Patents

Literature

41results about How to "Stable feed rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

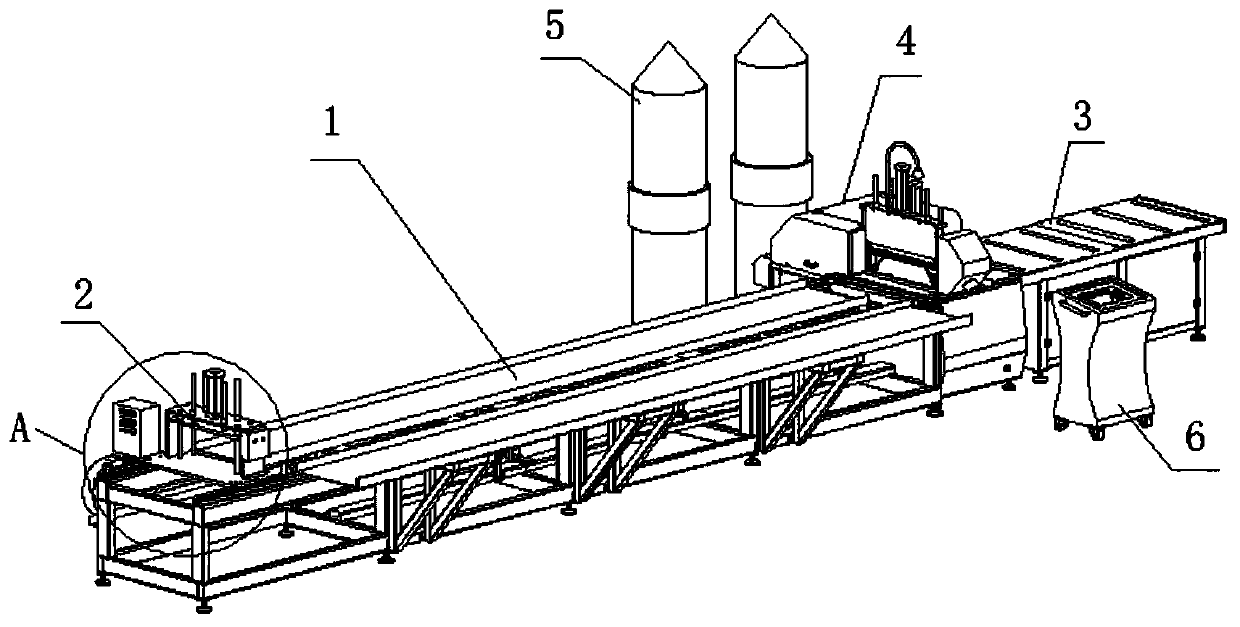

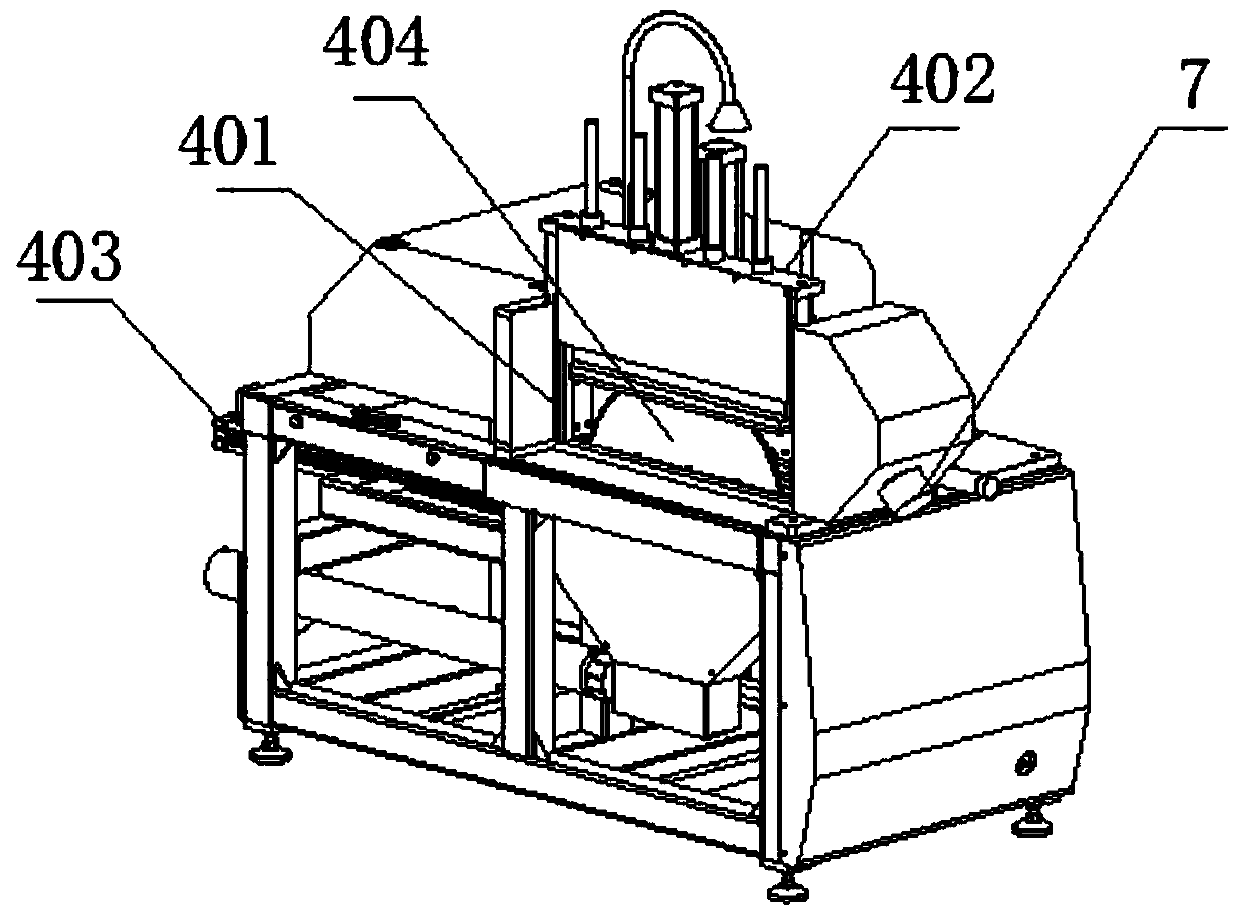

