Patents

Literature

42results about How to "Improve high temperature creep performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Die casting magnesium alloy and magnesium die casting

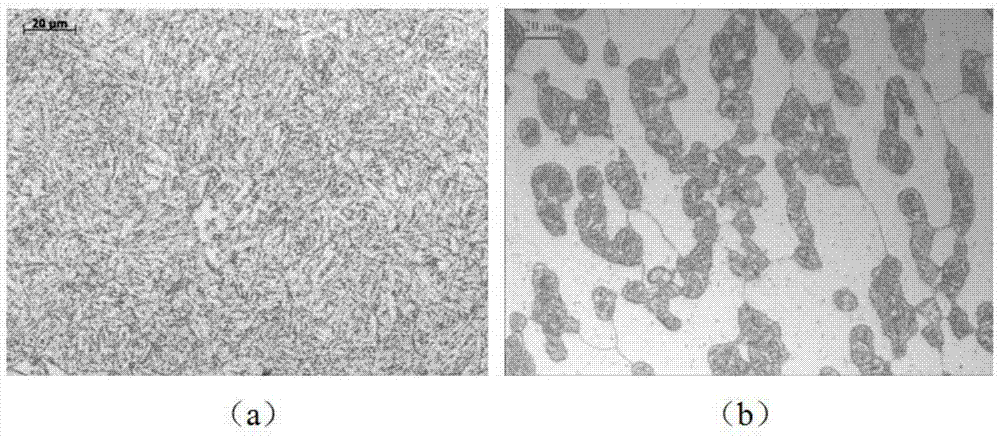

InactiveCN1637160ALarge particle sizePrevention of reduction in strength characteristicsUnderwater structuresReceptacle cultivationRare-earth elementMischmetal

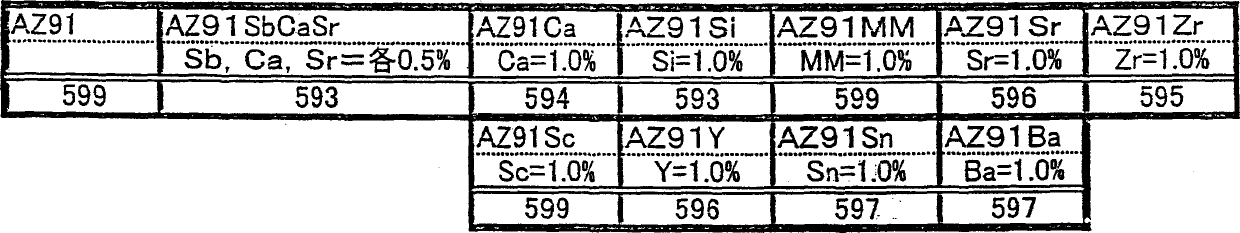

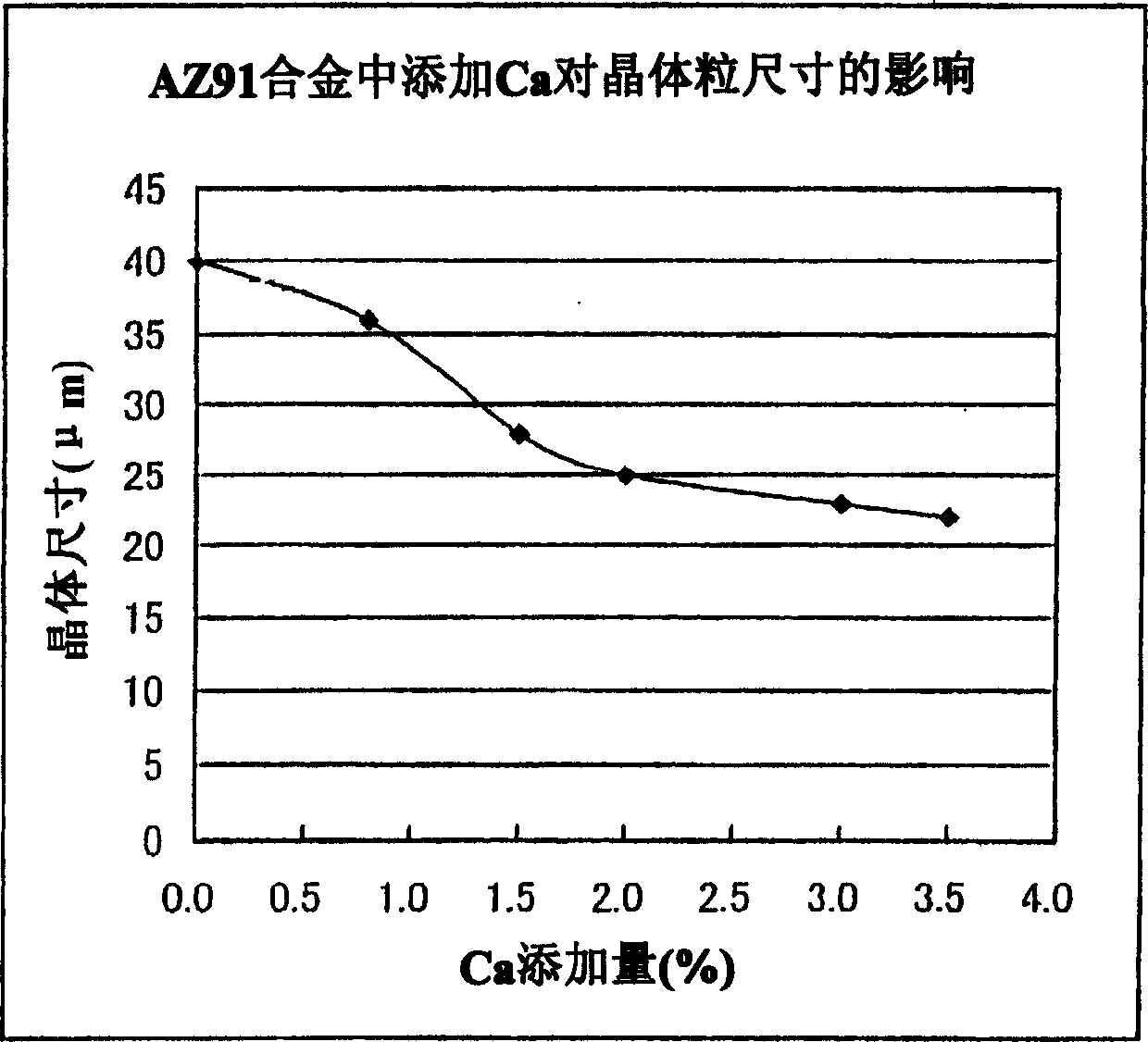

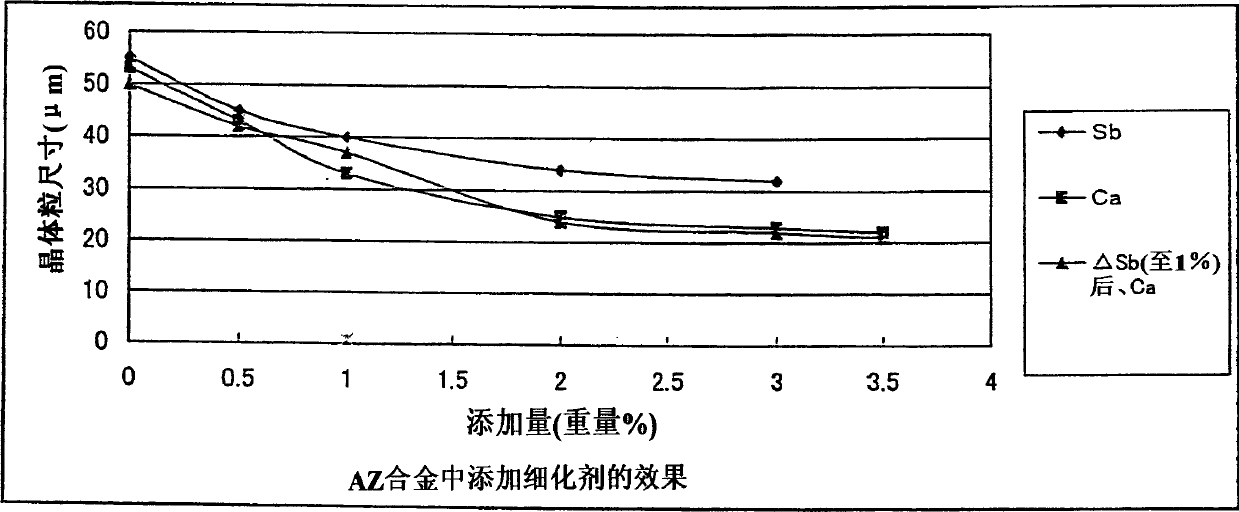

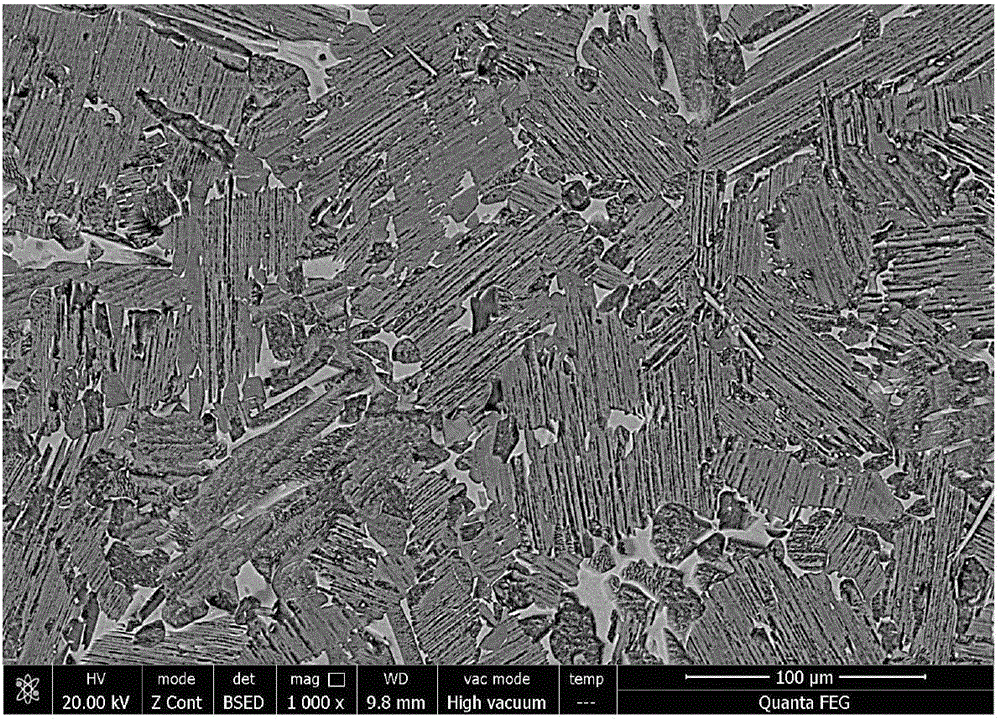

The invention provides a magnesium alloy for die-casting that can improve the high-temperature creep performance without reducing the strength at room temperature, and a magnesium die-cast product using the alloy. Manufacture of magnesium die-casting products using a magnesium alloy for die-casting, wherein the magnesium alloy for die-casting is an AZ91 series alloy of 6.0 to 11.0% by weight of aluminum, 0.1 to 2.5% by weight of zinc, and 0.1 to 0.5% by weight of manganese, and added silicon: 0.1 to 1.5% by weight 1. At least one of misch metal containing rare earth elements: 0.1-1.2% by weight, zirconium: 0.2-0.8% by weight, made into an AZ91-based matrix alloy, and adding 0.1-1.5% by weight of antimony to the AZ91-based matrix alloy and at least one of 0.05 to 3.5% by weight of calcium, and 0.1 to 2.5% by weight of strontium, and other components are unavoidable components.

Owner:ADVANCED TECH +1

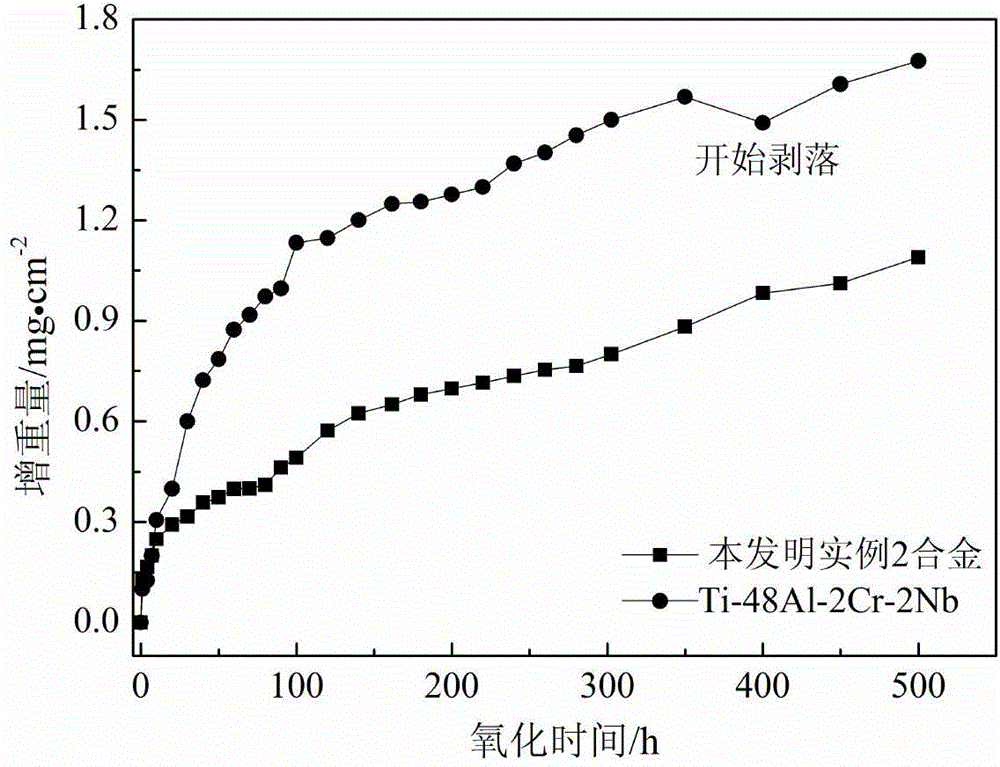

High-temperature-resistant aluminum titanium oxide alloy and preparation method thereof

InactiveCN104532061AImprove high temperature oxidation resistanceImprove hot workabilityElectric arc furnaceOxidation resistant

The invention relates to a preparation method of high-temperature-resistant beta-gamma aluminum titanium oxide alloy and belongs to the field of high-temperature alloys. The beta-gamma aluminum titanium oxide alloy comprises the following components: 40.0-44.0at% of Al, 3.0-5.0at% of Nb, 0.5-1.5at% of Mo, 0.1-0.5at% of Si, 0.1-0.3at% of B and the balance of Ti and inevitable impurity elements. The preparation method comprises the following step of repeatedly smelting titanium sponge, high-purity aluminum, a TiNb alloy, a TiMo alloy, pure Si and pure B powder as raw materials in a vacuum suspension furnace or a nonconsumable vacuum electrical arc furnace. The alloy has the advantages of good oxidation resistance and thermal processing performance, can be used at 800 DEG C in a long term without surface treatment and can be suitable for being processed into aerospace and automotive engine parts which work at about 800 DEG C.

Owner:UNIV OF SCI & TECH BEIJING +1

Novel nickel-chromium-iron electrothermal alloy

The invention discloses a novel nickel-chromium-iron electrothermal alloy. The novel nickel-chromium-iron electrothermal alloy is prepared from, by mass percent, 0.7%-1.6% of Si, 0.3%-0.6% of Mn, 20%-23% of Cr, 41%-43% of Ni and the balance iron and inevitable microelements. According to the alloy, due to the fact that the low-price and low-density iron element is adopted for replacing a high-price and high-density nickel element, compared with an original Cr20Ni80 alloy, the novel nickel-chromium-iron electrothermal alloy is low in density and low in price, plastic machinability, weldability, high-temperature mechanical performance, the service life and other main performance indexes remain unchanged, and the Cr20Ni80 alloy can be completely replaced.

Owner:JINCHUAN GROUP LIMITED +1

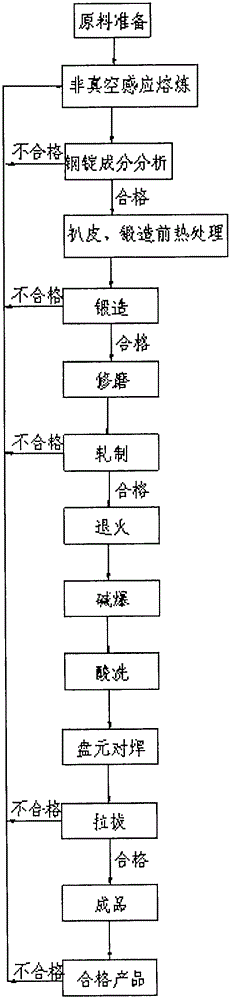

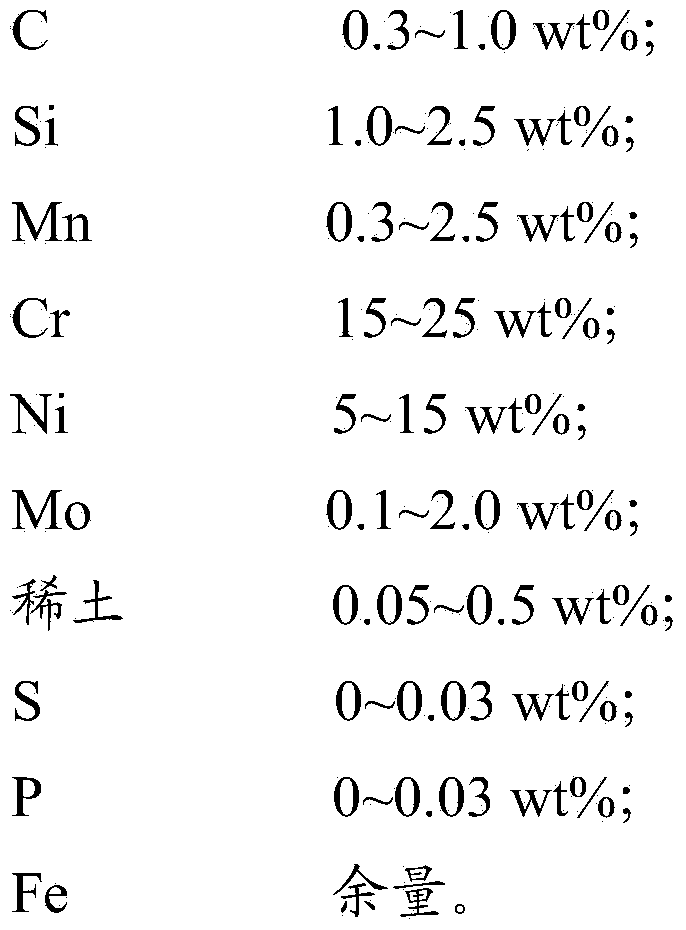

Heat-resisting steel and preparation method thereof

ActiveCN103397266AGood modification effectImprove high temperature elongationMicron scaleRare-earth element

The invention provides heat-resisting steel and a preparation method thereof. The method comprises the steps of mixing a first part by mass of Fe with C, Si, Mn, Cr, Ni, Mo, S and P, and smelting so as to obtain liquid steel; and covering a second part by mass of Fe on the surface of rare earth, pouring the liquid steel, and standing, thereby obtaining the heat-resisting steel, wherein the particle diameter of the rare earth is nano-scale and / or micron-scale. Compared with the prior art, the method has the advantages that the rare earth with the nano-scale or micron-scale particle diameter is adopted to modify the heat-resisting steel, the surface activation energy of the nano-scale and / or micron-scale rare earth is higher, the surface of the rare earth is covered by iron powder, and then, the liquid steel is added, so that the rare earth can be isolated from the air, the time of contact between the rare earth and the liquid steel is shortened, the oxidation burning loss is reduced, then, the modification effect of a rare-earth element on the heat-resisting steel is improved, basic crystal grains of the microstructure of the heat-resisting steel are refined and have the effect of refined crystal grains, meanwhile, the high-temperature elongation percentage of the heat-resisting steel can be increased, and the oxidation resistance of the heat-resisting steel is improved.

