Patents

Literature

30results about How to "The amount added is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

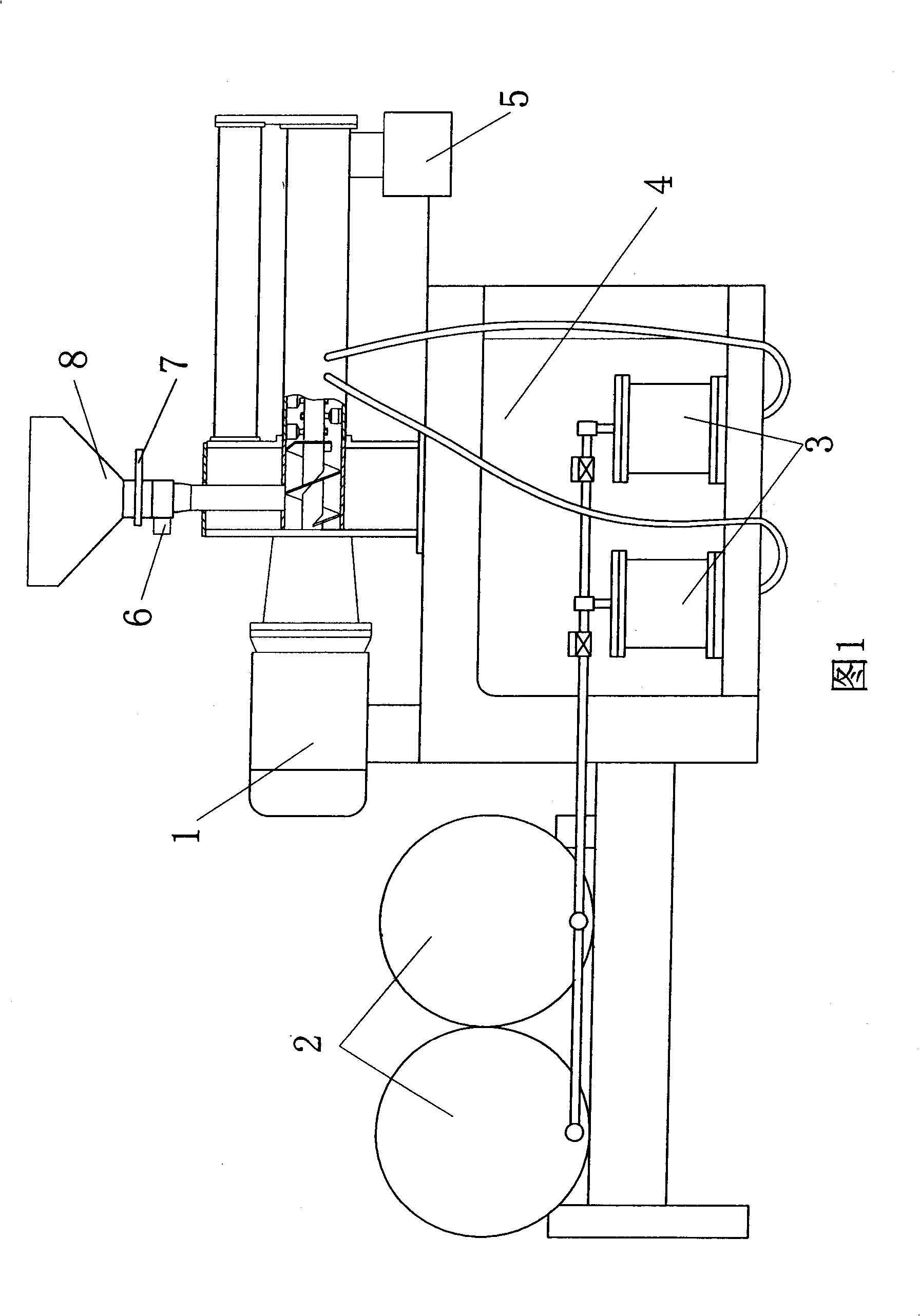

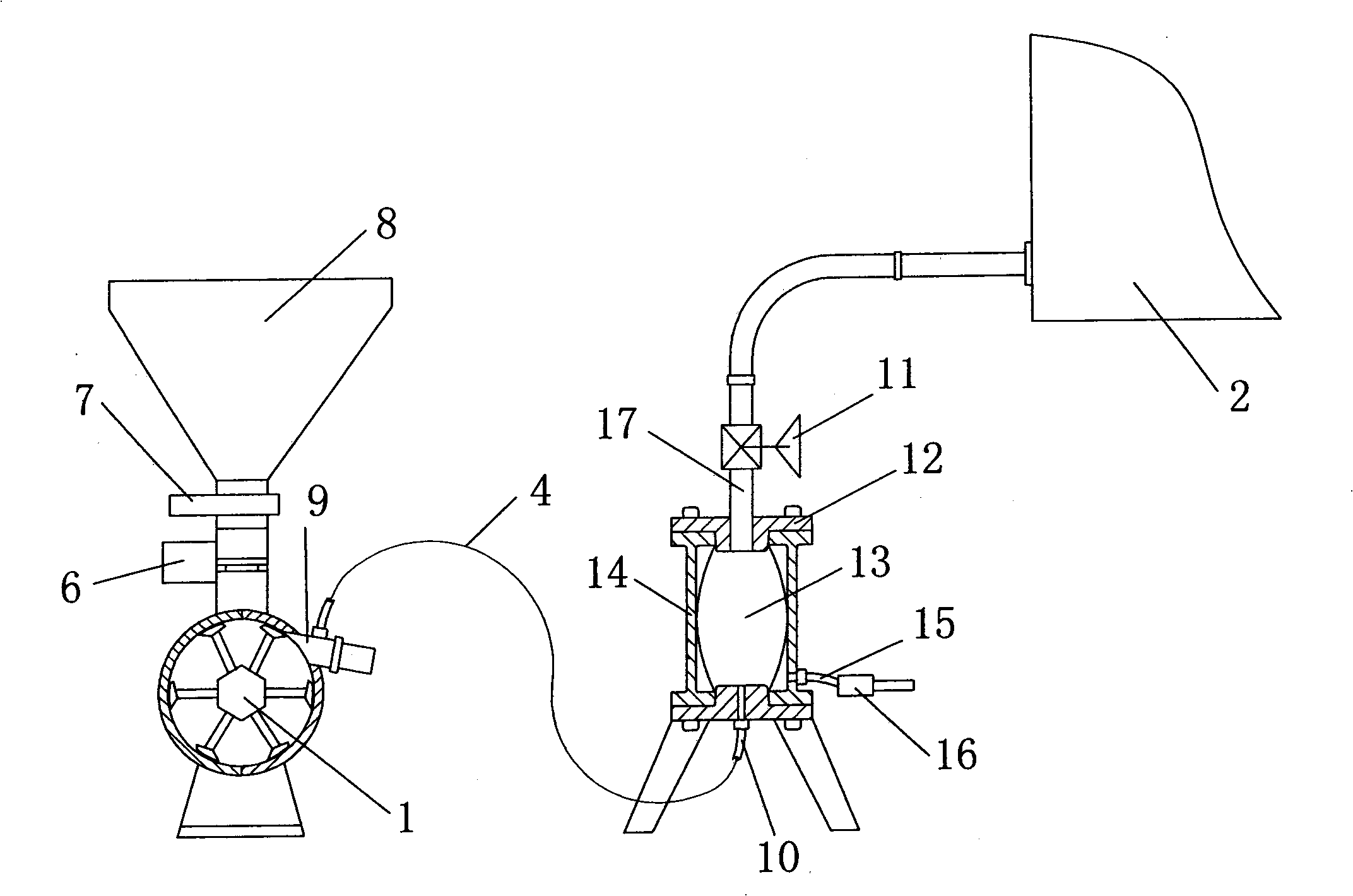

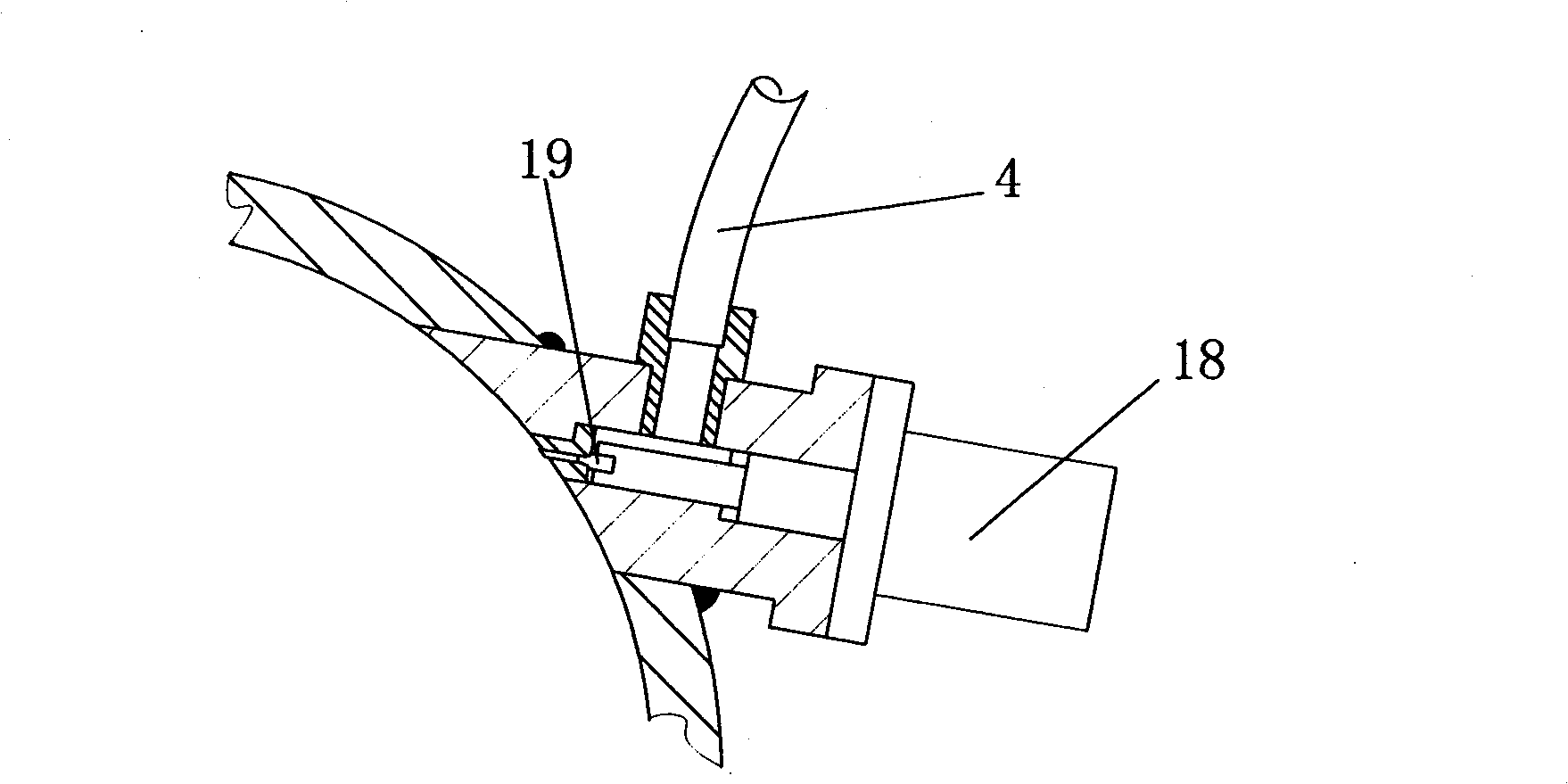

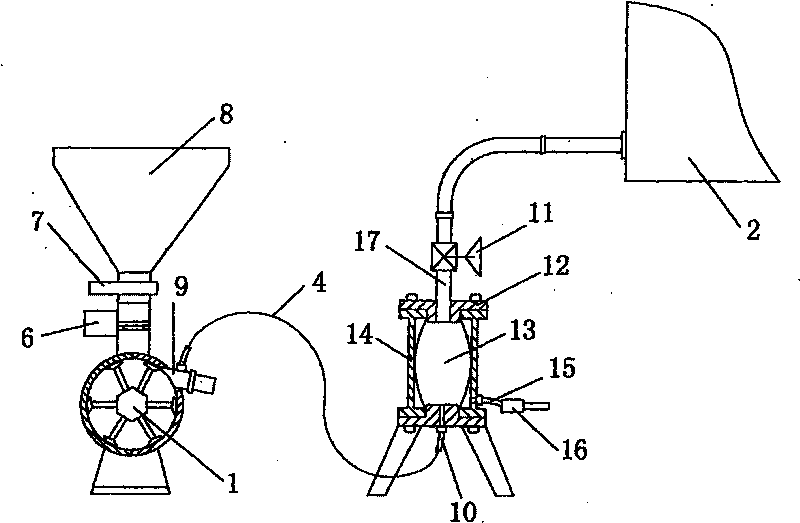

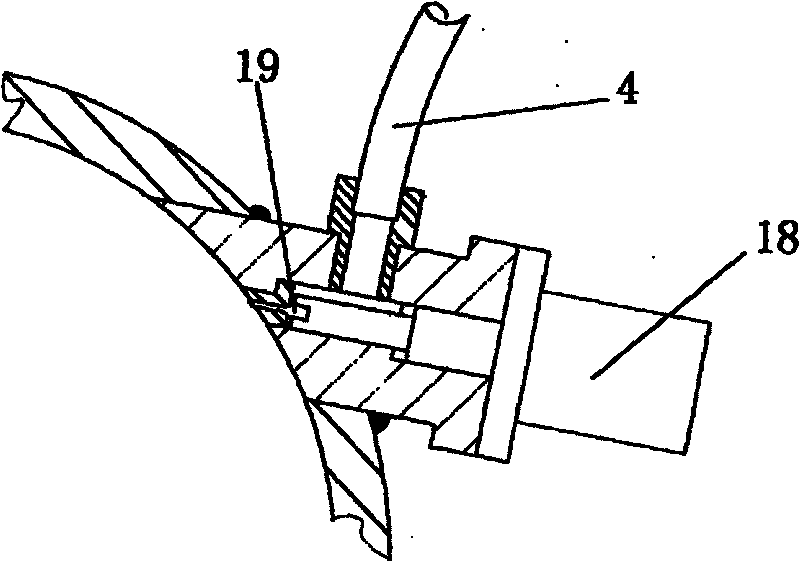

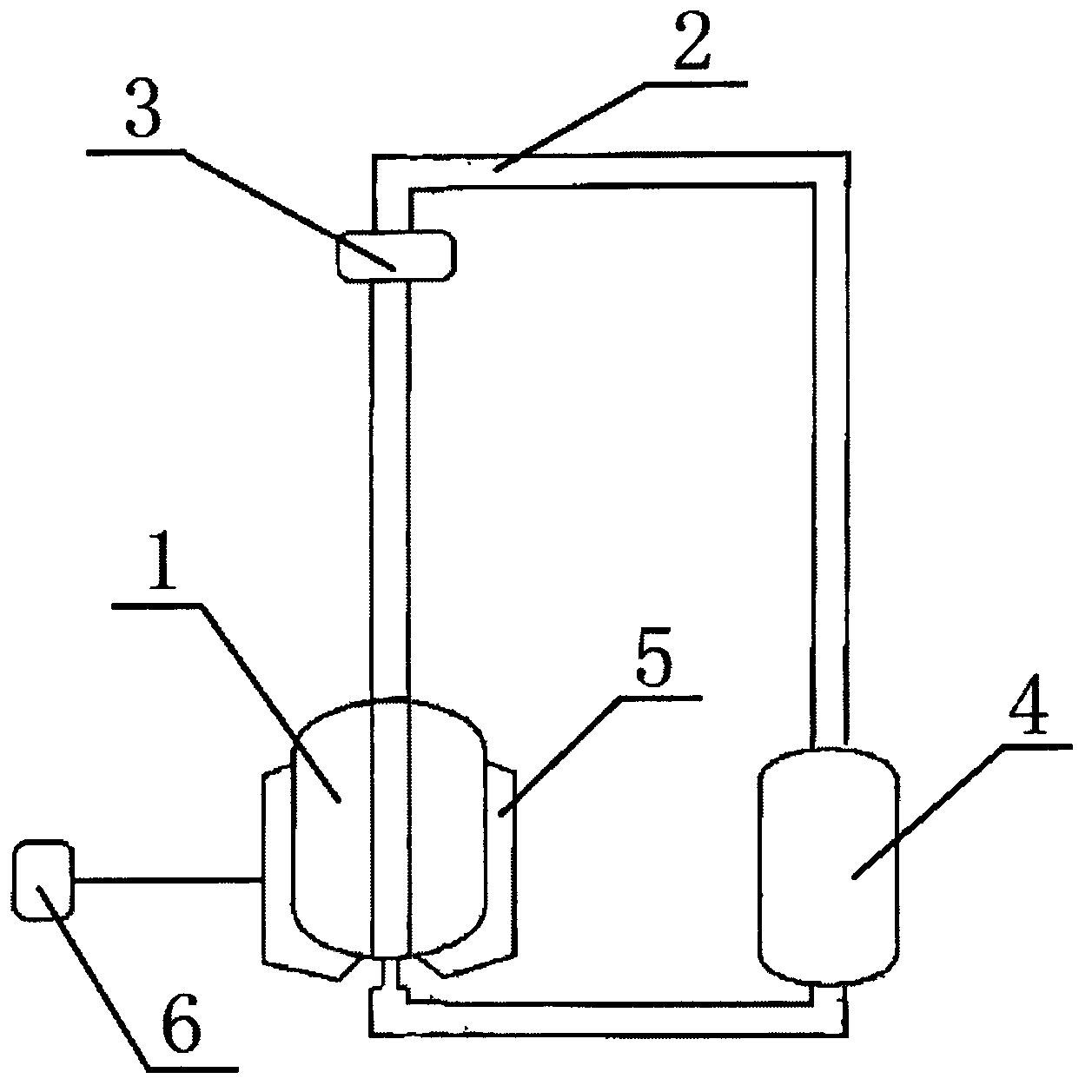

Continuous automatic pug mixer

InactiveCN101347818AHigh viscosityThe amount added is stableMould handling/dressing devicesProportional controlDry sand