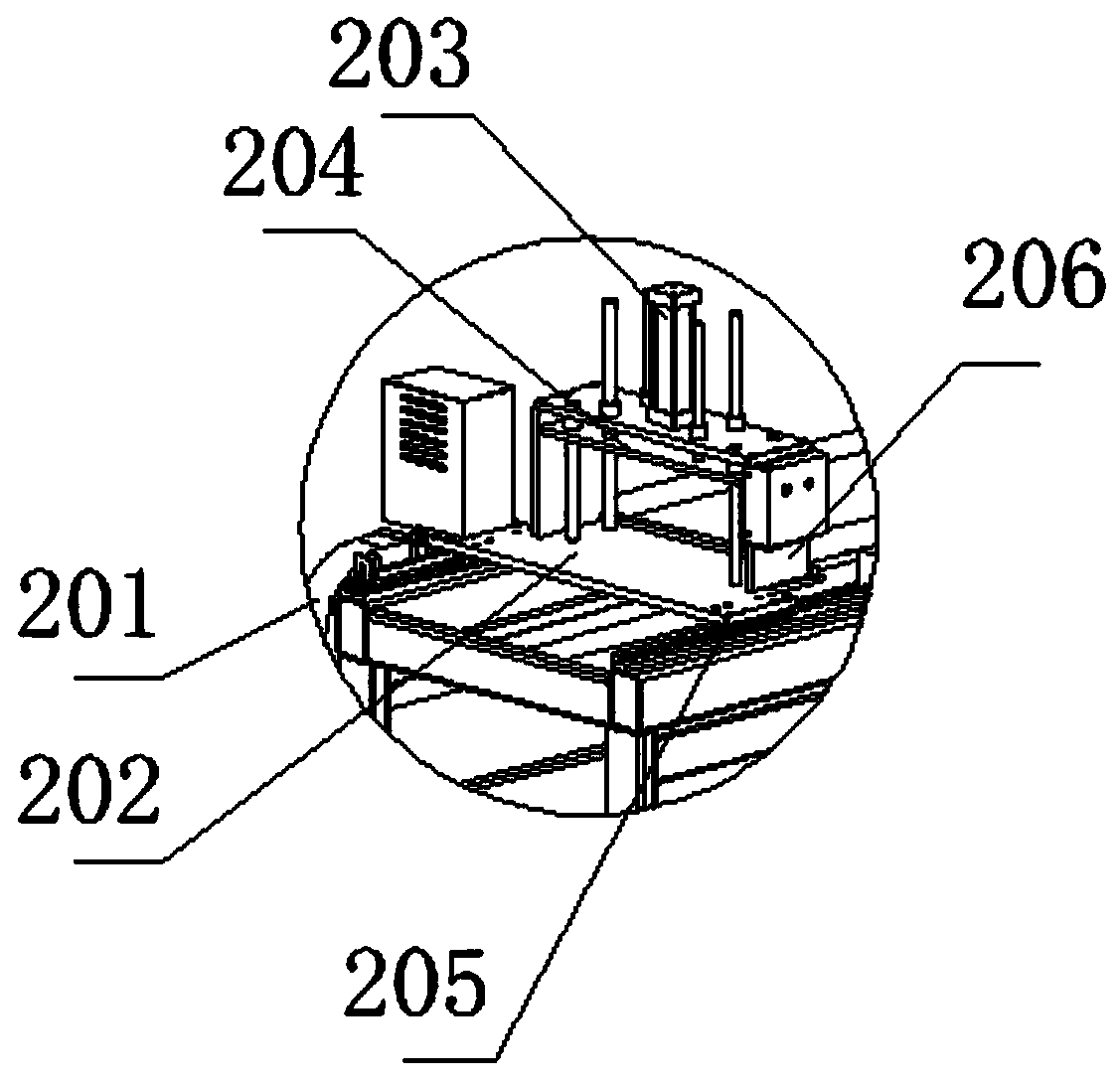

