High-strength Al-Cu-Mg-Mn-Er wrought aluminum alloy and preparation method thereof

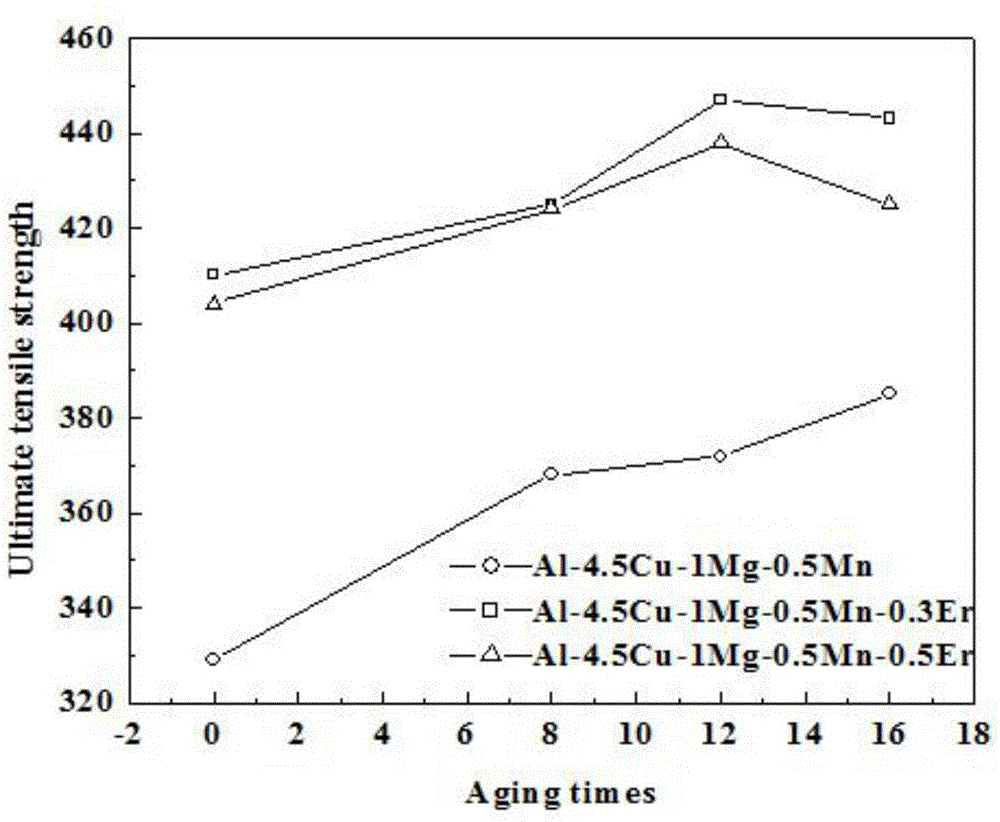

A technology of deformed aluminum alloy and al-cu-mg-mn-er, which is applied in the field of aluminum alloy materials, can solve the problems of insufficient mechanical properties of deformed aluminum alloy and inability to meet process requirements, and achieves shortening heat treatment time and fine grains. Grain effect, effect of high tensile and yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

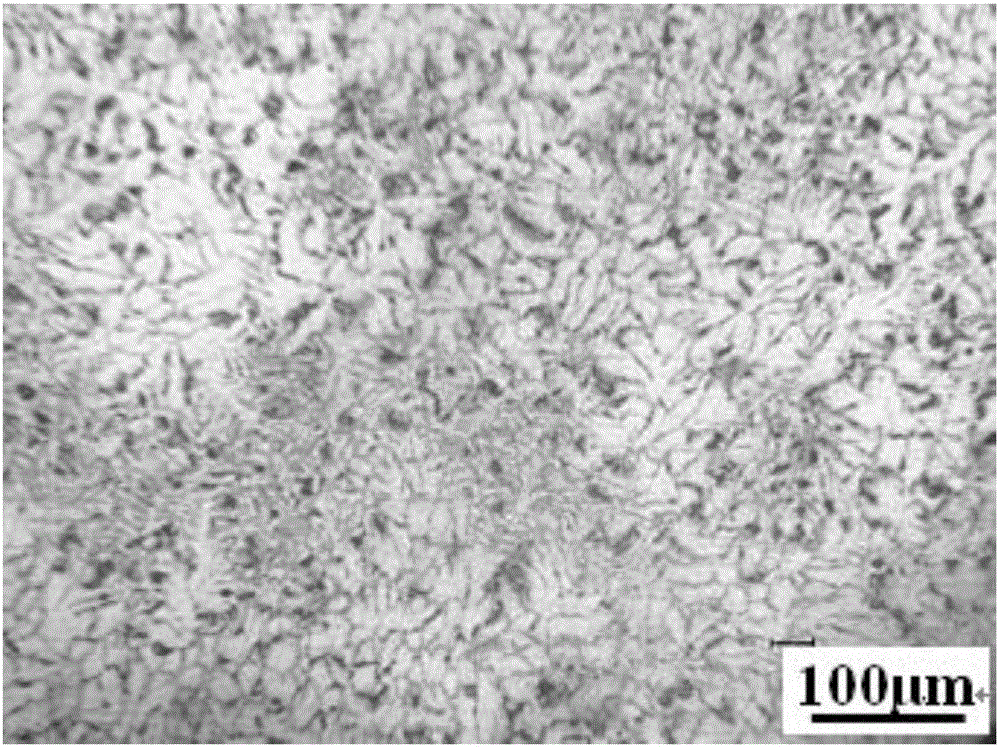

[0032] Embodiment 1 of the present invention provides a high-strength Al-Cu-Mg-Mn-Er deformed aluminum alloy, wherein the mass percentage of each content component is Cu: 4.3, Mg: 0.8, Mn: 0.5, Er: 0.3, and the balance is Al and inevitable impurities.

