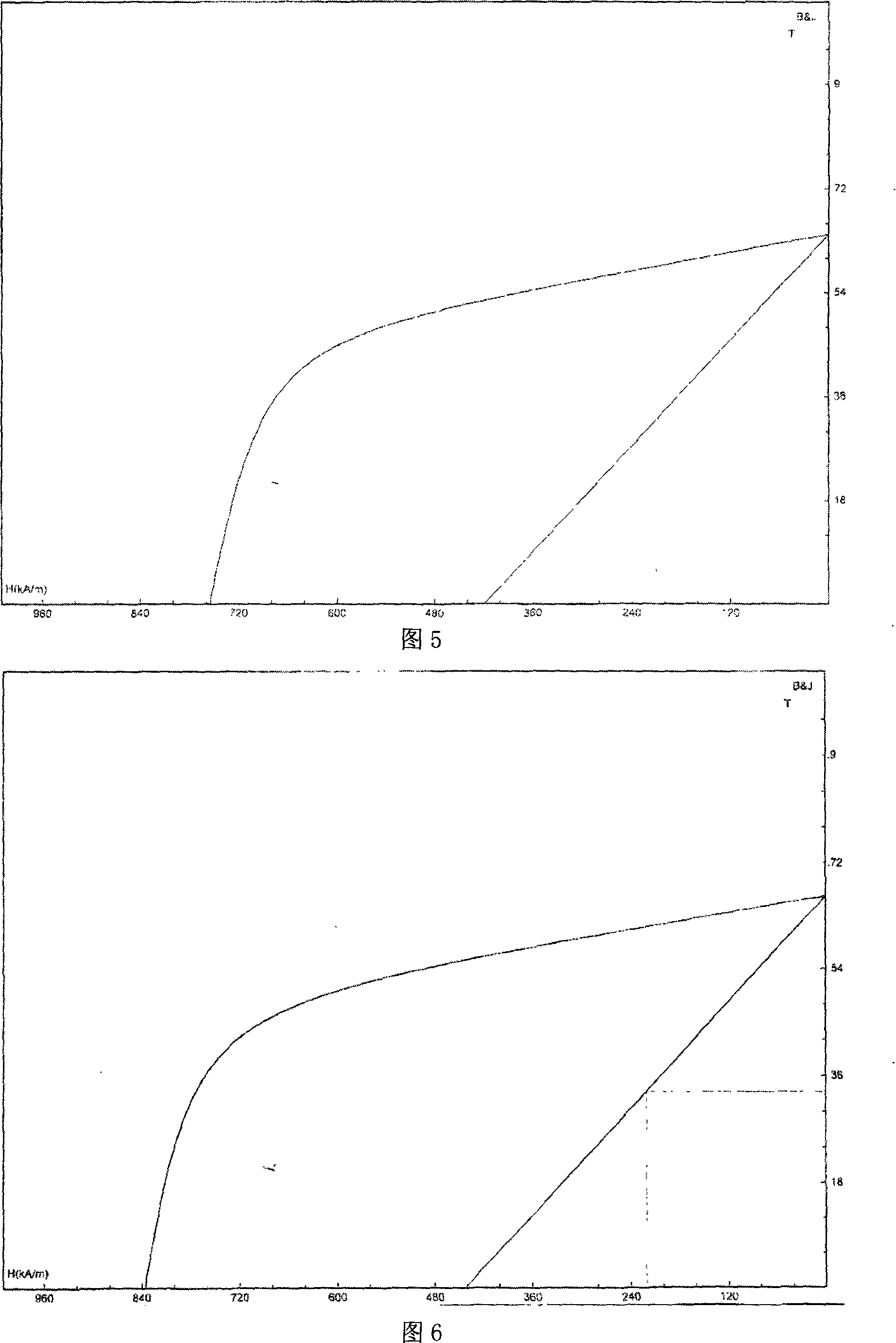

Low-cost permanent magnet prepared from misch metal (MM) and preparation method thereof

ActiveCN103035350AAchieve cost controlImprove magnetic propertiesPermanent magnetsInductances/transformers/magnets manufactureMischmetalMisch metal

The invention discloses a low-cost permanent magnet prepared from misch metal (MM) and a preparation method thereof. An atomic fraction formula of the permanent magnet is MMxNdy(Fe1-zMz)100-x-y-wBw, wherein MM is misch metal, comprising the following components: more than 48% of Ce, 20-35% of La, 10-20% of Nd, 4-7% of Pr and the balance of Fe, Si, S and the like; M is one or more of Nb, V, Ti, Co, Cr, Mo, Mn, Ni, Ga, Zr, Ta, Ag, Au, Al, Pb, Cu and Si; x plus y is more than or equal to 14.5, but less than or equal to 17.5; x / y is more than or equal to 1 / 3, but less than or equal to 1; z is more than or equal to 0.1, but less than or equal to 5; and w is more than or equal to 5, but less than or equal to 8.5. The permanent magnet provided by the invention substitutes Nd by using a low-cost MM part, and a grain boundary improving element and an indissolvable element are matched and doped with Fe, so that the cost is reduced to meet a market demand on the premise of ensuring certain magnetic performance.

Owner:ZHEJIANG UNIV

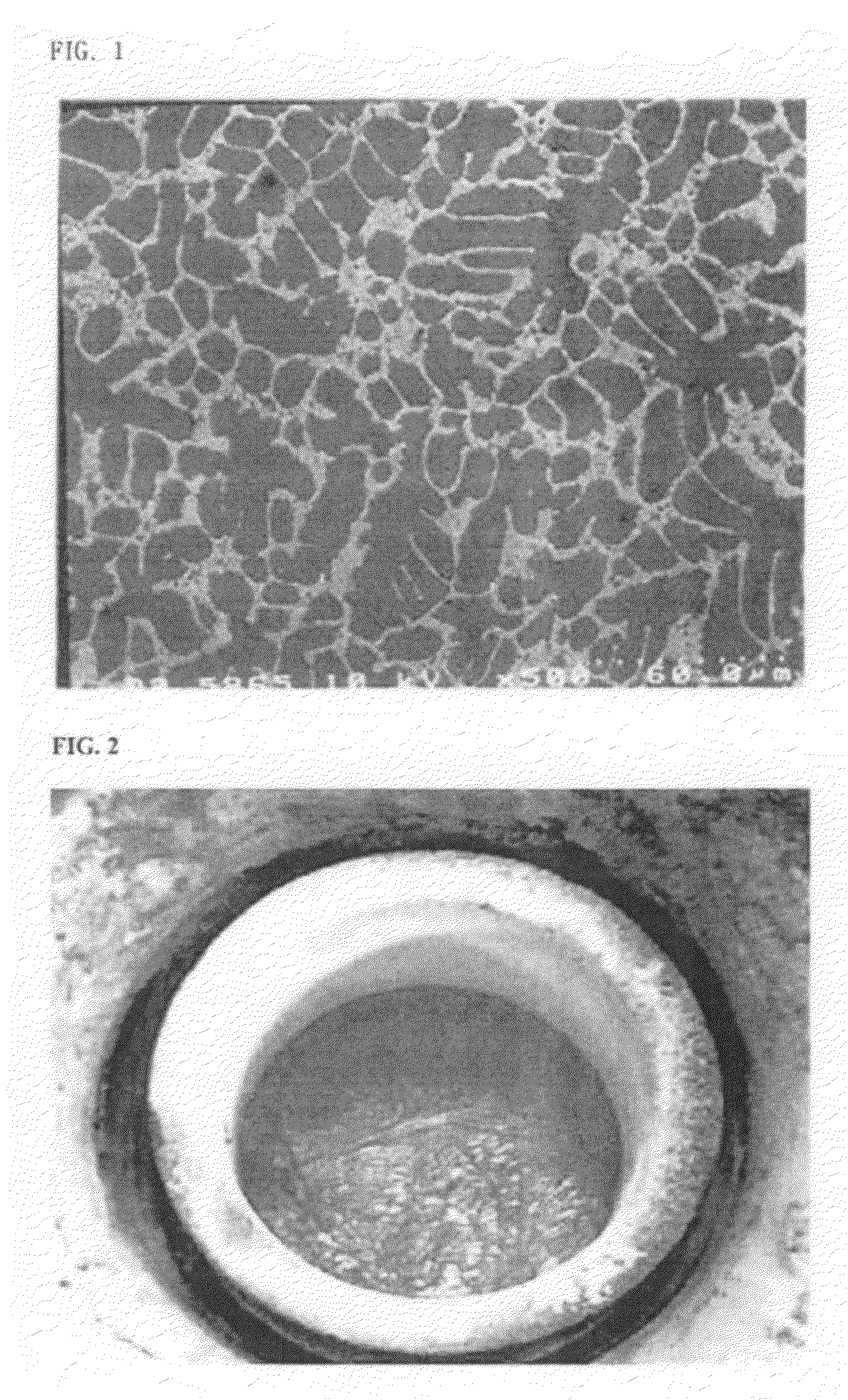

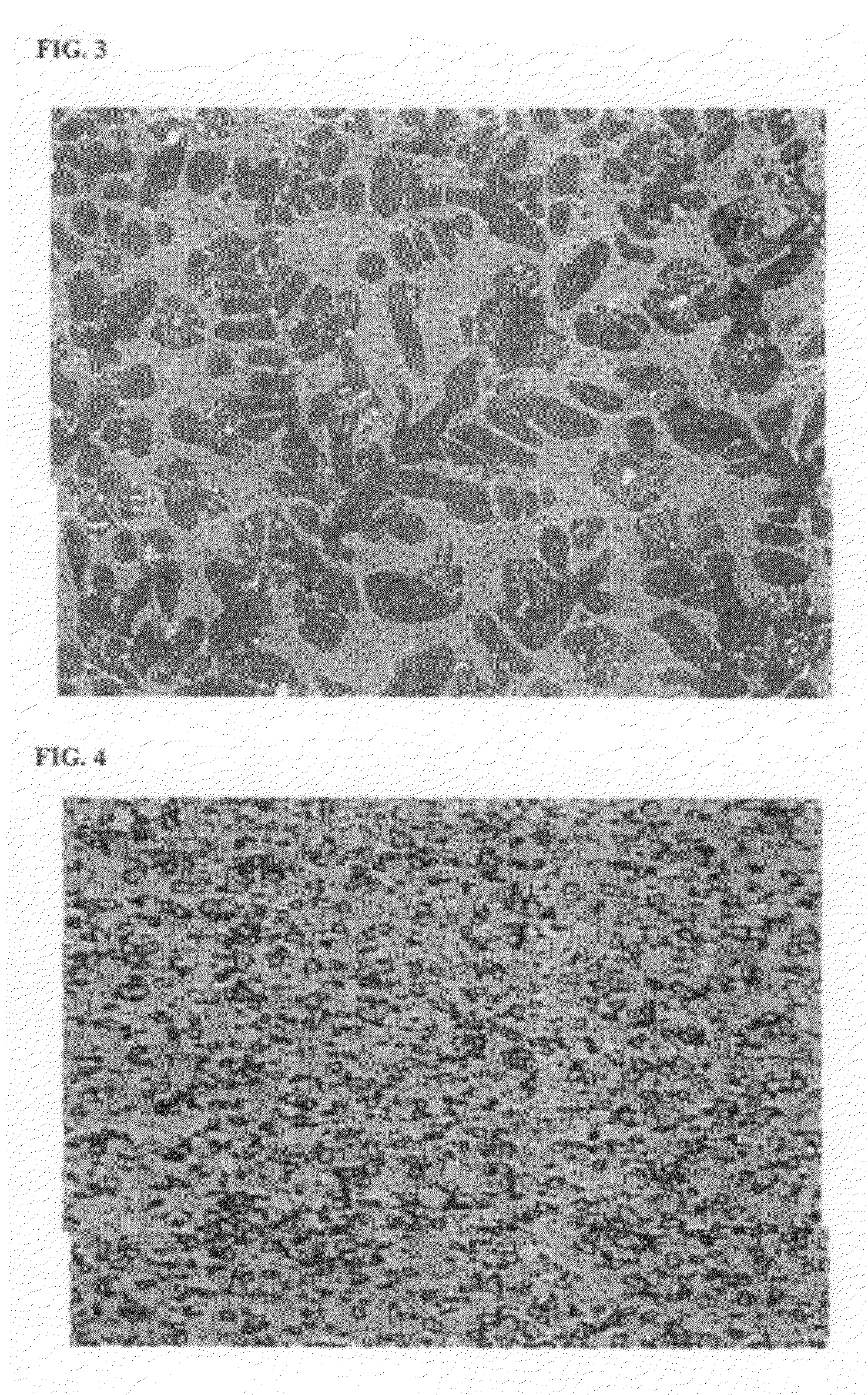

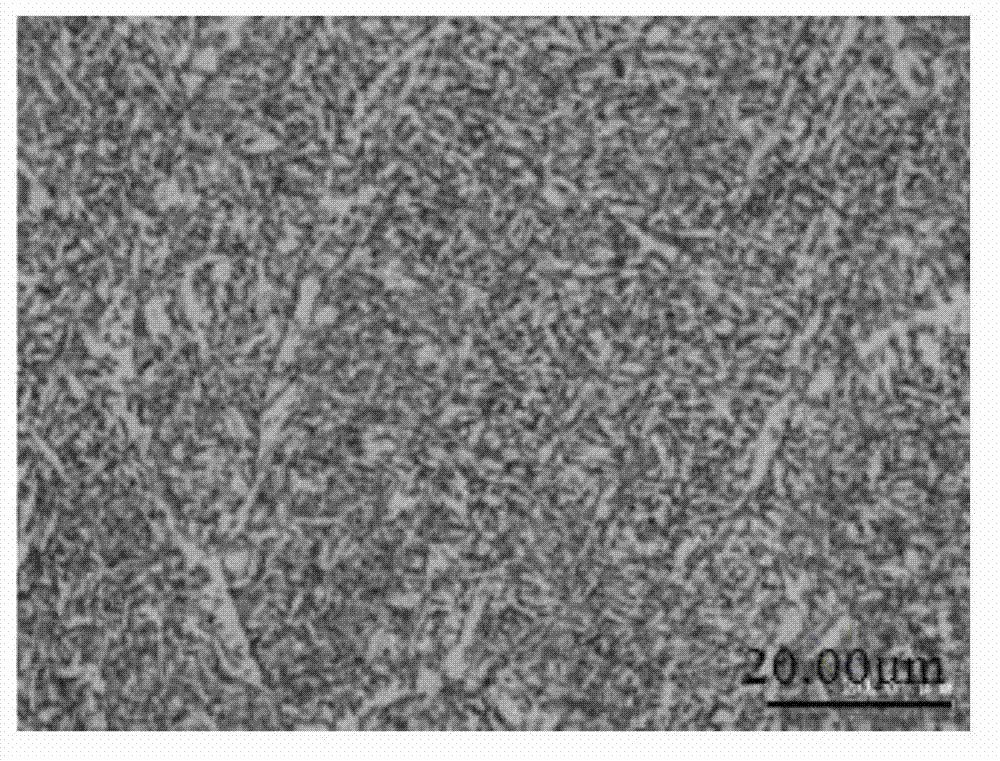

Mg alloys containing misch metal, manufacturing method of wrought mg alloys containing misch metal, and wrought mg alloys thereby

There are provided a magnesium alloy with a misch metal, a method of producing a wrought magnesium alloy with a misch metal, and a wrought magnesium alloy produced thereby, in which a great deal of misch metal is added to magnesium, and thus refractory eutectic phases or multi-phases are formed into a stable network structure or a stable dispersed phase, thereby inhibiting deformation of a magnesium matrix at a high temperature to maintain a high strength. The magnesium alloy with the misch metal has the formula of Mg100-x-y-z AxByCz , where A is zinc (Zn) or aluminum (Al); B is the misch metal; C is at least one element selected from the group consisting of manganese (Mn), nickel (Ni), copper (Cu), tin (Sn), yttrium (Y), phosphor (P), silver (Ag), and strontium (Sr); and x, y and z are the compositions of 0 at% = x =6 at%, 0.8 at% = y =7 at%, and 0 at% = z =2 at%, respectively.

