Patents

Literature

183results about How to "Improve cold forming properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

800 MPa-grade low-yield-ratio structural steel plate and production method thereof

ActiveCN102011068AGood welding performanceGood low temperature impact propertiesYield ratioHeat treated

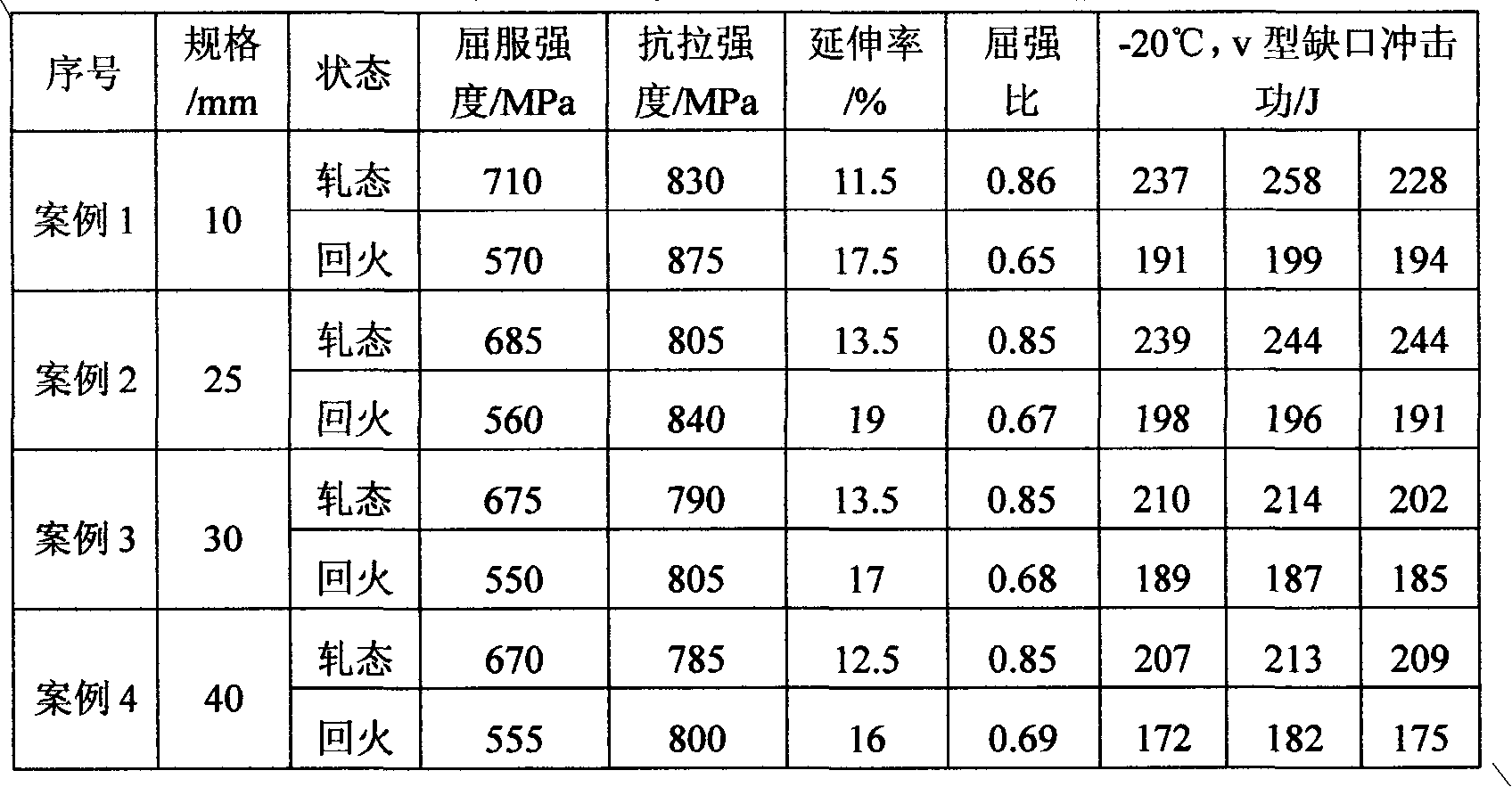

The method relates to an 800 MPa-grade low-yield-ratio structural steel plate and a production method thereof. The steel comprises the chemical components in percentage by weight: 0.045 to 0.075 percent of C, 0.30 to 0.55 percent of Si, 1.55 to 1.95 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.0025 percent of S, 0.012 to 0.035 percent of Al, 0.15 to 0.25 percent of Cr, 0.15 to 0.3 percent of Mo, 0.2 to 0.4 percent of Cu, 0.2 to 0.4 percent of Ni, 0.008 to 0.04 percent of Nb, 0.008 to 0.04 percent of V, 0.008 to 0.03 percent of Ti, 0.0008 to 0.0015 percent of B, and the balance of Fe and inevitable impurities. The steel is subjected to RH vacuum treatment, ladle furnace (LF) external refining, full protection casting, a thermo mechanical control process (TMCP), and tempering heat treatment to form the steel plate with low yield ratio, high strength and high work hardening rate. The steel plate has the thickness specification of between 10 and 40 mm, the yield strength of more than or equal to 550MPa, the tensile strength of more than or equal to 800 MPa and the yield ratio of less than 0.70, and has excellent low temperature compact performance, cold forming performance and welding performance.

Owner:SHOUGANG CORPORATION

Low-cost non-quenched and tempered high-strength weathering steel with yield strength level of 700MPa and manufacturing method thereof

InactiveCN101921965AAdd corrosion resistant elementsLow costUltimate tensile strengthContinuous rolling

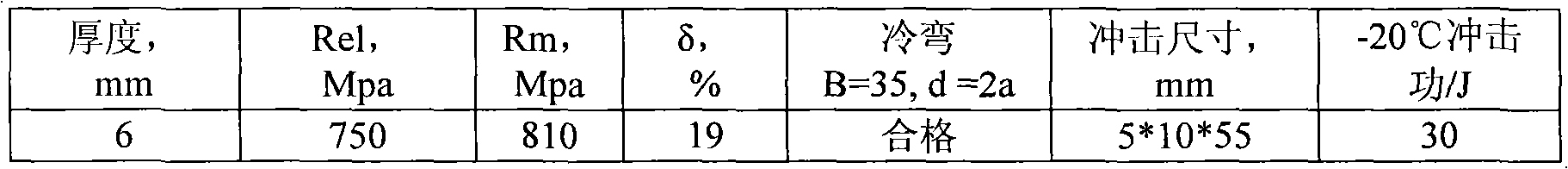

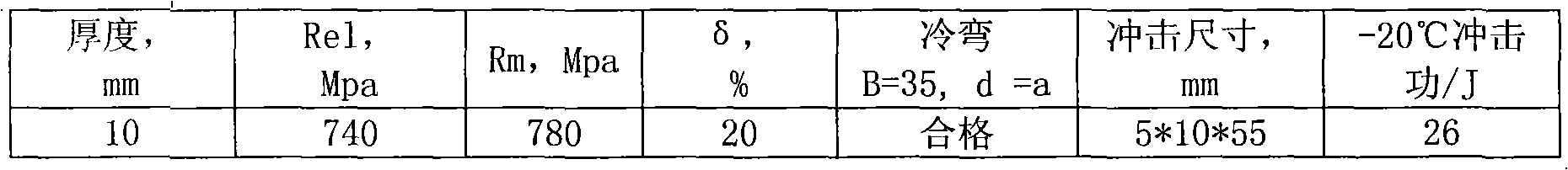

The invention provides low-cost non-quenched and tempered high-strength weathering steel with yield strength level of 700MPa for containers and a manufacturing method thereof. Based on the carbon manganese structural steel composition, the reinforcement effect is enhanced by adding a proper amount of micro-alloy elements such as Nb, Ti, Cu, Cr, Ni and the like, adopting a controlled rolling and controlled cooling technique, taking production characteristics of a normal hot continuous rolling machine into consideration and using a high-Ti component design. Meanwhile, Si content is reduced and high cold forming performance is ensured. The weathering steel for the containers comprises the following components in percentage by weight: 0.05 to 0.10 percent of C, less than or equal to 0.15 percent of Si, 1.5 to 2.0 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.01 percent of S, 0.3 to 0.8 percent o Cr, 0.2 to 0.4 percent of Cu, 0.15 to 0.4 percent of Ni, 0.09 to 0.15 percent of Ti, 0.02 to 0.08 percent of Nb, less than or equal to 0.005 percent of N, less than or equal to 0.002 percent of O and the balance of Fe and inevitable impurities. The yield strength is over 700MPa, the tensile strength is over 800MPa and the elongation is over 18 percent.

Owner:SHANDONG IRON & STEEL CO LTD

Corrosion resistant niobium-titanium alloy, and method for manufacturing plates and pipes with the same

InactiveCN102703757AImprove corrosion resistanceExpand the range of corrosion resistanceSolid solution strengtheningTitanium alloy

The invention relates to a corrosion resistant niobium-titanium alloy, and a method for manufacturing plates and pipes with the corrosion resistant niobium-titanium alloy, wherein the corrosion resistant niobium-titanium alloy contains the following components by weight: 0.1-4.9% o Nb, not more than 0.08% of C, not more than 0.03% of N, not more than 0.012% of H, not more than 0.1% of O, not morethan 0.1% of Fe, and the balance of Ti. In Ti-(0.8-6%) Nb alloy pipes disclosed by the invention, titanium is as a matrix; little niobium is added; mechanical property of the niobium is improved by asolid-solution strengthening way; shearing strength and tensile strength of the alloy are higher than pure titanium; the tensile strength is increased by 10-20%; good plasticity and formability are kept; cold working performance is excellent; the niobium is added to further increase corrosion resistance of titanium and enlarge corrosion resistant range of titanium, so that the corrosion resistantniobium-titanium alloy is a good easily-formed corrosion resistant material.

Owner:NINGXIA ORIENT TANTALUM IND

600MPa grade high-strength weathering steel and preparation method thereof

InactiveCN101225498ASimple chemical compositionThe production process is easy to controlMetal rolling arrangementsChemical compositionThin slab

The invention discloses a 600MPa high strength weathering steel and the manufacturing method, which is characterized in that: the 600MPa high strength weathering steel adopts electric stove-thin slab continuous casting and rolling process for preparation; the main chemical components of the refined molten steel for preparing the high strength weathering steel are: C: 0.045 wt % to 0.07wt%, Si: 0.10 wt % to 0.29wt%, Mn: 0.8 wt % to 1.5wt%, P: 0.005 wt% to 0.030wt%, S: 0.002 wt% to 0.008 wt%, Cu: 0.20 wt% to 0.5wt%, Cr: 0.3 wt% to 0.7wt%,Ni: 0.15 wt % to 0.35wt%, Ti: 0.06 wt% to 0.079wt%, Nb: 0.035 wt% to 0.050wt%, Alt: 0.025 wt% to 0.050wt%. The 600MPa high strength weathering steel has the advantages of low cost, strong competitiveness, cold formability, good welding performance and application to tower frame, heavy duty automobile, bridge, container, railway vehicle manufacture.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Stratified composite material for sliding elements and method for the production thereof

InactiveUS6273972B1High load carry capacityGood tribological propertyHot-dipping/immersion processesShaftsCorrosion resistantZinc

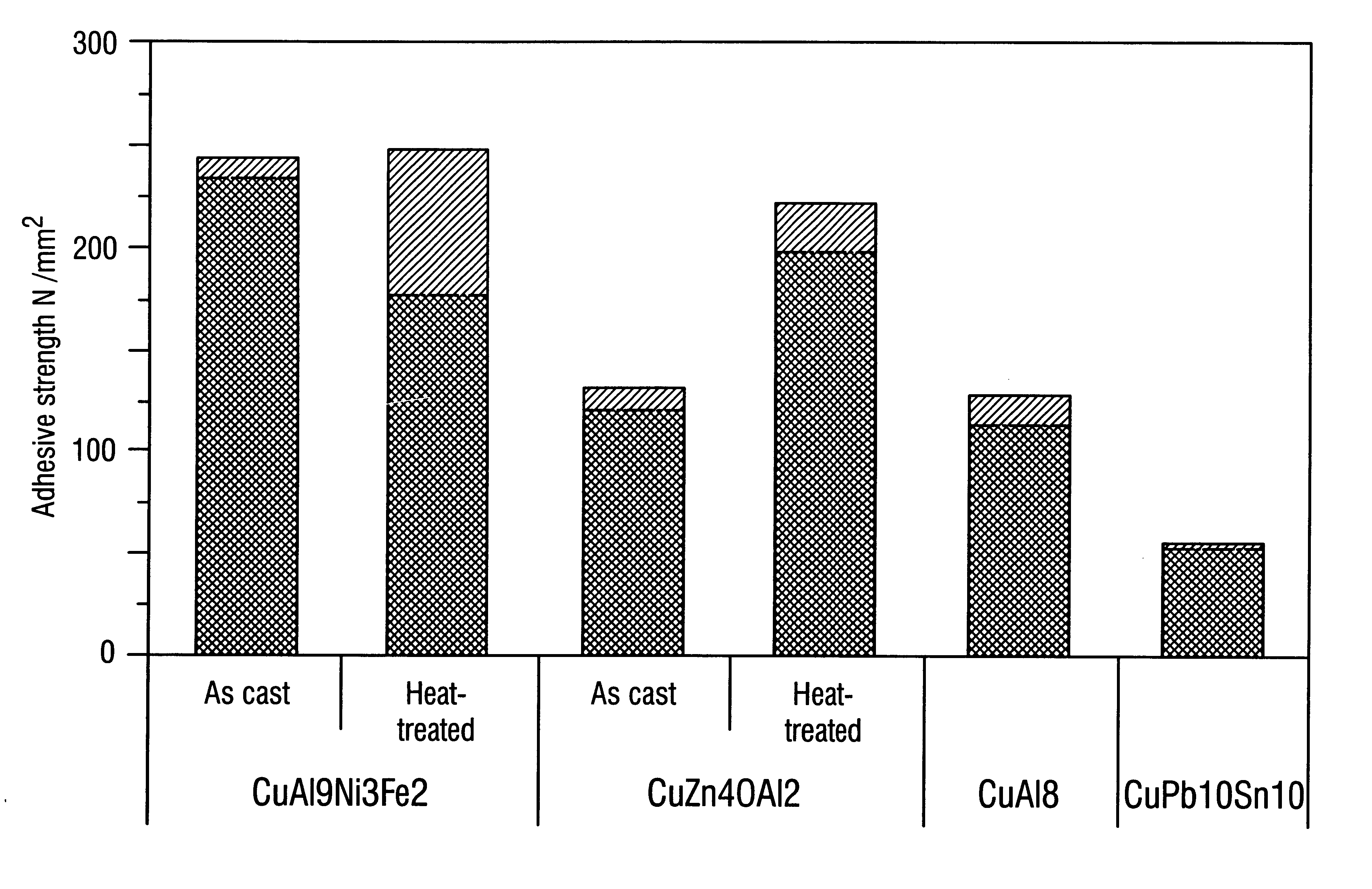

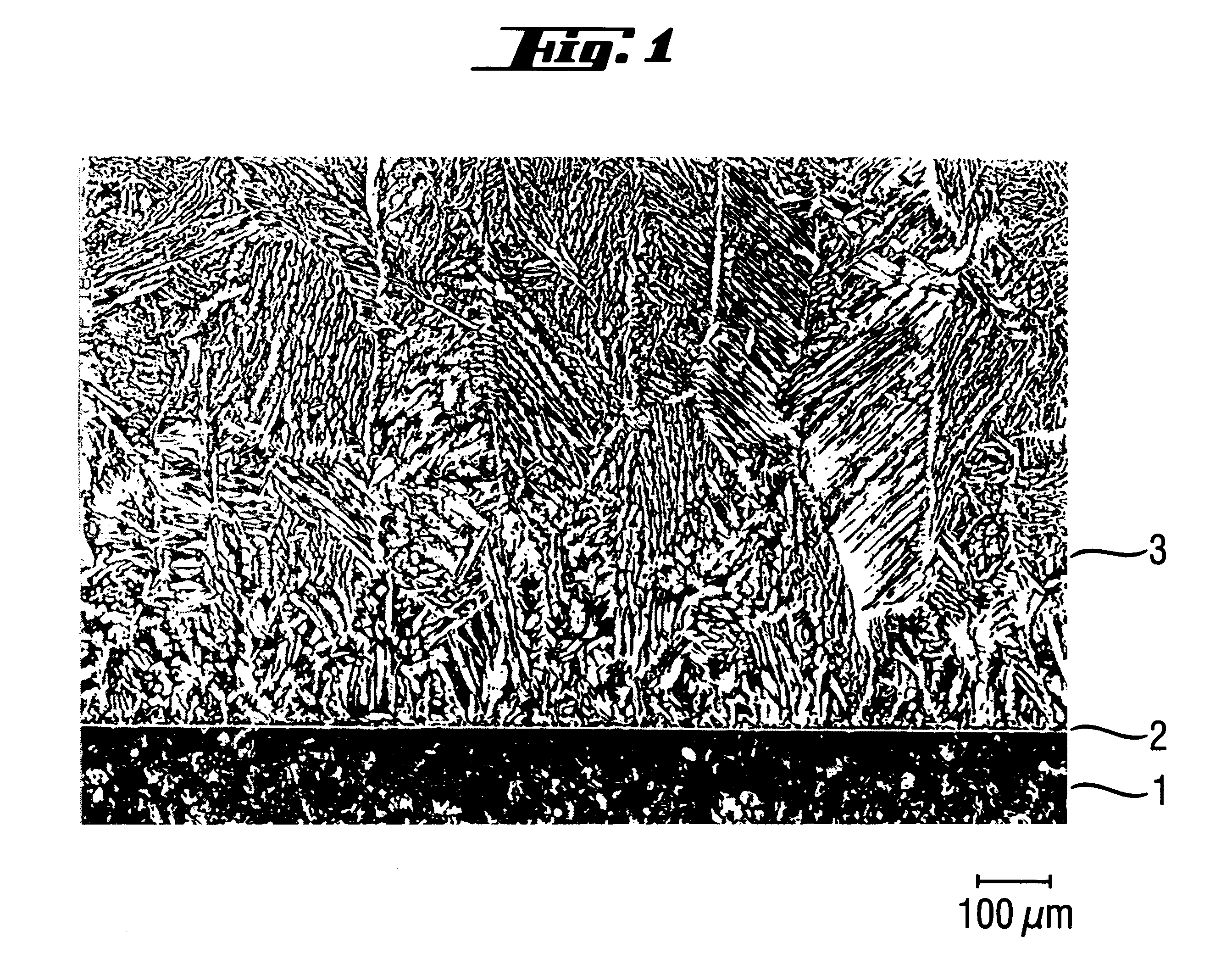

A composite multilayer material and a method for the production thereof are described which are suitable for bearing points subject to mixed friction, said material being corrosion-resistant and cold-formable and capable of withstanding extremely high loads. According to the method, the backing material is preheated to a temperature of 1000° C. to 1100° C., a heterogeneously developing, lead-free copper-zinc- or copper-aluminum-based bearing alloy at a temperature of from 1000° C. to 1250° C. is cast thereon, and the composite multilayer material is cooled from the casting temperature of the bearing alloy to 100° C. within 2 to 4 minutes. A metallurgical bond zone (2) is present between the bearing alloy (3) and the backing material (1), which metallurgical bond zone (2) comprises 80-95% iron and the usual impurities, the rest being copper, and is crystallised in cubic form.