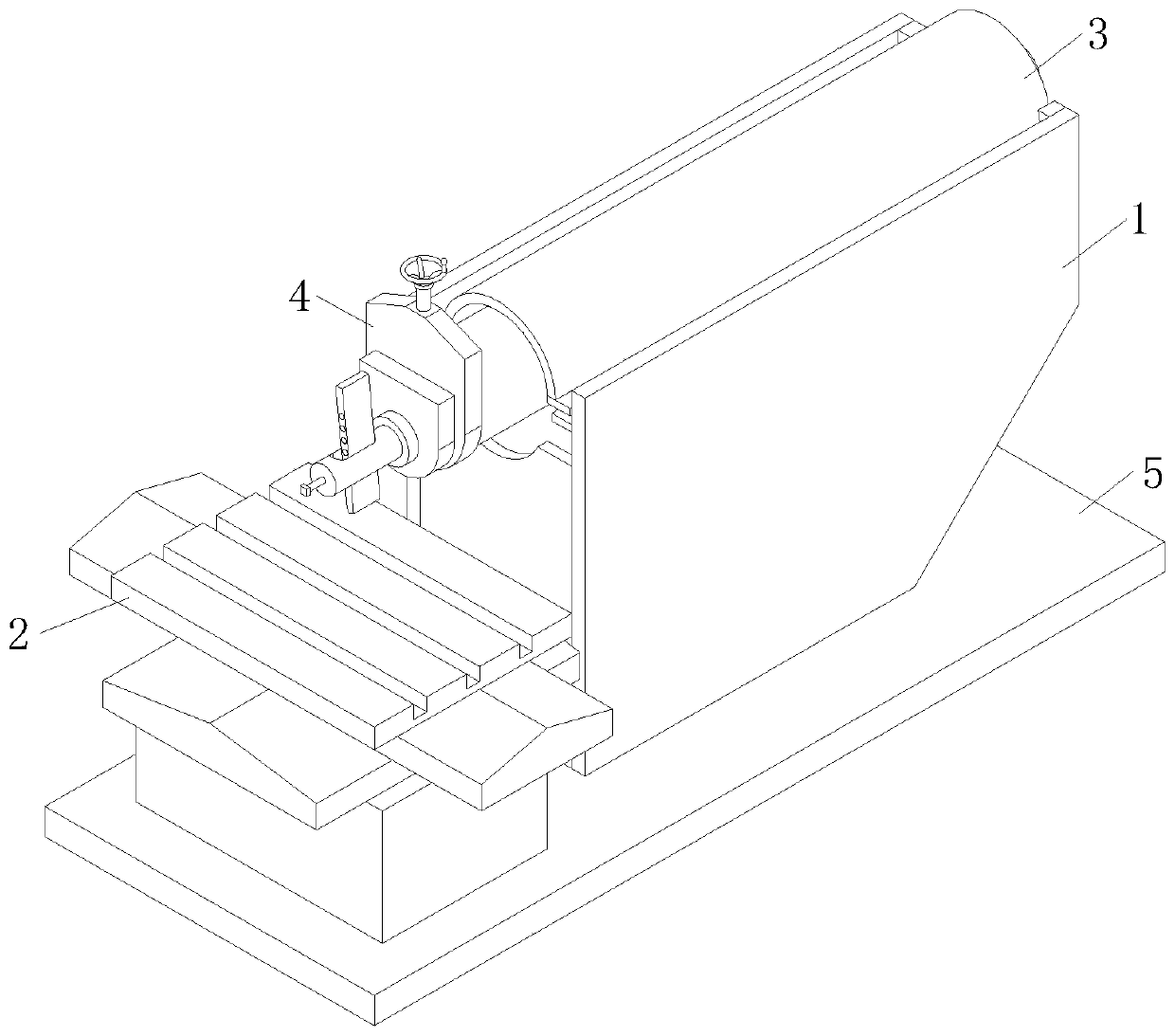

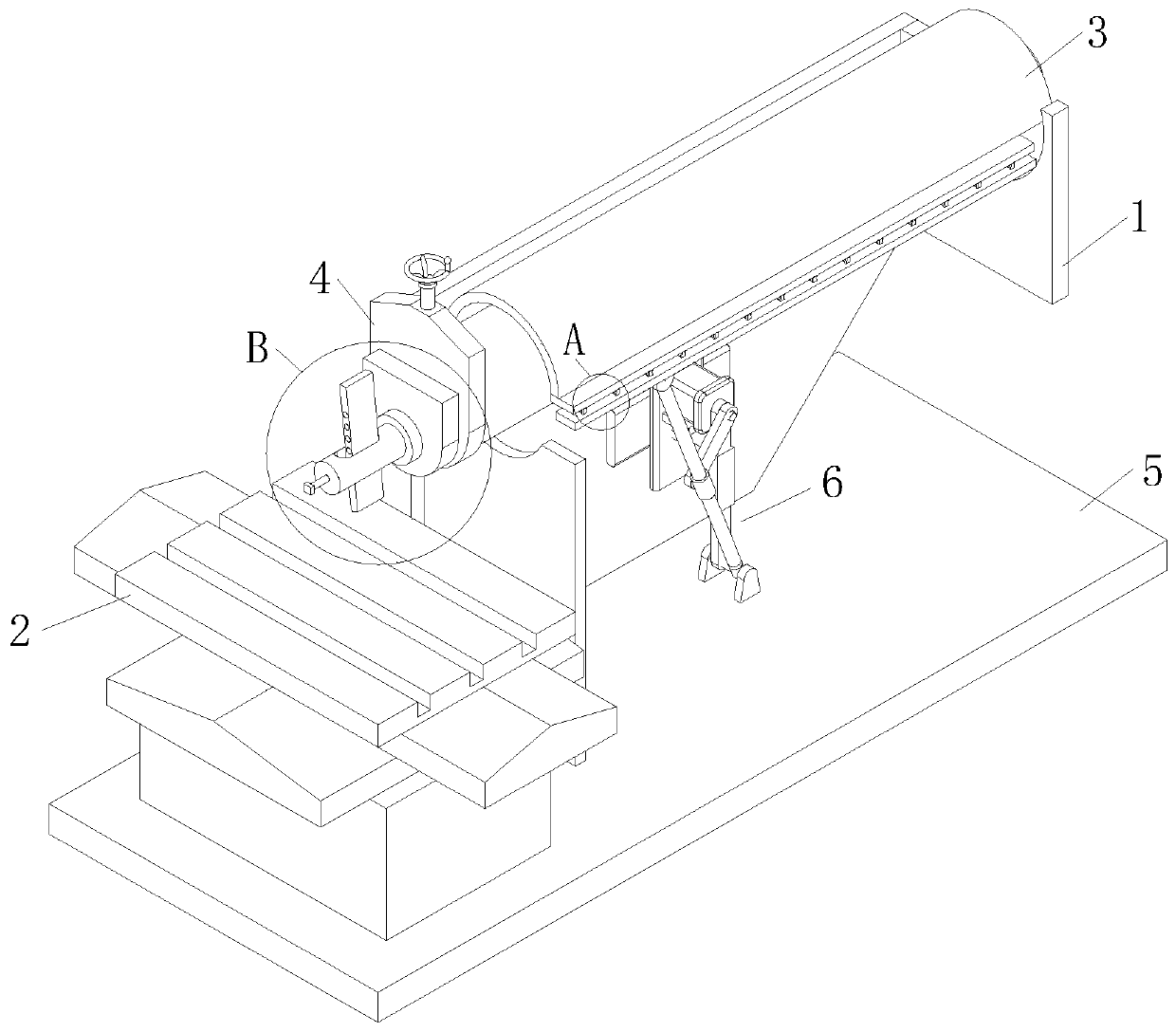

