Grain refiner for mg-al magnesium alloy and preparation method thereof

A grain refiner and magnesium alloy technology are applied in the field of production and processing of alloy materials, which can solve the problem of inability to meet the needs of grain refinement of aluminum-containing magnesium alloys, achieve a remarkable grain refinement effect, and improve the nucleation rate. , The effect of adding a stable amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

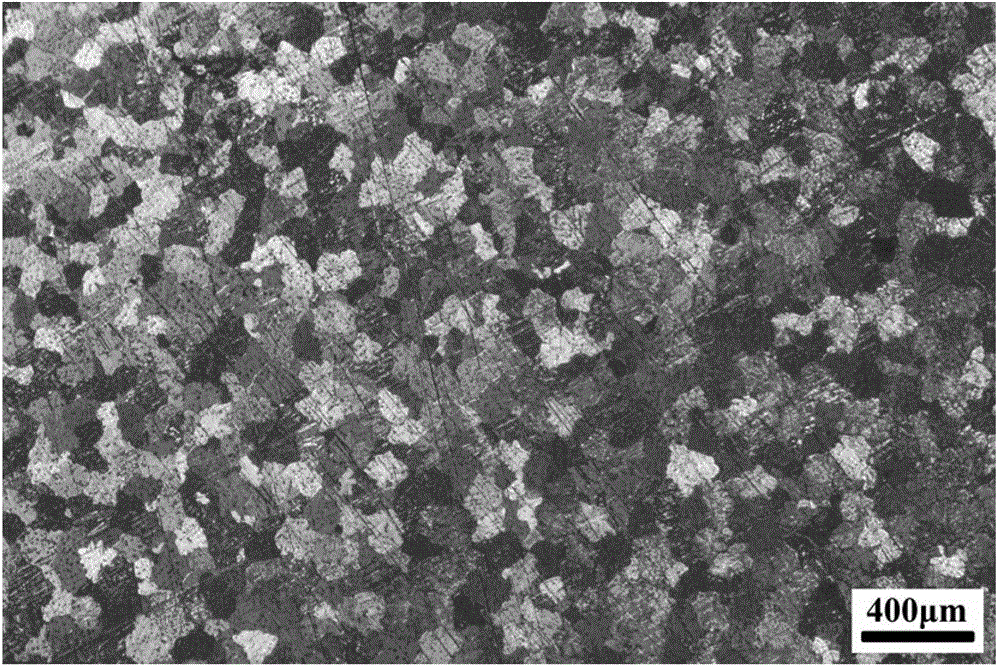

Embodiment 1

[0039] The grain refiner for Mg-Al series magnesium alloy of this embodiment is composed of CaMgSn intermediate compound and Mg, wherein the weight content of impurities (Mn, Fe, Si, Ni and Cu) is ≤0.3%.

[0040] Prepare the grain refiner for the Mg-Al series magnesium alloy according to the following steps:

[0041] a) According to the formula of the components Ca 0.6%, Sn 1.9%, and the balance Mg, take Ca and Mg and put them into a vacuum induction furnace with an inert gas. The addition of element Ca is realized by adding Mg-20Ca master alloy, Heat to 720°C, keep warm until the loaded material is completely melted, and stir evenly, then add Sn according to the formula amount, keep warm at 720°C until completely melted, stir evenly to fully react the elements, and obtain an alloy melt;

[0042] b) Clean the iron mold with an inner diameter of 85mm and a height of 350mm, and preheat it to 300°C and keep it warm for 10 minutes to make the temperature of the entire mold uniform...

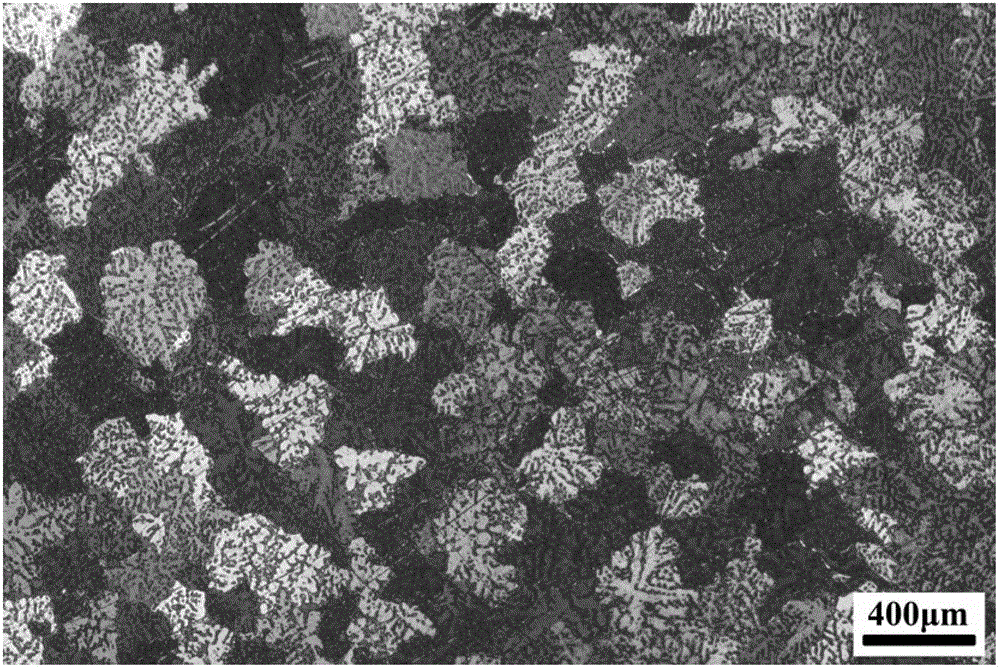

Embodiment 2

[0060] Prepare the grain refiner for the Mg-Al series magnesium alloy according to the following steps:

[0061] a) According to the formula of the components Ca 0.3%, Sn 0.95%, and the balance Mg, the Ca and Mg are loaded into a vacuum induction furnace with an inert gas, and the addition of the element Ca is realized by adding the Mg-20Ca master alloy, Heat to 720°C, keep warm until the loaded material is completely melted, and stir evenly, then add Sn according to the formula amount, keep warm at 720°C until completely melted, stir evenly to fully react the elements, and obtain an alloy melt;

[0062] b) Clean the iron mold with an inner diameter of 85mm and a height of 350mm, and preheat it to 300°C and keep it warm for 10 minutes to make the temperature of the entire mold uniform. Then, the alloy melt, which was completely melted, stirred and kept warm for 30 minutes, was cast into the preheated iron film under the protection of argon. After being completely solidified, ...

Embodiment 3

[0076] Prepare the grain refiner for the Mg-Al series magnesium alloy according to the following steps:

[0077] a) Take Ca and Mg according to the formula of element weight percentage components Ca3%, Sn9.5%, surplus Mg and pack into a vacuum induction furnace with an inert gas, the addition of element Ca is realized by adding Mg-20Ca master alloy, Heat to 720°C, keep warm until the loaded material is completely melted, and stir evenly, then add Sn according to the formula amount, keep warm at 720°C until completely melted, stir evenly to fully react the elements, and obtain an alloy melt;

[0078] b) Clean the iron mold with an inner diameter of 85mm and a height of 350mm, and preheat it to 300°C and keep it warm for 10 minutes to make the temperature of the entire mold uniform. Then, the alloy melt, which was completely melted, stirred and kept warm for 30 minutes, was cast into the preheated iron film under the protection of argon. After being completely solidified, the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com