An efficient method for grain refinement of aluminum and aluminum alloys

A grain refining, aluminum alloy technology, applied in the field of metal materials, can solve the problems of low particle utilization rate, limited refining effect, surface scratches on aluminum and aluminum alloy sheet structural parts, etc., and achieve stable grain refining effect. , Improve the effect of grain refinement and the effect of high grain refinement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, an efficient method for grain refinement of aluminum and aluminum alloys, the steps are as follows:

[0027] (1) Add 1kg of Al-Zn-Mg-Cu aluminum alloy ingots into two crucibles respectively, heat and melt and raise the temperature to 750°C to form two aluminum melts;

[0028] (2) adding 0.2% Ti and 0.04% B accounting for the weight of the aluminum melt to the above two aluminum melts in the form of an Al-Ti alloy (or pure Ti) and an Al-B alloy, Stir and keep warm for 20min;

[0029] (3) Pour the alloy melt containing B into the alloy melt containing Ti, so that the two melts are fully mixed;

[0030] (4) Adjust the temperature of the mixed melt to 700°C ± 20°C, and keep it warm for 5 minutes; keep it warm at a specific temperature of 720°C ± 20°C, its function is to adjust the size distribution of the core particles in the melt.

[0031] (5) Pour the mixed melt into a mold to cool and solidify to form an Al-Zn-Mg-Cu aluminum alloy ingot.

[0032] ...

Embodiment 2

[0034] In this embodiment, a highly efficient method for grain refinement of aluminum and aluminum alloys, the steps are as follows:

[0035] (1) Add 1kg of Al-Zn-Mg-Cu aluminum alloy ingots into two crucibles respectively, heat and melt and raise the temperature to 680°C to form two aluminum melts;

[0036] (2) adding 0.04% Ti and 0.008% B accounting for the weight of the aluminum melt to the two aluminum melts in the form of an Al-Ti alloy (or pure Ti) and an Al-B alloy, Stir and keep warm for 20min;

[0037] (3) Pour the alloy melt containing B into the alloy melt containing Ti, so that the two melts are fully mixed;

[0038] (4) Adjust the temperature of the mixed melt to 700°C±20°C and keep it warm for 5 minutes;

[0039] (5) Pour the mixed melt into a mold to cool and solidify to form an Al-Zn-Mg-Cu aluminum alloy ingot.

