Patents

Literature

43results about How to "Strong process versatility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recovering valuable metals from electroplating sludge

The invention relates the recovering metal method from electroplating sludge, comprising the following step: 1 using diluted acid to extract metal from electroplating sludge, filtering and separating, getting pickle liquor; 2 setting the copper from pickle liquor with sulphide at 85-100Deg.C, filtering and separating, getting cupric sulfide and deposition mother liquid; 3 adding 5-20% queous alkali into deposition mother liquid, and controlling the PH between 5.0 and 6.0, setting chromium and aluminium, filtering and getting the chromium-aluminium slag and the mother liquid containing iron, zinc and nickel. The method has the advantages of good technology versatility, easy controlling, simple equipment and low cost.

Owner:ZHEJIANG UNIV OF TECH +1

Method for comprehensively recovering valuable metals from electroplating waste mud

InactiveCN103343229AStrong process versatilityProcess conditions are easy to controlProcess efficiency improvementIonCopper

The invention relates to a method for comprehensively recovering valuable metals from electroplating waste mud. The method comprises the following steps of: leaching valuable metals contained in the electroplating waste mud by dilute sulphuric acid, and filtering and separating out acid-leaching slag and a filtrate; replacing copper ions in the filtrate by metallic iron, and filtering and separating copper powder and a filtrate; adding an alkali solution in the filtrate, adding a polymeric flocculant, controlling the pH value of the solution and reacting, and filtering and separating ferric hydroxide and a filtrate; adding the alkali solution in the filtrate, controlling the pH value of the solution and reacting, and filtering to obtain a chromium precipitate and a filtrate; adding the alkali solution in the filtrate, controlling the pH value of the solution, and converting zinc and nickel in the solution to nickel carbonate and zinc carbonate; and dissolving a nickel-zinc coprecipitate by the alkali solution, and filtering and separating out nickel carbonate and a sodium zincate solution, and concentrating and crystallizing the sodium zincate solution to obtain sodium zincate. The method disclosed by the invention is easy to control process conditions, low in treatment cost, and easy to realize large-scale production; the purpose of comprehensively recovering valuable metals is achieved by implementing harmless and resourceful treatment for the electroplating waste mud; and the recovery rate of copper is greater than 95%.

Owner:JIANGXI UNIV OF SCI & TECH

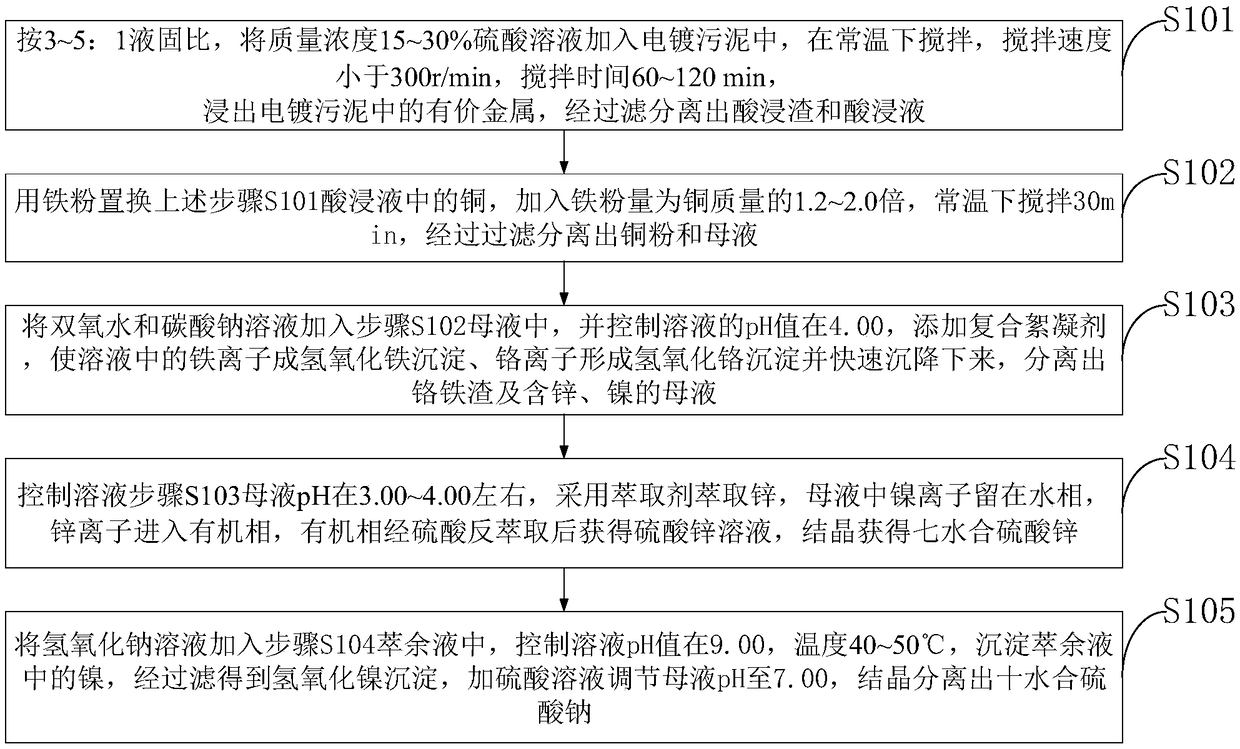

Method of comprehensively recycling valuable metals in plating sludge

The invention belongs to the technical field of plating sludge treatment and discloses a method of comprehensively recycling valuable metals in plating sludge. The method comprises: extracting value metals from plating sludge by leaching, and isolating acid leaching residue and acid leaching liquid; adding iron powder, stirring, and filtering to isolate copper powder and a mother liquid; adding hydrogen peroxide and sodium carbonate solution, adding a composite flocculating agent so that iron ions in the solution form iron hydroxide precipitate and chromium ions form chromium hydroxide precipitate, wherein the precipitates settle fast, and isolating ferrochromium slag and a mother liquid containing zinc and nickel; using P507 extracting agent to extract zinc in the mother liquid containingzinc and nickel, back-extracting an organic phase via sulfuric acid to obtain zinc sulfate solution, and crystallizing to obtain zinc sulfate septahydrate; adding the sodium hydroxide solution into nickel raffinate, filtering to obtain nickel hydroxide precipitate, adjusting mother liquid pH to 7 for the filtrate through sulfuric acid, and crystallizing to isolate sodium sulfate decahydrate. Precipitate washing liquids herein are cyclically used, emission of wastewater is decreased, and significant economic and social benefits are created.

Owner:JIANGXI UNIV OF SCI & TECH

Method for recovering valuable metals from electroplating sludge

The invention relates the recovering metal method from electroplating sludge, comprising the following step: 1 using diluted acid to extract metal from electroplating sludge, filtering and separating, getting pickle liquor; 2 setting the copper from pickle liquor with sulphide at 85-100Deg.C, filtering and separating, getting cupric sulfide and deposition mother liquid; 3 adding 5-20% queous alkali into deposition mother liquid, and controlling the PH between 5.0 and 6.0, setting chromium and aluminium, filtering and getting the chromium-aluminium slag and the mother liquid containing iron, zinc and nickel. The method has the advantages of good technology versatility, easy controlling, simple equipment and low cost.

Owner:ZHEJIANG UNIV OF TECH +1

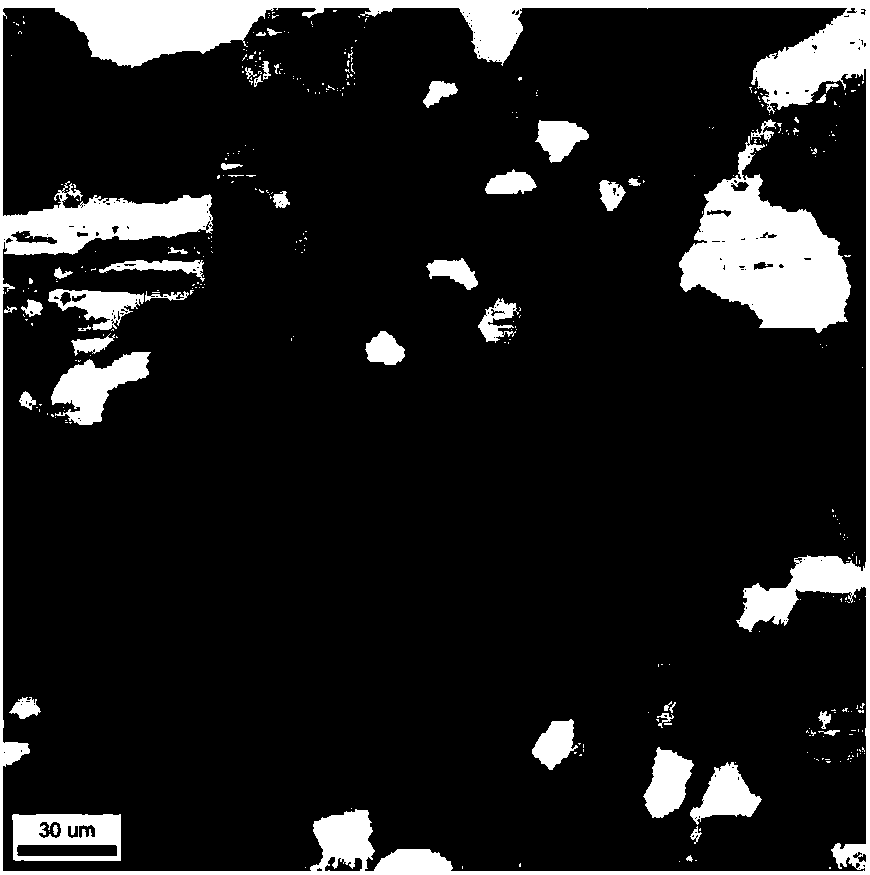

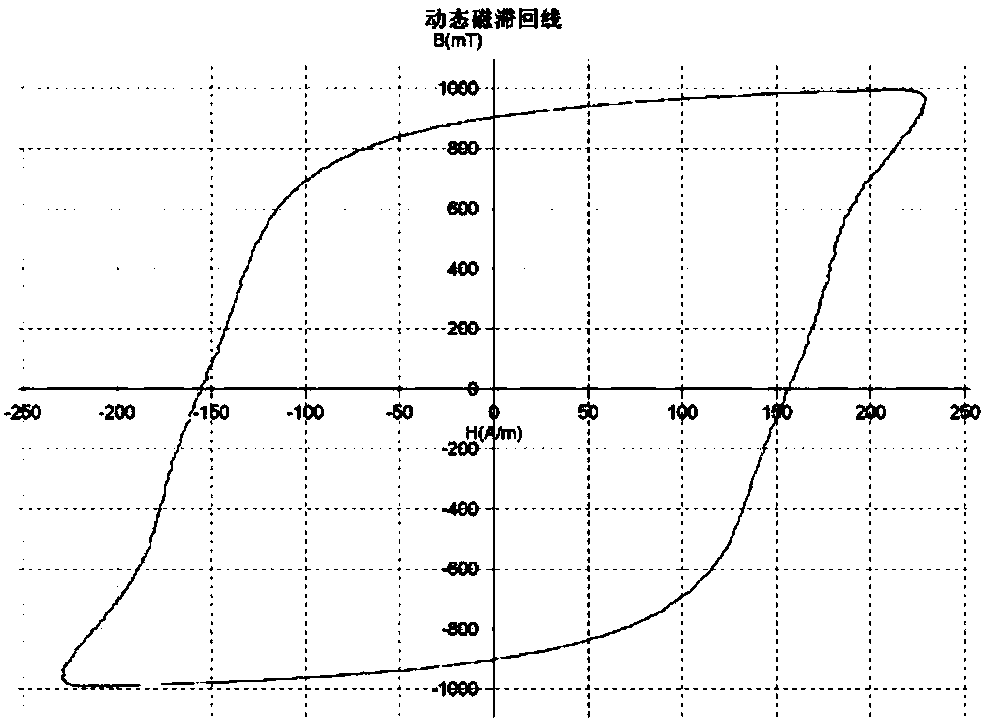

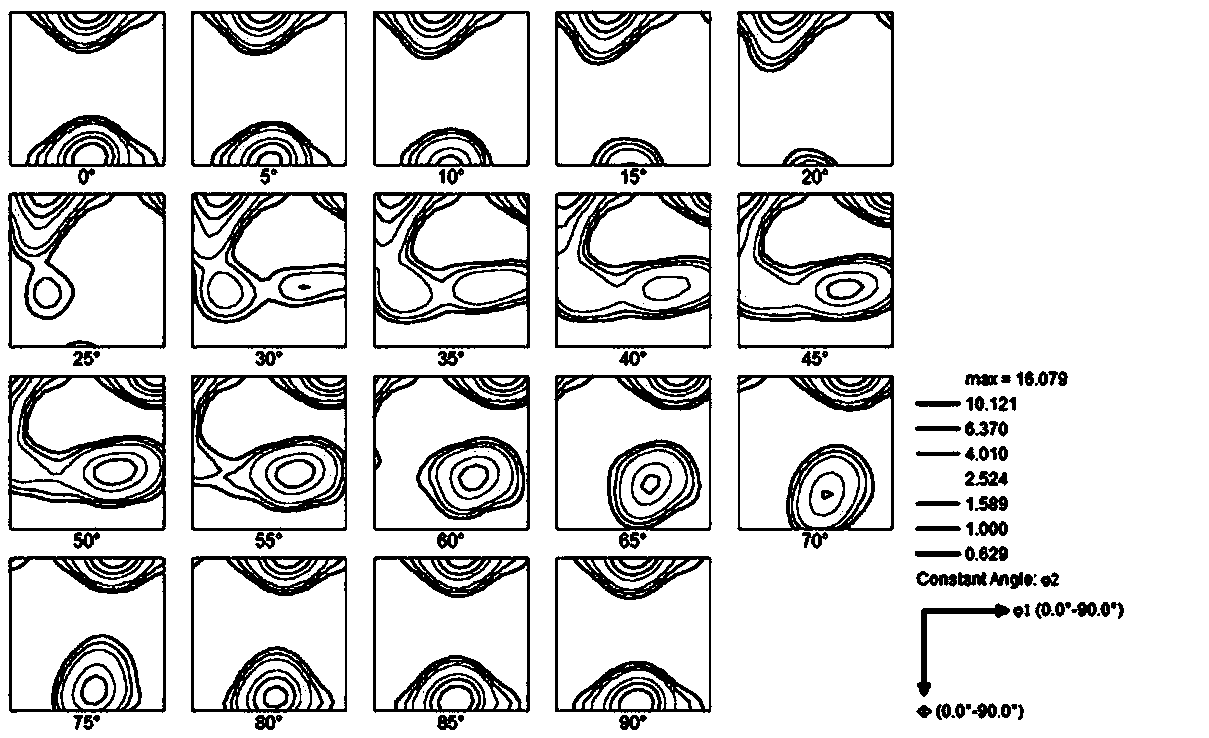

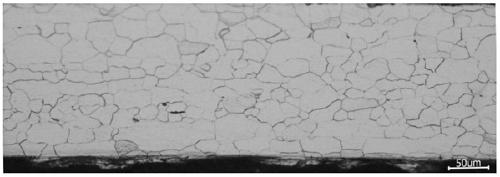

Preparation method of high-magnetic-strength thin-gauge non-oriented silicon steel

InactiveCN104294022ASignificantly improved magnetic senseSoft magnetic liftIngot castingMetallic materials

The invention belongs to the field of metal material processing and relates to high-magnetic-strength thin-gauge non-oriented silicon steel and a preparation method thereof. The preparation method of the high-magnetic-strength thin-gauge non-oriented silicon steel comprises the following steps: selecting a silicon steel ingot casting as a raw material, wherein the silicone steel ingot casting contains the following components (in percent by mass): 2.8-3.2% of Si, 0.025-0.045% of C, 0.05-0.35% of Mn, less than or equal to 0.008% of P, less than ore equal to 0.005% of N, less then or equal to 0.02% of S and balance of Fe and inevitable impurities, and volume percent of columnar crystals in the ingot casting is 50-100%; heating the silicon steel ingot casting to 1200-1350 DEG C, carrying out hot rolling, normalizing at the temperature of 1110-1150 DEG C, rolling until thickness is 0.12-0.2mm by adopting a two-stage cold-rolling method including intermediate annealing, then carrying out decarburizing annealing, and finally carrying out final annealing for 10-20 minutes at the temperature of 900-950 DEG C. The preparation method of the high-magnetic-strength thin-gauge non-oriented silicon steel has the advantages that a processing technology easier to implement is adopted and a thin-gauge non-oriented silicon steel product with magnetic strength B50 more than 1.73T is obtained.