Owner:SHANGHAI SUPEZET ENG TECH CO LTD +1

Novel heat-resistant steel for key hot end part of ultrahigh-parameter steam turbine

ActiveCN109763066AAvoid reunionImprove high temperature mechanical propertiesOxidation resistanceSteam turbine

The invention provides novel heat-resistant steel for a key hot end part of an ultrahigh-parameter steam turbine. The novel heat-resistant steel is prepared from the components in percentage by weight: 0.02-0.08% of C, 8.00-10.00% of Cr, 2.0-4.0% of Co, 2.0-4.0% of W, 0.10-0.80% of Mo, 0.10-0.30% of V, 0.30-0.70% of Ni, 0.05-0.15% of Nb, 0.010-0.050% of N, 0.010-0.030% of B, 0.1-1.0% of rare earthelements, no more than 0.10% of Si, 0.10-1.00% of Mn, and the balance of Fe and inevitable impurities. The novel heat-resistant steel belongs to martensitic heat-resistant steel and has the good high-temperature property and oxidation resistance property, thus temperature parameters of the steam turbine are increased, and the power generating efficiency of the steam turbine is improved advantageously.

Owner:DONGFANG TURBINE CO LTD

Magnesium alloy bused composite material and preparing method thereof

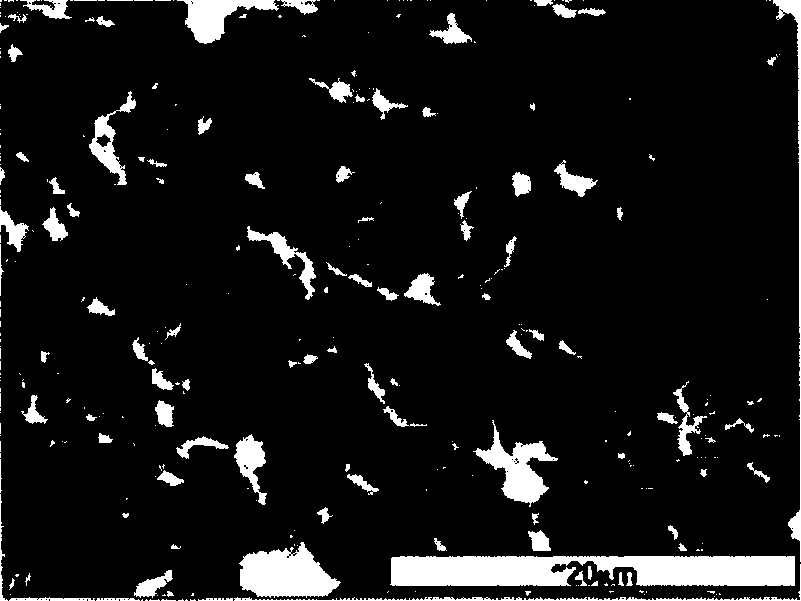

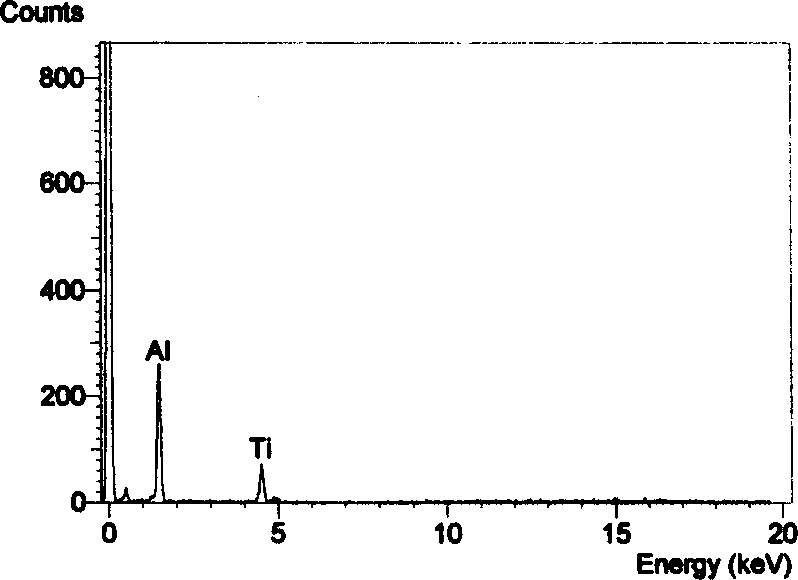

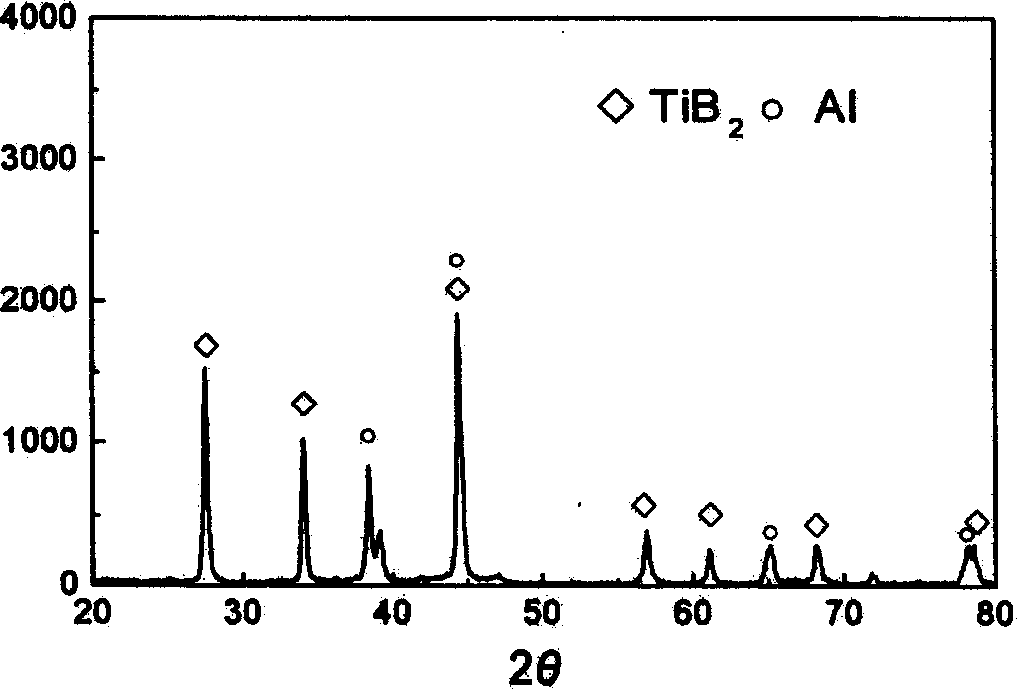

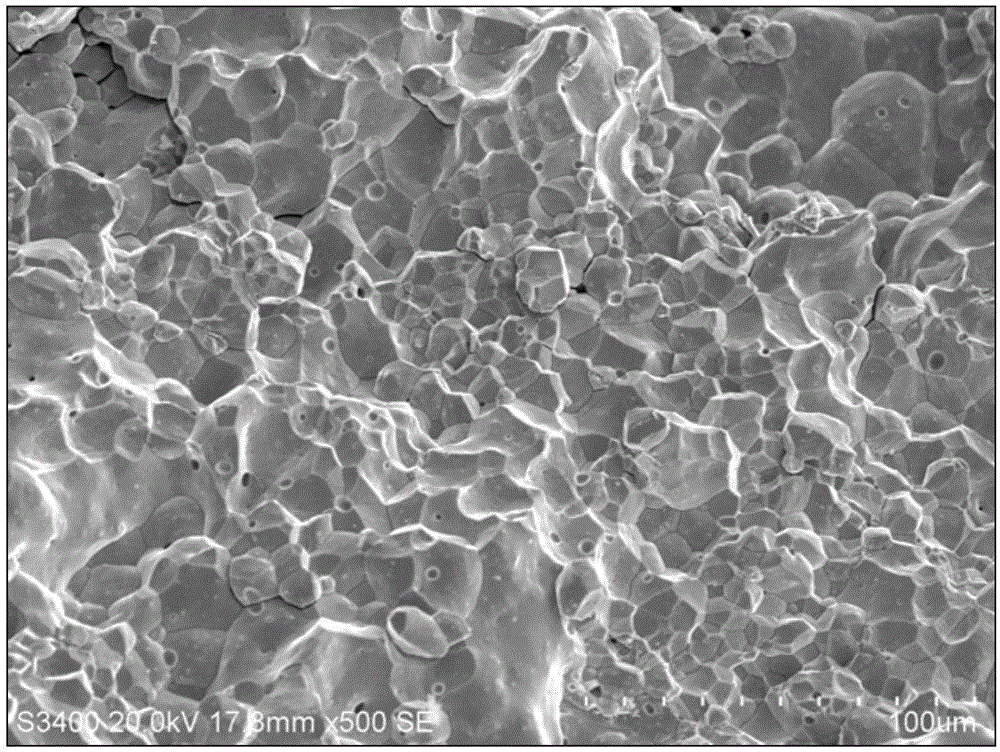

InactiveCN1470663AImprove mechanical propertiesImprove wear resistanceMaterials scienceMagnesium alloy

The present invention relates to a magnesium alloy base composite material, and is characterized by that it is a reinforced composite material obtained by making TiB2 granules be dispersed and uniformly distributed in the magnesium alloy base body. Its preparation includes the following processes: preparing reaction prefabricated block, preparing intermediate phase carrier containing reinforcement granules, dissolving and diffusing the intermediate phase carrier in magnesium alloy base body and dispersing and distributing the reinforcement granules in the magnesium alloy base body. Said composite material has good comprehensive performance, so that it has extensive application range.

Owner:JILIN UNIV

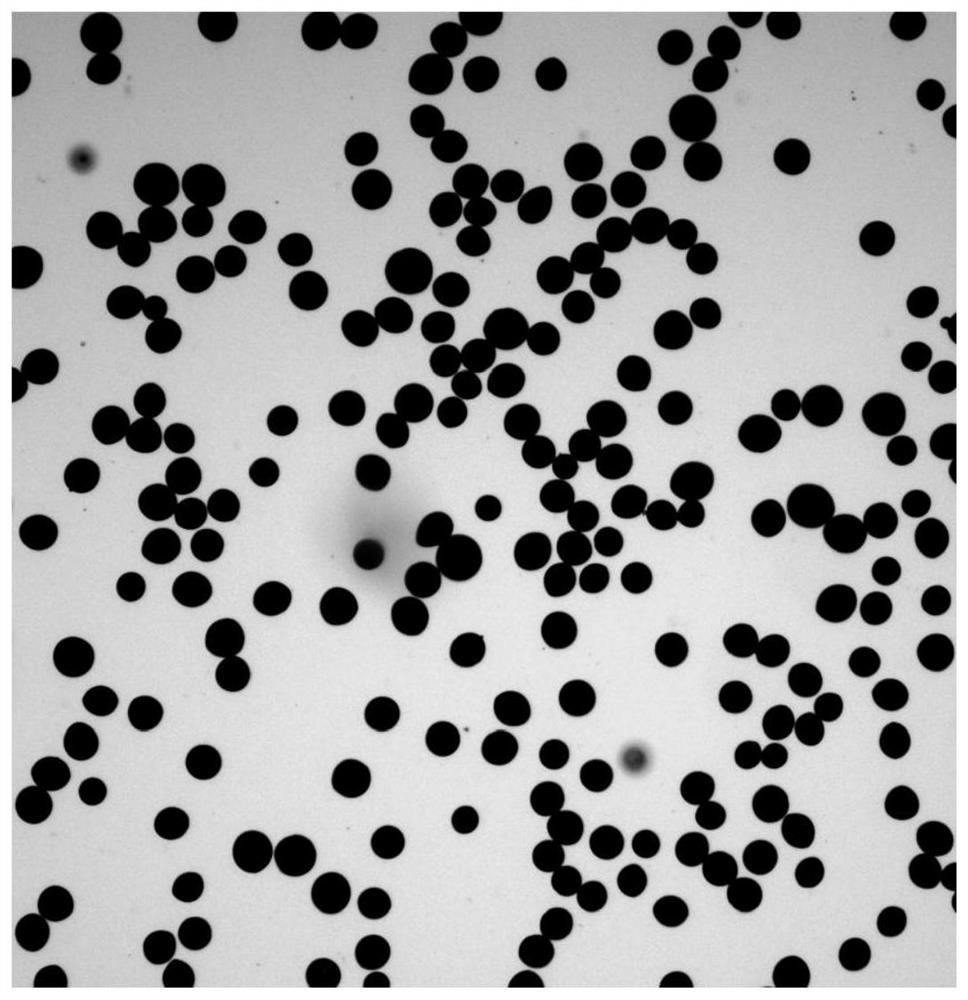

Preparation method of molybdenum rhenium lanthanum alloy material

The invention provides a preparation method of a molybdenum rhenium lanthanum alloy material. The preparation method comprises the following steps: (1) components of the molybdenum rhenium lanthanum alloy material are designed; and then, nanometer lanthanum oxide powder, rhenium powder and molybdenum dioxide powder are respectively weighed according to the designed components; (2) the nanometer lanthanum oxide powder is weighed again; (3) the nanometer lanthanum oxide powder weighed in the steps (1) and (2) is uniformly mixed to add in de-ionized water for dispersion and filtration to obtain filtrate; (4) the rhenium powder is added in the filtrate for dispersion to obtain mixed liquid, and is added in the molybdenum dioxide powder; (5) hydrogen is used for reduction to obtain a reduction material for screening and mixing to obtain reduction alloy powder; and (6) the isostatic pressing is performed to obtain a pressed blank; and the pressed blank is sintered to obtain the molybdenum rhenium lanthanum alloy material. The alloy material is uniform and fine in particles; grains in a slab fracture are fine; the grain boundary is clear and pure; and no visible agglomerated second-phase particle is in the grain boundary and crystals, so that the nanoparticles in the alloy material are excellent in dispersion effect to satisfy the technical requirements.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Method for reinforced 7075 aluminum alloy rolled sheets

The invention discloses a method for reinforced 7075 aluminum alloy rolled sheets. The method comprises the following steps that 1, an aluminum alloy enhancer which contains multi-phase multi-scale TiCN-AlN-TiB2 ceramic particles is prepared by in-situ reaction; 2, the aluminum alloy enhancer is added into 7075 aluminum alloy melt to prepare the multi-phase multi-scale particle reinforced 7075 aluminum alloy; and 3, the multi-phase multi-scale particle reinforced 7075 aluminum alloy is subjected to rolling and heat treatment to obtain the reinforced 7075 aluminum alloy rolled sheets. Accordingto the method, the addition amount of the aluminum alloy enhancer with the multi-phase multi-scale TiCN-AlN-TiB2 ceramic particles is added and controlled, so that the 7075 aluminum alloy rolled sheets are enhanced, and the mechanical property of the 7075 aluminum alloy rolled sheets is improved.

Owner:JILIN UNIV

Liquid metal corrosion-resistant high-chromium martensite heatproof steel

The invention discloses a liquid metal corrosion-resistant high-chromium martensite heatproof steel, and belongs to the field of heatproof metal materials. The steel comprises 0.18-0.26wt% of C, 1.0-1.5wt% (not including 1.0%) of Si, 10-11.5wt% (not including 10%) of Cr, 1.0-1.5wt% (not including 1.0%) of W, 0-1.0wt% (not including 0 or 1.0%) of Mn, 0.3wt% or less of Ta + Tb, 0-0.2wt% ((not including 0%) of V, and the balance of Fe. The reasonable high silicon and high chromium content is adopted to improve the liquid metal corrosion resistance, C, Mn and other elements are greatly adjusted to inhibit the generation of delta ferrite in order to improve the strength and toughness of a fully martensitic structure, and tantalum, niobium, vanadium and other micro alloying elements are adopted to carry out composite reinforcement in order to improve the high temperature creep resistance, so the heatproof steel has excellent strength and toughness, high temperature creep resistance and liquid metal corrosion resistance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

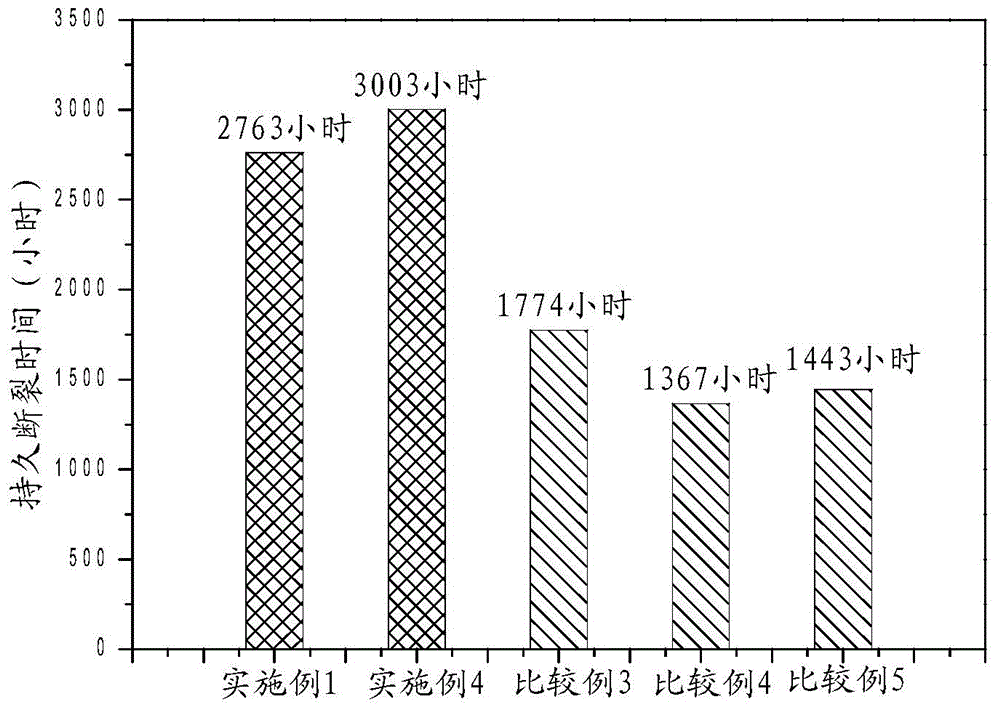

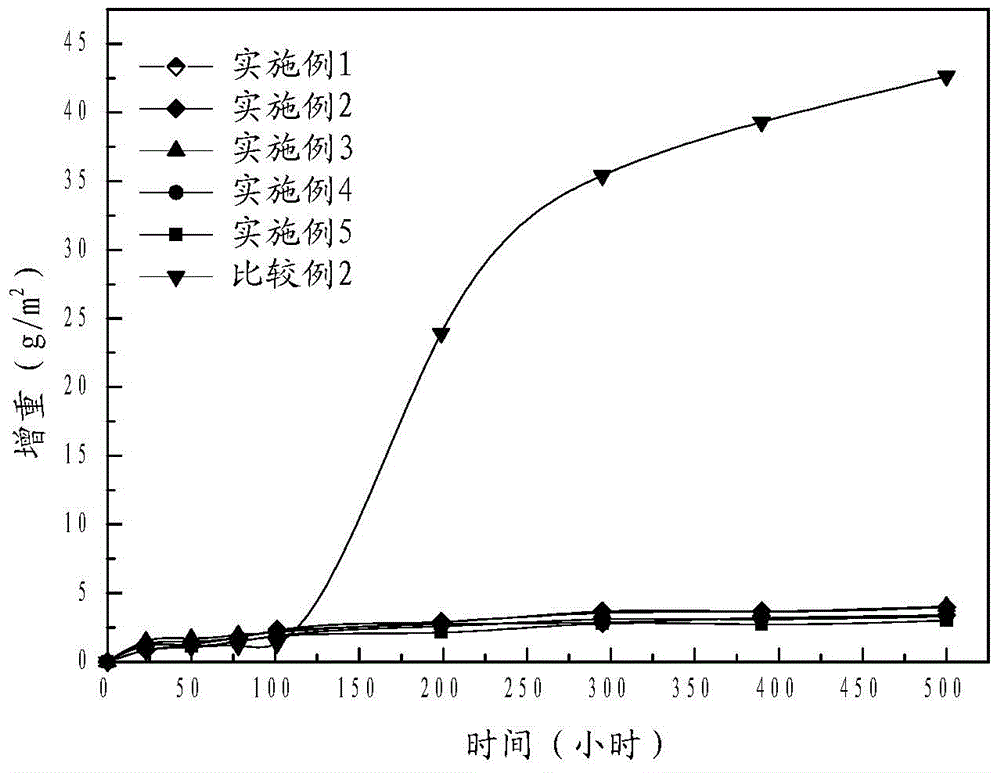

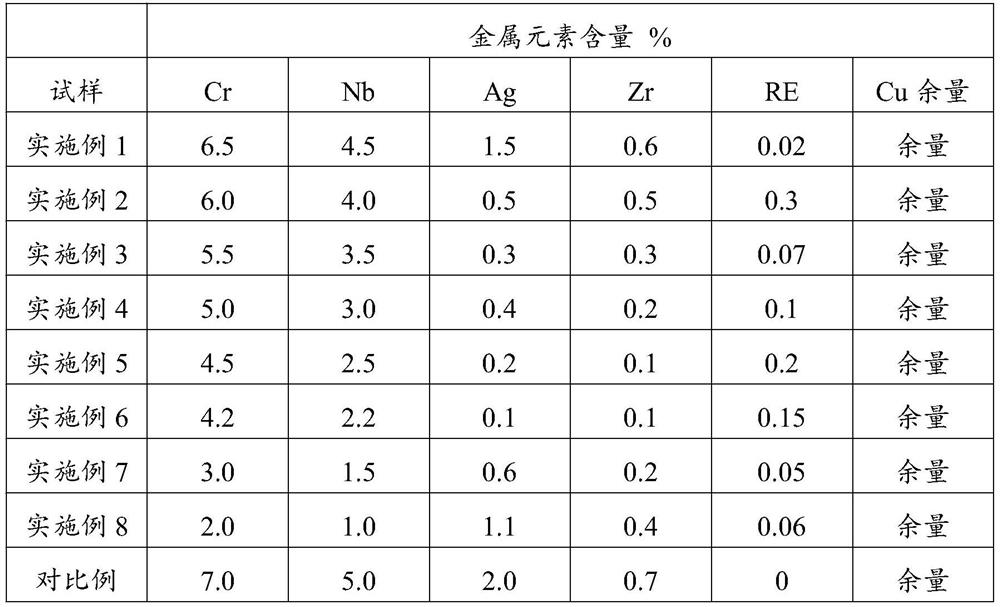

Copper alloy material and preparation method and application thereof

ActiveCN112030031AExcellent high temperature mechanical propertiesImprove high temperature mechanical propertiesAdditive manufacturing apparatusUltimate tensile strengthMechanical property