Owner:FEDERAL MOGUL WIESBADEN

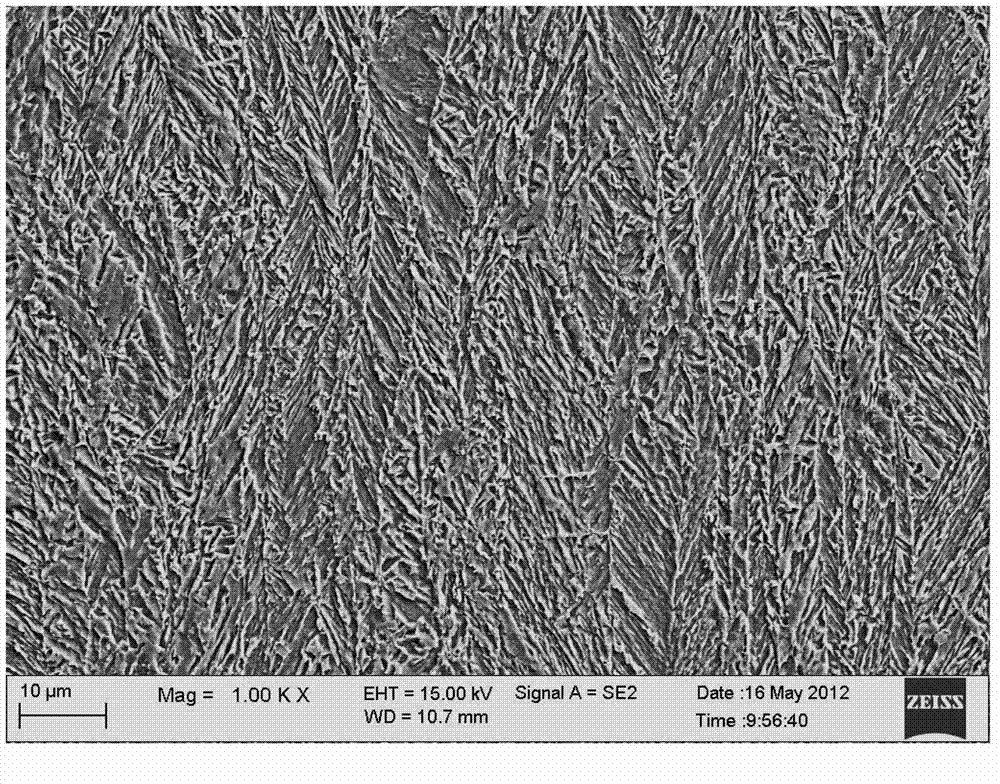

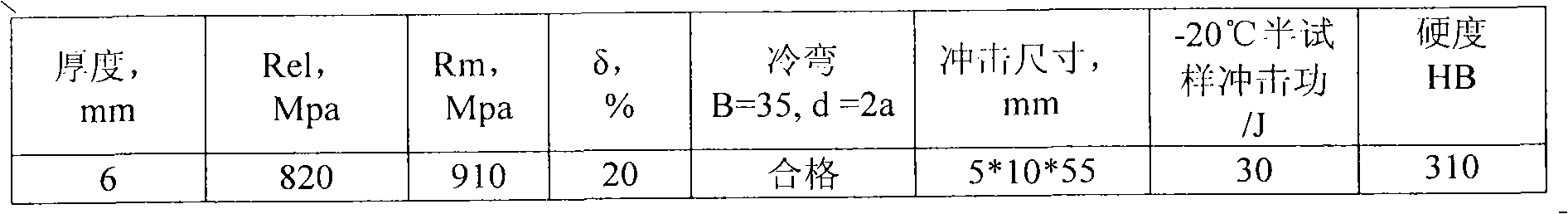

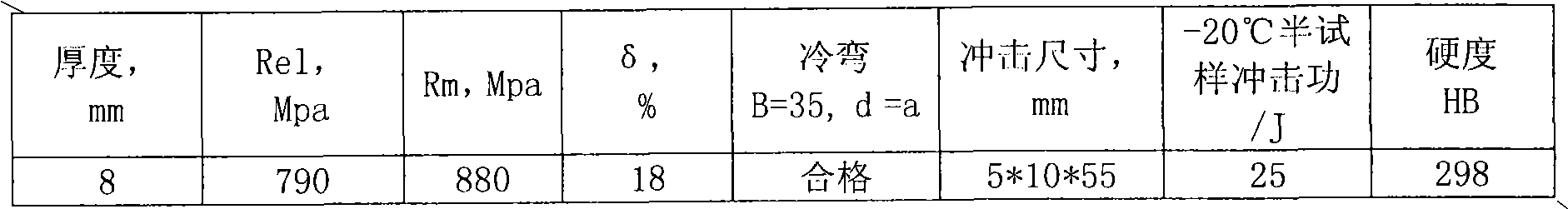

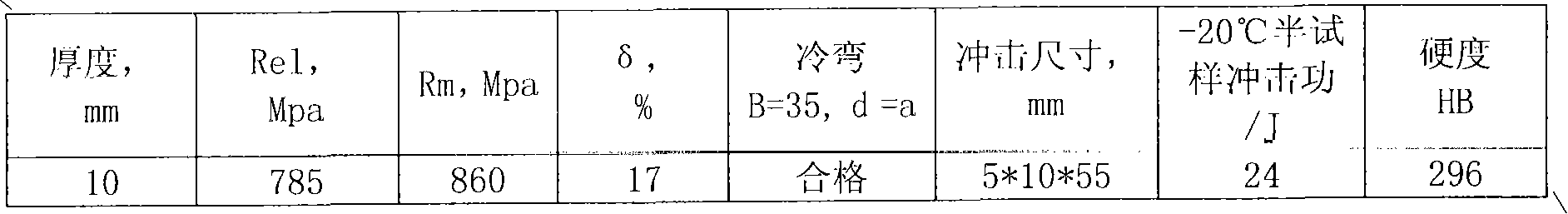

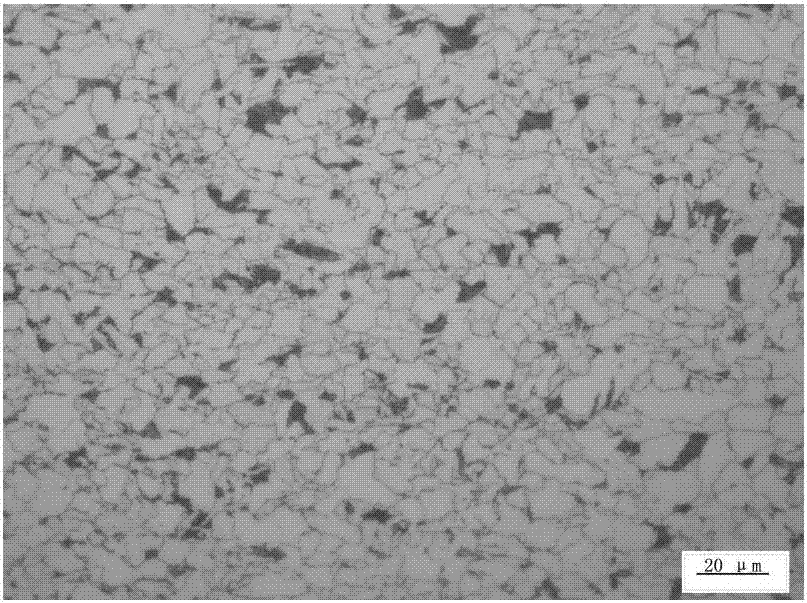

High-strength hot rolled steel plate with excellent cold forming property and preparation method thereof

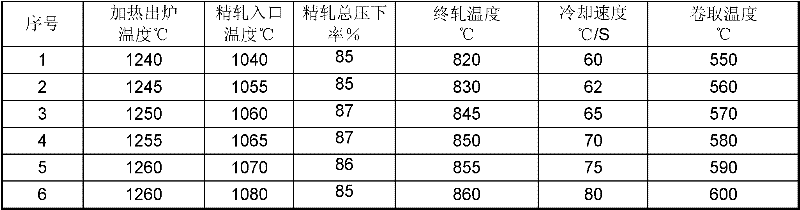

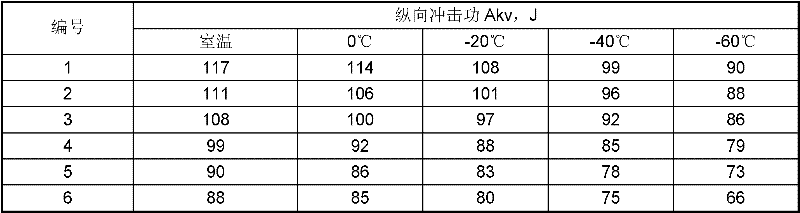

InactiveCN102226249AHigh accuracy of shape and sizeHigh dimensional accuracyRoll mill control devicesMetal rolling arrangementsSheet steelChemical composition

The invention discloses a high-strength hot rolled steel plate with excellent cold forming property. The steel plate comprises the following chemical components by weight: 0.04-0.08% of C, 0.15-0.3% of Si, 1.20-1.90% of Mn, 0.020-0.060% of Al, not more than 0.015% of P, not more than 0.0009% of S, 0.06-0.08% of Nb, 0.09-0.12% of Ti, 0.05-0.1% of Mo, not more than 0.002% of O and not more than 0.004% of N. A preparation method is characterized in that the heating temperature is 1240-1260 DEG C; the rough rolling temperature is 1230-1100 DEG C; the finish rolling inlet temperature is 1080-1040 DEG C; the final rolling temperature is 820-860 DEG C; the total finish rolling reduction ratio is not less than 85%; the laminar flow is cooled at a speed being not less than 60 DEG C / s after finish rolling; and the coiling temperature is controlled between 550 DEG C and 600 DEG C.

Owner:MAANSHAN IRON & STEEL CO LTD

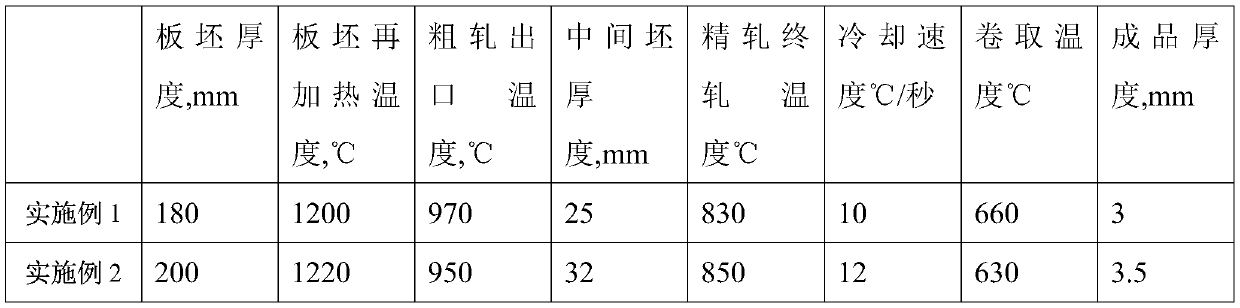

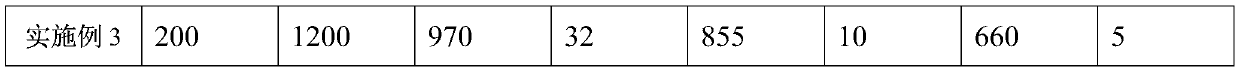

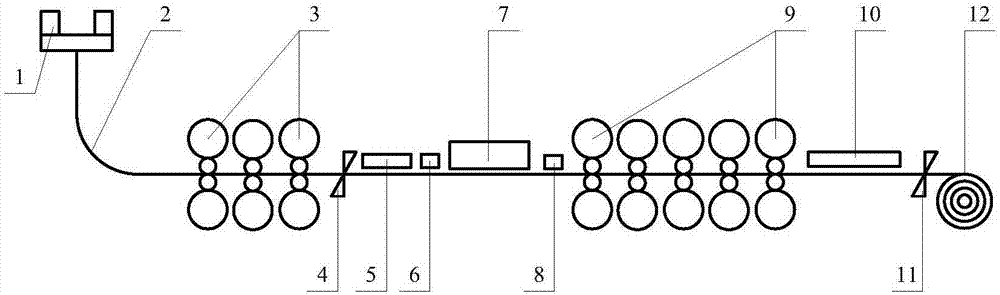

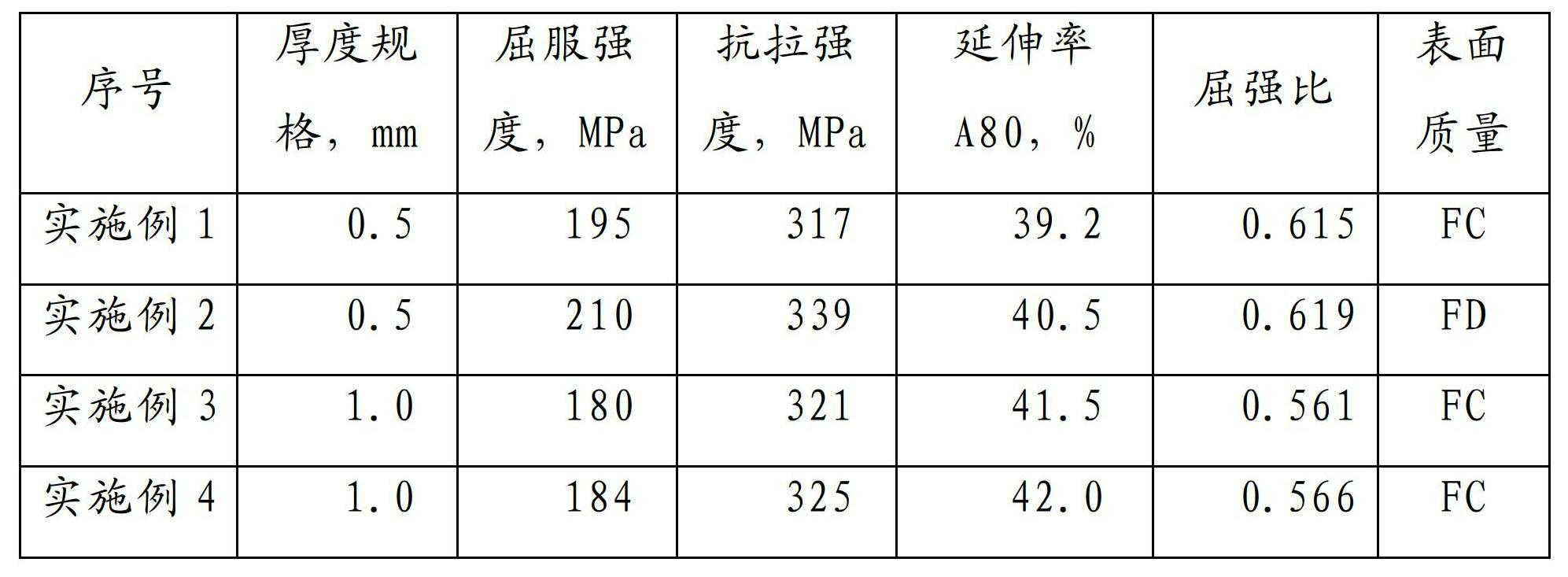

Preparation method of hot-rolled acid-washing high-strength steel for automobile carriage

The invention relates to a preparation method of hot-rolled acid-washing high-strength steel for an automobile carriage. The hot-rolled acid-washing high-strength steel comprises the following major ingredients in percentage by weight: 0.07 percent to 0.1 percent of C, at most 0.05 percent of Si, 1.5 percent to 1.9 percent of Mn, at most 0.015 percent of P, at most 0.01 percent of S, at most 0.005 percent of N, 0.1 percent to 0.2 percent of Mo, 0.04 percent to 0.06 percent of Nb, 0.15 percent to 0.2 percent of Ti, 0.02 percent to 0.04 percent of Al, 0.001 percent to 0.004 percent of B, 0.002 percent to 0.01 percent of Ca and the balance of Fe and inevitable impurities, Ti / B is greater than or equal to 35, and the carbon equivalent Ceq is smaller than or equal to 0.45 percent. The preparation method has the advantages that the ingredients are simple, the production process is simple, the tempering or hardening and tempering treatment is not needed after hot rolling, the surface qualityis good, the obdurability, the welding performance and the cold forming performance are excellent, and the cost is low.