Owner:UNIV OF SCI & TECH BEIJING

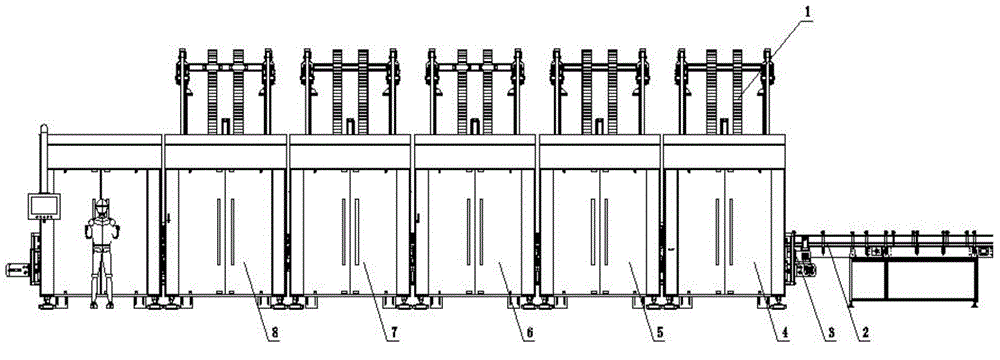

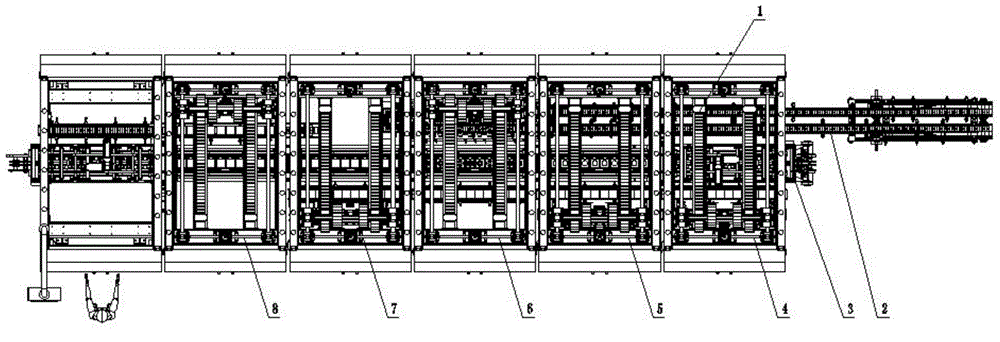

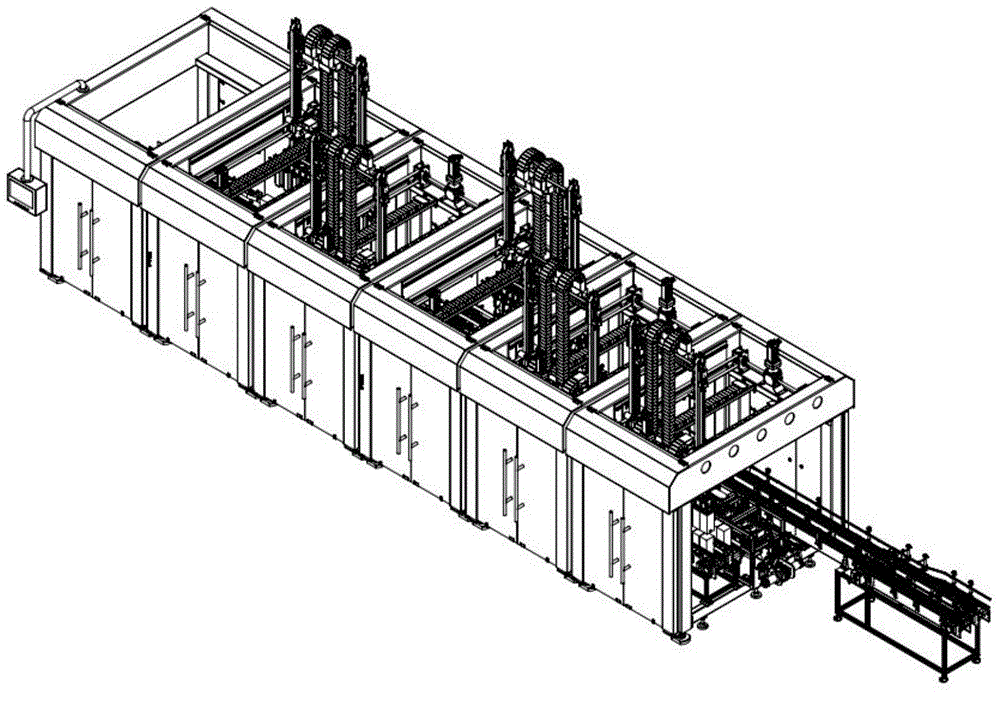

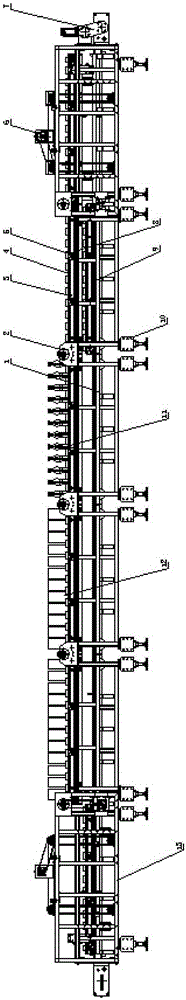

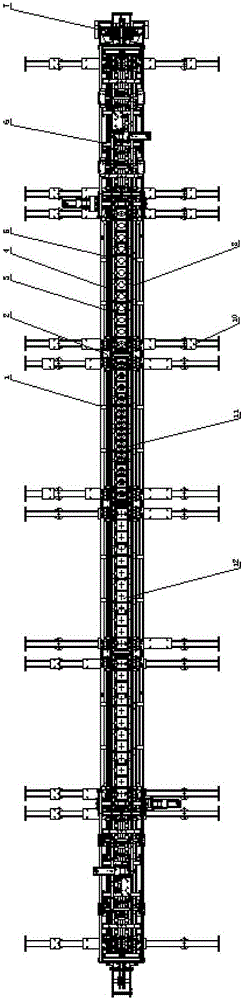

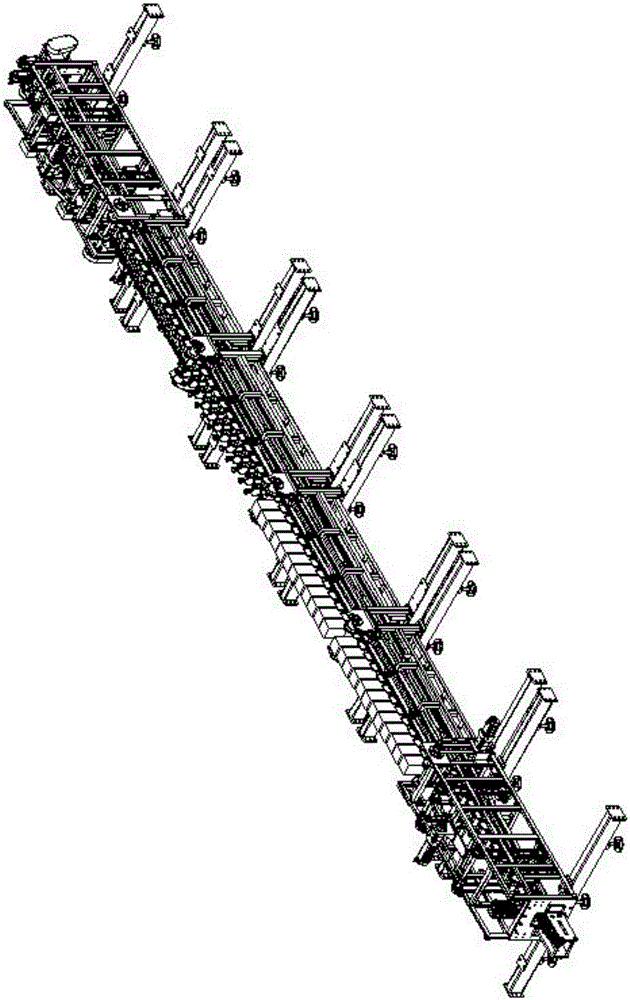

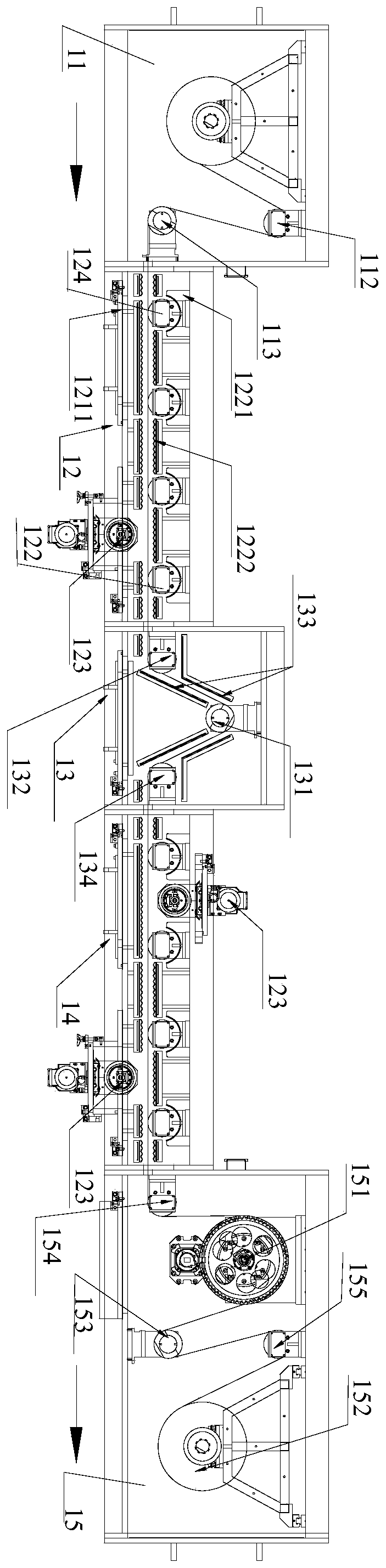

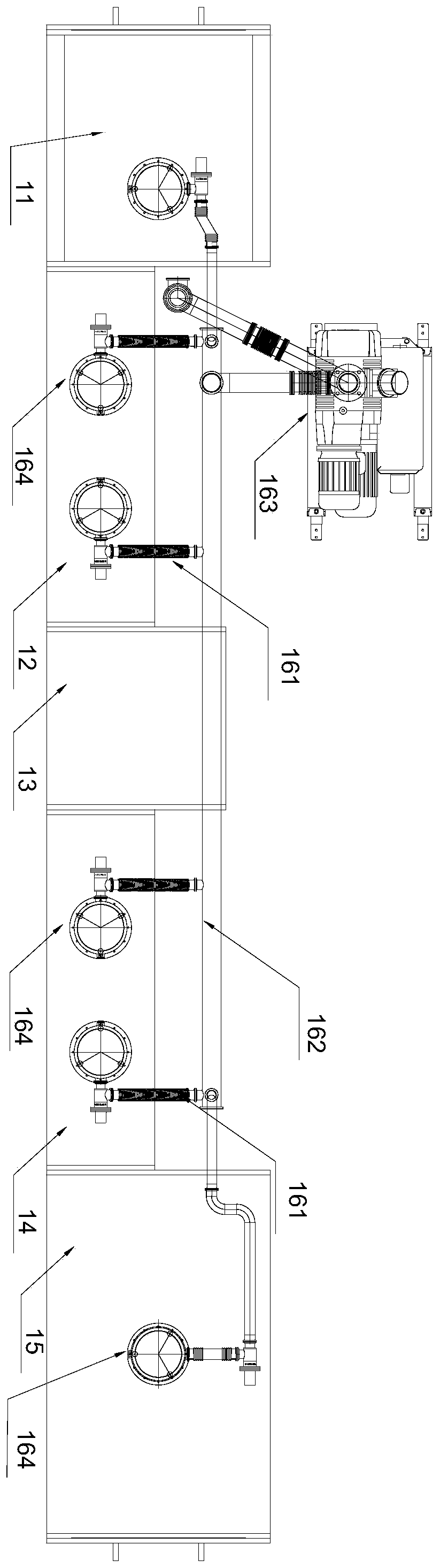

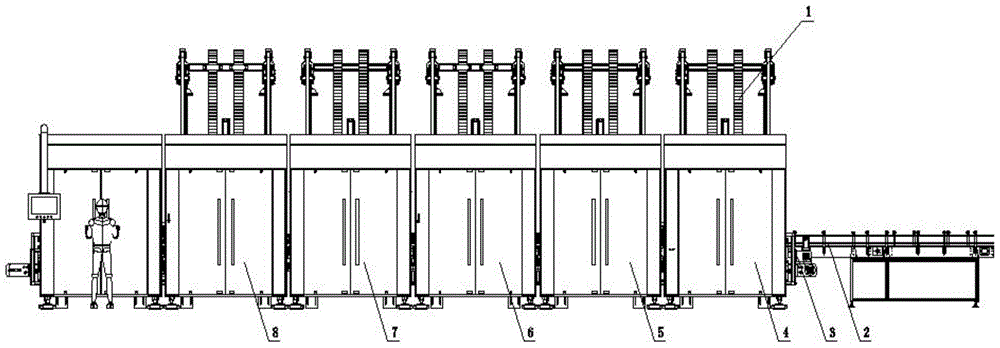

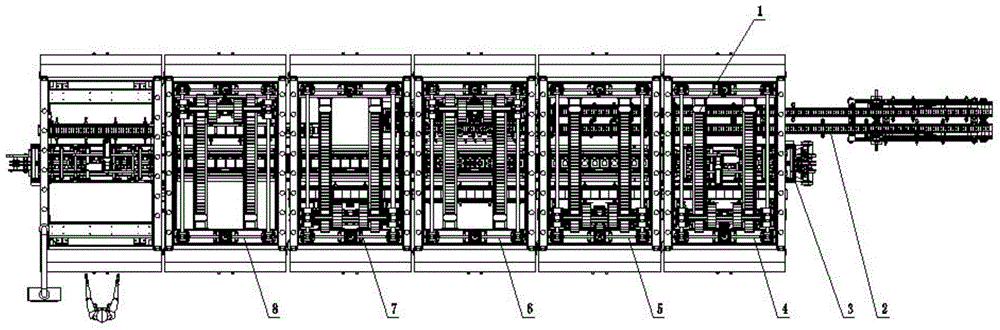

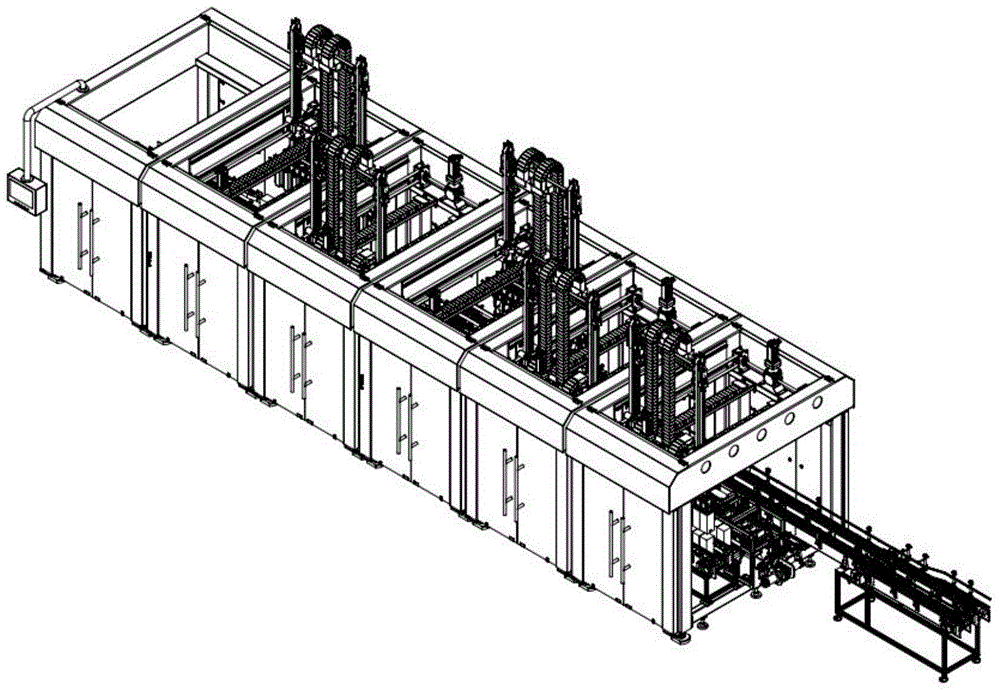

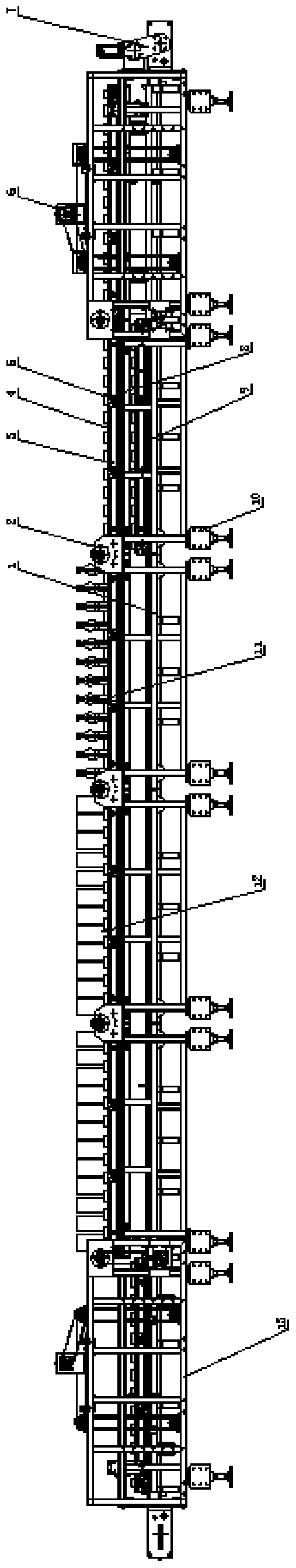

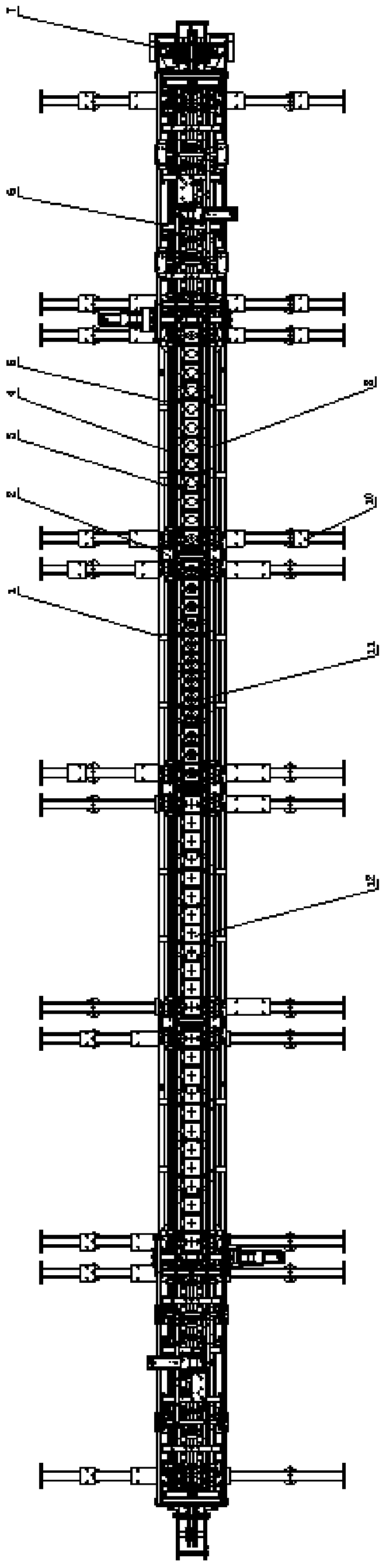

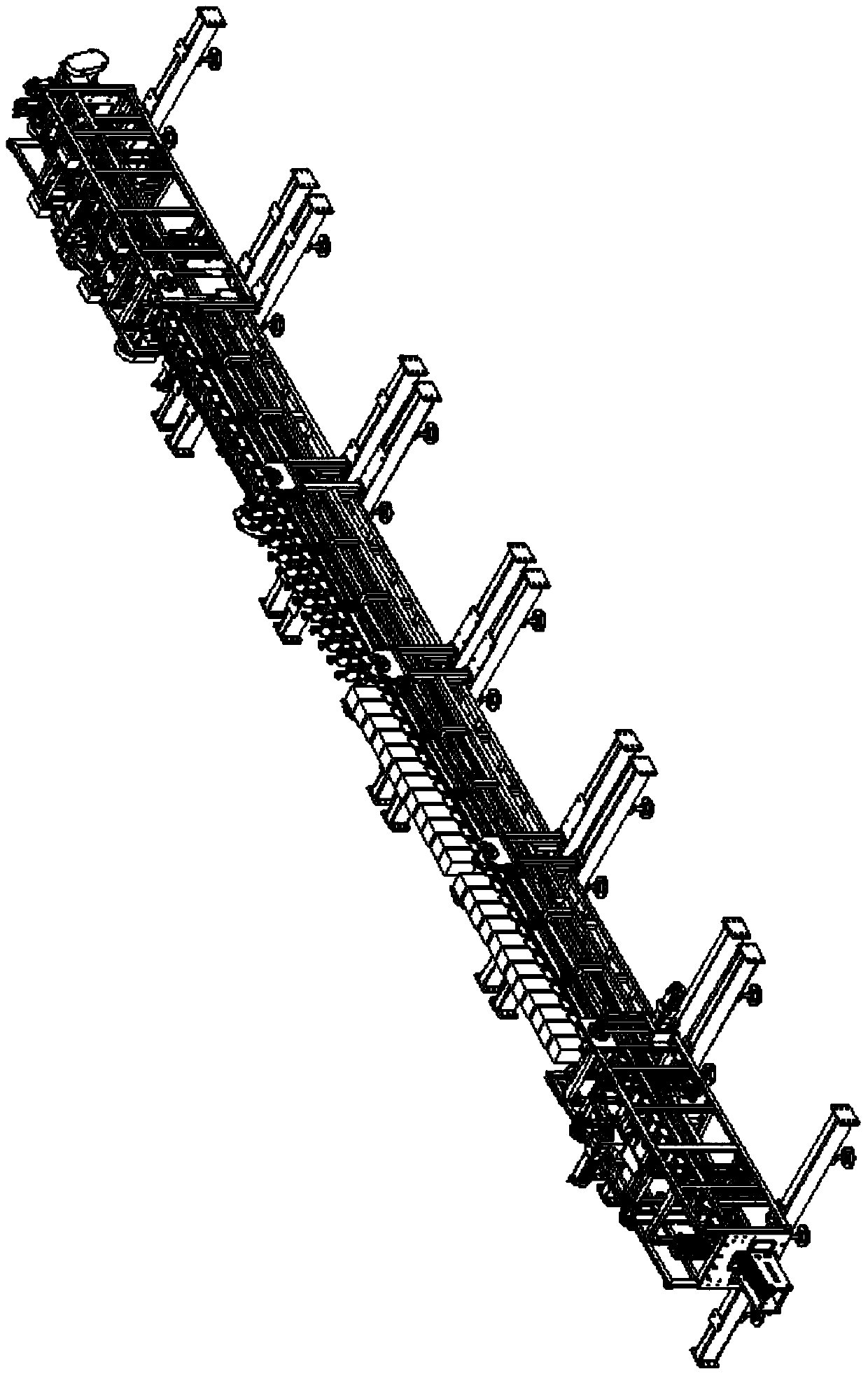

Gift box type white spirit automatic packing system

ActiveCN104986372AImprove packaging efficiencyGuaranteed packaging qualityPackaging bottlesModular designEngineering

The invention relates to a gift box type white spirit automatic packing system. The gift box type white spirit automatic packing system comprises a splitting module, a white spirit support feeding module, a bottle feeding module, a box cover buckling module and a gift box discharging module which are arranged in sequence. A double-servo moving mechanism is arranged at the top end of a door type frame of the splitting module, the white spirit support feeding module, the bottle feeding module, the box cover buckling module and the gift box discharging module. A circulation feeding mechanism is coaxially arranged in the middle of the inner sides of the splitting module, the white spirit support feeding module, the bottle feeding module, the box cover buckling module and the gift box discharging module in the horizontal transverse direction. The circulation feeding mechanism is controlled by a system program for circulation running for conveying of a support bottom. Conveying belts are horizontally arranged on the two longitudinal sides of the circulation feeding mechanism respectively, and the conveying belts on the two sides are used for conveying bottles and gift boxes respectively. According to the system, the modular design production is adopted, and the number of the modules is increased and reduced according to different technical processes. The system is widely applied to white spirit package and production, the packaging efficiency is improved, and the packaging quality of products is guaranteed.