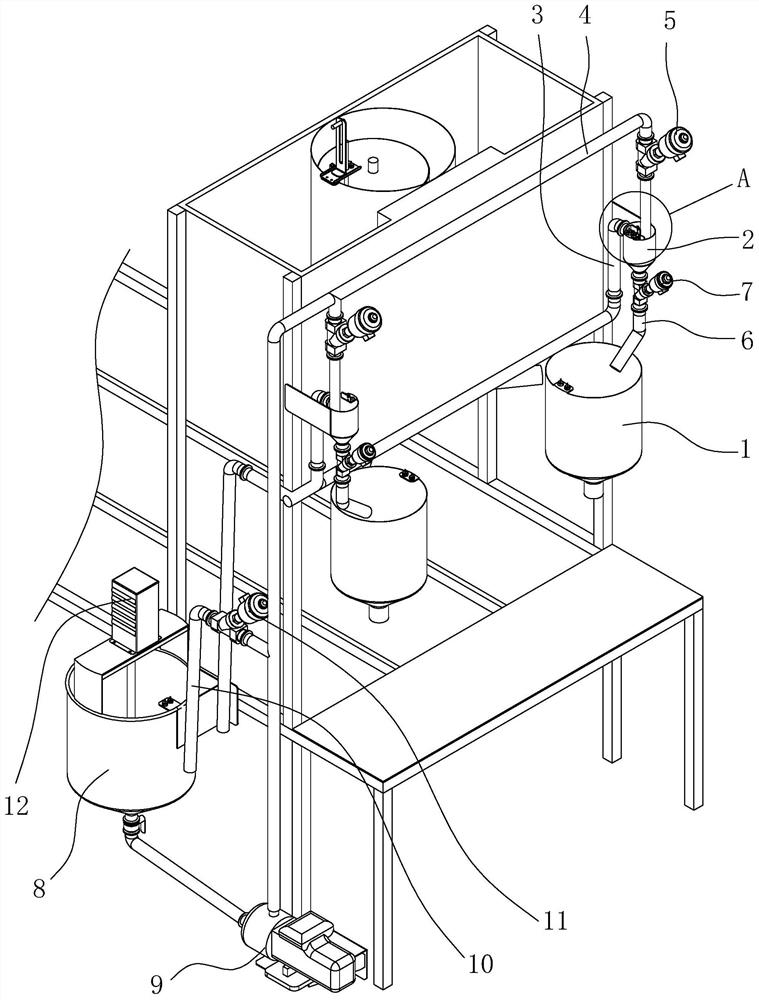

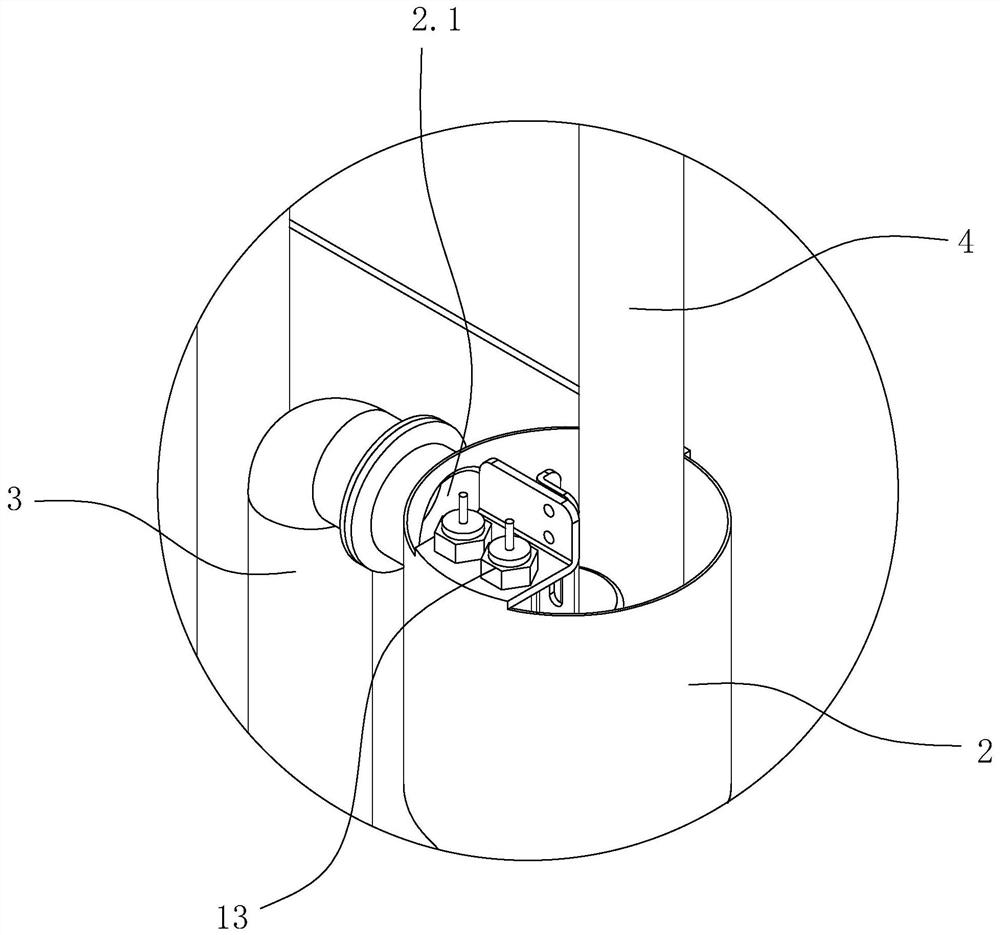

The invention provides a continuous automatic sand mixing machine, comprising a sand mixing packing auger, a dry sand bin and an enclosed resin quantitative device; the material inlet of the sand mixing packing auger is connected with the lower mouth of the dry sand bin; the lower mouth of the dry sand bin is provided with a proportion control valve and a sand adding valve; the material outlet of the sand mixing packing auger is provided with a funnel; the shell of the sand mixing packing anger is provided with a resin feeding valve; the enclosed resin quantitative device is connected with the resin feeding valve on the sand mixing packing auger by a delivery pipe; the sand adding valve and the resin feeding valve are connected with the same electromagnetic control valve. The sand adding valve and the resin feeding valve are controlled by the same electromagnetic control valve, thus ensuring the synchronous adding of the dry sand and the resin and ensuring the normal proportion and the strength of sand core. The adopted enclosed resin quantitative device has an anti-oxidation function and can ensure that the resin flux is stable, the quantification is exact and the material inlet of the resin is not blocked.

Owner:济南林青铸造技术有限公司

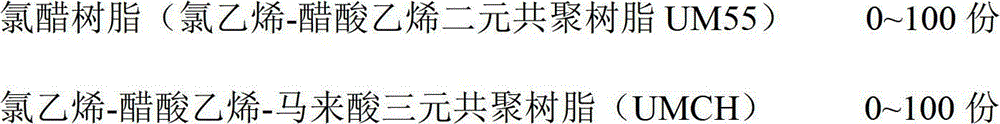

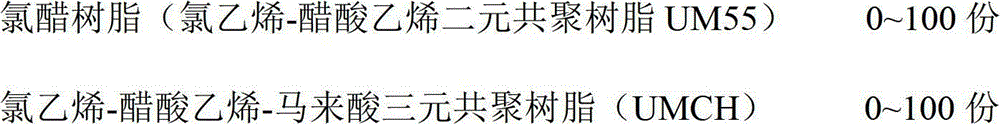

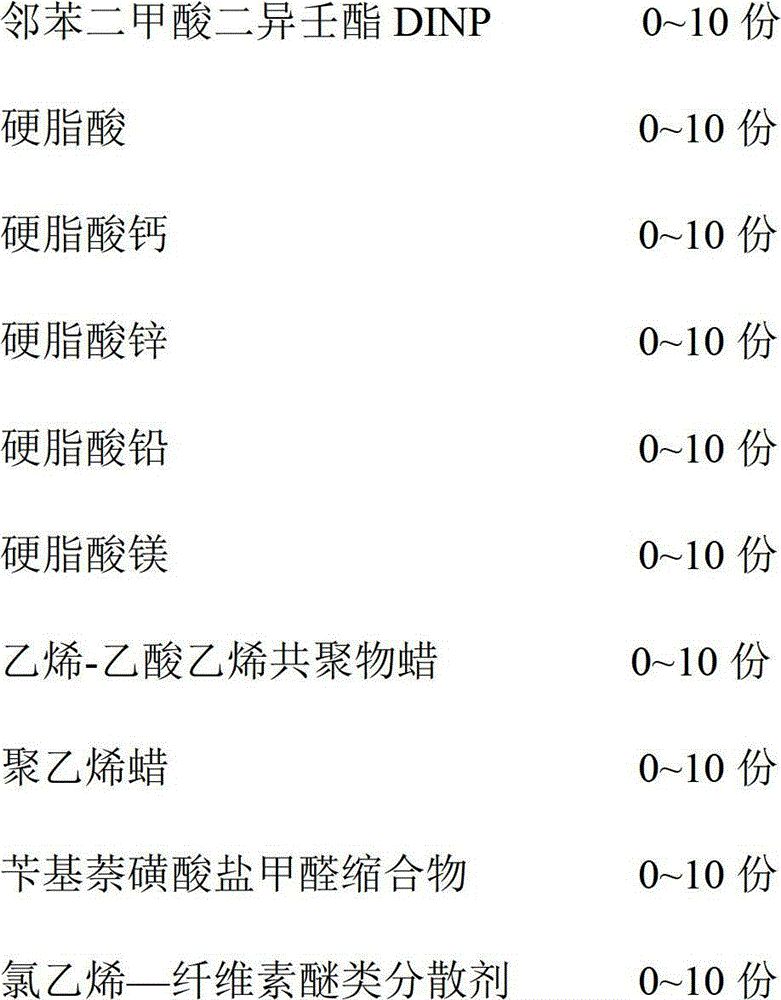

Smalt for PVC (Poly Vinyl Chloride) plastic processing

The invention provides a smalt for PVC (Poly Vinyl Chloride) plastic processing, consisting of the following components in percentage by weight: 20-45% of carrier, 5-10% of adjuvant, and 50-70% of pigment. The carrier is one or more of chloride-vinyl resin, chloroethylene-vinyl acetate-maleic acid ternary polymerization resin, chloroethylene-vinyl acetate-hydroxy crylic acid ternary polymerization resin, chloroethylene, PVC or methyl methacrylate. According to the invention, the additive is well dispersed, keeps stable chemical stability and is correct and stable in addition amount. In term of a processing technology, as a powdery additive and resin are quite different in the size of particles, uneven addition in amount often happens. However, as the smalt and PVC particles are very similar in diameter, the addition amount can be kept stable. The addition process is convenient. The smalt can keep the environment clean, and is beneficial to production of PVC products with high quality.

Owner:SHANGHAI YIPIN PIGMENTS CO LTD

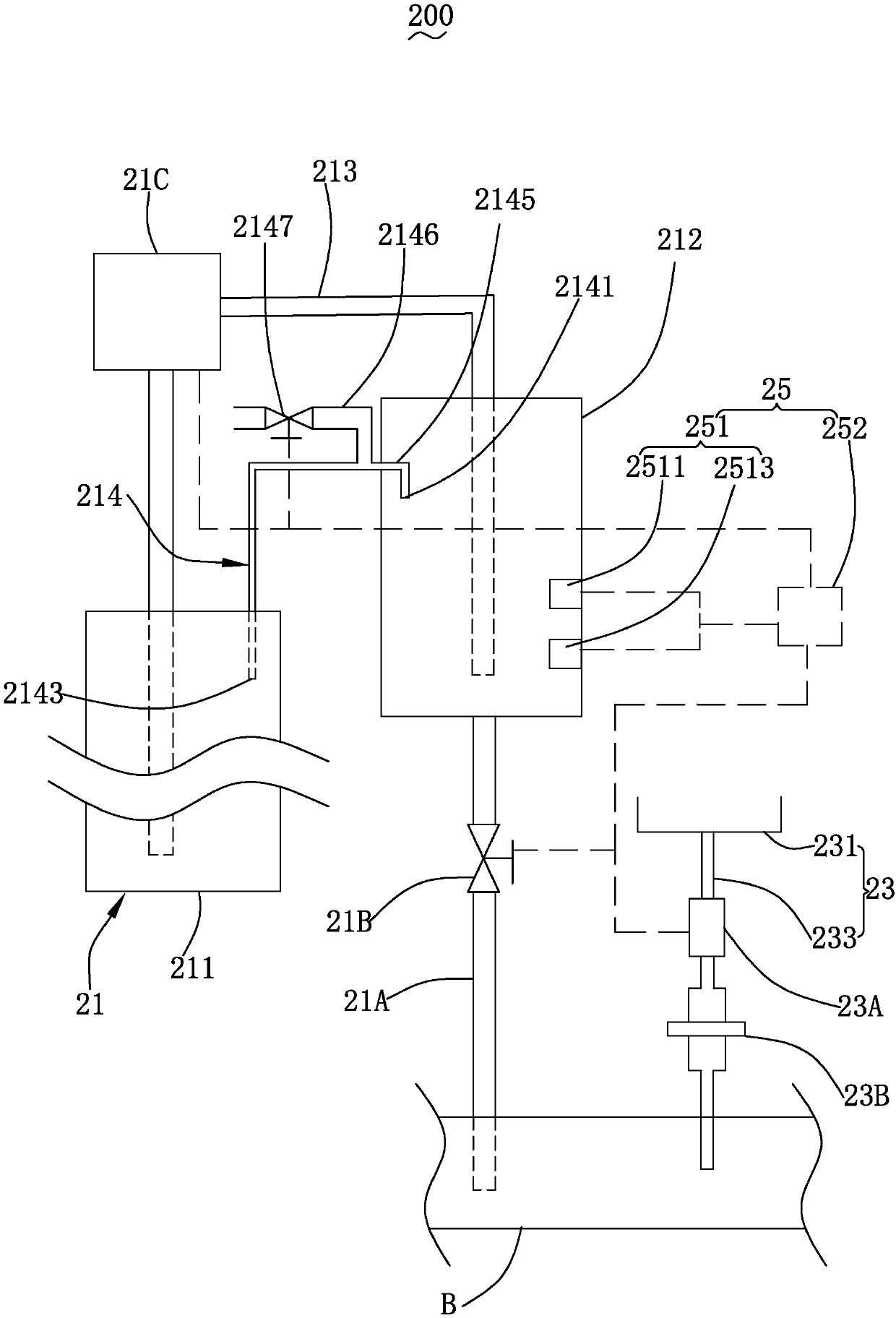

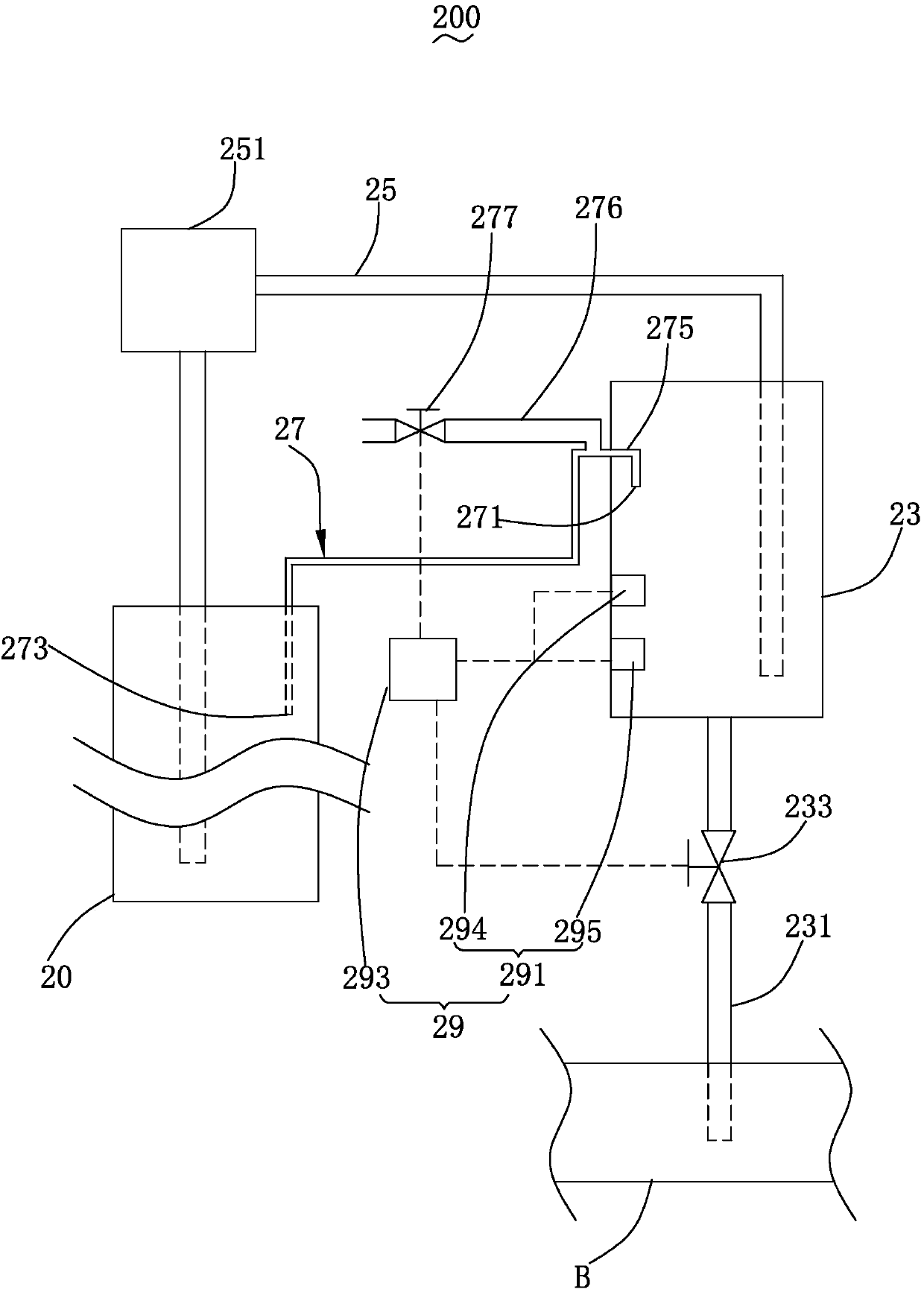

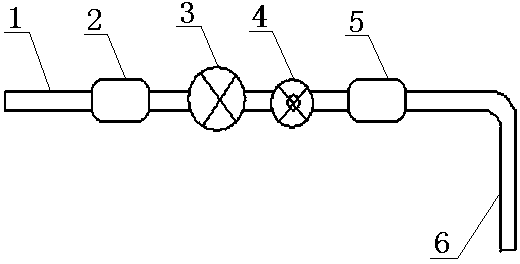

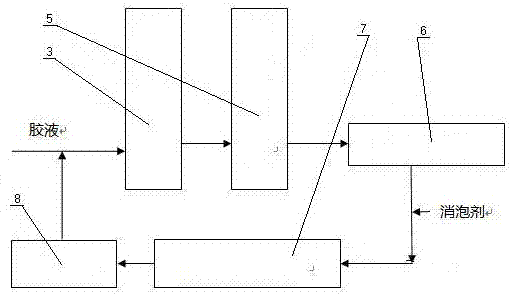

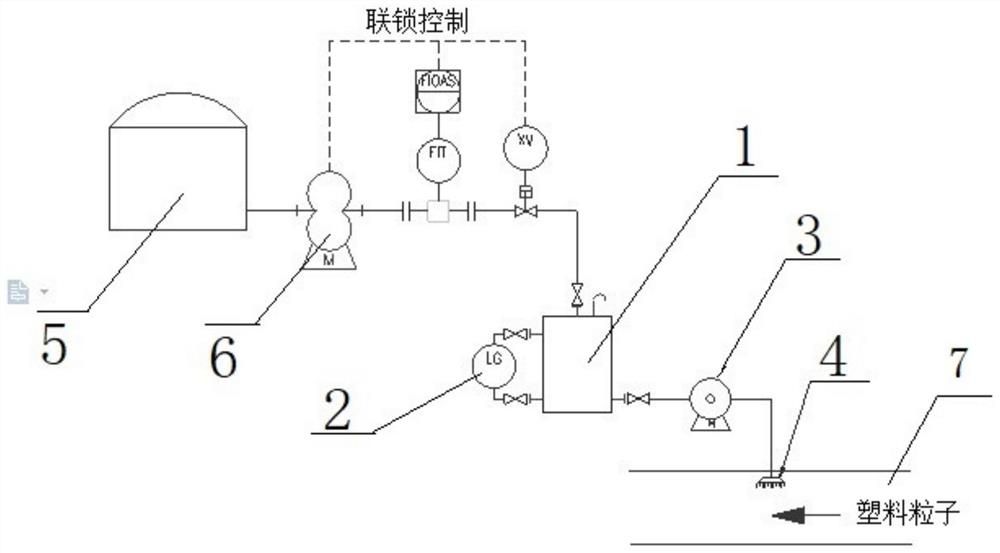

Solution automatic addition system

PendingCN107835576AReduce wasteReduce manufacturing costConductive material chemical/electrolytical removalProcess engineeringControl valves

The present invention provides a solution automatic addition system. The objective of the invention is to achieve automation liquid adding and addition stabilization of an antifoaming agent. The solution automatic addition system comprises a liquid medicine addition device, an antifoaming agent addition device and a control device. The liquid medicine addition device comprises a liquid medicine source, a container provided with a liquid outlet pipeline, a liquid inlet pipeline and a siphon pipeline; the liquid outlet pipeline is provided with a first control valve, and the liquid inlet pipeline is provided with a liquid pump; the antifoaming agent addition device comprises an antifoaming agent source and a delivery line; the delivery line is provided with a second control valve and a flowcontrol valve; the control device comprises a liquid level detection device and a controller; the controller controls opening and closing of the second control valve and controls the liquid valve to add liquid in the container according to the liquid level detection device, after the liquid medicine in the container reaches a first preset liquid level, the siphon pipeline can siphon the liquid medicine in the container to the outer portion of the container, and when the liquid level detection device detects that the volume of the liquid medicine in the container is adjusted to a second presetliquid level, the controller controls the first control valve to release the liquid medicine.

