Low-cost non-quenched and tempered high-strength wear-resistant steal plate with yield strength of 780 MPa grade and manufacturing method thereof

A yield strength, low-cost technology, applied in the field of hot-rolled high-strength steel production, can solve the problems of complex process, high manufacturing cost, and many alloys, and achieve the effects of significantly reducing costs, reducing yield ratio, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

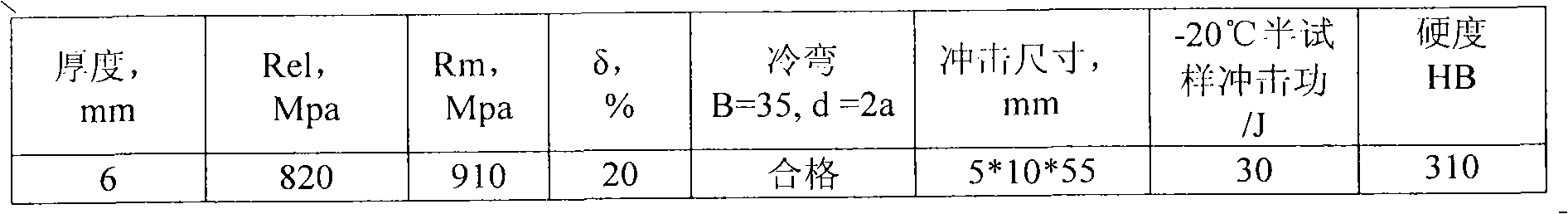

example 1

[0027]Example 1: The chemical composition of selected high-strength steel, the weight percentage is: C: 0.1%, Si: 0.30%, Mn: 1.80%, Nb: 0.05%; Ti: 0.15%; Cr: 0.6%; P: 0.008%; S: 0.006%; the rest is iron Fe and unavoidable impurities. The above-mentioned prepared raw materials were smelted on a 120-ton converter, and continuously cast into a continuous casting slab of 160mm×1230mm×11800mm, the continuous casting slab was heated to 1230°C for 150 minutes, and rolled on a hot continuous rolling mill. The rolling start temperature is controlled at 1150°C, the rough rolling finish rolling temperature is controlled at 1050°C, the rough rolling is carried out for 5 passes, the intermediate billet thickness is 31mm, the finish rolling start rolling temperature is controlled at 1020°C, and the finish rolling finish rolling temperature is controlled at 880°C , 6 passes of finish rolling, the average reduction of each pass of finish rolling is controlled at 25%, and water cooling is used...

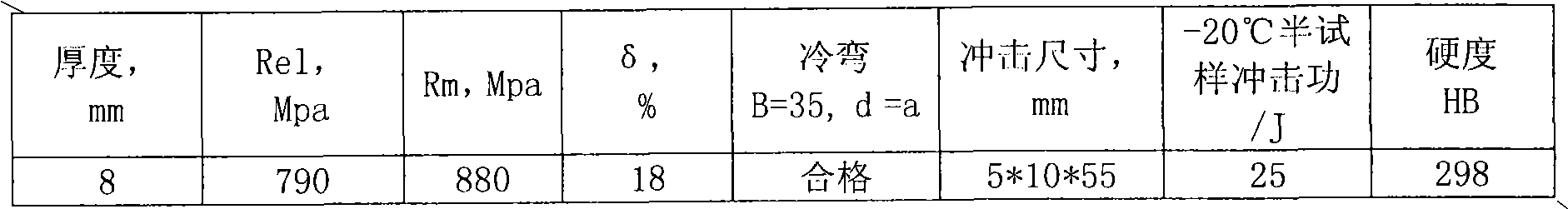

example 2

[0030] Example 2: The chemical composition of selected high-strength steel, the weight percentage is: C: 0.12%, Si: 0.2%, Mn: 1.7%, Nb: 0.04%; Ti: 0.15%; Cr: 0.8%; P: 0.008%; S: 0.003%; the rest is iron Fe and unavoidable impurities.

[0031] The above-mentioned prepared raw materials were smelted on a 120-ton converter, and continuously cast into a continuous casting slab of 160mm×1230mm×11800mm, the continuous casting slab was heated to 1230°C for 145 minutes, and the rough rolling start temperature was controlled at 1180°C , the rough rolling finish rolling temperature is controlled at 1050°C, the rough rolling is carried out for 5 passes, and the thickness of the intermediate billet is 40mm. After that, the intermediate billet is finished rolling, the finish rolling start temperature is controlled at 1020°C, and the finish rolling finish rolling temperature is controlled at 900°C. 5 passes of finish rolling, the average reduction of each pass of finish rolling is controlle...

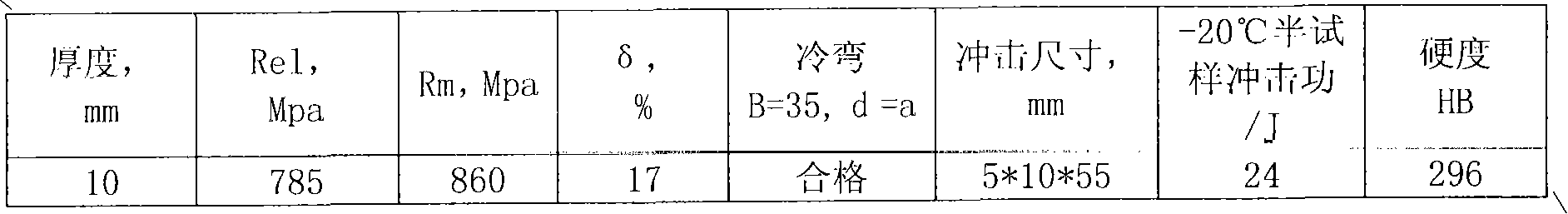

example 3

[0034] Example 3: The chemical composition of selected high-strength steel, the weight percentage is: C: 0.10%, Si: 0.3%, Mn: 1.8%, Nb: 0.05%; Ti: 0.12%; Cr: 0.9%; P: 0.008%; S: 0.003%; the rest is iron Fe and unavoidable impurities.

[0035] The above-mentioned prepared raw materials were smelted on a 120-ton converter, and continuously cast into a continuous casting slab of 160mm×1230mm×11800mm, the continuous casting slab was heated to 1220°C for 150 minutes, and the rough rolling start temperature was controlled at 1160°C , the rough rolling finish rolling temperature is controlled at 1030°C, the rough rolling is 5 passes, the middle billet thickness is 41mm, after that, the middle billet is finished rolling, the finish rolling start temperature is controlled at 1000°C, the finish rolling finish rolling temperature is controlled at 890°C, 5 passes of finish rolling, the average reduction of each pass of finish rolling is controlled at 23%, and water cooling is adopted betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com