Owner:UNIV OF SCI & TECH BEIJING

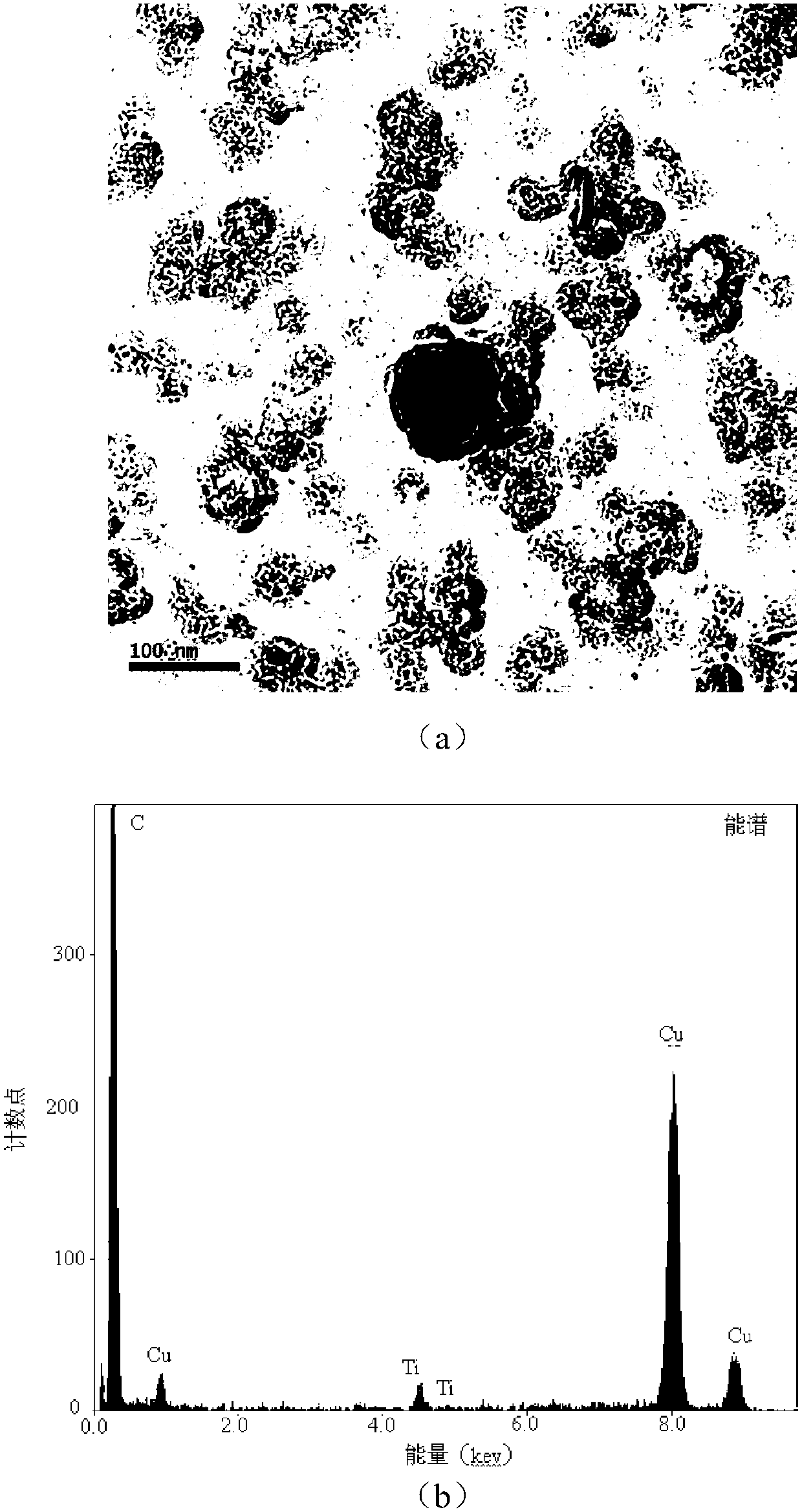

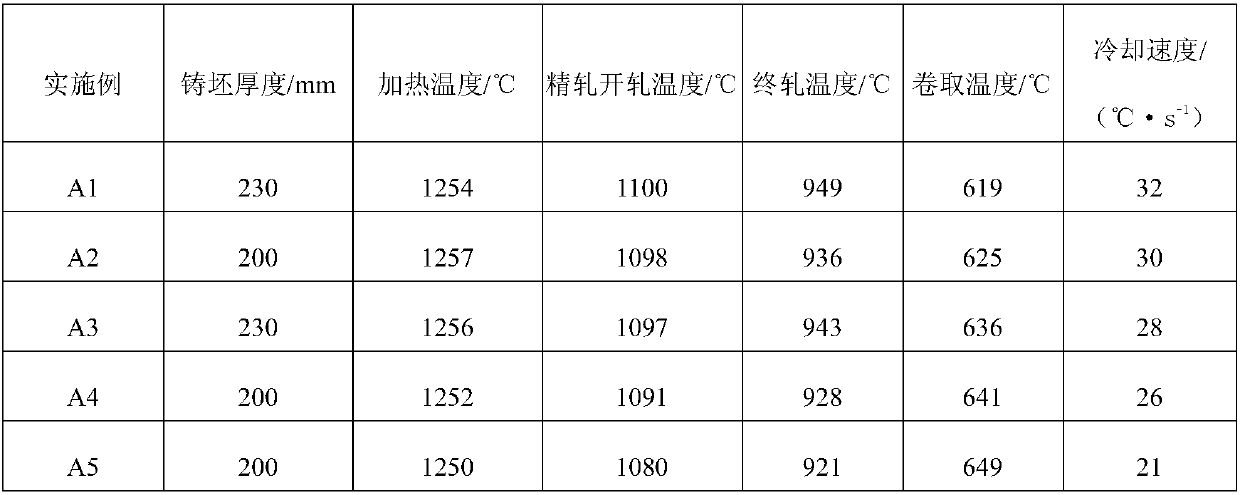

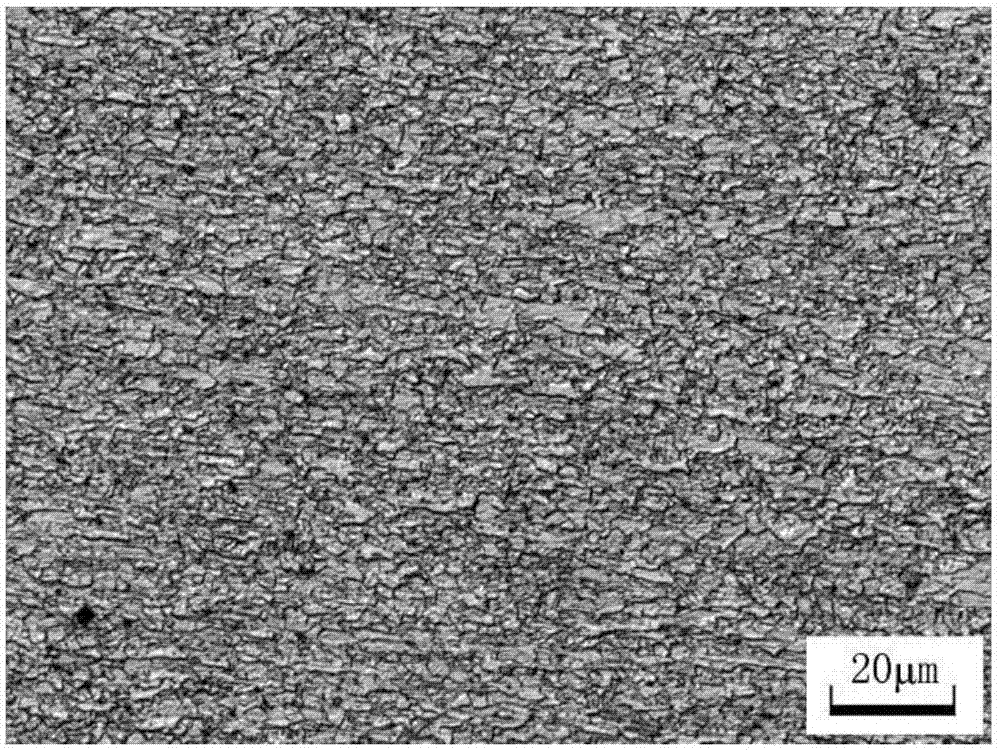

Weathering resistant steel for low-cost 550MPa hot rolling container and manufacturing method thereof

The invention discloses low-cost 550MPa hot-rolled container weathering steel and a manufacturing method thereof. Steel contains C 0.049%~0.069%, Si 0.20%~0.30%, Mn 0.51%~0.79%, P≤0.020%, S≤0.006%, Als 0.015%~0.045%, Cr 0.31%~0.41%, Ni 0.079 %~0.099%, Cu 0.21%~0.29%, Ti 0.057%~0.077%, N≤0.006%, and the rest are Fe and unavoidable impurities. The thickness of the slab is 200-230mm, the heating temperature of the slab is ≥1250°C, the starting temperature of the finishing rolling is 1080-1100°C, the finishing rolling temperature is 921-949°C, laminar cooling is adopted after rolling, and the cooling rate is >20°C / s, the coiling temperature is 619~649℃, after coiling, enter the slow cooling hood for slow cooling, if the thickness of the finished product is ≤2.0mm, it needs to be leveled. The thickness of the steel plate is 1.5~5.0mm, which is used in the container industry.

Owner:ANGANG STEEL CO LTD

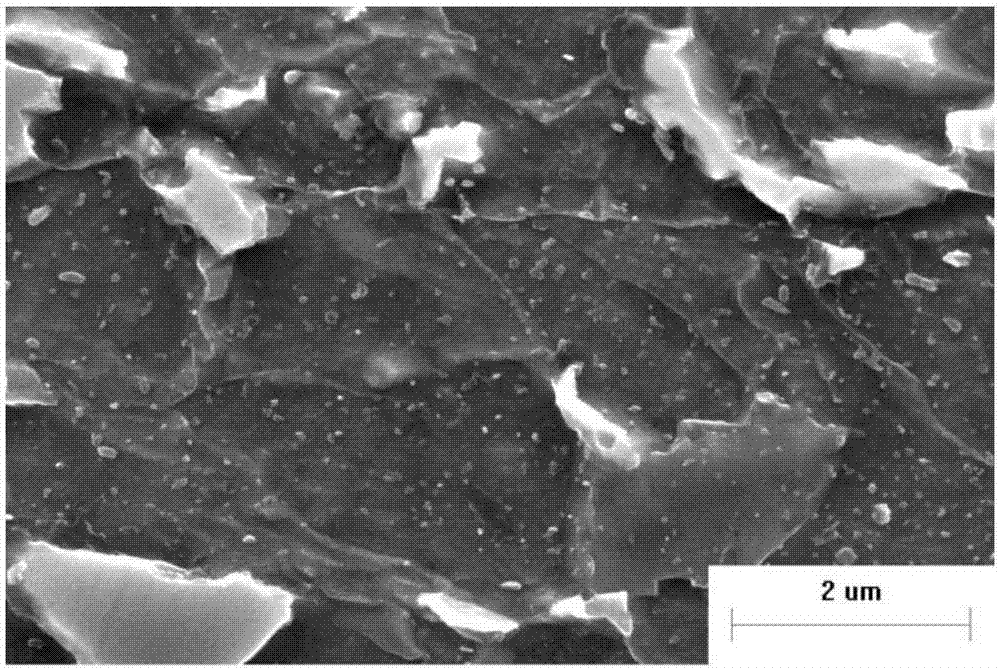

Preparation method of high carbon steel with good cold mouldability

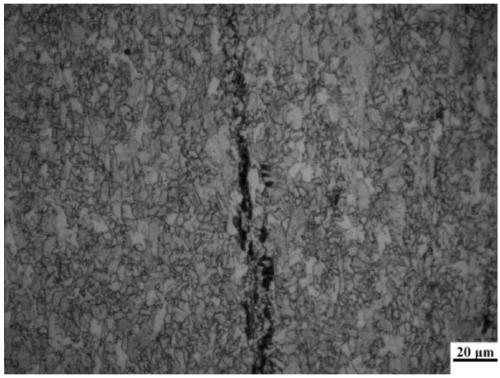

The invention discloses a preparation method of high carbon steel with good cold mouldability. The preparation method sequentially comprises the following steps: molten iron desulphurization; bessemerizing; argon blowing; refining; continuous casting; soaking pit; finish rolling; laminar cooling; taking up; slow cooling of a coil yard; leveling; and annealing. By means of controlling the chemical components of a steel product as well as a hot rolling process, a laminar cooling process, a take-up temperature and annealing process and the like, fine and dispersed globular pearlites are formed in steel, wherein the rate of spheroidization of pearlites is greater than or equal to 60%, the pearlites with the diameter which is greater than or equal to 2 mu m are greater than or equal to 60%, the tensile strength is 400-800MPa, the ductility is greater than or equal to 25% and the hardness is 130-290 HV. The preparation method disclosed by the invention not only is short in process flow, but also the prepared high carbon steel plate material is good in cold mouldability. In the moulding processes of cold punching, cold bending and the like, the material is not cracking, so that the yield and the usability of the material are greatly improved.

Owner:武汉钢铁有限公司

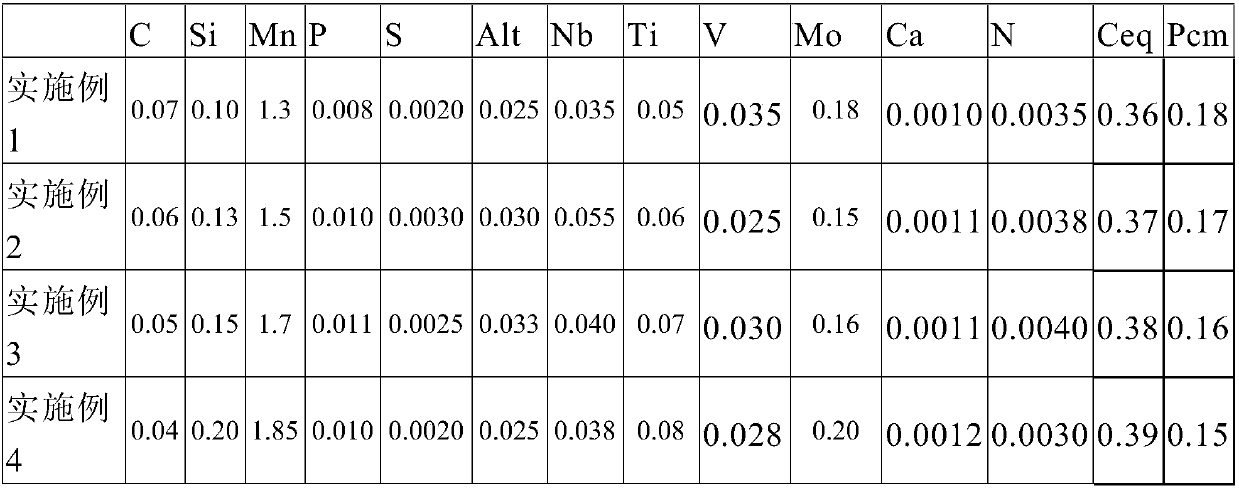

Thin-gauge and high-strength hot-rolled steel strip for cold forming and production method of thin-gauge and high-strength hot-rolled steel strip

ActiveCN107151763AReduce consumptionReduce manufacturing costManufacturing convertersProduction lineUltimate tensile strength

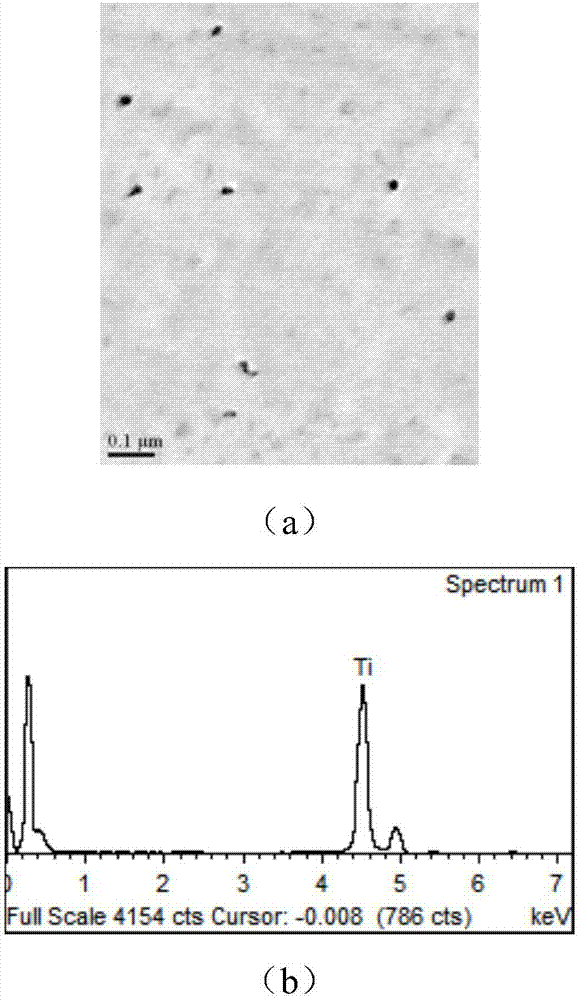

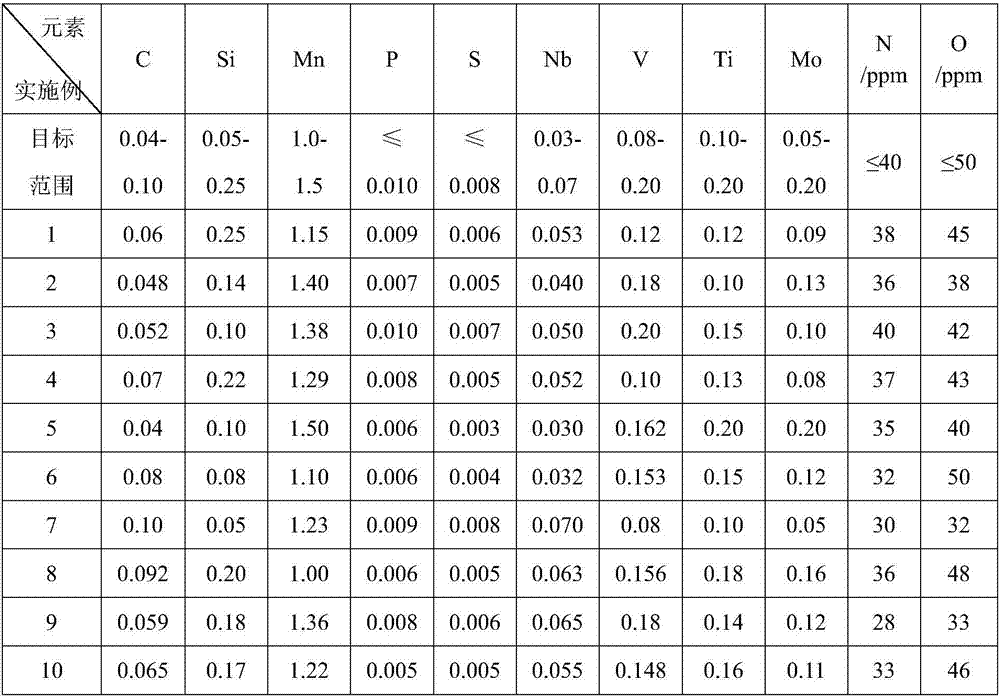

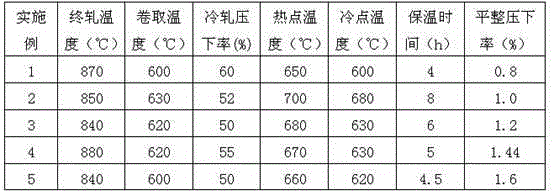

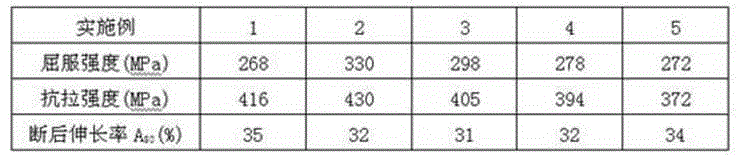

The invention discloses a thin-gauge and high-strength hot-rolled steel strip for cold forming and a production method of the thin-gauge and high-strength hot-rolled steel strip. The steel strip comprises the chemical components in percentage by weight: 0.04-0.10% of C, 0.05-0.25% of Si, 1.0-1.5% of Mn, less than or equal to 0.010% of P, less than or equal to 0.008% of S, 0.03-0.07% of Nb, 0.08-0.20% of V, 0.10-0.20% of Ti, 0.05-0.20% of Mo, less than or equal to 40ppm of N, less than or equal to 50ppm of O and the balance of Fe and unavoidable impurities. The production method of the steel strip comprises the following steps: 1) element smelting; 2) continuous casting; 3) rolling; and 4) natural cooling of a hot-rolled steel coil after rolling. By using the thin-gauge and high-strength hot-rolled steel strip, the thin-gauge and high-strength hot-rolled steel strip for cold forming is stably produced in batches on the traditional hot rolling production line, and the comprehensive performances of steel are improved.