Owner:AOSHIKANG TECH CO LTD

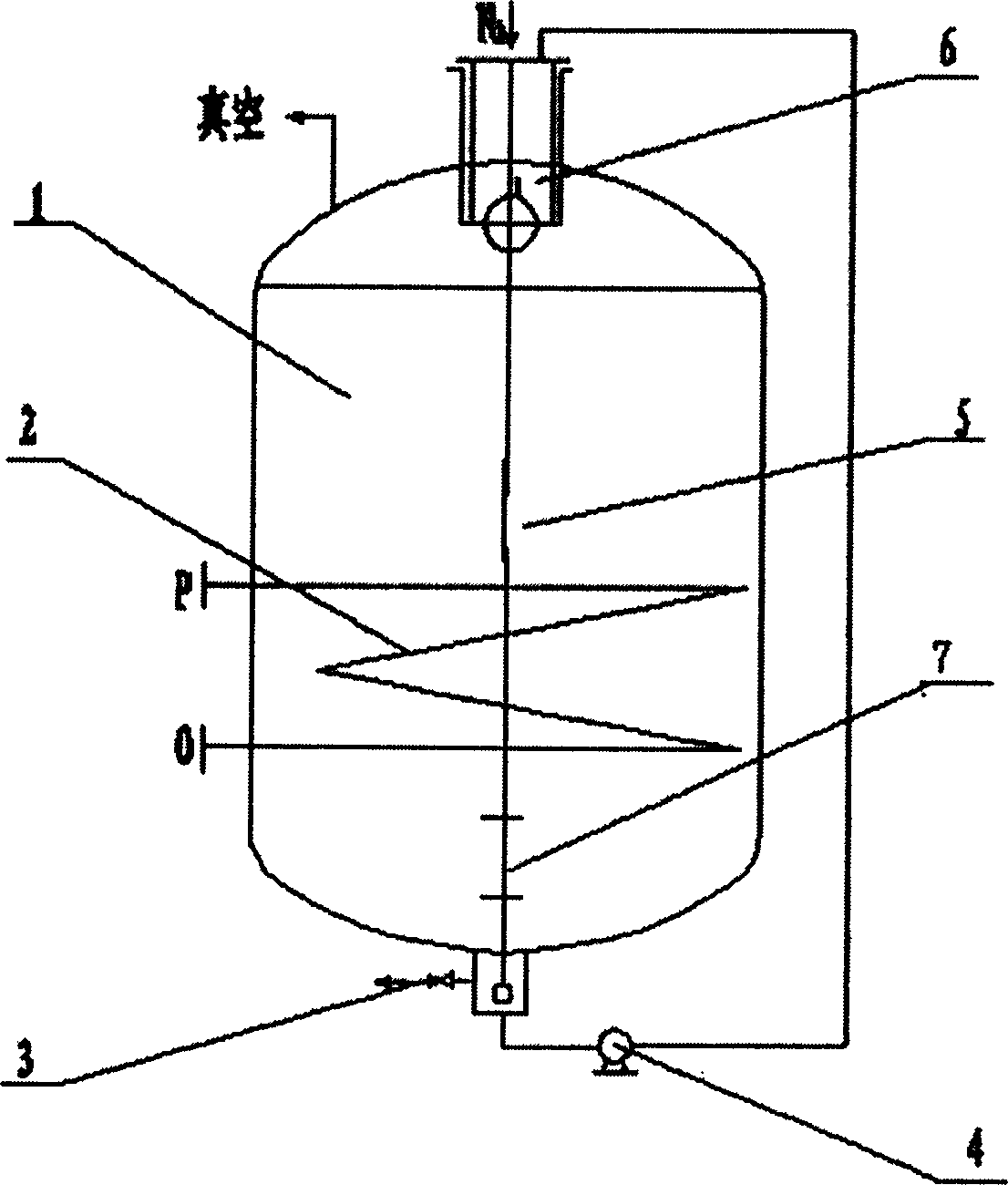

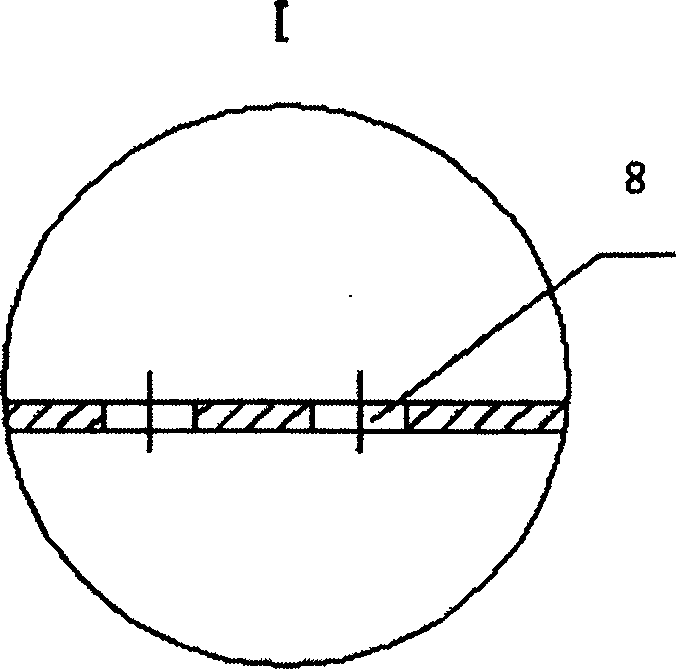

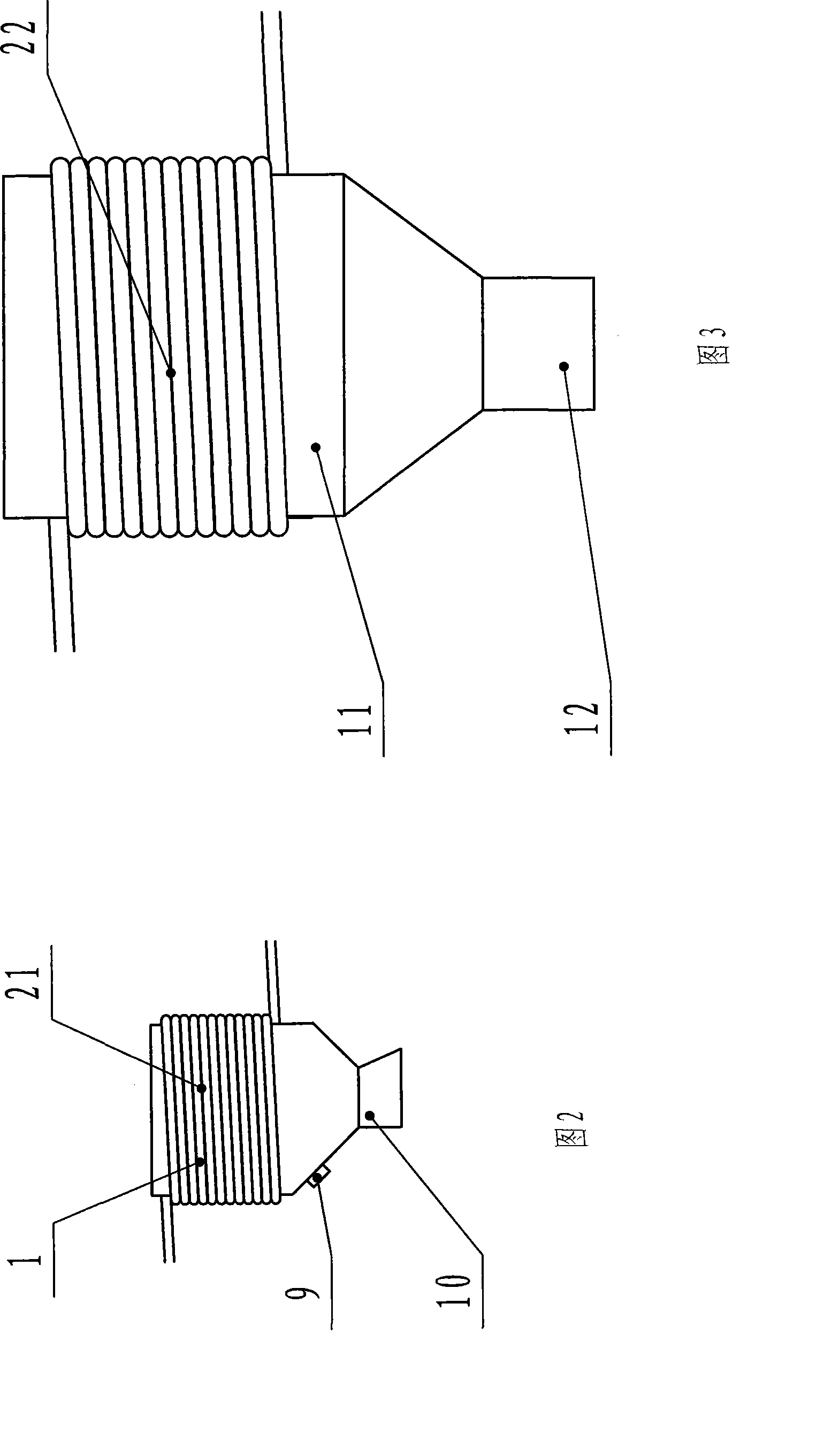

Method for preparing organic silicon high-temperature-resistant adhesive by removing micro-water from methylcyclosiloxane used as raw materials and device therefor

InactiveCN1663938ATrace moisture reductionImprove mechanical propertiesOrganic decompositionPolymer scienceAdhesive

The invention relates to a method for preparing organosilicon high-temperature glue, comprising ventilating nitrogen through the bottom pipe and steam through steam coil to increase temperature directly; dehydrating the mixing methyl in the stock, the favorable improvement of the dehydrating effect of this invention compared with previous technique is that after the dehydrating the micro-hydration in stock decreases dramatically, at an average of below 10ppm. The addition quantity of regent for head closure in the polymerization process preparing high-temperature glue gradually becomes stable, the molecular weight of raw rubber polymerization is relatively stable. The quantity of terminal hydroxyl group decreases dramatically in the high-temperature glue preparing process, the moulding is faster in the process, the storing time of the mixed glue and its physical-mechanical properties and processing property have been improved considerably.

Owner:JIANGSU HONGDA NEW MATERIAL

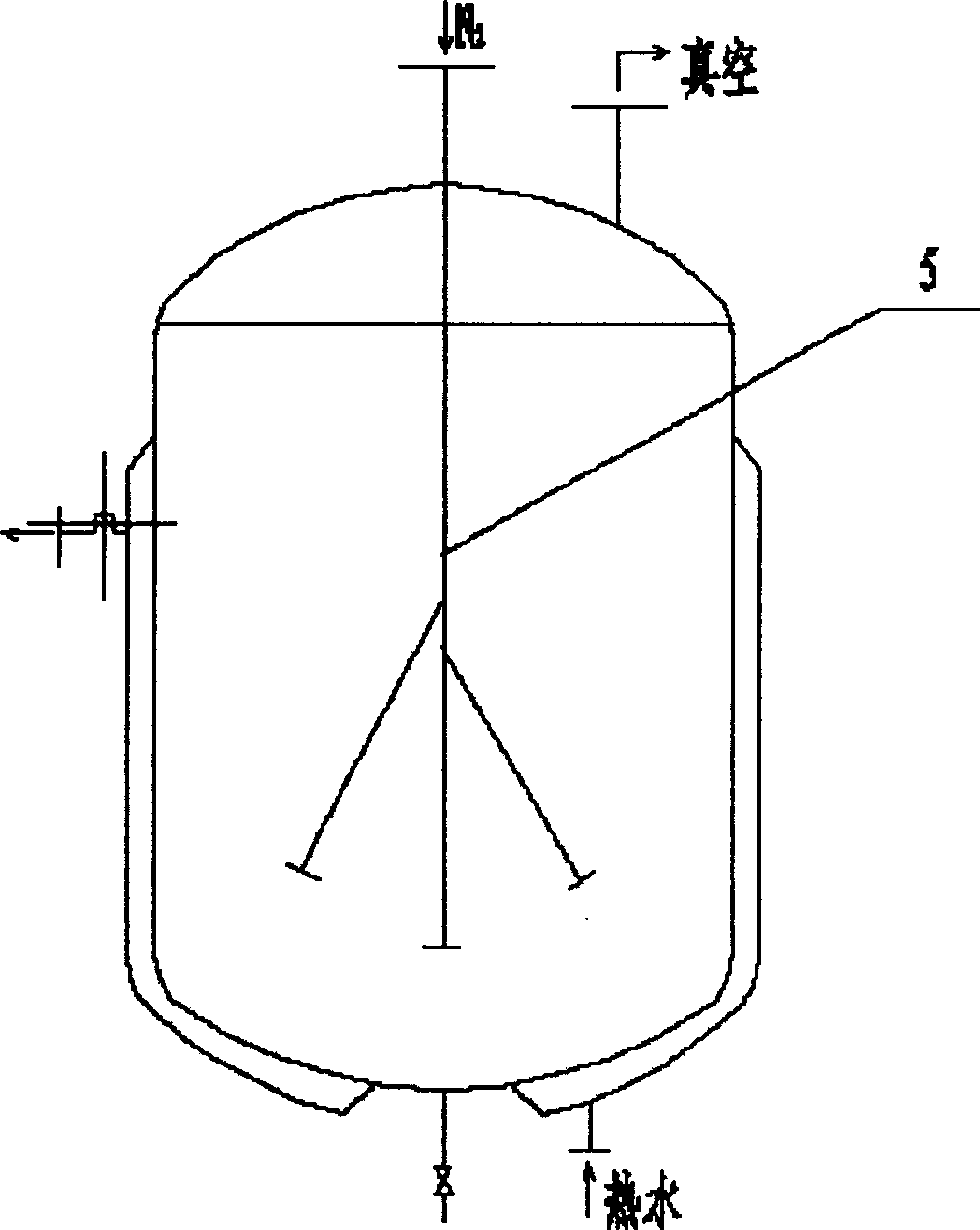

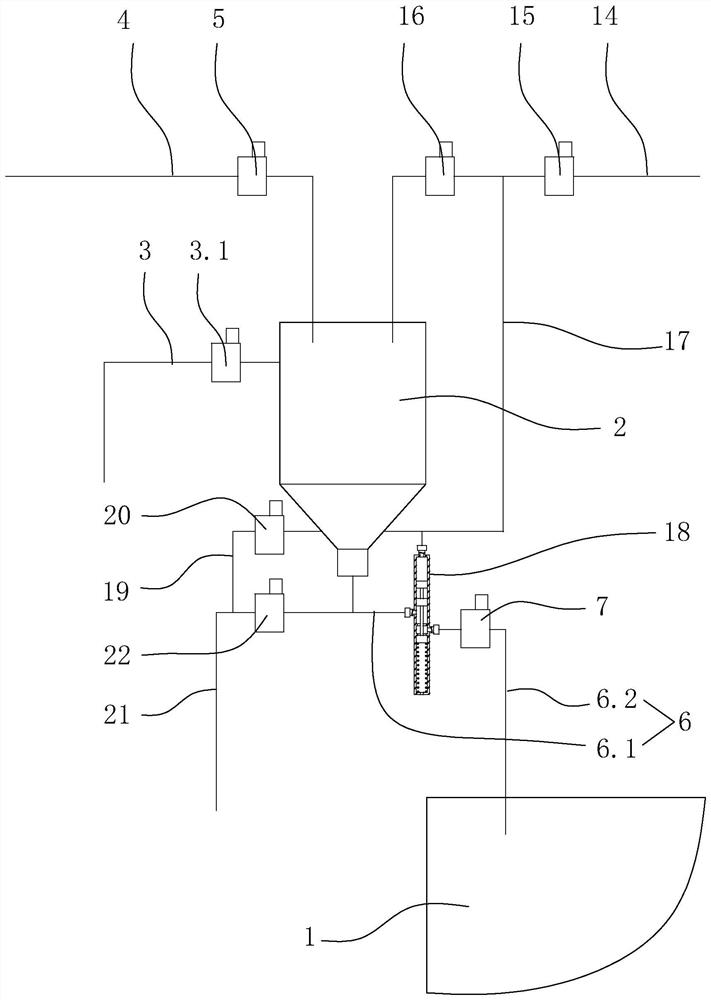

Engineering plastic processing device and glass fiber content control method

The invention aims to provide an engineering plastic processing device and a glass fiber content control method. The engineering plastic processing device comprises a double-screw extruder with a discharge hole in the front end, a particle main ingredient weigh-feeding mechanism and a glass fiber weigh-feeding mechanism located above the double-screw extruder, and a controller. The double-screw extruder comprises a cylinder, two screw rods arranged in the cylinder, and a motor electrically connected with the controller; and a particle main ingredient feed inlet corresponding to the particle main ingredient weigh-feeding mechanism, a frustum-shaped glass fiber guiding port connected with the cylinder and corresponding to the glass fiber weigh-feeding mechanism, and a vacuum orifice are sequentially arranged on the cylinder from back to front. According to the engineering plastic processing device, the addition amount of glass fiber is stable, the error is less, the accuracy in detectingthe glass fiber content in engineering plastic is higher, and the glass fiber content can be monitored and adjusted in real time.

