A control device for automatic quantitative addition of gypsum soft tofu coagulant

A control device and coagulant technology, applied in dairy products, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as product quality fluctuations, coagulant addition time and dosage instability, etc., to achieve coagulant addition time and the effect of adding a stable amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

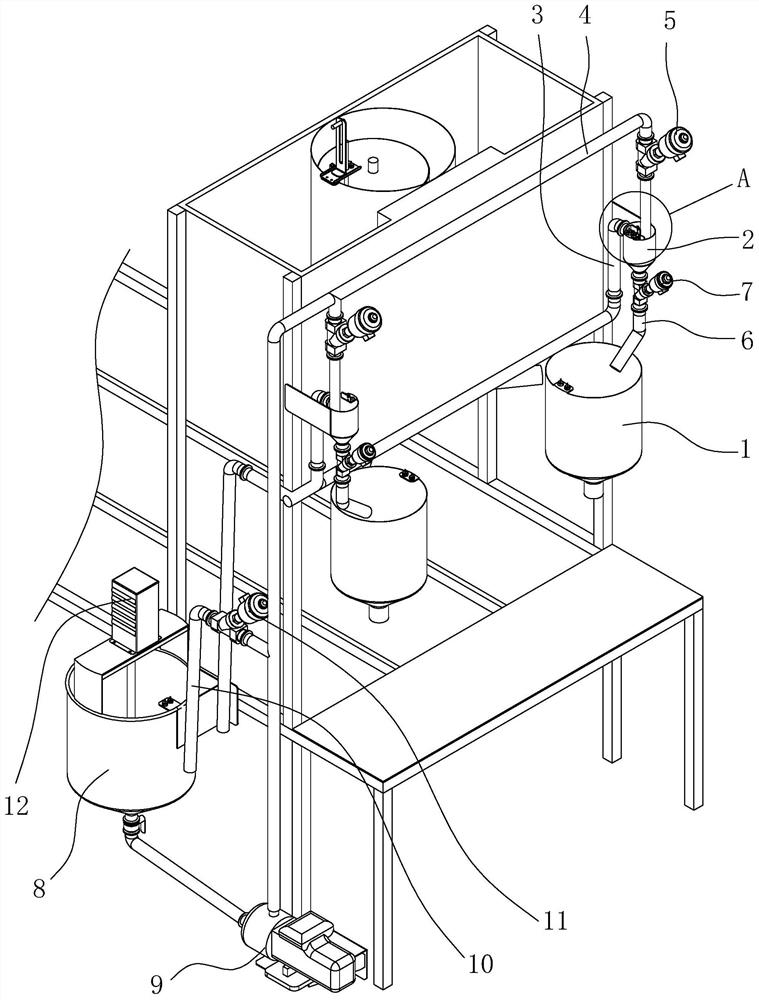

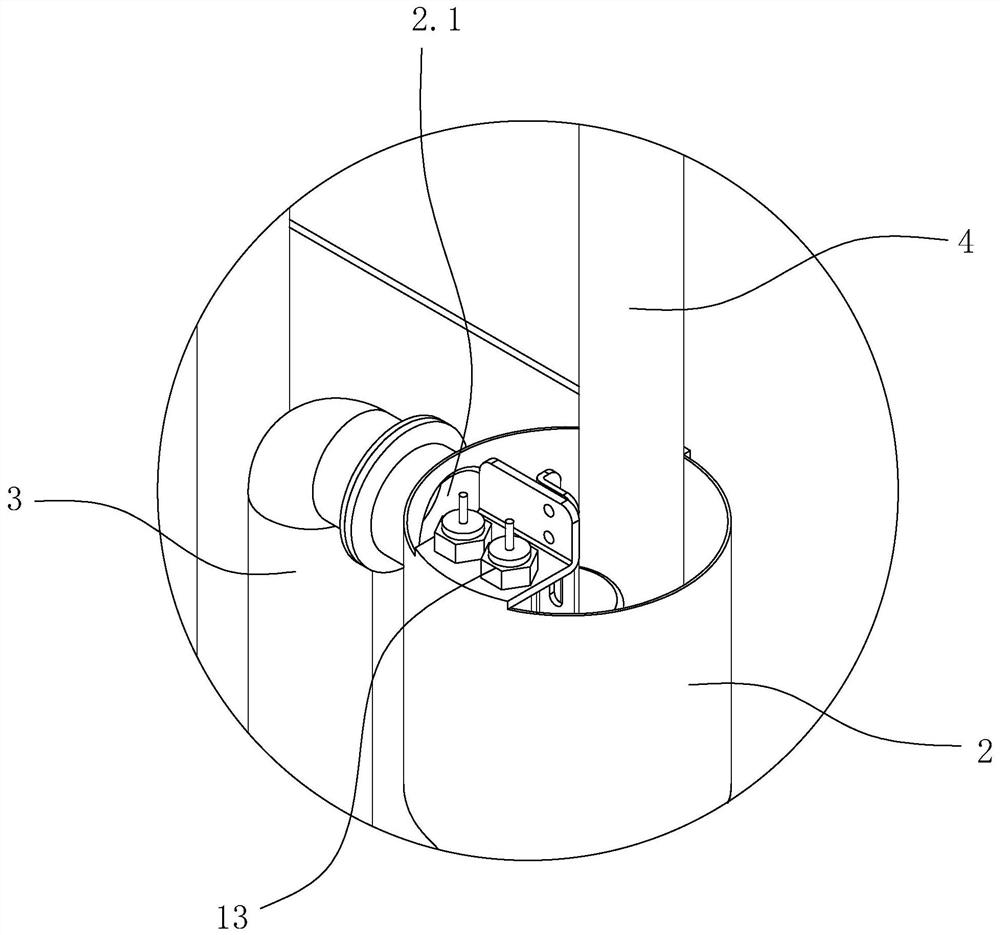

[0076] Specific embodiment one: as figure 1 , figure 2 As shown, a gypsum soft tofu coagulant automatic quantitative addition control device includes a frame, a coagulant quantitative bucket 2, a coagulant return pipeline 3, a coagulant liquid level detection switch 13, a coagulant supply pipeline 4 and a coagulant blanking pipeline6. The frame is provided with a soybean milk bucket 1. In the present embodiment, the bottom of the soybean milk bucket is provided with a discharge port, the discharge port is provided with a discharge solenoid valve, and the upper end of the soybean milk bucket is open.

[0077] The coagulant quantitative bucket 2 is positioned above the soybean milk bucket, and the upper part of the side wall of the coagulant quantitative bucket is provided with an overflow port 2.1. In the present embodiment, the upper end of the coagulant quantitative bucket is open. One end of the coagulant return pipe 3 communicates with the overflow port.