Owner:武汉钢铁有限公司

Production method of 260-330MPa low-alloy high-strength steel

InactiveCN104928576AGood combination of strength and plasticityOptimized designChemical compositionMaterials science

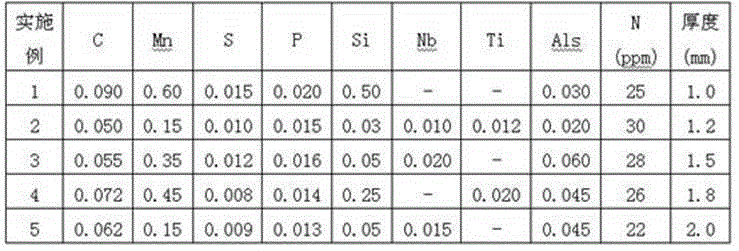

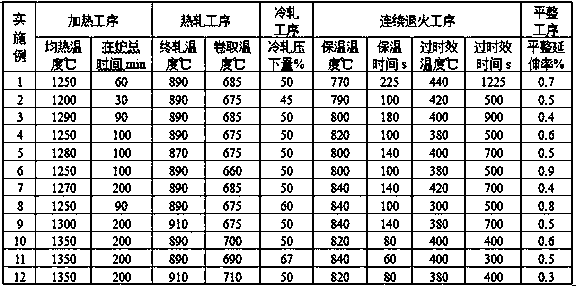

The invention discloses a production method of 260-330MPa low-alloy high-strength steel. The low-alloy high-strength steel comprises the following chemical components by mass percentage: 0.05-0.09% of C, 0.15-0.60% of Mn, less than or equal to 0.015% of S, less than or equal to 0.020% of P, less than or equal to 0.50% of Si, less than or equal to 0.020% of Nb, less than or equal to 0.020% of Ti, 0.020-0.060% of Als, less than or equal to 30ppm of N, and the balance of Fe and unavoidable impurities. The method comprises the procedures of hot rolling, pickling, cold rolling, box annealing, leveling and rewinding. The low-alloy high-strength steel obtained by the method has yield strength of 260-330MPa, tensile strength of 350-430MPa, percentage elongation after fracture of greater than or equal to 26.0%, and good combination of strength and plasticity. The method achieves stable production of the product via optimal design of components, and can obtain the cold rolling low-alloy high-strength steel with stable mechanical properties and good cold forming performance.

Owner:TANGSHAN IRON & STEEL GROUP

980MPa-grade automobile cold-rolled high-strength Q&P steel and production method thereof

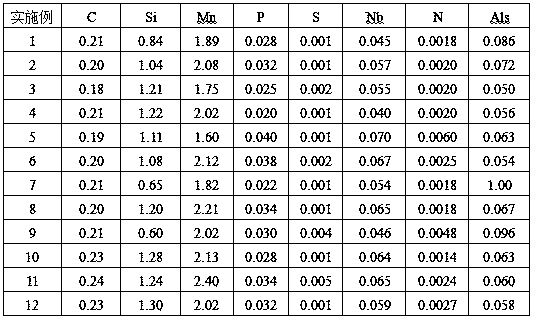

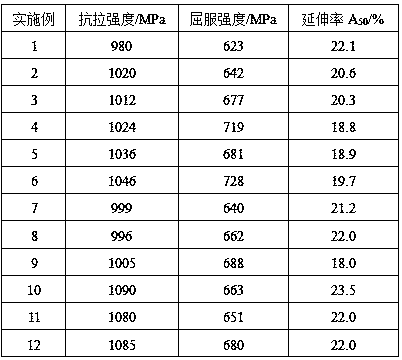

The invention discloses 980MPa-grade automobile cold-rolled high-strength Q&P steel and a production method thereof, and belongs to the technical field of steel production. The Q&P steel comprises thefollowing components, by weight percentage: 0.18-0.24% of C, 0.60-1.30% of Si, 1.60-2.40% of Mn, 0.02-0.04% of P, less than or equal to 0.005% of S, 0.040-0.070% of Nb, less than or equal to 0.0060%of N, 0.50-1.0% of Als and the balance of Fe and inevitable impurities. The production method comprises the steps of carrying out steel-making, carrying out heating, carrying out hot rolling, carryingout cold rolling, carrying out continuous annealing and carrying out leveling, wherein the holding temperature of a soaking zone in the continuous annealing process is 770-840 DEG C, and the holdingtemperature of an overaging zone is 300-440 DEG C. The obtained Q&P steel has the advantages that the mechanical property is excellent, the yield strength is greater than or equal to 550MPa, the tensile strength is greater than or equal to 980MPa, the elongation percentage is greater than or equal to 18%, and the cold forming property is good.

Owner:TANGSHAN IRON & STEEL GROUP +1

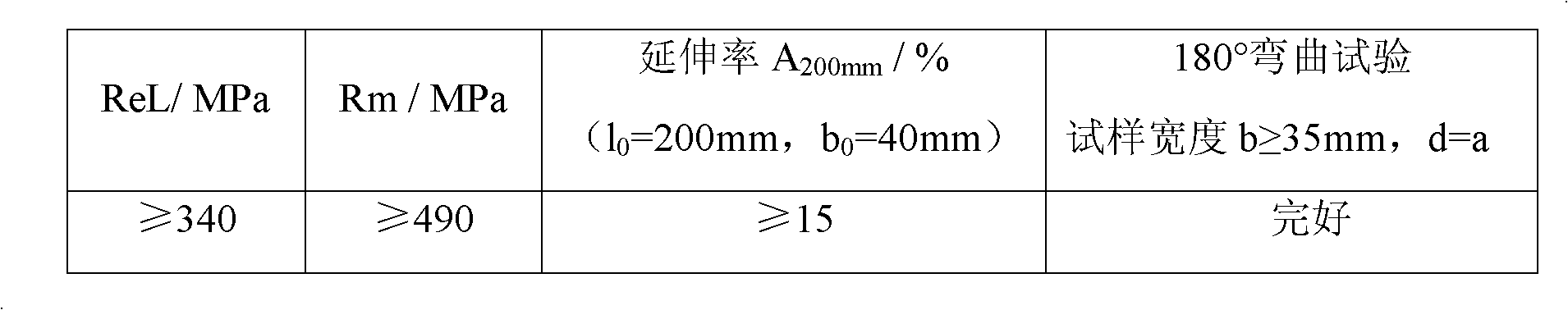

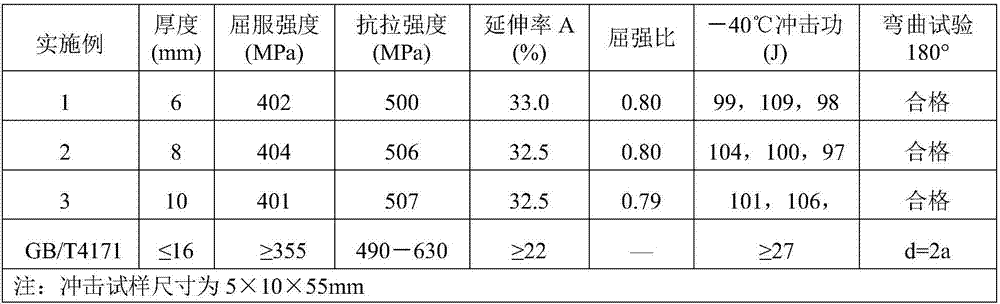

Hot rolled steel plate of 490 MPa level and production method thereof

InactiveCN101935801AGood cold bending performanceGood welding performanceSheet steelRoom temperature

The invention belongs to the technical field of metallurgy, and in particular relates to a micro-niobium alloy hot rolled steel plate of a 490 MPa level and a production method thereof, aiming to solving the first technical problem of providing the hot rolled steel plate of the 490 MPa level with excellent comprehensive performance. The hot rolled steel plate of the 490 MPa level is prepared from the following chemical components in percentage by weight: 0.04-0.11 percent of C, 0.13-0.27 percent of Si, 0.9-1.30 percent of Mn, 0.001-0.007 percent of N, 0-0.027 percent of P, 0-0.017 percent of S, 0.01-0.09 percent of Al, 0.013-0.027 percent of Nb, 0.004-0.012 percent of Ti and the balance of Fe. The hot rolled steel plate of the 490 MPa level, which is provided by the invention, reaches the yield strength not less than 380 MPa, tensile strength not less than 490 MPa, elongation not less than 17 percent and excellent cold bending performance, has favorable room-temperature mechanical performance and process performance and fully accords with the requirements on technical indexes.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

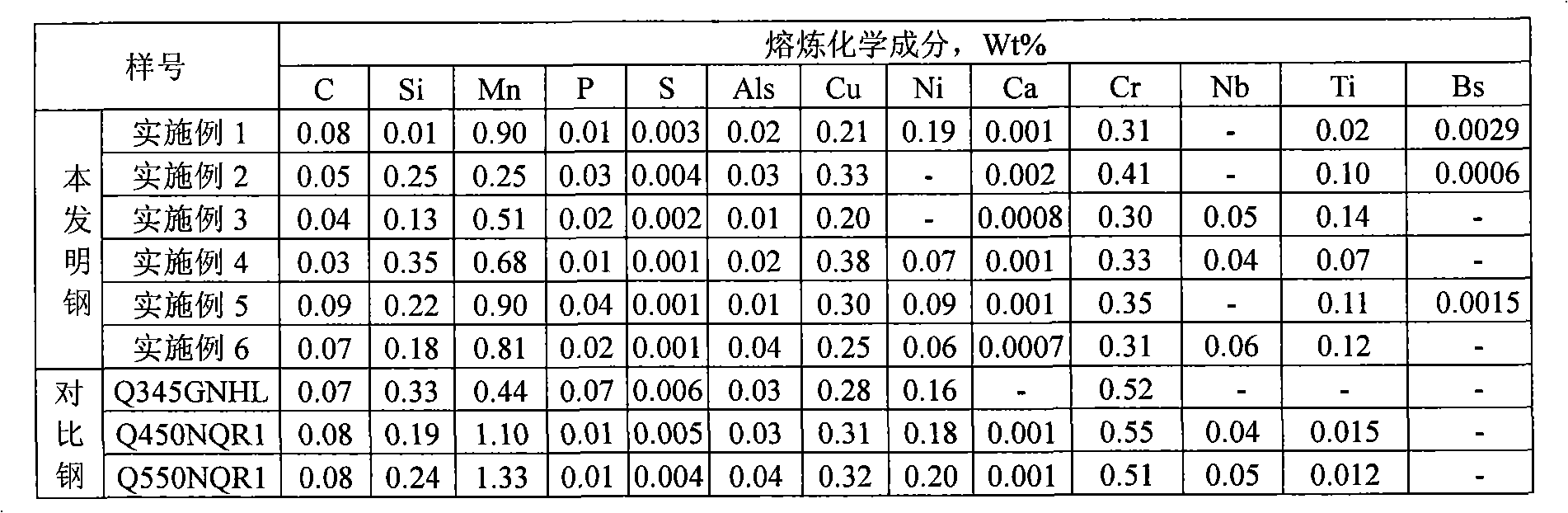

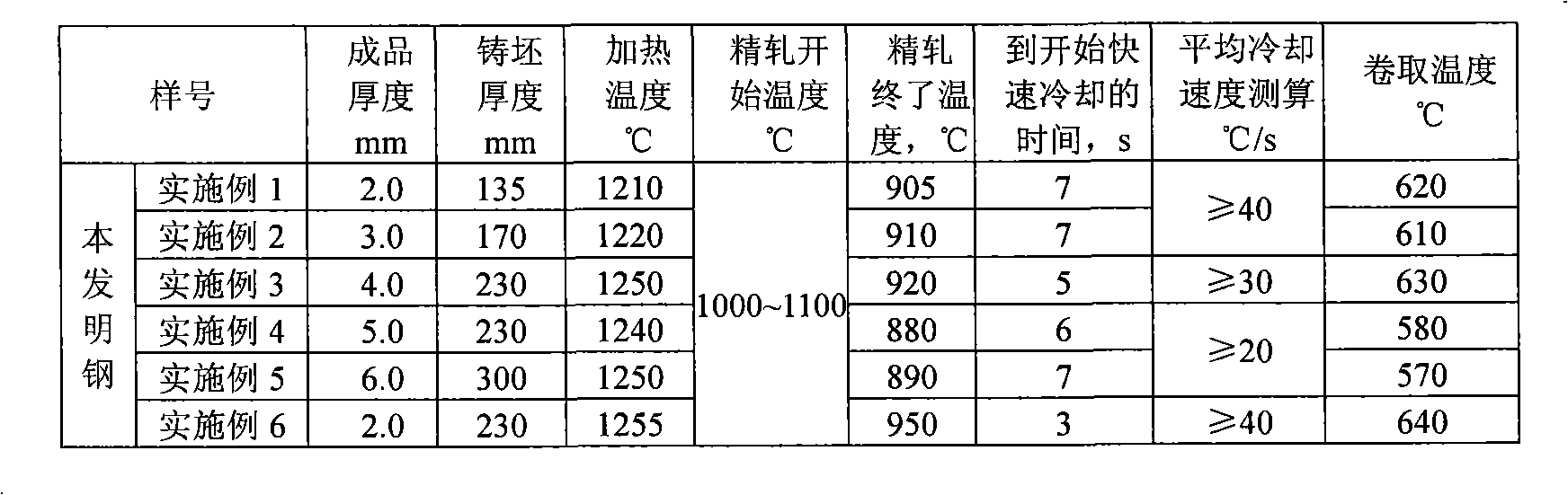

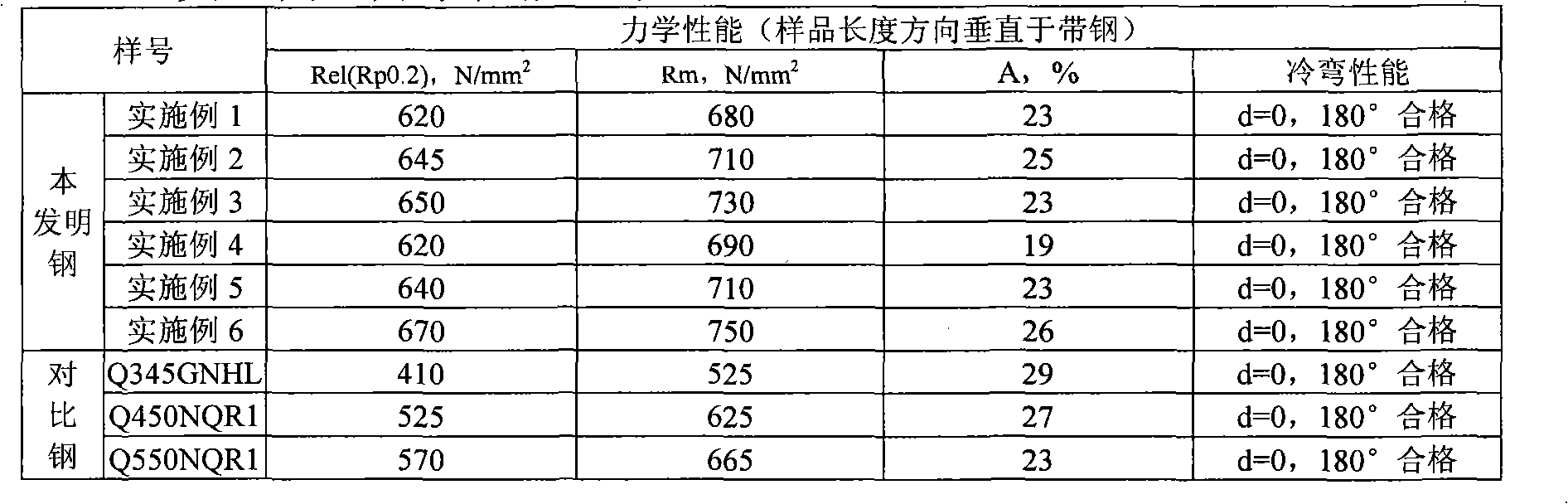

600MPa level hot rolling thin steel plate and manufacturing method thereof

InactiveCN101550520ALow costStrong anti-wearTemperature control deviceMetal rolling arrangementsSheet steelChemical composition

The invention discloses a 600MPa level hot rolling thin steel plate and a manufacturing method thereof. The steel plate comprises the following chemical compositions by weight percentage: 0.02-0.09 of C, 0.01-0.35 of Si, 0.20-0.90 of Mn, lower than 0.04 of P, lower than 0.005 of S, lower than 0.20 of Ni, 0.2-0.4 of Cu, 0.30-0.45 of Cr, 0.005-0.050 of Als, 0.0005-0.005 of Ca and 0.02-0.15 of Ti, one or more than one types of 0-0.070 of Nb and 0-0.003 of Bs, the balance of Fe and inevitable impurities. The steel is continuously cast into plate blanks of 120-300mm; then the obtained plate blanks are heated uniformly at the temperature of 1260 DEG C-1200 DEG C, is roughly rolled in the range of higher than 1040 DEG C, starts to finishing rolling at the temperature of 1100 DEG C-1000 DEG C, ends rolling at the temperature of 950 DEG C-880 DEG C, is cooled at the cooling speed of 20 DEG C / s in 10s after rolling and is reeled up at the temperature of 550 DEG C-650 DEG C. The weight of a container manufactured by the steel plate is reduced by 15-40 percent, therefore, the production cost is reduced.

Owner:ANGANG STEEL CO LTD

Low-cost non-quenched and tempered high-strength wear-resistant steal plate with yield strength of 780 MPa grade and manufacturing method thereof

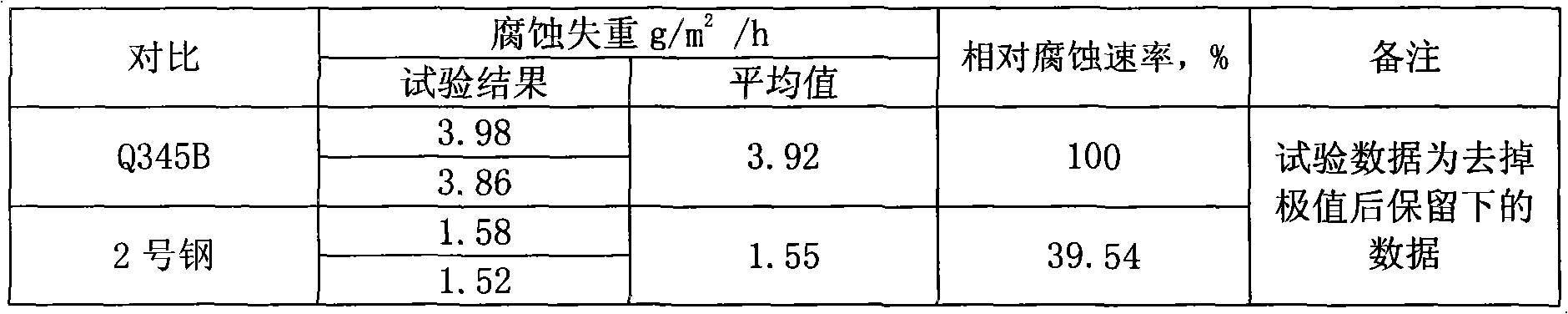

The invention discloses a low-cost non-quenched and tempered high-strength wear-resistant steal plate with a yield strength of 780 MPa grade, which comprises the following chemical components in percentage by weight: 0.08 to 0.13 percent of C, less than or equal to 0.5 percent of Si, 1.6 to 1.9 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.01 percent of S, 0.6 to 1.0 percent of Cr, 0.1 to 0.15 percent of Ti, 0.02 to 0.06 percent of Nb, less than or equal to 0.005 percent of N, less than or equal to 0.002 percent of O, and the balance of iron (Fe) and inevitable impurities. A manufacturing method of wear-resistant steel comprises the steps of electric furnace or converter smelting, refining, continuous casting, continuous casting bloom heating, hot continuous rolling, laminar flow cooling, coiling, decoiling and cutting to obtain a finished plate. A high-strength steel strip of the invention can achieve the following combination properties that: the ReL is 780 to 840 MPa, the Rm is 850 to 930 MPa, delta is more than or equal to 16 percent, the high-strength steel strip meets high wear resistance, and compared with Q345B, the wear resistance is improved by more than 2 times.