Owner:宁波华腾首研新材料有限公司

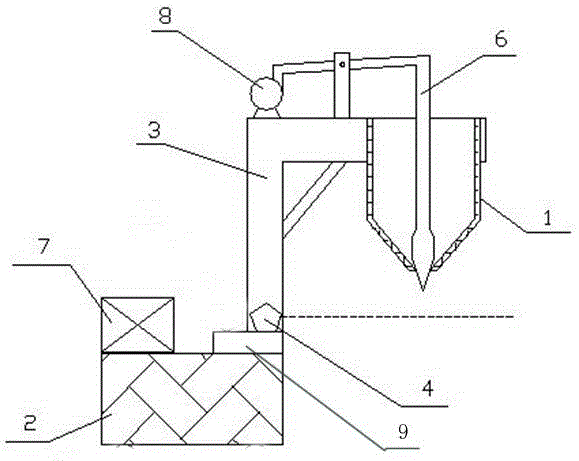

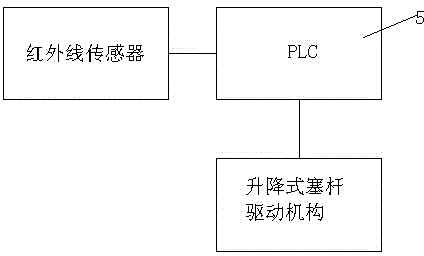

Quantitative feeding device for casting spheroidal graphite cast iron

InactiveCN105618724ATime stableThe amount added is stableMolten metal supplying equipmentsInterference factorInstability

The invention relates to a quantitative feeding device for casting. The quantitative feeding device comprises a material storage bin, a supporting frame and a cantilever; the quantitative feeding device is characterized in that the material storage bin is fixed to the cantilever, the cantilever is arranged on the supporting frame, a balancing weight is arranged on the other side of the supporting frame, an infrared sensor is arranged on the supporting frame, and the discharging direction of the material storage bin and the detecting direction of the infrared sensor are located in one plane; and a lifting type plug stick is arranged in the material storage bin and connected with a lifting type plug stick driving mechanism located on the cantilever. The quantitative feeding device has the beneficial effects that when molten iron flows through a detecting position of the infrared sensor, a PLC drives the lifting type plug stick to upwards move, the material storage bin is opened, automatic feeding is achieved, and conversely, feeding is stopped; through the feeding process synchronous to metal liquid, the material adding time and the stability of adding amount of materials are guaranteed, operation of quantitative feeding in the pouring process is achieved, instability of manual operation and other interference factors are avoided, the operation stability is improved, operation risks are reduced, and the controllable operation process is achieved.

Owner:锦州捷通铁路机械股份有限公司

Method for preparing organic silicon high-temperature-resistant adhesive by removing micro-water from methylcyclosiloxane used as raw materials and device therefor

InactiveCN1271017CTrace moisture reductionImprove mechanical propertiesOrganic decompositionPolymer scienceAdhesive

The invention relates to a method for preparing organosilicon high-temperature glue, comprising ventilating nitrogen through the bottom pipe and steam through steam coil to increase temperature directly; dehydrating the mixing methyl in the stock, the favorable improvement of the dehydrating effect of this invention compared with previous technique is that after the dehydrating the micro-hydration in stock decreases dramatically, at an average of below 10ppm. The addition quantity of regent for head closure in the polymerization process preparing high-temperature glue gradually becomes stable, the molecular weight of raw rubber polymerization is relatively stable. The quantity of terminal hydroxyl group decreases dramatically in the high-temperature glue preparing process, the moulding is faster in the process, the storing time of the mixed glue and its physical-mechanical properties and processing property have been improved considerably.

Owner:JIANGSU HONGDA NEW MATERIAL

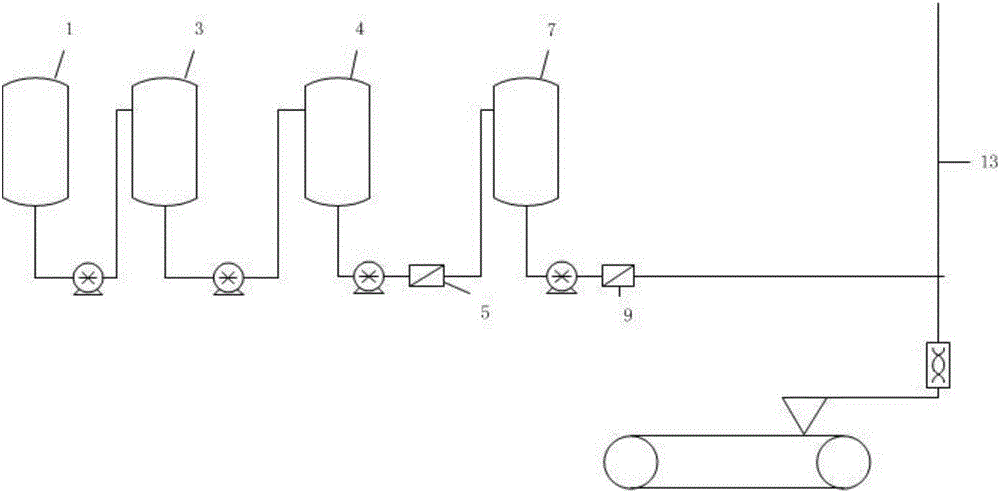

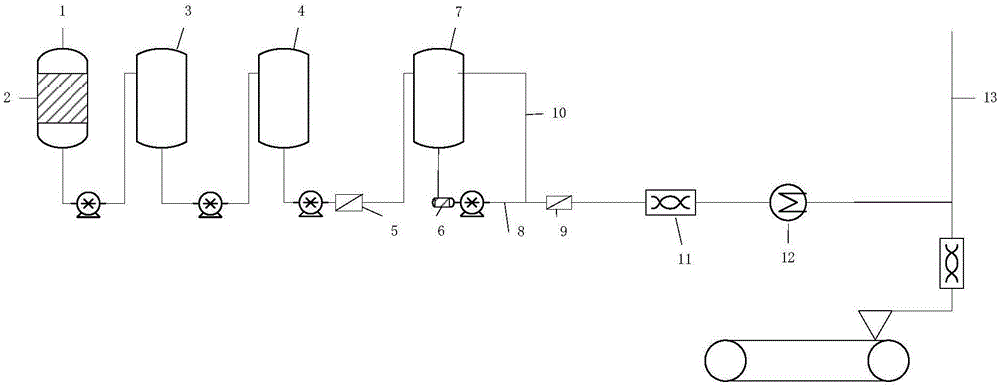

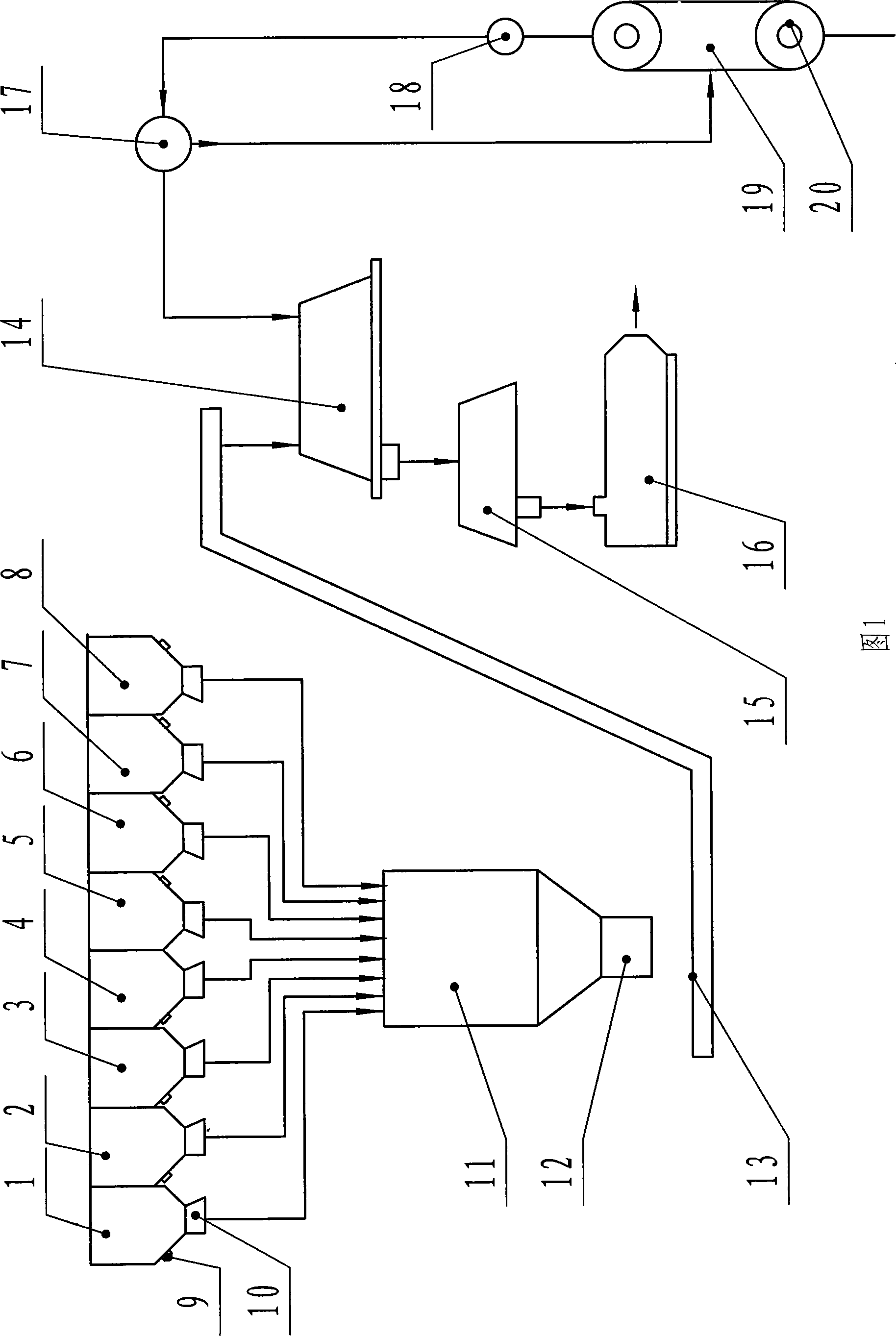

Beneficiation method for copper and lead zinc separation by adopting liquid sulfur dioxide

ActiveCN103447154AIncrease pulp concentrationImprove the separation effectFlotationSulfur dioxideSulfide

The invention discloses a beneficiation method for copper and lead zinc separation by adopting liquid sulfur dioxide and solves the problems that in the existing method, the influence is generated on the separation operation concentration, and further, the effective separation of copper from lead zinc is not favorably realized. The beneficiation method adopts a sulfur dioxide addition regulating control system, and the copper and lead zinc separation comprises the following specific processes that A, sodium sulfide is added into ore pulp for stirring; B, sulfur dioxide is added into the ore pulp for stirring through the addition regulating control system; C, liquid sulfur dioxide enters the ore pulp in a gas state through being gasified by the regulating control system; and D, the pH value of the ore pulp is regulated to 6.0 to 6.7, and then, the copper and lead zinc sulfide separation flotation is carried out. The beneficiation method has the advantages that the sulfur dioxide is added into the ore pulp, the ore pulp concentration can be effectively improved, meanwhile, the sulphurous acid concentration in the ore pulp can also be ensured, the sodium sulfide is also added into the ore pulp, and the separation effect of copper and lead zinc sulfide can be further improved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

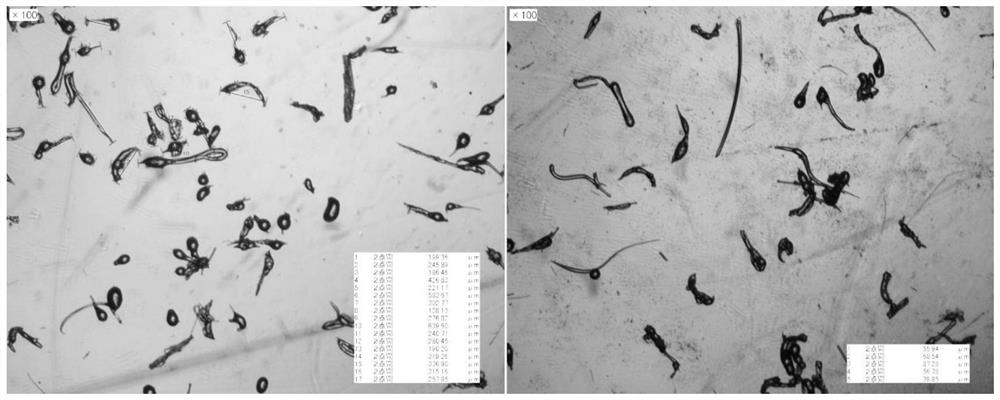

Cellulose triacetate film

ActiveCN106696154AShorten dispersion timeStirring frequency is smallFlat articlesCoatingsUltrasonic cavitationCellulose acetate

The invention relates to a cellulose triacetate film. Preparation steps comprise preparation of a cellulose triacetate celloidin liquid, dispersion and addition of a matting agent and tape casting, wherein in the dispersion and addition link of the matting agent, the matting agent is mixed and dispersed through ultrasonic cavitation and mechanical stirring, the dispersing time and the grinding time of the matting agent are effectively shortened by means of a method of controlling a flow rate of a pipeline, an agglomeration phenomenon in the matting agent adding process is avoided, and in the dispersion liquid adding process, the content of particles, less than 10 [mu]m, of the matting agent is stabilized to 99.5% above, so that the service life of a filter element is effectively prolonged, and the cost is lowered. Compared with the prior art, the cellulose triacetate film prepared by the invention has the advantages of being low in haze, high in light transmittance, few in crystal points, few in moisture absorption points and the like.