[0078] The c...

specific Embodiment 2

[0089] Specific embodiment two, all the other structures of this embodiment refer to specific embodiment one, and its difference is:

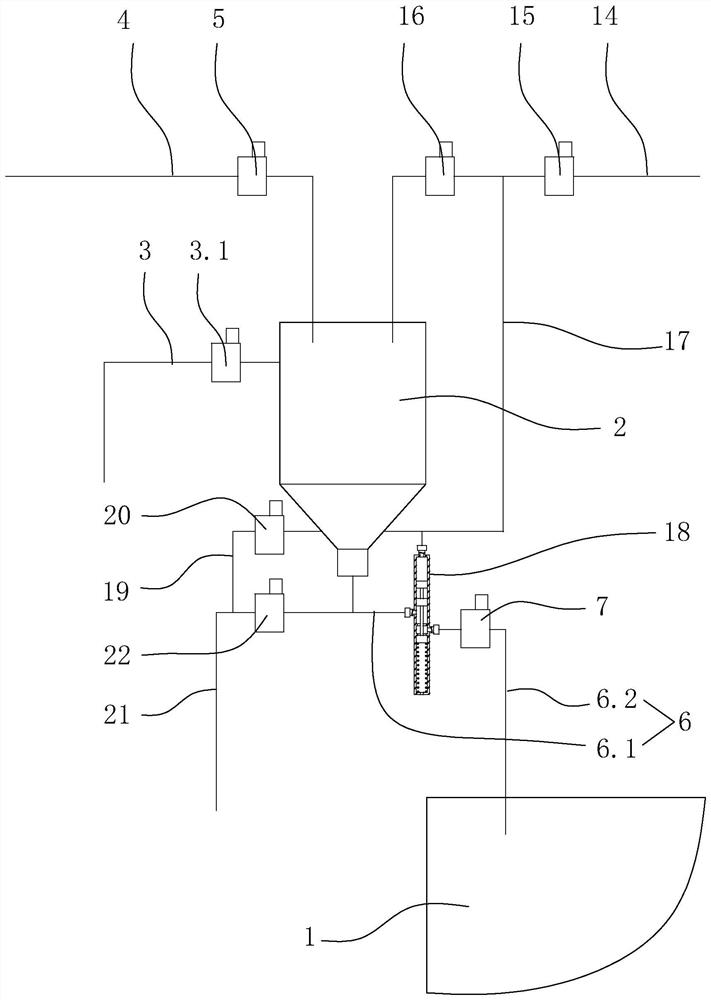

[0090] Such as image 3 As shown, a gypsum soft tofu coagulant automatic quantitative addition control device also includes a coagulant quantitative barrel cleaning device.

[0091] The coagulant quantitative bucket cleaning device includes a water supply pipeline 14 and a drainage pipeline 21 . The water supply pipeline is provided with a first water supply solenoid valve 15 . One end of the water supply pipeline communicates with the upper end of the coagulant quantitative barrel. The drain pipe is provided with a drain electromagnetic valve 22, and one end of the drain pipe communicates with the bottom of the coagulant quantitative barrel. A return pipe solenoid valve 3.1 is provided on the coagulant return pipe, and the return pipe solenoid valve is close to the overflow port.

[0092] Although the excess coagulant in the coagulant quan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com