Owner:SHANDONG IRON & STEEL CO LTD

Rare-earth weather-proofing bridge steel plate with yield strength being 420MPa and production method of rare-earth weather-proofing bridge steel plate

InactiveCN107574374ASimple preparation processShorten the production cycleRare earthHeating temperature

The invention relates to a rare-earth weather-proofing bridge steel plate with the yield strength being 420MPa and a production method of the rare-earth weather-proofing bridge steel plate. The production method comprises the steps of smelting and casting, heating and rolling, and cooling. In the step of the heating and rolling, the heating temperature is 1200-1220 DEG C and the total time insidea furnace is greater than or equal to 240 min; the first stage of the rolling is carried out in an austenite recrystallization zone, the initial rolling temperature is 1130-1180 DEG C in the rolling process, the reduction rate in the first pass to the second pass shall be greater than 10%, and the reduction rate in at least 1-2 of the rest passes is controlled above 25%; and the second stage of the rolling is carried out in an austenite non-recrystallization zone, the initial rolling temperature is less than or equal to 930 DEG C, the thickness of a middle blank is 2.0-3.5 times of the thickness of a finished product, and the finish rolling temperature is 830-850 DEG C. The yield strength of the steel plate is greater than 420MPa, and has the advantages that the steel plate is low in yieldstrength ratio, and good in corrosion resistance, low temperature toughness, cold forming performance and welding performance, and can be used in a coating-free manner; a production process flow is simple; a production cycle is short; and the cost is low.

Owner:BAOTOU IRON & STEEL GRP

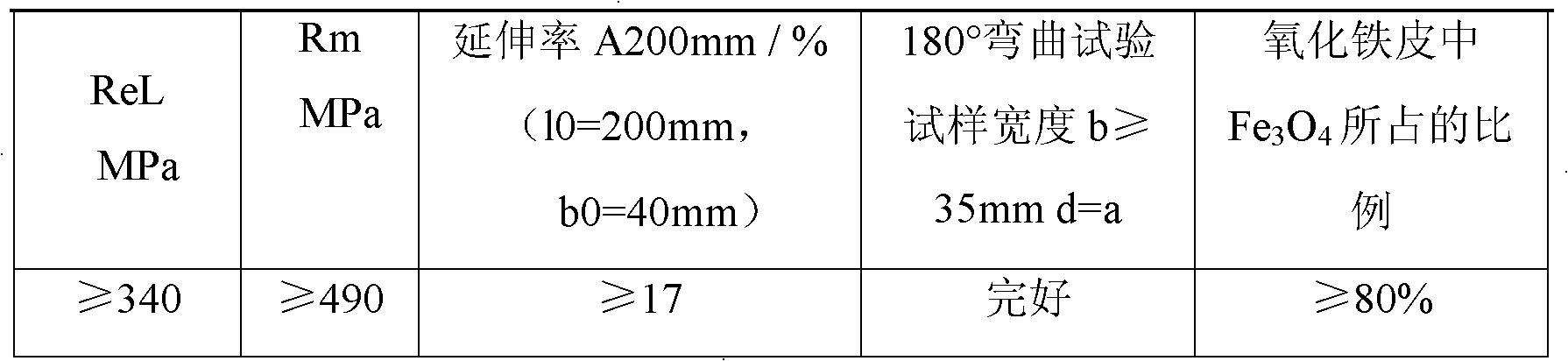

Method for producing 490MPa level acid-washing-free hot rolled steel plate

ActiveCN101935802AGood cold bending performanceGood welding performanceChemical compositionAcid washing

The invention belongs to the technical field of metallurgy, and particularly relates to a method for producing a 490MPa level acid-washing-free hot rolled steel plate. The method comprises the following steps of: heating a continuous casting billet; hot rolling; cooling; reeling, and the like, wherein the billet comprises the following chemical compositions in percentage by weight: 0.04-0.11 percent of C, 0.13-0.27 percent of Si, 0.9-1.30 percent of Mn, 0.001-0.007 percent of N, 0-0.027 percent of P, 0-0.017 percent of S, 0.01-0.09 percent of Al, 0.013-0.027 percent of Nb, 0.004-0.012 percent of Ti and the balance of Fe; the heating temperature of the billet is 1,200-1,240 DEG C, the initial rolling temperature of the hot rolling is 1,120-1,220 DEG C, and the finish rolling temperature is 870-910 DEG C; front-section laminar flow water-cooling after rolling is used by the cooling step; and the temperature of the reeling step is 550-585 DEG C. In the invention, the yield strength of a finished steel band product obtained by the method is larger than or equal to 380MPa, the tensile strength is larger than or equal to 490 MPa, the elongation is larger than or equal to 17 percent, the cold bending property is good, and the proportion of Fe3O4 in an oxidized iron sheet on the surface of the finished product exceeds 80 percent.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

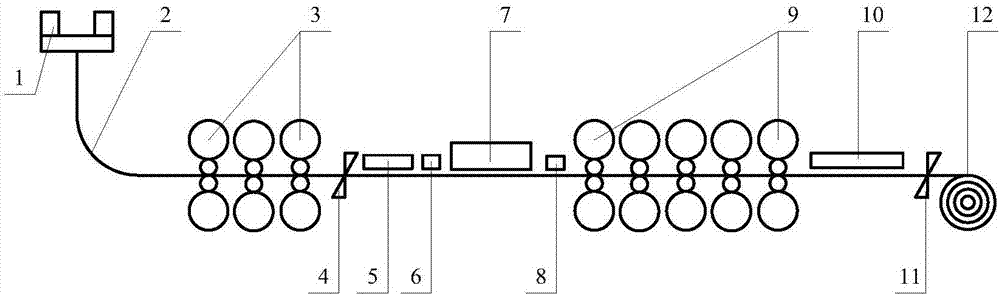

Preparation method and application of 550 MPa-grade ultra-fine grain high-strength weather-resistant steel

InactiveCN107460413AImprove mechanical propertiesGood atmospheric corrosion resistanceWeather resistanceAustenite grain

The invention relates to a preparation method and application of 550 MPa-grade ultra-fine grain high-strength weather-resistant steel and belongs to the technical field of metallurgy. The preparation method comprises the steps that continuous casting blanks directly enter an M rack rough rolling unit under the high pulling speed and are subjected to M-pass continuous heavy reduction (50-60%) rough rolling, and austenite grains are greatly refined; after rough rolling, middle blanks are rapidly heated through an induction heating furnace to the temperature needed for a finish rolling inlet, and meanwhile a reverse temperature field is formed; and then sequentially through a finish rolling set, laminar flow cooling and a reeling machine, finally the organization characteristics that the surface and the core part are coarse, and the portion of the 1 / 4 thickness position is fine are formed. In the production process, finish rolling and rough rolling are both full-headless rolling. An ultra-fine grain high-strength weather-resistant hot-rolling steel belt with the weather resistance being equivalent to corten-A is obtained, and the effects that the thin effect replaces the thick effect and the hot effect replaces the cold effect are achieved; while the weight of a car body is small, the service life of a car plate is prolonged, the production efficiency is improved, and the production cost is reduced; and meanwhile energy consumption is reduced, emission is reduced, and resource-saving and environment-friendly production is achieved.

Owner:UNIV OF SCI & TECH BEIJING +1

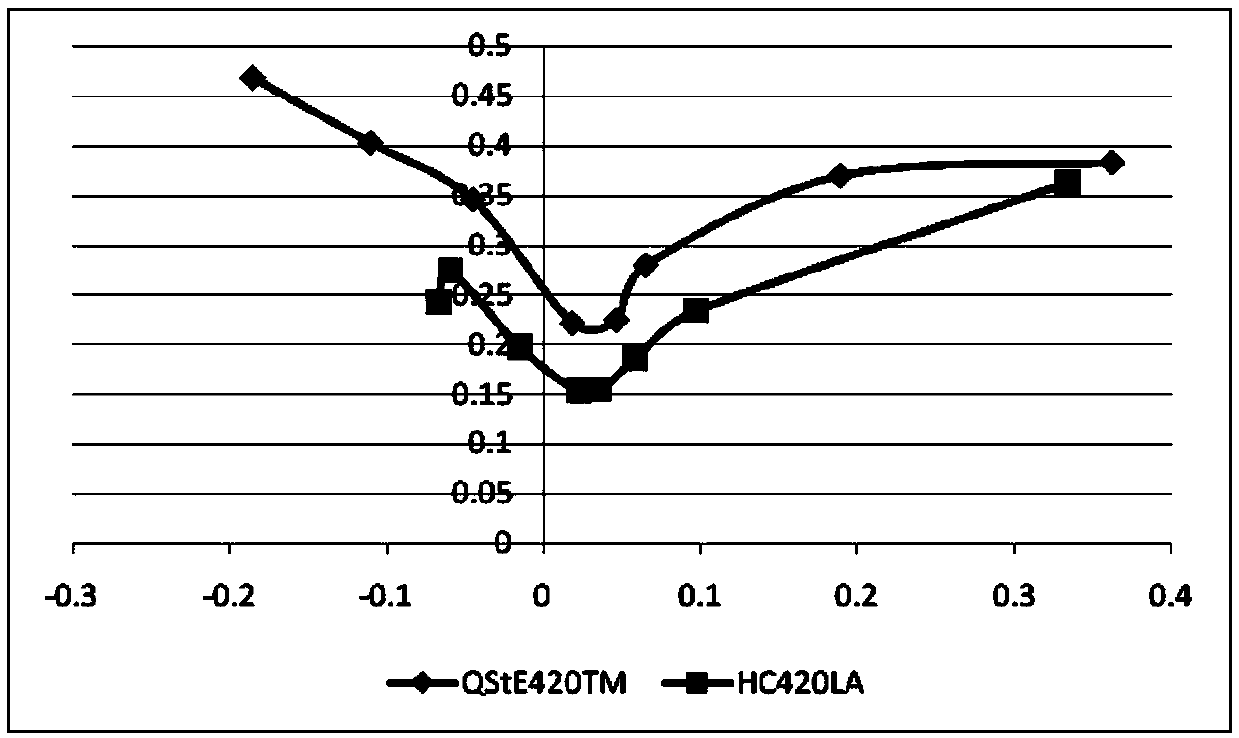

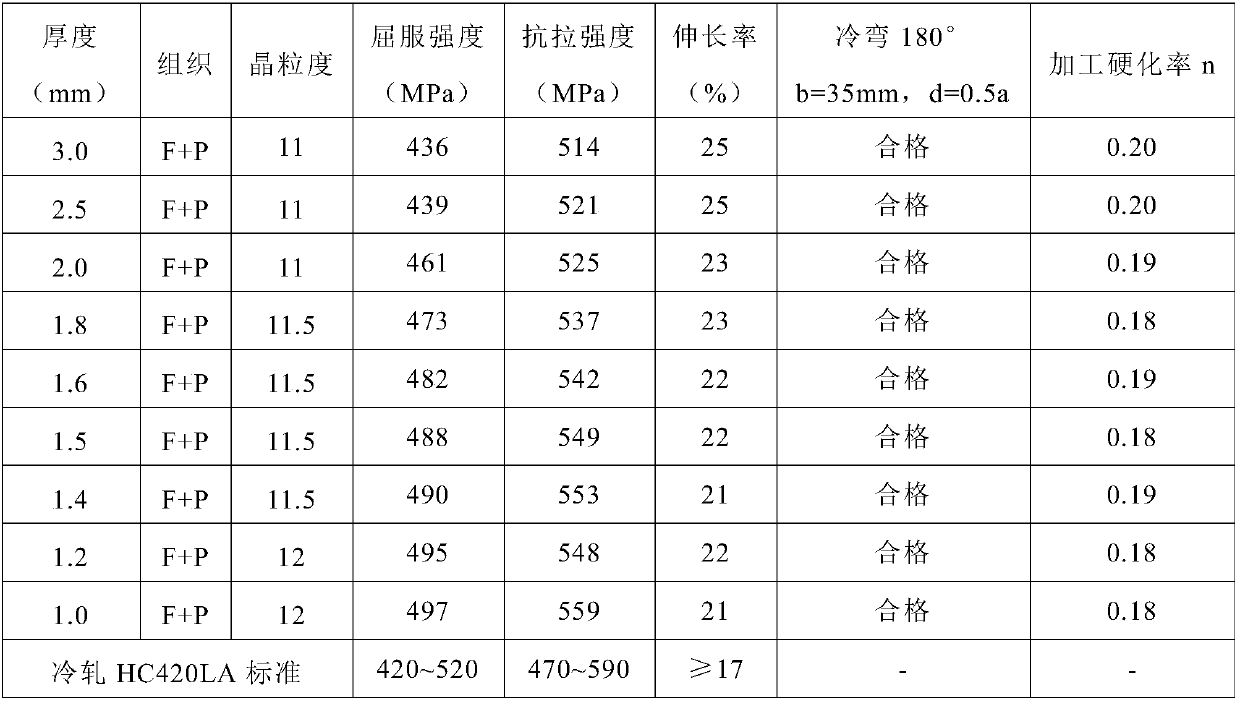

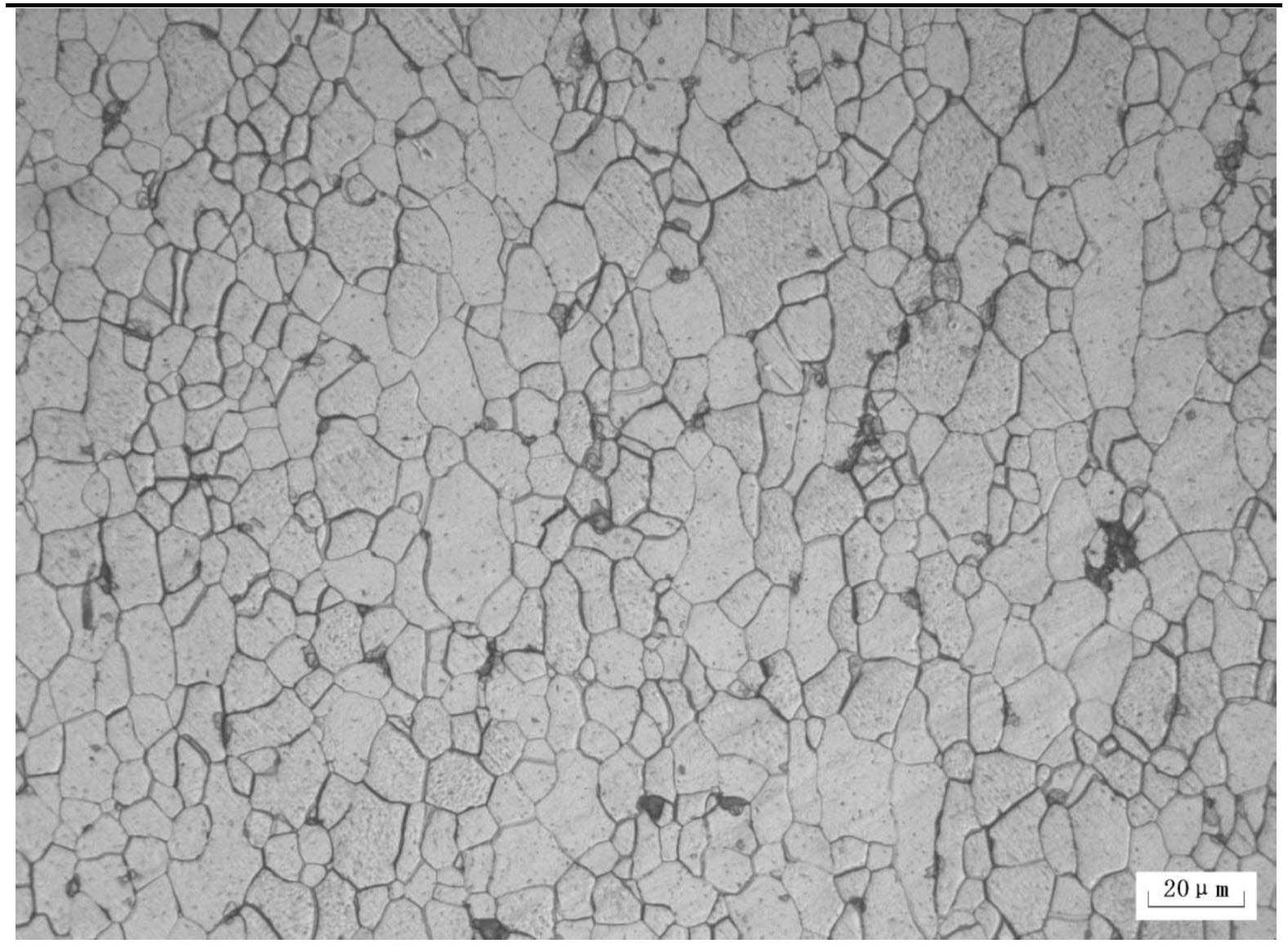

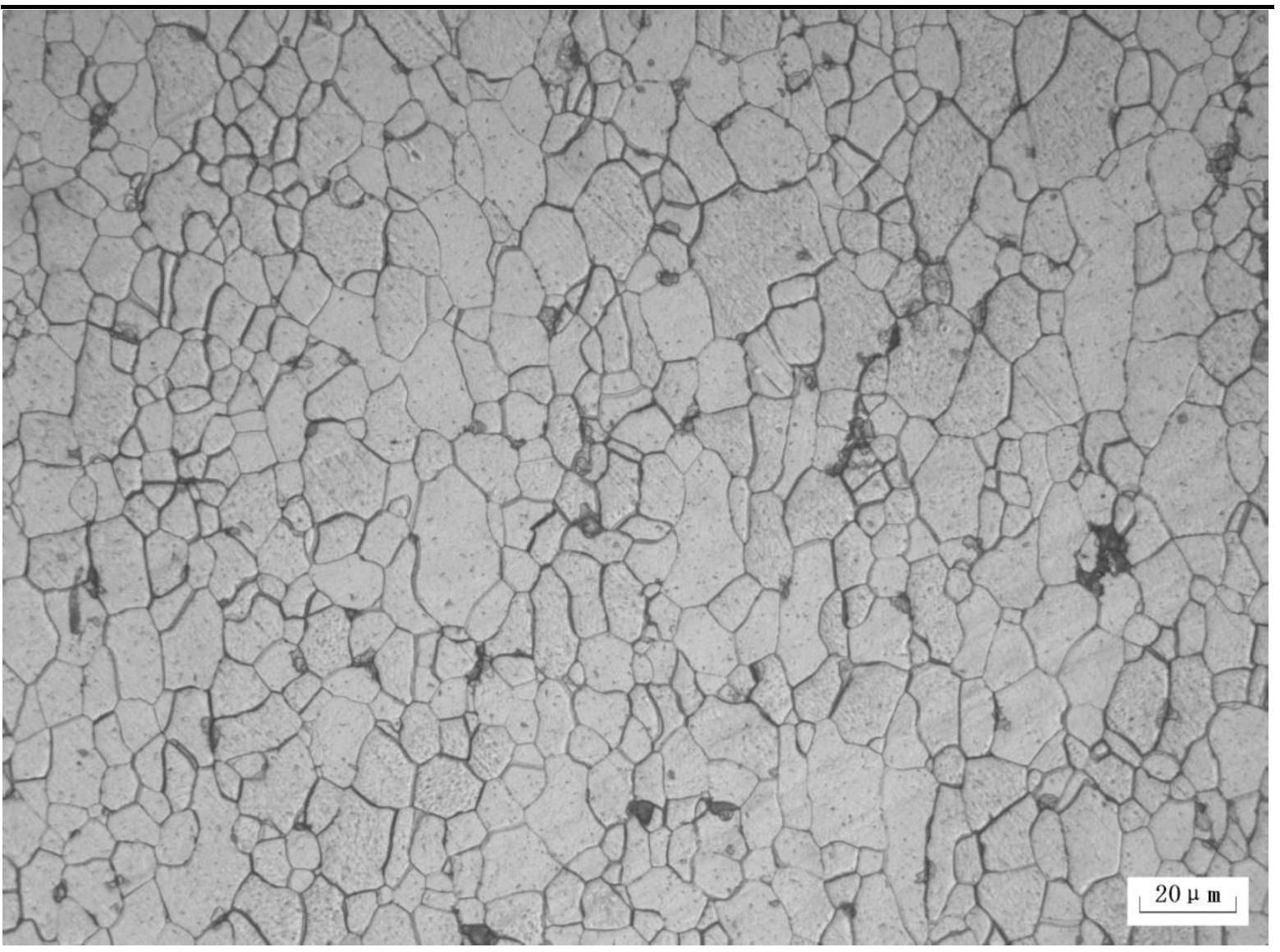

Hot-rolled automobile structural steel plate with yield strength of 420MPa and excellent cold-forming performance and manufacturing method

