Sn-cu-based lead-free solder alloy for improving solder joint creep performance and its preparation process

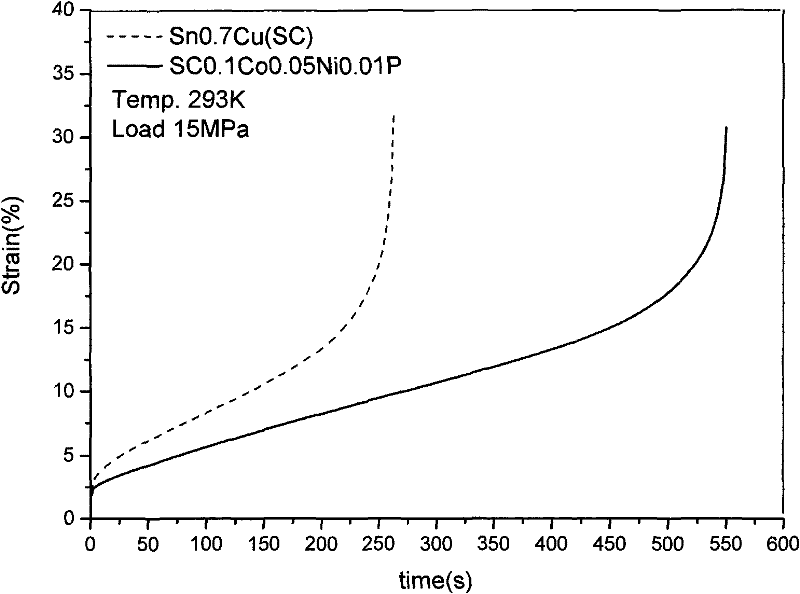

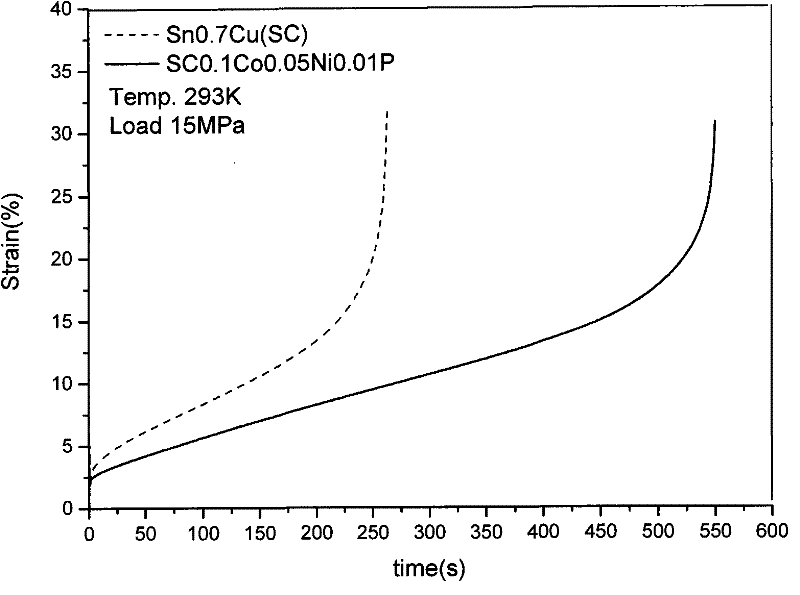

A technology of lead-free solder and creep performance, applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problem of the decline of high-temperature creep performance of welded joints and the failure of high-temperature creep resistance of Sn-Cu solder Effectively improve and unsolved problems, to achieve the effects of prolonging the creep rupture time, inhibiting the appearance of brittle compounds, and decreasing the creep rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The Sn-Cu-based lead-free solder alloy and its preparation process for improving solder joint creep performance of the present invention are described in conjunction with the accompanying drawings and examples.

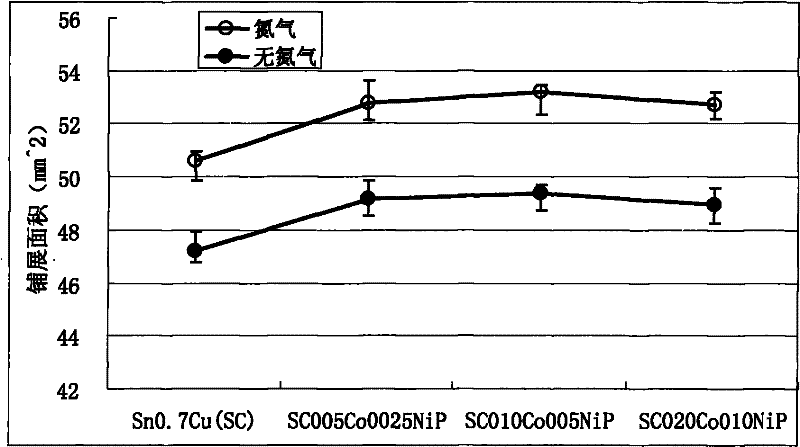

[0018] The Sn-Cu based lead-free solder alloy for improving solder joint creep performance of the present invention, the content of Cu in the solder alloy is 0.7wt%, the content of Co is 0.5-0.05wt%, and the content of Ni is 0.25-0.025 wt%, the content of P is 0.05-0.005 wt%, and the balance is Sn. The P content is added to the Sn-Cu-based lead-free solder alloy in the form of a P-Cu master alloy with a P content of 1-7wt%; the weight percentage of Co and Ni is 1:1 to 2 : 1.

[0019] A kind of preparation technology of making above-mentioned lead-free solder alloy of the present invention, this technology comprises the following steps:

[0020] 1) Put the Sn weighed according to the above ratio into a ceramic crucible, and heat it to a temperature of 350-400 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com