Owner:CHINA LUCKY FILM CORP +1

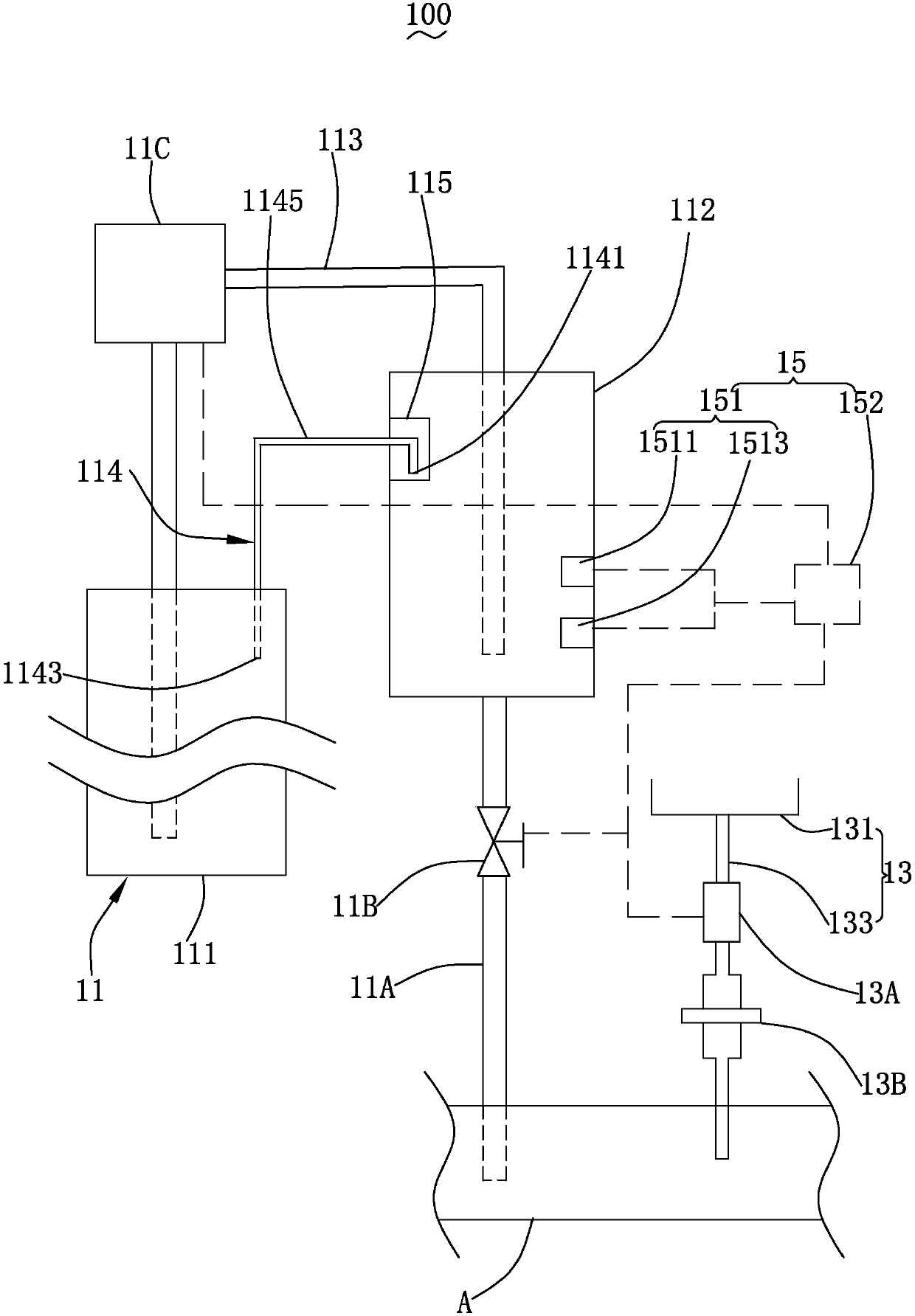

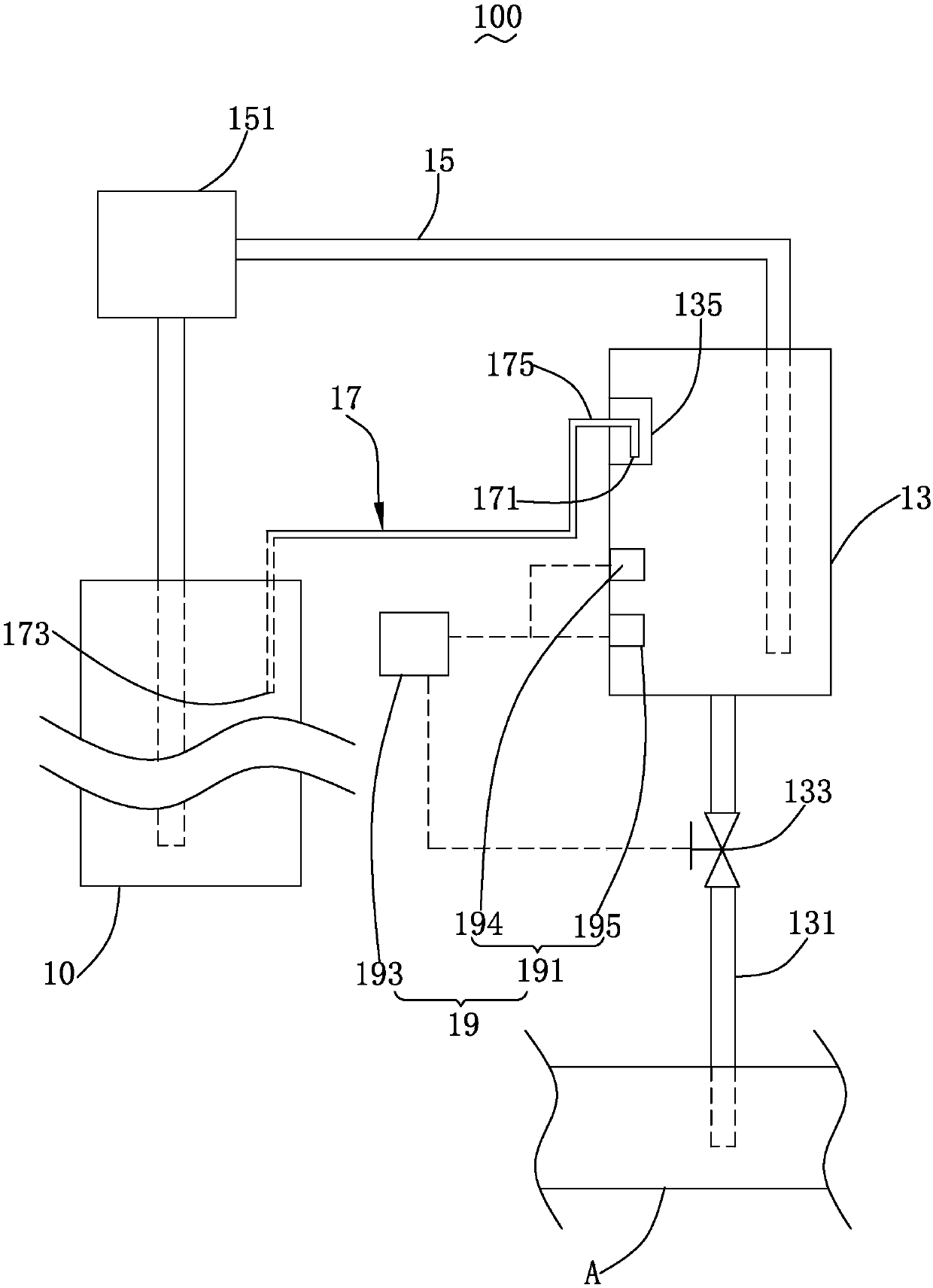

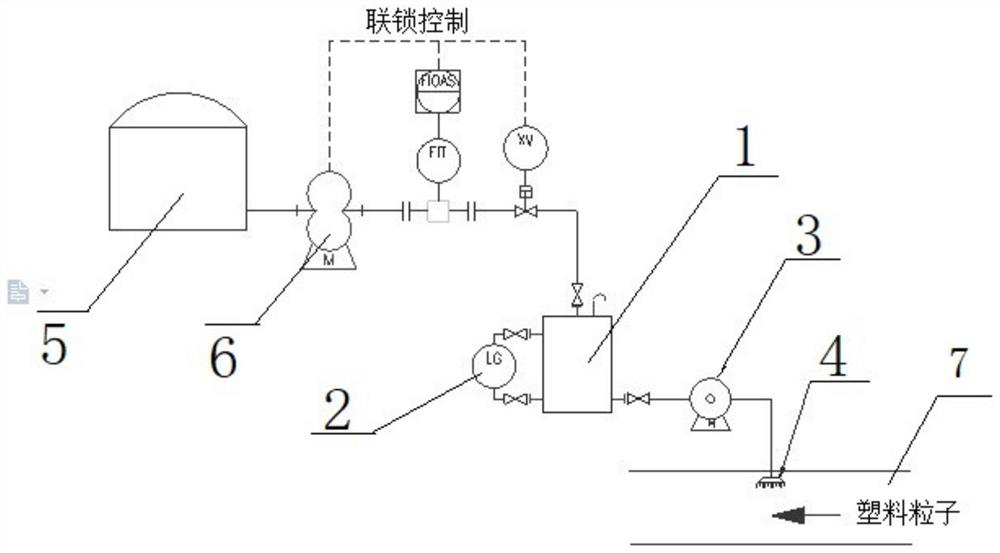

Liquid constant-volume automatic adding system

The invention provides a liquid constant-volume automatic adding system to achieve the goals of automatic liquid adding and stable adding amount of liquid. The liquid constant-volume automatic addingsystem comprises a liquid source, a container provided with a liquid-outlet pipeline at the bottom, a liquid-inlet pipeline, a siphoning pipeline and a control device, the liquid-outlet pipeline is provided with a first control valve, the liquid-inlet pipeline is provided with a liquid pump, the control device comprises a liquid level detection device and a controller, and the controller controlsthe liquid pump to add the liquid to the container according to a detection value of the liquid level detection device until the liquid reaches a first preset liquid level. When the liquid in the container reaches the first preset liquid level, the siphoning pipeline can siphon the liquid in the container to the outside of the container to enable the liquid in the container to reach a second preset liquid level in a constant-volume manner; and when the liquid level detection device detects that the liquid in the container reaches the second preset liquid level in the constant-volume manner, the controller controls the first control valve to release the liquid.

Owner:AOSHIKANG TECH CO LTD

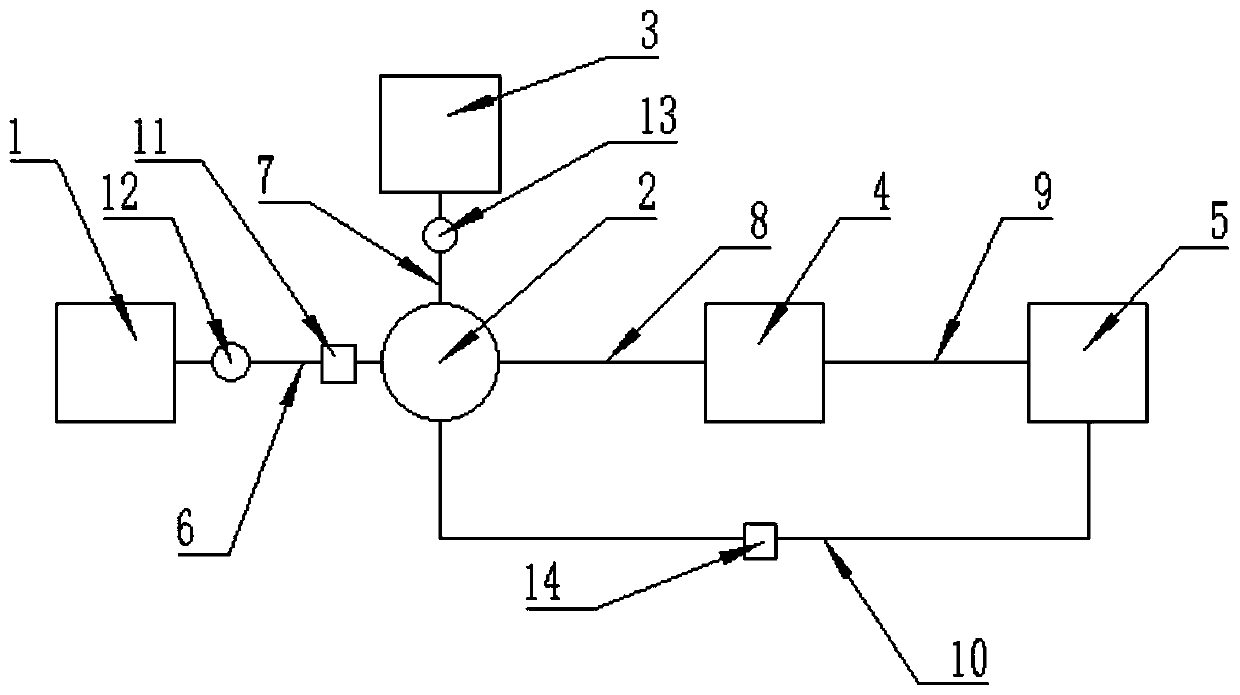

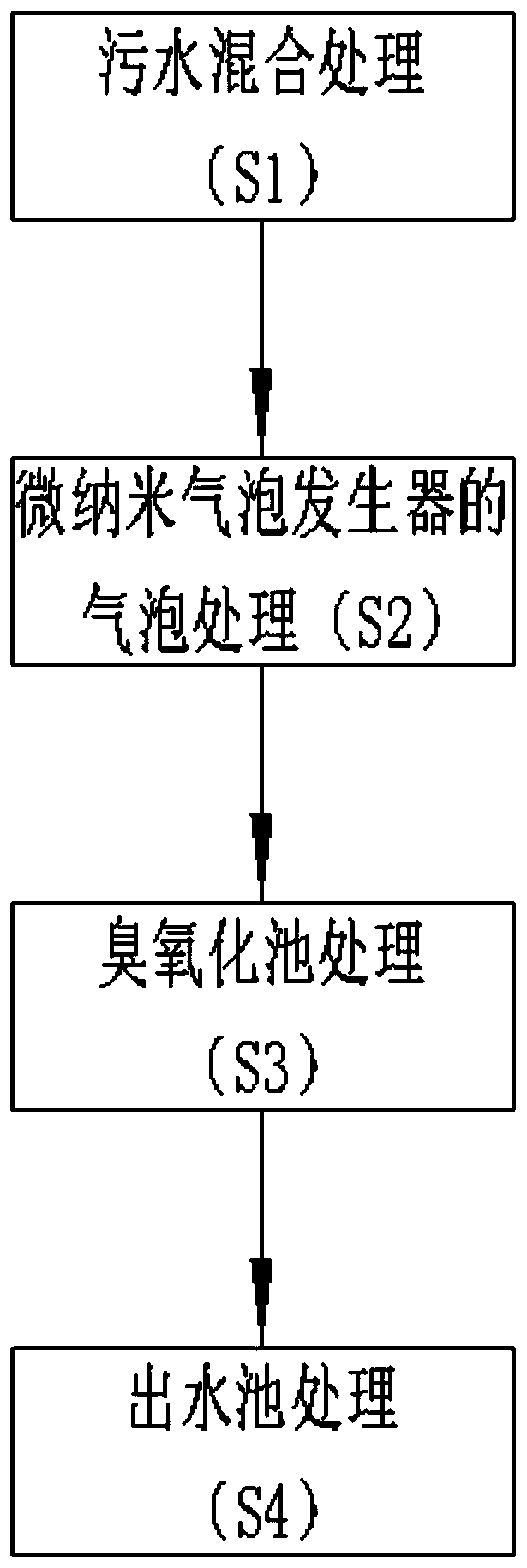

Micro-nano ozone oxidation water treatment method and device

InactiveCN110734123AImprove mass transfer efficiencySolve the problem of poor mass transfer effectSpecific water treatment objectivesWater contaminantsMicro nanoWater treatment system

The invention relates to a micro-nano ozone oxidation water treatment method and device. The micro-nano ozone oxidation water treatment device comprises a raw water tank, a micro-nano bubble generator, an ozonization tank, a water outlet tank and an ozonization generator, a micro-nano ozone oxidation water treatment system is constructed by combining ozone with the micro-nano bubble generator, sothat the mass transfer efficiency between the ozone and water is improved, the ozone efficiency and the water treatment effect are improved, the problem of poor mass transfer effect in traditional bubbling aeration is solved, and the micro-nano ozone oxidation water treatment system is high in practicability and good in working effect; by adopting the micro-nano bubble generator, the ozone gas generated by the ozonization generator is converted into micro-nano small bubbles, so that the specific surface area of the ozone bubbles is greatly increased, the gas-water contact area is increased, and meanwhile, the retention time of the micro bubbles in the water is prolonged, so that the mass transfer efficiency of a gas-liquid interface is enhanced.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

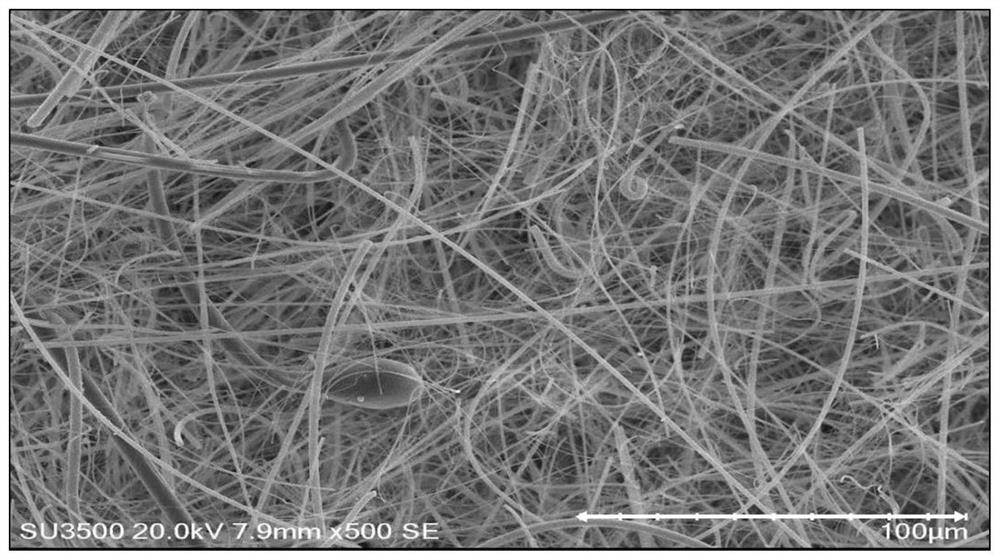

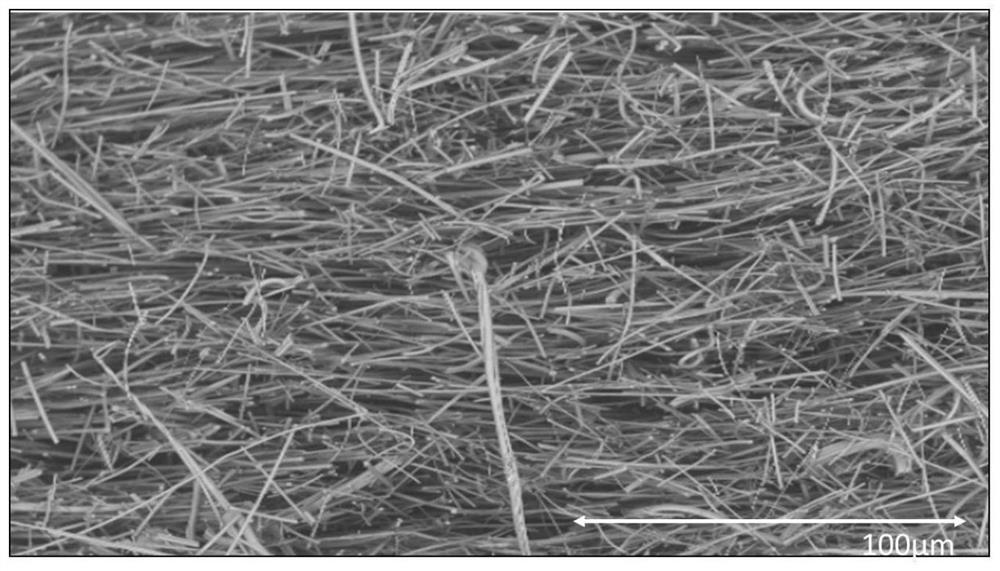

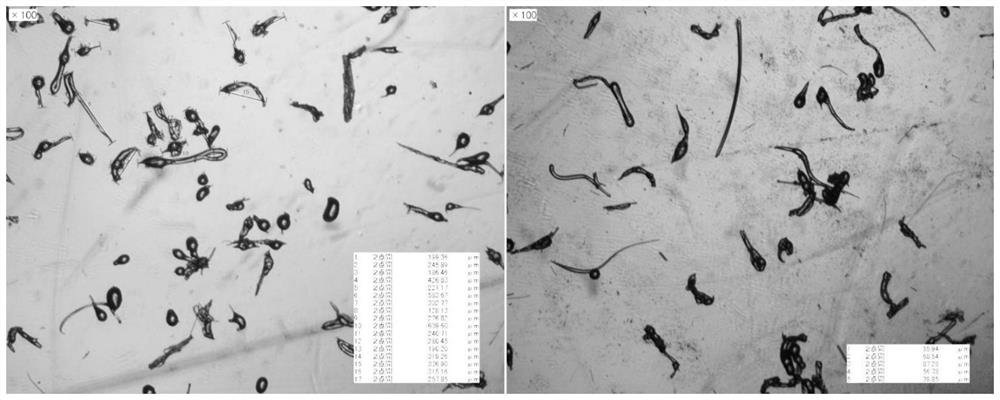

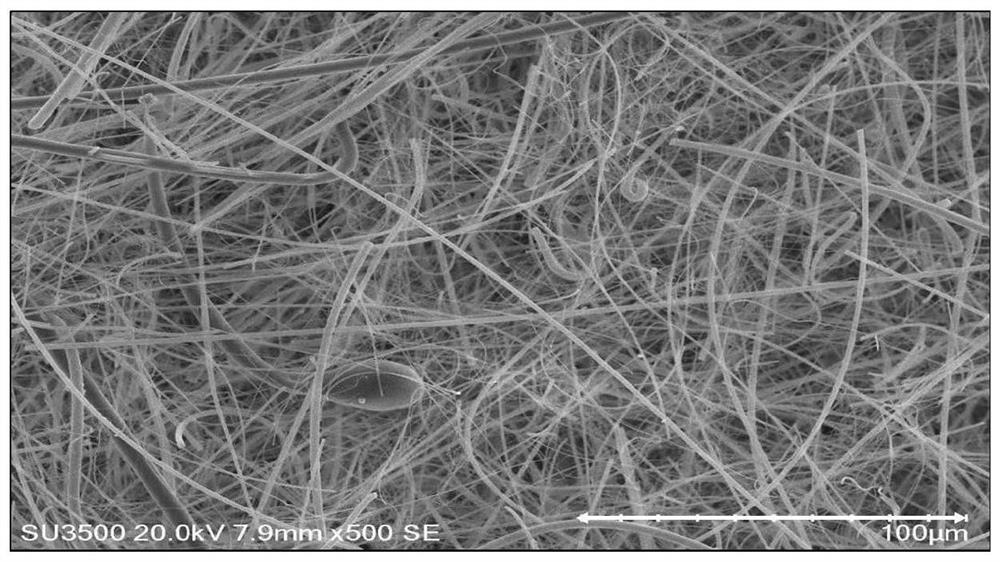

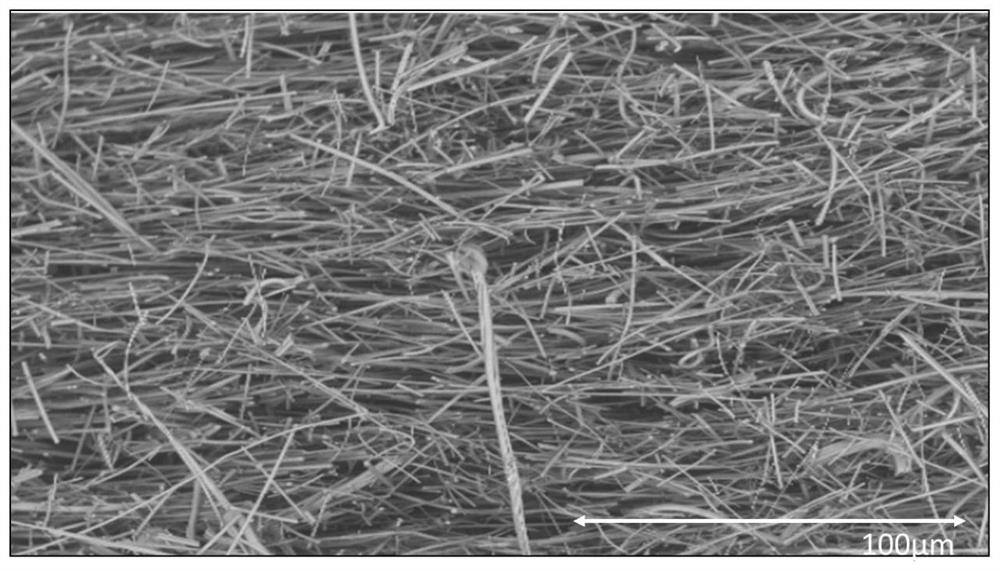

Glass fiber group and manufacturing method thereof, and glass fiber reinforced resin-based composite material and manufacturing method thereof