Owner:GALLOY TECH

High-performance electrophoresis aluminum alloy construction section bar and method for making same

InactiveCN101298644AUnique featuresReduce adhesionAnodisationElectrophoretic coatingsMisch metalElectrophoresis

The invention discloses an electrophoretic aluminum alloy building proximate matter with high performance and a preparation method thereof, and belongs to the technical field of aluminum alloy application. The electrophoretic aluminum alloy building proximate matter consists of following ingredients by mass: 0.5 to 0.54 percent of Mg, 0.4 to 0.44 percent of Si, 0.04 to 0.08 percent of RE, 0.01 to 0.02 percent of Ti, 0.002 to 0.004 percent of B, 0 to 0.2 percent of Fe and remaining aluminum. The preparation method of the electrophoretic aluminum alloy building proximate matter consists of following steps: a misch metal ingot, an alloy of Al, Ti and B, and a pure aluminum ingot are smelted into a refining and modifying agent of RE, Al, Ti and B; the refining and modifying agent is added during an alloy smelting process and cast into an aluminum rod; the electrophoretic proximate matter with high performance is prepared by techniques of squeeze aging and oxidizing electrophoresis, etc. By utilizing rare earth to subdivide second-phase particles, electrophoretic paint films of the proximate matter that are obtained by improving surface processing performance have higher uniformity, adhesive attraction, wear resistance, corrosion resistance and large film thickness than common proximate matters, and can be widely used for aluminum alloy doors and windows of buildings and curtain walls.

Owner:CHENGDU SUNSHINE ALUMINUM

Mg Alloys Containing Misch Metal Manufacturing Method of Wrought Mg Alloys Containing Misch Metal, and Wrought Mg Alloys Thereby

There are provided a magnesium alloy with a misch metal, a method of producing a wrought magnesium alloy with a misch metal, and a wrought magnesium alloy produced thereby, in which a great deal of misch metal is added to magnesium, and thus refractory eutectic phases or multi-phases are formed into a stable network structure or a stable dispersed phase, thereby inhibiting deformation of a magnesium matrix at a high temperature to maintain a high strength. The magnesium alloy with the misch metal has the formula of Mg100-x-y-gAxByCz, where A is zinc (Zn) or aluminum (Al); B is the misch metal; C is at least one element selected from the group consisting of manganese (Mn), nickel (Ni), copper (Cu), tin (Sn), yttrium (Y), phosphor (P), silver (Ag), and strontium (Sr); and x, y and z are the compositions of 0 at %≦x≦6 at %, 0.8 at %≦y≦7 at %, and 0 at %≦z≦2 at %, respectively.

Owner:G ALLOY TECHNOLOGY CO LTD

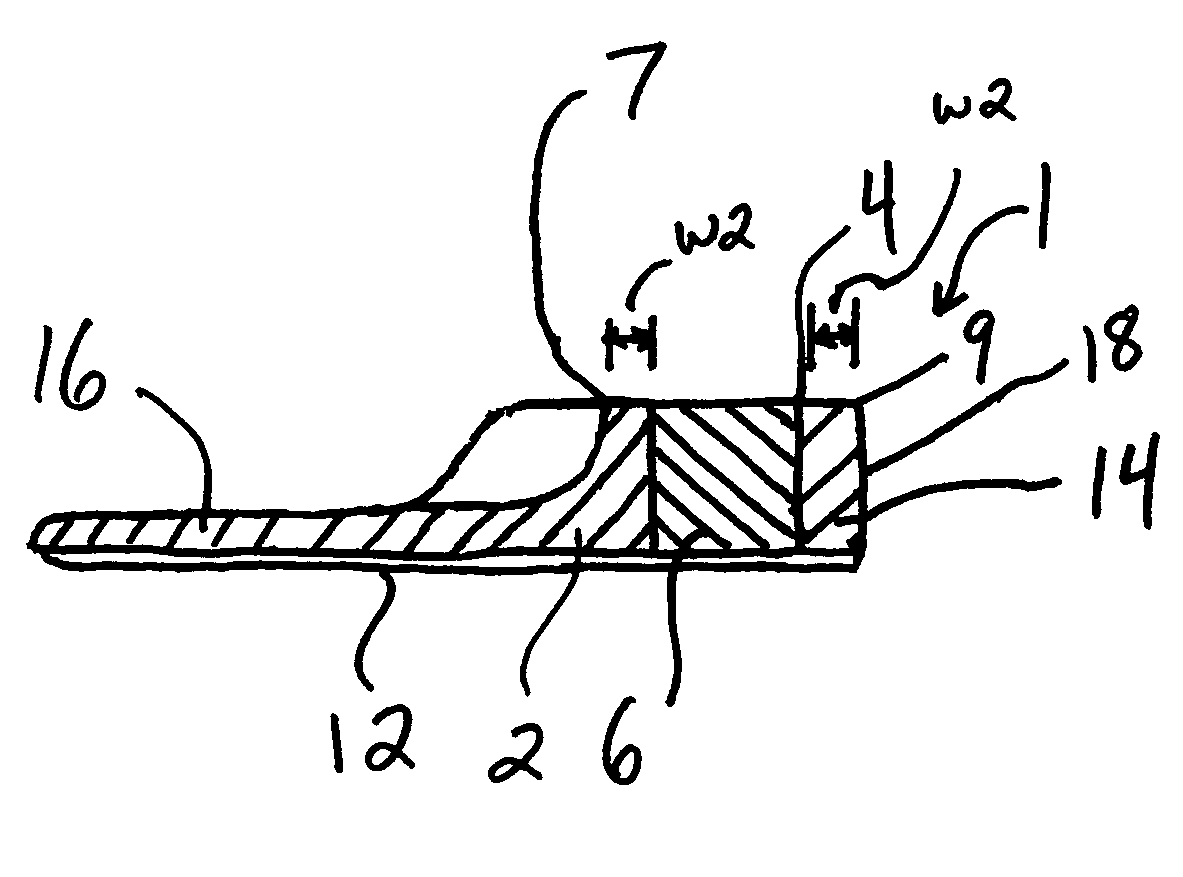

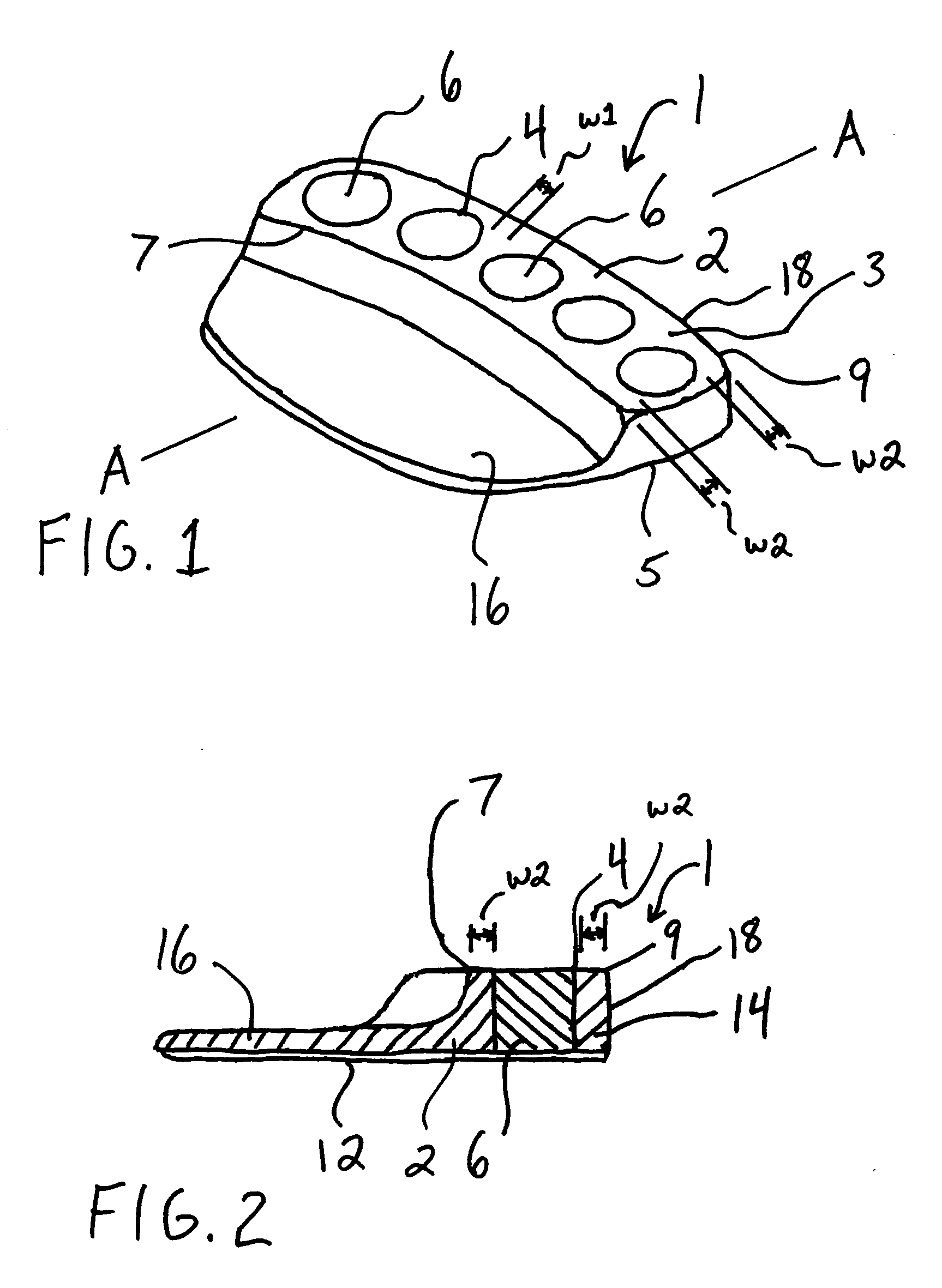

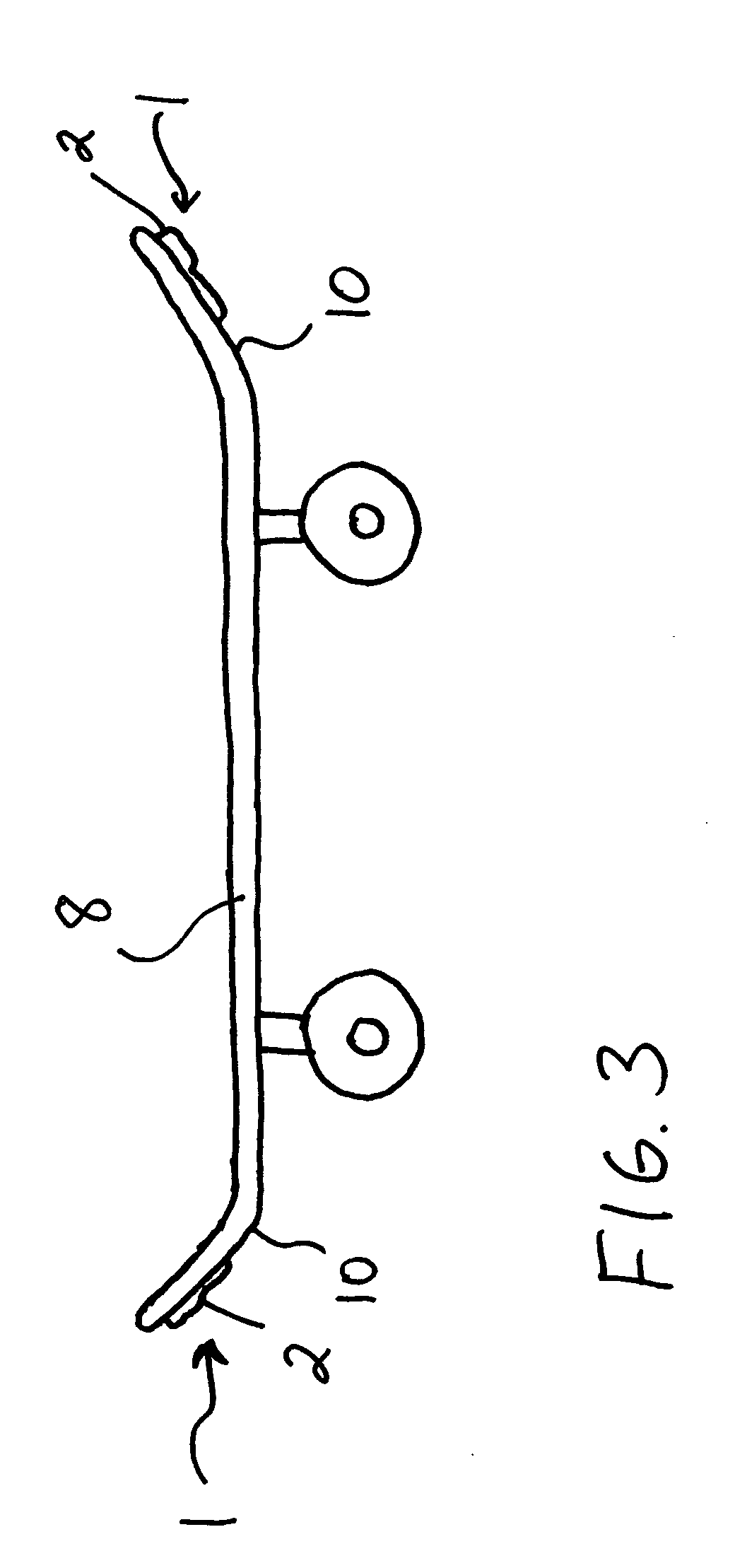

Spark-emitting device for a skateboard

A spark-emitting device for a skateboard. The spark-emitting device includes a housing and a plurality of misch metal barrels inserted into a housing and spaced apart so that the wear rate of the housing in the misch metal barrels is compatible and a desired sparking effect is achieved.

