A composite alloy that can replace vanadium-iron alloy and its production process and application

A composite alloy and vanadium slag technology, applied in the field of steelmaking, can solve the problems of inconsistent addition of vanadium slag, different particle size of vanadium slag, and increased difficulty in on-site operation, and achieves significant cost reduction, small equipment investment, and reduced cost. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 A composite alloy and its production process

[0034] The composite alloy includes the following raw materials and their mass percentages: 96.0Kg of vanadium slag, 2.0Kg of graphite, and 2.0Kg of organic binder; the particle size of the vanadium slag is 1.0mm; the mass percentage of each element in the vanadium slag is: vanadium 5.0% , carbon 0.2%, silicon 0.5%, phosphorus 0.05%, sulfur 0.05%, aluminum 5.0%, and the rest is iron. The particle size of the graphite is 1.0mm, and the mass percentages of the elements in the graphite are: carbon 98.5%, phosphorus 0.045%, sulfur 0.02%, and the balance is other components. The organic binder can be bisphenol A liquid epoxy resin.

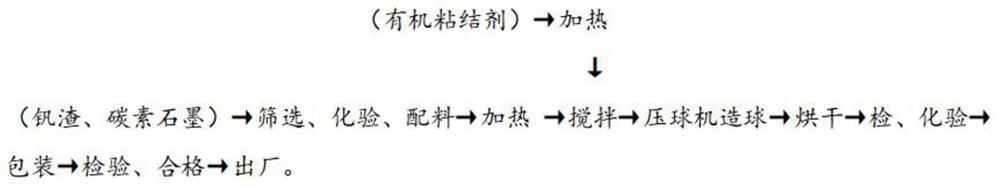

[0035] The composite alloy production process comprises the steps of:

[0036] Collect vanadium slag and graphite waste materials, screen, test, and batch; the particle size of the vanadium slag is 1.0mm; the mass percentage of each element in the vanadium slag is: vanadium 5.0%, carbon ...

Embodiment 2

[0037] Example 2 A composite alloy and its production process

[0038]The composite alloy includes the following raw materials and their mass percentages: 93.0Kg of vanadium slag, 3.0Kg of graphite, and 4.0 Kg of organic binder; the particle size of the vanadium slag is 5.0mm; the mass percentage of each element in the vanadium slag is: vanadium 2.5% , carbon 0.1%, silicon 0.2%, phosphorus 0.02%, sulfur 0.02%, aluminum 2.0%, and the rest is iron. The particle size of graphite is 5.0mm, and the mass percentage of each element in the graphite is: carbon 99.5%, phosphorus 0.025%, sulfur 0.01%, and the balance is other components. The organic binder can be bisphenol A liquid epoxy resin.

[0039] The composite alloy production process comprises the steps of:

[0040] Collect vanadium slag and graphite waste materials, screen, test, and batch; the particle size of the vanadium slag is 5.0mm; the mass percentage of each element in the vanadium slag is: vanadium 2.5%, carbon 0.1%, ...

Embodiment 3

[0041] Example 3 A composite alloy and its production process

[0042] The composite alloy includes the following raw materials and their mass percentages: 95Kg of vanadium slag, 2.0Kg of graphite, 3.0Kg of organic binder; the particle size of the vanadium slag is 3mm; the mass percentage of each element in the vanadium slag is: 2.8% of vanadium, carbon 0.15%, silicon 0.5%, phosphorus 0.035%, sulfur 0.03%, aluminum 2.0, and the rest is iron. The particle size of the graphite is 2.0mm, and the mass percentages of the elements in the graphite are: carbon 99%, phosphorus 0.035%, sulfur 0.02%. The organic binder can be bisphenol A liquid epoxy resin.

[0043] The composite alloy production process comprises the steps of:

[0044] Collect vanadium slag and graphite waste materials, screen, test, and batch; the particle size of the vanadium slag is 3.0mm; the mass percentage of each element in the vanadium slag is: vanadium 2.8%, carbon 0.15%, silicon 0.5%, phosphorus 0.035%, sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com