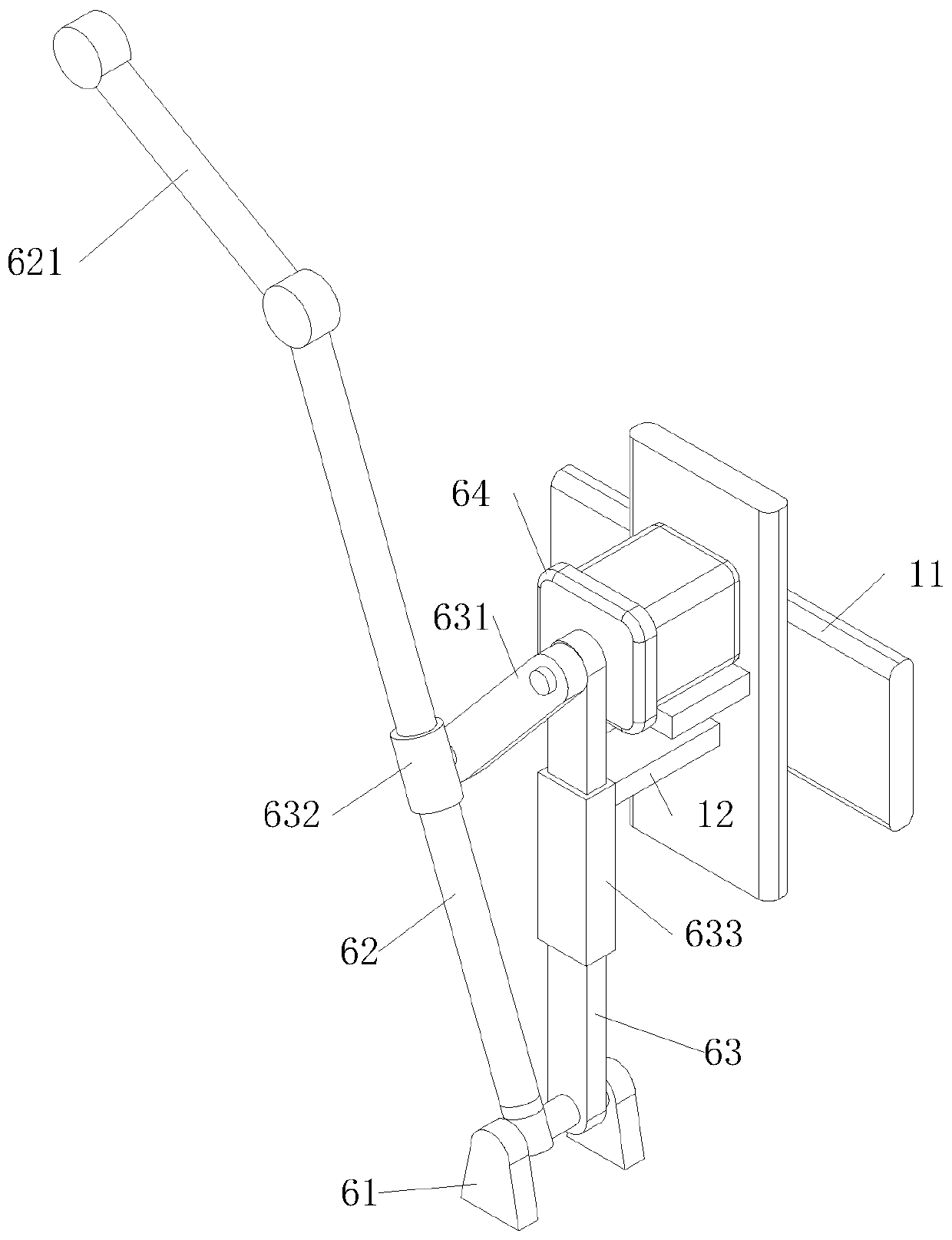