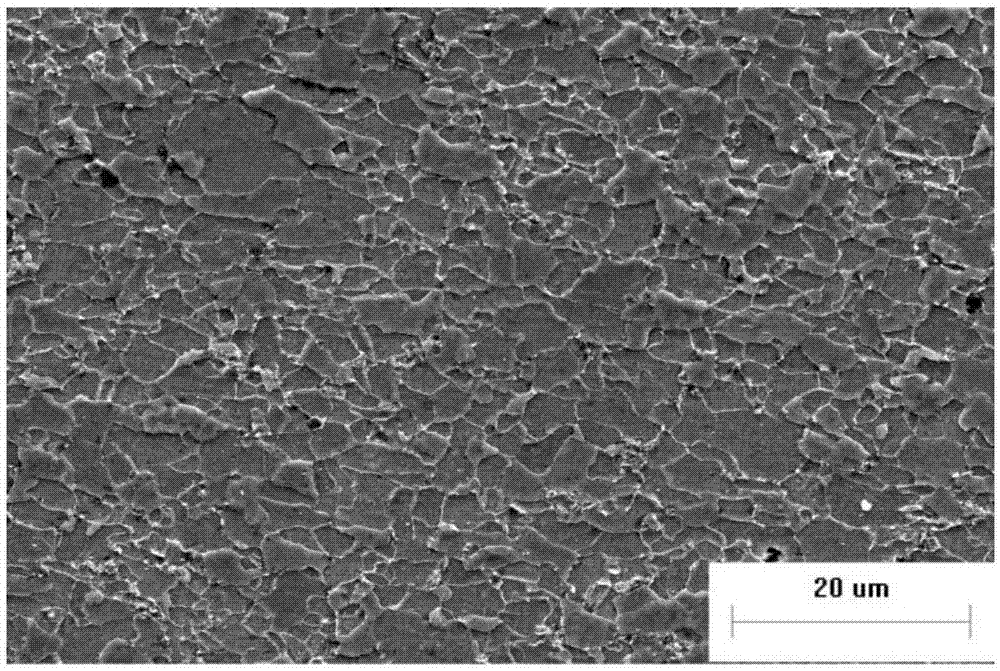

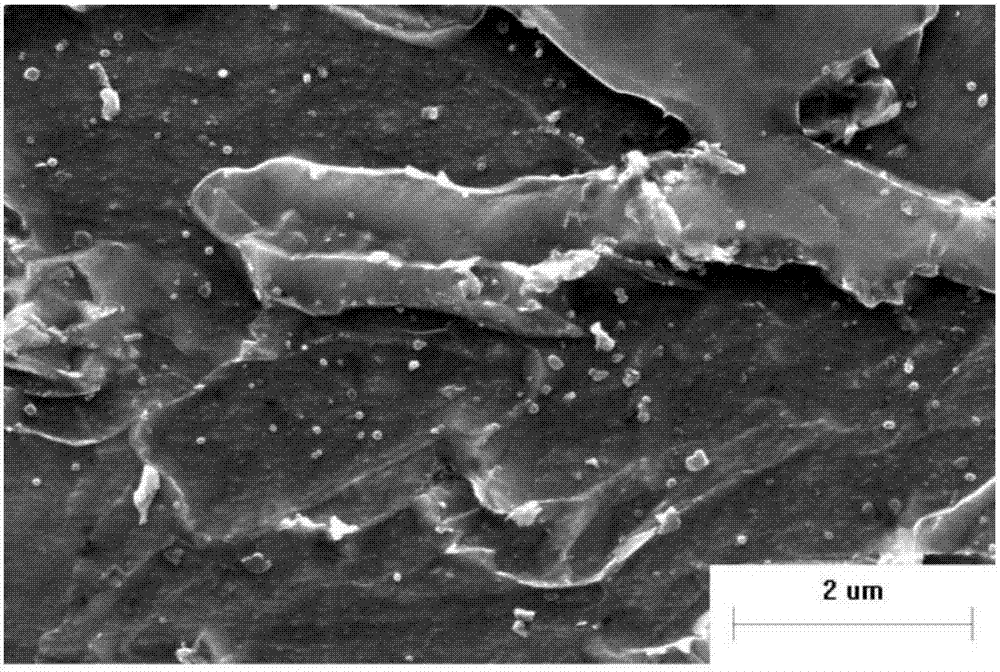

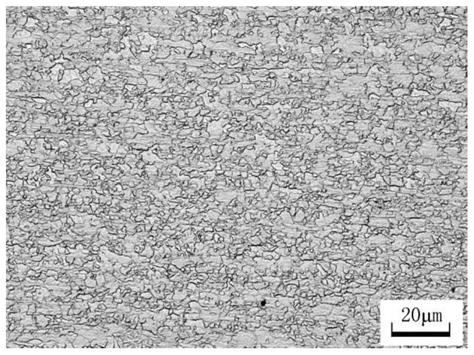

The invention discloses a hot-rolled automobile structural steel plate with the yield strength of 420MPa and excellent cold-forming performance and a manufacturing method. The hot-rolled automobile structural steel plate with the yield strength of 420MPa and the excellent cold-forming performance comprises, by weight, 0.03-0.06% of carbon, 0.7-0.9% of manganese, 0.020-0.030% of niobium, 0.020-0.030% of titanium, less than 0.10% of silicon, no more than 0.005% of sulfur, no more than 0.015% of phosphorus, no more than 40 ppm of nitrogen, 0.025-0.050% of acid soluble aluminum, and the balance iron and inevitable impurities. According to the hot-rolled automobile structural steel plate with the yield strength of 420MPa and the excellent cold-forming performance and the manufacturing method, the Nb-Ti microalloying technique is adopted for a short process, S and N (S<=0.005%, and N<=40 ppa) in steel are fixed through a trace of Ti, the grain refining effect of Nb is brought into full playto obtain a fine F+P structure, and thus the cold-forming performance of the steel is improved while high strength is obtained.

Owner:武汉钢铁有限公司

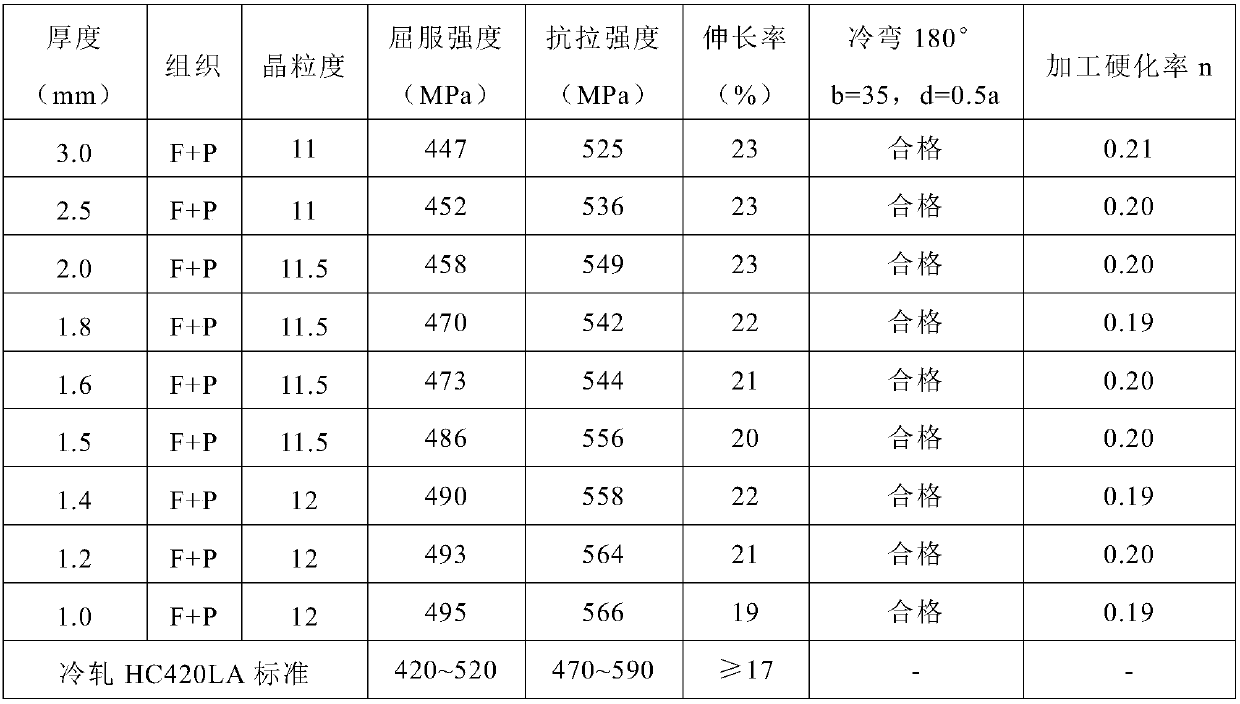

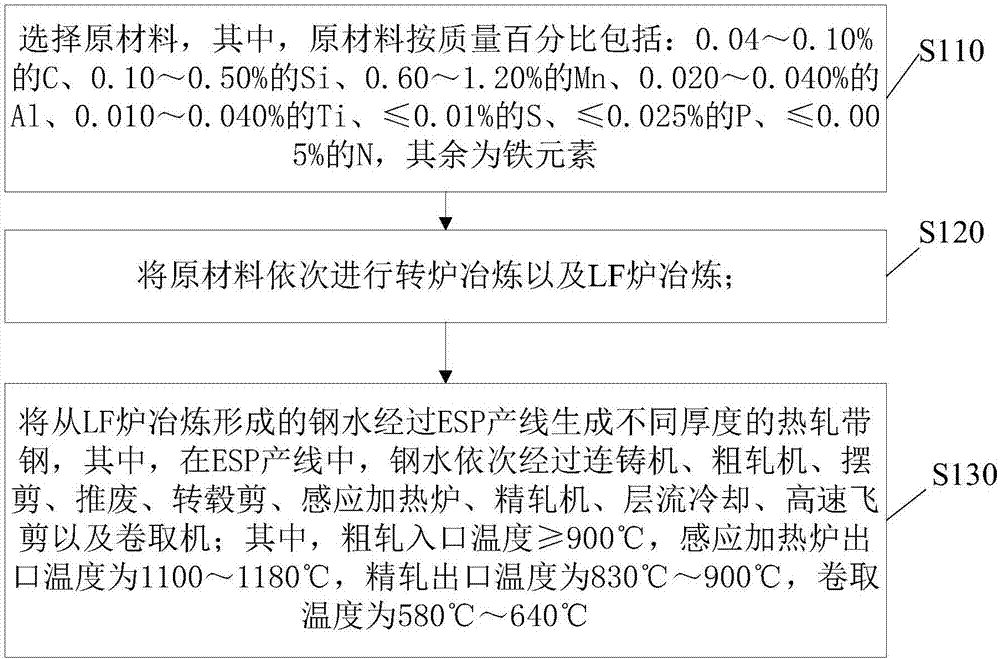

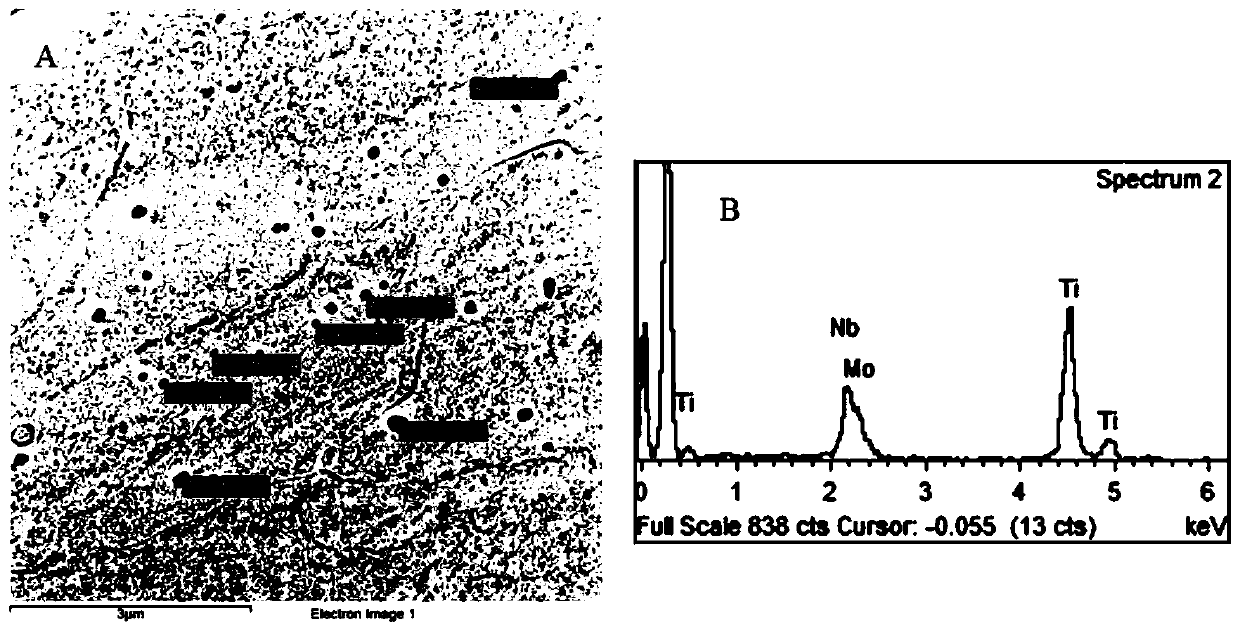

Method for producing titanium-microalloyed steel based on completely endless thin-slab continuous casting and continuous rolling process

The invention provides a method for producing titanium-microalloyed steel based on completely endless thin-slab continuous casting and continuous rolling process. The method comprises the following steps of: selecting raw materials which comprise 0.04-0.10% of C, 0.10-0.50% of Si, 0.60-1.20% of Mn, 0.020-0.040% of Al, 0.010-0.040% of Ti, less than or equal to 0.01% of S, less than or equal to 0.025% of P, less than or equal to 0.005% of N and the balance being an iron element according to the mass percentage; carrying out converter smelting and LF (ladle furnace) smelting on the raw materials in sequence; and carrying out completely endless thin-slab continuous casting and continuous rolling on molten steel formed through LF smelting to produce hot rolled strip steel with different thicknesses, wherein in the completely endless thin-slab continuous casting and continuous rolling production line, the inlet temperature of rough rolling is greater than or equal to 900 DEG C, the outlet temperature of an induction heating furnace is 1100-1180 DEG C, the outlet temperature of finish rolling is 830 DEG C-900 DEG C, and the rolling temperature is 580-640 DEG C. The method solves the problems of high cost, high energy consumption and the like existing in a traditional technological method for producing the titanium-microalloyed steel and achieves the purposes of energy conservation, environmental protection and cost reduction.