Owner:TIANJIN XINJINJIA TECH DEV CO LTD

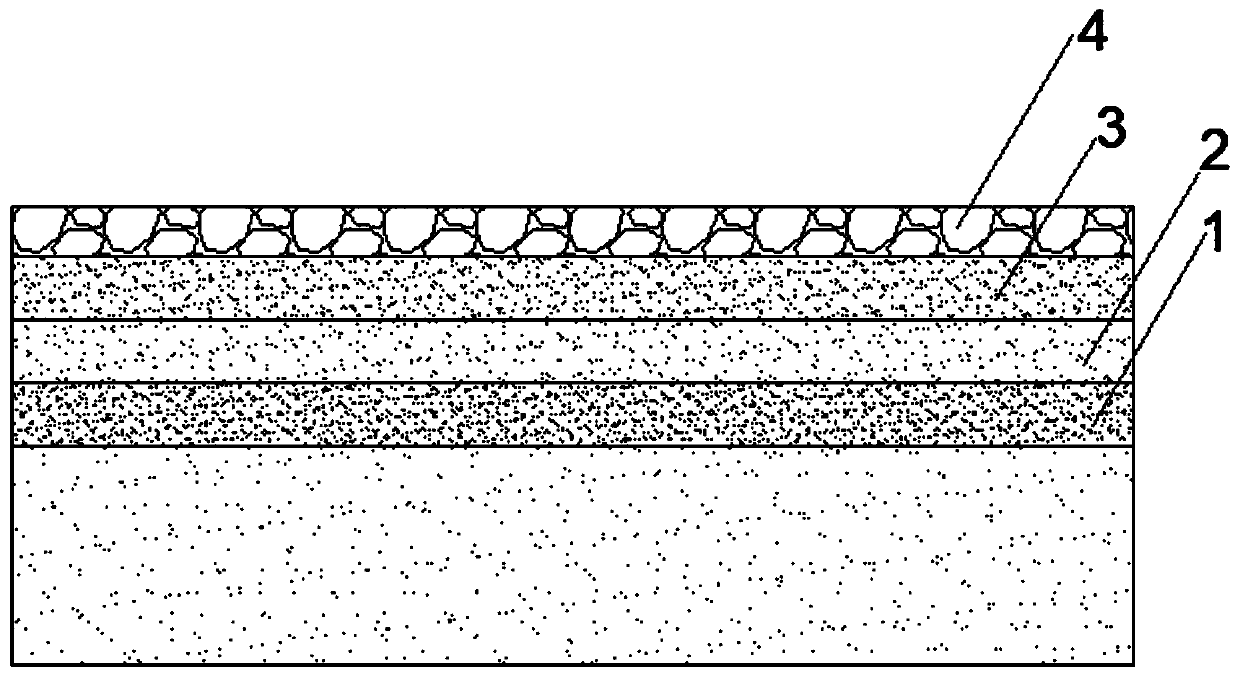

Self-luminous road pavement structure and construction method thereof

PendingCN110004796ANot easy to accumulate waterImprove close bondingIn situ pavingsSidewalk pavingsSurface layerChipseal

The invention discloses a self-luminous road pavement structure and a construction method thereof. The self-luminous road pavement structure comprises a water sealing layer, a water guiding layer, a permeable layer and a self-luminous surface layer, the water sealing layer, the water guiding layer, the permeable layer and the self-luminous surface layer are arranged from the bottom up in a layer-by-layer mode, the self-luminous surface layer is filled with artificial luminescent stone particles, road water removing can be accelerated through the structure, and the phenomena of instability of clearance and gravel embedded into a soil matrix are eliminated; and the construction method comprises the following steps that (1) the water sealing layer is poured; (2) the water guiding layer is paved; (3) the permeable layer is poured; and (4) the self-luminous surface layer is poured. According to the self-luminous road pavement structure and the construction method thereof, construction is convenient, universality of the technology is high, and cost engineering is saved.

Owner:ANHUI ZHONGYI NEW MATERIAL TECH CO LTD

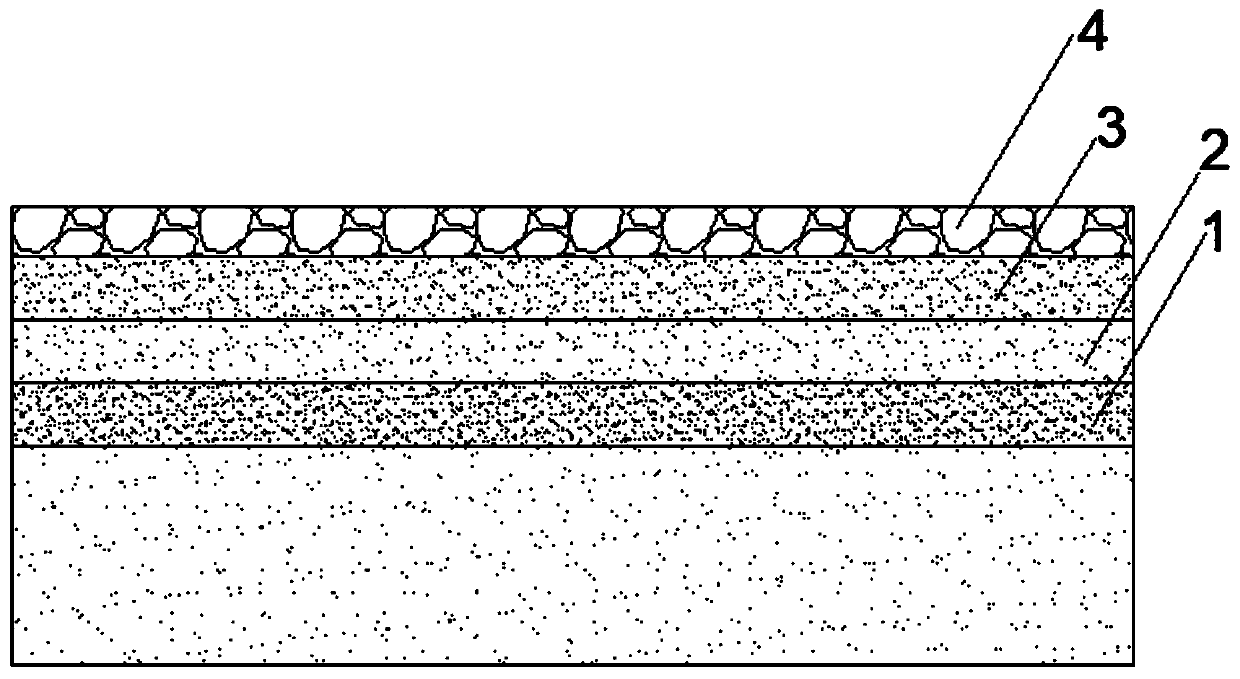

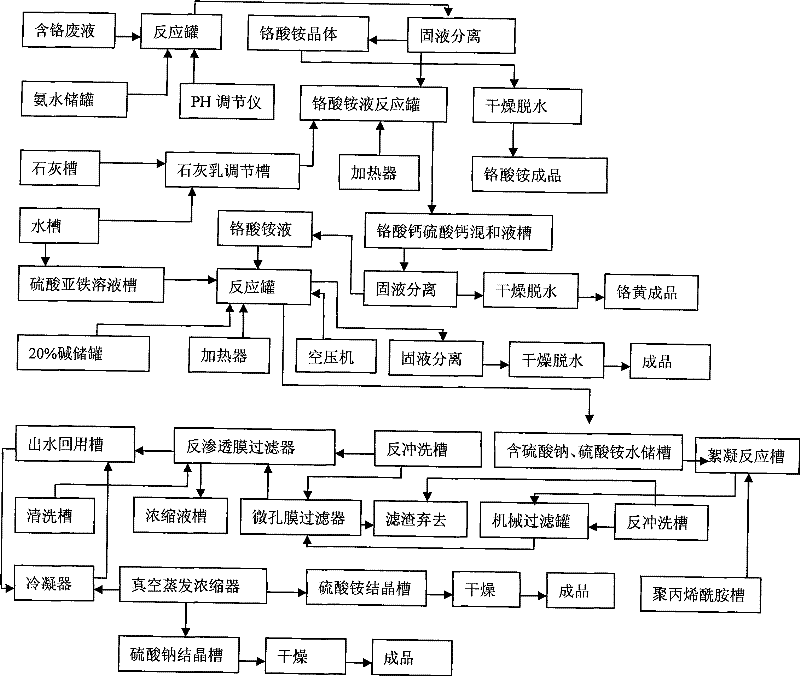

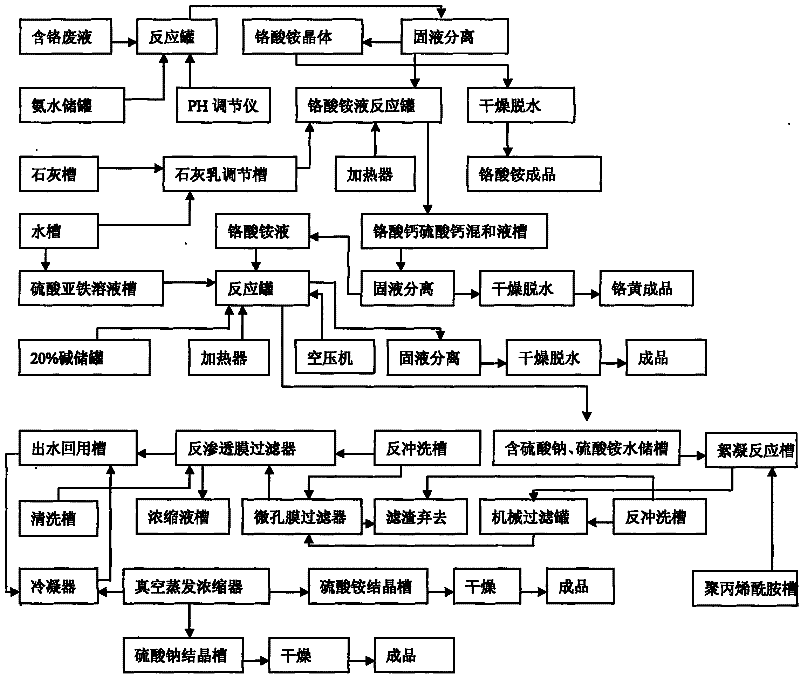

Zero emission treatment method of completely turning chromium-containing waste liquor into useable resources.

InactiveCN101618902AStrong process versatilityEasy to controlWater contaminantsWater/sewage treatment bu osmosis/dialysisLiquid wasteFiltration

The invention relates to a zero emission treatment method of completely turning chromium-containing waste liquor into useable resources. In the method, first enabling chromium-containing waste liquor to react with ammonia water to form ammonium chromate crystallized sediment; using sulphuric acid liquid to adjust pH value of mother liquor, then adding lime cream alkaline liquor to carry out neutralization reaction to generate cocrystallized sediment of calcium chromate and calcium sulphate; solid-liquid separating the liquid part and the sediment part; drying and dewatering the sediment part to obtain chrome yellow; adding ferrous sulphate to the liquid part to react and then carrying out atmospheric oxidation and solid-liquid separation to obtain the sediment part which is ferrite; carrying out filtration, concentration and cooling crystallization to respectively generate sodium sulphate crystallization and ammonium sulphate crystallization and then carrying out solid-liquid separation; drying and dewatering the sediment part and recovering the sodium sulphate and ammonium sulphate; mixing the liquid part and the liquid part before reverse osmosis membrance is filtered and then treating the mixture in recycling manner. The method of the invention not only features good commonality but also treats various conventional chromium-containing waste liquor; in addition, the method features easily controlled process conditions, simple equipment, easy realization of large-scale production, reduction of treatment cost, thus being a technology featuring reduction and decontamination for treating chromium-containing waste liquor as a usable resource.