Owner:RICHARDSON BRYSON +1

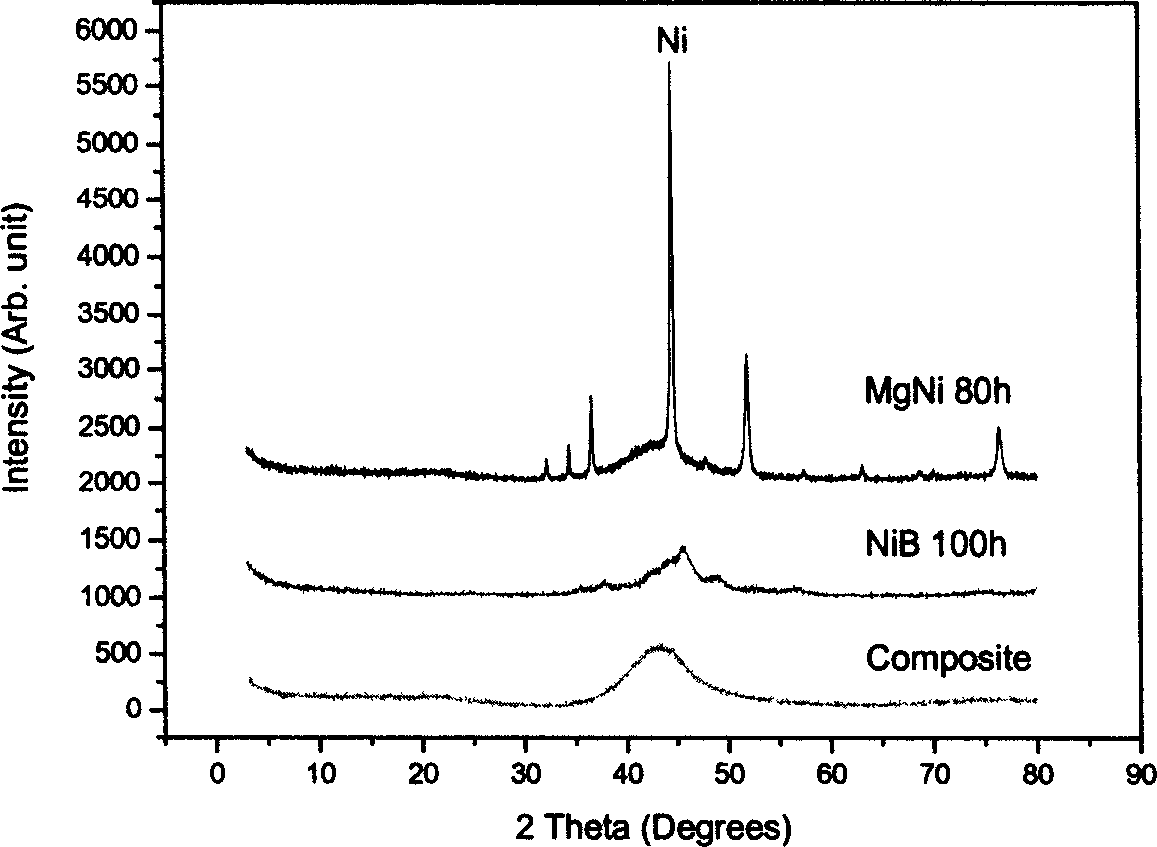

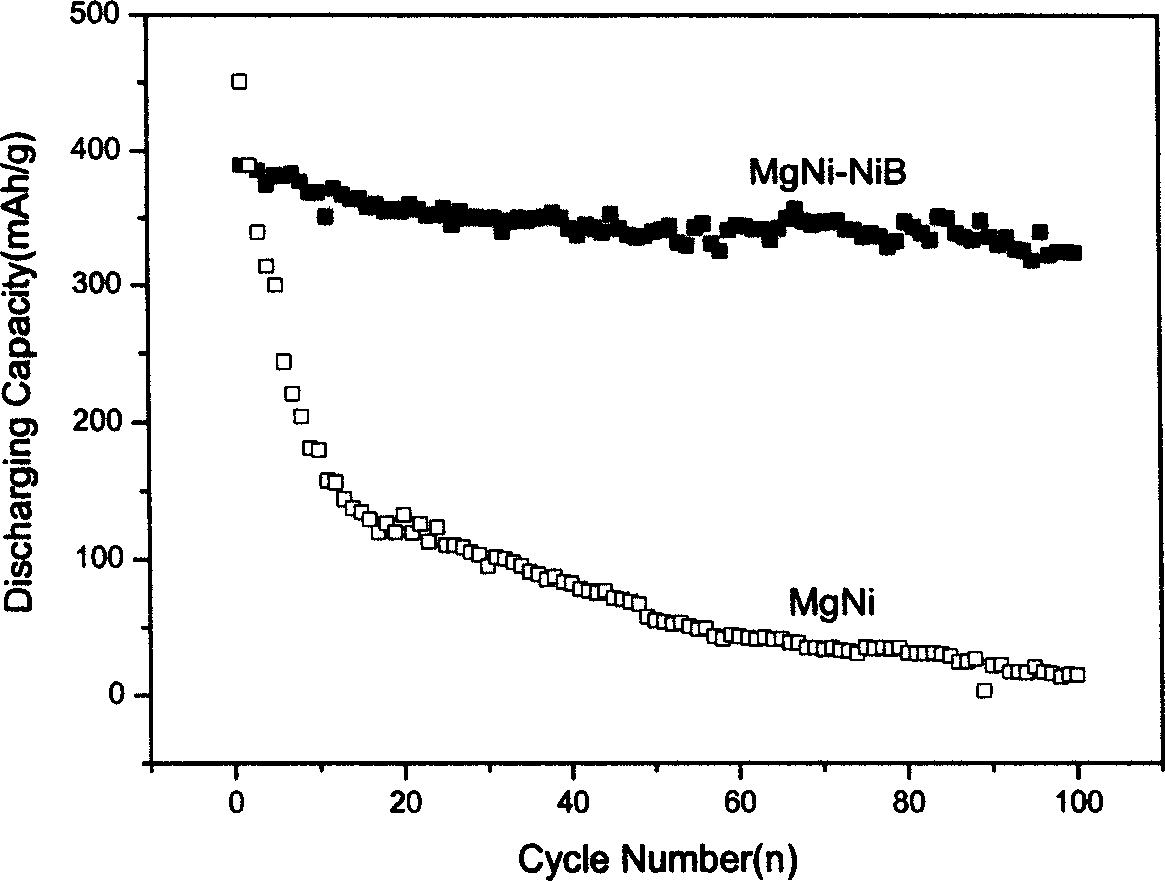

Magnesium based hydrogen storing alloy composite material and production thereof

The invention is about Mg-base hydrogen storage material and the method of the procedure. It has the chemical composition of Mgp-xMxNi-yNy-NieBf, M has the alternative of Al, Mn, Sn, Ca, Li, B, Na, B, Na, K, La, Ce, Nd, Pr, Y and misch metal. N has the alternative of V, Cu, Ti, Co, Fe, Ag, Cr, Zr, Se, Nb, Mo, W, Nb, C, Si and Sn, 1.0 <=p<=2.5, 0<=x<=1.0, 0<=y<=0.8, 1<=e<=3, 1<=f<=3. It has a good property under normal temperature and pressure, the electric pole that made by it has a high galvano-chemistry capability and cycle life. Its advantages include stable property; low price; extensive use of Ni-H battery, H accumulator, H power auto and fuel battery.

Owner:NANKAI UNIV

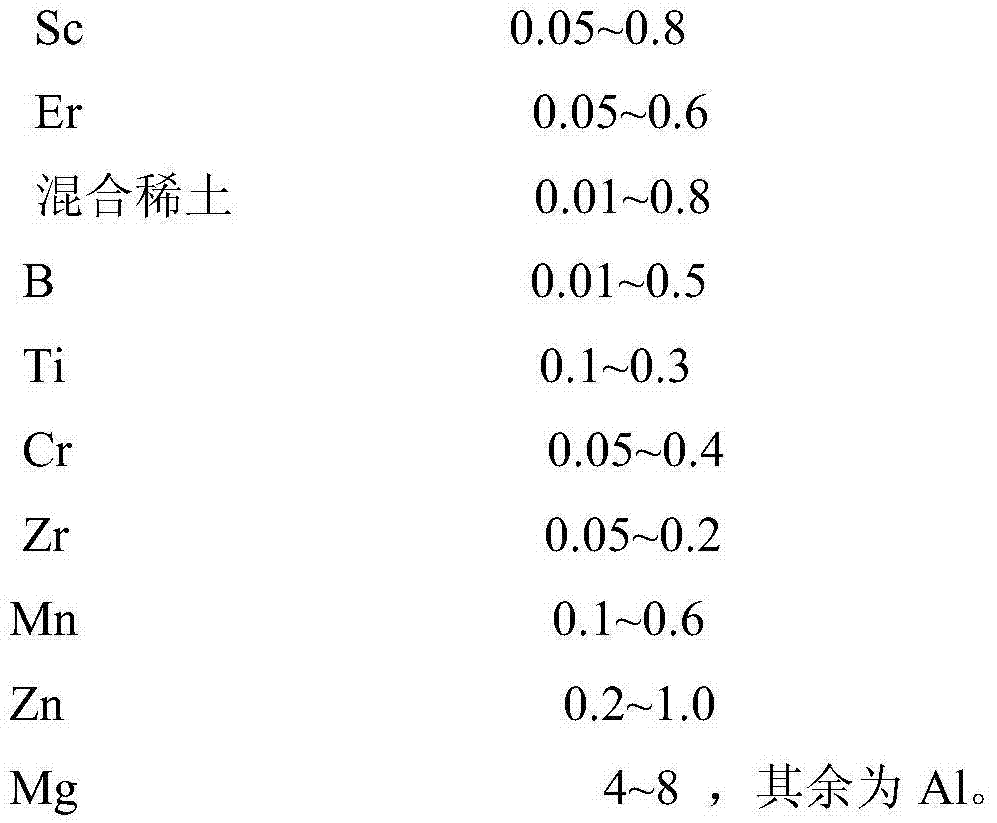

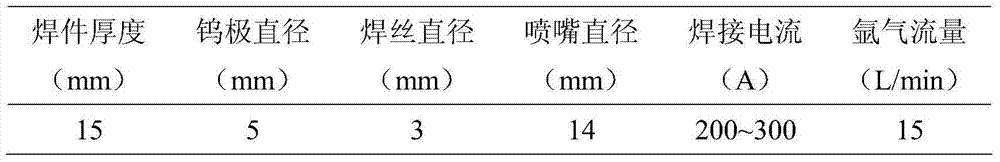

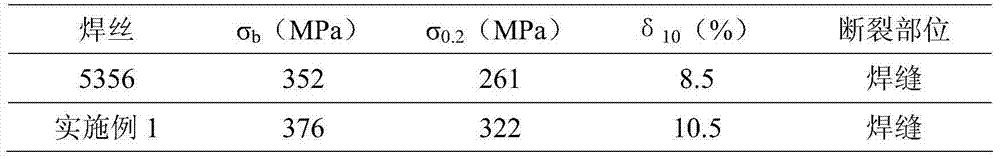

Ultra-fine grain aluminum alloy gold welding wire and preparation method thereof

InactiveCN104722945AQuality improvementImprove welding effectWelding/cutting media/materialsSoldering mediaMisch metalIngot casting

The invention relates to an ultra-fine grain aluminum alloy gold welding wire and a preparation method of the ultra-fine grain aluminum alloy gold welding wire. The ultra-fine grain aluminum alloy gold welding wire includes the following components: SC 0.05%-0.8%, Er 0.05%-0.6%, misch metal 0.01%-0.8%, B 0.01%-0.5%, Ti 0.1%-0.3%, Cr 0.05%-0.4%, Zr 0.05%-0.2%, Mn 0.1%-0.6%, Zn 0.2%-1.0%, Mg 4%-8%, and the rest is Al. The preparation method is as follows: adding an aluminum ingot or the molten aluminum into a semi-closed reverberatory furnace firstly; adding Mn, Ti, Zr, Cr and Zn; adding B and the misch metal; conducting the furnace refining on the alloy melt; slagging the alloy melt after the refining; pressing Mg into the alloy melt after stewing; adjusting the temperature of the melt for standby; pouring the melt in an electromagnetic continuous casting machine; preparing an aluminum alloy ingot casting; lifting up the aluminum alloy ingot casting for homogenizing annealing and scalping for standby; putting the aluminum alloy ingot casting into an extrusion die for extrusion, extruding an aluminum alloy wire disc; and conducting wire drawing till the specification and the diameter reach the standard and using. The ultra-fine grain aluminum alloy gold welding wire can effectively improve the structural strength of a welding structure and the welding performance, and overcomes the welding defects of the low strength of an aluminum alloy welding joint and welding cracks.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