[0033] Specifically, the preparation method of the high-strength Al-4.3Cu-0.8Mg-0.5Mn-0.3Er deformed aluminum alloy includes the following steps:

[0034] (1) Smelting;

[0035] Prepare pure aluminum, pure zinc, pure magnesium, pure copper, Al-10% Mn master alloy and Al-4.77% Er master alloy as raw materials for smelting. Specifically, put pure aluminum and pure aluminum in the preheated crucible in turn Copper, Al-10% Mn master alloy and Al-4.77% Er master alloy, the melting temperature is 750 ℃, and stir, add pure magnesium after complete melting, stir evenly after melting, add refining agent to remove slag, adjust the temperature When the temperature reaches 720°C, the aluminum alloy ingot is poured after the temperature is kept ...

Embodiment 2

[0044] Embodiment 2 of the present invention provides a high-strength Al-Cu-Mg-Mn-Er deformed aluminum alloy, wherein the mass percentage of each content component is Cu: 4.4, Mg: 0.9, Mn: 0.5, Er: 0.4, and the balance is Al and inevitable impurities.

[0045] Specifically, the preparation method of the high-strength Al-4.4Cu-0.9Mg-0.5Mn-0.4Er deformed aluminum alloy includes the following steps:

[0046] (1) Smelting;

[0047] Prepare pure aluminum, pure zinc, pure magnesium, pure copper, Al-10% Mn master alloy and Al-4.77% Er master alloy as raw materials for smelting. Specifically, put pure aluminum and pure aluminum in the preheated crucible in turn Copper, Al-10% Mn master alloy and Al-4.77% Er master alloy, the melting temperature is 750 ℃, and stir, add pure magnesium after complete melting, stir evenly after melting, add refining agent to remove slag, adjust the temperature When the temperature reaches 720°C, the aluminum alloy ingot is poured after the temperature is kept ...

Embodiment 3

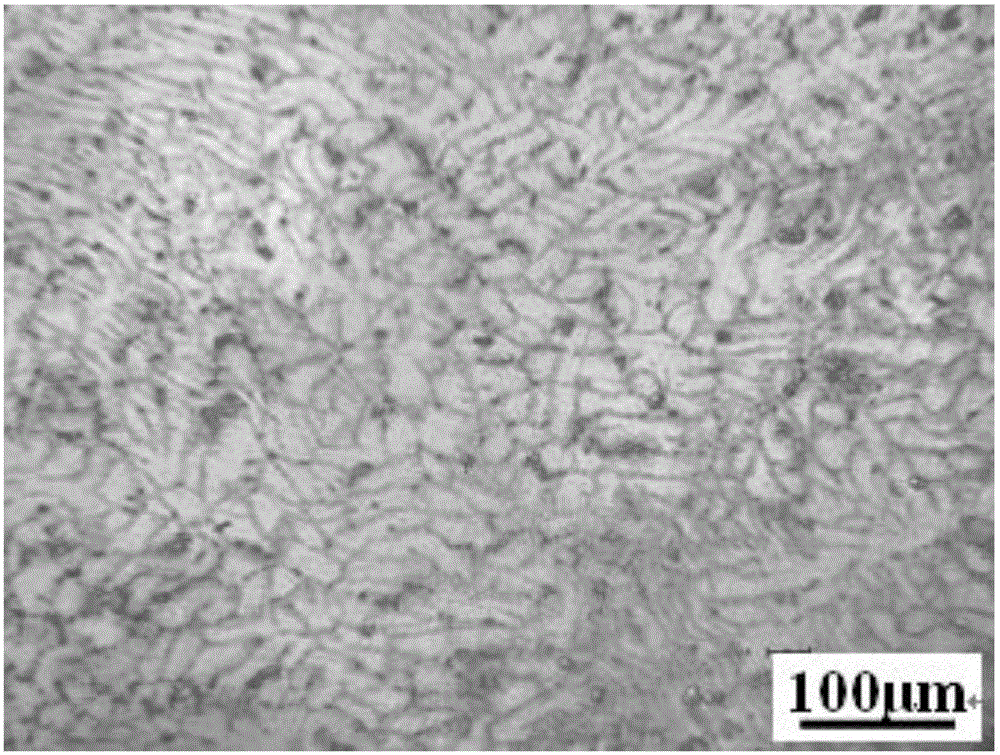

[0056] Embodiment 3 of the present invention provides a high-strength Al-Cu-Mg-Mn-Er deformed aluminum alloy, wherein the mass percentage of each content component is Cu: 4.5, Mg: 1.0, Mn: 0.5, Er: 0.5, and the balance is Al and inevitable impurities.

[0057] Specifically, the preparation method of the high-strength Al-4.5Cu-1Mg-0.5Mn-0.5Er deformed aluminum alloy includes the following steps:

[0058] (1) Smelting;

[0059] Prepare pure aluminum, pure zinc, pure magnesium, pure copper, Al-10% Mn master alloy and Al-4.77% Er master alloy as raw materials for smelting. Specifically, put pure aluminum and pure aluminum in the preheated crucible in turn Copper, Al-10% Mn master alloy and Al-4.77% Er master alloy, the melting temperature is 750 ℃, and stir, add pure magnesium after complete melting, stir evenly after melting, add refining agent to remove slag, adjust the temperature When the temperature reaches 720°C, the aluminum alloy ingot is poured after the temperature is kept fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength σb | aaaaa | aaaaa |

| Yield strength σ0.2 | aaaaa | aaaaa |

| Tensile strength σb | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com