ActiveCN112759250AGuaranteed contentStable tensile strengthGlass making apparatusGlass fiberResin-Based Composite

The invention discloses a glass fiber group and a manufacturing method thereof, and a glass fiber reinforced resin-based composite material and a manufacturing method thereof. The manufacturing method of the glass fiber group is characterized by comprising the following steps: producing glass fibers by using a centrifugal method, and carrying out a wet-process molding or dry-process molding process on the glass fibers to obtain the glass fiber group with a predetermined shape. According to the invention, since the glass fibers are manufactured by adopting a centrifugal method, glass residues and powdery glass can be obviously reduced through a wet molding process, and the non-fibrosis phenomenon in the composite material is reduced, so that the added glass material can achieve the effect of enhancing the resin performance. The retention length of the glass fibers in the glass fiber reinforced resin-based composite material is larger, the content of the glass fibers is stable and controllable, and the glass fibers are uniformly dispersed. The mechanical strength and the performance of the glass fiber reinforced resin-based composite material are improved, and the glass fiber reinforced resin-based composite material is more stable.

Owner:袁飞 +1

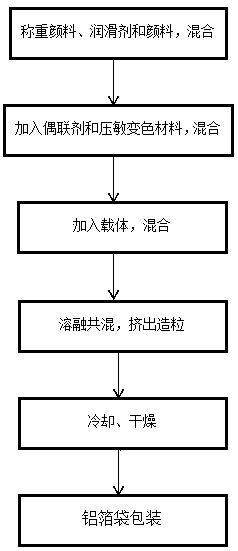

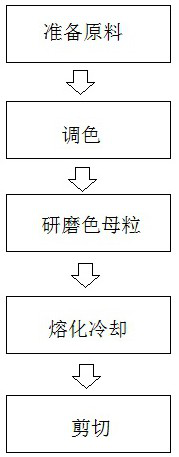

Degradable compressive discoloring plastic color masterbatch and preparation method thereof

A degradable compressive discoloring plastic color masterbatch consists of the following substances by the mass fraction: 10-30% of a pigment, 10-40% of a filler, 0.1-1% of a coupling agent, 0.5-5% ofa lubricant, 40-80% of a carrier and 4-10% of a pressure sensitive discoloring material. With polylactic acid or butylene terephthalate as a carrier, the proportion of the pigment and the additive isoptimized, the degradable compressive discoloring color masterbatch is obtained, has the advantages of uniform coloring, low cost, easy control of processing technology, excellent dispersibility andthe like, and has broad industrial application prospects.

Owner:DONGGUAN JINFULIANG PLASTIC & RUBBER TECH CO LTD

Beneficiation method for copper and lead zinc separation by adopting liquid sulfur dioxide

The invention discloses a beneficiation method for copper and lead zinc separation by adopting liquid sulfur dioxide and solves the problems that in the existing method, the influence is generated on the separation operation concentration, and further, the effective separation of copper from lead zinc is not favorably realized. The beneficiation method adopts a sulfur dioxide addition regulating control system, and the copper and lead zinc separation comprises the following specific processes that A, sodium sulfide is added into ore pulp for stirring; B, sulfur dioxide is added into the ore pulp for stirring through the addition regulating control system; C, liquid sulfur dioxide enters the ore pulp in a gas state through being gasified by the regulating control system; and D, the pH value of the ore pulp is regulated to 6.0 to 6.7, and then, the copper and lead zinc sulfide separation flotation is carried out. The beneficiation method has the advantages that the sulfur dioxide is added into the ore pulp, the ore pulp concentration can be effectively improved, meanwhile, the sulphurous acid concentration in the ore pulp can also be ensured, the sodium sulfide is also added into the ore pulp, and the separation effect of copper and lead zinc sulfide can be further improved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Glass fiber group and glass fiber reinforced resin-based composite material

ActiveCN112759794AGuaranteed contentStable tensile strengthGlass making apparatusSynthetic cellulose/non-cellulose material pulp/paperGlass fiberResin-Based Composite

The invention discloses a glass fiber group and a glass fiber reinforced resin-based composite material. The glass fiber group is characterized in that the glass fiber group comprises a plurality of glass fibers or modified glass fibers with the diameter of 1-7 microns. According to the invention, since the glass fibers are manufactured by adopting a centrifugal method, glass residues and powdery glass can be obviously reduced through a wet molding process, and the non-fibrosis phenomenon in the composite material is reduced, so that the added glass material can achieve the effect of enhancing the resin performance. The retention length of the glass fibers in the glass fiber reinforced resin-based composite material is larger, the content of the glass fibers is stable and controllable, and the glass fibers are uniformly dispersed. The mechanical strength and the performance of the glass fiber reinforced resin-based composite material are improved, and the glass fiber reinforced resin-based composite material is more stable.

Owner:袁飞 +1

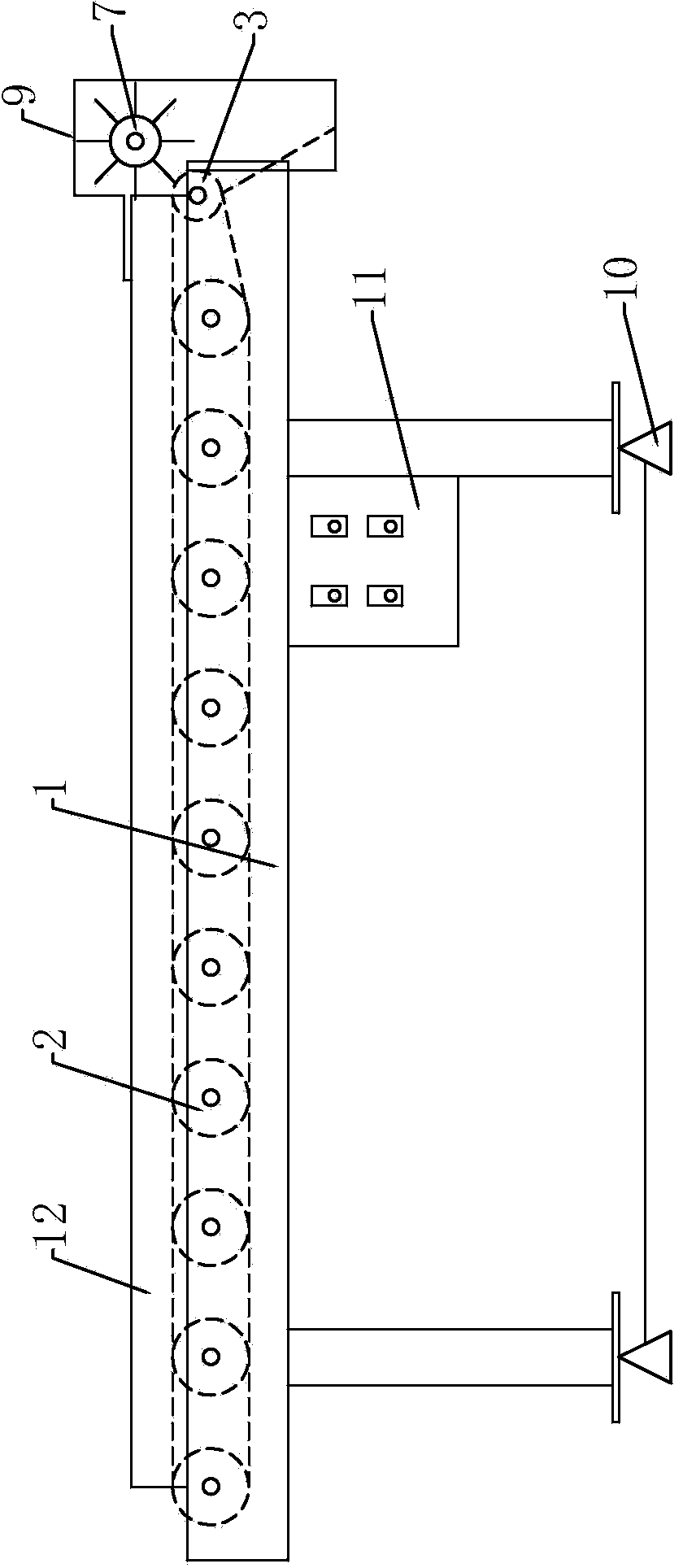

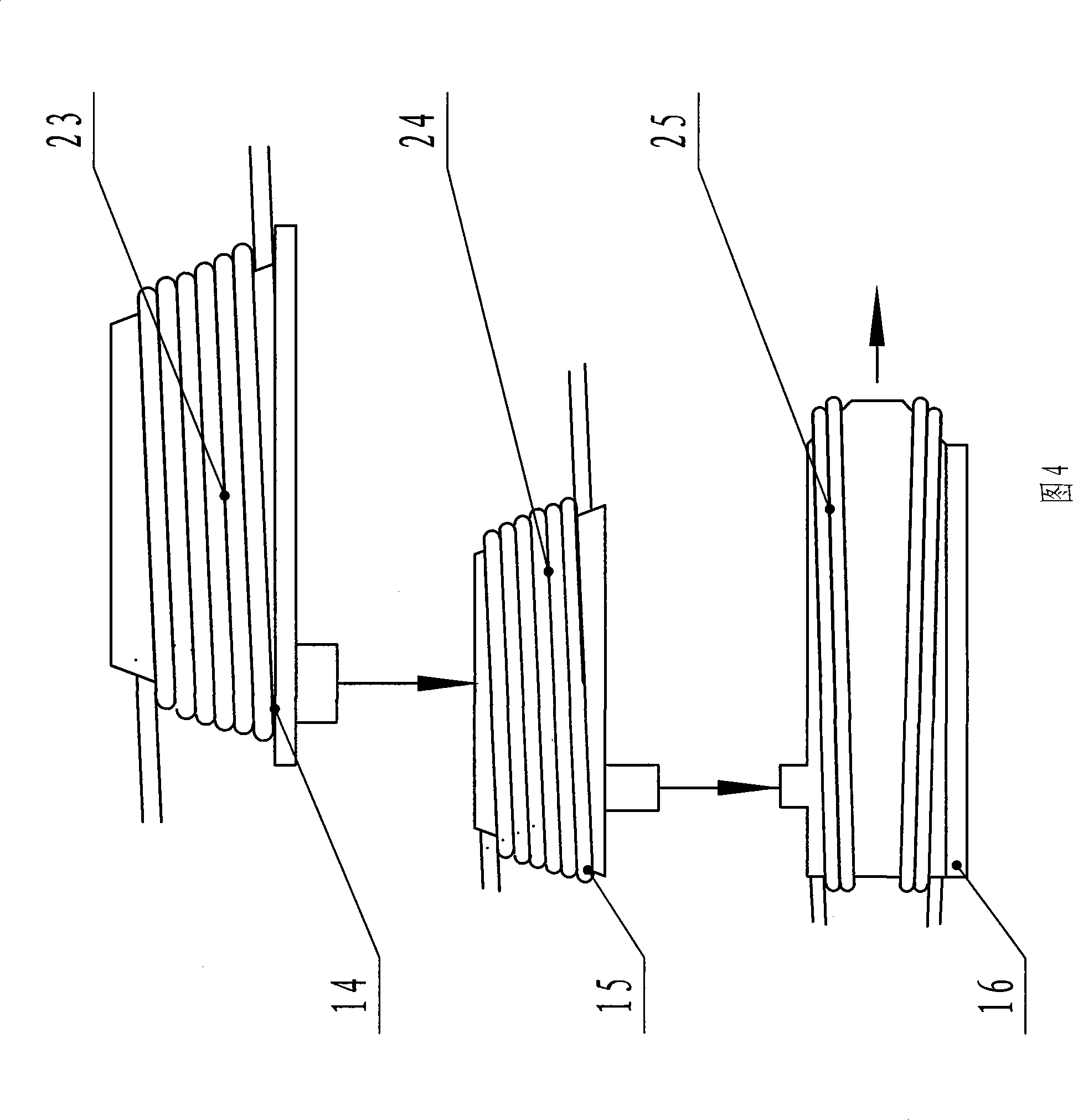

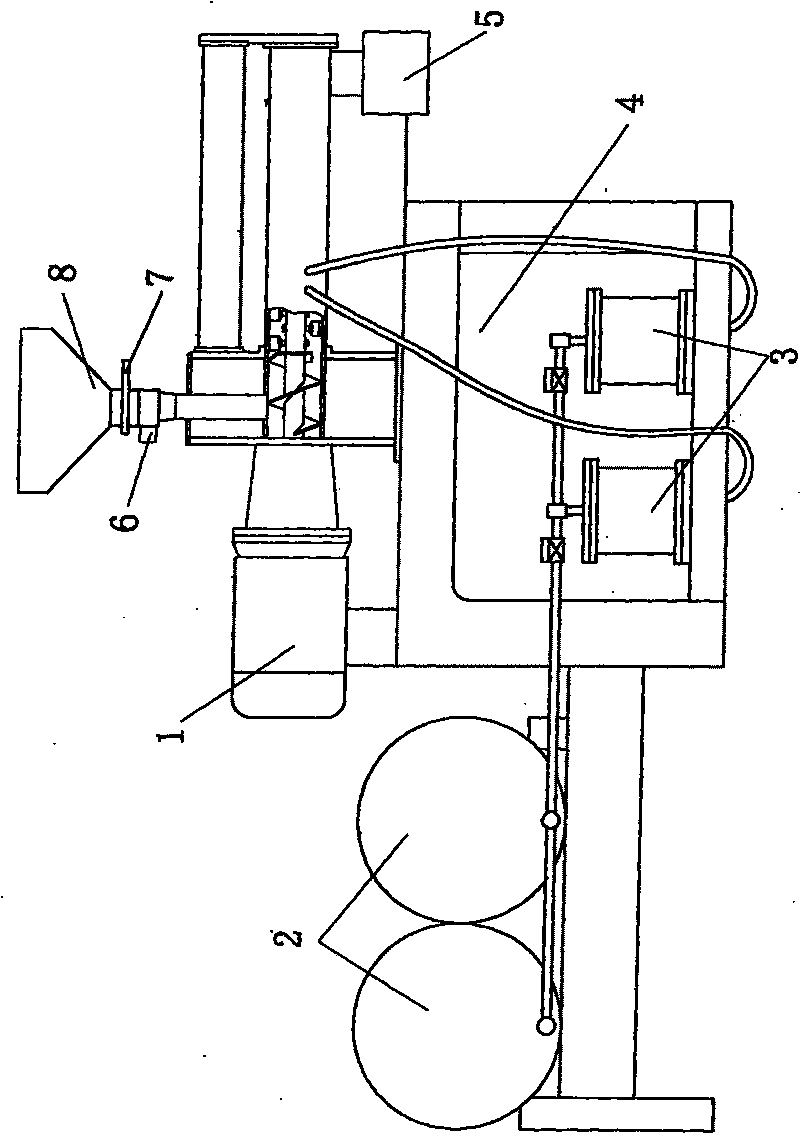

Automatic quantitative glass fiber feeding machine

InactiveCN103802216AReasonable structureThe amount added is stableSold ingredients supply apparatusEngineeringMechanical engineering

The invention relates to a feeding machine, and particularly relates to an automatic quantitative glass fiber feeding machine. The automatic quantitative glass fiber feeding machine comprises a rack which is provided with a feeding mechanism, a scattering mechanism and a controlling device, wherein the feeding mechanism comprises a driving drum and a plurality of transmission drums which are continuously horizontally arranged along the length direction of the rack, the scattering mechanism comprises a needling roller which is movably arranged on the rack in front of the driving drum along the forward direction of a material and is parallel to the driving drum, and a weight sensor is arranged at the bottom of the rack and is connected with the controlling device. The automatic quantitative glass fiber feeding machine has a reasonable structure, is convenient and practical, can feed quantitative glass fibers automatically, enables the adding amount to be stable and the quantity to be controllable, greatly lowers the labor intensity of workers, and improves the work efficiency and the product quality.

Owner:山东聚源石膏建材开发有限公司

Method for manufacturing blast furnace stemming

A preparation method for blast furnace taphole clay has the following processes, bulk raw materials are heated to 20 to 40 DEG C and are mixed evenly, the particle size of the bulk raw materials is 3 to 0.074mm, binder is then added, the mixture is grinned for 40 to 60 minutes, which is then pressed and formed, the additive and each bulk raw material are put into separate holding tank, the binderis put into a holding tank, the raw material is heated to 20 to 40 DEG C in the holding tank, binder is added into the clay mill to be grinned for 40 to 60 minutes, when the temperature is 50 to 70DEG C, material is pressed and formed in a forming machine, the heating method is that lateral heating pipes are arranged outside the equipment, and medium with the melting point equal to or above 100 DEG C is pumped in. The preparation method of the blast furnace taphole clay has low labor intensity and high production efficiency.