The invention provides a copper alloy material and a preparation method and application thereof, and belongs to the technical field of additive manufacturing. The copper alloy material is prepared from the following components in percentage by mass: 2.0%-7.0% of Cr, 1.0%-5.0% of Nb, 0.1%-2.0% of Ag, 0.1%-0.7% of Zr, 0.02%-0.3% of RE and the balance of Cu; and the RE is prepared from the followingcomponents in percentage by mass: 88%-93% of La, 6%-9% of Ce, 1.5%-1.9% of Pr and less than or equal to 0.3% of Nd, and the sum of the mass percent is 100%. According to the copper alloy material, through the synergistic effect of RE, Cr, Nb, Ag, Zr and Cu, the heat-conducting property, high-temperature creep property, high-temperature strength and high-temperature fatigue of the copper alloy material are effectively improved, and the problem that in the prior art, the high-temperature mechanical property of the copper alloy material is poor is solved.

Owner:HEBEI LIEN NEW MATERIAL TECH CO LTD

Aluminum alloy wire harness for light automobile and preparation method thereof

InactiveCN110157958AHigh strengthImprove high temperature creep performanceConductive materialManufacturing wire harnessesElectrical conductorPotassium

The invention discloses an aluminum alloy wire harness for a light automobile. The aluminum alloy wire harness for the light automobile comprises a conductor wire core and an outer layer insulating layer, wherein the conductor wire core comprises the following components of 0.2wt%-0.4wt% of V, 0.01wt%-0.3wt% of Cu+Mg, 0.001wt%-0.01wt% of Sb, 0.01wt%-0.05wt% of Ti, 0.001wt%-0.002wt% of Ag+F, 0.001wt%-0.003wt% of Zr, 0.1wt%-0.3wt% of RE, and the balance is Al; the alloy does not contain Si and Fe; Ce and La are 50% of the total amount of the RE or more; and in a wire drawing process, the conductor wire core is firstly subject to dipping in a mixed solution of potassium fluoborate and polydimethylsiloxane, intermediate annealing in a nitrogen atmosphere containing 5% oxygen concentration is carried out, and then wire drawing is carried out. According to the aluminum alloy wire harness and the preparation method, V, Ti, Ag, F and Zr are adopted as reinforcing systems and secondary smeltingis adopted, so that the elongation at break and the tensile strength of the aluminum alloy wire harness for the light automobile are improved.

Owner:CHANGSHA QIUDIANBING INFORMATION TECH CO LTD

Pre-deformed magnesium alloy and processing method thereof

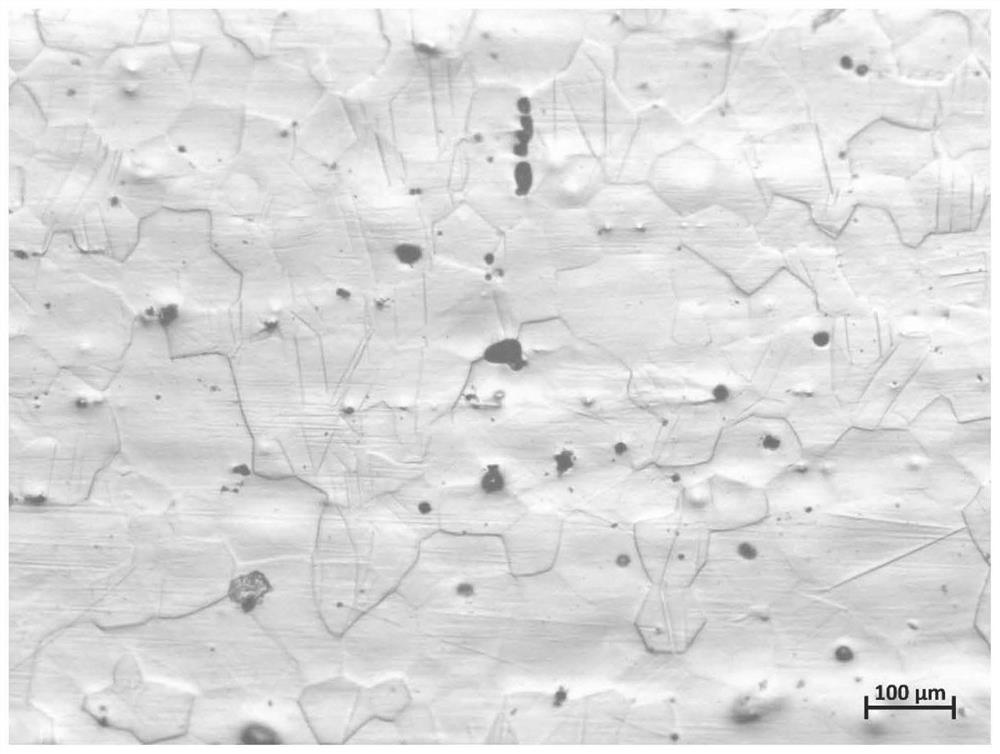

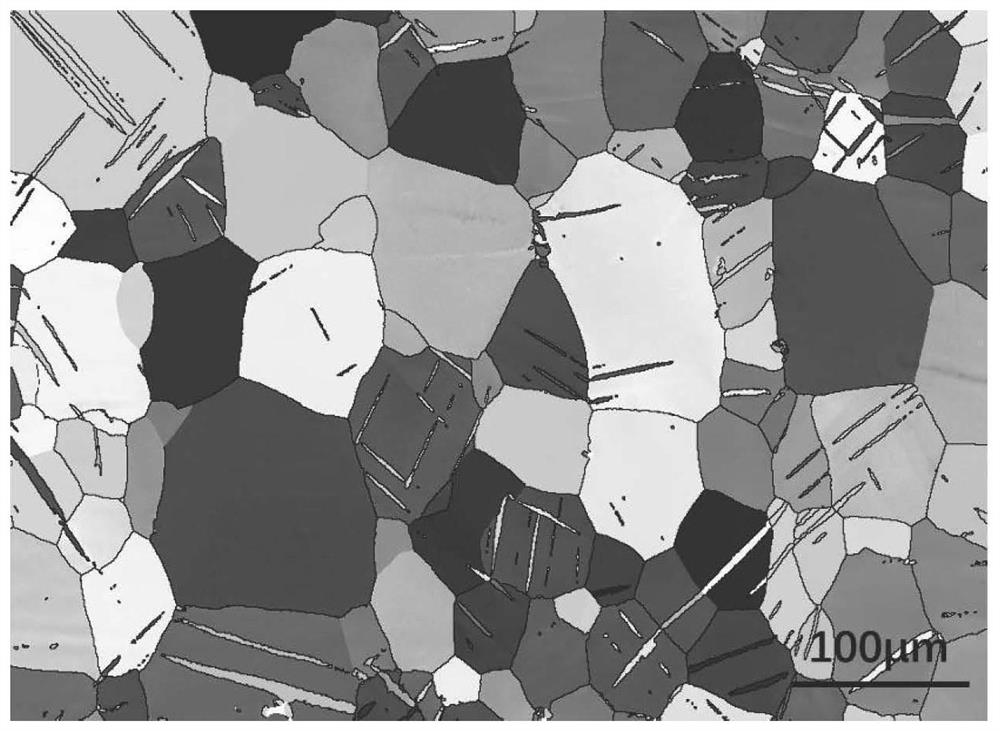

The invention discloses a pre-deformed magnesium alloy. The pre-deformed magnesium alloy comprises the following components in percentage by mass: 8.5%-9.5% of Al, 0.45%-0.90% of Zn, 0.15%-0.4% of Mn, 0.3%-0.8% of Y and the balance of magnesium and non-removable impurity elements. The magnesium alloy is obtained after being treated by a solution treatment process, a preferred orientation processing process and a twin crystal pre-deformation process in sequence, and twin crystals exist in more than 40% of crystal grains in a microscopic structure of the magnesium alloy. The invention further relates to a processing method of the pre-deformed magnesium alloy. According to the pre-deformed magnesium alloy and the processing method thereof, by regulating and controlling the magnesium alloy structure, the magnesium alloy is subjected to creep dynamic precipitation in the high-temperature creep process, the thermal stability of the material is improved through the creep dynamic precipitation phase, the creep loading range is expanded, and the creep resistance of the material is improved; and the magnesium alloy is simple in processing process, low in equipment requirement, easy and convenient to operate, relatively low in cost and high in production efficiency. Application and popularization of the magnesium alloy have important significance.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

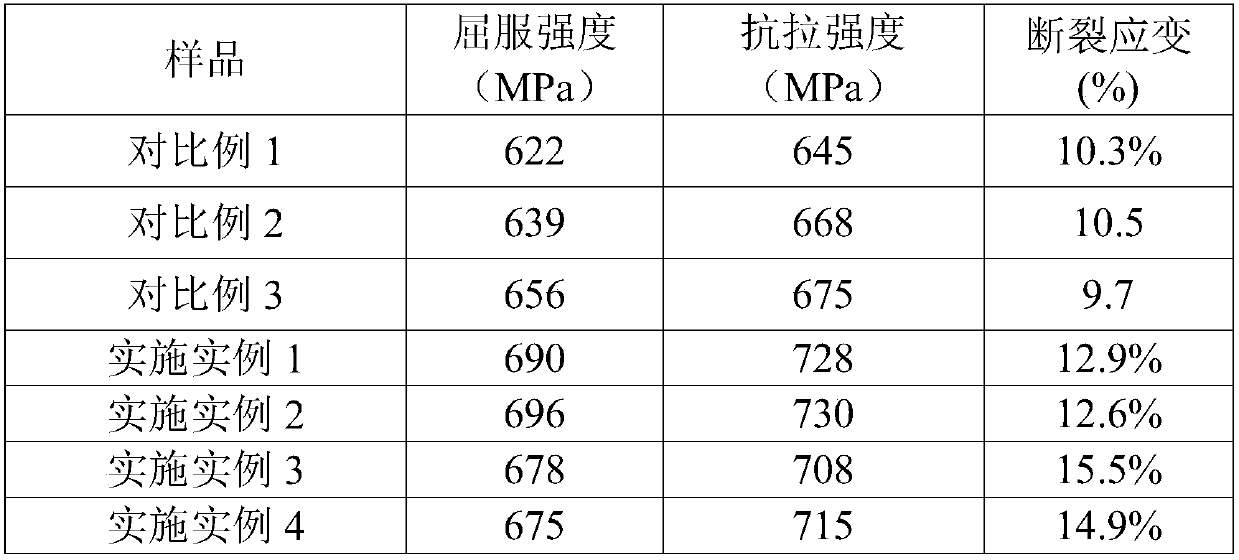

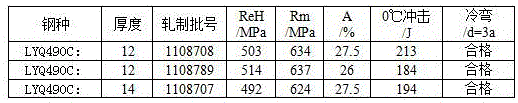

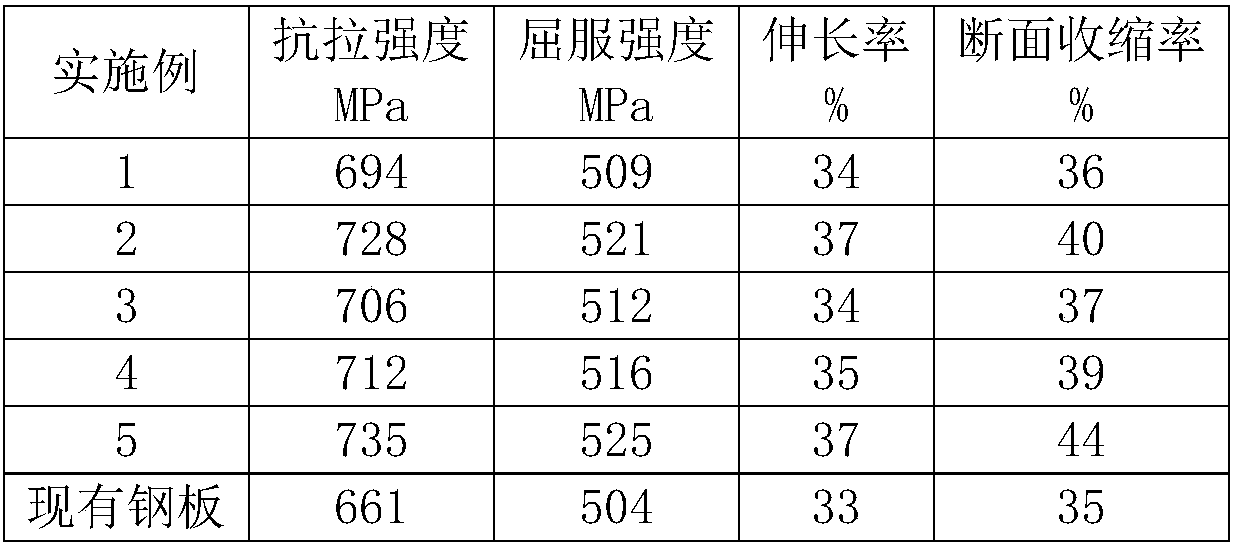

Cold-pressed steel plate for automotive axle housing and production method thereof

The invention relates to a steel and iron smelting technology, in particular to a cold-pressed steel plate for an automotive axle housing and a production method of the cold-pressed steel plate. The cold-pressed steel plate for the automotive axle housing comprises, by mass percentage, 0.10%-0.16% of C, 0.30%-0.45% of Si, 1.45%-1.60% of Mn, smaller than or equal to 0.15% of P, smaller than or equal to 0.005% of S, 0.045%-0.060% of V, 0.015%-0.030% of Nb, 0.025%-0.050% of Als and the balance Fe. According to the cold-pressed steel plate for the automotive axle housing and the production method, a trace of V elements and a trace of Nb elements are added to ordinary carbon structural steel, and the content of P elements and the content of S elements are reduced, so that the rolling and cooling technology is appropriately changed to improve the strength of the steel plate, and the cold forming performance of the steel plate is improved. By means of the element design and the design of the production technology process, various performance indexes of the steel plate are guaranteed, and the indexes, such as mechanical properties including the stretching property and the impact property, and the ultrasonic flaw detection index, of the steel plate are better than those of similar products.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

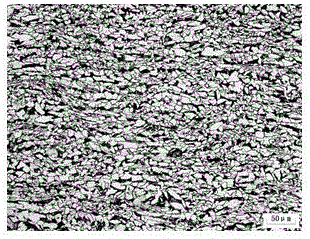

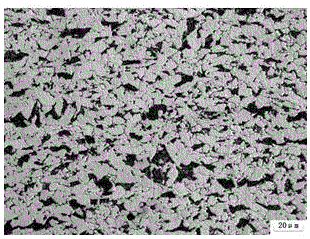

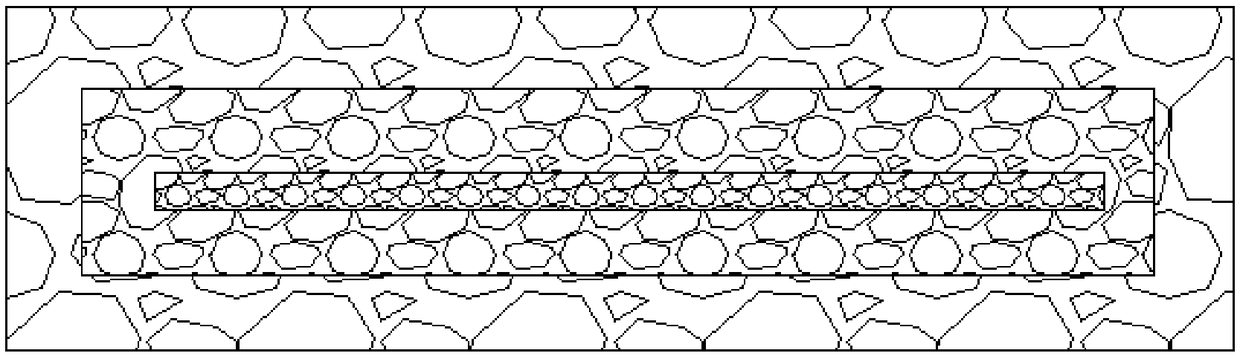

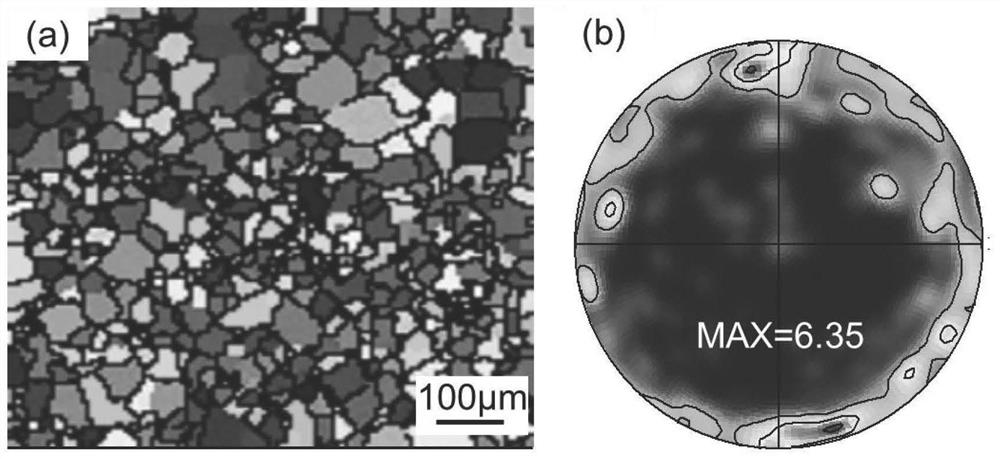

Ferrite steel plate with heterogeneous structure and preparation method thereof

ActiveCN108405649AGuaranteed StrengthSolve the problem of poor plasticityArc welding apparatusMetal rolling arrangementsUltimate tensile strengthToughness

The invention discloses a ferrite steel plate with a heterogeneous structure and a preparation method of the ferrite steel plate, and belongs to the technical field of steel plate preparation. According to the preparation method, coarse grains and fine grains are reasonably mixed through resurfacing welding, rolling and annealing, so that the problem that the plasticity of an existing steel plateis relatively poor is solved, the strength of the plate is guaranteed, and finally the toughness of the steel plate is guaranteed. The preparation method is simple, the processing efficiency is improved, the cost is saved, and the microscopic structure and the macroscopic mechanical property of a workpiece are effectively regulated and controlled.