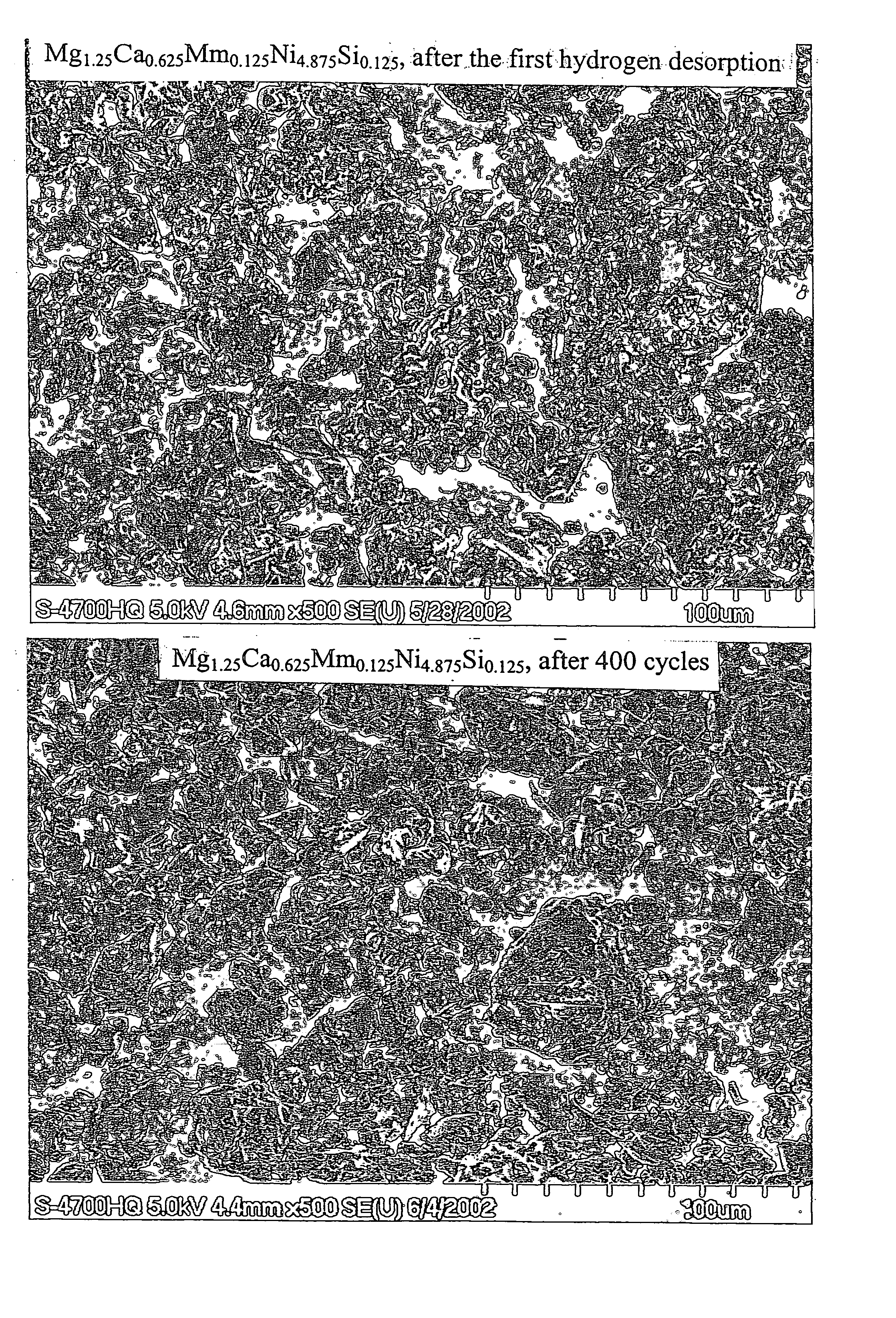

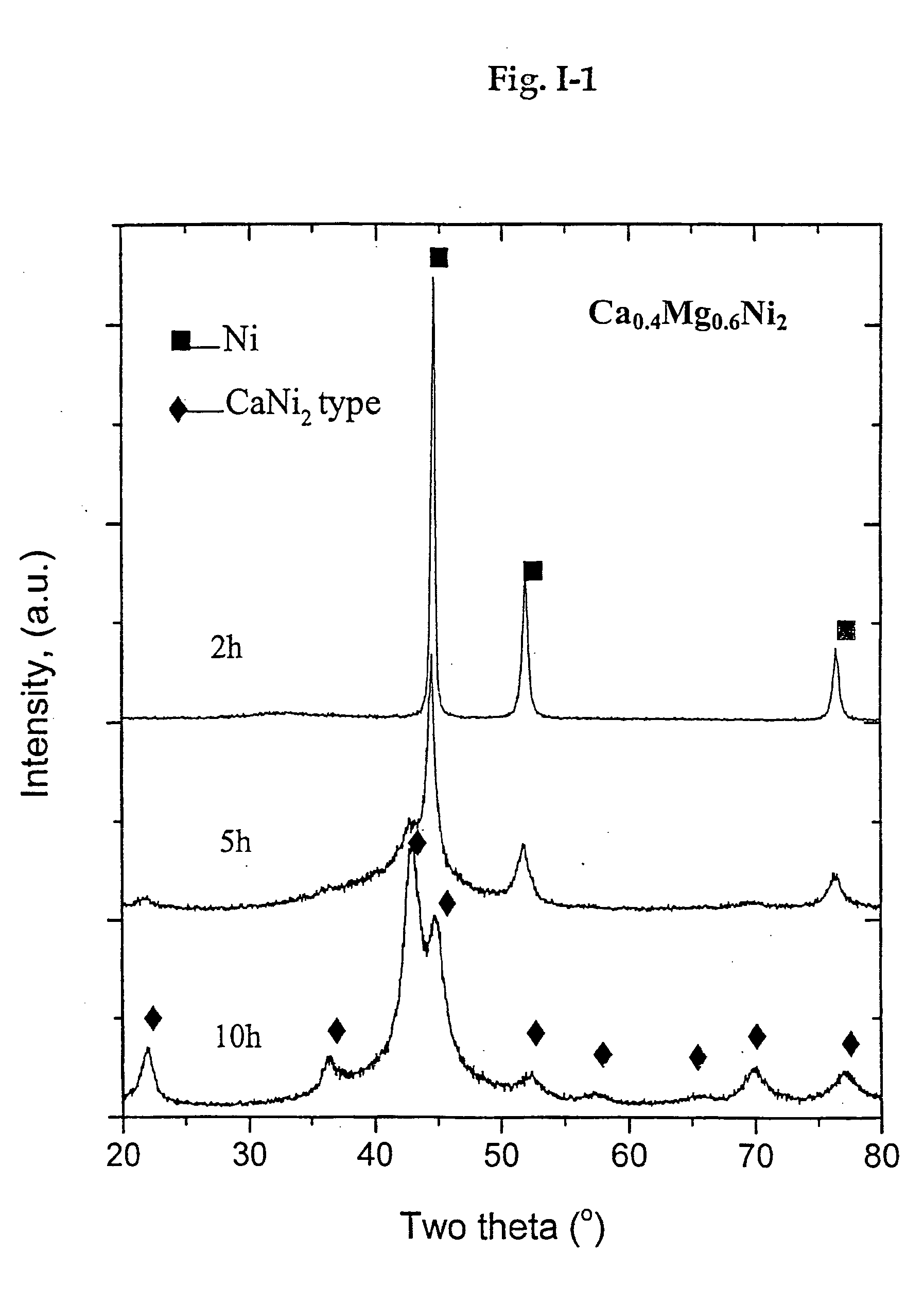

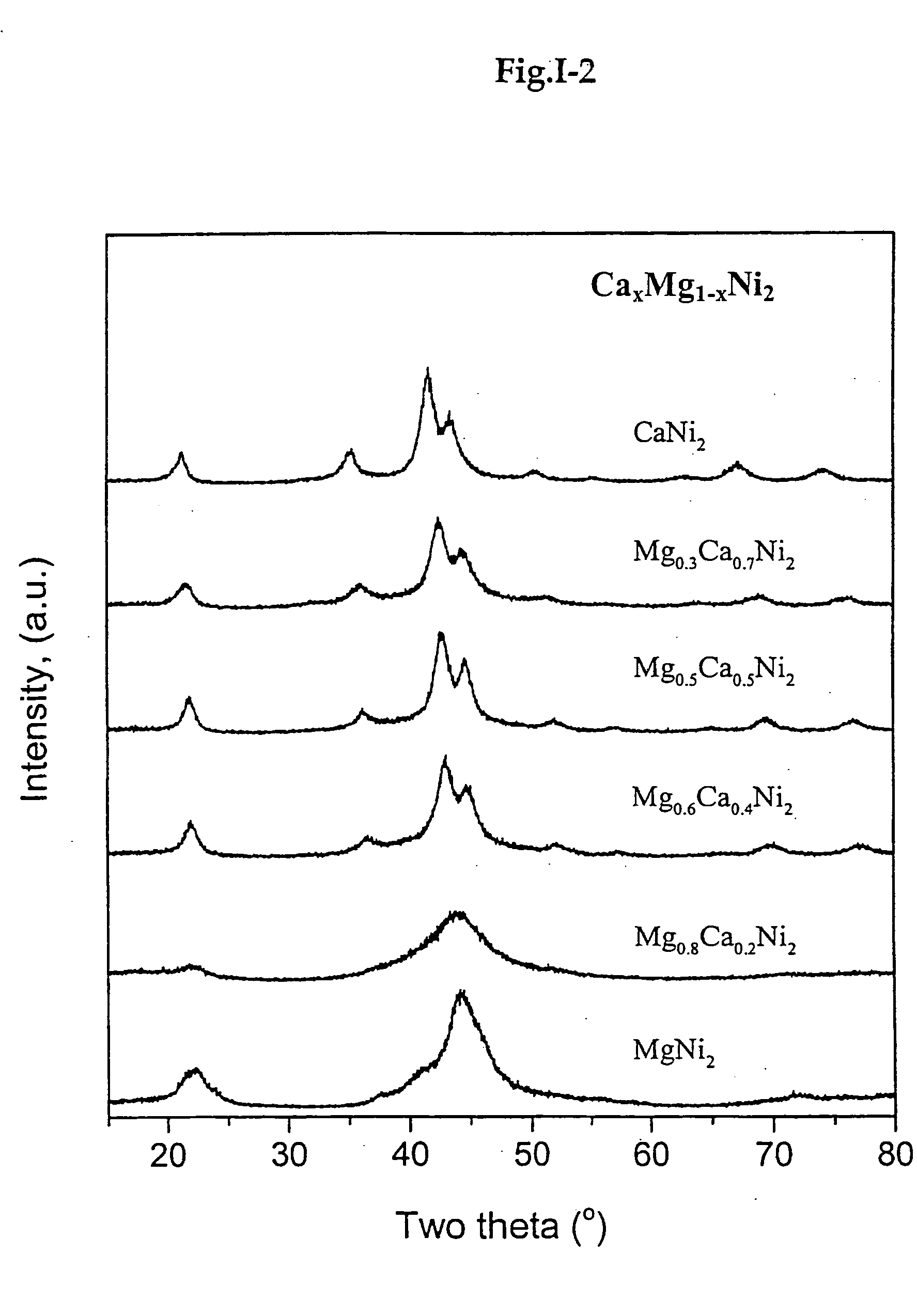

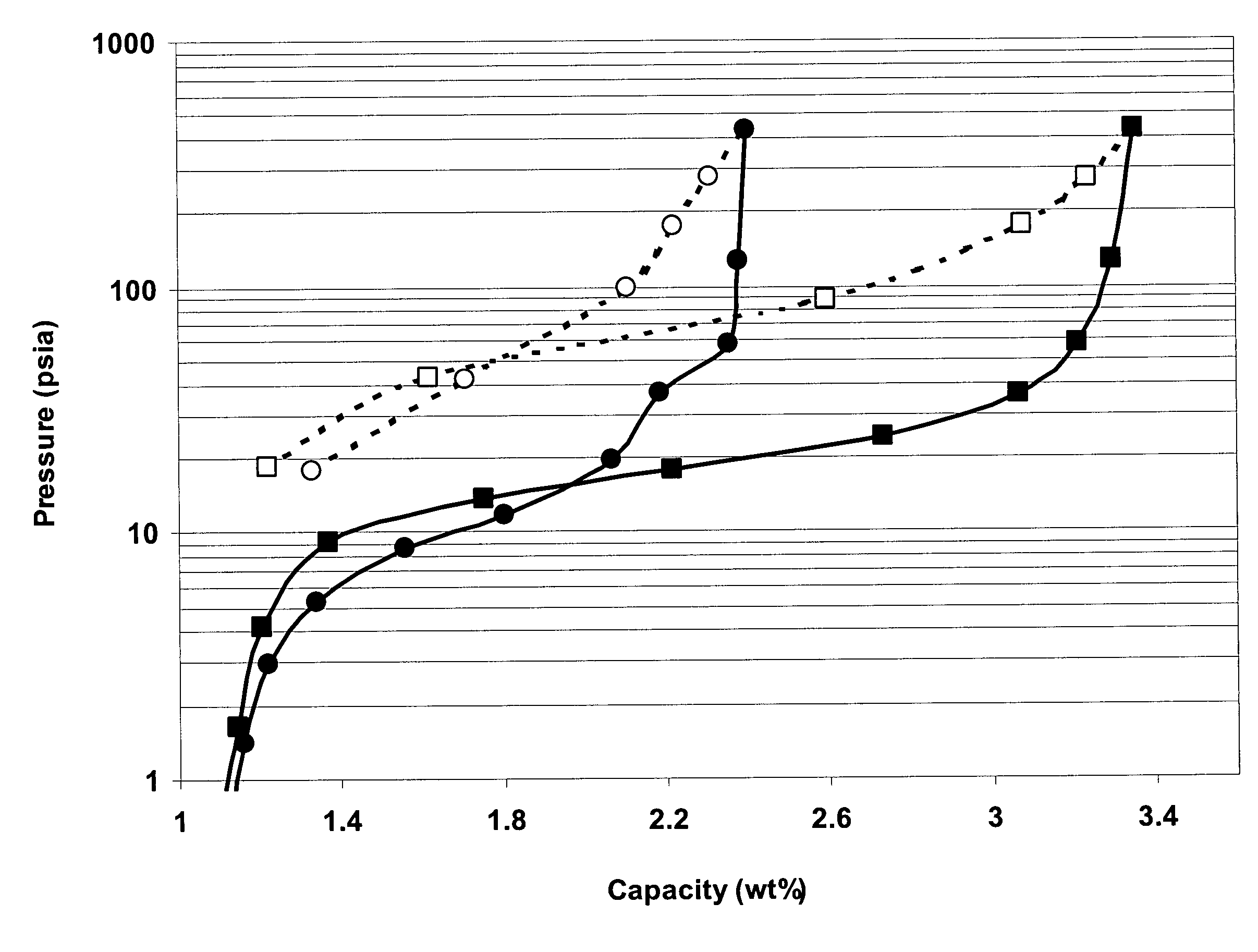

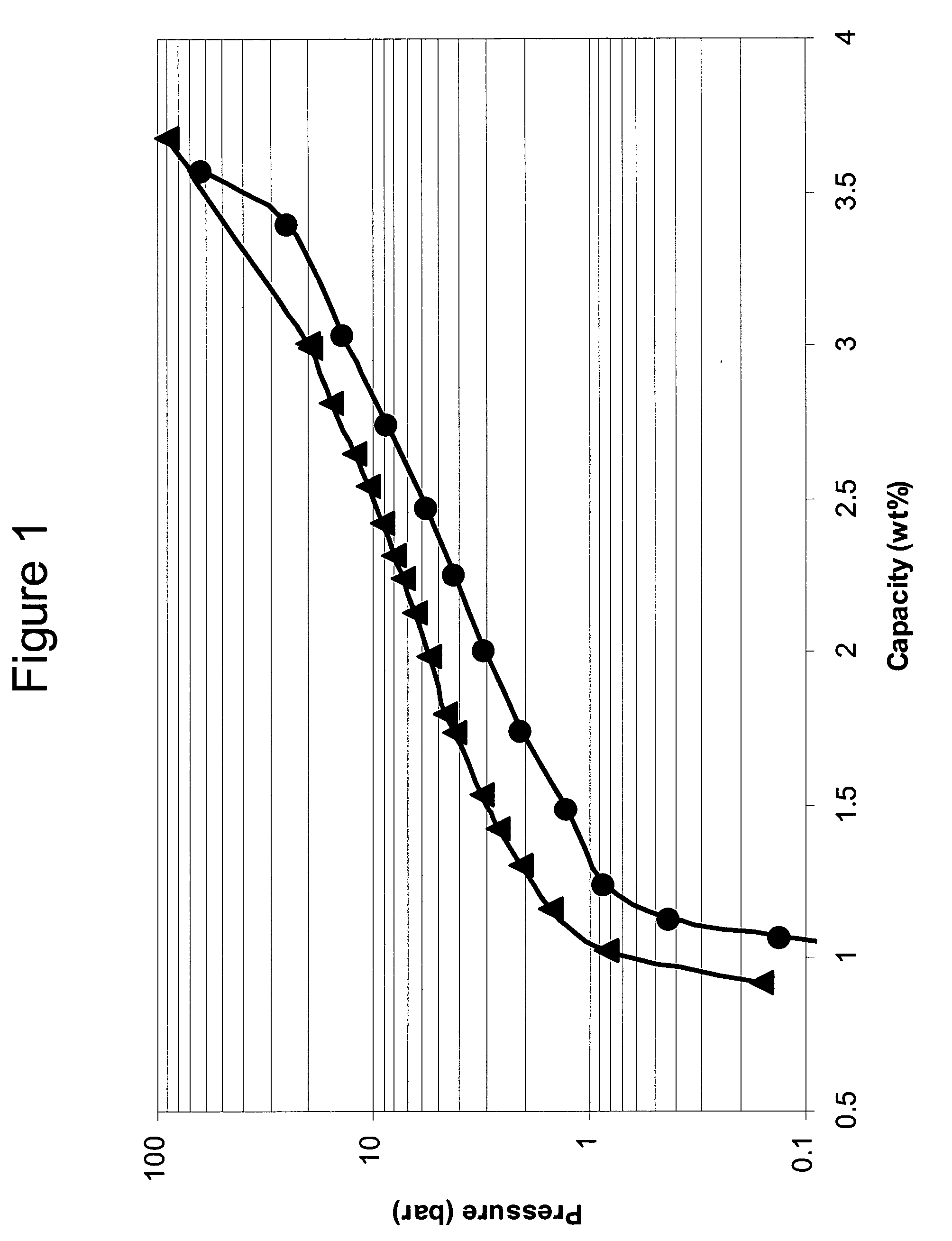

Ca-Mg-Ni containing alloys, method for preparing the same and use thereof for gas phase hydrogen storage

Disclosed are new Ca, Mg and Ni-containing alloys of the general formula: (CacMgdMe)b(Ni1-zTz)a where: M is at least one metal selected from the group consisting of Y, Ce, La, Pr, Nd, Th, Nd, Ti, V, Zr, Ta, Hf, Sr, Ba and Misch metals; T is at least one element selected from the group consisting of Al, Zn, Cu, Fe, Co, Mn, Cr, Mo, W, Si, Ga, Ge, In, Sn, Ag, C