Ferrite steel plate with heterogeneous structure and preparation method thereof

A technology of heterogeneous structure and ferritic steel, applied in the direction of manufacturing tools, welding equipment, metal rolling, etc., can solve the problem that the steel plate cannot take into account high strength and high plasticity at the same time, so as to achieve good weld bead surface formation and ensure strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

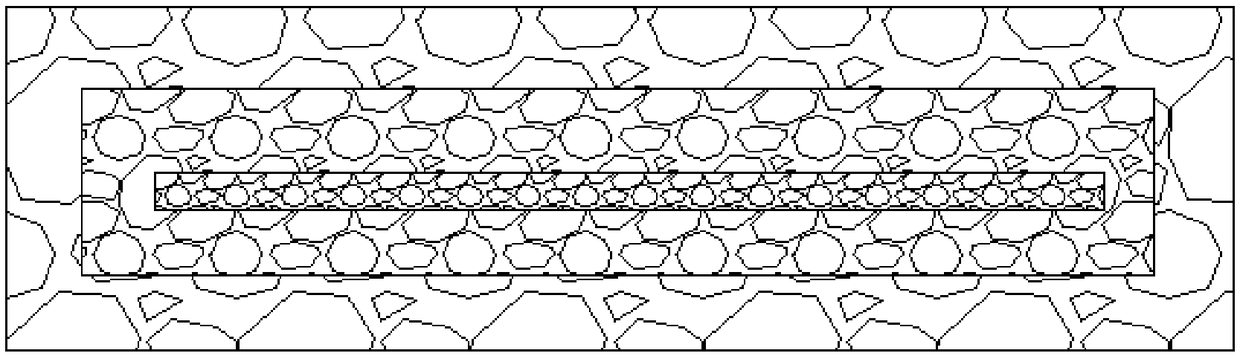

[0024] The preparation method of the heterogeneous structure ferritic steel plate of this embodiment includes:

[0025] (1) Use ferritic steel welding consumables to surfacing ferrite surfacing layers on both sides of the ferritic steel plate. The surfacing welding conditions are: welding current 160A, welding voltage 22V, wire feeding speed 450mm / min, walking The speed is 250mm / min, the flow rate of argon shielding gas is 10L / min, the angle of the workbench is 15°, the height of the welding torch from the ferritic steel plate is 4mm; the overlap between two adjacent weld beads is 1 / 3 of the weld bead thickness ; The thickness ratio of the ferrite surfacing layer to the ferrite steel plate is 1:2.

[0026] (2) The welded plate was rolled 7 times under the conditions of a rolling speed of 0.3 m / min and a rolling pressure of 0.8 mm per pass.

[0027] (3) The rolled plate was kept at 650° C. for 6 minutes, and then air-cooled to room temperature to obtain a ferritic steel plate ...

Embodiment 2

[0029] The preparation method of the heterogeneous structure ferritic steel plate of this embodiment includes:

[0030] (1) Use ferritic steel welding consumables to surfacing ferrite surfacing layers on both sides of the ferritic steel plate. The surfacing welding conditions are: welding current 200A, welding voltage 26V, wire feeding speed 550mm / min, walking The speed is 350mm / min, the flow rate of argon shielding gas is 20L / min, the angle of the workbench is 20°, the height of the welding gun from the ferritic steel plate is 5mm; the overlap between two adjacent weld beads is 1 / 3 of the weld bead thickness ; The thickness ratio of the ferrite surfacing layer to the ferrite steel plate is 1:3.2.

[0031] (2) Roll the welded sheet for 10 passes under the condition that the rolling speed is 0.5 m / min and the rolling pressure per pass is 1.2 mm.

[0032] (3) The rolled plate was kept at 750° C. for 4 minutes, and then air-cooled to room temperature to obtain a ferritic steel p...

Embodiment 3

[0034] The preparation method of the heterogeneous structure ferritic steel plate of this embodiment includes:

[0035] (1) Use ferritic steel welding consumables to surfacing ferrite surfacing layers on both sides of the ferritic steel plate. The surfacing welding conditions are: welding current 170A, welding voltage 23V, wire feeding speed 480mm / min, walking The speed is 280mm / min, the flow rate of argon shielding gas is 14L / min, the angle of the workbench is 16°, the height of the welding torch from the ferritic steel plate is 4.2mm; the overlap between two adjacent weld beads is 1 / of the weld bead thickness 3. The thickness ratio of the ferrite surfacing layer to the ferrite steel plate is 1:2.5.

[0036] (2) Roll the welded plate for 8 passes under the condition that the rolling speed is 0.4 m / min and the rolling pressure per pass is 1 mm.

[0037] (3) The rolled plate was kept at 680° C. for 5 minutes, and then air-cooled to room temperature to obtain a ferritic steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com