Owner:SOUTHWEST JIAOTONG UNIV

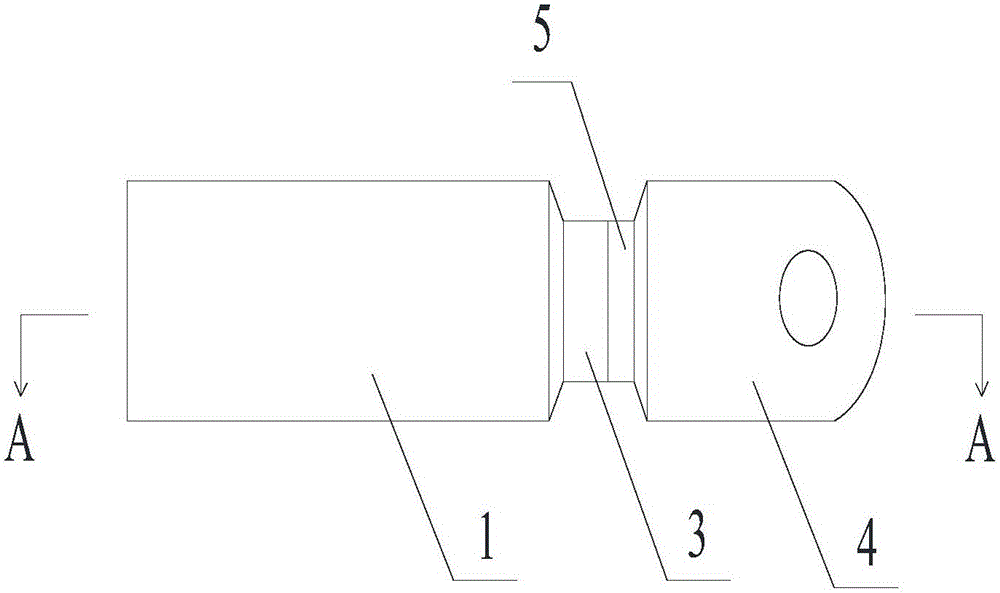

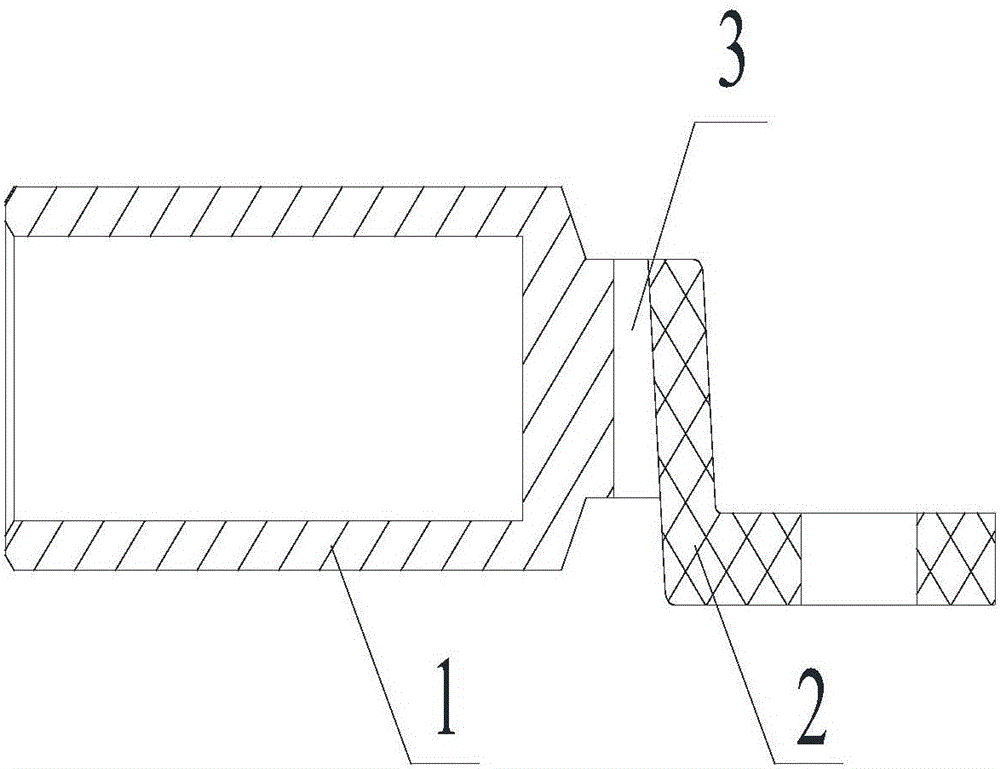

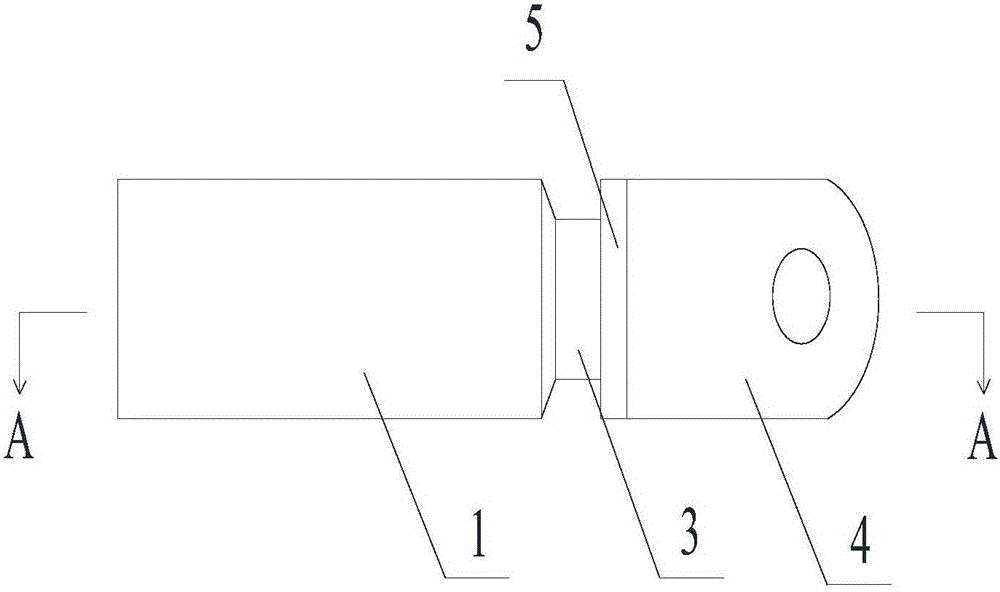

Copper-aluminum transition terminal of Al-Fe-Mn-RE aluminum alloy cable and preparation method thereof

PendingCN105703096APromote mutual solubilityPrevent brittle phaseLine/current collector detailsMulticonductor cable end piecesElectrical conductorSolid structure

The invention discloses a copper-aluminum transition terminal of an Al-Fe-Mn-RE aluminum alloy cable, and belongs to the technical field of the copper-aluminum transition terminal. The copper-aluminum transition terminal of the Al-Fe-Mn-RE aluminum alloy cable comprises an aluminum alloy connecting pipe connected with a cable conductor and a copper nose connected with the other end of the aluminum alloy connecting pipe; a copper-aluminum transition part is arranged between the aluminum alloy connecting pipe and the copper nose; and the copper-aluminum transition part is an aluminum alloy in a columnar solid structure. The invention also provides a preparation method of the copper-aluminum transition terminal of the Al-Fe-Mn-RE aluminum alloy cable. The preparation method is simple, and easy to operate; and the prepared copper-aluminum transition terminal is excellent in electrical properties, mechanical properties and creep resistance, also has reliable connectivity under a condition of a constantly changing temperature, is outstanding in thermal stability and electric conductivity and can transit steadily and mildly from the aluminum alloy cable to the connecting pipe and to the copper nose.

Owner:河北欣意电缆有限公司

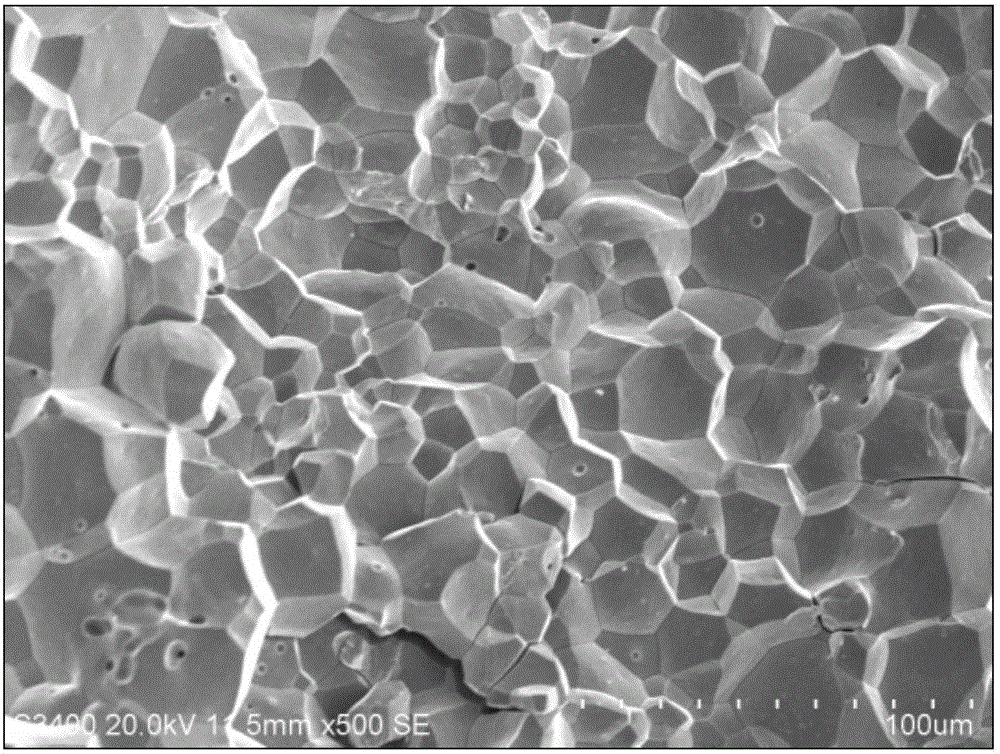

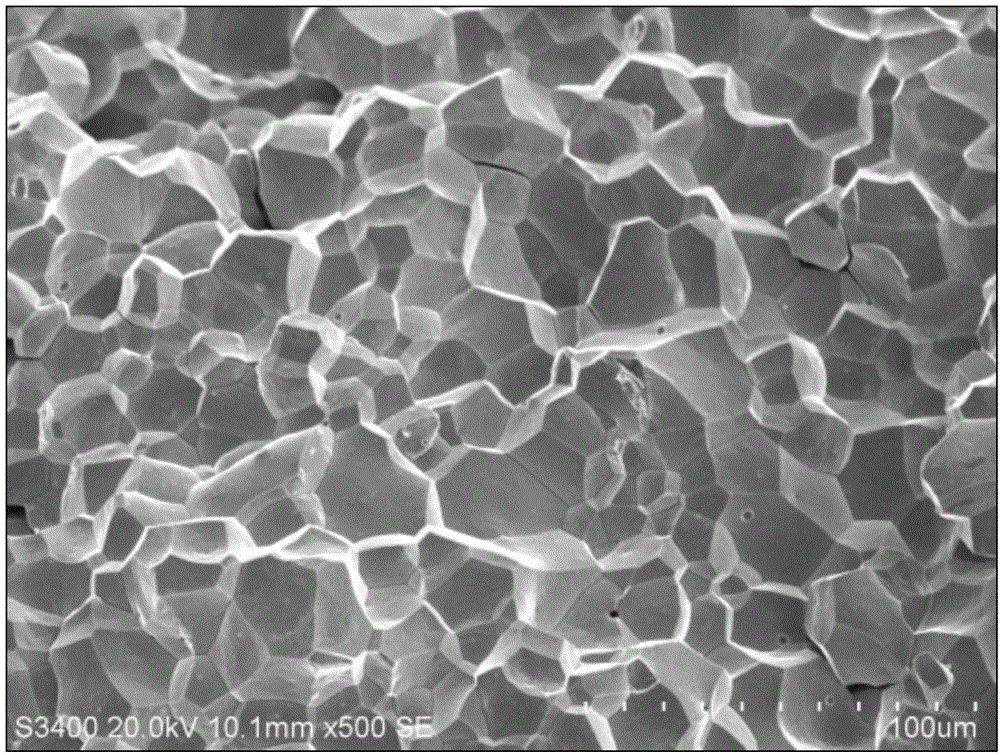

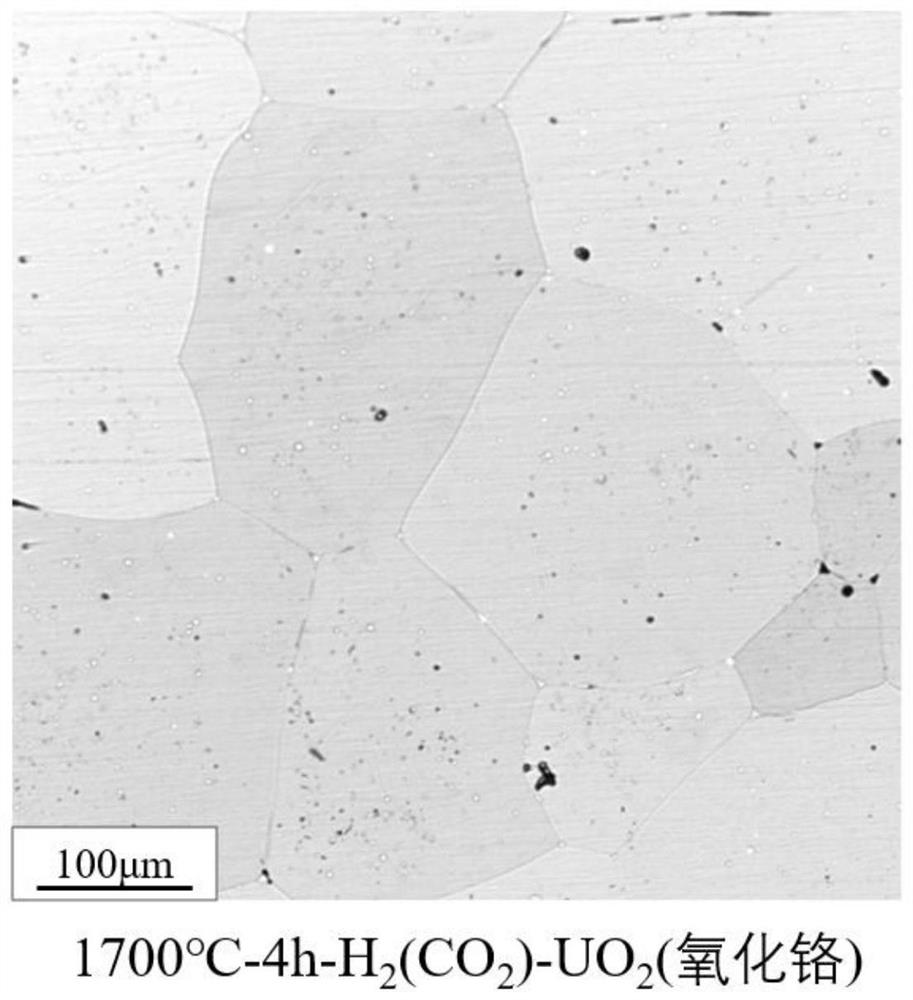

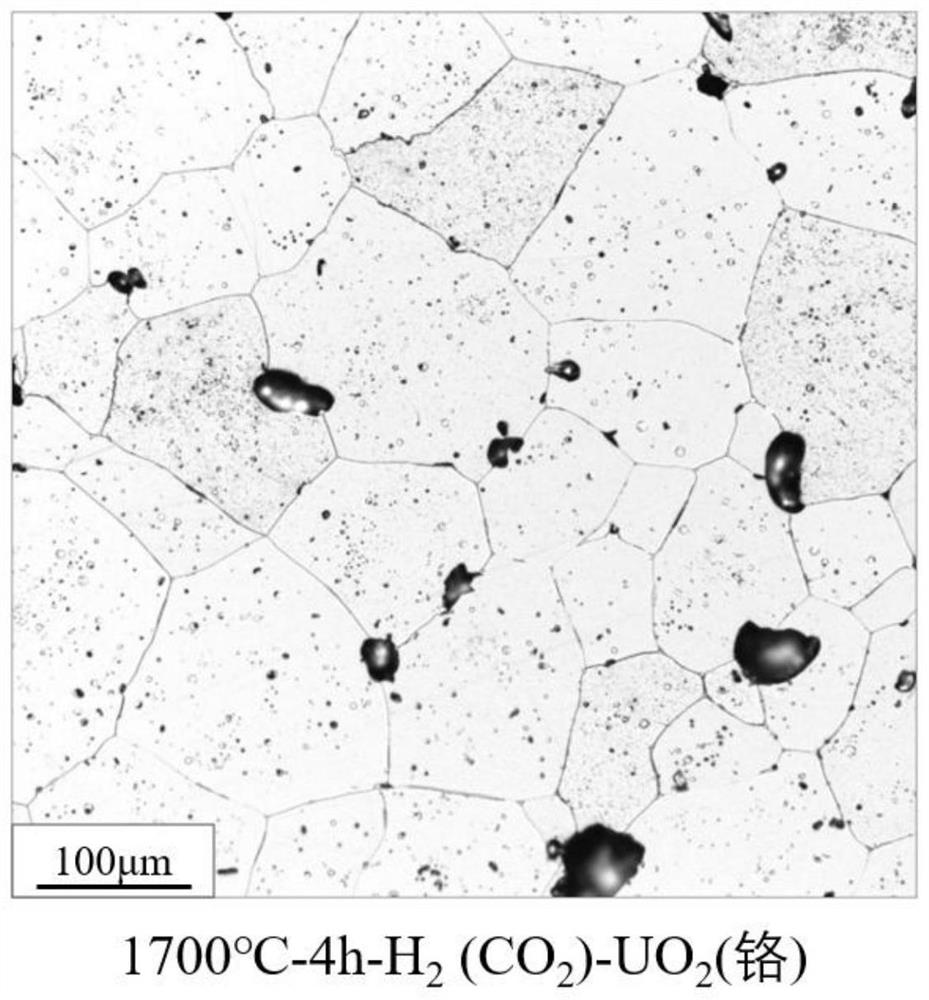

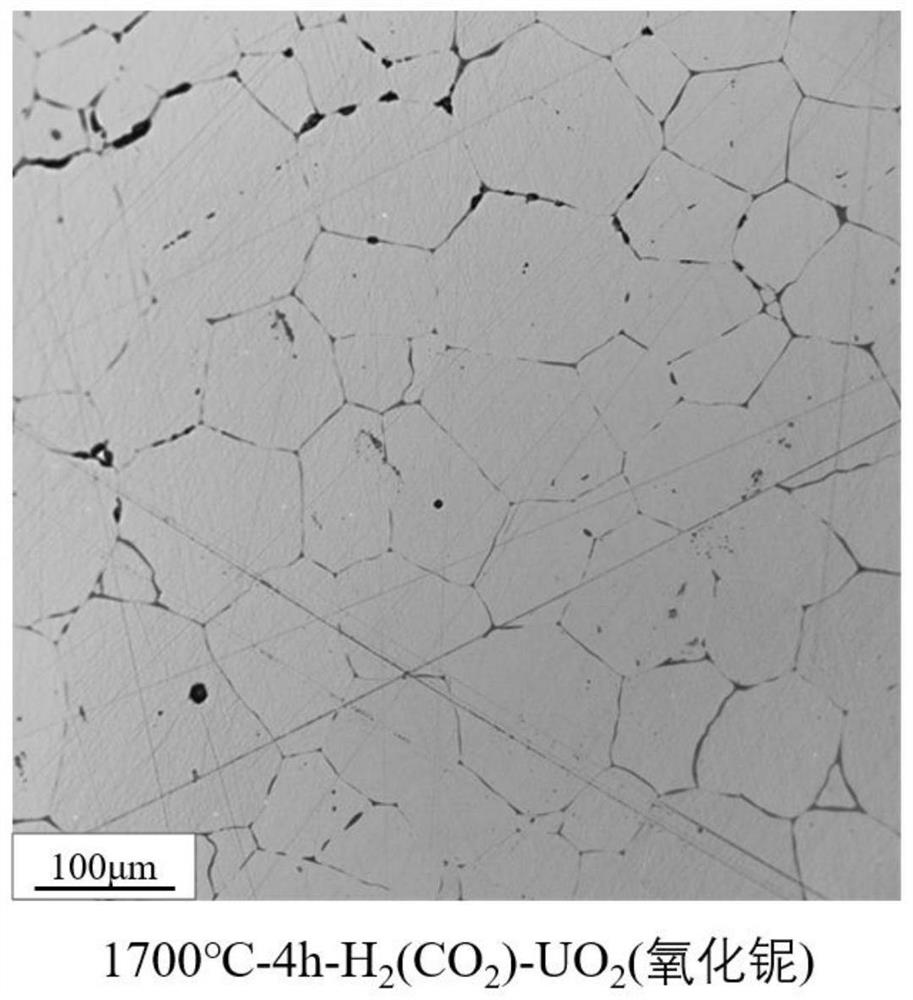

Large-grain UO2 ceramic fuel, and preparation method and application thereof

ActiveCN113683422AImprove high temperature creep performanceImprove retentionNuclear energy generationReactor fuel susbtancesMetallurgyGrain growth