and B; a is an integer equal to 2 or 5; z is a number ranging from 0 to 0.5; and when a is equal to 2, then 0.9≦b≦1.1; and when a is equal to 5, then either 1.75≦b≦2.25 or 0.75≦b≦1.31. These alloys which are of the AB2, A2B5 or AB5 types, may be single phase or multiphase and are useful for reversibly absorbing hydrogen from a gas phase. Also disclosed is a method for preparing the above alloys.

Owner:HERA HYDROGEN STORAGE SYST

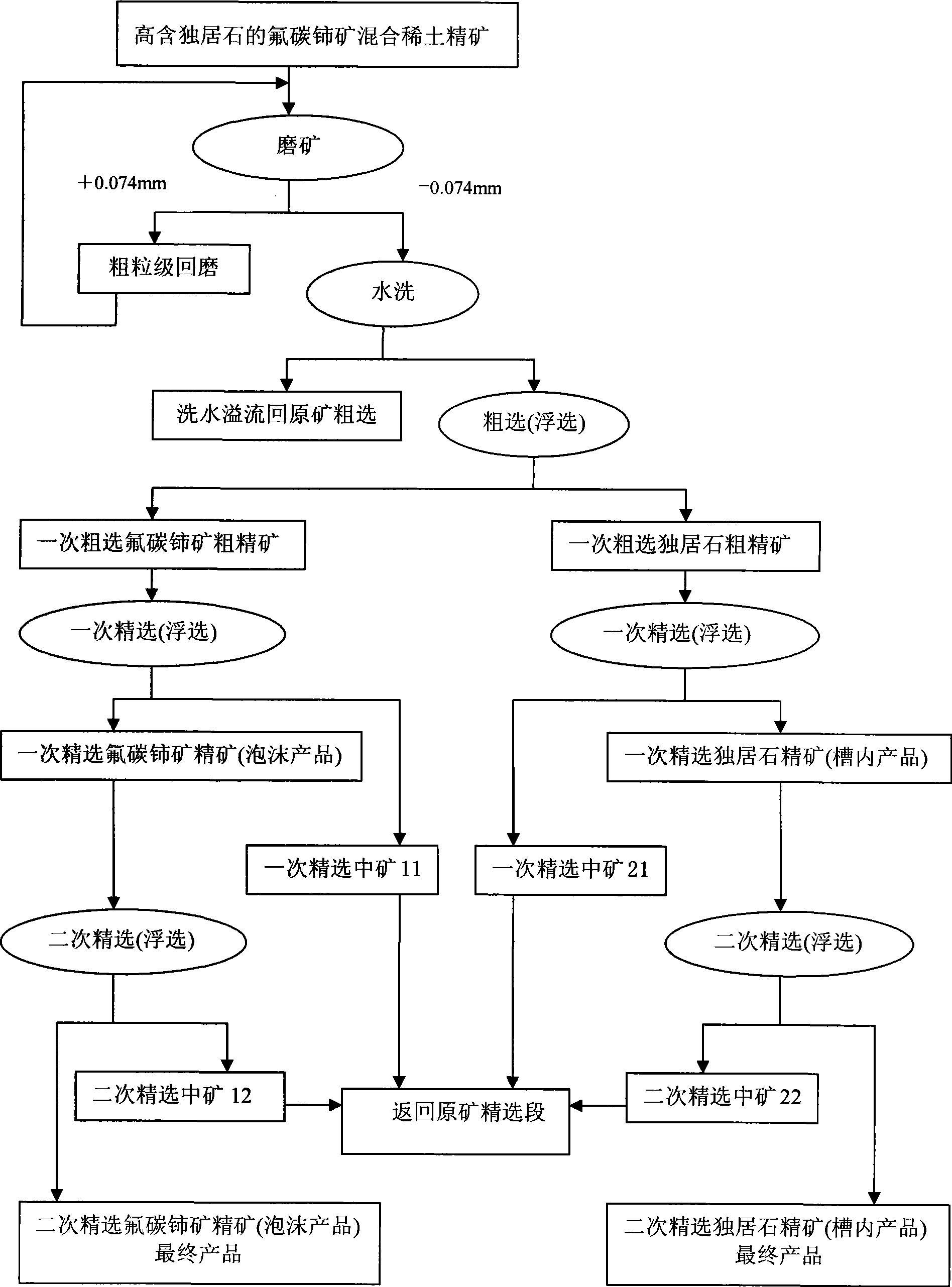

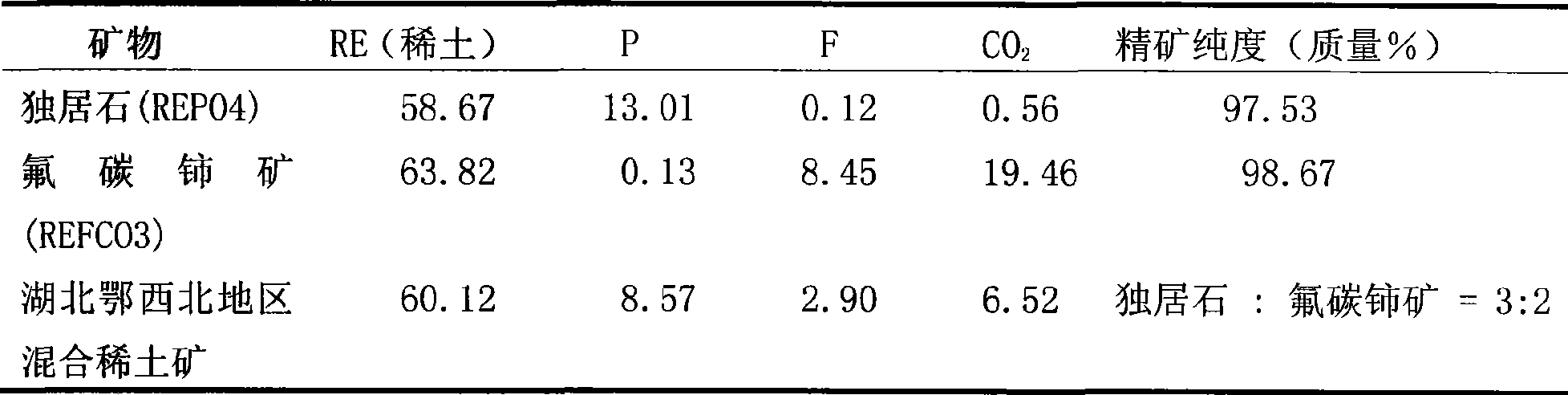

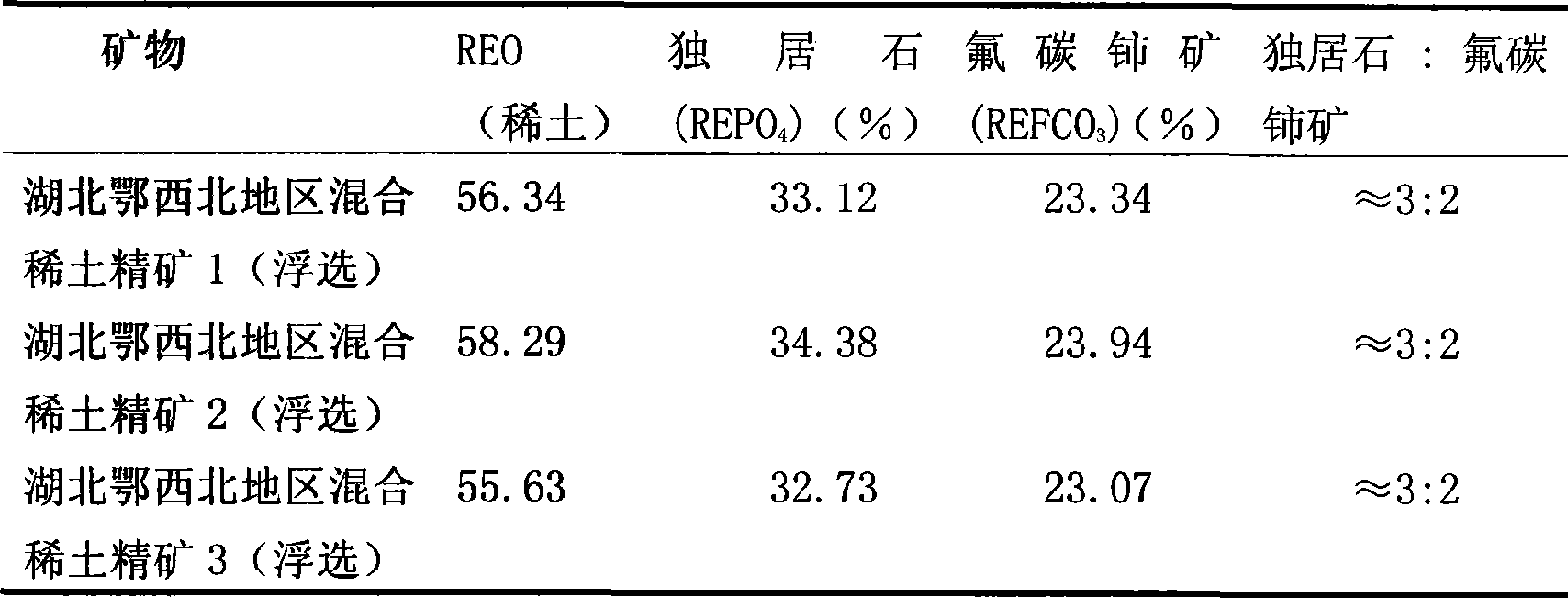

Floatation separation method for mengite and hamartite in misch metal ore concentrate