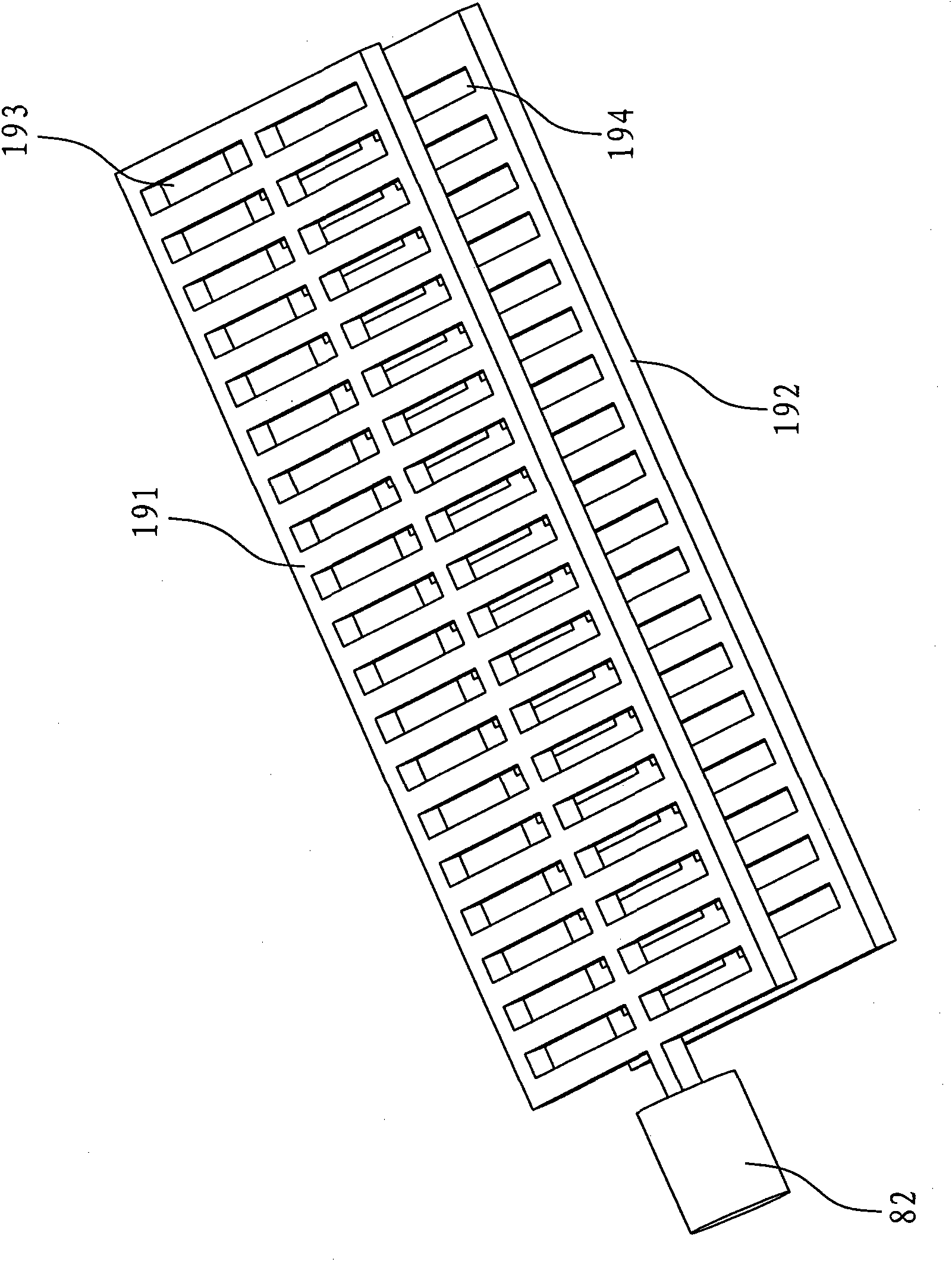

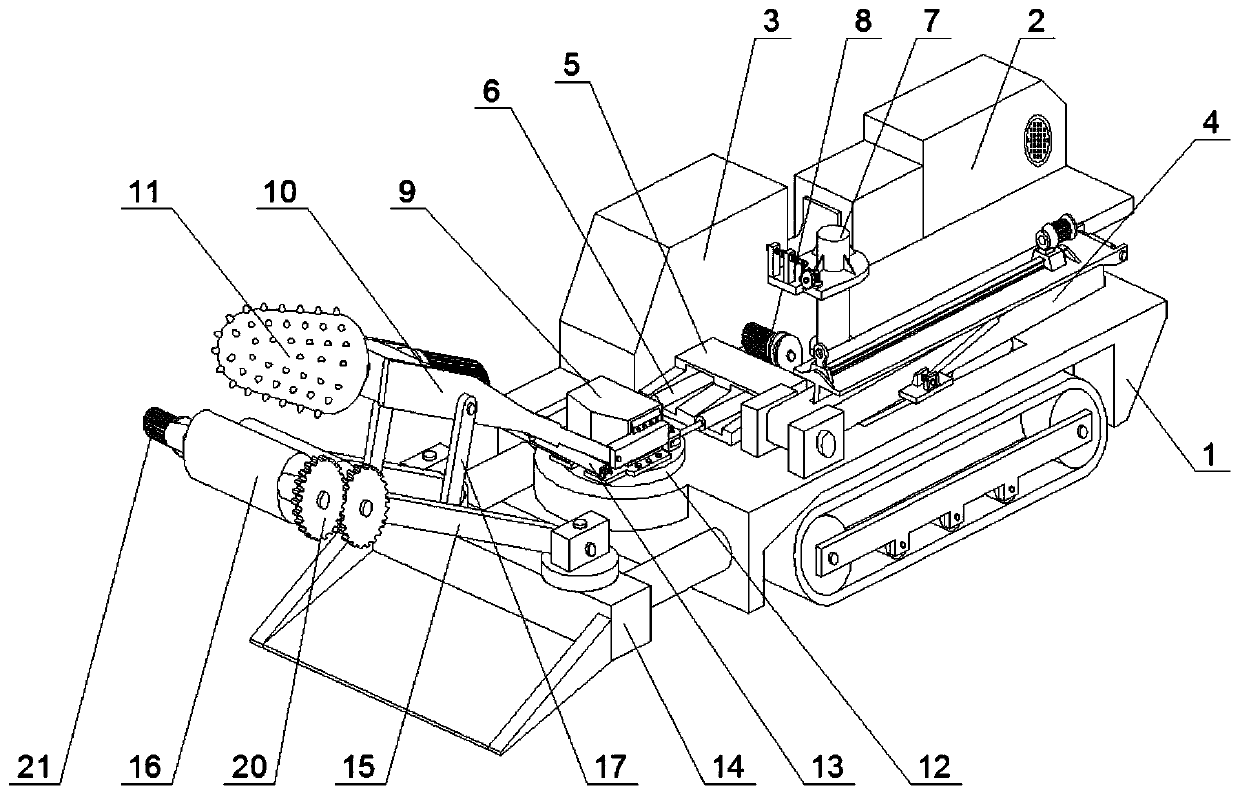