The invention provides a large-grain UO2 ceramic fuel, and a preparation method and application thereof, and belongs to the technical field of nuclear fuel development. According to the invention, the additive is used as a grain growth assistant, and in the sintering process, the additive enters a lattice gap through a lattice charge balance (charge state) and defect structure (interstitial atom size / coordination relationship) mechanism, so that the vacancy concentration of uranium is improved, the lattice diffusion rate is improved, UO2 lattice rearrangement is promoted to obtain grain growth, the grain growth of the UO2 fuel is accelerated, and the average grain size (50-180 [mu]m) of the UO2 ceramic fuel is rapidly and effectively improved. Moreover, the grain boundary specific surface area can be reduced by obtaining the large grain size, so that the UO2 has the characteristics of low thermal expansion coefficient, higher high-temperature creep property, higher retention property on fission products and the like, thereby improving the economical efficiency and safety of a reactor and being capable of being used as a novel nuclear fuel of the reactor.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +1

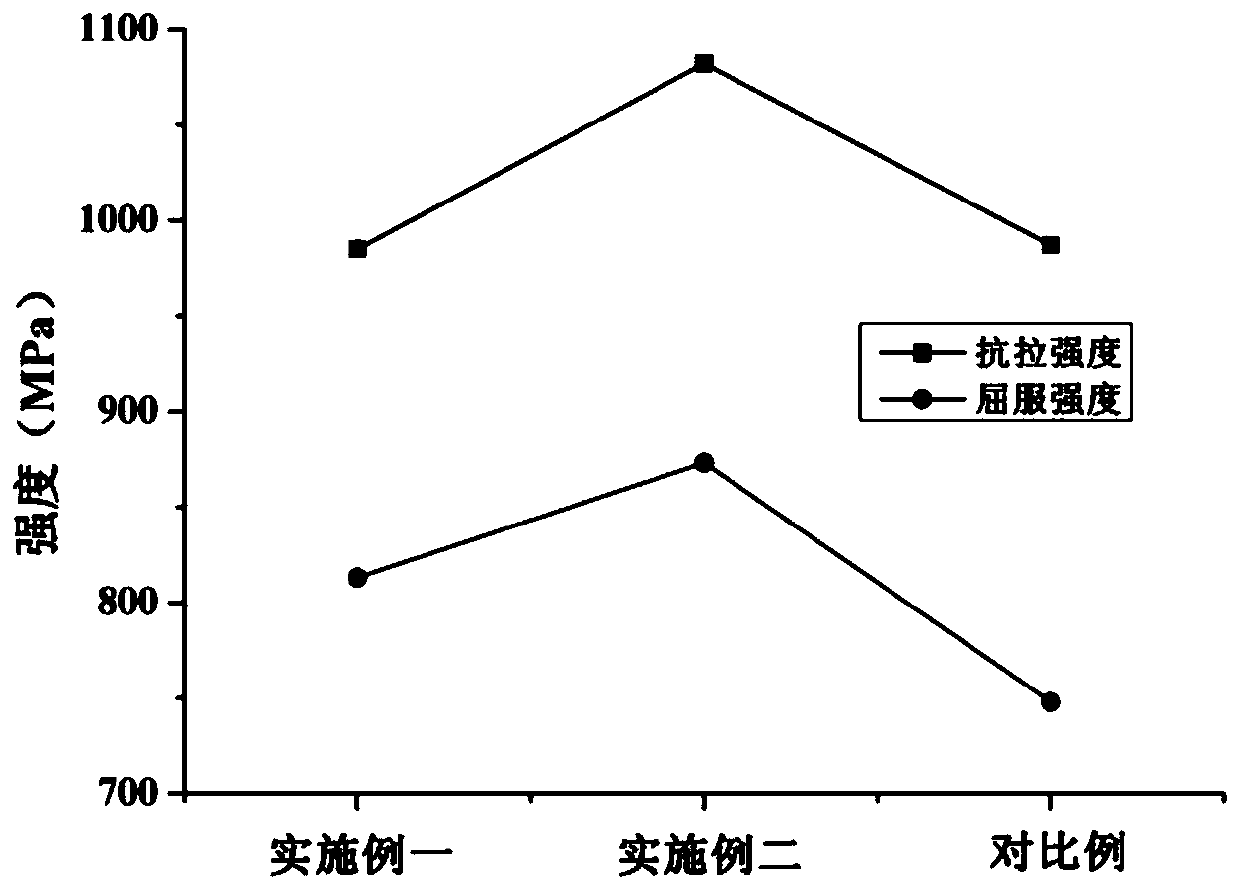

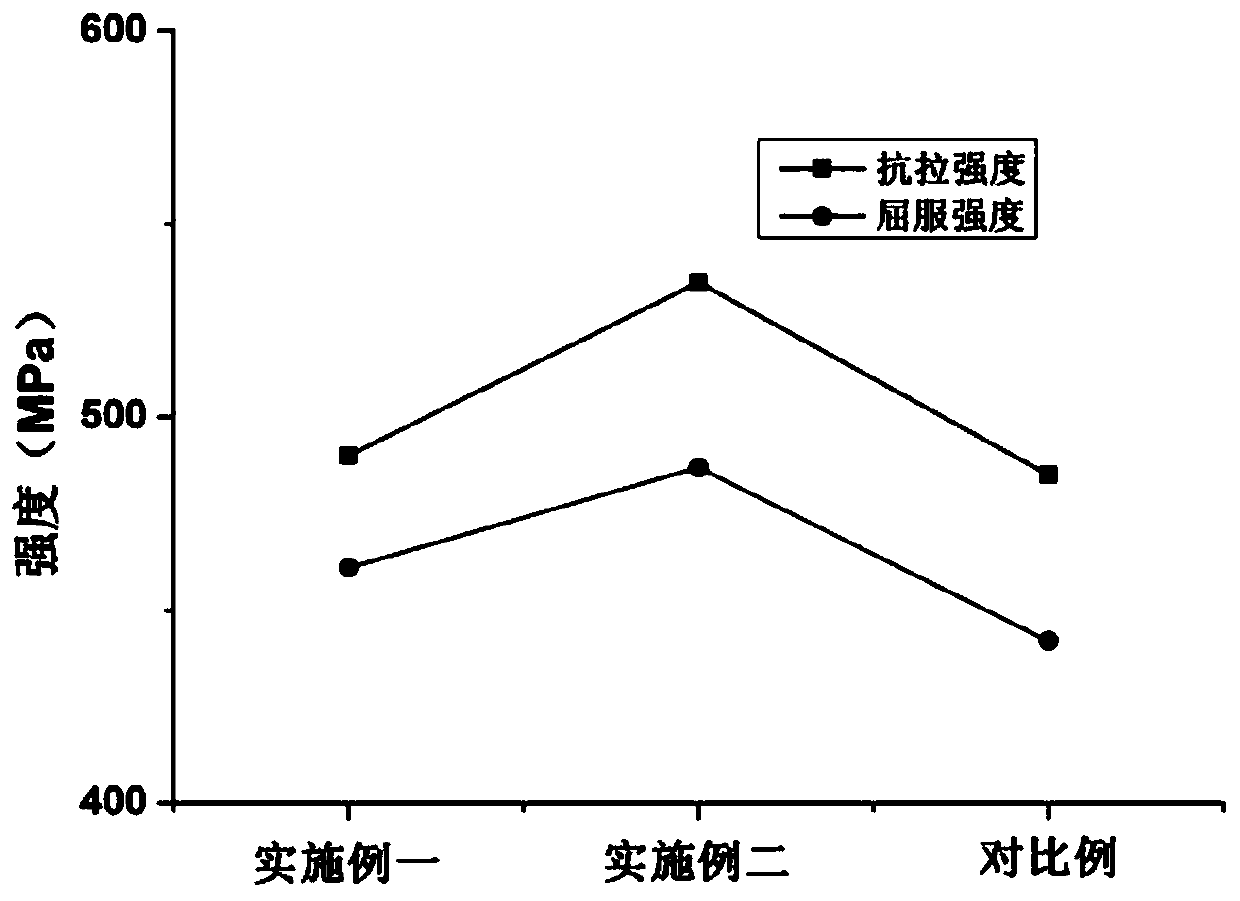

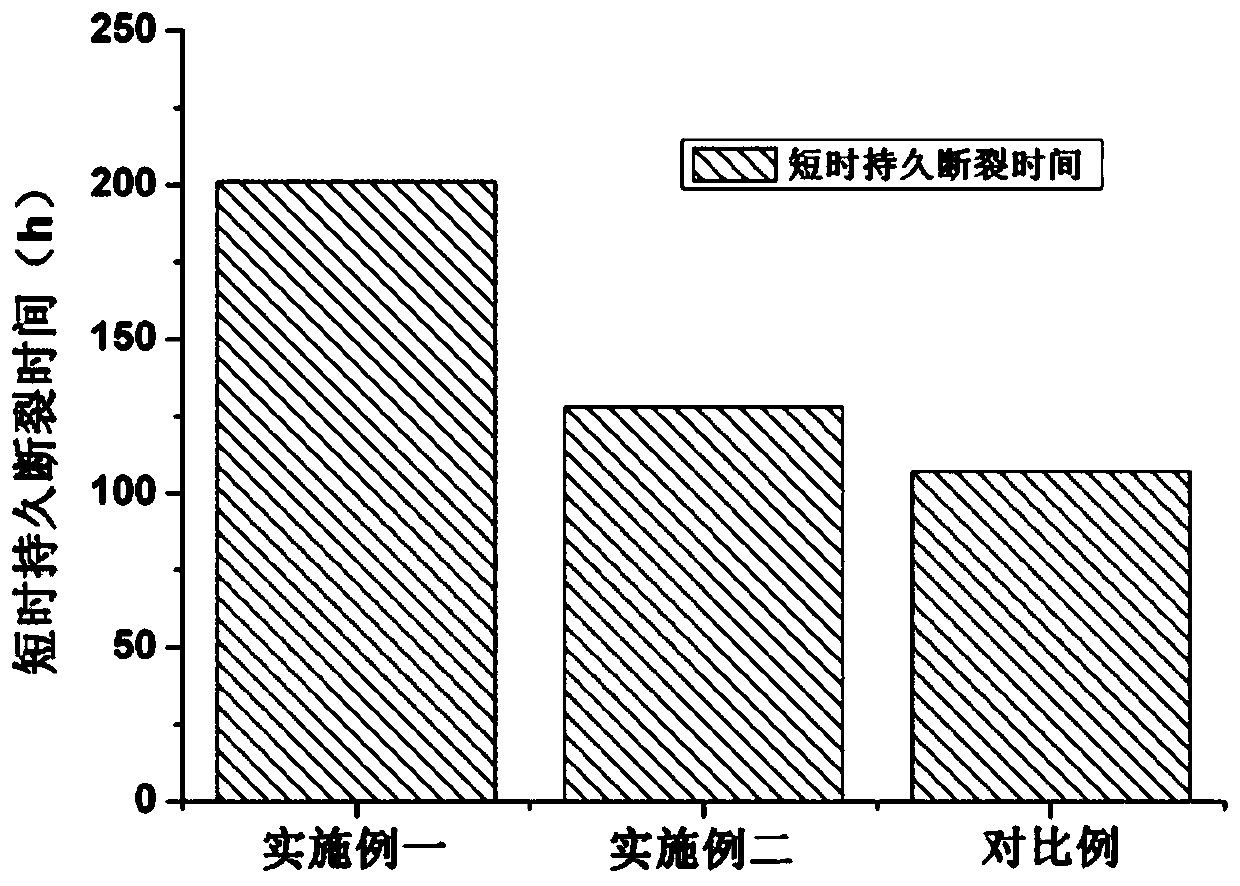

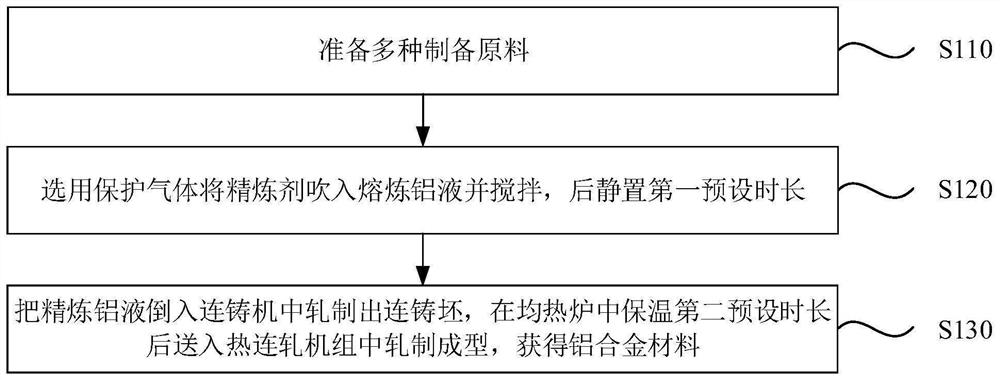

Composite brazing aluminum sheet/foil core material alloy for intercooler and preparation method of core material alloy

The invention discloses a composite brazing aluminum sheet / foil core material alloy for an intercooler and a preparation method of the core material alloy. The core material alloy consists of the following components in percentage by weight: 0.12-0.46% of iron, 0.01-0.25% of silicon, 0.45-1.4% of manganese, 0.04-0.5% of copper, 0.1-0.21% of magnesium, 0.05-0.2% of zirconium, 0.01-0.4% of ytterbium and the balance of aluminum. The preparation method of the core material alloy mainly comprises the steps of 1. smelting, stirring, purifying and keeping all alloys except for aluminum-ytterbium alloy; 2. adding aluminum-ytterbium alloy, stirring, standing by, and casting molten aluminum into a core material aluminum alloy sheet; and 3. homogenizing the core material aluminum alloy sheet, preserving heat, discharging the core material aluminum alloy sheet out of furnace, air-cooling, and implementing surface treatment. The core material alloy disclosed by the invention has the advantages of being effective to inhibit erosion of molten solder and obvious to improve high-temperature creep performance of aluminum alloy; and the method disclosed by the invention is simple and easy to implement, and applicable to industrial production.

Owner:SOUTHEAST UNIV +1

Al-Cu-Sr-RE-Ge aluminium alloy wire for power cable and preparation method thereof

InactiveCN110923529AHigh tensile strengthHigh yield strengthApparatus for heat treatmentConductive materialPower cableThermal insulation

The invention provides an Al-Cu-Sr-RE-Ge aluminium alloy wire for a power cable and a preparation method thereof. The Al-Cu-Sr-RE-Ge aluminium alloy wire comprises the following components: 0.4-0.8wt%of Cu, 0.15-0.36wt% of Sr, 0.12-0.32wt% of RE, 0.13-0.28wt% of Ge, 0.11-0.18wt% of Si, 0.02-0.09wt% of Co, 0.03-0.07wt% of Ca, 0.01-0.05wt% of Cr and the balance of Al and unavoidable impurities. Thepreparation method comprises the following steps: 1, smelting and pouring; 2, quenching at 505-520 DEG C, and carrying out aging treatment at 210-225 DEG C; 3, extruding into an aluminium alloy rod at 485-510 DEG C; 4, drawing into a first aluminium alloy wire at 290-310 DEG C; 5, drawing into a second aluminium alloy wire with the diameter of 1-2.5mm at 330-360 DEG C; and 6, carrying out thermalinsulation on the second aluminium alloy wire for 3-5 hours at 350-380 DEG C, then reducing the temperature to 230-260 DEG C, carrying out thermal insulation for 6-10 hours, and air cooling to the room temperature. The Al-Cu-Sr-RE-Ge aluminium alloy wire has excellent electric conductivity and heat resistance and is high in strength, toughness and fatigue resistance.

Owner:安徽峰创云通数据科技有限公司

A high-chromium martensitic heat-resistant steel resistant to liquid metal corrosion

The invention discloses a liquid metal corrosion-resistant high-chromium martensitic heat-resistant steel, which belongs to the field of heat-resistant metal materials. It is characterized in that the weight percentage (wt.%) of the alloy composition is: 0.18%≤C≤0.26%, 1.0%<Si≤1.5%, 10%<Cr≤11.5%, 1.0%<W≤1.5%, 0%< Mn<1.0%, Ta+Nb: ≤0.3%, 0%<V≤0.2%, the balance is iron. The beneficial effect of the present invention is that the liquid metal corrosion resistance is improved by adopting a more reasonable high silicon and high chromium content, and the generation of δ ferrite is suppressed by adjusting the content of carbon, manganese and other elements to obtain a full The martensitic structure improves the strength and toughness, and the microalloying elements such as tantalum, niobium and vanadium are used for composite strengthening to improve the high-temperature creep performance, so that the heat-resistant steel has excellent strength and toughness, high-temperature creep performance and liquid metal corrosion resistance. .