Owner:SHANXI LUWEIBAO TAIGANG REFRACTORIES CO LTD

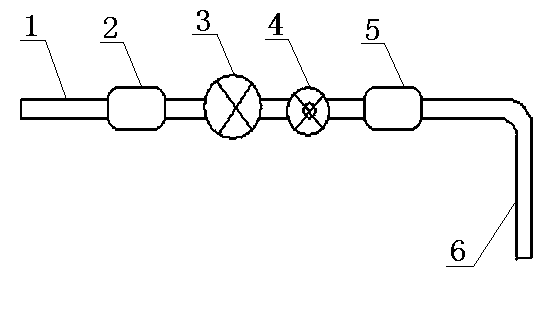

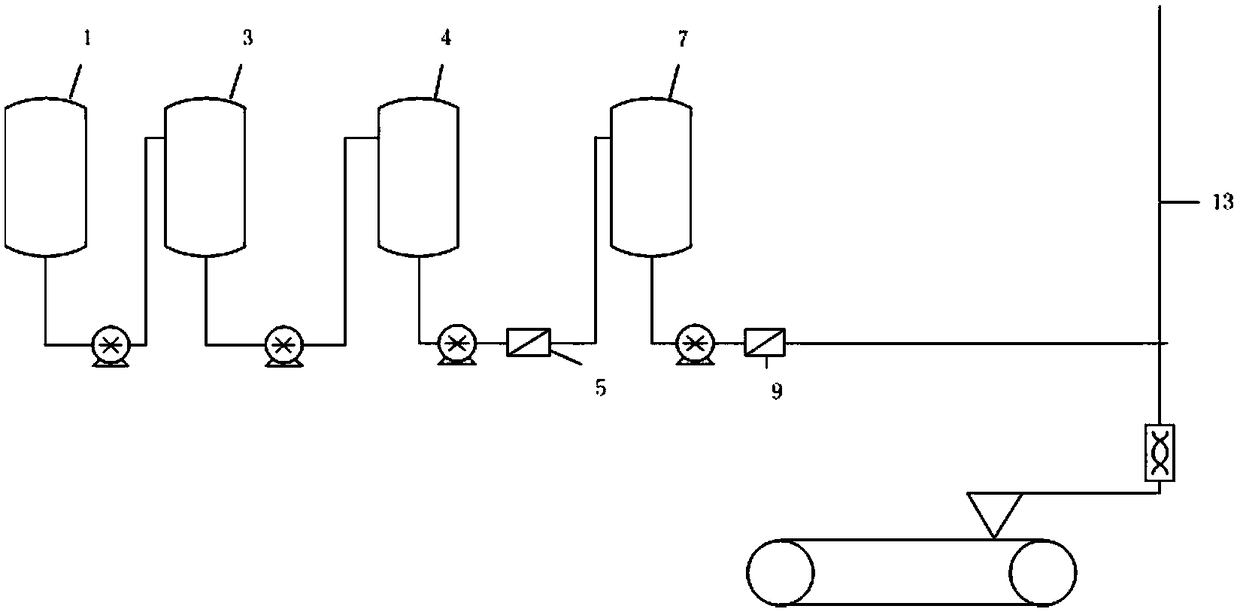

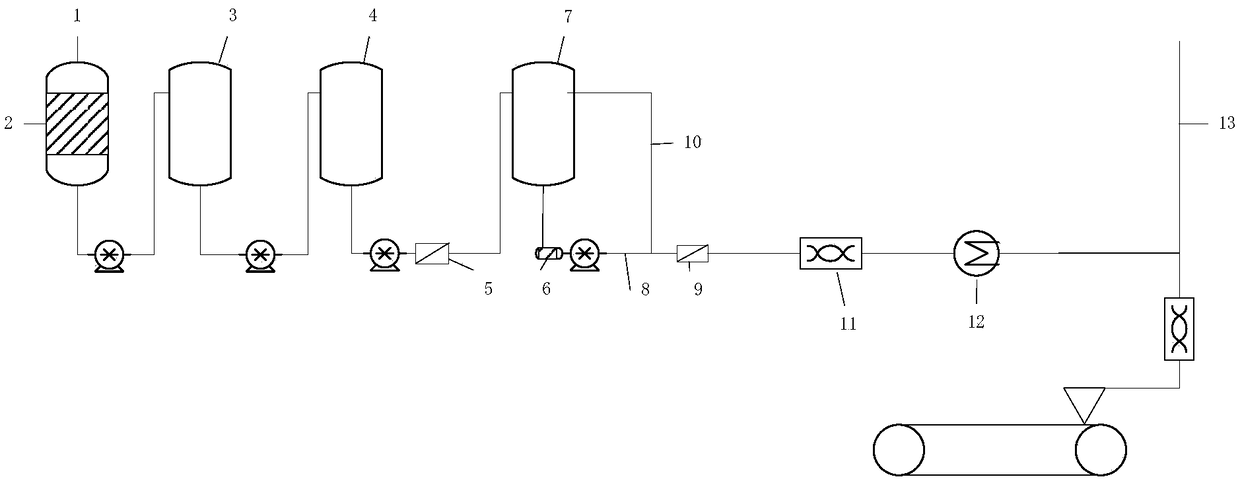

Granulation external lubricant adding system and method

ActiveCN113399143ACompact structureSmall footprintLiquid spraying apparatusElectrical controlMineral oil

The invention relates to a granulation external lubricant adding system, and belongs to the field of resin synthesis. The system comprises a liquid storage tank, a liquid level meter, a metering pump, a valve, a pipeline and an electrical control cabinet which are arranged on a same base, and the liquid storage tank is used for storing a liquid external lubricant and is connected with a mineral oil storage tank through a mineral oil pump; the liquid level meter is used for monitoring the liquid level in the liquid storage tank and is arranged on the liquid storage tank; the pipeline is communicated with the liquid storage tank and a granular material air conveying pipe; the metering pump is used for quantitatively pumping the liquid lubricant and is arranged on the pipeline; and the electrical control cabinet is used for controlling the system and is communicated with the liquid level meter and the metering pump. The invention further provides a granulation external lubricant adding method which is applied to the system. The liquid lubricant is adopted to replace a powdery lubricant, so that the appearance of product particles is improved, the production cost is reduced, and the product processing efficiency is improved; and meanwhile, dust pollution is reduced, and environmental protection and emission reduction are facilitated. The system provided by the invention is compact in structure, small in occupied area and easy to install.

Owner:GUANGDONG RASTAR SYNTHETIC MATERIAL COMPANY

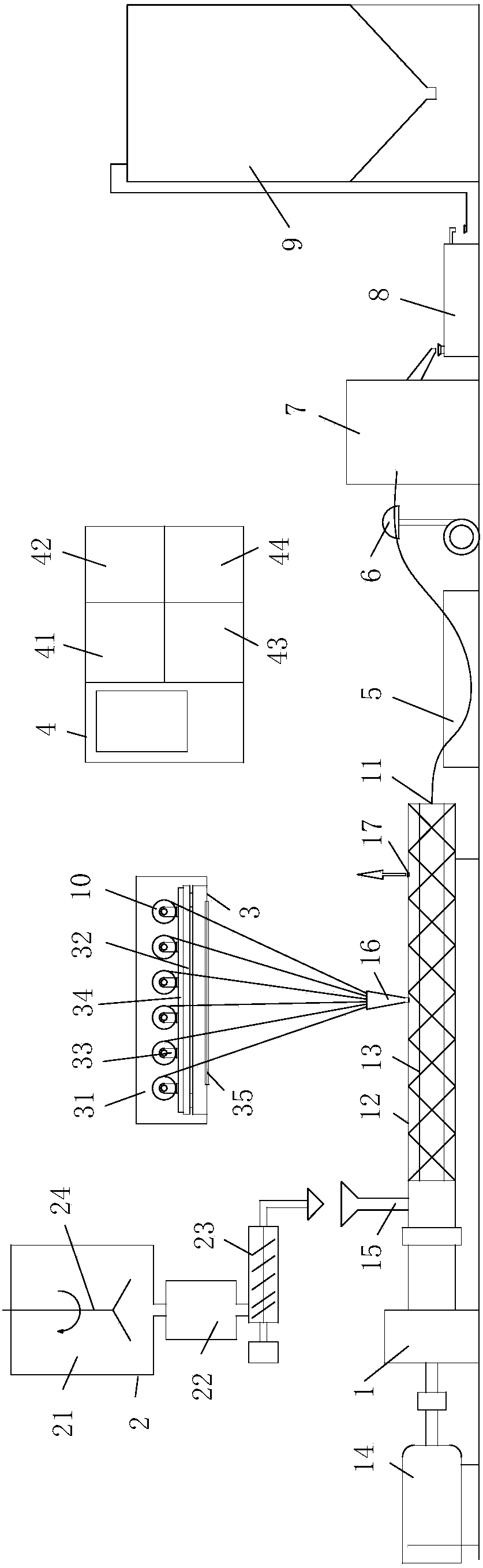

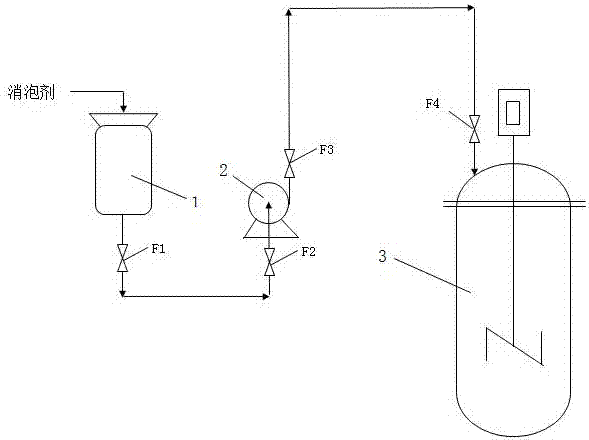

Defoaming agent adding device for chlorosulfonated polyethylene wet condensation post-processing

InactiveCN107469739AOutstanding FeaturesHighlight significant progressFeed devicesFoam dispersion/preventionProcess engineeringMetering pump

The invention discloses a defoaming agent adding device for chlorosulfonated polyethylene wet condensation post-processing. The defoaming agent adding device is characterized by comprising a defoaming agent metering tank and a defoaming agent metering pump; an outlet in the bottom of the defoaming agent metering tank is connected with an inlet of the defoaming agent metering pump; an outlet of the defoaming agent metering pump is connected with the top of a 1# condensation kettle. A working process of the defoaming agent adding device comprises the following steps: detecting that all valves of the device disclosed by the invention are in a closed state, the defoaming agent metering pump is in a closed standby state, and all pipelines do not leak; adding a defoaming agent into the defoaming agent metering tank; opening a discharging valve, a first feeding valve, an outlet valve and a second feeding valve in sequence; starting the defoaming agent metering pump and observing the operating situation of the defoaming agent metering pump to ensure that the defoaming agent enters the 1# condensation kettle stably and quantitatively. The defoaming agent adding device for the chlorosulfonated polyethylene wet condensation post-processing has the advantages that the acting position is precise, the defoaming agent works while being added, the adding amount is stable, the operation is simple and convenient, and the labour intensity is reduced.

Owner:PETROCHINA CO LTD

Preparation method of medical transparent polypropylene material

The invention relates to the technical field of polypropylene, in particular to a preparation method of a medical transparent polypropylene material. The medical transparent polypropylene material is prepared from the following raw materials in parts by weight: 100 parts of homo-polypropylene resin, 0.2-0.4 part of a transparent nucleating agent, 2-6 parts of phthalate, 7-15 parts of a toughening agent, 6-28 parts of expansible graphite, 1-4 parts of a halogen-free flame retardant, 0.3-1.8 parts of a coupling agent, 0.3-2.4 parts of an antistatic agent, 65 parts of a curing agent, 10-30 parts of a coloring agent, 0.3-0.6 part of an antioxidant, 0.4-1.5 parts of lubricating grease, 3-5 parts of a stabilizer and 10-40 parts of low-dielectric-loss glass fiber. The medical transparent polypropylene material is excellent in oxidation resistance, has good antistatic property, is convenient to color, and is high in thermal stability, high in fluidity and high in transparency.

Owner:高邮市汉升高分子材料有限公司

A kind of granulation external lubricant adding system and method

ActiveCN113399143BCompact structureSmall footprintLiquid spraying apparatusLiquid storage tankElectrical control

The invention relates to an external lubricant addition system for granulation, which belongs to the field of resin synthesis. The system includes: a liquid storage tank, a liquid level gauge, a metering pump, a valve, a pipeline, and an electrical control cabinet, which are arranged on the same base. storage tank; the liquid level gauge is used to monitor the liquid level in the liquid storage tank, and is arranged on the liquid storage tank; the pipeline communicates with the liquid storage tank and the pellet air supply pipe; the metering pump is used for The quantitative pumping liquid lubricant is arranged on the pipeline; the electrical control cabinet is used to control the system and communicates with the liquid level gauge and the metering pump. The present invention also provides a method for adding an external lubricant to granulation, which is applied to the above system. The invention adopts liquid lubricant to replace powder lubricant, improves the appearance of product particles, reduces production cost, and improves product processing efficiency; meanwhile, reducing dust pollution is beneficial to environmental protection and emission reduction. The system provided by the invention has compact structure, small footprint and easy installation.

Owner:GUANGDONG RASTAR SYNTHETIC MATERIAL COMPANY

A kind of cellulose triacetate film

ActiveCN106696154BShorten dispersion timeStirring frequency is smallFlat articlesCoatingsUltrasonic cavitationCellulose acetate

Owner:CHINA LUCKY FILM CORP +1

Continuous automatic pug mixer

InactiveCN101347818BHigh viscosityThe amount added is stableMould handling/dressing devicesProportional controlDry sand

Owner:济南林青铸造技术有限公司

Smalt for PVC (Poly Vinyl Chloride) plastic processing

The invention provides a smalt for PVC (Poly Vinyl Chloride) plastic processing, consisting of the following components in percentage by weight: 20-45% of carrier, 5-10% of adjuvant, and 50-70% of pigment. The carrier is one or more of chloride-vinyl resin, chloroethylene-vinyl acetate-maleic acid ternary polymerization resin, chloroethylene-vinyl acetate-hydroxy crylic acid ternary polymerization resin, chloroethylene, PVC or methyl methacrylate. According to the invention, the additive is well dispersed, keeps stable chemical stability and is correct and stable in addition amount. In term of a processing technology, as a powdery additive and resin are quite different in the size of particles, uneven addition in amount often happens. However, as the smalt and PVC particles are very similar in diameter, the addition amount can be kept stable. The addition process is convenient. The smalt can keep the environment clean, and is beneficial to production of PVC products with high quality.

Owner:SHANGHAI YIPIN PIGMENTS CO LTD

Special master batch for nucleic acid detection kit

Owner:昆山飞彩塑胶五金有限公司

Preparation method of piston cast aluminium alloy

InactiveCN106756303AComponent composition is scientific and reasonableSimple recipeSlag5005 aluminium alloy

The invention discloses a preparation method of piston cast aluminium alloy. The piston cast aluminium alloy is composed of aluminium ingot, copper element, magnesium element, silicon element, nickel element, chromium element, iron element, manganese element, zinc element, titanium element, lead element and tin element, and the piston cast aluminium alloy is formed by adding high-phosphorus alloy type alterant for treatment during the production process. According to the invention, 11 elements including nickel, chromium, iron and the like are added in the cast aluminium alloy to remarkably improve the alloy performance and stabilize quality. In addition, the high-phosphorus alloy type alterant is adopted for modification treatment and is small in added amount and free of pollution; the reaction slag is less, the phosphorus absorptivity is stable, and a furnace lining, a crucible and a tool are prevented from corrosion, so that the service life of the furnace lining and the crucible is prolonged; the added amount can be precisely controlled, so that alloy loss is reduced, the casting yield of the alloy is increased, and the high-phosphorus alloy type alterant is environment-friendly. Moreover, emission of waste residue and exhaust gas is also reduced during the melting process of the aluminium ingot, the environment is protected, and the economic benefit and the social benefit are remarkable.

Owner:广西中才铝业有限公司

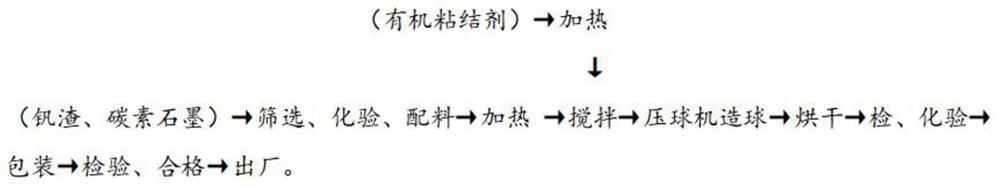

A composite alloy that can replace vanadium-iron alloy and its production process and application

ActiveCN111088425BSimple production processHigh recovery rateManufacturing convertersProcess efficiency improvementSteelmakingCarbon graphite

The invention belongs to the technical field of steelmaking and relates to the application of vanadium slag in replacing vanadium-iron alloy, in particular to a composite alloy which can replace vanadium-iron alloy and its production process and application. The composite alloy includes the following raw materials and their mass percentages: 93.0-96.0% of vanadium slag, 2.0-3.0% of graphite, and 2.0-4.0% of organic binder; the production process includes the following steps: collecting vanadium slag and graphite waste materials, Screening, testing, and batching; heating vanadium slag, graphite, and organic binder materials separately, mixing and stirring, briquetting, drying, and packaging; collection of vanadium and carbon elements during the pelletizing process of vanadium slag and carbon graphite The yield can reach 99%. The application of the composite alloy of the invention in steelmaking instead of vanadium ferroalloy. By adopting the composite alloy of the present invention to carry out vanadium alloying on molten steel during the tapping process of the converter, the recovery rate of alloy elements is high, and the recovery rate of vanadium can reach 93-96%.

