Die casting magnesium alloy and magnesium die casting

A magnesium alloy and alloy technology, applied in the field of magnesium alloy for die-casting and magnesium die-casting products, can solve the problems of no description of formability, no precedent for Mg alloy, no mention of fluidity and formability of molten metal, etc., to prevent low strength characteristics , improve the high temperature creep performance, improve the effect of the alloy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

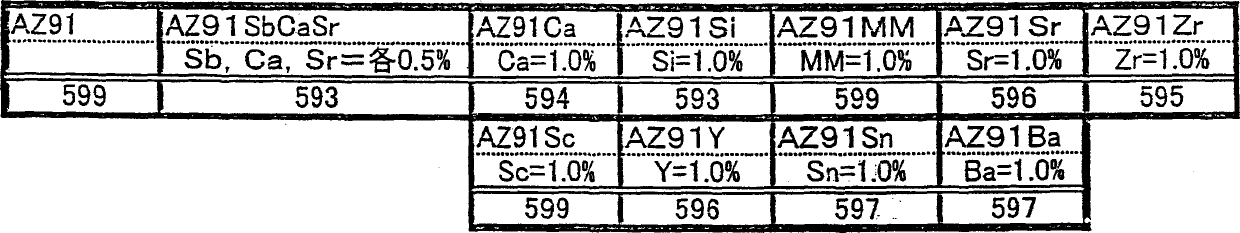

[0071] As described above, the inventors of the present invention conducted various studies on magnesium alloys for die-casting and die-cast products from the viewpoint of improving the high-temperature creep performance of existing alloys without causing a decrease in room temperature strength. Maintain the excellent characteristics of AZ91 alloy, and improve the high temperature creep characteristics. In the following, the consideration methods and research results are explained in order. In addition,% in the text indicates% by weight.