Owner:RIZHAO STEEL HLDG GROUP

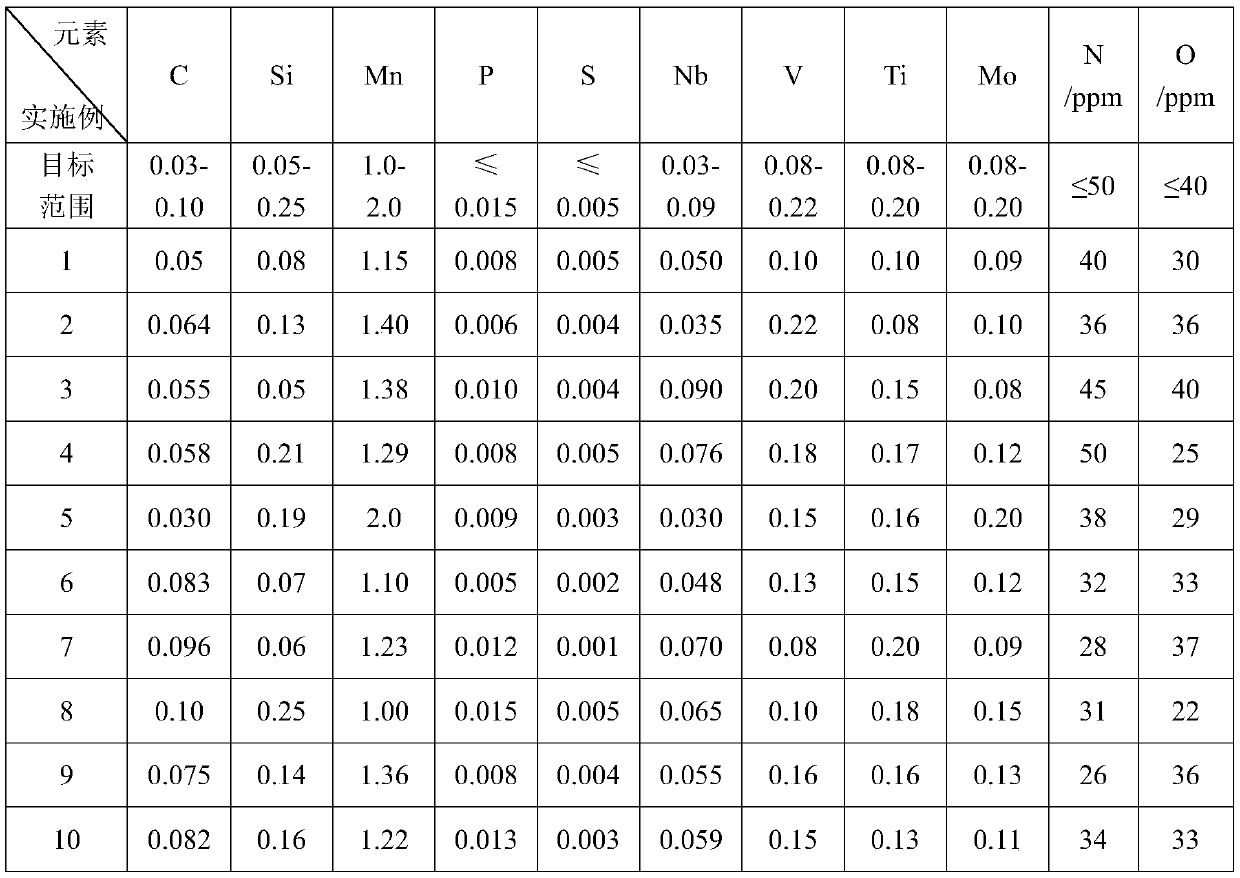

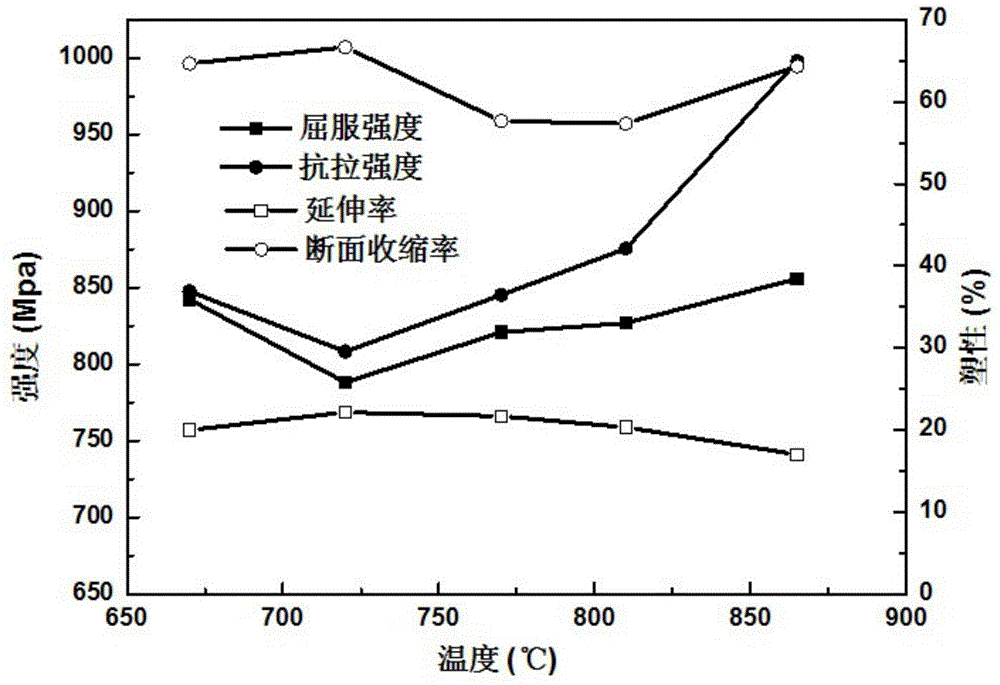

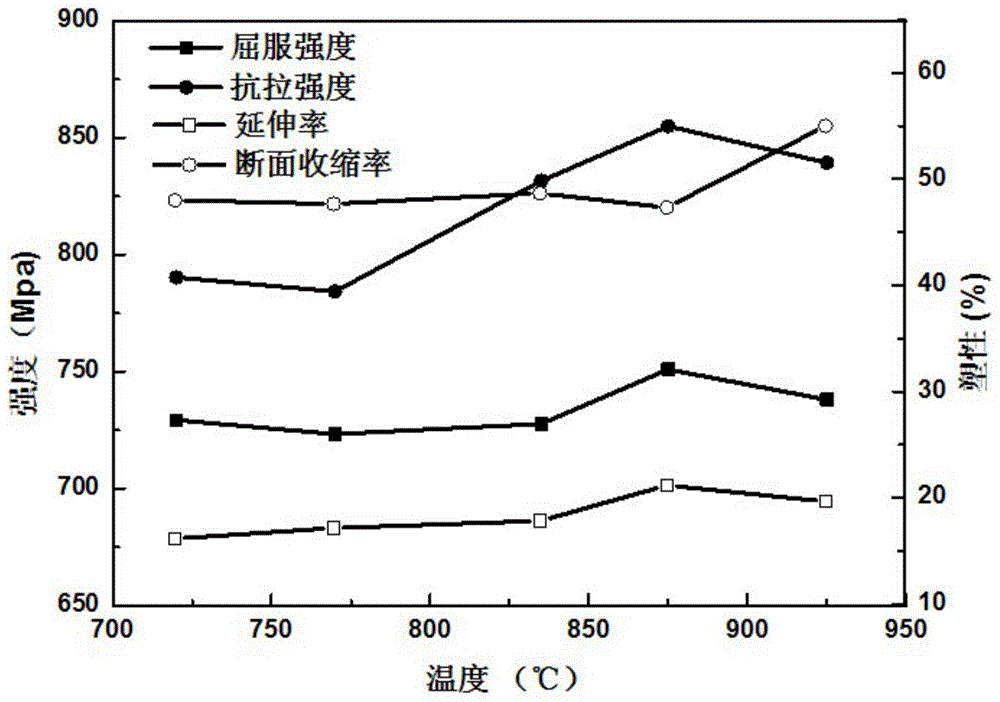

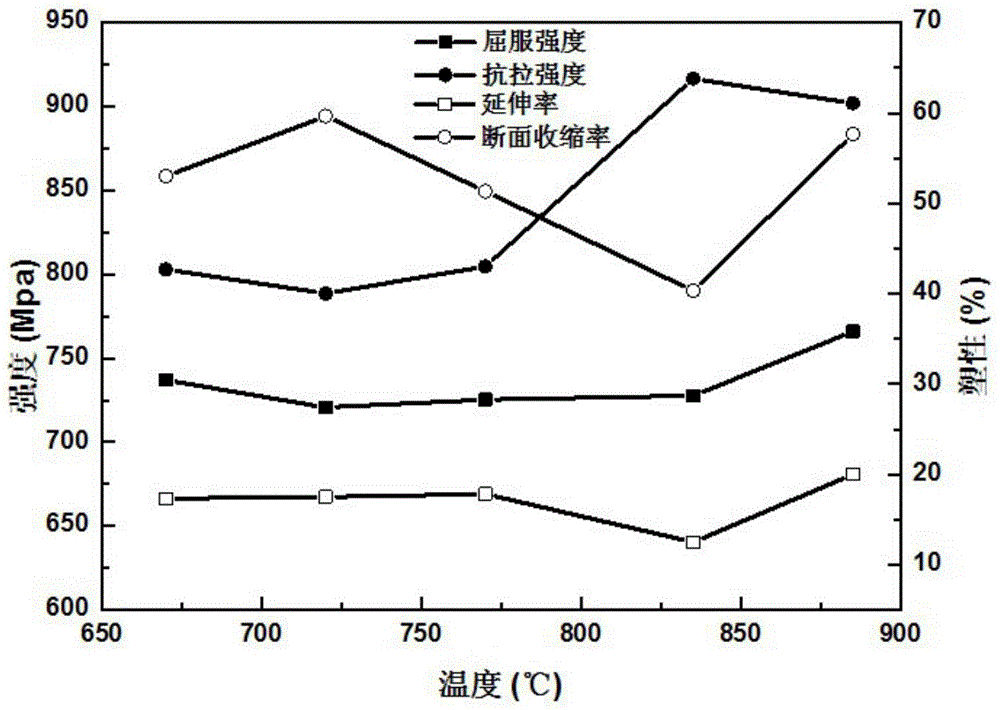

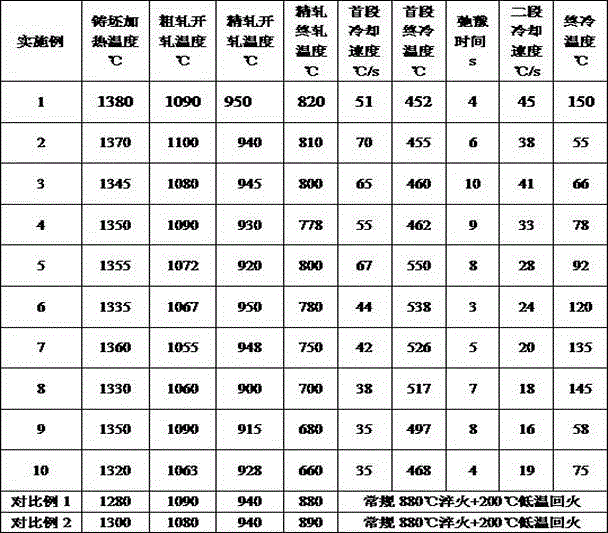

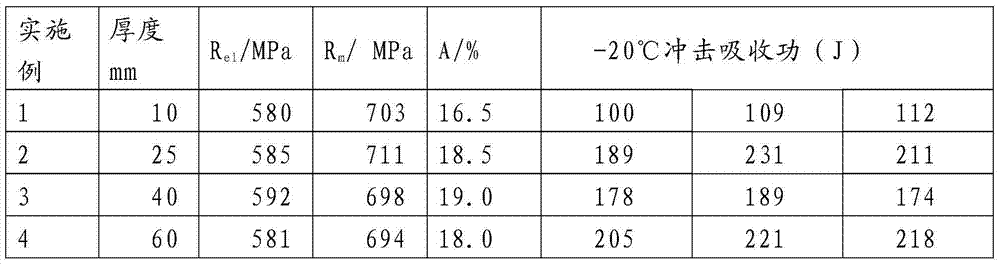

800MPa-grade heavy-gauge hot-rolled high-strength steel plate roll with excellent low-temperature toughness for cold forming and manufacturing method thereof

InactiveCN111455278AReduce consumptionReduce manufacturing costManufacturing convertersCold formedSlow cooling

The invention discloses an 800MPa-grade heavy-gauge hot-rolled high-strength steel plate roll with excellent low-temperature toughness for cold forming and a manufacturing method thereof. The steel comprises the following chemical components in percentage by weight: 0.03% to 0.10% of C, 0.05% to 0.25% of Si, 1.0% to 2.0% of Mn, not more than 0.015% of P, not more than 0.005% of S, 0.03% to 0.09% of Nb, 0.08% to 0.22% of V, 0.08% to 0.20% of Ti, 0.08% to 0.20% of Mo, not more than 50ppm of N, not more than 40ppm of O and the balance of Fe and inevitable impurities, wherein the steel is manufactured by the six steps of element smelting, continuous casting, direct loading and heating, rolling, ultra-fast cooling and winding and natural slow cooling. Through the adoption of a low-cost design route, the 800MPa-grade heavy-gauge hot-rolled plate rolls with excellent low-temperature toughness, cold forming performance and welding performance are developed and stably produced in batches, and the products are widely applied to the light-weight field of special vehicles such as dump trucks, trailers, semi-trailers and the like.

Owner:武汉钢铁有限公司

Ti-Al-Zr-Mo-V system medium-strength high-plasticity titanium alloy and preparation method thereof

The invention discloses a Ti-Al-Zr-Mo-V system medium-strength high-plasticity titanium alloy and a preparation method thereof, and belongs to the technical field of titanium alloy materials. The titanium alloy comprises, by weight, 3.0%-5.0% of Al, 1.0%-3.5% of Zr, 2.0%-4.5% of Mo, 1.0%-3.5% of V, and the balance Ti and unavoidable impurity elements. According to the Ti-Al-Zr-Mo-V system medium-strength high-plasticity titanium alloy and the preparation method thereof, the Ti-Al-Zr-Mo-V system medium-strength high-plasticity titanium alloy is obtained by adding the alloy elements of Mo and Zr and adjusting the proportion of Al equivalent weight and Mo equivalent weight properly, the extension strength of the Ti-Al-Zr-Mo-V system medium-strength high-plasticity titanium alloy is 800 MPa to 1000 MPa, and the extension rate is greater than 18%; the strength and the plasticity are matched well, and excellent machinability and excellent cold-forming performance are obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

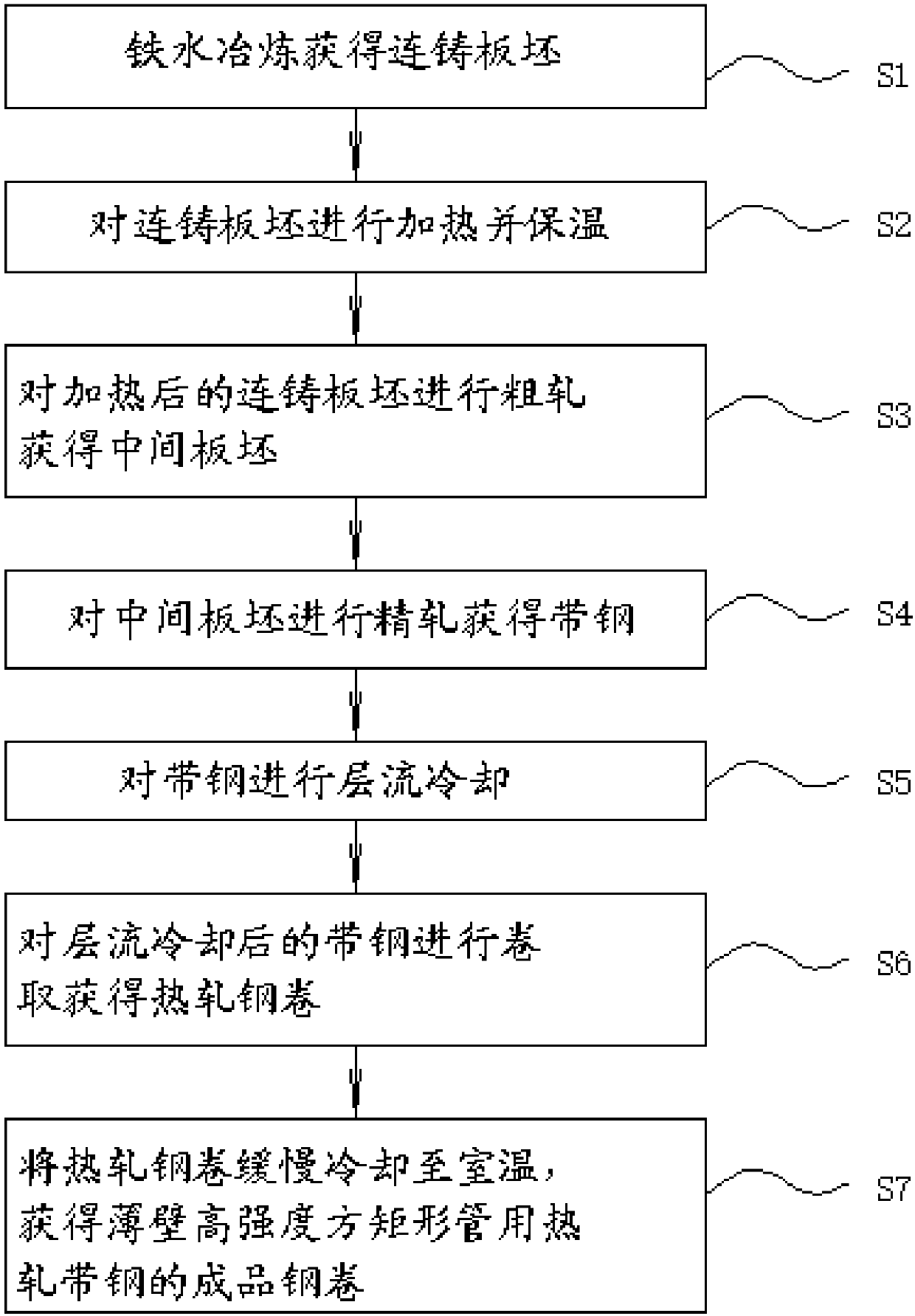

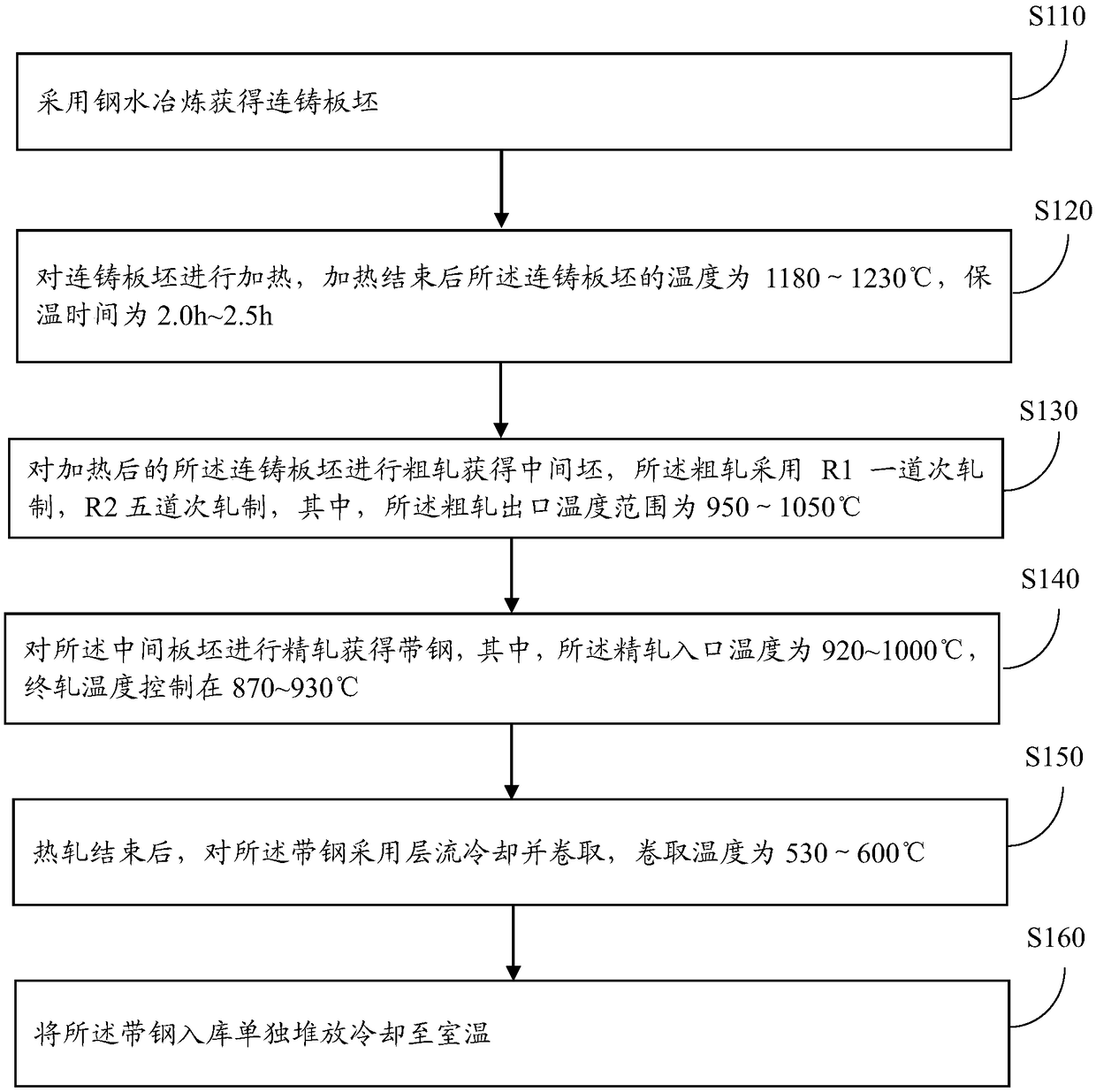

Thin-wall high-strength hot rolled strip steel for square rectangular tube and manufacturing method thereof

The invention relates to thin-wall high-strength hot rolled strip steel for a square rectangular tube and a manufacturing method thereof. The manufacturing method comprise the following steps that molten iron smelting is carried out to obtain a continuous casting slab; heating and preserving heat are carried out on the continuous casting slab; rough rolling is carried out on the heated continuouscasting slab to obtain an intermediate slab; finish rolling is carried out on the intermediate slab to obtain strip steel; the temperature of the strip steel subjected obtained after finish rolling is800-950 DEG C; laminar cooling is carried out on the strip steel; the strip steel is subjected to slow cooling in a temperature range of 650-800 DEG C before laminar cooling, and the slow cooling time is 3 10 seconds; coiling is carried out on the strip steel obtained after laminar cooling to obtain a hot rolled steel coil, the coiling temperature is 580-660 DEG C; and the hot rolled steel coil is slowly cooled to the room temperature, and the finished steel coil of the thin-wall high-strength hot rolled strip steel for the square rectangular tube is obtained. The hot rolled strip steel for the square rectangular tube prepared by the manufacturing method has excellent cold formability and weldability so as to adapt to roller press forming for production of structural members such as a rectangular tube and reprocessing requirement of the finished product tube, and the use requirements of a passenger car body framework are met.