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

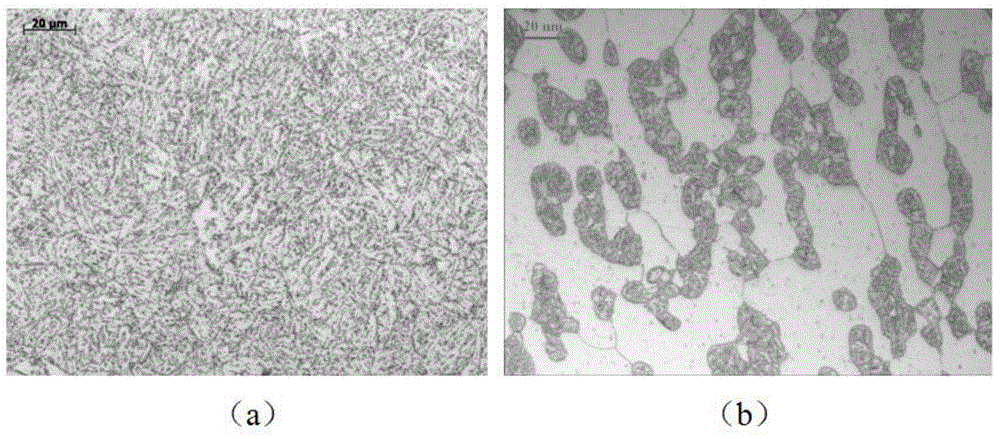

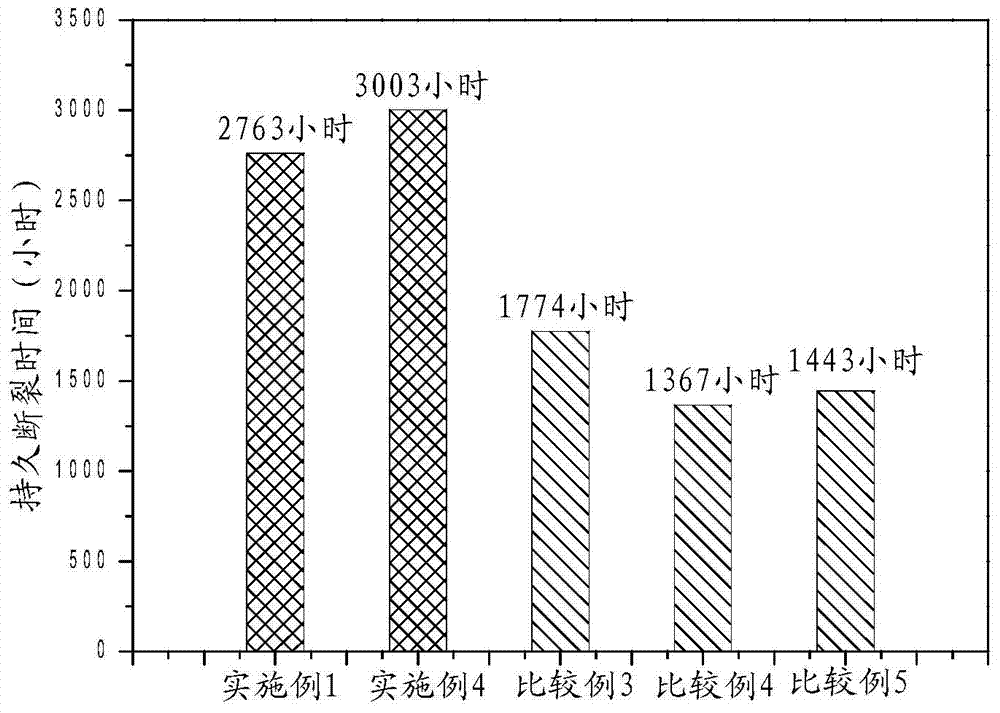

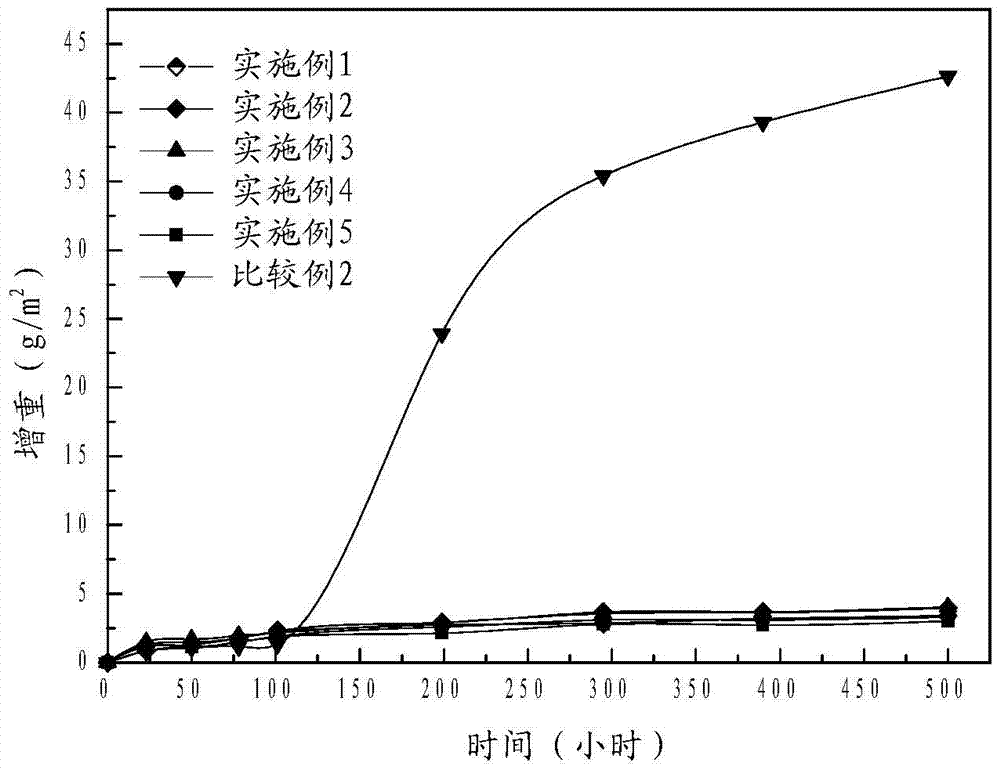

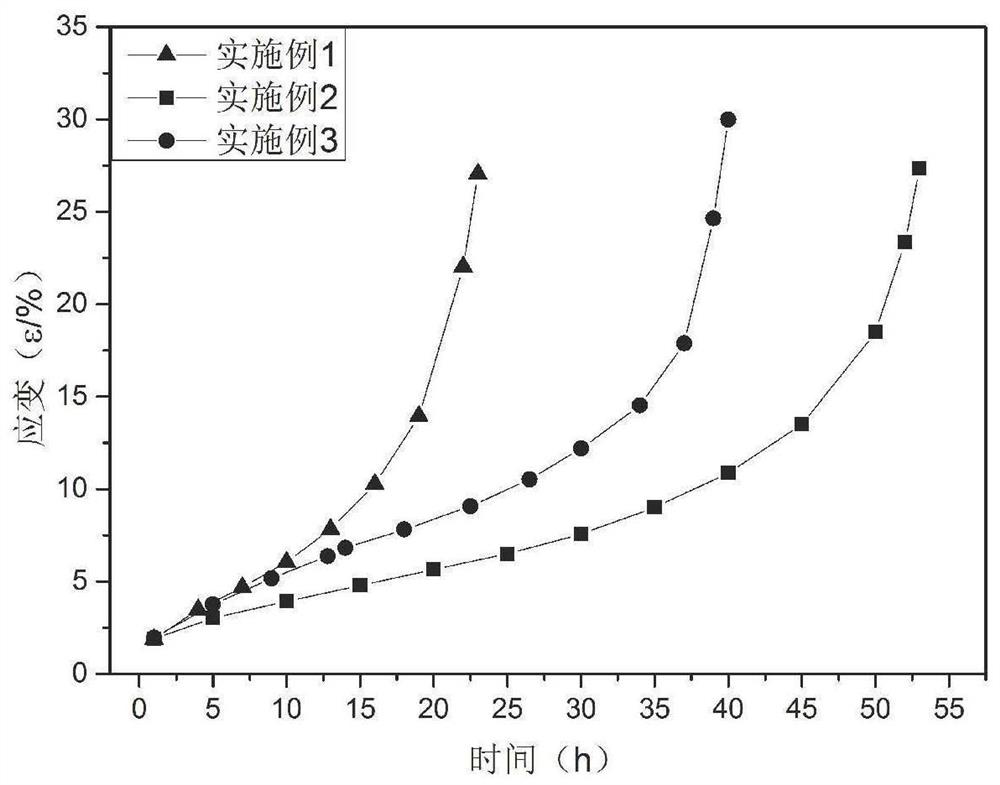

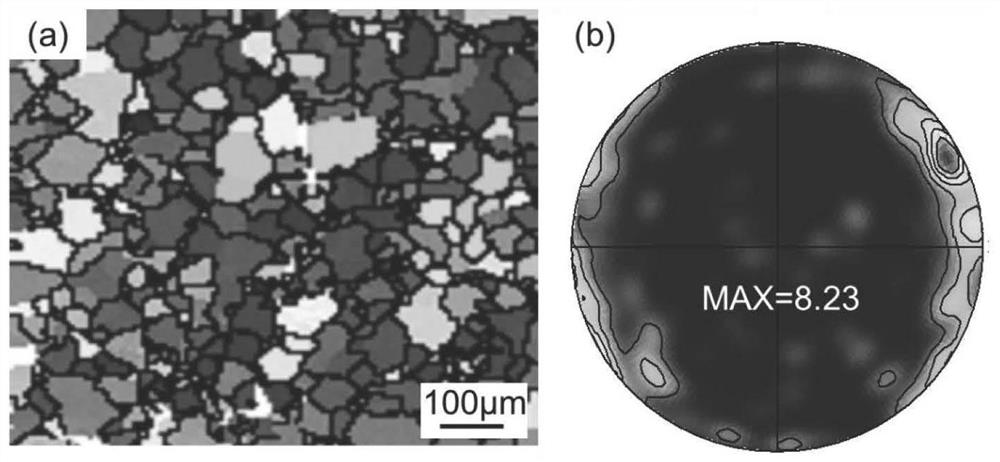

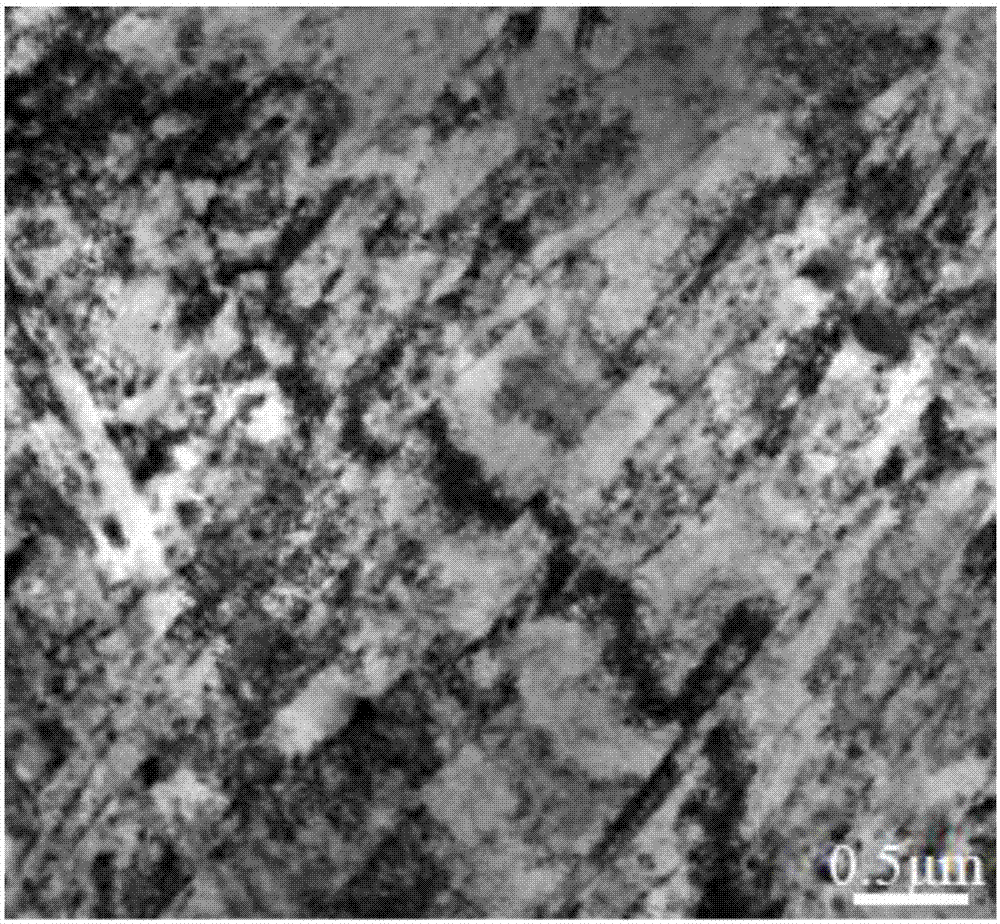

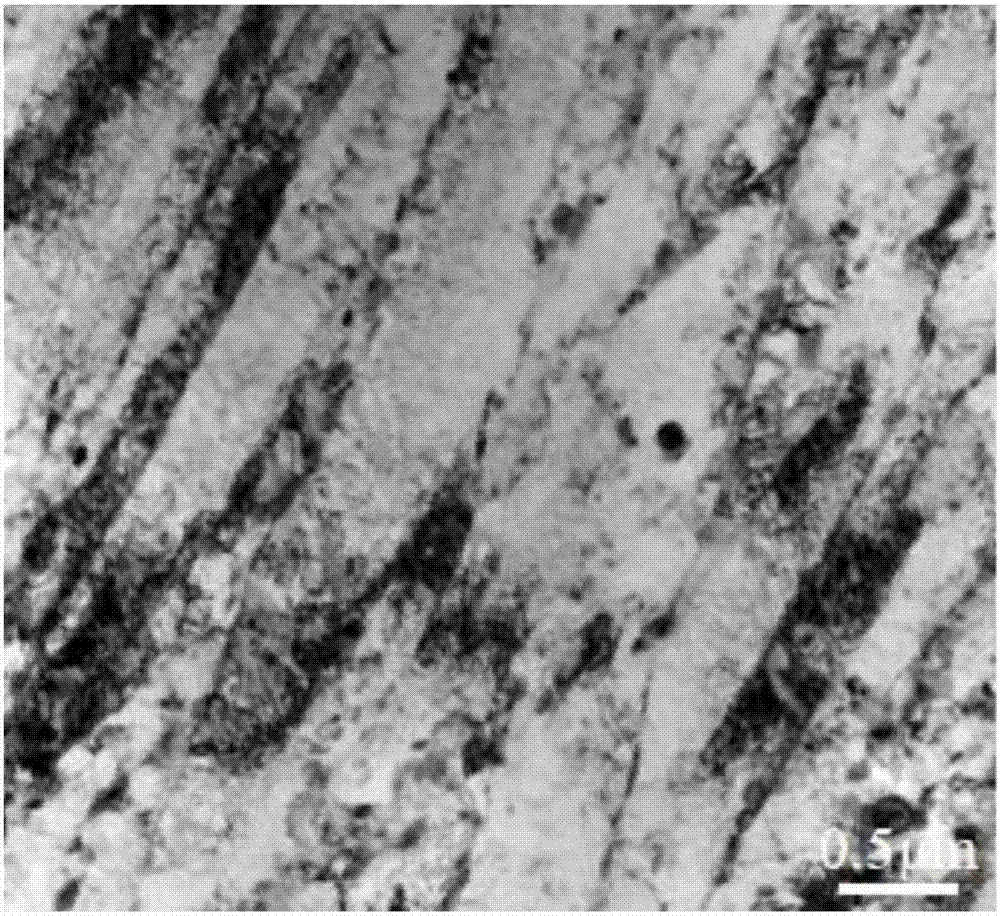

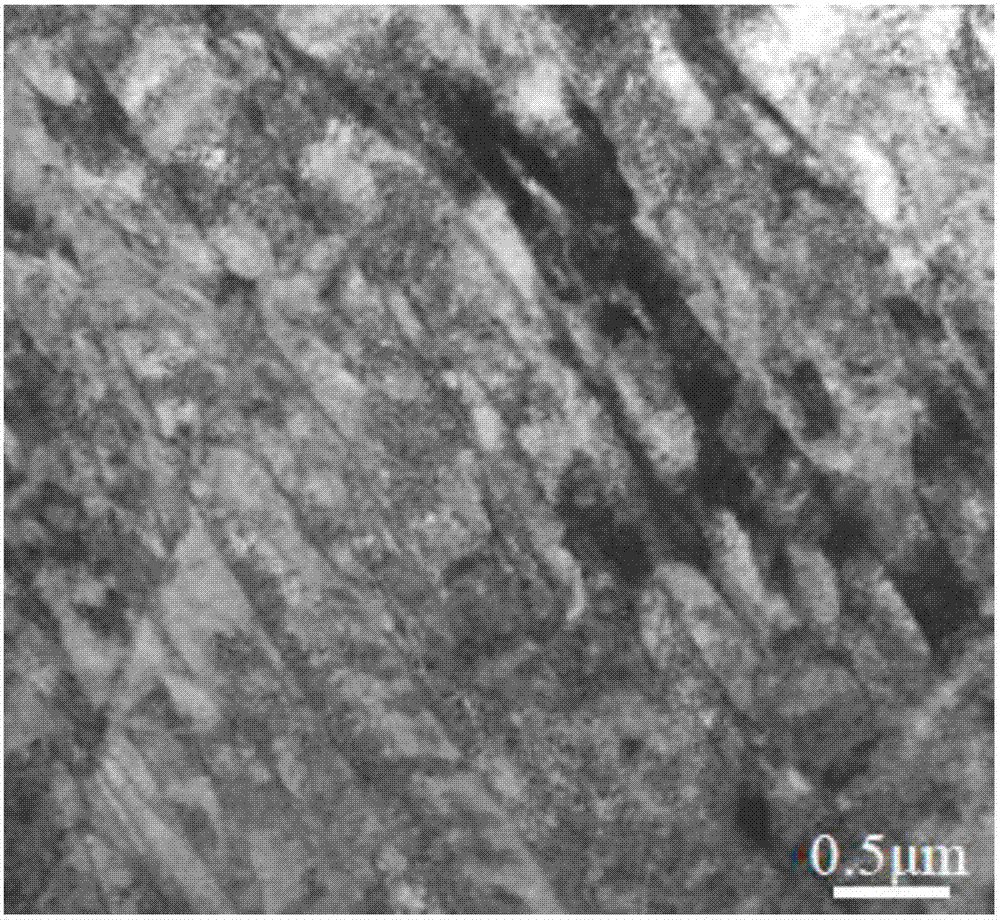

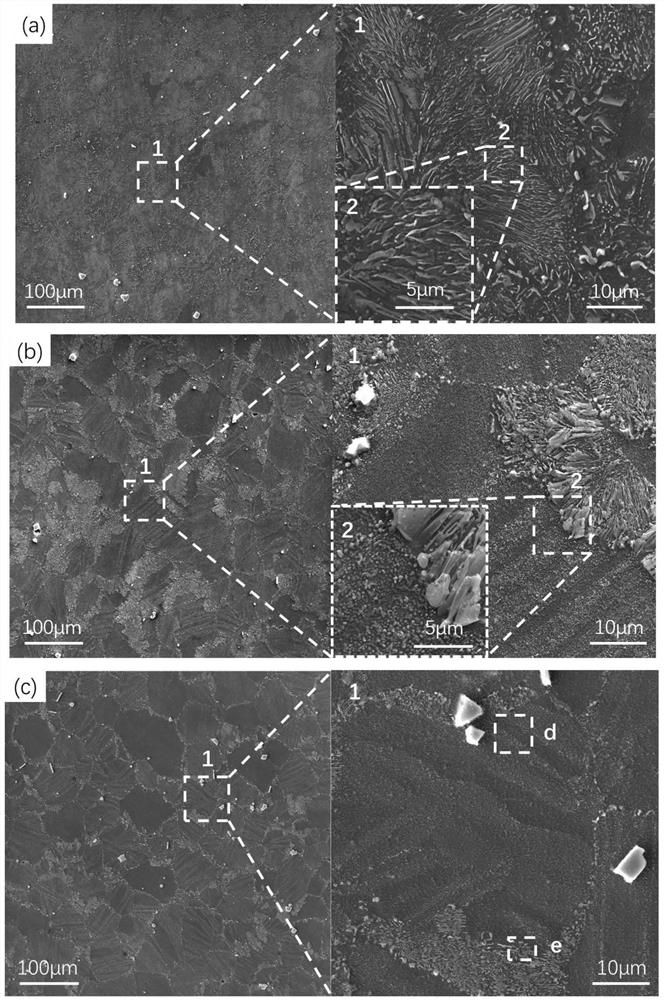

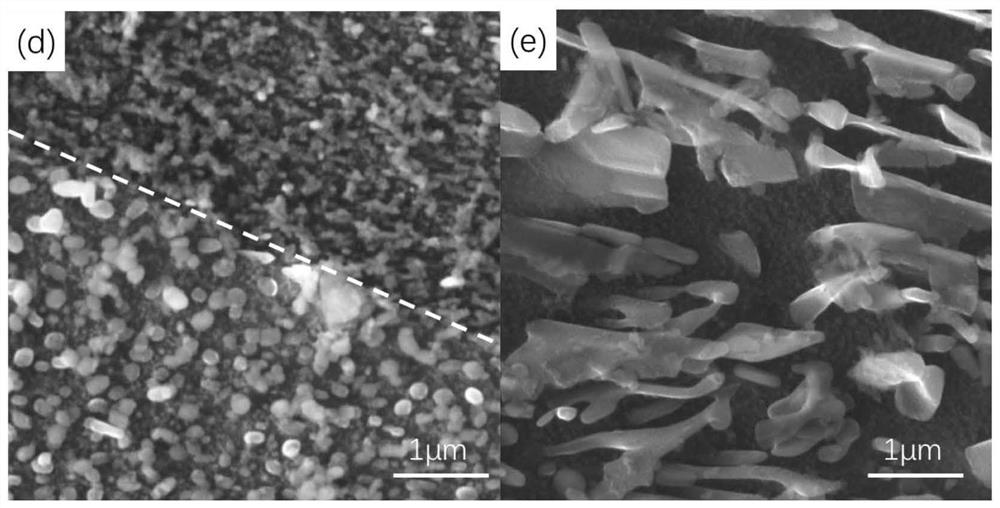

Processing method for improving high temperature creep properties of magnesium alloys by extrusion and hammering

ActiveCN112831738BAvoid crackingInfluence of High Temperature Creep Performance ParametersSolution treatmentHeat stability

The invention discloses a processing method for improving the high-temperature creep performance of a magnesium alloy through extrusion and hammering, and is characterized in that: the mass percentage composition of the magnesium alloy is: Al: 8.5%-9.5%, Zn: 0.45%-0.90%, Mn : 0.15% to 0.4%, Y: 0.3% to 0.8%, and the rest are magnesium and impurity elements that cannot be removed; the processing method includes the following steps: 1), carrying out solid solution treatment on magnesium alloy; The magnesium alloy is extruded, the extrusion temperature is 350-450°C, the extrusion rate is 15-20mm / min, and the extrusion ratio is 8:1-25:1; 3) Air hammer is carried out on the extruded magnesium alloy Hammering, the hammering direction is parallel to the extrusion direction, the hammering temperature is room temperature, the number of hammering is 1-4 times, the cumulative hammering strain is 1-3%, and the speed of the hammer head before it touches the magnesium alloy is 1m / s ~40m / s. In the present invention, by adjusting the microstructure of magnesium alloy, the magnesium alloy undergoes creep dynamic precipitation during high-temperature creep process, and the creep dynamic precipitation phase improves the thermal stability of the material and improves the high-temperature creep performance. Application promotion is of great significance.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A brick with high thermal shock resistance and low creep for hot blast stove and its manufacturing method

The invention relates to a brick with high thermal shock resistance and low creep for a hot blast stove and a manufacturing method thereof, belonging to the technical field of refractory materials. It is characterized in that the parts by weight are: 19-27 parts of 3-1mm bauxite, 11-14 parts of 1-0.5mm brown corundum, 8-12 parts of brown corundum with a particle size of <320 mesh, 10-20 parts of 3-1mm andalusite Parts, 9~16 parts of andalusite 0.5‑0.1mm, 14~23 parts of andalusite with particle size<200 mesh, 4.5~7.5 parts of alumina micropowder with particle size<5μm, 5~8 parts of Suzhou soil with particle size<0.045mm, Particle size <240 mesh silicon carbide 4.5~5.5 parts, pulp 3.5~4.5 parts, phosphoric acid 0.2~0.5 parts, dextrin 0.3~0.7 parts, sodium tripolyphosphate 0.1~0.2 parts. The invention introduces silicon carbide and andalusite and brown corundum of specific particle size, on the basis of improving the load softening temperature and high temperature creep performance of fire bricks, the thermal shock resistance stability of the product is improved, and as a refractory material for hot blast stoves, it can Significantly extend its service life.