The invention relates to a method for the flotation separation of a collective rare earth ore, in particular to a method for the flotation separation of monazite and bastnaesite of a collective rare earth ore concentrate. The method is characterized by comprising the following steps: an aluminium sulphate inhibitor, a hydroximic acid collecting agent and a frothing agent are used as floating agents, and bastnaesite collective rare earth ore concentrate with the high content of monazite is processed at a temperature ranging from 18 to 30 DEG C; first-stage roughing parisite rough concentrate and first-stage roughing monazite rough concentrate are obtained by first-stage separation and rougher flotation; the first-stage roughing parisite rough concentrate is processed by the operation of second-stage close sizing to obtain second-stage close sizing bastnaesite concentrate; the first-stage roughing monazite rough concentrate is also processed by the operations of size mixing and second-stage close sizing to obtain second-stage close sizing parisite concentrate; and the first-stage roughing monazite rough concentrate is processed by the operations of size mixing and second-stage close sizing to obtain second-stage close sizing monazite concentrate. High grade single monazite concentrate and single bastnaesite concentrate can be produced by the separation roughing and the flotation operation of the respective close sizing of the first-stage roughing parisite rough concentrate and the first-stage roughing monazite rough concentrate. The method has the advantages of simple process and low production cost, and can produce the high grade single monazite and the single bastnaesite.

Owner:武汉工大科技园发展有限公司

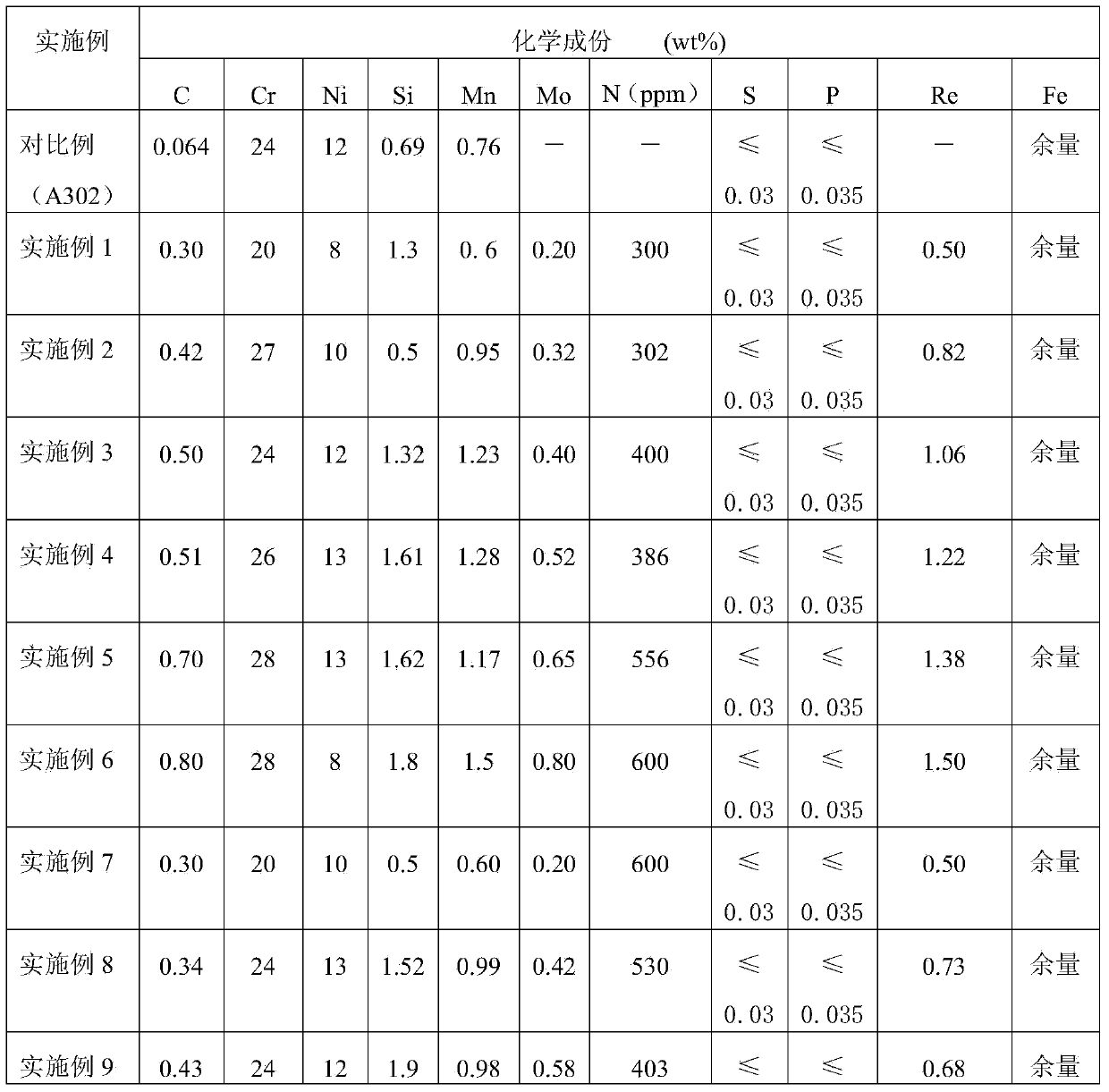

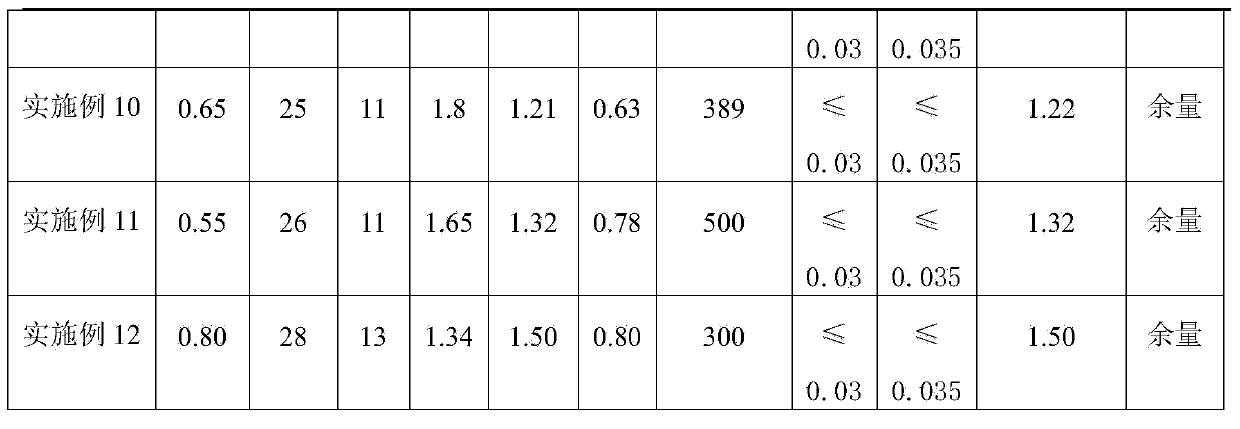

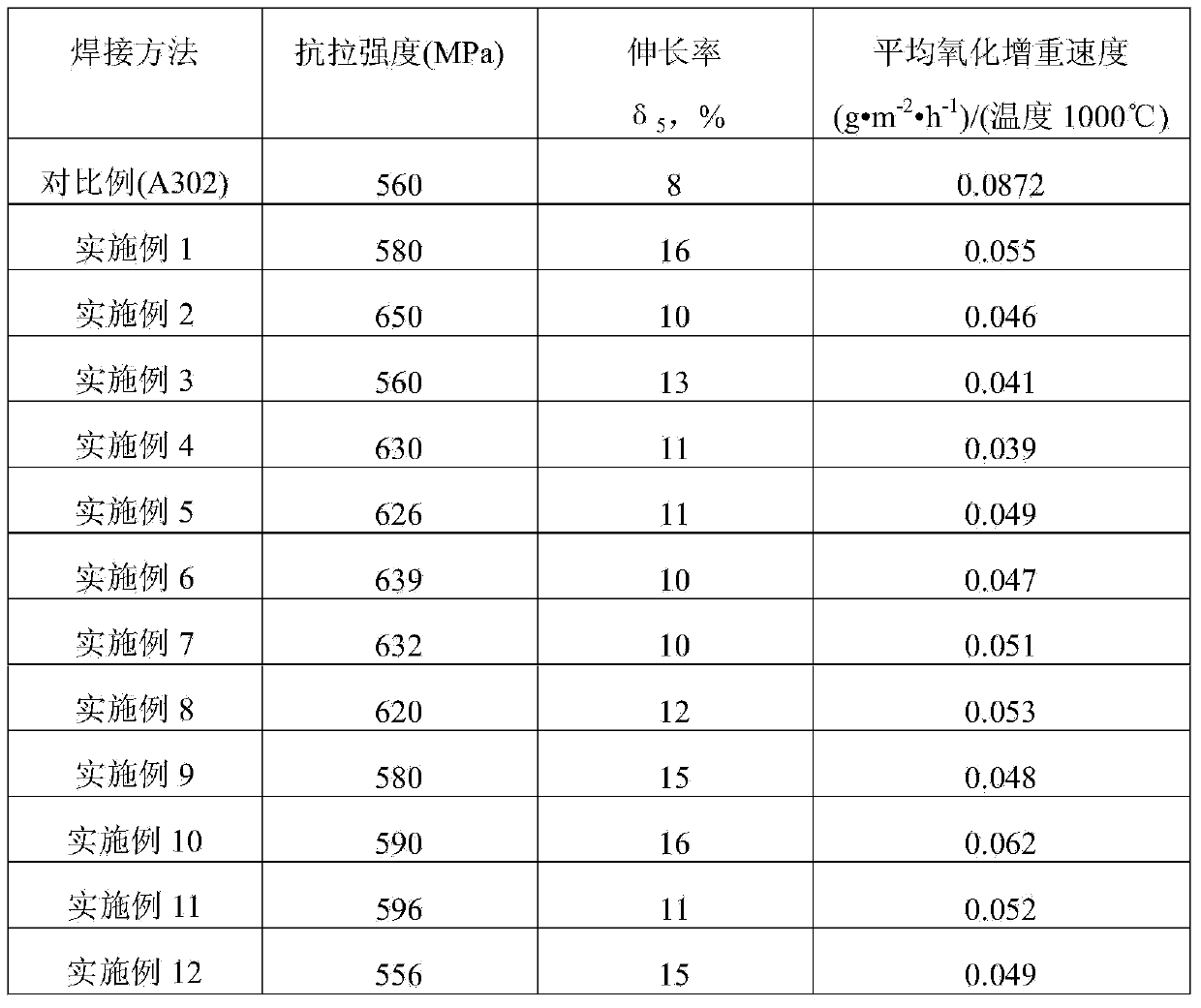

Stainless heat-proof self-protecting flux-cored wire for magnesium smelting reduction tank

ActiveCN104259690AQuality improvementHigh welding currentWelding/cutting media/materialsSoldering mediaMisch metalVulcanization

A stainless heat-proof self-protecting flux-cored wire for a magnesium smelting reduction tank belongs to the technical field of materials processing engineering. A normal stainless steel band 304L or common carbon steel serves as a coating layer, and alloys in a powder core are rutile, sodium carbonate, feldspar, compound fluorides, chromium, nickel, manganese, molybdenum, chromium nitride, aluminium-magnesium alloy, misch metal and iron power. Compared with a conventional stainless steel welding rod, the stainless heat-proof self-protecting flux-cored wire has the advantages that higher welding current can be used; higher welding speed can be realized; the production efficiency is improved; and the labor intensity is lowered; c. Compared with a conventional stainless steel submerged-arc welding solid wire, the stainless heat-proof self-protecting flux-cored wire has the advantages that all-position welding can be realized; the heat input is small; the slag detachability is good; and the manufacturing technique is simpler. A welded joint formed by using the stainless heat-proof self-protecting flux-cored wire provided by the invention has favorable heat resistance, oxidation resistance, vulcanization and corrosion resistance and high-temperature creep resistance compared with welded joints formed by welding the stainless steel welding rod and the stainless steel solid wire.