Owner:SHOUGANG CORPORATION

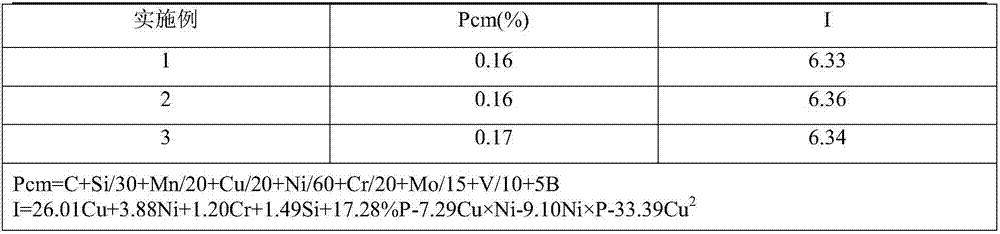

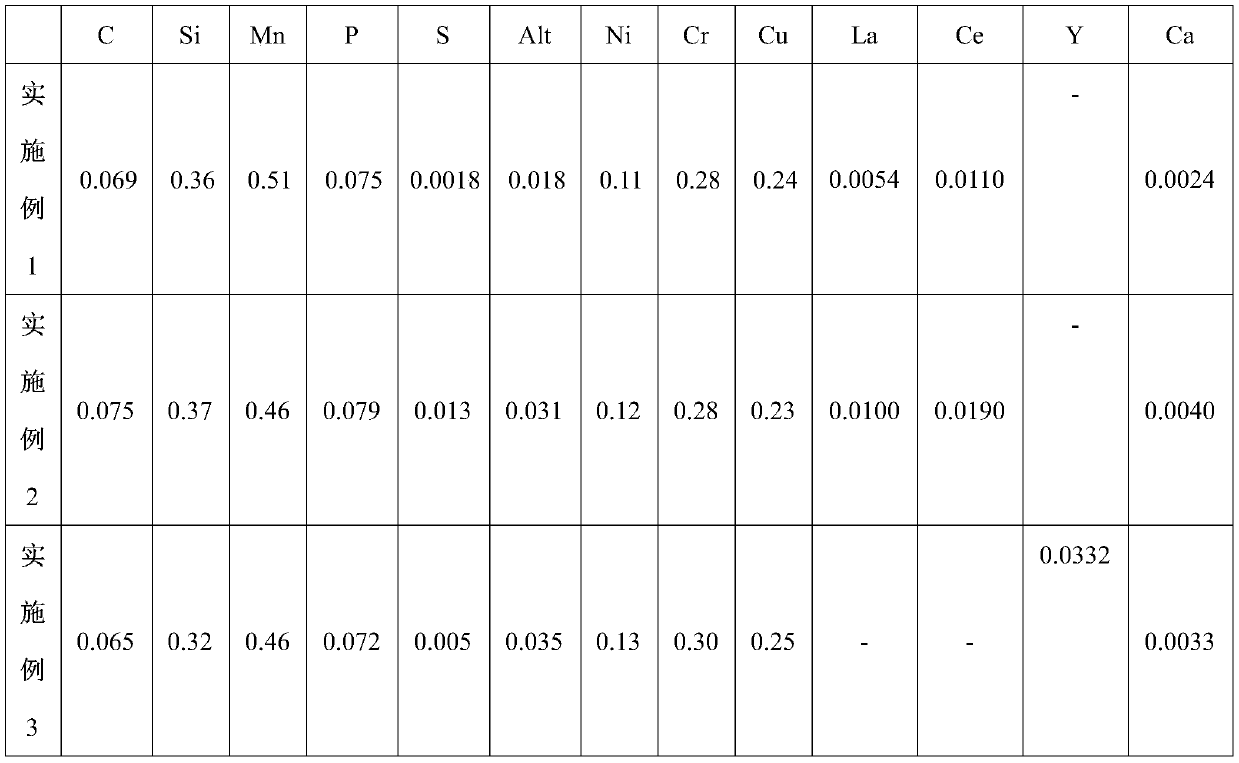

Rare earth weathering steel rich in alloying rare earth elements and manufacturing method of rare earth weathering steel

InactiveCN110923572AGood mechanical propertiesImprove cold forming propertiesSteelmakingRare-earth element

The invention discloses rare earth weathering steel rich in alloying rare earth elements and a manufacturing method of the rare earth weathering steel. The rare earth elements are one or more of threeelements of Ce, La and Y, in terms of mass percentage wt%, the content of the alloying rare earth elements is controlled within 0.005 wt% to 0.045 wt% through the process of feeding rare earth wiresinto steelmaking, weathering steel with a yield strength level of more than 355 MPa and an atmospheric corrosion resistant performance [a 240-hour periodic infiltration test, the corrosion rate is less than or equal to 1.2 g / (m<2>*hr)] which is equivalent to Q355GNH in national standard 'weathering structural steel' GB / T4171-2008, good mechanical properties, cold formability and welding performance are achieved, and the rare earth weathering steel can be widely applied to steel structure projects of vehicles, container manufacturing and construction, bridges, tower and mast structures and thelike.

Owner:SHANGHAI UNIV +2

Preparation method and application of 700 MPa grade ultra-fine grain high-strength weathering steel

InactiveCN107365940AIncrease surface temperatureReduce the temperatureAustenite grainResource saving

The invention relates to a preparation method and application of 700 MPa grade ultra-fine grain high-strength weathering steel. The preparation method includes the steps that a continuous casting blank directly enters an M rack rough rolling unit at a high pulling speed and is subject to M-gate continuous high reduction (50%-60%) rough rolling, austenite grains are greatly refined, after rough rolling is carried out, an intermediate billet is quickly heated by an induction heating furnace to the temperature needed by a finish rolling inlet, and meanwhile a reverse temperature field is formed; and then the blank sequentially passes through a finish rolling unit, a laminar cooling part and a reeling machine, and the microstructure characteristics that the surfaces and core parts are thick and 1 / 4 thickness parts are thin are finally formed. In the production process, finish rolling and rough rolling are both full-endless rolling. By means of the preparation method, an ultra-fine grain high-strength weathering steel strip with the weather fastness equal to that of corten-A can be obtained, the effects of replacing thick parts with thin parts and replacing cold with heat are achieved, and the automotive body weight is small; and meanwhile, the service life of an automotive sheet is prolonged, the production efficiency is improved, the production cost is reduced, energy consumption is reduced, emission is reduced, and resource-saving and environment-friendly production is achieved. The preparation method and application belong to the technical field of metallurgy.

Owner:UNIV OF SCI & TECH BEIJING +1

Preparation method of cold-rolled sheet for flux-cored wire

ActiveCN102676917ALower yield strengthHigh tensile strengthFurnace typesHeat treatment furnacesChemical compositionAcid washing

The invention discloses a preparation method of a cold-rolled sheet for a flux-cored wire, belonging to the field of processing of metal materials. The cold-rolled sheet comprises the following chemical components in percentage by mass: 0.005-0.045 percent of C, less than or equal to 0.03 percent of Si, 0.15-0.26 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.010percent of S, less than or equal to 0.030 percent of Alt, less than or equal to 0.0030 percent of N and the balance of Fe. The method comprises the following steps of: performing hot rolling, acid washing and cold rolling in sequence on a steel billet to obtain a cold-rolled strip coil; and performing continuous annealing and flat processing methods. The cold-rolled sheet has the advantages of low yield strength, high tensile strength, excellent cold molding performance, excellent puling performance, high production speed, short period, high yield and high quality; and compared with the conventional process, the method has excellent advantages, and the use requirement of steel for the flux-cored wire can be better met.

Owner:SHOUGANG CORPORATION

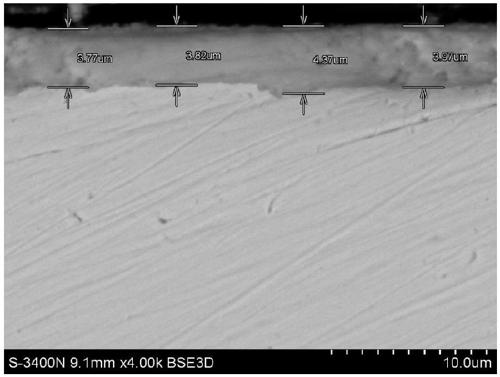

Hot-rolled strip steel for automobile structure and manufacturing method

The invention discloses hot-rolled strip steel for an automobile structure and a manufacturing method of the hot-rolled strip steel. The strip steel comprises, by mass percent, 0.030wt%-0.080wt% of C,0.15wt%-0.25wt% of Si, 1.00wt%-1.60wt% of Mn, not larger than 0.020wt% of P, not larger than 0.005wt% of S, 0.02wt%-0.05wt% of Al, 0.020wt%-0.060wt% of Nb, 0.01wt%-0.03wt% of Ti, 0.02wt%-0.06wt% of V, 0.10wt%-0.30wt% of Cr and the balance Fe and inevitable impurities. The hot-rolled strip steel is used for solving the technical problems that in the prior art, the influence of alloy elements on scale on the surface of strip steel is not studied, the scale on the surface of the high-strength and thick-specification strip steel is prone to falling off, and the high ductility of the strip steel is contradictory to the high-surface-quality controlled rolling and controlled cooling process; and development of the green environment-friendly hot-rolled strip steel with the thick specification andhigh strength and ductility is achieved, and the technical effects that excellent cold formability is achieved so as to meet the requirement of forming of complex parts, and the scale on the surfaceis not prone to falling off so as to avoid mold surface damage are achieved.

Owner:SHOUGANG CORPORATION

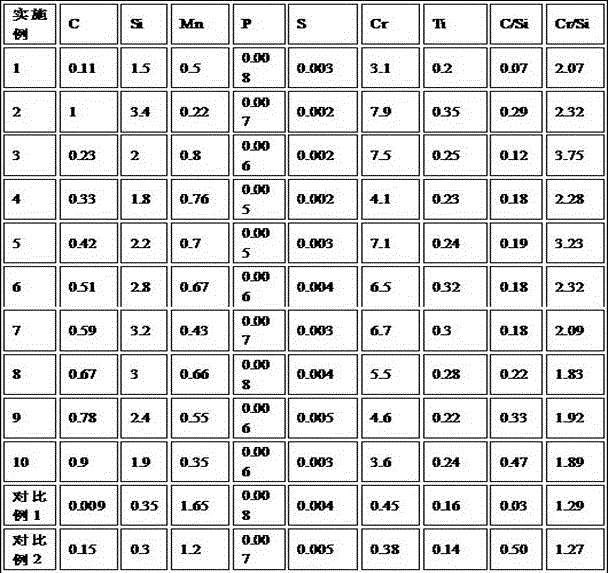

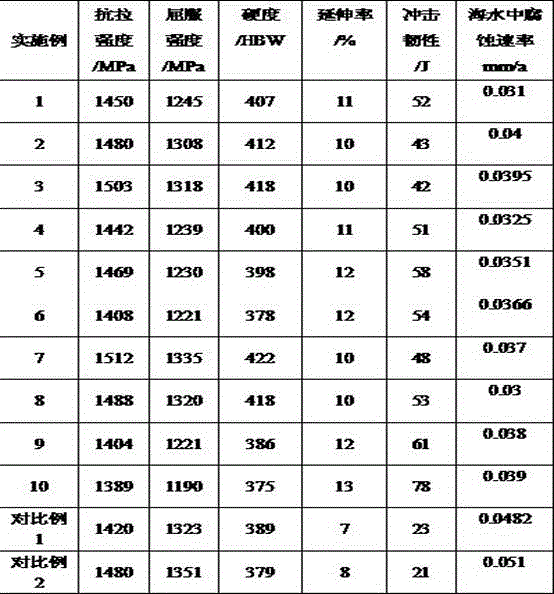

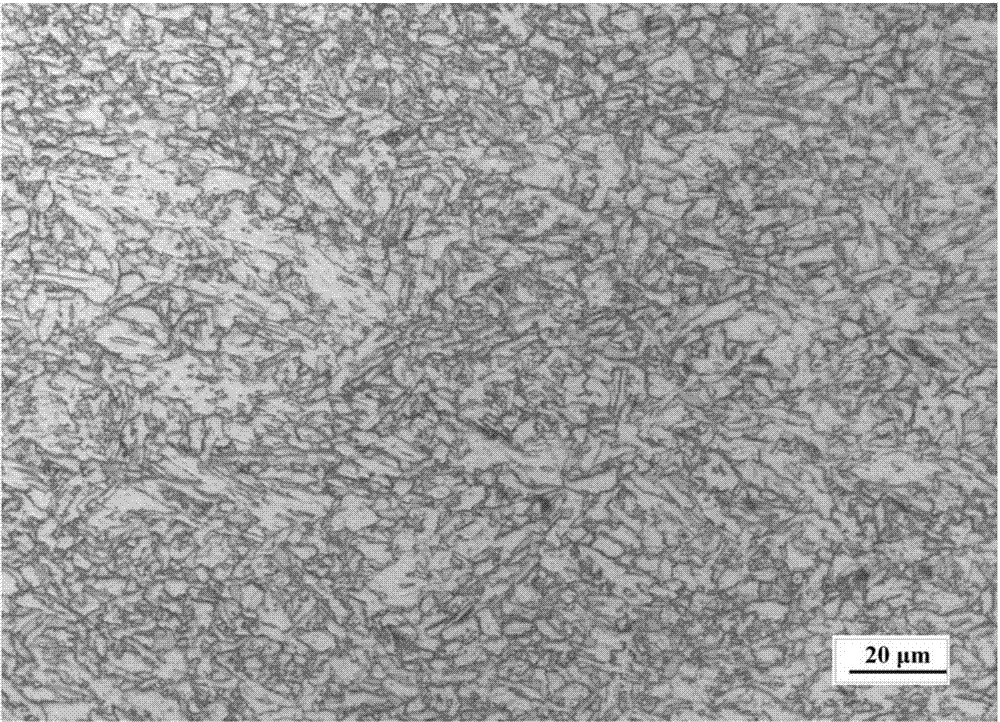

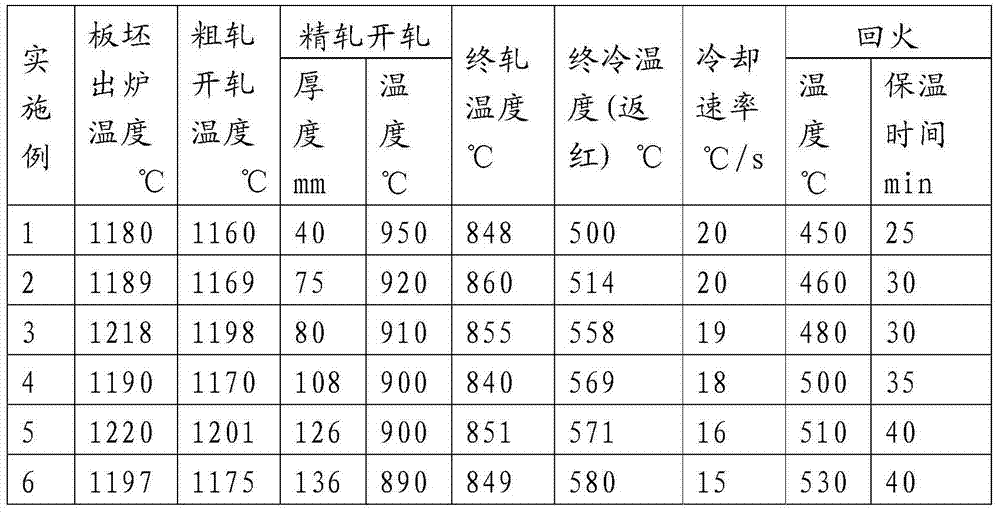

Super wear-resistant steel with hardness not smaller than 400 HBW and production method

Super wear-resistant steel with hardness not smaller than 400 HBW is prepared from, by weight percent, 0.10%-1.00% of C, 1.5%-3.5% of Si, 0.2%-0.8% of Mn, 0.20%-0.35% of Ti and 3.0%-8.0% of Cr. According to the production steps, a casting blank is heated after being formed through conventional smelting and pouring; double-pass high-pressure descaling is conducted till the surface is clean; hot rolling is conducted, and single-piece rolling is adopted; two-segment type cooling is adopted; and pit cooling is conducted till the room temperature. According to the super wear-resistant steel, by obtaining the metallographic structure of tempered martensite and ferrite, the brinell hardness can be larger than 400 HBW; and the corrosion rate does not exceed 0.04 mm / a under seawater soaking.

Owner:武汉钢铁有限公司

Low-cost Q550D steel plate and manufacturing method thereof

InactiveCN104498832AGood welding performanceImprove cold forming propertiesProcess efficiency improvementSlagHeat treated

The invention relates to a low-cost Q550D steel plate and a manufacturing method thereof. The manufacturing method comprises the following steps: smelting molten iron in a converter, heating to 1250-1350 DEG C, adding scrap steel, adding aluminum to perform deoxidizing alloying by a single slag technique, and tapping while skimming, wherein the ladle needs bottom argon blowing operation in the tapping process; and after smelting the molten steel in the converter, refining the molten steel outside the LF (ladle furnace), adding manganese iron, ferroniobium, silicon iron, chromium iron and boron iron, carrying out RH vacuum degassing, adding ferrotitanium, sending the molten steel to a casting machine to carry out continuous casting, heating the prepared plate blank, and carrying out descaling, rough rolling, finish rolling, cooling, thermal straightening, heat treatment, shearing, hardening and tempering, sampling, inspection and finished product warehousing. By adopting the low-carbon component design, proper addition is adopted to enhance the hardenable element, thereby enhancing the steel cleanliness and optimally controlling the heat-treatment hardening and tempering technique to manufacture the low-cost Q550D steel plate.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Low-cost high-tenacity super wear-resistant steel and manufacturing method thereof

The invention discloses low-cost high-tenacity super wear-resistant steel. The steel comprises, by weight percentage, 0.40%-1.00% of C, 1.5%-3.5% of Si, 0.2%-0.8% of Mn, 0.20%-0.35% of Ti, 0.001%-0.005% of B and the balanced Fe. The invention further discloses a manufacturing method of the steel. According to the steel and the manufacturing method, the appropriate chemical element proportion and the heat treatment process are adopted, the tempered martensite is taken on the surface of the manufactured low-cost high-tenacity super wear-resistant steel as a main, the bayesian-retained austenite is taken on the core portion as a main, and therefore the tenacity of the steel is improved while the abrasion performance is strengthened.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com