Owner:刘文治 +2

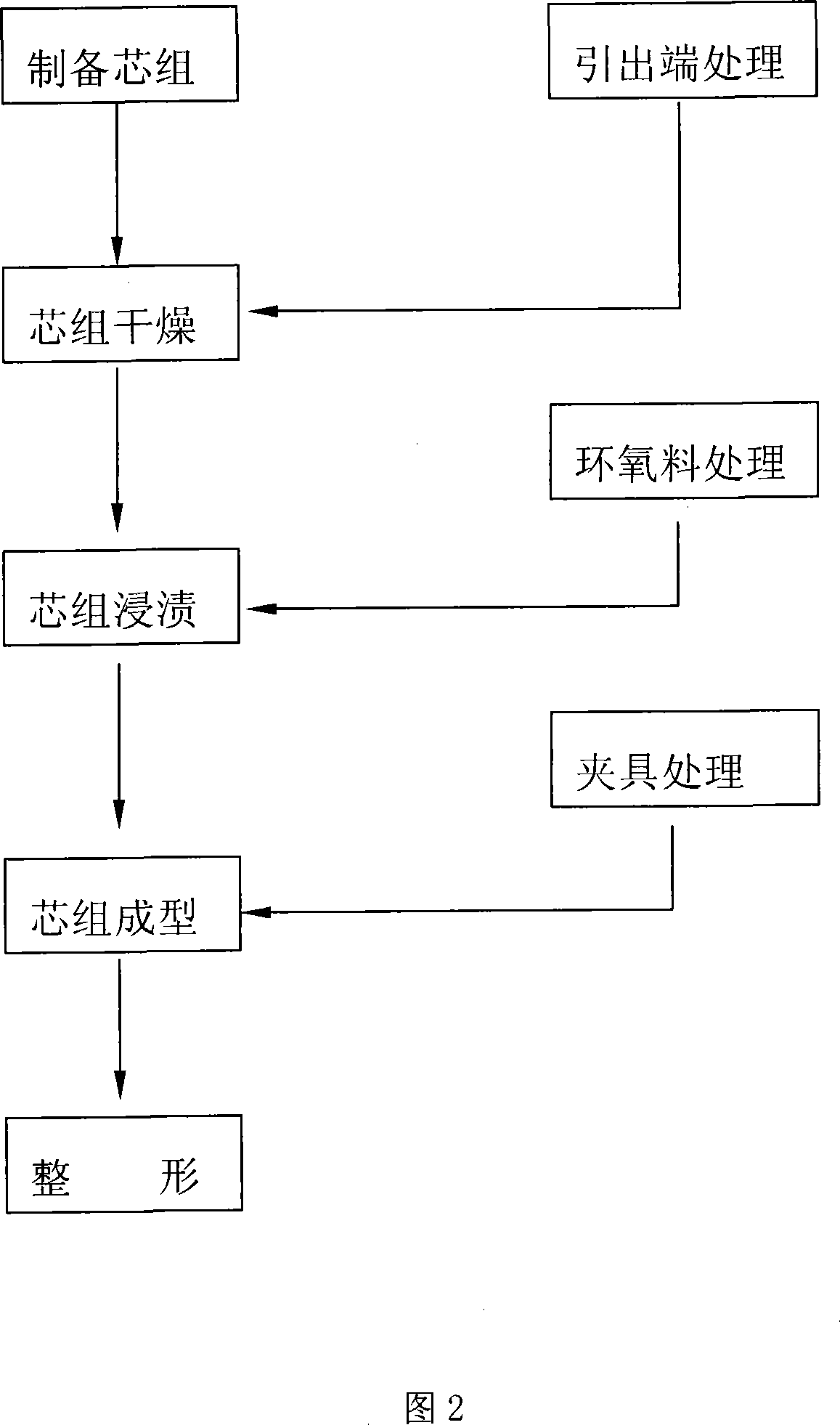

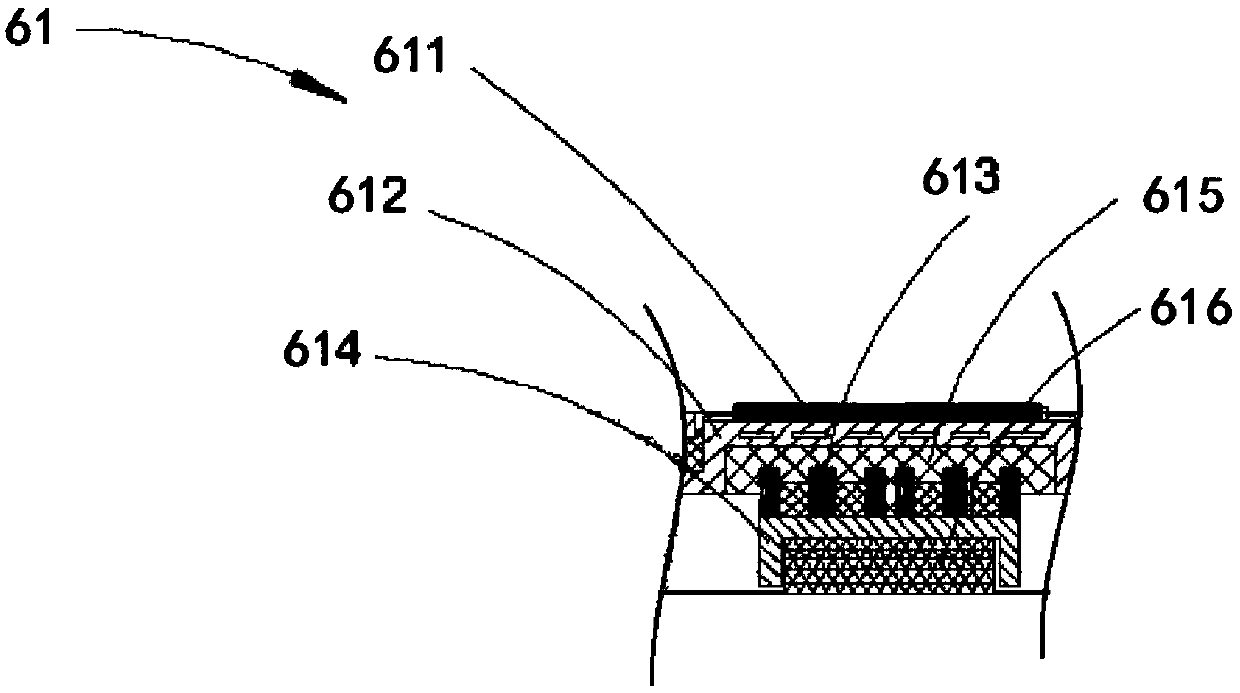

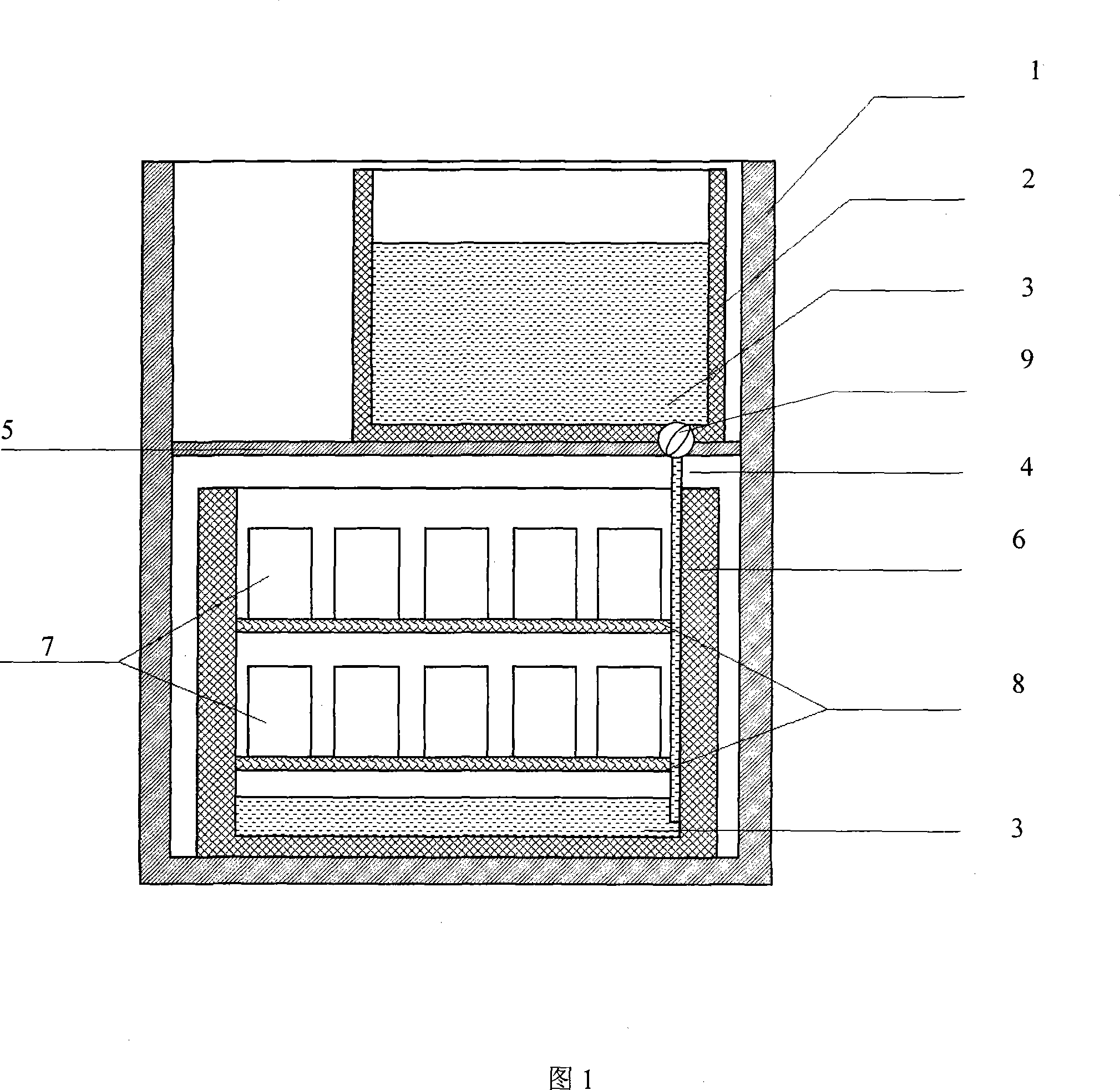

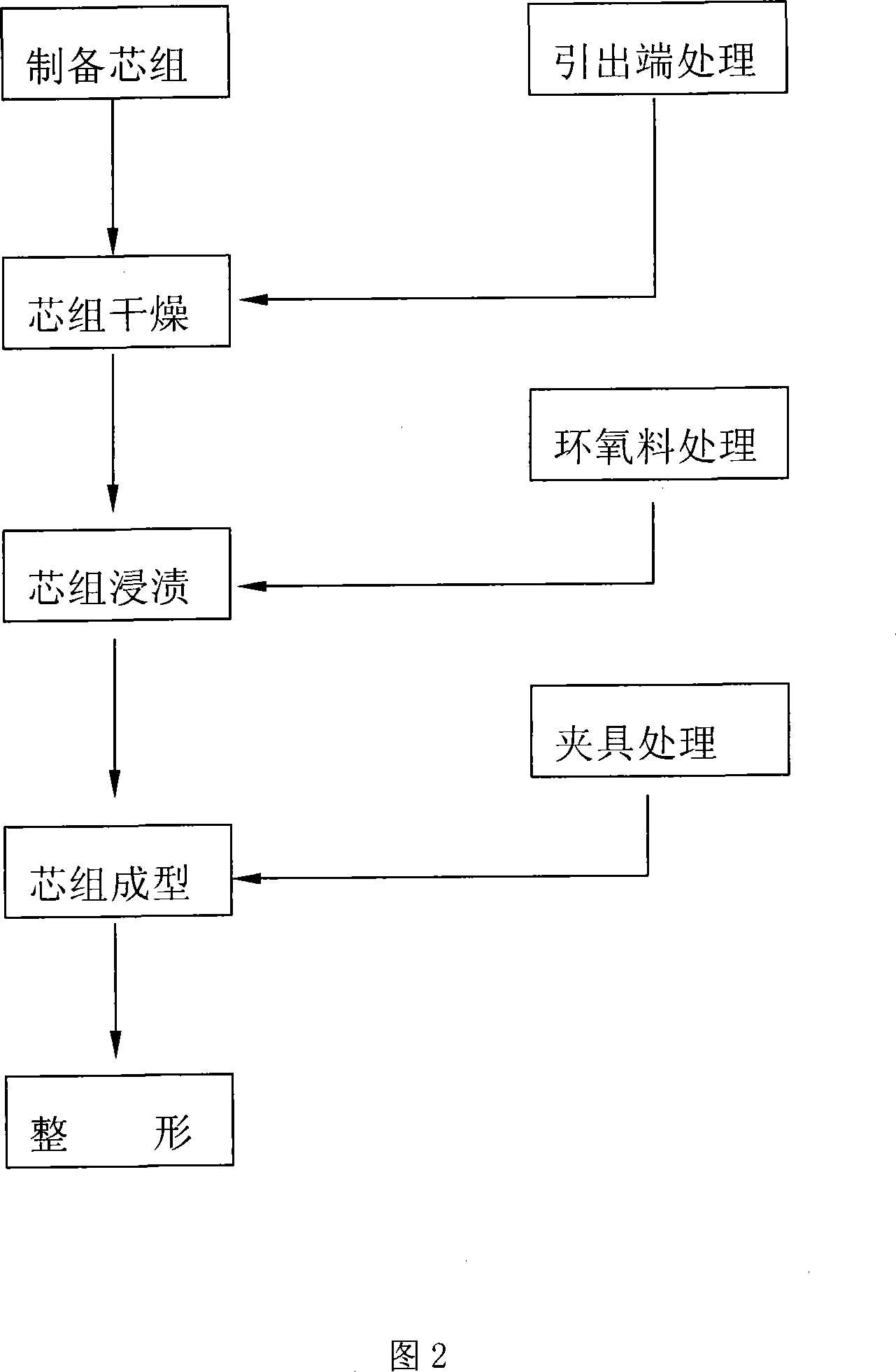

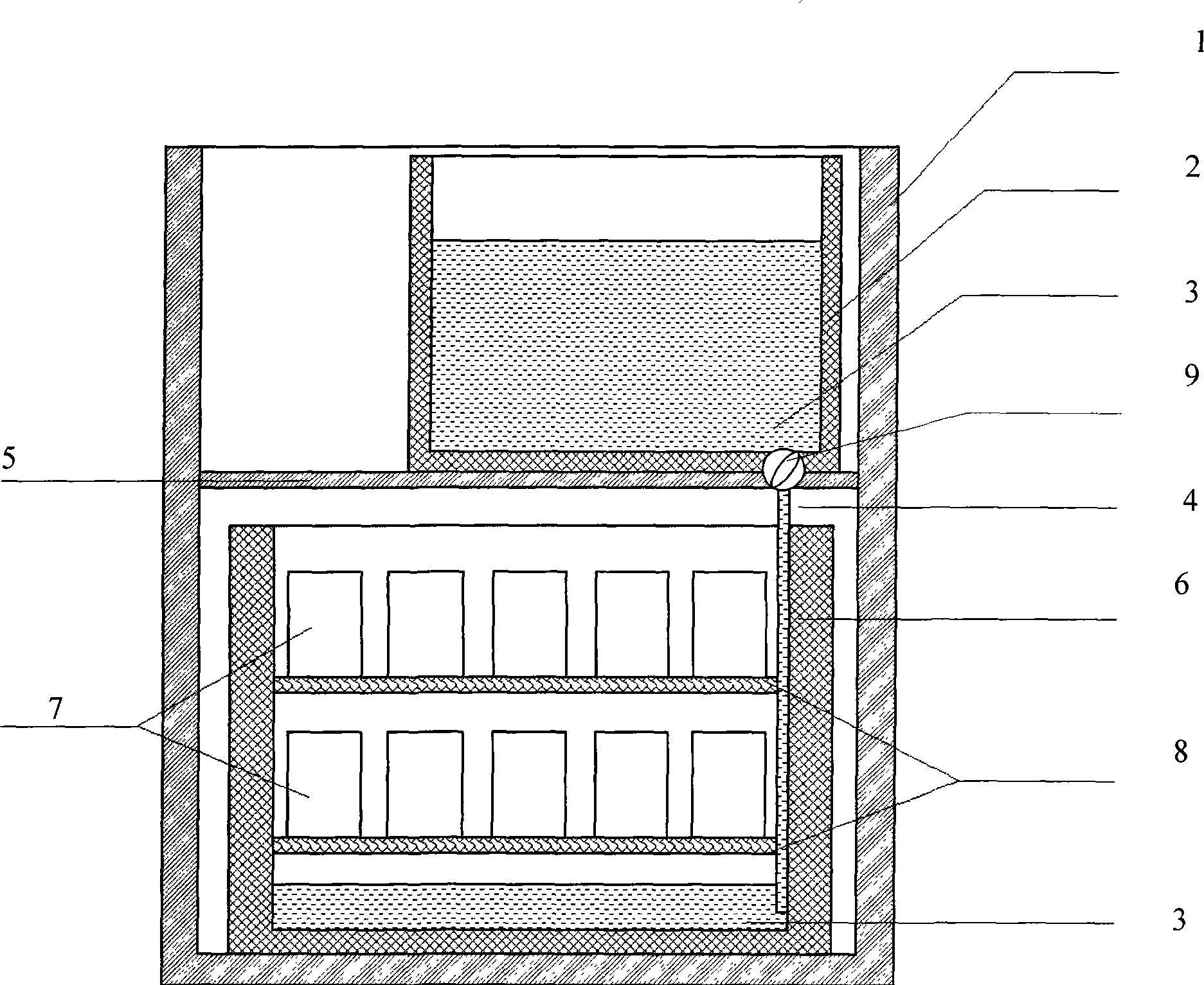

Impregnation forming method for capacitor core assembly

ActiveCN101121159AStable feed rateLower the surface tension of the liquidPretreated surfacesCoatingsAirplaneEngineering

The present invention relates to a novel dip forming method of a specific dry-type capacitor. An isolation screen is added. A core group, which dips the dipping material from bottom to upside, is adopted, and a glass rod is used in a diversion step. The core group is thoroughly solidified by the heat preservation of a multi-temperature zone. The purpose of the present invention is to solve the problems of dipping and an encapsulation of the specific capacitors and the relevant electronic equipments. With a strong technical generality, less implementation difficulty, little investment and stable and reliable quality, the dip forming can satisfy the requirements of the electronic equipment of miniaturization, dry-type (solidification), large span of working temperature-zones and strong environmental applicability. The present invention can be used for manufacturing specific capacitors which are applied to high current with high temperature and high voltage, such as a filter capacitor which is used for high-voltage electrical source of airplane, an engine-igniting capacitor, a deep-well pulse sound wave exploration etc. The present invention can also be used in the encapsulation field of high-performance electronic equipment.

Owner:CHENGDU HONGMING ELECTRONICS CO LTD

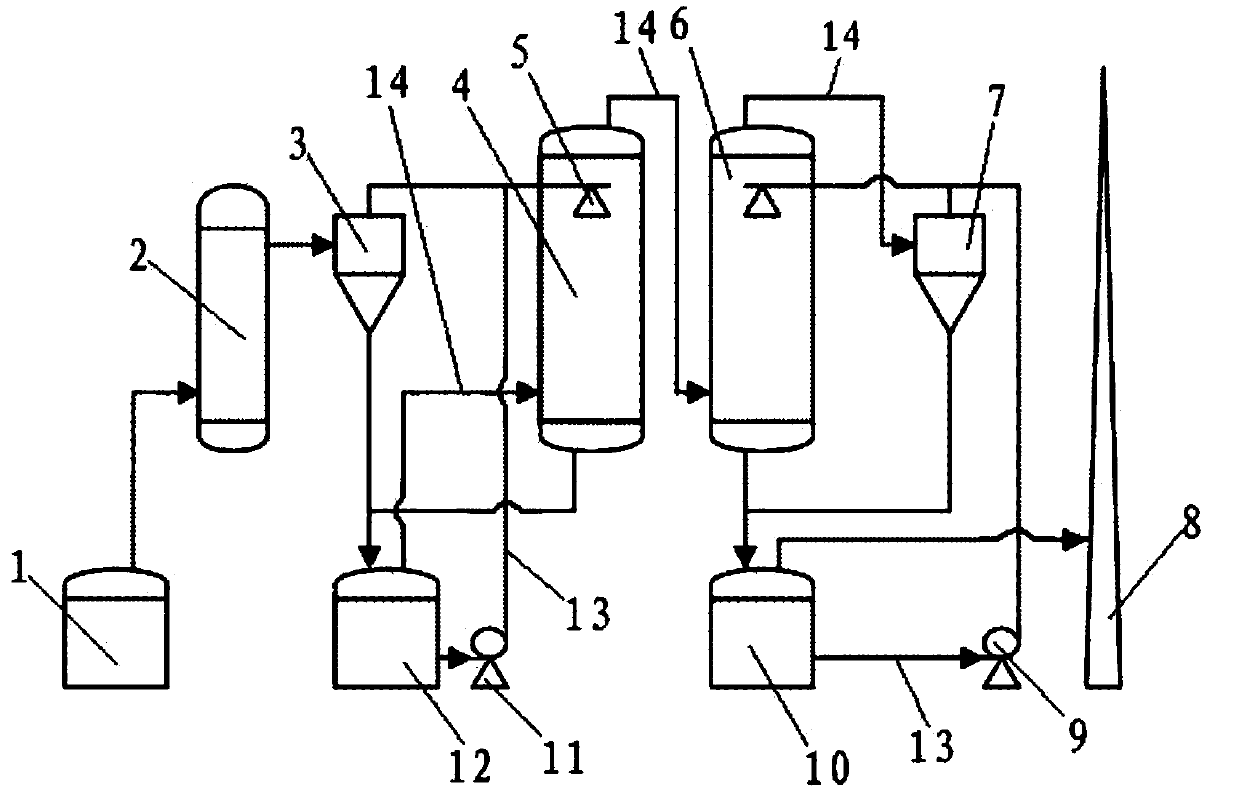

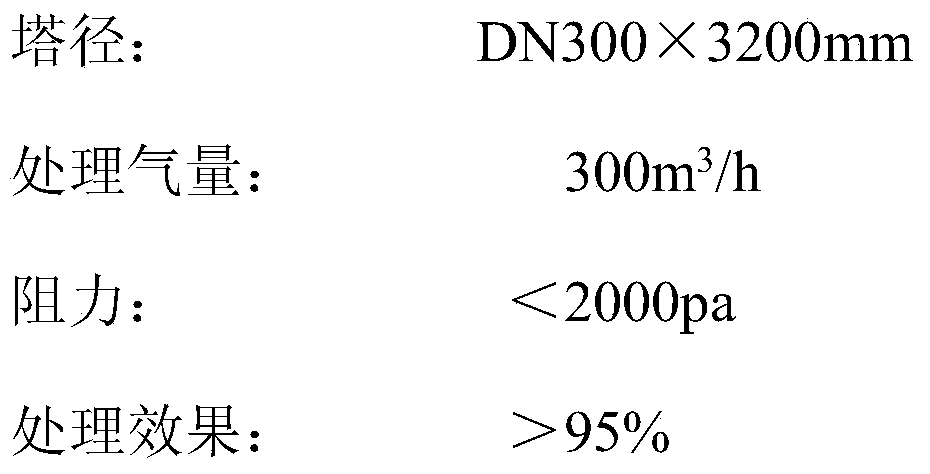

Device and method for purifying in treatment of volatile gas of petrochemical coke cooling water tank

The invention discloses a device and a method for purifying in treatment of volatile gas of a petrochemical coke cooling water tank. The device comprises a buffering tank, a condenser, a first ejector, a first cyclone absorbing tower, a spraying head, a second cyclone absorbing tower, a second ejector, an exhaust barrel, a second circulating pump, a second circulating tank, a first circulating pump, a first circulating tank, an air guide pipe and an absorbent circulating pipe. According to the device, waste gas is collected and exported from the petrochemical coke cooling water tank, the buffering tank is used for smoothening the flow and separating out more of easily-condensed oil gas and water vapor, and then the waste gas enters the condenser (the waste gas from the petrochemical coke cooling water tank is cooled to be less than 50 DEG C) and finally enters the absorbing towers; two-stage cyclone plate towers are connected in series to perform circular absorbing; two-stage parallel ejectors are mounted at the front and back of the absorbing towers to be used as gas exporting power; meanwhile, absorbents and waste gas are fully mixed and absorbed through the ejectors; the mixed liquid enters an absorbent circulating tank to be subjected to gas-liquid separation and finally the separated liquid enters the exhaust barrel to be exhausted. The device has the advantages of being efficient, energy-saving, safe, reliable, and long in service life.