Owner:BEIJING UNIV OF TECH

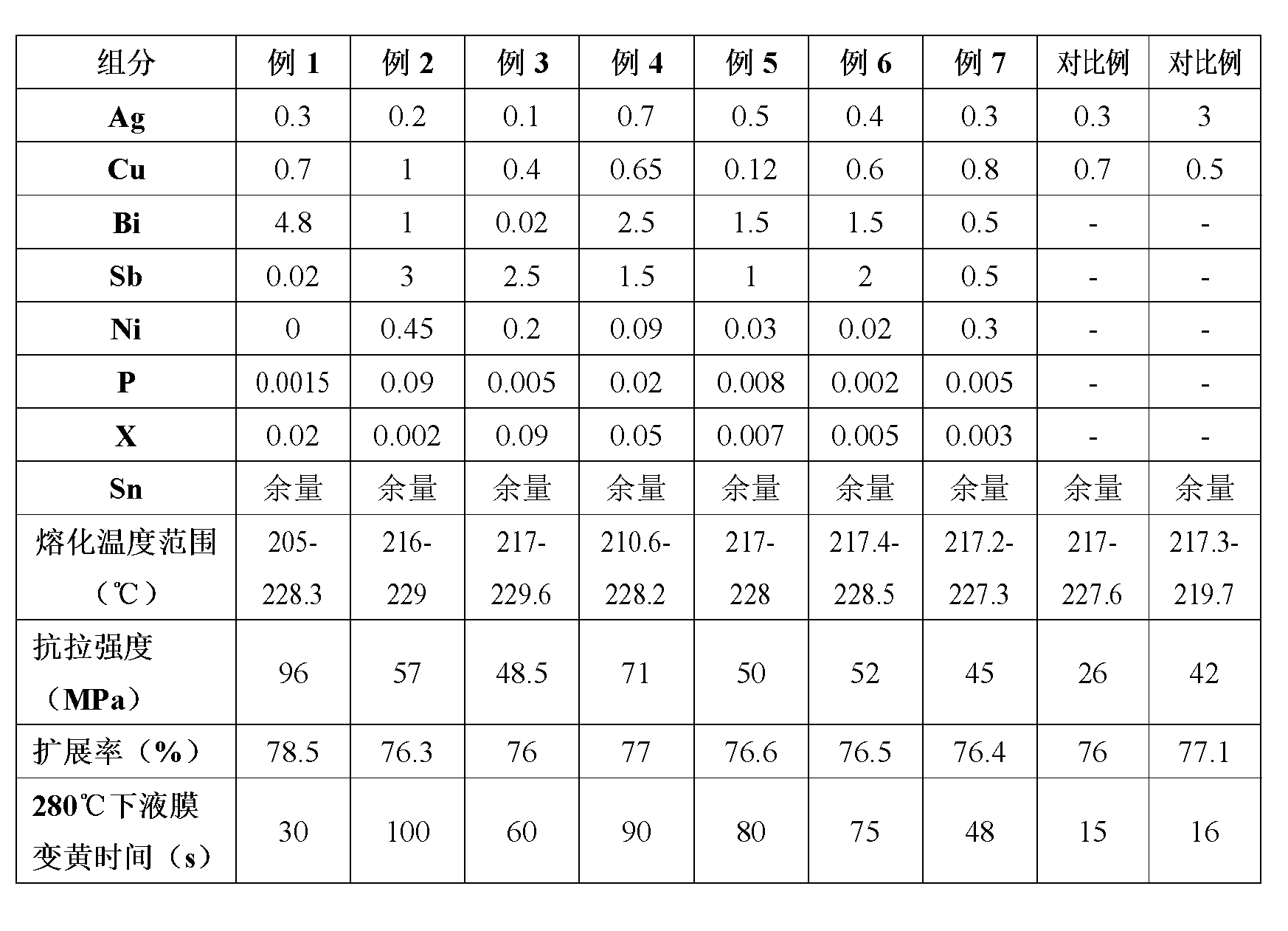

Low-silver lead-free soft solder

InactiveCN102699563ALow costImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaMisch metalRare earth

The invention discloses a low-silver lead-free soft solder, which is moderate in melting point, strong in tensile strength and low in cost. Based on the total weight of the solder, the solder contains 0.1 to 0.7 weight percent of Ag, 0.1 to 1.0 weight percent of Cu, 0.01 to 5 weight percent of Bi, 0.01 to 3 weight percent of Sb, 0 to 0.5 weight percent of Ni, 0.001 to 0.1 weight percent of P, 0.001 to 0.1 weight percent of X and the balance of Sn, wherein X is any one or combination of Ga, Ge and misch metal. The low-silver lead-free soft solder is applied to wave soldering, reflow soldering and manual soldering in the field of electronic and microelectronic packaging.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL

Preparation method of copper and magnesium alloy contact wire for railway electrification

ActiveCN103276237AIncrease production capacityReduce the temperatureSingle bars/rods/wires/strips conductorsMetal/alloy conductorsMisch metalNiobium

A copper and magnesium alloy contact wire for railway electrification comprises a copper base and alloy metal, wherein the alloy metal comprises components in percentage by weight as follows: 0.5-0.6% of magnesium, 0.012-0.014% of zirconium, 0.012-0.014% of niobium, 0.005-0.008% of titanium and 0.02-0.04% of misch metal. A preparation technology adopts an upward continuous casting extrusion-cold rolling-stretching technology. The oxygen content of the prepared contact wire reaches an oxygen-free copper level, the grain is fine, the mechanical property is remarkably improved, the contact wire is uniform in a length direction, the flatness is good, the locomotive picking-up performance is good, the tensile strength, the elongation percentage, the grain size and the toughness are greatly improved when the copper and magnesium alloy contact wire is compared with a conventional wire, and the copper and magnesium alloy contact wire has wide popularization and application values in the high-speed railway electrification field.

Owner:山东维点技术有限公司

Copper alloy

InactiveUS20080047634A1Good bending propertiesExcellent stress relaxation resistanceMisch metalMaterials science

A copper alloy, containing: Ni and / or Si, and at least one or more of B, Al, As, Hf, Zr, Cr, Ti, C, Fe, P, In, Sb, Mn, Ta, V, S, O, N, Misch metal (MM), Co, and Be, with a balance being Cu and inevitable impurities; the copper alloy having a precipitate X composed of Ni and Si; and a precipitate Y composed of Ni and / or Si, and at least one or more of B, Al, As, Hf, Zr, Cr, Ti, C, Fe, P, In, Sb, Mn, Ta, V, S, O, N, Misch metal (MM), Co, and Be, in which a grain diameter of the precipitate Y is 0.01 to 2 μm.

Owner:FURUKAWA ELECTRIC CO LTD

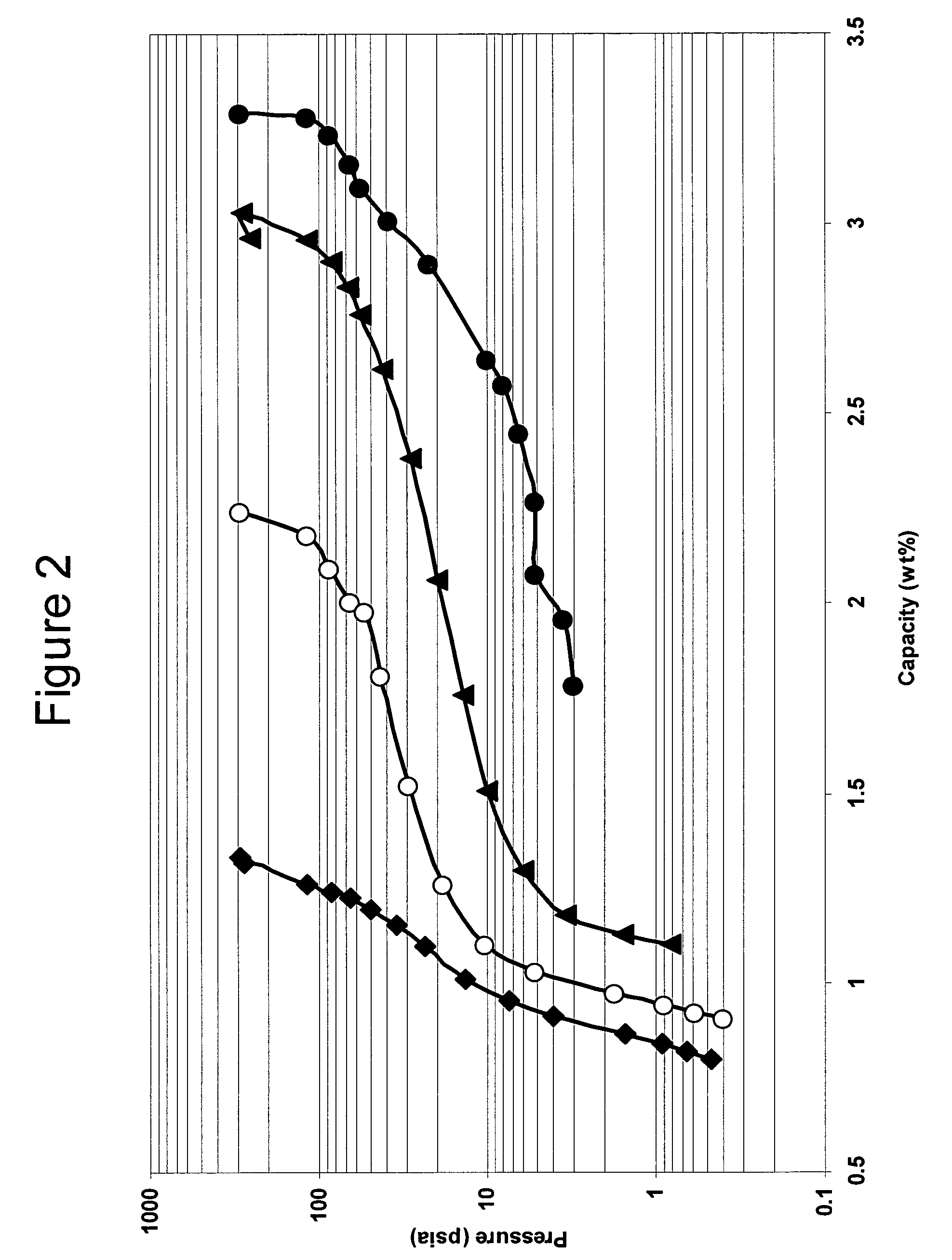

Hydrogen storage alloys providing for the reversible storage of hydrogen at low temperatures

ActiveUS20050067060A1Guaranteed uptimeHydrogenNon-aqueous electrolyte accumulator electrodesMisch metalScavenger

A reversible hydrogen storage alloy capable of storing large amounts of hydrogen and delivering reversibly large amounts of hydrogen at temperatures ranging from 0° C. up to 40° C. The hydrogen storage alloy is generally composed of titanium, vanadium, and chromium. The alloy may further include manganese. Modifier elements such as zirconium, iron, nickel, molybdenum, ruthenium, and / or cobalt, and scavenger elements such as misch metal, calcium, and / or magnesium may be included in the alloy to improve performance.

Owner:HARNYSS IP LLC +1

Rare earth permanent magnet prepared from bayan obo accompany raw ore misch metal and preparation method of rare earth permanent magnet

ActiveCN104700973ALow priceReduce pollutionInductances/transformers/magnets manufactureMagnetic materialsMisch metalThermal deformation

The invention relates to a rare earth permanent magnet prepared from a bayan obo accompany raw ore misch metal and a preparation method of the rare earth permanent magnet. The rare earth permanent magnet is prepared from the components as shown in the following equation: (PrNd)x(MM)y(Fe(1-a)Aa)zB, wherein x+y is greater than or equal to 2 and is less than or equal to 2.5, z is greater than or equal to 11 and less than or equal to 14, and MM is bayan obo accompany raw ore misch metal. The rare earth permanent magnet can be prepared by using a powder metallurgy process and a rapid-quenching hot-press thermal deformation process. The bayan obo accompany raw ore misch metal is adopted to develop a novel resource-saving rare earth permanent magnet for replacing a conventional rare earth permanent magnet, the rare earth permanent magnet provided by the invention has the advantages of low price and environment pollution reduction, the magnetic energy product of the prepared rare earth permanent magnet ranges from 25-45 MGOe, and the blank of the application range of ferrite and SmCo rare earth permanent magnets can be well made up.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

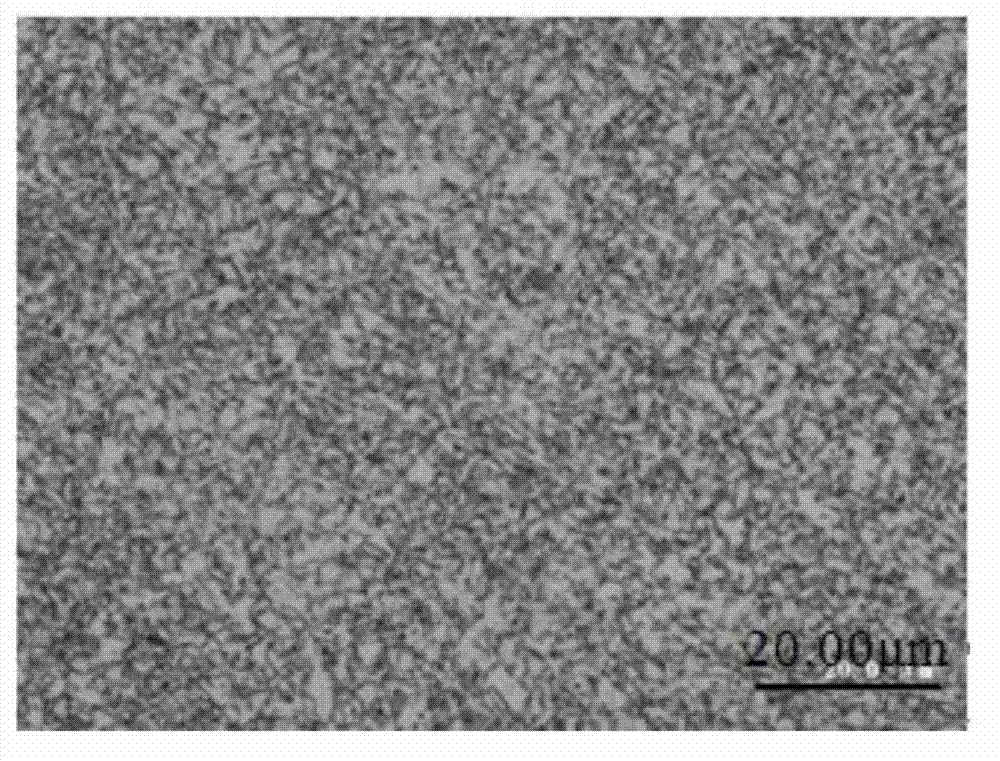

High-strength heat-resisting magnesium alloy containing Ce-rich misch metal and Gd and manufacturing method thereof

InactiveCN102485929ASolve the problem of low solid solubilitySolve the problem that the strengthening effect is not highMisch metalRare earth