Owner:SHANDONG VOCATIONAL COLLEGE OF IND

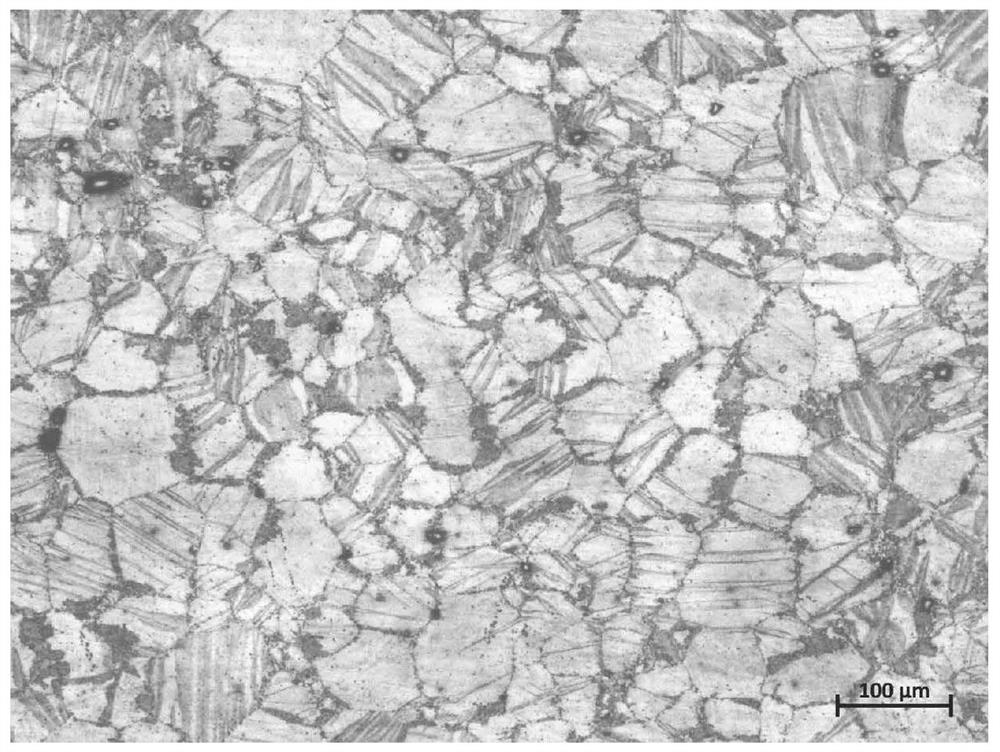

Processing method for improving high-temperature creep properties of magnesium alloys by rolling and pre-compression

ActiveCN113136512BWill not be affected by high temperature creep propertiesGrain refinementMetal rolling arrangementsSolution treatmentMetallurgy

The invention discloses a processing method for improving the high-temperature creep performance of a magnesium alloy through rolling and pre-compression, which is characterized in that the mass percentage composition of the magnesium alloy is: Al: 8.5%-9.5%, Zn: 0.45%-0.90%, Mn : 0.15%~0.4%, Y: 0.3%~0.8%, and the rest are magnesium and impurity elements that cannot be removed; the processing method includes the following steps: 1) performing solid solution treatment on magnesium alloy; The magnesium alloy is rolled, the rolling temperature is 300~400°C, the rolling speed is 0.2m / s-0.6m / s, the number of rolling passes is 3-8 times, and the total deformation is 50%-80%; 3) Perform pre-compression deformation on the rolled magnesium alloy, the pre-compression direction is perpendicular to the rolling plate surface, the pre-compression temperature is 20°C-100°C, the compressive strain is 0.01-0.02, and the strain rate is 1×10 ‑4 the s ‑1 -2×10 ‑4 the s ‑1 , and keep the compression deformation for more than 5min. The invention adjusts the microstructure of the magnesium alloy so that the magnesium alloy undergoes creep dynamic precipitation during the high-temperature creep process, and the creep dynamic precipitation phase improves the thermal stability of the material and improves the high-temperature creep performance.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

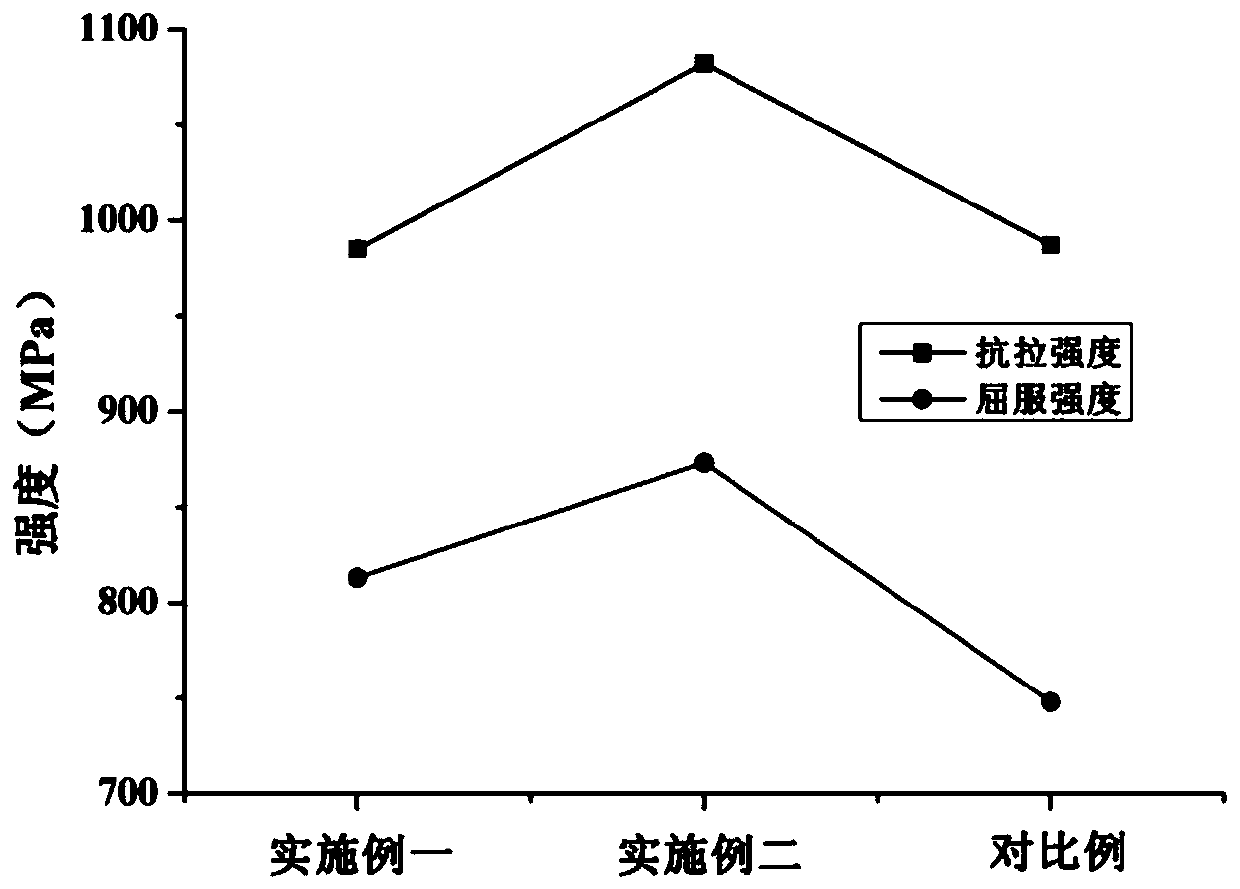

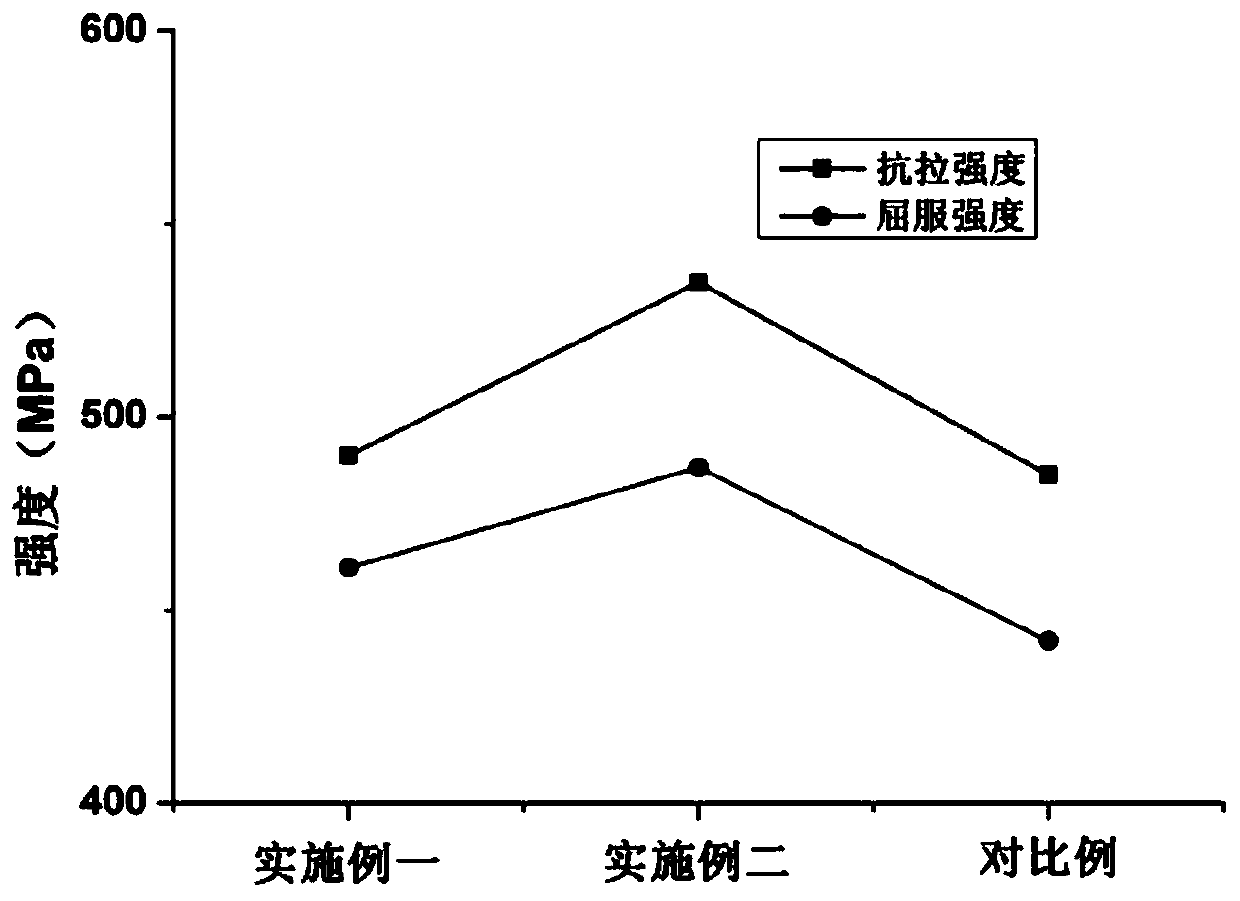

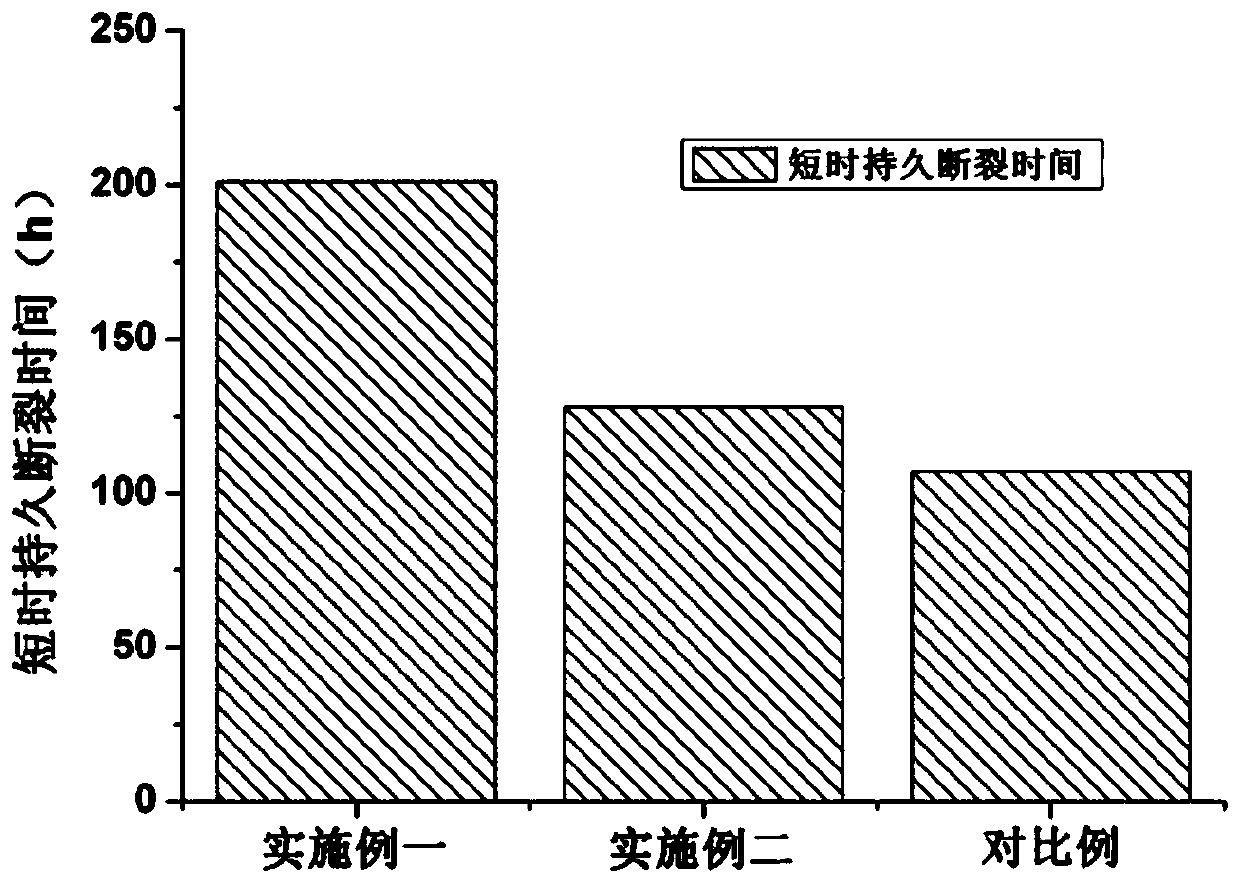

A process method for improving high temperature creep performance of 403nb heat-resistant blade steel

InactiveCN105734237BImprove high temperature creep performanceImprove high temperature creep resistanceChemical compositionThermal deformation

A process method for improving the high-temperature creep performance of 403Nb heat-resistant blade steel, belonging to the field of metallurgical materials technology; including the following steps: (1) heating the 403Nb heat-resistant blade steel in two stages for temperature uniformization; (2) preliminary thermal deformation Treatment; (3) Secondary thermal deformation treatment; (4) Tempering treatment. The method of the present invention does not change the chemical composition of the existing 403Nb heat-resistant blade steel, but only changes the organizational structure state through minor adjustments to the production process, thereby achieving the purpose of improving high-temperature mechanical properties, especially high-temperature resistance. The creep performance has been greatly improved; there are no restrictions on the shape of the processed materials or finished products, and there are no special requirements for the forming methods used. Bars, plates, pipes, etc., as well as rolling, extrusion, forging and other processing methods can all be processed according to This summary describes the implementation of the invention.