Owner:上海景凯环保科技有限公司

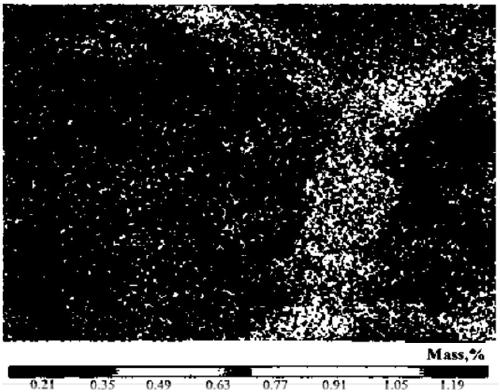

A kind of high-strength copper-containing cold-rolled non-oriented silicon steel and manufacturing method

ActiveCN107130169BStrong process versatilitySimple production processCopperUltimate tensile strength

The invention provides high-strength copper-contained cold-rolled non-oriented silicon steel and a manufacturing method, and belongs to the technical field of steel and iron machining. The silicon steel comprises the following components: 0.001-0.0015 wt.% of C, 2.5-3.0 wt.% of Si, 0.8-1.0 wt.% of Al, 0.5-0.8 wt.% of Mn, 1.5-2.0 wt.% of Cu, 0.75-1.5 wt.% of Ni, no more than 0.005 wt.% of Nb, and the balance of Fe and inevitable impurities; and through control of secondary cold rolling reduction, an annealing process and an aging process, the magnetic induction strength, the iron loss and the yield strength of the non-oriented silicon steel are balanced. After the steel is coldly rolled, annealed and aged, the magnetic induction strength B50 is 1.64-1.66 T, the iron loss W1.0 / 50 is 2.5-3.5 W / kg, W1.0 / 400 is 20.04-25.04 W / kg, the lower yield strength ReL is 750-810 MPa, the tensile strength Rm is 800-870 MPa, and the ductility is 15-20%; and the silicon steel reaches and exceeds the performance requirements of common high-strength non-oriented silicon steel.

Owner:UNIV OF SCI & TECH BEIJING

Method for wet separation of mixed solution containing nickel and zinc

InactiveCN101713025AStrong process versatilityProcess conditions are easy to controlProcess efficiency improvementSocial benefitsEconomic benefits

The invention discloses a method for the wet separation of mixed solution containing nickel and zinc. The method comprises the following steps of: adding ammonia water or chlorhydric acid into the mixed solution containing the nickel and the zinc; adjusting the pH value of the solution to between 6.25 and 7.5; filtering the solution; and drying a filter cake to obtain a zinc deposit, wherein the filtrate is solution of nickel ammine. The method has strong process universality, is suitable for various mixed solution containing the nickel and the zinc, can control the process condition easily, has simple devices, easily realizes large-scale production, and has a low processing cost and significant economic benefits and social benefits.

Owner:ZHEJIANG UNIV OF TECH

Heat-resistant cross-linked high-density polyethylene pipe

The invention discloses a heat-resistant cross-linked high-density polyethylene pipe. The pipe is prepared from the following raw materials: high-density polyethylene, polybutadiene, 3methacryloyloxytrimethoxysilane, montmorillonite powder, an ethylene-vinyl acetate copolymer, a styrene-maleic anhydride copolymer, an olefin processing mixed additive, a lubricant, a cross-linking agent, an assistant cross-linking agent, polycarbosilane, N-ethyl-o-toluenesulfonamide, 4,4'-diaminodiphenyl sulfone, an ethylene-octene copolymer, cobalt sesquioxide, resorcinol and cordierite powder. According to theheat-resistant cross-linked high-density polyethylene pipe disclosed by the invention, the heat resistance and the creep resistance are improved, meanwhile, the ageing resistance, the mechanical property, the transparency and the like of the pipe are obviously improved, and if the crosslinking degree is improved, the improvement of the properties is more obvious. Meanwhile, the pipe has better chemical corrosion resistance and flexibility.

Owner:含山县领创新材料科技有限公司

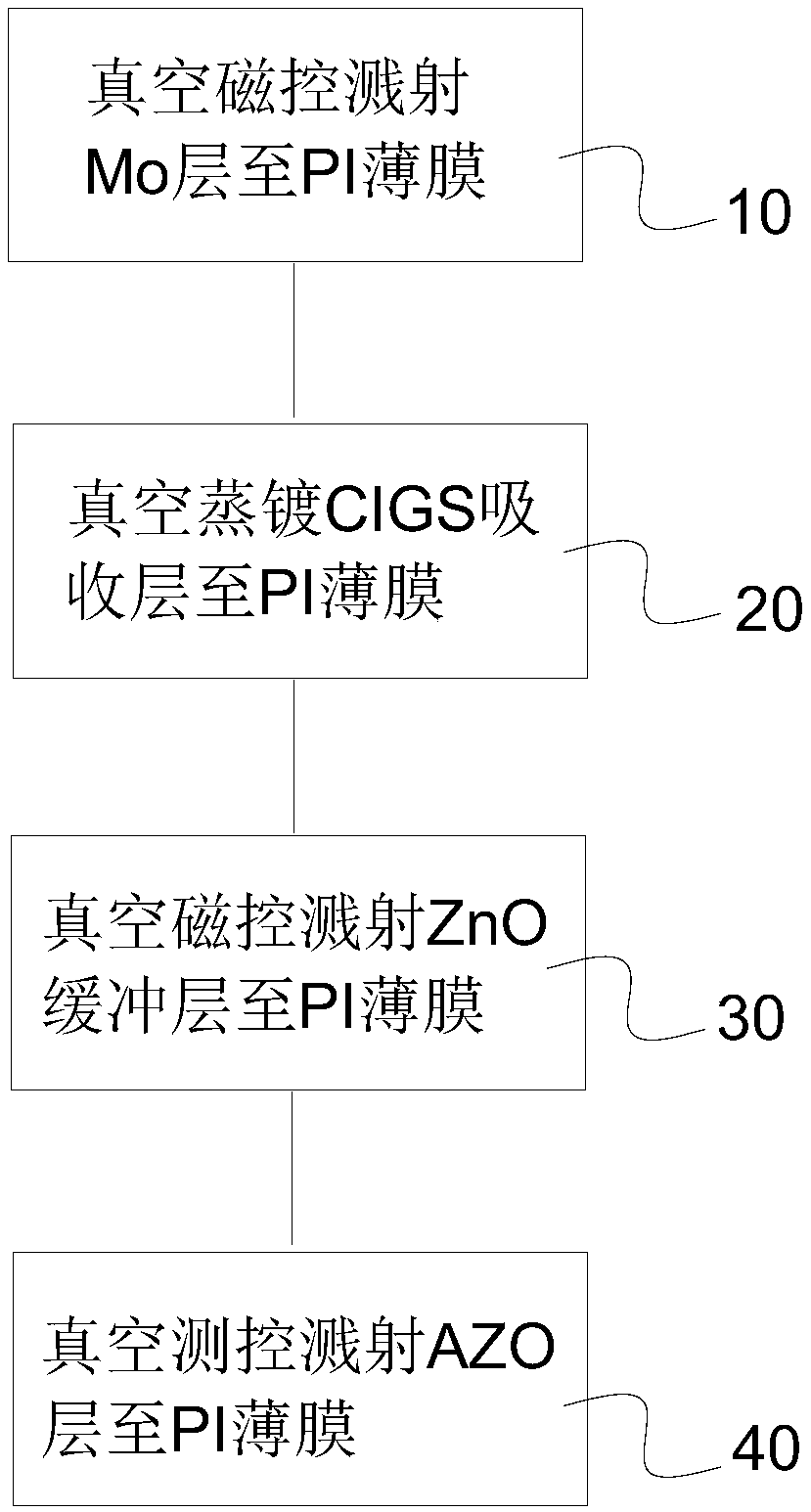

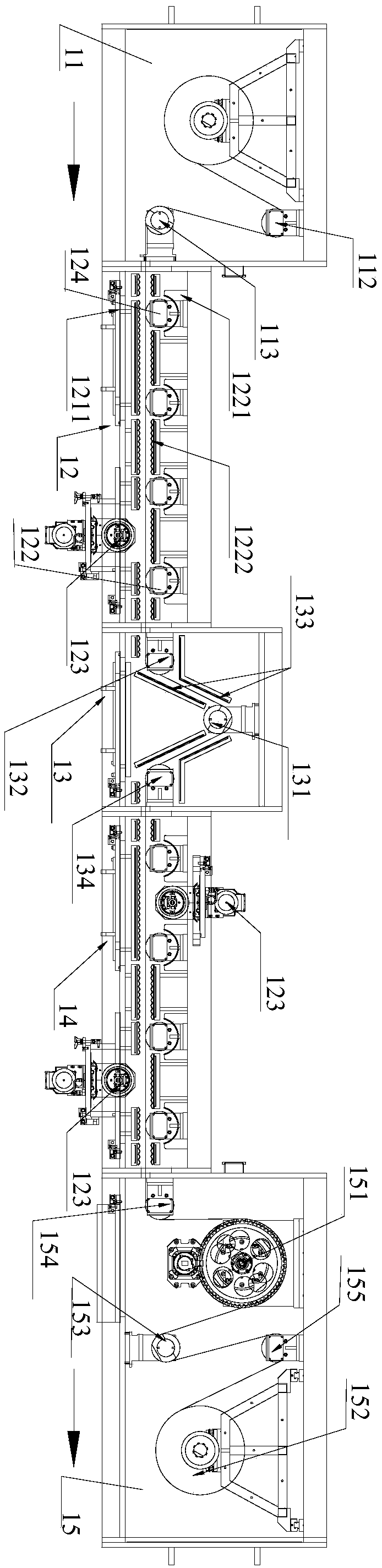

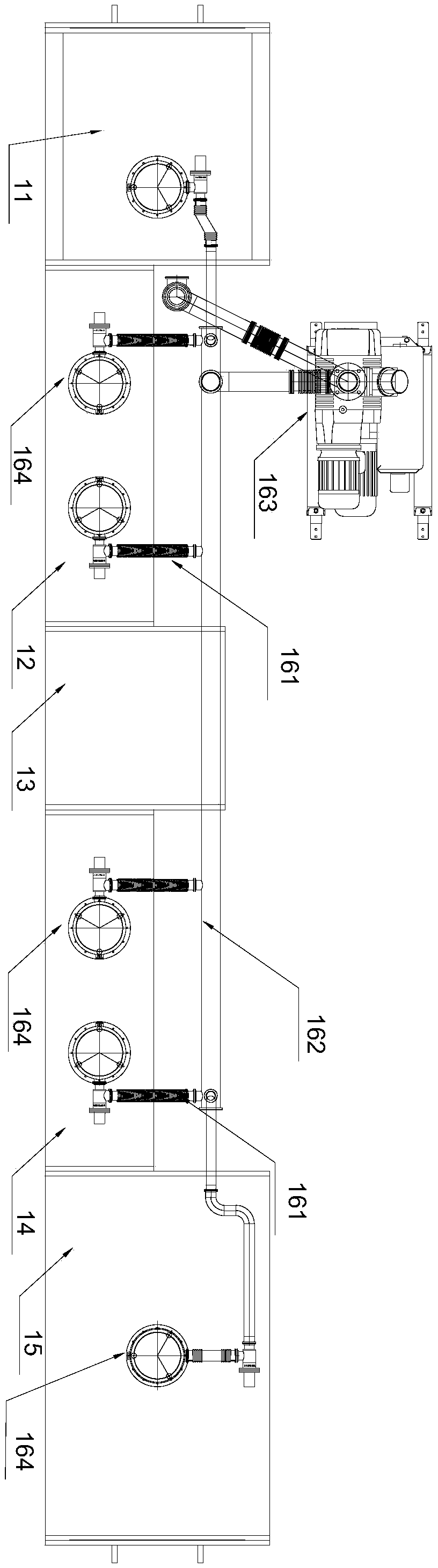

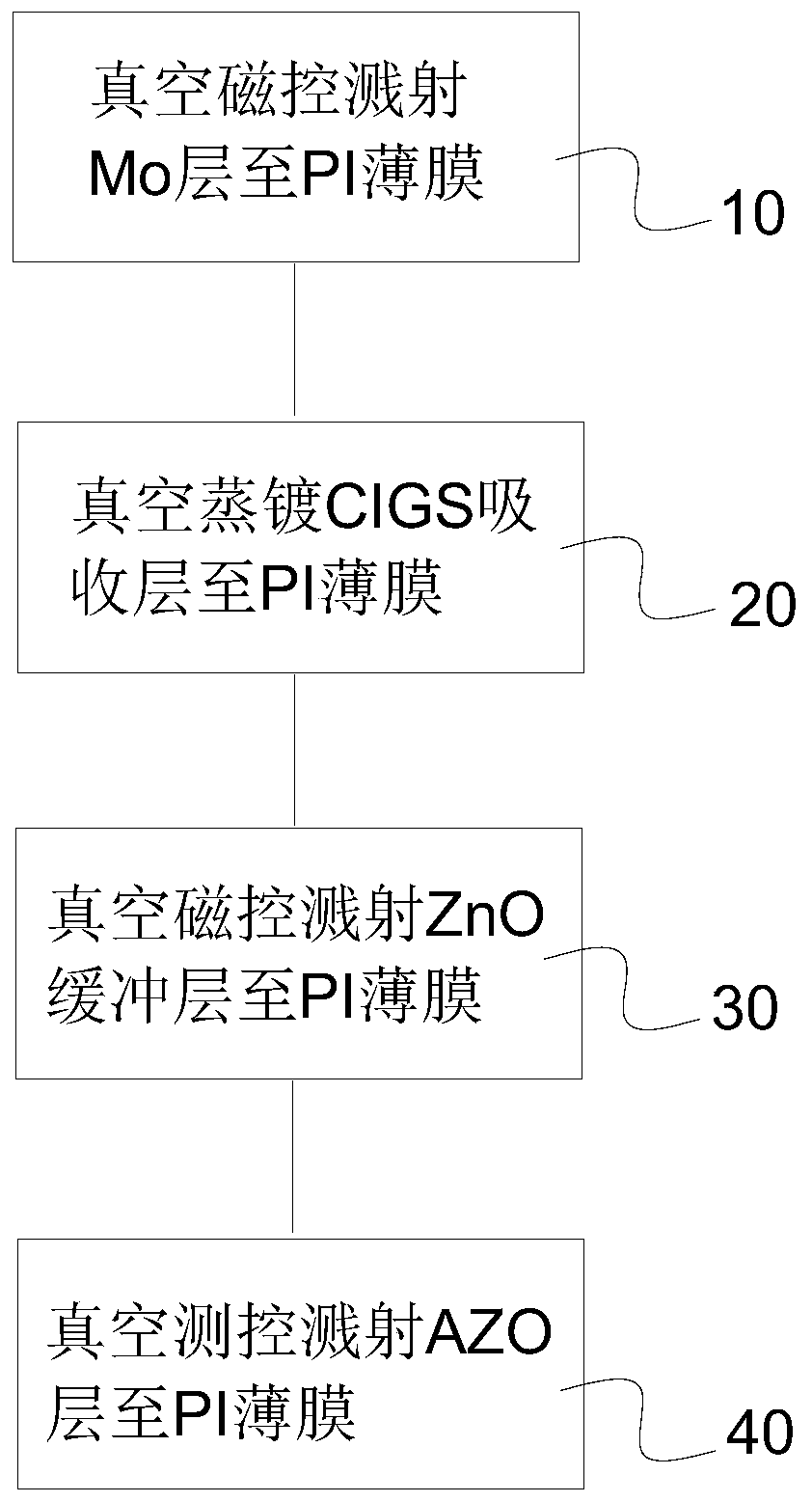

cigs solar cell film production line

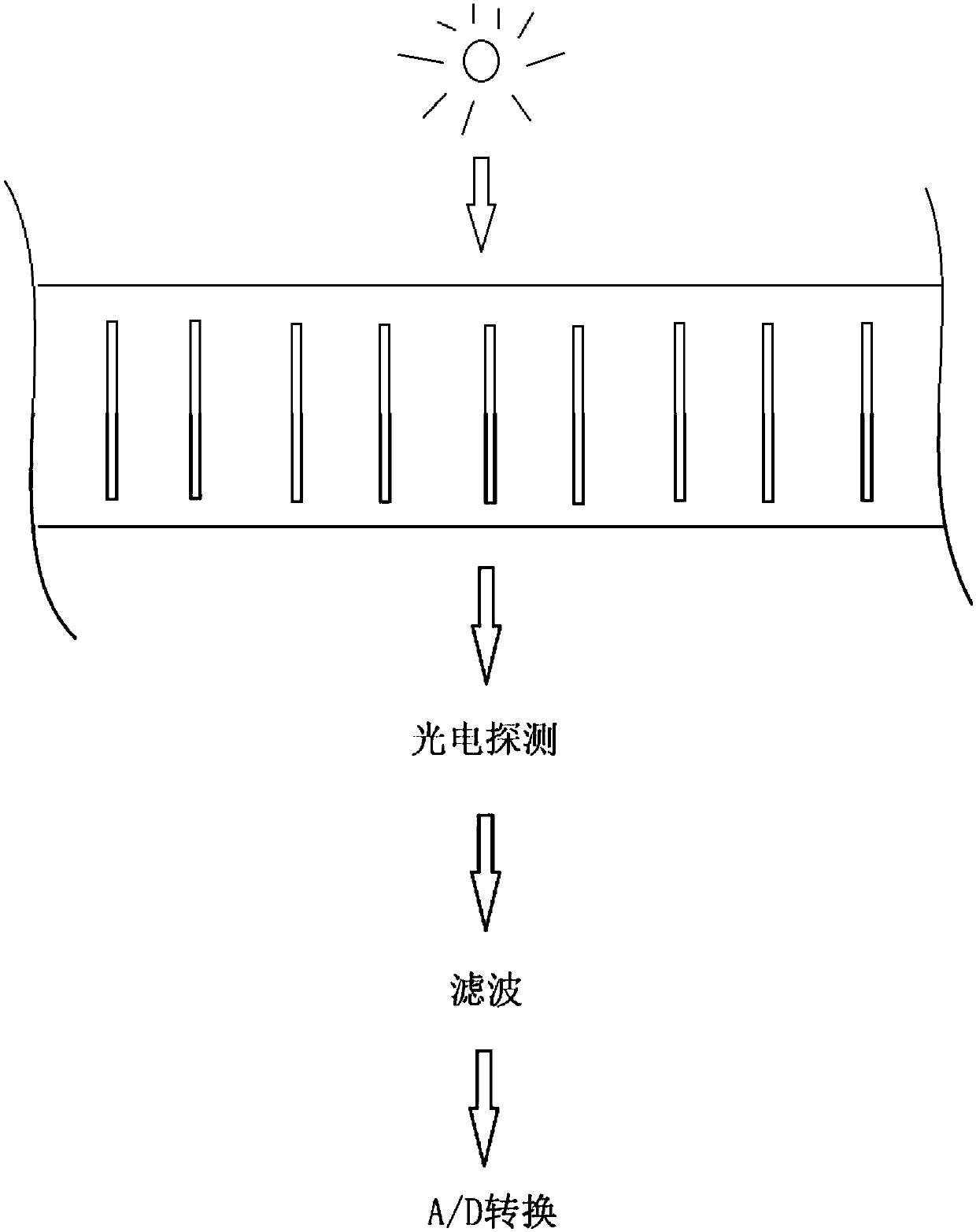

ActiveCN106319473BReduce exposureAvoid destructionFinal product manufactureVacuum evaporation coatingProduction lineEvaporation

The invention discloses a CIGS solar cell film production line. The CIGS solar cell film production line comprises a plurality of coating sub-lines. The sub-lines sequentially and independently conduct vertical coating on a film. Each sub-line at least comprises an unreeling chamber, a coating chamber and a reeling chamber in the film unfolding direction, wherein a main drive roller is arranged in the unreeling chamber and the reeling chamber, a plurality of transmission rollers are arranged in cavities of the sub-line, and a tension detection roller and a tension adjusting roller are arranged in at least one cavity of the sub-line. The tension detection rollers are adjacent to the tension adjusting rollers, the tension detection rollers are used for monitoring the tension of the film in real time, and the tension adjusting rollers adjust the rotation speed of the tension adjusting rollers according to the feedback of the tension detection rollers so as to adjust the transmission speed of the film in the cavities; and the tension adjusting rollers are non-transmission rollers, and the unfolding track that the film passes the tension detection rollers and the tension adjusting rollers is the nonlinear track. According to the provided CIGS solar cell film production line, the element diffusion path is short, intermediate products are avoided, element evaporation is avoided, the film efficiency is high, and the CIGS solar cell film production line is particularly suitable for large-area scale industrial production.