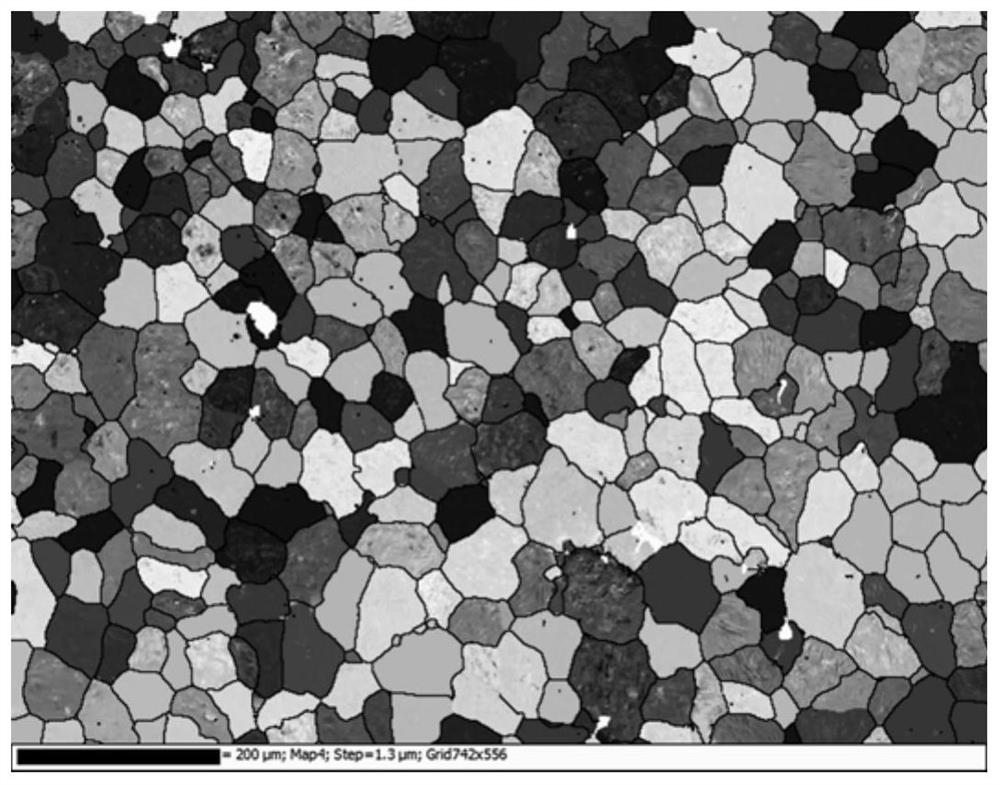

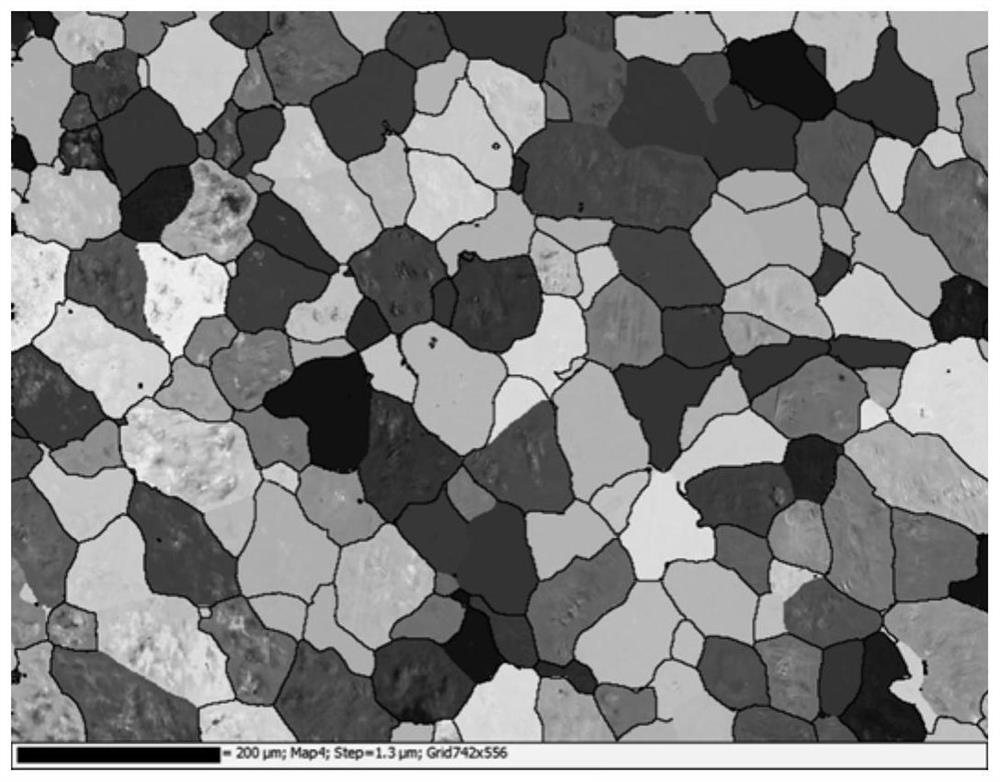

[0040] The structure and morphology of the Al-Zn-Mg-Cu aluminum alloy prepared in this example has an average grain size of about 45.2 μm, which is...

Embodiment 3

[0042] In this embodiment, a highly efficient method for grain refinement of aluminum and aluminum alloys, the steps are as follows:

[0043] (1) Add 1kg of Al-Zn-Mg-Cu aluminum alloy ingots into two crucibles respectively, heat and melt and raise the temperature to 720°C to form two aluminum melts;

[0044] (2) adding 0.04% Ti and 0.008% B accounting for the weight of the aluminum melt to the two aluminum melts in the form of an Al-Ti alloy (or pure Ti) and an Al-B alloy, Stir and keep warm for 10 minutes;

[0045] (3) Pour the alloy melt containing B into the alloy melt containing Ti, so that the two melts are fully mixed;

[0046](4) Keep the mixed melt at 700°C±20°C for 5 minutes;

[0047] (5) Pour the mixed melt into a mold to cool and solidify to form an Al-Zn-Mg-Cu aluminum alloy ingot.

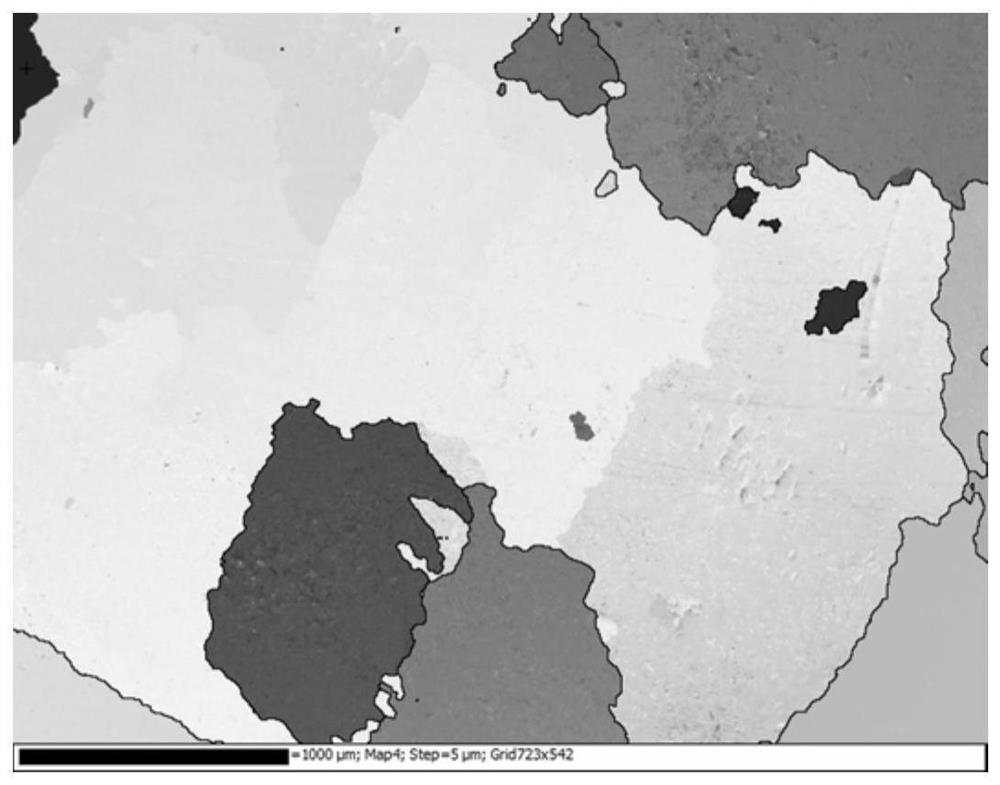

[0048] The structure and morphology of the Al-Zn-Mg-Cu aluminum alloy prepared in this example has an average grain size of about 42.5 μm, which is much smaller than the average gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com