Owner:NORTHEASTERN UNIV LIAONING

A kind of pre-deformed magnesium alloy and processing method thereof

The invention discloses a pre-deformed magnesium alloy. The mass percentage composition of the magnesium alloy is: Al: 8.5%-9.5%, Zn: 0.45%-0.90%, Mn: 0.15%-0.4%, Y: 0.3%-0.8%. , the rest are magnesium and non-removable impurity elements; the magnesium alloy is obtained after successively undergoing solid solution treatment, preferred orientation processing and twinning pre-deformation, and more than 40% of the grains in the microstructure of the magnesium alloy There are twins. The present invention also relates to a processing method of the above-mentioned pre-deformed magnesium alloy. The invention adjusts the structure of the magnesium alloy, so that the magnesium alloy undergoes creep dynamic precipitation during the high-temperature creep process, and the creep dynamic precipitation phase improves the thermal stability of the material, expands the creep loading range, and improves the creep resistance of the material ; and the magnesium alloy has simple processing technology, low equipment requirements, simple operation, low cost and high production efficiency; the application and promotion of the magnesium alloy has important significance.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

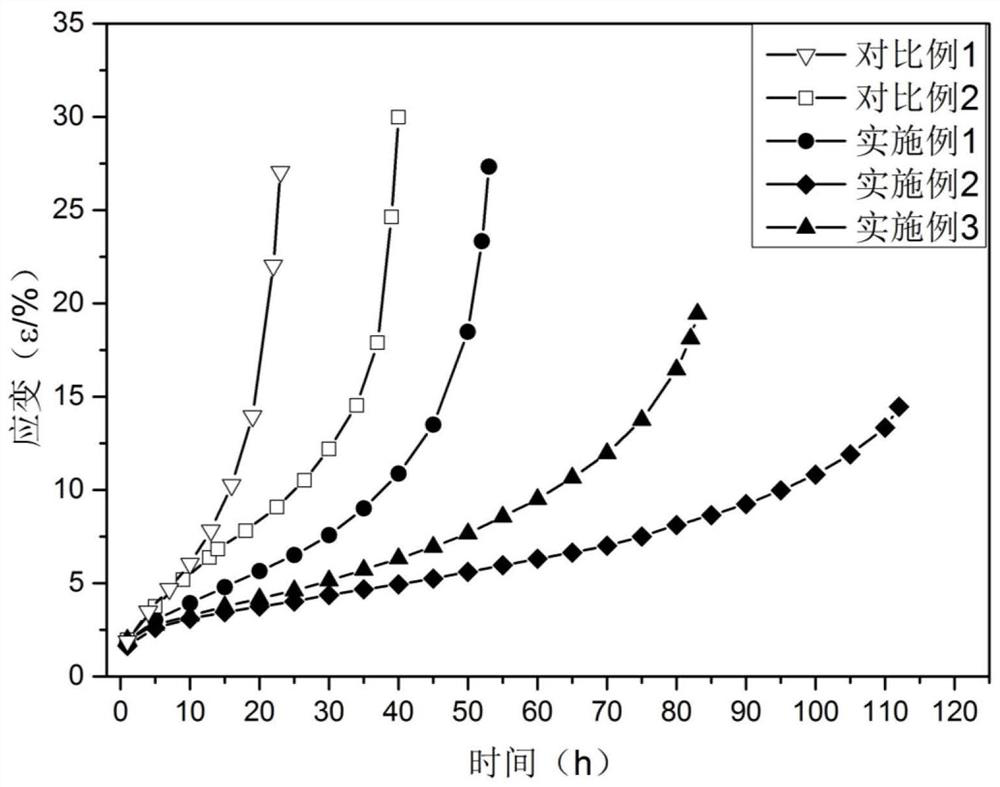

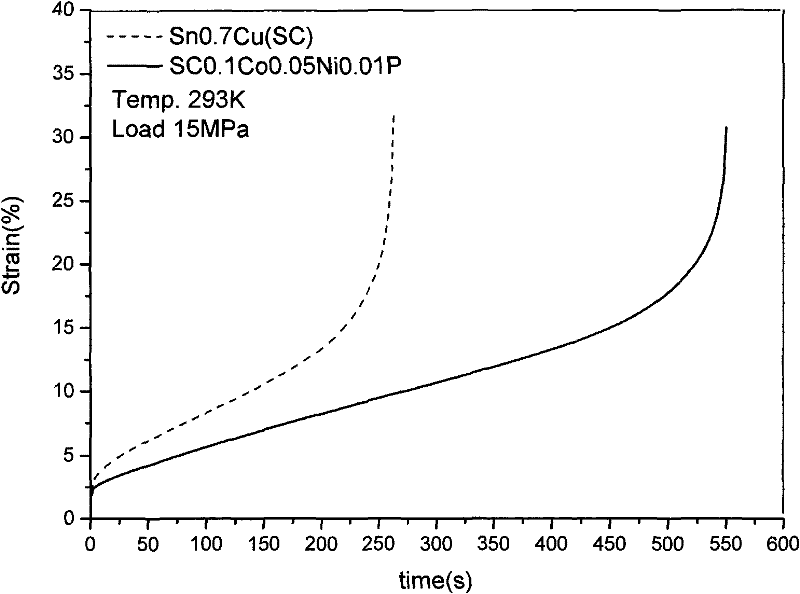

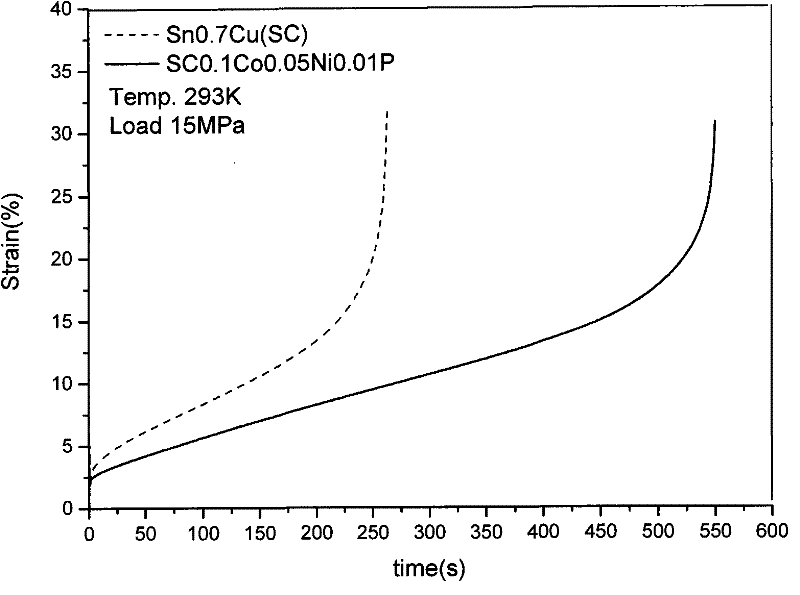

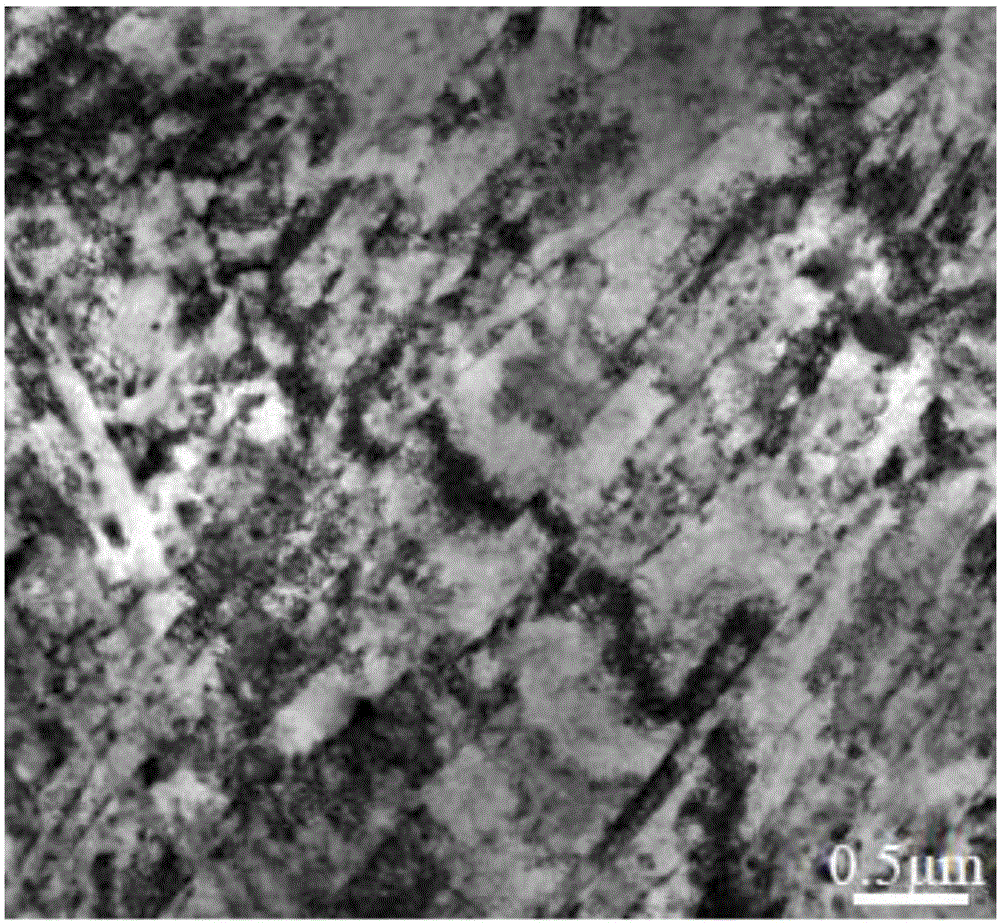

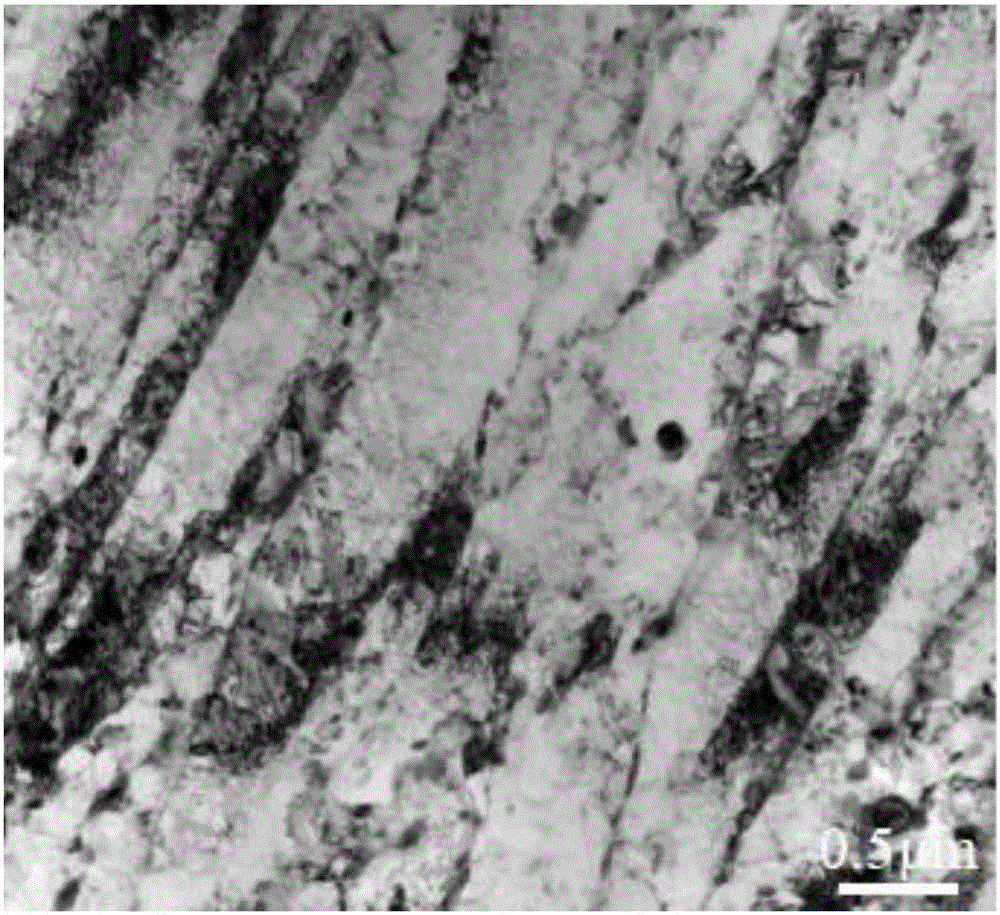

Sn-cu-based lead-free solder alloy for improving solder joint creep performance and its preparation process

InactiveCN101664861BIncrease the areaImprove wettabilityWelding/cutting media/materialsSoldering mediaElectronic assembliesElectron

The invention provides a Sn-Cu based lead-free solder alloy which improves the creep performance of solder joints. The content of Cu in the solder alloy is 0.7 wt%, the content of Co is 0.5-0.05 wt%, and the content of Ni is 0.25 wt%. -0.025wt%, the content of P is 0.05-0.005wt%, and the balance is Sn. At the same time, a preparation process for making the above-mentioned lead-free solder alloy is also provided. The effect of the present invention is that by adding trace amounts of Co, Ni and P elements to the Sn-0.7Cu eutectic solder, the morphology of the interface compound is effectively improved, the supercooling degree of the alloy is reduced, and the oxidation resistance is improved. Furthermore, the growth of the interfacial compound layer Cu6Sn5 and the appearance of the brittle compound Cu3Sn on the side of the Cu substrate are suppressed in a high-temperature environment, thereby improving the high-temperature creep resistance of the welded joint. The alloy can be widely used in wave soldering and manual soldering processes in the field of electronic assembly.

Owner:TIANJIN UNIV

Technological method for improving high temperature creep resistant property of heat-resistant 403Nb blade steel

ActiveCN105734237AGood strong plastic fitImprove high temperature creep resistanceThermal deformationChemical composition

The invention provides a technological method for improving the high temperature creep resistant property of heat-resistant 403Nb blade steel, and belongs to the technical field of metallurgy materials. The method comprises the following steps that 1, the heat-resistant 403Nb blade steel is subjected to temperature homogenization according to two-stage heating; 2, primary thermal deformation treatment is conducted; 3, secondary thermal deformation treatment is conducted; 4, tempering treatment is conducted. According to the technological method for improving the high temperature creep resistant property of the heat-resistant 403Nb blade steel, on the basis that chemical components of existing heat-resistant 403Nb blade steel are not changed, a change of the structure state is achieved only through minor adjustment of the production technology, the purpose of improving the high-temperature mechanical property is achieved, and particularly, the high temperature creep resistant property is greatly improved; shapes of processing materials or finished products are not limited, no special requirement on applied forming methods exists, and the processing methods such as rolling, extruding and forging for bars, boards, pipes and the like can be implemented according to the technological method.

Owner:NORTHEASTERN UNIV

A method for in-situ synthesis of nano-oxide particle dispersion-strengthened alloys

ActiveCN109175391BSimple methodReduce processAdditive manufacturing apparatusTransportation and packagingManufacturing technologyOxygen content

The invention discloses an in-situ method for synthesizing a dispersion-strengthened alloy of nanometer oxide particles, which comprises the following steps: (1) designing the alloy so that the alloy contains elements capable of forming oxides; During the preparation process, the oxygen content in the alloy powder is increased; (3) using metal additive manufacturing technology, the oxide-forming elements and oxygen elements are combined to form dispersed nano-oxide particles during the localized solidification process of the alloy, and the obtained Nano-oxide particle dispersion strengthened alloy. This method can reduce the process and cycle of preparing nano-oxide dispersion strengthened alloys, realize in-situ precipitation of nano-oxide particles and evenly distribute them in the alloy matrix, and at the same time, can prepare columnar crystal structure in situ to ensure that in the subsequent heat treatment process No pores will be formed.

Owner:BEIHANG UNIV

Processing method for improving high-temperature creep property of magnesium alloy through rolling and hammering

ActiveCN112831739AWill not adversely affect high temperature creep performance parametersAvoid crackingTemperature control deviceMetal rolling arrangementsSolution treatmentHeat stability

The invention discloses a processing method for improving the high-temperature creep property of a magnesium alloy through rolling and hammering. The magnesium alloy comprises, by mass, 8.5%-9.5% of Al, 0.45%-0.90% of Zn, 0.15%-0.4% of Mn and 0.3%-0.8% of Y. The processing method comprises the following steps: (1) solution treatment is carried out on the magnesium alloy; (2) the magnesium alloy in the solid solution state is rolled, specifically, the rolling temperature ranges from 300 DEG C to 400 DEG C, the rolling speed ranges from 0.2 m / s to 0.6 m / s, the number of passes of rolling is 3-8, and the total deformation ranges from 50% to 80%; and (3) the magnesium alloy in the rolled state is hammered through an air hammer, specifically, the hammering direction is perpendicular to the plate face of a rolled plate, the hammering temperature is the room temperature, the hammering frequency is 1-4 times, the accumulated hammering strain is 1-3%, and the speed of a hammer before making contact with the magnesium alloy is 1-40 m / s. By regulating and controlling the magnesium alloy structure, the magnesium alloy is subjected to creep dynamic precipitation in the high-temperature creep process, the thermal stability of the material is improved through the creep dynamic precipitation phase, the high-temperature creep performance is improved, and the method has important significance on application and popularization of the magnesium alloy.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A kind of heat-resistant steel for key hot-end parts of ultra-high parameter steam turbine

ActiveCN109763066BImprove high temperature performanceImprove antioxidant capacityRare-earth elementOxidation resistant

The invention provides a heat-resistant steel for the key hot end parts of an ultra-high parameter steam turbine, which contains: C: 0.02-0.08, Cr: 8.00-10.00, Co: 2.0-4.0, W: 2.0 in weight percentage ~4.0, Mo: 0.10~0.80, V: 0.10~0.30, Ni: 0.30~0.70, Nb: 0.05~0.15, N: 0.010~0.050, B: 0.010~0.030, rare earth elements: 0.1~1.0, Si: ≤0.10 , Mn: 0.10 ~ 1.00, the balance consists of Fe and unavoidable impurities. The heat-resistant steel belongs to martensitic heat-resistant steel and has good high-temperature performance and oxidation resistance, thereby improving the temperature parameter of the steam turbine and helping to improve the power generation efficiency of the steam turbine.

Owner:DONGFANG TURBINE CO LTD

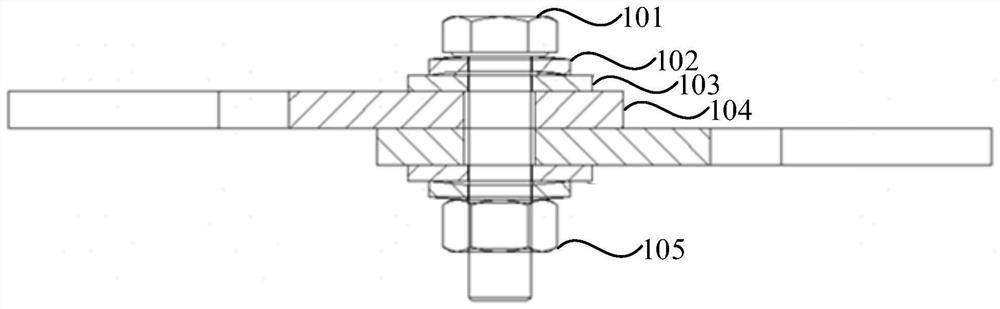

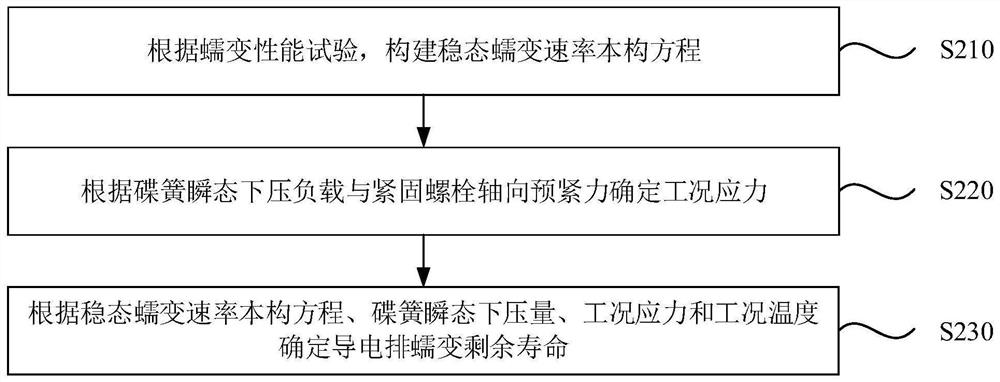

Aluminum alloy material, conducting bar and calculation method of creep residual life of conducting bar

PendingCN114427055AImprove mechanical propertiesRefinement recrystallization temperatureSingle bars/rods/wires/strips conductorsConductive materialRare-earth elementMechanical property

The embodiment of the invention discloses an aluminum alloy material, a conducting bar and a creep residual life calculation method of the conducting bar. The aluminum alloy material comprises an aluminum element, a boron element, a zirconium element and a rare earth element, the content of the boron element is smaller than or equal to 0.025%, the content of the zirconium element is smaller than or equal to 0.2%, and the content of the rare earth element is smaller than or equal to 0.15%. According to the embodiment, grain refinement is achieved by setting the content of the boron element, and the mechanical property and the electric conductivity of the aluminum alloy are improved; by setting the content of the zirconium element, the stress corrosion resistance and other properties of the aluminum alloy are improved; by setting the content of rare earth elements, the high-temperature creep property of the aluminum alloy is improved, and oxide inclusions and the like in the aluminum alloy are reduced. Therefore, according to the embodiment of the invention, the conductivity and creep resistance of the aluminum alloy for the conducting bar can be enhanced, and the problem of failure of a circulating chain type connection area caused by material creep after the existing aluminum alloy conducting bar is used for a long time can be relieved and even solved.

Owner:SUNGROW POWER SUPPLY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com