Owner:旭科新能源股份有限公司 +1

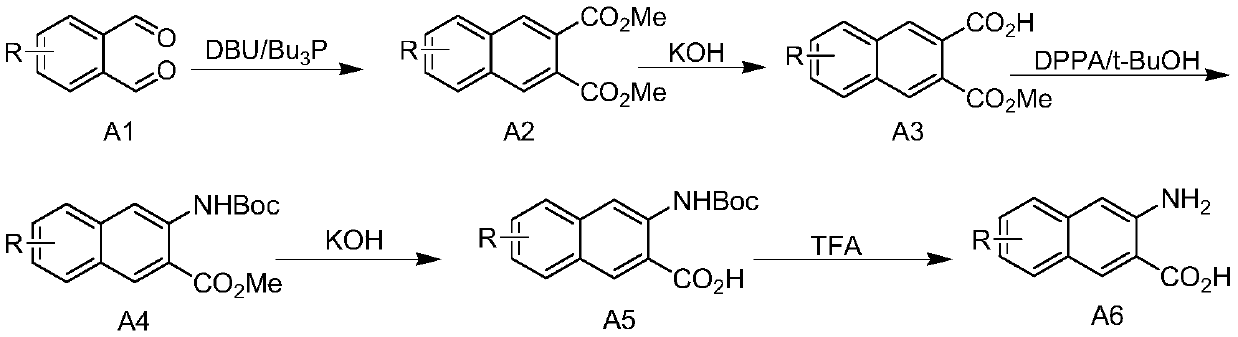

Process for preparing 3-amino-2-naphthoic acid compound

ActiveCN109796360AStrong process versatilityMild reaction conditionsCarbamic acid derivatives preparationOrganic compound preparationCarboxyl radicalTert-Butyloxycarbonyl protecting group

The invention discloses a process for preparing a 3-amino-2-naphthoic acid compound, which is characterized in that a condensed ring-2, 3-dimethyl naphthalene dicarboxylate is prepared from phthalic dicarboxaldehyde under the action of tri-n-butyl phosphine; then, the condensed ring-2, 3-dimethyl naphthalene dicarboxylate is hydrolyzed to 2, 3-monomethyl naphthalene dicarboxylate under an alkalinecondition; then, the carboxyl group is converted to the amino group through DPPA reaction to obtain 3-tert-formamido-2-naphthoate methyl; finally, the ester is hydrolyzed, and the tert-butoxycarbonylgroup is further removed to obtain the 3-amino-2-naphthoic acid. The method has mild reaction conditions, is suitable for different substrates, does not need to use high-temperature and high-pressurekettle equipment, reduces the safety risk in the production process, reduces the equipment investment, reduces the production energy consumption, and is suitable for large-scale production.

Owner:SHANGHAI JINGCHUN BIOCHEM TECH CO LTD

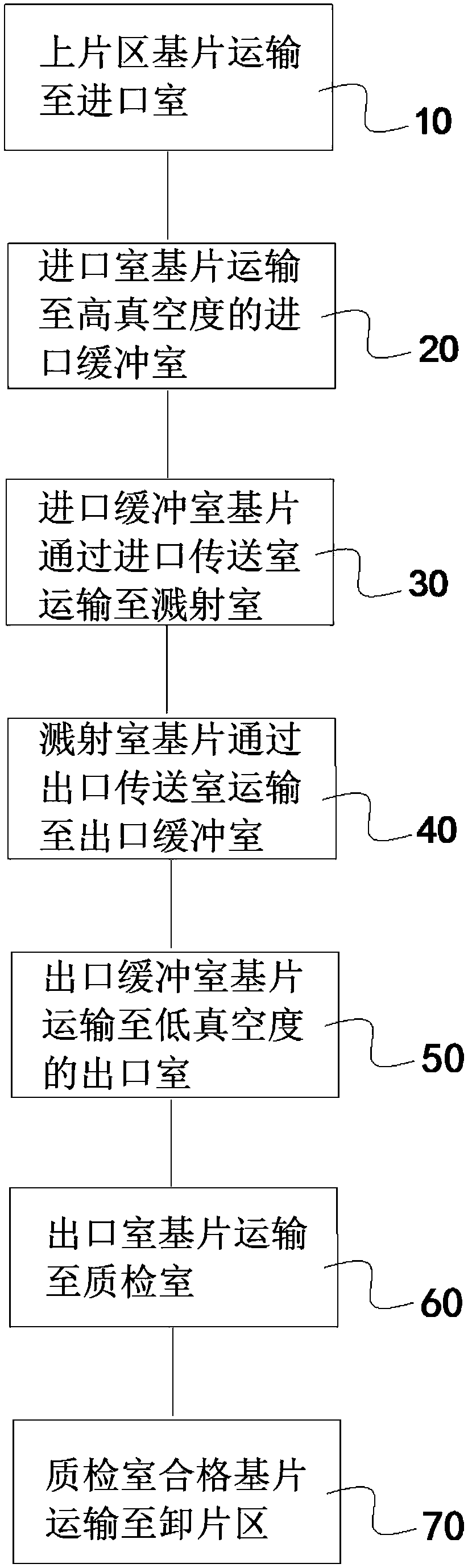

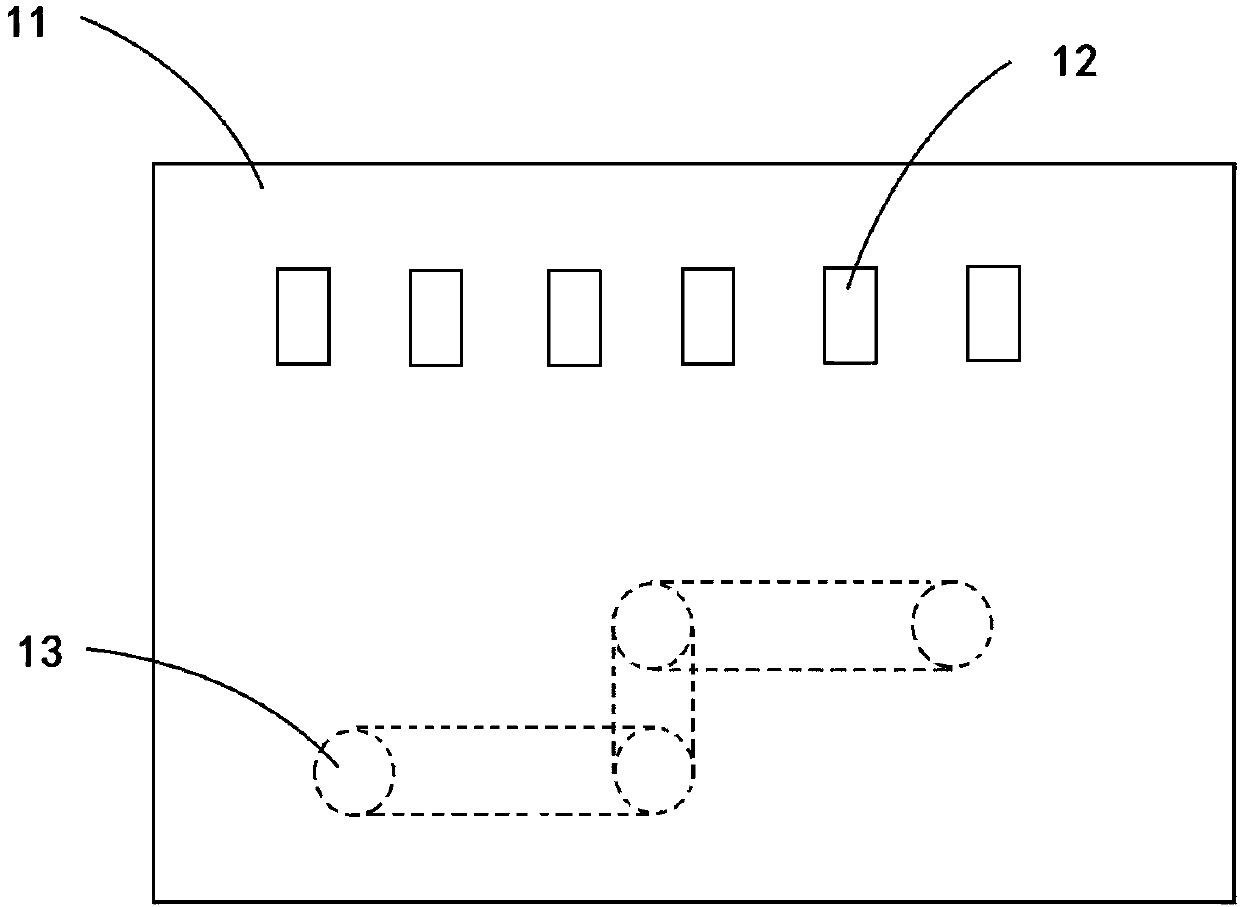

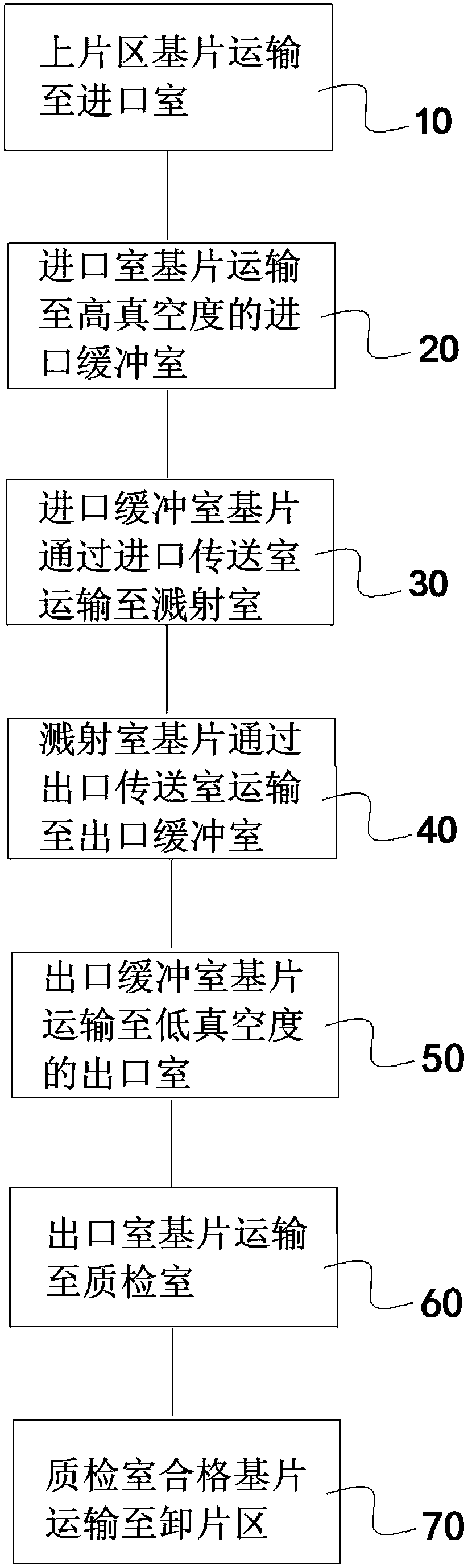

Vacuum magnetron sputtering coating production line for arc-shaped glass

InactiveCN109957769AIncrease profitAvoid formingVacuum evaporation coatingSputtering coatingProduction lineEngineering

The invention discloses a vacuum magnetron sputtering coating production line for arc-shaped glass. The production line comprises a loading area, an inlet cavity, an inlet buffer cavity, an inlet conveying cavity, a sputtering cavity, an outlet conveying cavity, an outlet buffer cavity, an outlet cavity, a quality inspection cavity and an unloading area which are connected in sequence, transmission tables connected in sequence are arranged in the loading area, the inlet cavity, the inlet buffer cavity, the inlet conveying cavity, the sputtering cavity, the outlet conveying cavity, the outlet buffer cavity, the outlet cavity and the unloading area, a coating quality inspection table and a quality inspection system are arranged in the quality inspection cavity, and the transmission table inthe outlet cavity is connected with the coating quality inspection table. The vacuum magnetron sputtering coating production line for arc-shaped glass provided by the invention can realize large-batchand low-cost production of various coatings, and is high in sputtering deposition rate, high in process universality and particularly suitable for large-scale industrial production.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

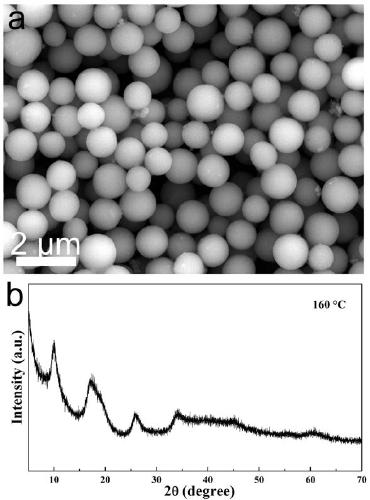

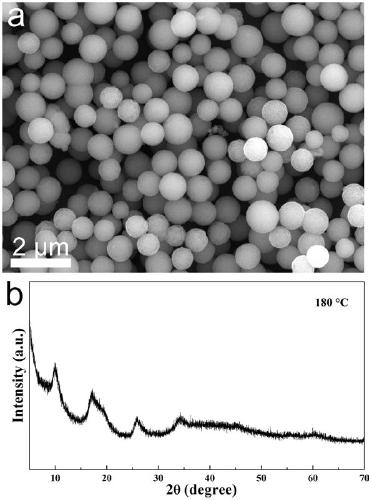

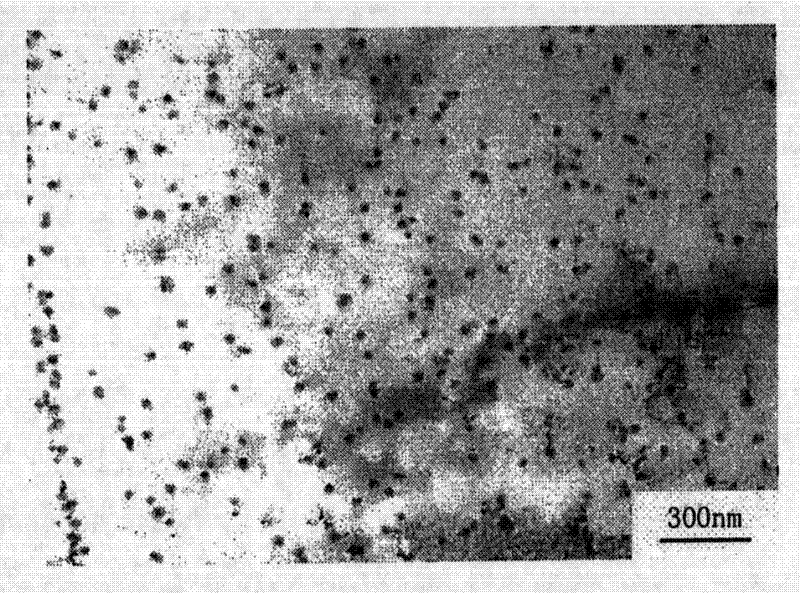

MNx super crystal and preparing method and application thereof

ActiveCN108996478AHigh purityUniform shapeSulfide/polysulfide preparationMetal selenides/telluridesReaction temperatureSolvent

The invention relates to an MNx super crystal and a preparing method and application thereof, belonging to the field of functional material structure control. The method includes subjecting an M salt,as a raw material, to a reaction in an autoclave at 120-260 DEG C in an acidic environment for one hour to one week to obtain the MNx super crystal material, with a mixture of alcohol and water beingadopted as a solvent and thiourea (selenourea) being adopted as a sulfur (selenium) source. The method and the super crystal are characterized in that hollow, solid or core-shell MNx super crystal sphere, sheet and butterfly-shaped materials having uniform particle size and adjustable composition can be obtained by self-assembling of a two-dimensional sheet material through adjusting the varietyof metal salts, the reaction temperature, reaction time, surfactants and the dosage of thiourea (selenourea). More importantly, semiconductor-phase (2H phase) and metal-phase (1T phase) MNx super crystal sphere and sheet materials can be selectively prepared through controlling reaction temperatures.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

