Large-area AZO glass coating film production line

A coating production line, large-area technology, applied in the field of large-area AZO glass coating production line, can solve the problems of non-tempering and short storage time, and achieve the effects of saving energy consumption, improving utilization rate, and short vacuum pumping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, the present invention will be further described in detail and completely in combination with examples and comparative examples.

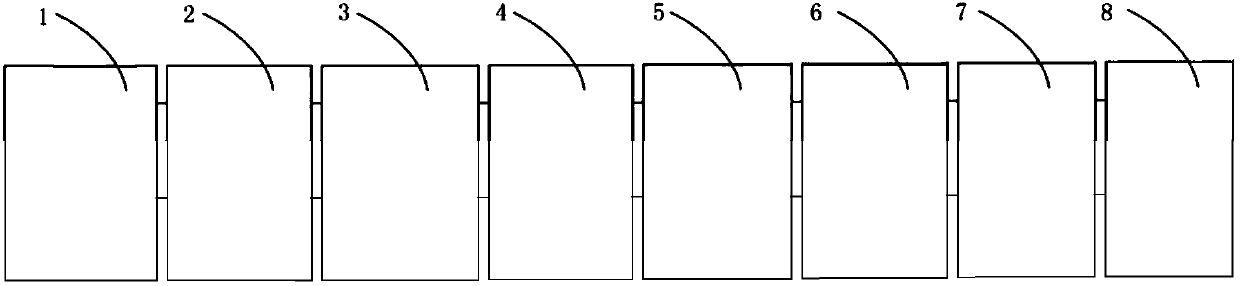

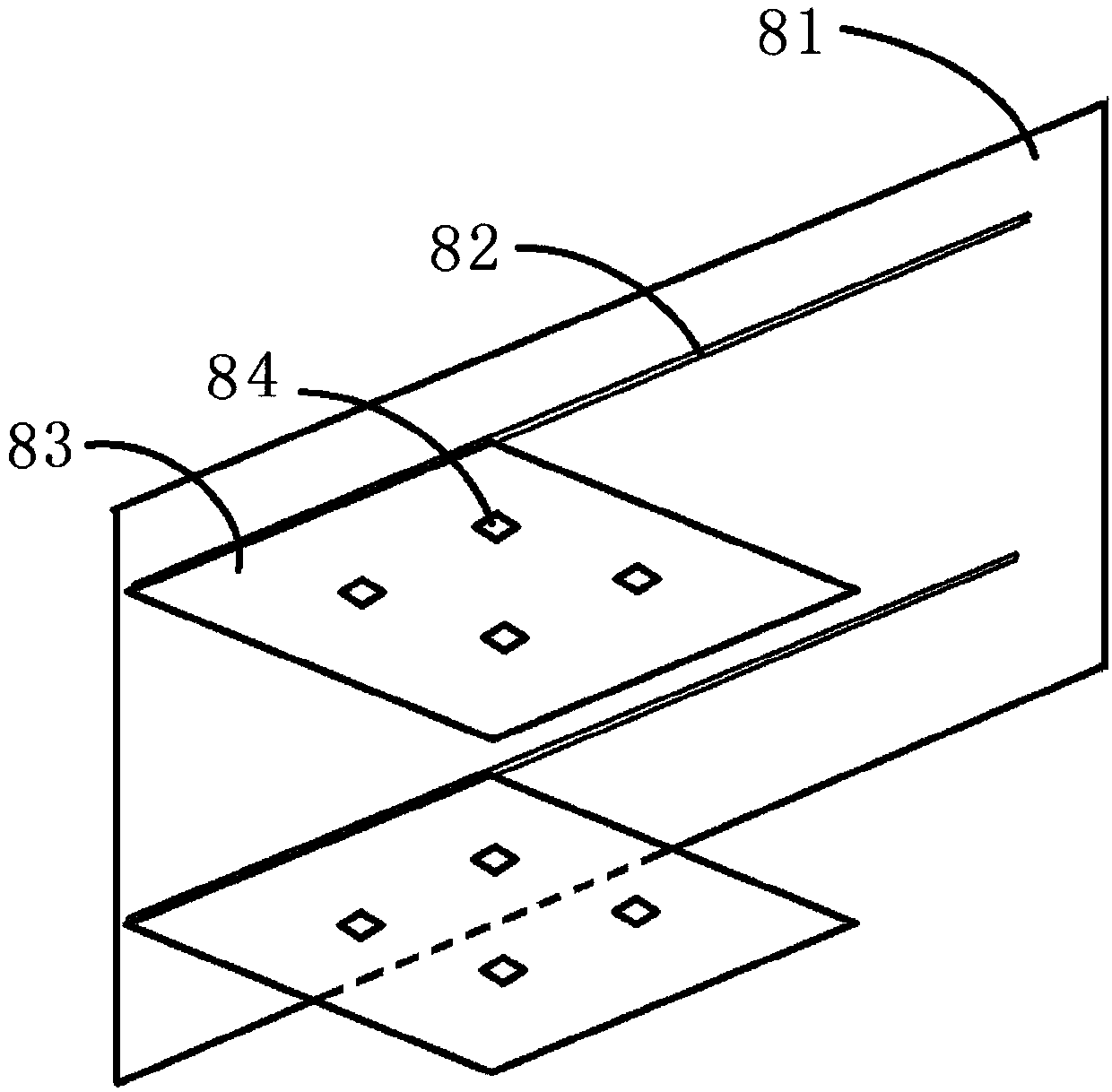

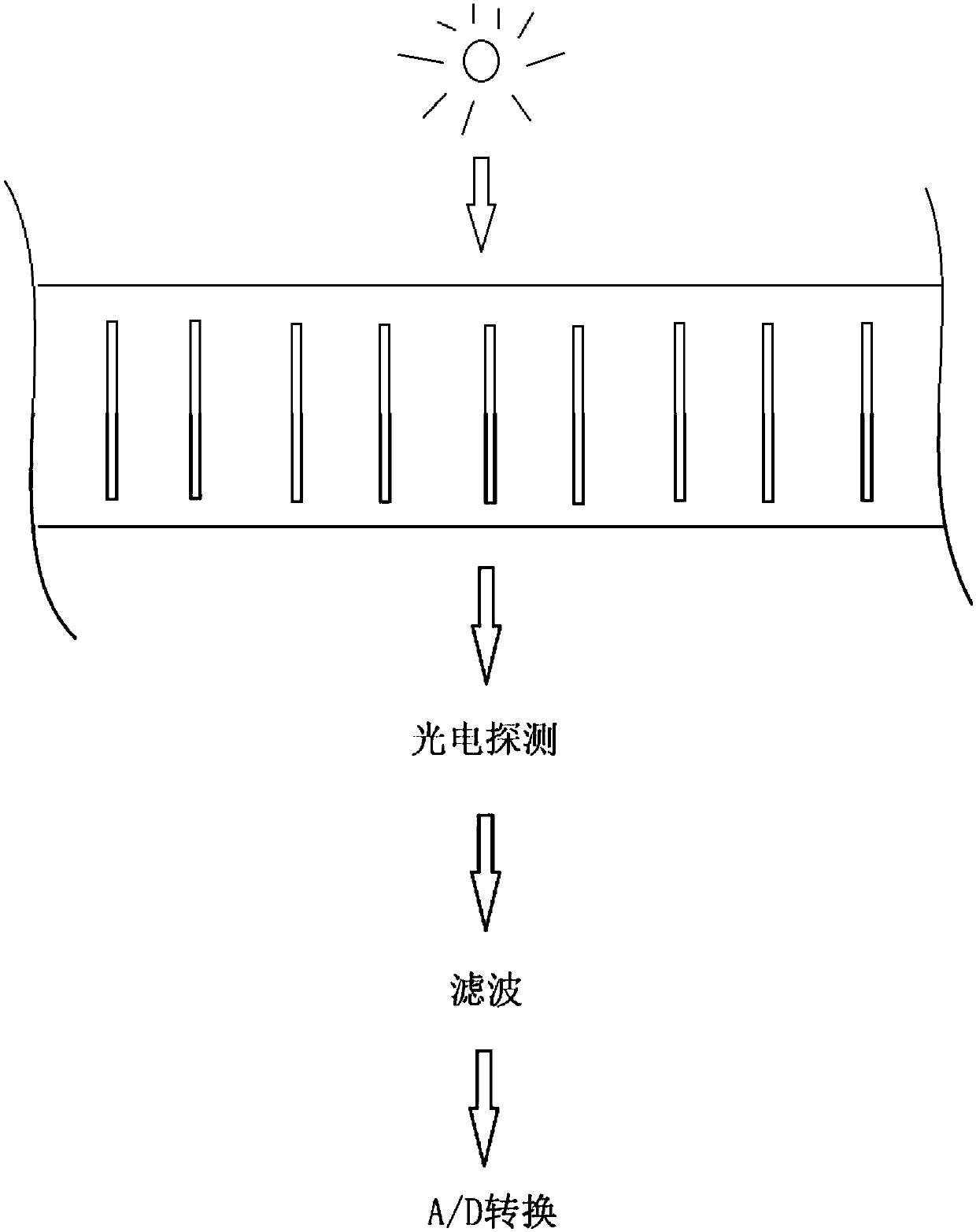

[0039] The large-area AZO glass coating production line of the present invention is a vertical single-sided coating, and is designed as an eight-chamber structure, which is an inlet chamber, an inlet buffer chamber, an inlet transfer chamber, and a sputtering chamber (determined to be divided into several sections according to the processing and installation conditions ), the outlet transfer room, the outlet buffer room, the outlet room and the quality inspection room, each process room is connected by a flap valve; figure 1 It can be seen that the process steps for the preparation of the production line are: the substrate in the upper section is transported to the inlet chamber, the substrate in the inlet chamber is transported to the high-vacuum inlet buffer chamber, and the substrate in the inlet buffer chamber is transported to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com