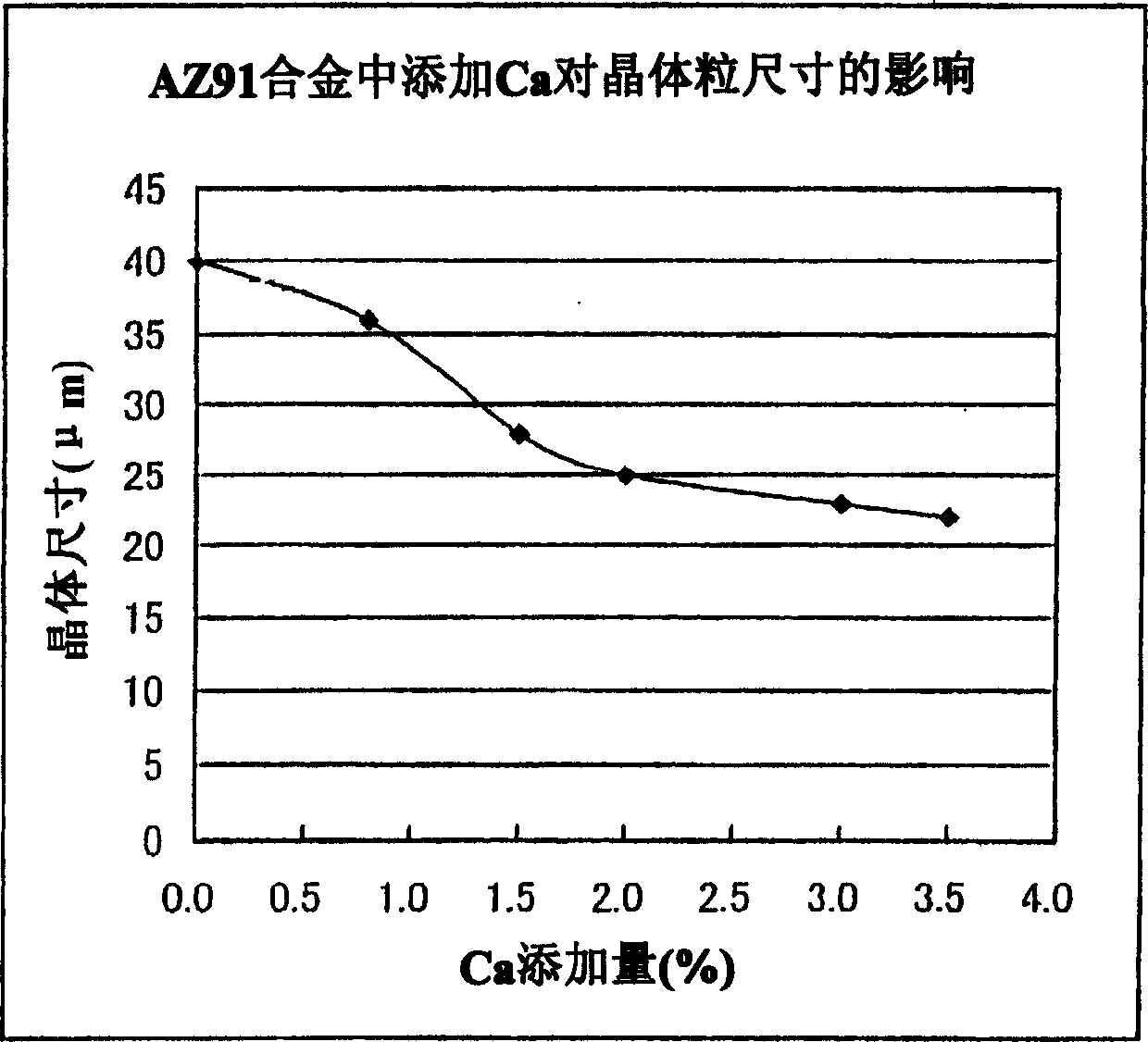

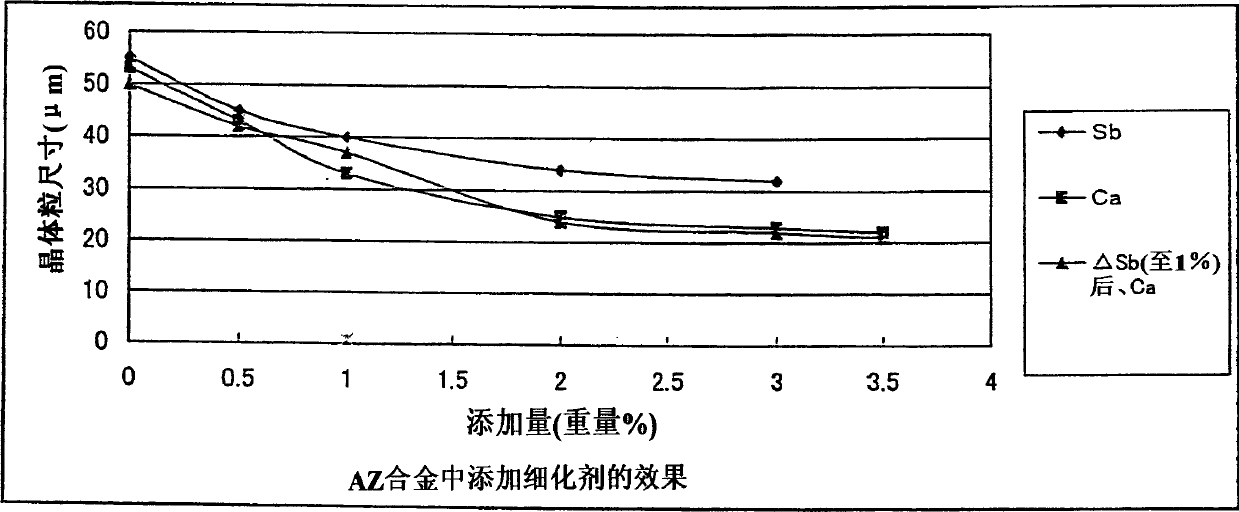

[0072] (1) Refinement of crystal grain size

[0073] First of all, the present inventors conducted research in order to improve the characteristics of AZ91 alloy die-cast products.

[0074] The crystal grain size when the AZ91 alloy is die-casted is about 40 μm, and the crystal grains are considerably refined compared to the case where the crystal grain size is 200 to 300 μm during normal gravity casting. Therefore, the crystal refiner used in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com