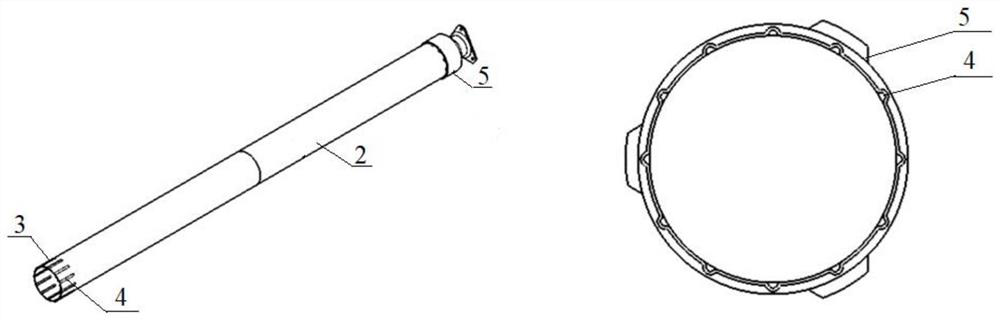

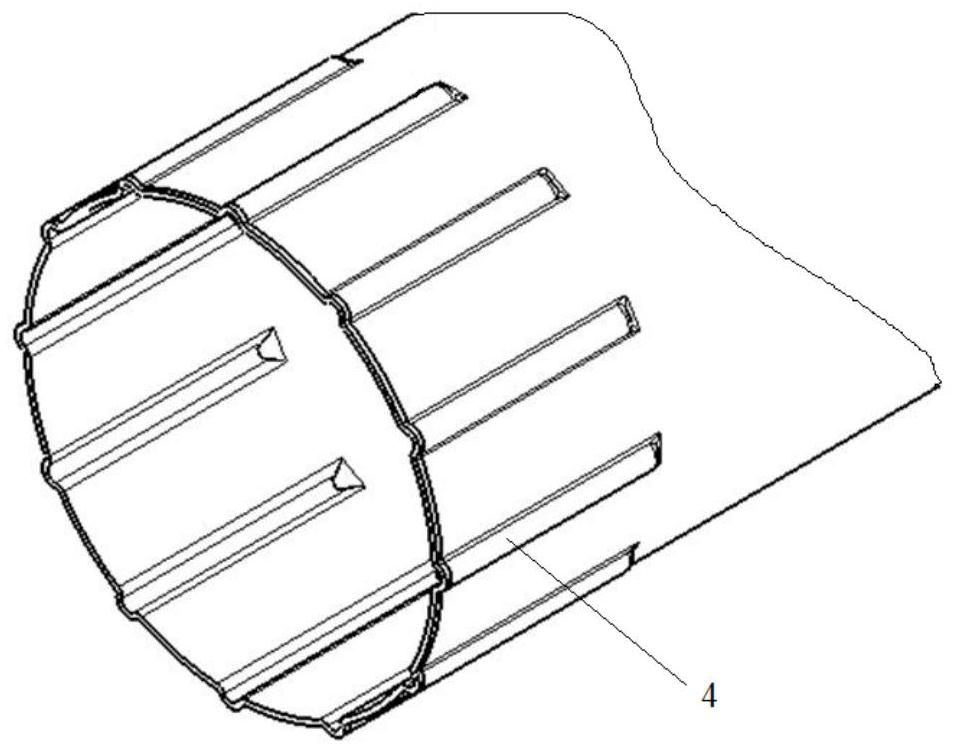

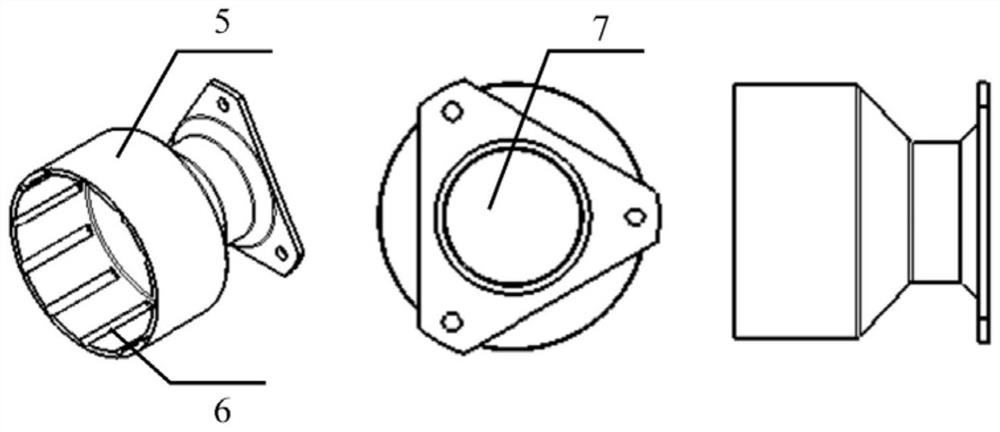

Composite axle tube connected with metal joint

ActiveCN114593133ASufficient torqueStrong process versatilityFinal product manufactureShaftsStructural engineeringAxial distribution

The invention relates to the technical field of composite materials, in particular to a composite material shaft tube connected with a metal connector, which comprises a shaft tube body and the metal connector, the shaft tube body comprises a non-matching area located in the middle and matching areas integrally formed at the two axial ends of the non-matching area, and a plurality of salient points or bosses are uniformly arranged on the outer surfaces of the matching areas around the circumferential direction; the number of the convex points or the bosses in each matching area is not less than 3, if the convex points are designed, at least one row of convex points are distributed in the axial direction, the number n of the convex points or the bosses meets the formula, and r is the outer radius of the non-matching area of the shaft tube body; l is the length of the boss in the axial direction or the total length of a row of salient points distributed in the axial direction in the axial direction; alpha is the maximum angle, except 90 degrees, in the laying layer angles; the metal connector is provided with a recess matched with the boss or the salient point, the metal connector is in clearance fit with the matching area, and a glue film is arranged on the peripheral face of the matching area in advance. The composite material axle tube can transmit enough torque (at least 1800 N.m).

Owner:江苏集萃碳纤维及复合材料应用技术研究院有限公司

Large-area AZO glass coating film production line

The invention discloses a large-area AZO glass coating film production line, which comprises a coating film line and a conveying line, wherein the coating film line comprises an inlet chamber, an inlet buffer chamber, an inlet conveying chamber, a sputtering chamber, an outlet conveying chamber, an outlet buffer chamber, an outlet chamber and a quality inspection chamber, the inlet chamber, the inlet buffer chamber, the inlet conveying chamber, the sputtering chamber, the outlet conveying chamber, the outlet buffer chamber, the outlet chamber and the quality inspection chamber are sequentiallyconnected, at least a valve is arranged between the adjacent chambers, the conveying line comprises transmission rollers and a coating film quality inspection roller, the sequentially connected transmission rollers are respectively arranged in the inlet chamber, the inlet buffer chamber, the inlet conveying chamber, the sputtering chamber, the outlet conveying chamber, the outlet buffer chamber and the outlet chamber, the coating film quality inspection roller is arranged in the quality inspection chamber, the transmission roller in the outlet chamber is connected to the coating film qualityinspection roller, and the transmission rollers and the coating film quality inspection roller are used for conveying a coating film substrate. According to the present invention, with the large-areaAZO glass coating film production line, the large-batch and low-cost production of various large-area coating films can be achieved, the sputter deposition rate is high, the process has strong versatility, the diffusion path is short, no intermediate product is generated, and no element is evaporated, such that the preparation is fast, the efficiency is high, the yield rate is over 95%, and the production line is especially suitable for large-scale industrial production.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

Multipurpose metal film layer vacuum coating production line

InactiveCN109913846AReduce the impactIncrease profitVacuum evaporation coatingSputtering coatingProduction lineEvaporation

The invention discloses a multipurpose metal film layer vacuum coating production line. The production line comprises an inlet chamber, an inlet buffer chamber, an inlet conveying chamber, a sputtering chamber, an outlet conveying chamber, an outlet buffer chamber, an outlet chamber and a quality inspection chamber, wherein the inlet chamber, the inlet buffer chamber, the inlet conveying chamber,the sputtering chamber, the outlet conveying chamber, the outlet buffer chamber and the outlet chamber are connected in sequence; transferring rollers connected with each other are arranged in the inlet chamber, the inlet buffer chamber, the inlet conveying chamber, the sputtering chamber, the outlet conveying chamber, the outlet buffer chamber and the outlet chamber; a film coating quality inspection roller and a quality inspection system are arranged in the quality inspection chamber; the transferring roller in the outlet chamber is connected with the film coating quality inspection roller;and the transferring rollers and the film coating quality inspection roller are used for transferring a film coating substrate. According to the multipurpose metal film layer vacuum coating productionline, mass and low-cost production of various coatings are achieved with high sputtering deposition rate and strong process universality; an element diffusion path is short with no intermediate product and no element evaporation, so that the preparation speed and the efficiency are high, the yield is 95% or above, and the production line is particularly suitable for large-scale industrial production.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