Owner:淄博淄翼金属材料有限公司

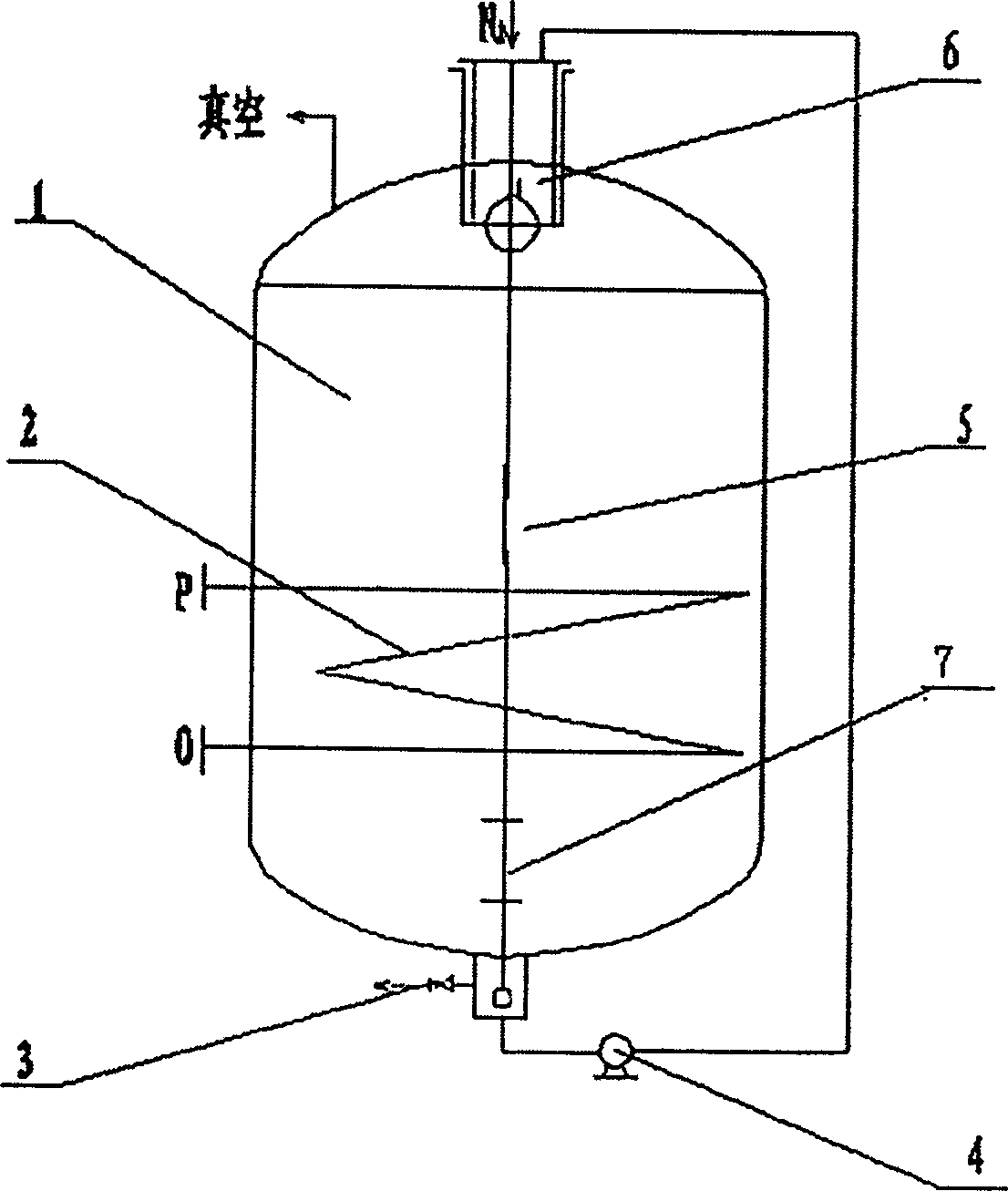

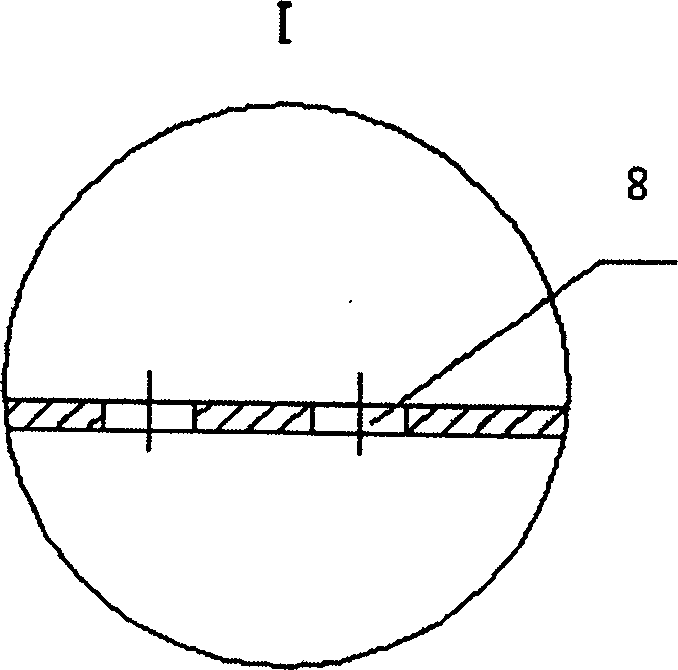

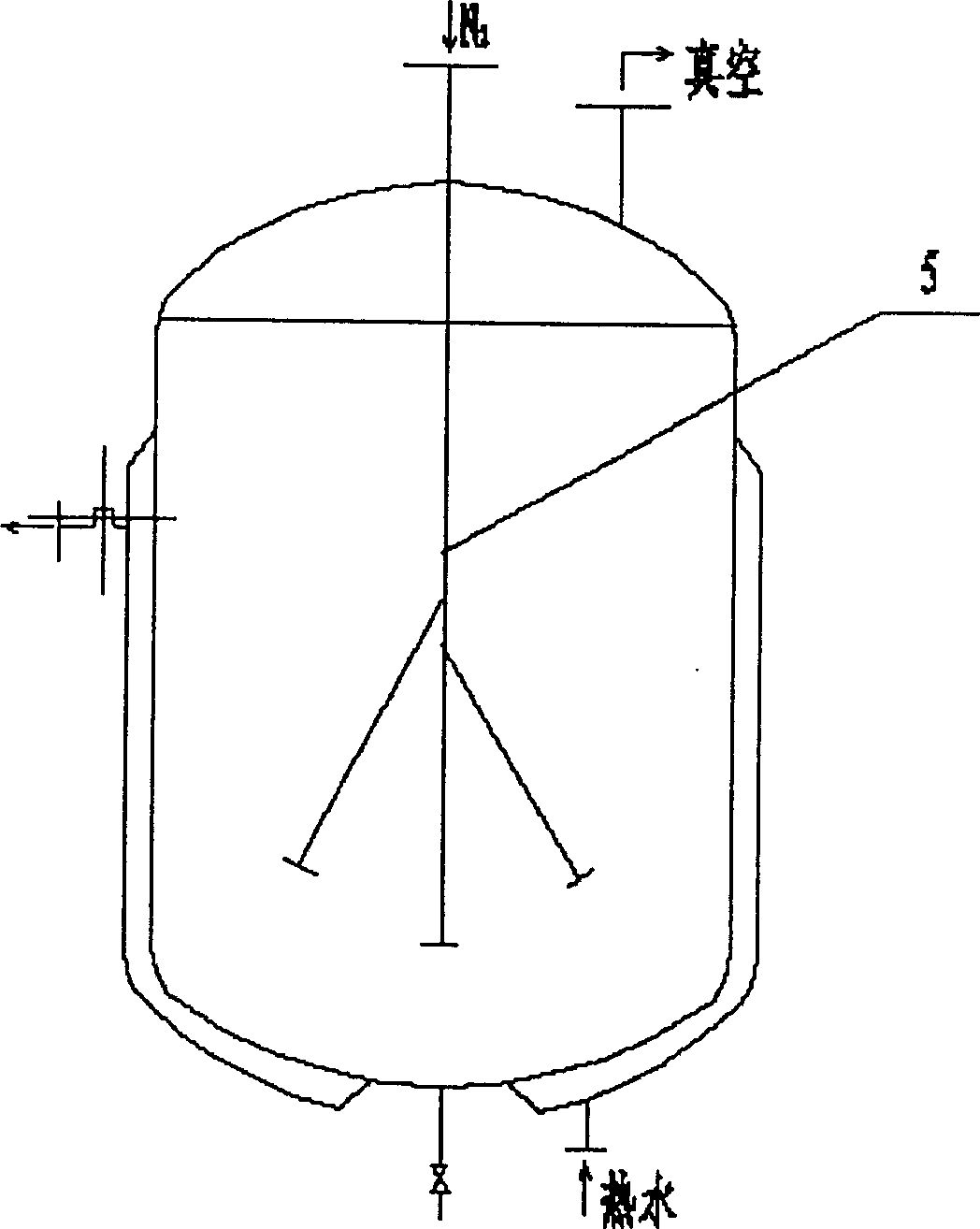

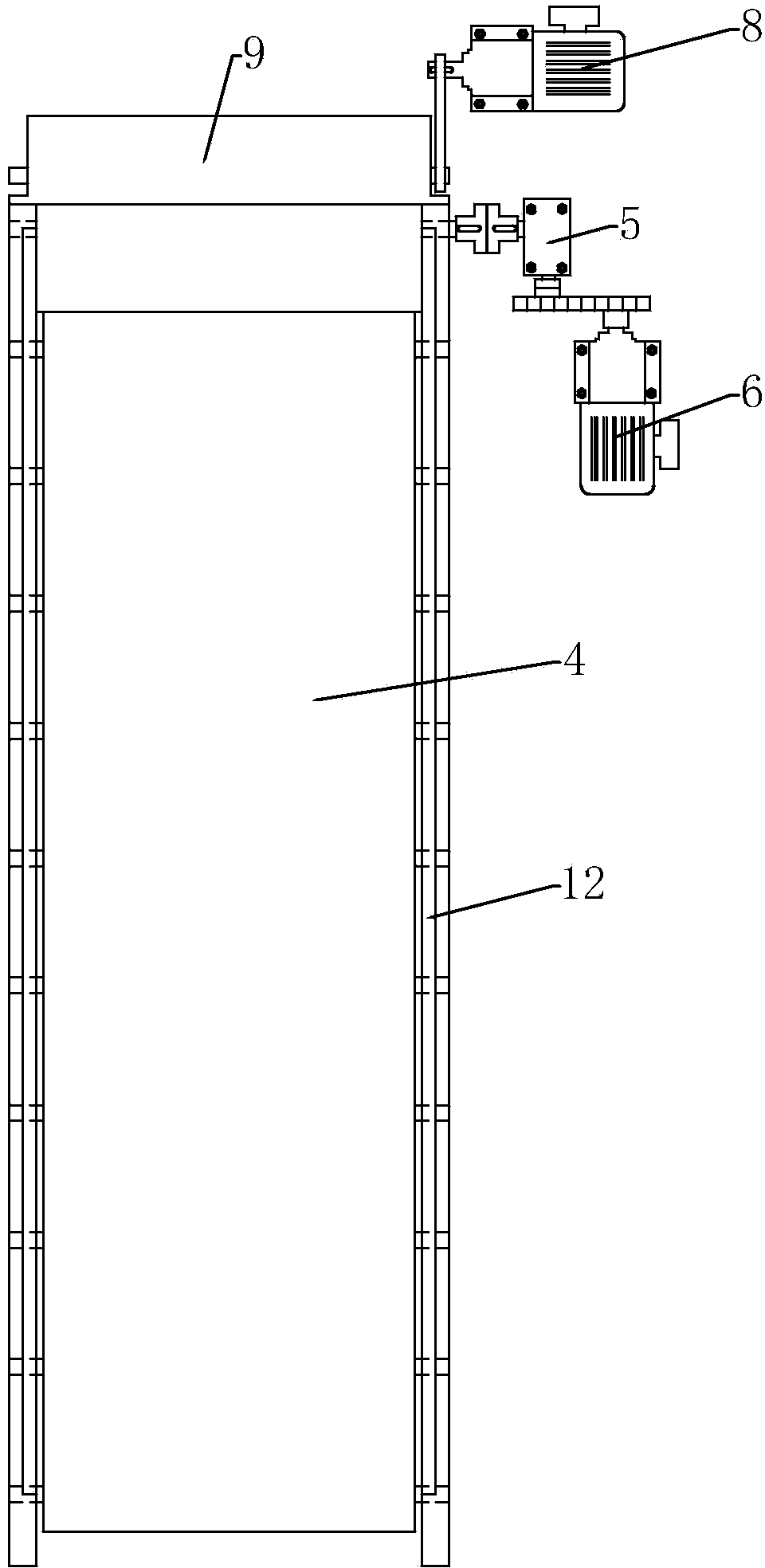

Organosilicone dehydration device

InactiveCN103537102ATrace moisture reductionThe amount added is stableEvaporator accessoriesEnd-groupNitrogen

The invention discloses an organosilicone dehydration device, comprising a dehydration kettle, a nitrogen tube, a vacuum kettle and a heating cover, wherein one end of the nitrogen tube is arranged inside the dehydration kettle in a penetrating manner; the nitrogen tube is arranged outside the dehydration kettle and connected with a circulating pump; one section of the vacuum kettle is connected with the circulating pump through a pipeline; the other end of the vacuum kettle is connected with a dehydration pump through the pipeline; the heating cover is sleeved at the outer side of the dehydration kettle. A trace of moisture in a raw material is obviously reduced, and is less than 10ppm in general after the organosilicone dehydration device disclosed by the invention carries out dehydration treatment; the adding amount of an end socket agent in a high-temperature polymerization process is gradually stabilized; the molecular weight of rubber aggregation is stable. The end-group quantity is greatly reduced when a high-temperature rubber product is synthetized; molding is obvious quick when mixing processing is carried out; the storage time, the physical and mechanical properties and the processability of a rubber compound product are improved.

Owner:上海氟聚化学产品股份有限公司

A control device for automatic quantitative addition of gypsum soft tofu coagulant

ActiveCN113229456BThe amount added is stableOvercoming quality fluctuationsHollow article cleaningCheese manufactureSolenoid valveProcess engineering

The invention discloses an automatic quantitative addition control device for gypsum tender bean curd coagulant, which aims to provide a stable addition time and amount of coagulant, so as to effectively overcome the pulping link in the production process of gypsum tender bean curd in the prior art Among them, there is an automatic quantitative addition control device for gypsum soft tofu coagulant, which has the problem of unstable addition time and amount of coagulant, which causes fluctuations in product quality. It includes a frame, on which a soybean milk tank is arranged; a coagulant quantitative bucket, and an overflow port is arranged on the upper part of the side wall of the coagulant quantitative bucket; The liquid level detection switch of the coagulant; the coagulant supply pipeline, the coagulant supply solenoid valve is arranged on the coagulant supply pipeline, and the coagulant supply pipeline is used to input the coagulant into the coagulant quantitative barrel; the coagulant feeding pipeline, the coagulant feeding The pipeline is used for inputting the coagulant in the quantitative bucket of the coagulant into the soybean milk bucket.

Owner:ZUMING BEAN PROD

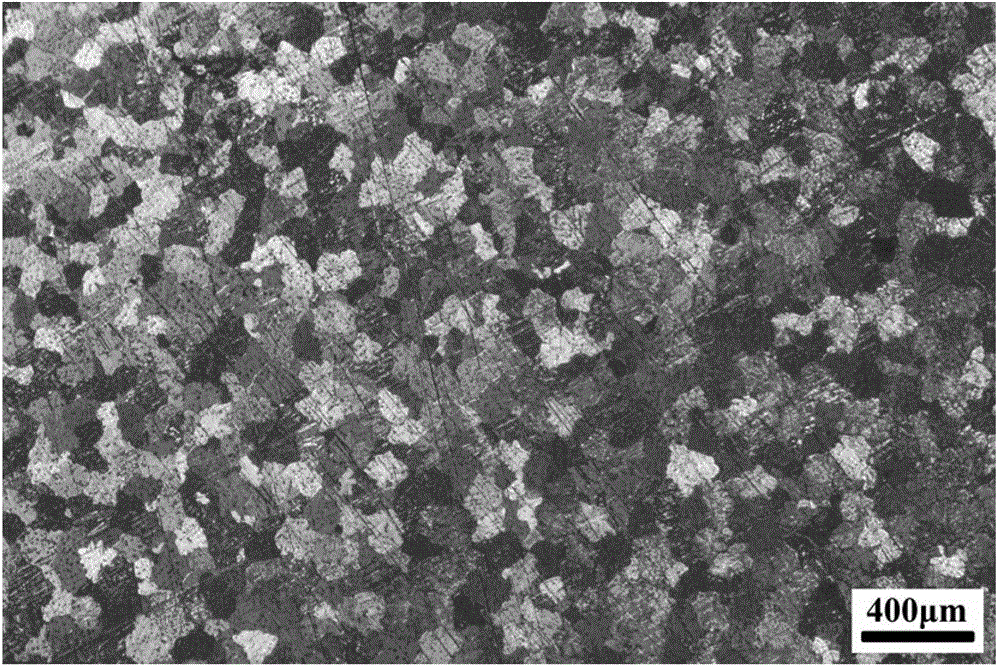

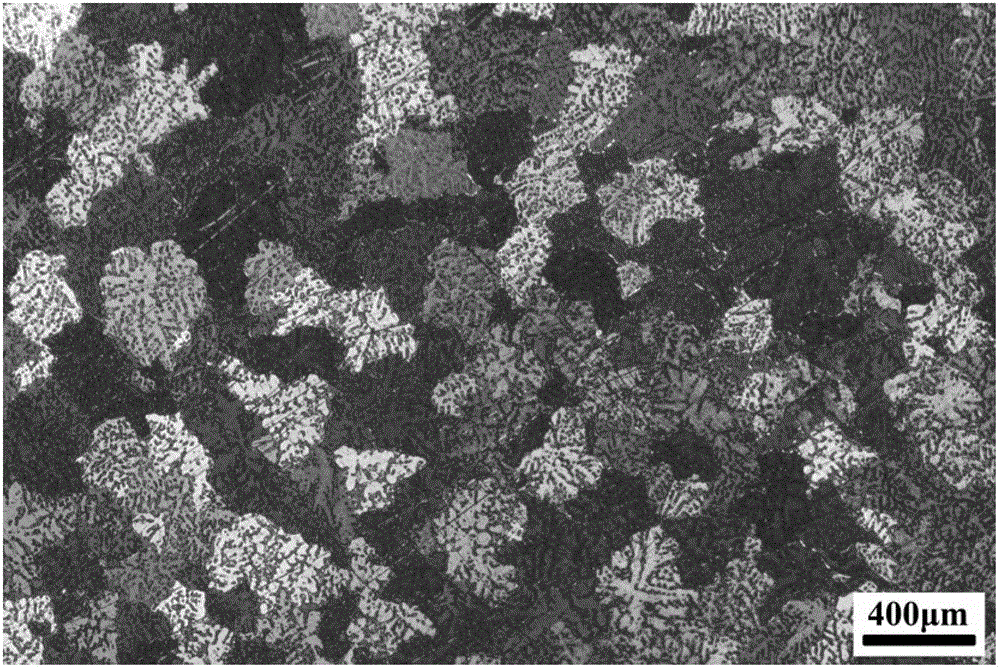

Grain refiner for mg-al magnesium alloy and preparation method thereof

The invention discloses a grain refiner for magnesium-aluminum (Mg-Al) magnesium alloy and a preparation method thereof. The grain refiner consists of a calcium magnesium stannum (CaMgSn) intermediate compound and magnesium, wherein the weight content of impurities is less than or equal to 0.3 percent; and the CaMgSn intermediate compound with small granularity is used as a heterogeneous nucleation core of a substrate in solidification, the formed crystal particle is fine, the addition quantity is stable, and the crystal particle is high efficient to refine and stable. The refiner is prepared in a vacuum induction furnace according to a reasonable formula, the burning of elements can be effectively avoided, the controllability of components is strong, CaMgSn can be dispersed and distributed in the substrate through squeezing, the size is fine, and the refining capacity is further improved. In addition, The AZ31 aluminum-magnesium alloy crystal particle is refined according to the formula and process disclosed by the invention, the size of the cast crystal particle of the magnesium alloy is 70 micrometers, and the crystal particle refining effect is remarkable compared with the size 170 micrometers of the crystal particle of the magnesium alloy without the crystal particle refiner under the same state.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com