The invention discloses high-strength heat-resisting magnesium alloy containing Ce-rich misch metal and Gd and a manufacturing method thereof. The alloy comprises 7.5-15 wt% of Gd, 0.7-3.0 wt% of Ce-rich misch metal, 0.4-1.2 wt% of Zr, and the balance consisting of Mg. The method comprises the following steps: (1) preparing materials, preheating, fusing a preheated pure magnesium ingot, dissolving a preheated pure Gd ingot, a preheated Ce-rich misch metal ingot, and an Mg-Zr intermediate alloy ingot in a magnesium melting liquid to obtain a magnesium alloy melting liquid, pouring or casting the magnesium alloy melting liquid into a magnesium alloy ingot blank; (2) carrying out uniformization heat treatment, that is, heating up the magnesium alloy ingot blank to 490-540 DEG C and keeping warm for 10-60 h to uniformly distribute Gd, Ce-rich misch metal and Zr in a base metal; (3) carrying out thermal deformation processing; (4) carrying out waste heat quenching processing; and (5) carrying out aging treatment. The magnesium alloy manufactured by the invention can satisfy the requirements of high mechanical properties and high temperature creep-resistant performance. According to the invention, by carrying out direct large thermal deformation processing and waste heat quenching and aging treatment after uniformization heat treatment, the problem that Ce, La, Pr and other alloy elements in Ce-rich misch metal have low reinforcement effect and are unstable is solved.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

High-tenacity low-hydrogen alkaline welding rod and preparation method thereof

InactiveCN103084757AImproved arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaFiberMisch metal

The invention discloses a high-tenacity low-hydrogen alkaline welding rod which comprises a coating and a welding core, wherein the coating comprises, by weight, 38%-44% of marble, 20%-25% of fluorite, 3%-5% of zircon sand, 1%-5% of ferrosilicon, 10%-15% of ferrotitanium, 5%-7% of mid-carbon ferromanganese, 2%-4% of titanium dioxide, 3%-6% of mica, 1.5%-2% of microcrystalline fiber, 1.2%-1.8% of nickel powder, and 1%-1.5% of misch metal, wherein sum of weight percentages of all components is 100%. The invention further discloses a preparation method of the high-tenacity low-hydrogen alkaline welding rod. The preparation method of the high-tenacity low-hydrogen alkaline welding rod includes the steps: enabling coating materials and K-Na mixing water glass to be mixed, crushing the mixture into a power ball with a cylindrical shape, putting the power ball into a pressing coating machine, coating the power ball with the cylindrical shape on a H08A welding core to form the welding rod, and then grinding the head and the tail and getting the high-tenacity low-hydrogen alkaline welding rod after drying. When the high-tenacity low-hydrogen alkaline welding rod is used for welding high-strength steel, no preheating is needed before welding, no heat treatment is needed after welding, content of diffusible hydrogen of deposited metal is controlled effectively, and the preparation method is simple.

Owner:XIAN UNIV OF TECH

Method for rapidly and efficiently recycling neodymium iron boron waste

PendingCN108359798AIncrease added valueRealize collaborative recyclingProcess efficiency improvementMisch metalElectric arc furnace

The invention discloses a method for rapidly and efficiently recycling neodymium iron boron waste. The method comprises the steps that neodymium iron boron magnet waste is collected; the waste is divided into blocky waste and powdery waste, and oil sludge of the powdery waste is pretreated; the powdery waste is pressed into blocks and then charged, and a deoxidant is added according to the addingproportion of the powdery waste and the blocky waste; other alloy element oxides except rare earth in the waste are subjected to smelting reduction and deoxidation through rare earth metal in the blocky waste and the deoxidant; smelting reduction can be conducted in a medium-frequency induction furnace or an electric-arc furnace; a ferroalloy product and furnace slag are obtained after smelting iscompleted; the furnace slag is crushed, then molten salt electrolysis is conducted, and misch metal or rare earth ferroalloy is obtained; and chemical components of ferroalloy and chemical componentsof rare earth alloy are detected, alloy composition and impurity content of cast ingots are obtained, and the cast ingots are provided for neodymium iron boron manufacturers to be used as raw materials or used as intermediate alloy for other purposes after being detected to be qualified.

Owner:江西离子型稀土工程技术研究有限公司

A lanthanon permanent magnetic powder and its making method

InactiveCN101241789AImprove stabilityImprove coercive forceInorganic material magnetismMetal alloyRare earth

The present invention provides a rare-earth permanent-magnetic powder and the preparing method thereof. The basic representation of the rare-earth permanent-magnetic powder is as follows: (R<1-a>La)uFe<100-u-x-y>MxBy, wherein R is Nd, Pr or NdPr or the mixed rare earth metal alloy which is mainly La, Ce and Nd. La is metal lanthanum element. Fe is metal iron element. M is metal Zr, Hf, Nb, V or the alloy. B is boron element. The rare-earth permanent-magnetic powder of the invention can be prepared with arc remelting fast quenching method or induction remelting fast quenching method. Under the condition that the Nd content is reduced greatly, the invention keeps higher synthetic magnetic character and has better temperature stability. After the 150 DEG C high temperature aging experiment, the irreversible flux loss is only 3to 5 The performance-price ratio of the rare-earth permanent-magnetic powder of the invention is higher and the invention has better market applying prospect.

Owner:绵阳西磁科技开发公司

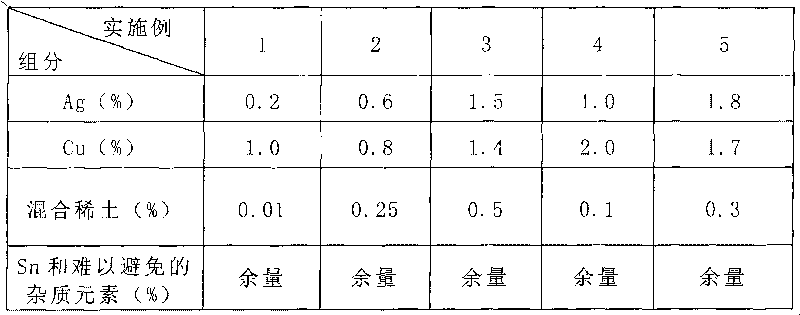

Sn-Ag-Cu misch metal lead-free solder with low content of Cu and preparation method thereof

ActiveCN101700606AReduce dosageImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaMisch metalPotassium

The invention relates to a Sn-Ag-Cu misch metal lead-free solder with low content of Cu and a preparation method thereof. The method solves the problems of overhigh content of Ag and inferior brazing performance in current lead-free solder. The lead-free solder is composed of the following components by weight percent: 0.1-2.0% of Ag; 0.2%-2.5% of Cu; 0.1%-3.0% of misch metal; and Sn and unavoidable impurity elements as the balance. The preparation method thereof comprises the following steps: A: completely melting the metal Sn; B: adding the metal Ag and Cu into the molten metal of Sn and sufficiently stirring the molten metal to form alloy liquid; and C: adding the misch metal into the alloy liquid fast until the misch metal is completely molten, removing the mixed salt of potassium chloride and potassium oxide on the surface to result in the lead-free solder. The Sn-Ag-Cu misch metal lead-free solder with low content of Cu according to the invention has the advantages of low content of Ag, low cost, excellent brazing performance, etc.

Owner:上海一远电子科技有限公司

High strength and high ductility magnesium alloy and its preparation method

The present invention relates to a high strength and high ductility magnesium alloy and its preparation method. The magnesium alloy in the present invention contains 3˜9 wt % of aluminum, 3.5˜9 wt % of zinc, 0.15˜1 wt % of manganese, 0.01˜2 wt % of antimony, and balanced magnesium. The alloy may further comprise 0˜2 wt. % of one element selected from the group consisting of mischmetal, calcium, and silicon. The room temperature mechanical properties of the T6 heat-treated typical alloy in the present invention are as following: Ultimate Tensile Strength of more than or equal to 270 Mpa, Yield Tensile Strength of more than or equal to 140 Mpa, Elongation of more than or equal to 6%, Brinell hardness of more than or equal to 70, Impact Energy of more than or equal to 12 J. Some of the alloys in the present invention not only possess superior room temperature mechanical properties, but also have very good high temperature mechanical properties. The main alloying elements are easily obtainable and the preparation cost is low enough to meet the demands of large-scale production. The alloy according to the present invention was applicable for most of the casting processes, such as permanent casting, sand casting, die casting, and squeeze casting.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

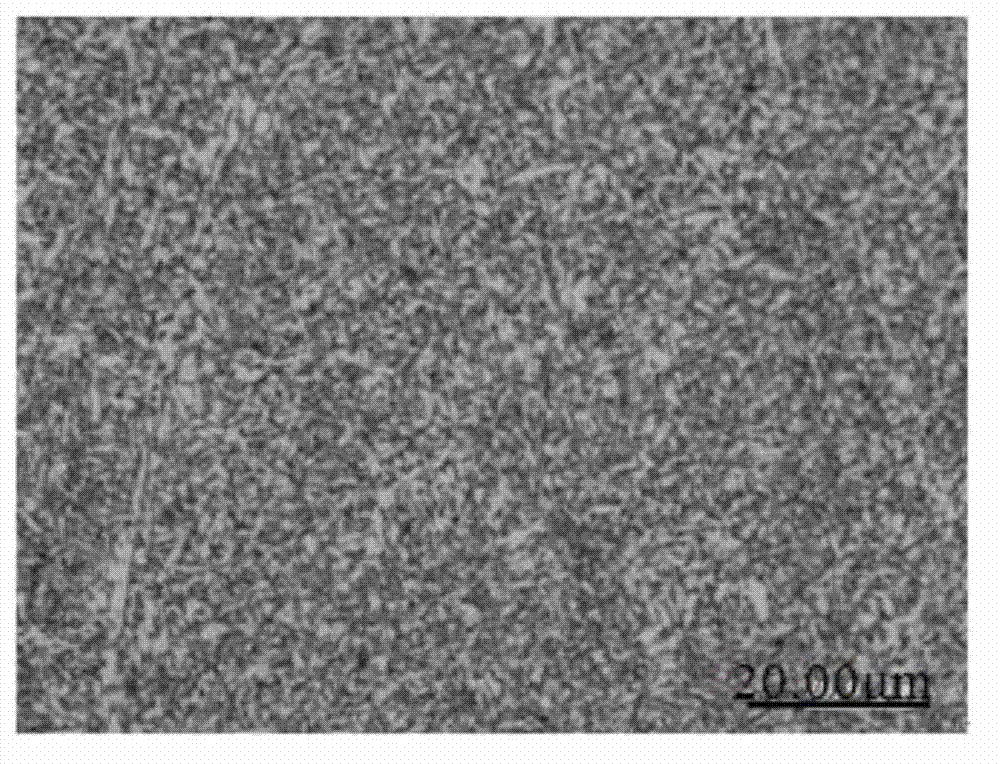

Material for casting high damping manganese copper alloy and manufacturing method thereof

The invention discloses a aterial for casting high damping manganese copper alloy and a manufacturing method thereof. The alloy material comprises the components of, by mass, 19-21% of Cu, 4.5-5.5% ofNi, 3-4% of Fe, 0.01-0.05% of Al, 0.01-0.05% of RE, and 0.001-0.01% of Ca, wherein the RE is the single element, rare earth or misch metal, in the Ce and the La, and the balance Mn and other unavoidable impurities. The alloy material is melted under the protective atmosphere in a vacuum induction melting furnace, a transverse strong magnet field of 0-5T is imposed, and effective heat treatment iscarried out. The alloy content of the material is low and the production cost is low; magnet field magnet braking effect is used for improving macro segregation and refining solidified branch crystalline organization; the magnet field thermal electromagnet convection effect is used for facilitating floating of the carried impurities, and therefore the effects of purifying a melted body and improving the performance of the damping are achieved. The damping material is dense in structure, excellent in performance and low in production cost.

Owner:SHANGHAI UNIV

Environmental self-lubricating wear-resistant copper alloy and preparation method thereof

The invention discloses environmental self-lubricating wear-resistant copper alloy, comprising the following components by mass percent: 5-13% of Sn, 2-9% of Ni and / or Co, 2-11% of Bi, 0.05-0.3% of Zr, 0.05-0.5% of RE, the balance of Cu and inevitable impurities, wherein the content of the impurity is smaller than or equal to 0.3%, the RE is Ce-La misch metal. Meanwhile, the preparation method of the environmental self-lubricating wear-resistant copper alloy is disclosed. The environmental self-lubricating wear-resistant copper alloy has the advantages that the conventional wear-resistant copper alloy containing lead is replaced, and the environmental self-lubricating wear-resistant copper alloy is the wear-resistant copper alloy material with environment-friendly and self-lubricating effects. The alloy solidification molding process is interfered by adopting a strong pulsed electromagnetic physical field in the manufacturing process, the as-cast segregation and loosening of the obtained environmental self-lubricating wear-resistant copper alloy are significantly reduced, the alloy is fine and even in as-cast structure, and high in density, the hardness of the molded casting is greater than 70HB, the tensile strength is greater than 230MPa, and the alloy density is greater than 8.7g / cm<3>. The environmental self-lubricating wear-resistant copper alloy has good overall performance, the preparation method is good in stability, and low in cost, the preparation process is green and free of pollution, and industrialization is easily achieved.

Owner:镇江金鑫有色合金有限公司 +2

High-precision nickel-chromium/copper-nickel thermocouple alloy wires

InactiveCN102735361AReduce temperature measurement deviationImprove stabilityThermometers using electric/magnetic elementsUsing electrical meansMisch metalChromium nickel

The invention discloses high-precision nickel-chromium / copper-nickel thermocouple alloy wires and a production process thereof. A nickel-chromium thermocouple alloy wire comprises the components of chromium, cobalt, silicon, calcium, yttrium, carbon, sulfur, iron, nickel and a misch metal; a copper-nickel thermocouple alloy wire comprises the components of nickel, manganese, magnesium, calcium, carbon, sulfur and copper; and the process comprises the following steps of: (a), preparing raw materials; (b), performing vacuum melting; (c), performing hot rolling; (d), performing wire drawing and annealing; and (e), testing finished products, packaging the finished products to leave factory. The nickel-chromium / copper-nickel thermocouple alloy wires, which are produced according to a unique product formula and by the unique production process, can reach a high-precision I-grade level.

Owner:JIANGSU HUAXIN ALLOY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com