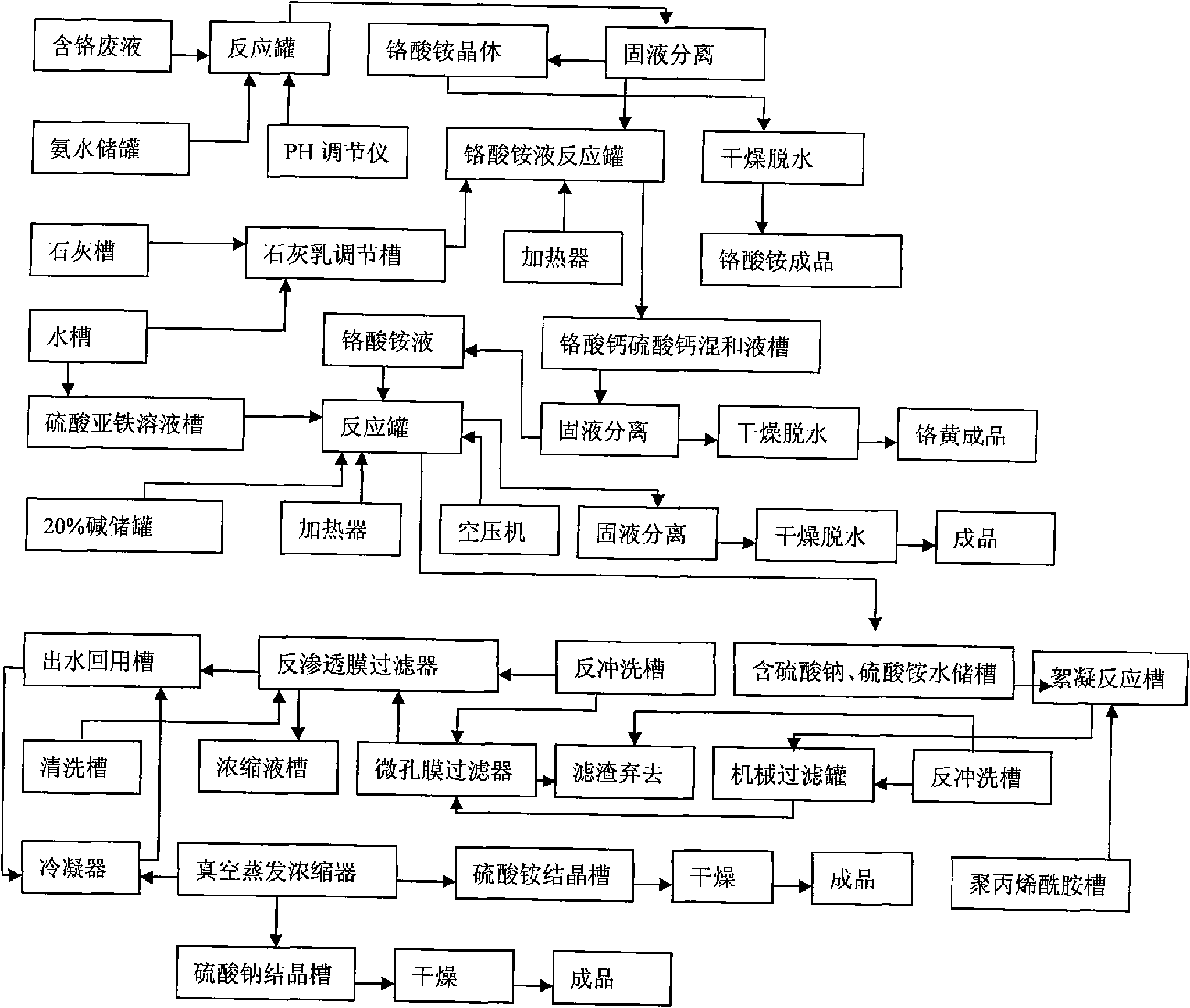

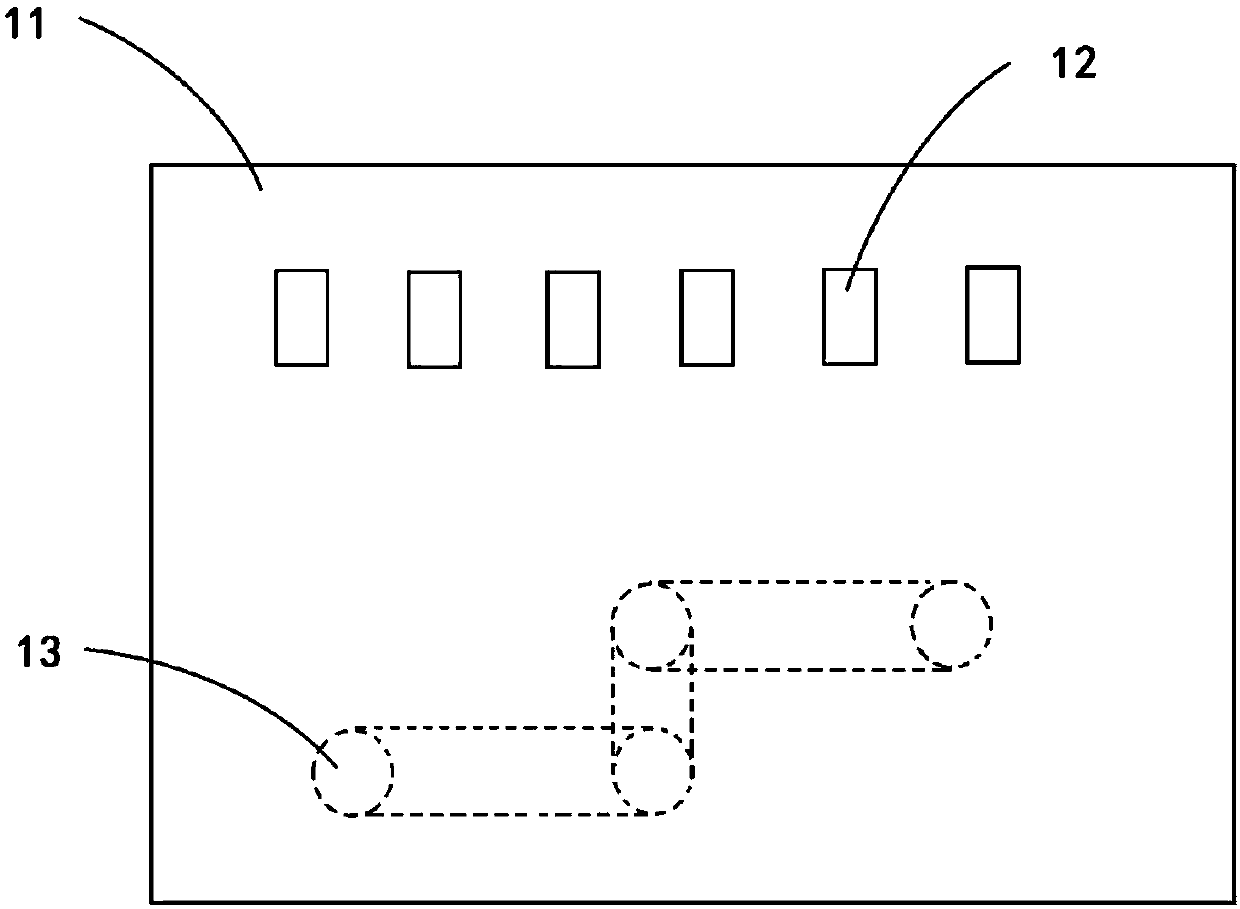

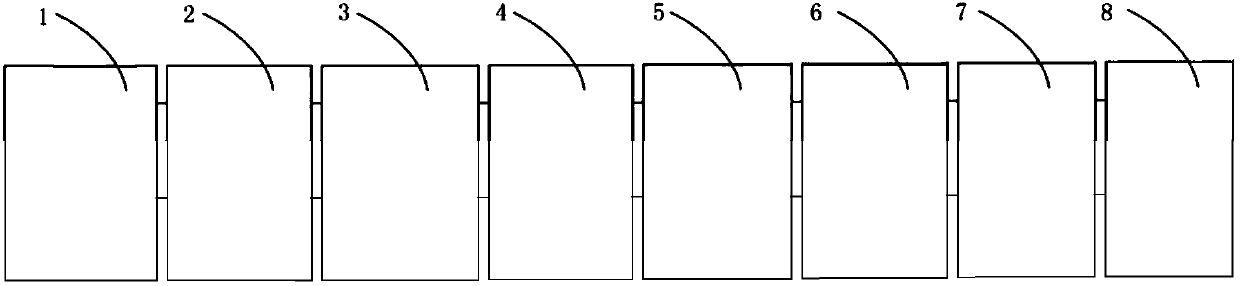

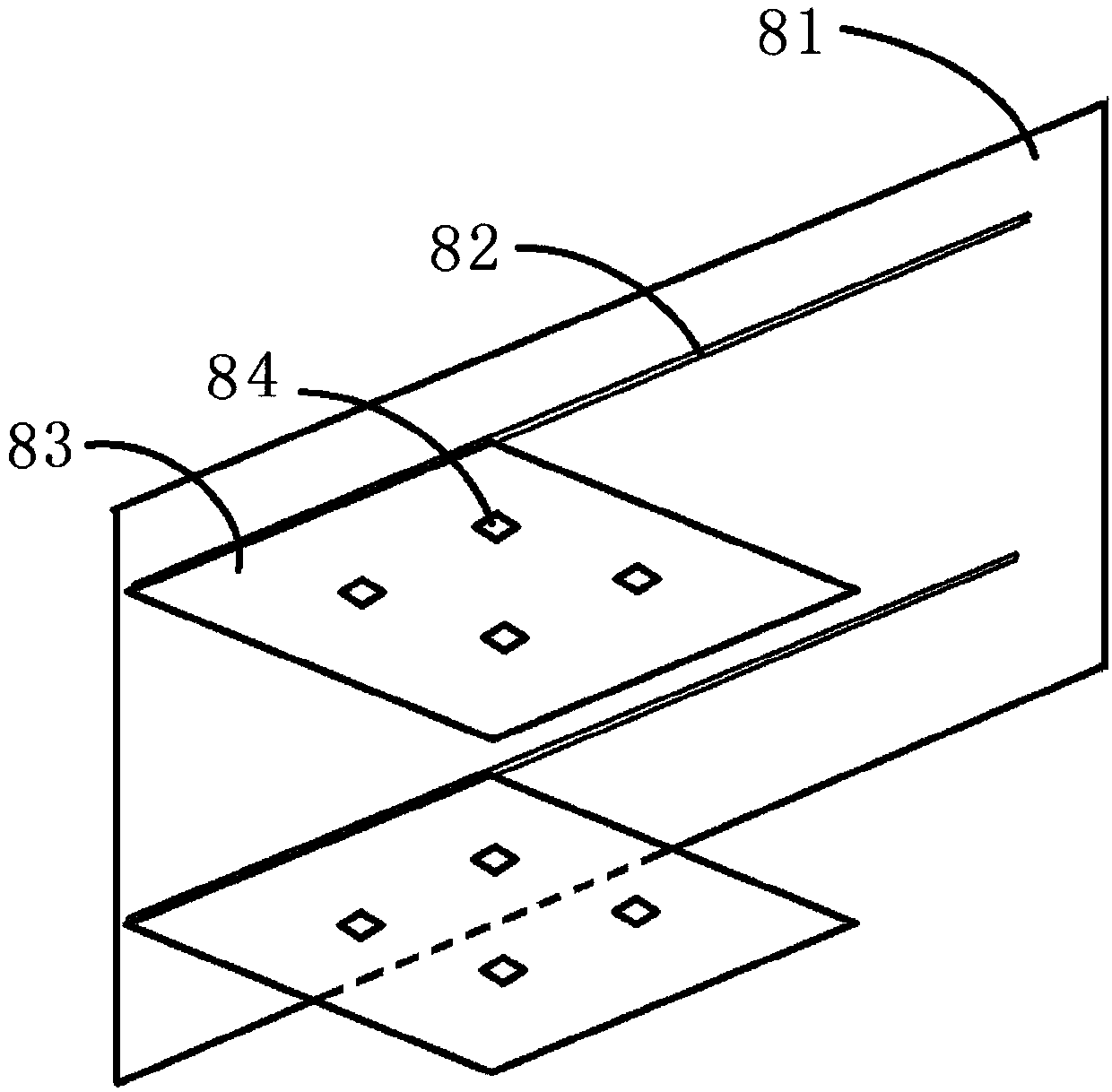

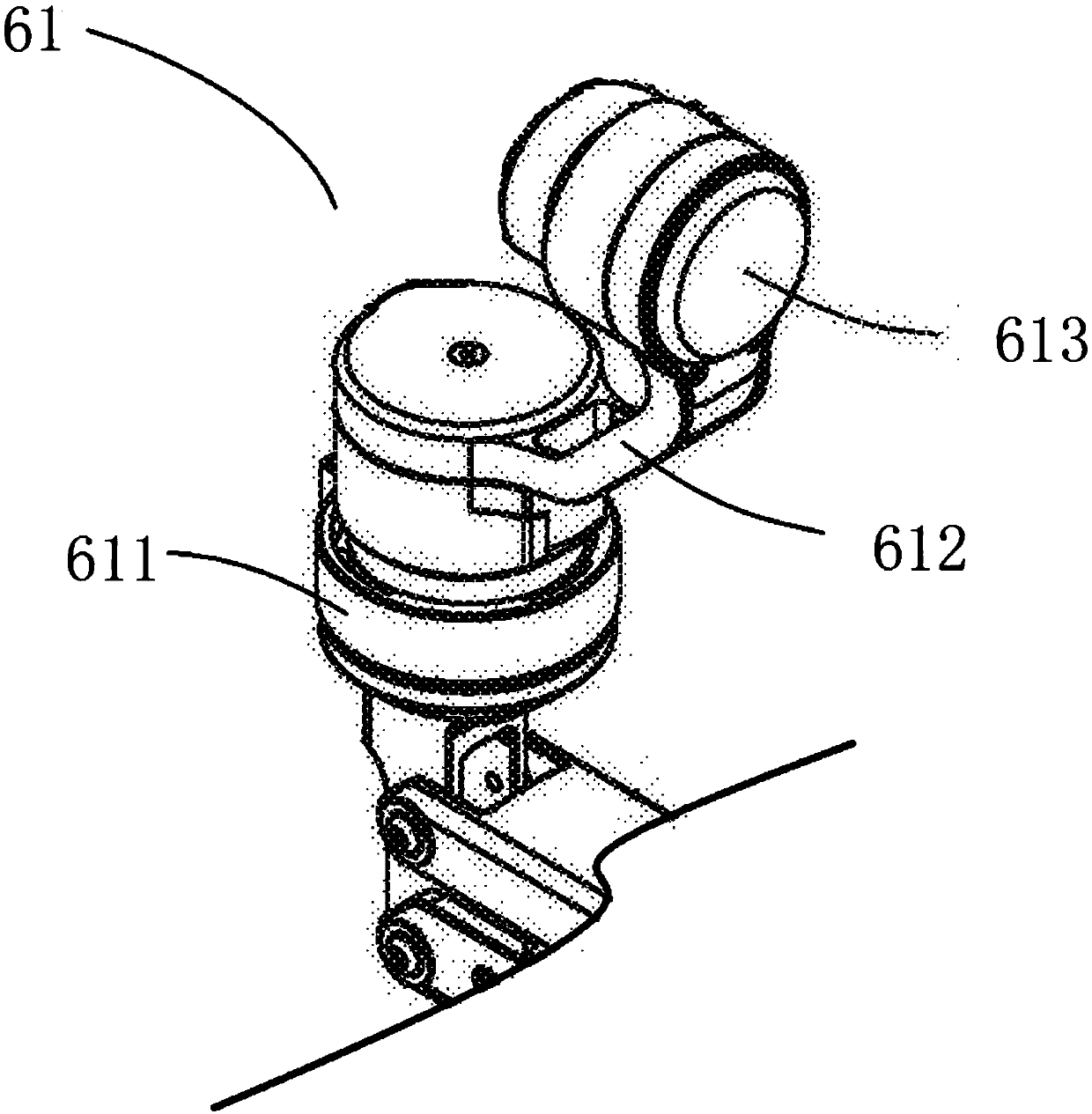

Intermittent circulation rotary system and working method thereof

ActiveCN105173263AStrong process versatilityImprove applicabilityPackagingEngineeringMechanical engineering

The invention relates to an intermittent circulation rotary system and a machining method thereof. The intermittent circulation rotary system comprises a rack, an input end lifting mechanism, an output end lifting mechanism, an upper layer track, a lower layer track and trays. The rack is a rectangular cubic frame which is horizontally and transversely arranged. The input end lifting mechanism is installed at the input end of the rack, the output end lifting mechanism is installed at the output end of the rack, and the input end lifting mechanism, the rack and the output end lifting mechanism are horizontally and transversely arranged in a coaxial manner. The upper layer track and the lower layer track are installed in the rack in a vertically spaced manner. The multiple trays are horizontally installed on the upper layer track in a guide manner and sequentially connected end to end. The intermittent circulation rotary system can be widely adapted to different types of gift box type white spirit packaging boxes from different manufacturers. By reasonably splitting an original production technology and implementing an automatic solution at key points, targeted automatic production is achieved, packaging efficiency is improved, and product packaging quality is guaranteed.

Owner:TIANJIN XINJINJIA TECH DEV CO LTD

Flexible film vertical vacuum coating production line

ActiveCN107794510BReduce exposureAvoid destructionFinal product manufactureVacuum evaporation coatingProduction lineThin membrane

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

Vertical composite film system continuous magnetron sputtering production line for automobile glass

InactiveCN109957781AReduce the impactIncrease profitVacuum evaporation coatingSputtering coatingProduction lineComposite film

The invention discloses a vertical composite film system continuous magnetron sputtering production line for automobile glass. The production line comprises a feeding section and a discharging section, the feeding section is sequentially connected with a group of primary vacuum chamber, low vacuum chamber, middle vacuum chamber and high vacuum chamber from front to back; the discharging section issequentially connected with the other group of high vacuum chamber, middle vacuum chamber, low vacuum chamber and primary vacuum chamber from front to back; a sputtering chamber comprises at least one coating subarea, each coating subarea is provided with at least one rotary cathode device, the rotary cathode device is connected with an angle adjusting device, and the angle adjusting device is connected with the anode boxes of the coating subareas through a plurality of connecting arms extending along the longitudinal axis. The vertical composite film system continuous magnetron sputtering production line for automobile glass provided by the invention can realize large-batch and low-cost production of various coating films, is high in sputtering deposition rate and high in process universality, and is particularly suitable for large-scale industrial production.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

A high-strength cold-rolled non-oriented silicon steel for driving motors and its manufacturing method

The invention provides high-strength cold-rolled non-orientation silicon steel used for a driving motor and a manufacturing method and belongs to the technical field of steel and iron processing. Thehigh-strength cold-rolled non-orientation silicon steel comprises the components of, by weight, 0.001-0.0015% of C, 2.5-3.0% of Si, 0.8-1.0% of Al, 0.5-0.8% of Mn, 1.0-2.0% of Cr, 0.002% or the less of N, 0.1-0.2% of Nb and the balance Fe and inevitable impurities. The secondary cold-rolling reduced quantity and an annealing technology are controlled, so that the magnetic inductive strength, the iron loss and the yield strength of the non-orientation silicon steel are balanced. According to developed steel types, after the cold-rolling and annealing technologies, the magnetic inductive strength B50 is 1.67-1.70 T, the iron loss W1.0 / 50 is 2.0-5.5 W / kg, the iron loss W1.0 / 400 is 18.8-32.12 W / kg, the lower yield strength ReL is 460-510 MPa, the tensile strength Rm is 560-640 MPa, the elongation percentage is 16.08-23.3%, and the requirements for the property aspect of common high-strength cold-rolled non-orientation silicon steel are met and exceeded.

Owner:UNIV OF SCI & TECH BEIJING

Zero emission treatment method of completely turning chromium-containing waste liquor into useable resources.

InactiveCN101618902BStrong process versatilityEasy to controlWater contaminantsWater/sewage treatment bu osmosis/dialysisLiquid wasteFiltration

Owner:刘文治 +2

A gift box type liquor automatic boxing system

ActiveCN104986372BImprove packaging efficiencyGuaranteed packaging qualityPackaging bottlesModular designEngineering

The invention relates to a gift box type white spirit automatic packing system. The gift box type white spirit automatic packing system comprises a splitting module, a white spirit support feeding module, a bottle feeding module, a box cover buckling module and a gift box discharging module which are arranged in sequence. A double-servo moving mechanism is arranged at the top end of a door type frame of the splitting module, the white spirit support feeding module, the bottle feeding module, the box cover buckling module and the gift box discharging module. A circulation feeding mechanism is coaxially arranged in the middle of the inner sides of the splitting module, the white spirit support feeding module, the bottle feeding module, the box cover buckling module and the gift box discharging module in the horizontal transverse direction. The circulation feeding mechanism is controlled by a system program for circulation running for conveying of a support bottom. Conveying belts are horizontally arranged on the two longitudinal sides of the circulation feeding mechanism respectively, and the conveying belts on the two sides are used for conveying bottles and gift boxes respectively. According to the system, the modular design production is adopted, and the number of the modules is increased and reduced according to different technical processes. The system is widely applied to white spirit package and production, the packaging efficiency is improved, and the packaging quality of products is guaranteed.

Owner:TIANJIN XINJINJIA TECH DEV CO LTD

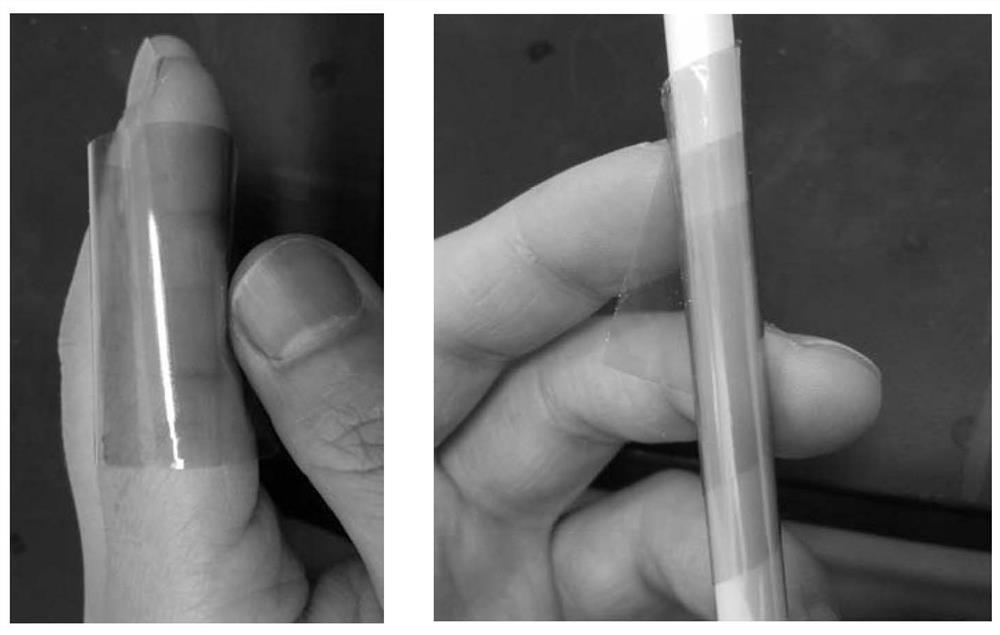

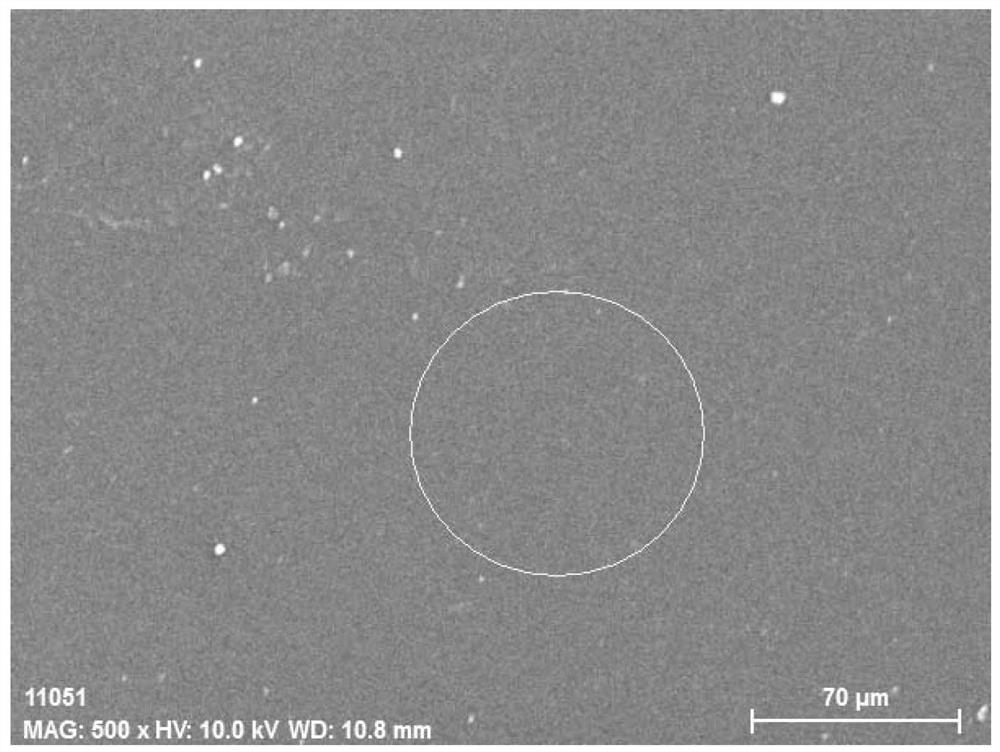

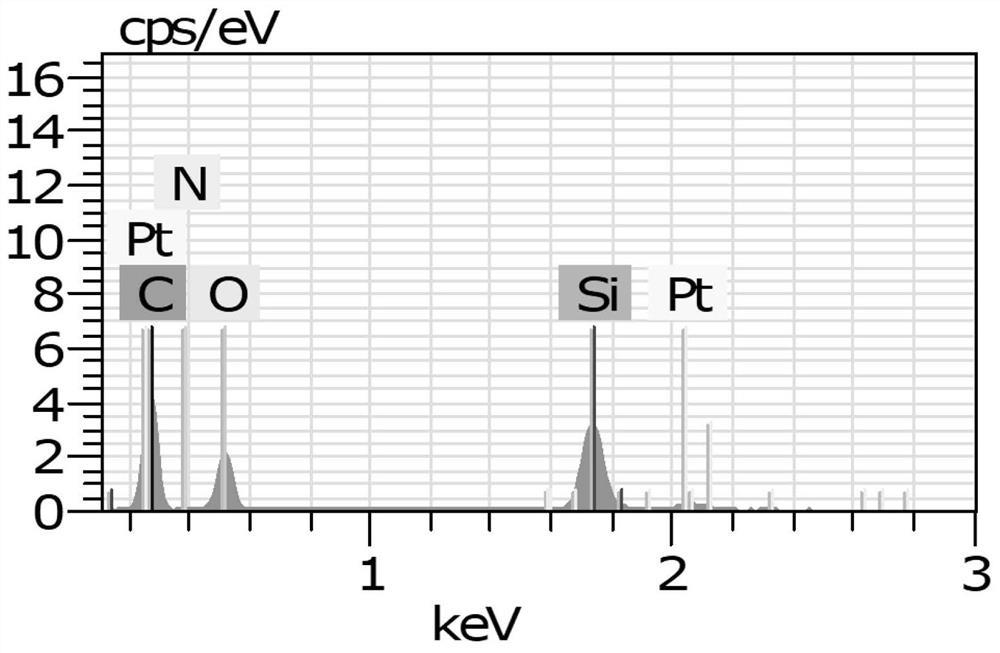

A kind of anti-atomic oxygen polyimide composite film and preparation method thereof

The invention relates to an atomic oxygen-resistant polyimide composite film and a preparation method thereof. The preparation method of the atomic oxygen-resistant polyimide film comprises: (1) coating a polyamic acid resin solution on the surface of a carrier to obtain The polyamic acid liquid film is then dried at 60-220°C for 1-20 minutes and peeled off from the carrier to obtain a polyamic acid gel film; (2) Coating polyamic acid / polyamic acid on at least one side of the polyamic acid gel film After the solution of polysiloxane block copolymer, dry at 50-100°C for 10-180 seconds to form a transition layer on at least one side of the polyamic acid gel film; (3) Continue coating on the surface of the transition layer After self-crosslinking the trapezoidal polysilsesquioxane solution, dry at 60-120°C for 10-120 seconds to obtain a multi-layer composite film; (4) The obtained multi-layer composite film is subjected to multi-stage drying treatment in a clamped state , to obtain the anti-atomic oxygen polyimide film.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Impregnation forming method for capacitor core assembly

ActiveCN101121159BSolving Packaging ChallengesStrong process versatilityPretreated surfacesCoatingsWorking temperatureMiniaturization

The present invention relates to a novel dip forming method of a specific dry-type capacitor. An isolation screen is added. A core group, which dips the dipping material from bottom to upside, is adopted, and a glass rod is used in a diversion step. The core group is thoroughly solidified by the heat preservation of a multi-temperature zone. The purpose of the present invention is to solve the problems of dipping and an encapsulation of the specific capacitors and the relevant electronic equipments. With a strong technical generality, less implementation difficulty, little investment and stable and reliable quality, the dip forming can satisfy the requirements of the electronic equipment of miniaturization, dry-type (solidification), large span of working temperature-zones and strong environmental applicability. The present invention can be used for manufacturing specific capacitors which are applied to high current with high temperature and high voltage, such as a filter capacitor which is used for high-voltage electrical source of airplane, an engine-igniting capacitor, a deep-well pulse sound wave exploration etc. The present invention can also be used in the encapsulation field of high-performance electronic equipment.

Owner:CHENGDU HONGMING ELECTRONICS CO LTD

Cold-rolled non-oriented silicon steel with high magnetic induction and low iron loss for high-efficiency motor and manufacture method thereof

The invention belongs to the technical fields of steel metallurgy and processing, in particular to cold-rolled non-oriented silicon steel with high magnetic induction and low iron loss for a high-efficiency motor and a manufacture method thereof. The manufacture method is characterized in that 0.5-0.6 percent of Mn and 0.1-0.4 percent of Cu are added to the cold-rolled non-oriented silicon steel containing Si and Al with the weight percentage of 1.1-1.3 percent, a great amount of Cu-contained compounds precipitated from a hot-rolled strip are utilized to stimulate the formation of beneficial texture components (110) in steel under the conditions of rolling and coiling processes and lessen the formation of adverse texture components (111) so that the magnetic performance of steel is greatly improved. The cold-rolled non-oriented silicon steel with high magnetic induction and low iron loss for a high-efficiency motor, which is manufactured by using the method, has magnetic induction strength B50 over 1.7T and iron loss P1.5 less than 4.0 W / kg.

Owner:UNIV OF SCI & TECH BEIJING +1

An intermittent circulation rotary system and its working method

ActiveCN105173263BStrong process versatilityImprove applicabilityPackagingMechanical engineeringWhite spirit

The invention relates to an intermittent circulation rotary system and a machining method thereof. The intermittent circulation rotary system comprises a rack, an input end lifting mechanism, an output end lifting mechanism, an upper layer track, a lower layer track and trays. The rack is a rectangular cubic frame which is horizontally and transversely arranged. The input end lifting mechanism is installed at the input end of the rack, the output end lifting mechanism is installed at the output end of the rack, and the input end lifting mechanism, the rack and the output end lifting mechanism are horizontally and transversely arranged in a coaxial manner. The upper layer track and the lower layer track are installed in the rack in a vertically spaced manner. The multiple trays are horizontally installed on the upper layer track in a guide manner and sequentially connected end to end. The intermittent circulation rotary system can be widely adapted to different types of gift box type white spirit packaging boxes from different manufacturers. By reasonably splitting an original production technology and implementing an automatic solution at key points, targeted automatic production is achieved, packaging efficiency is improved, and product packaging quality is guaranteed.

Owner:TIANJIN XINJINJIA TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com