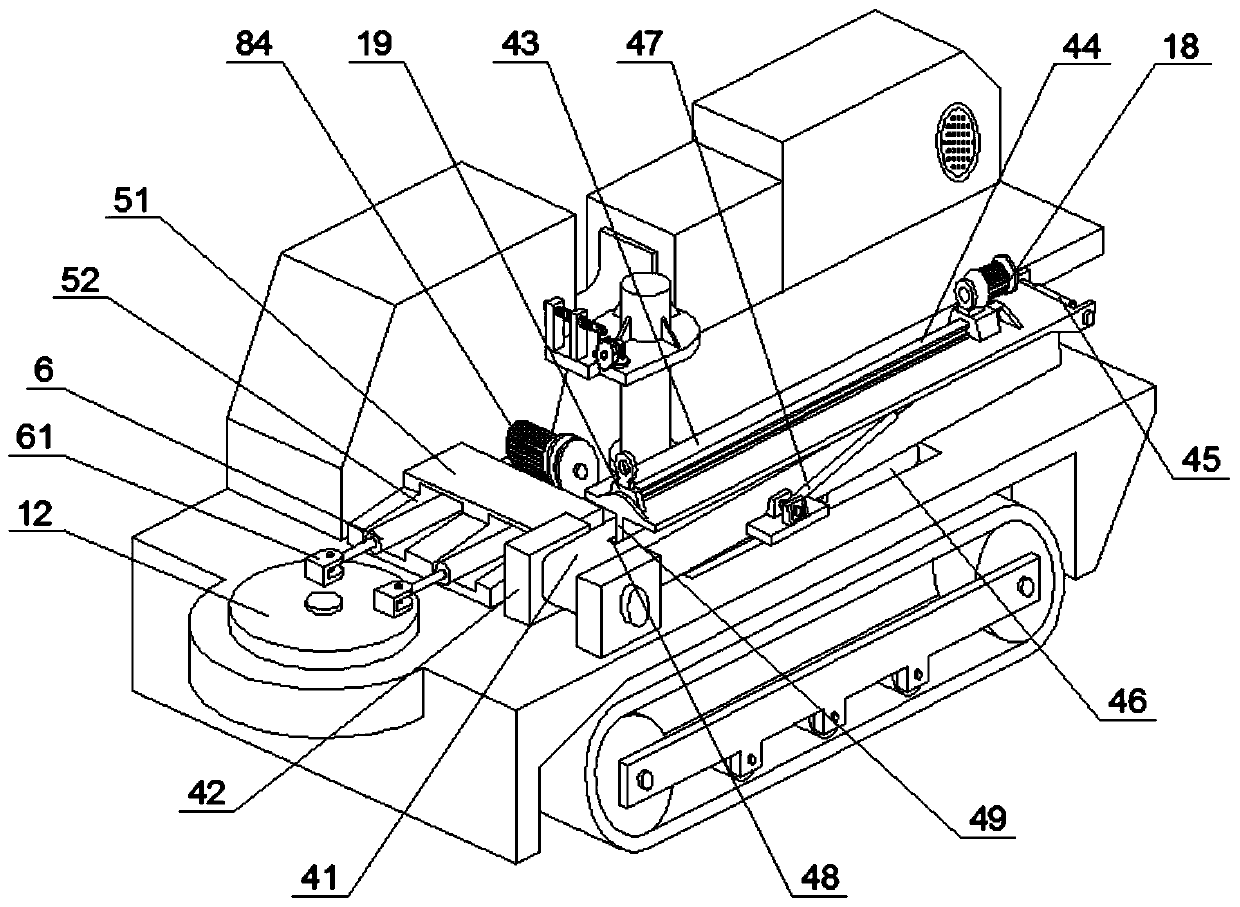

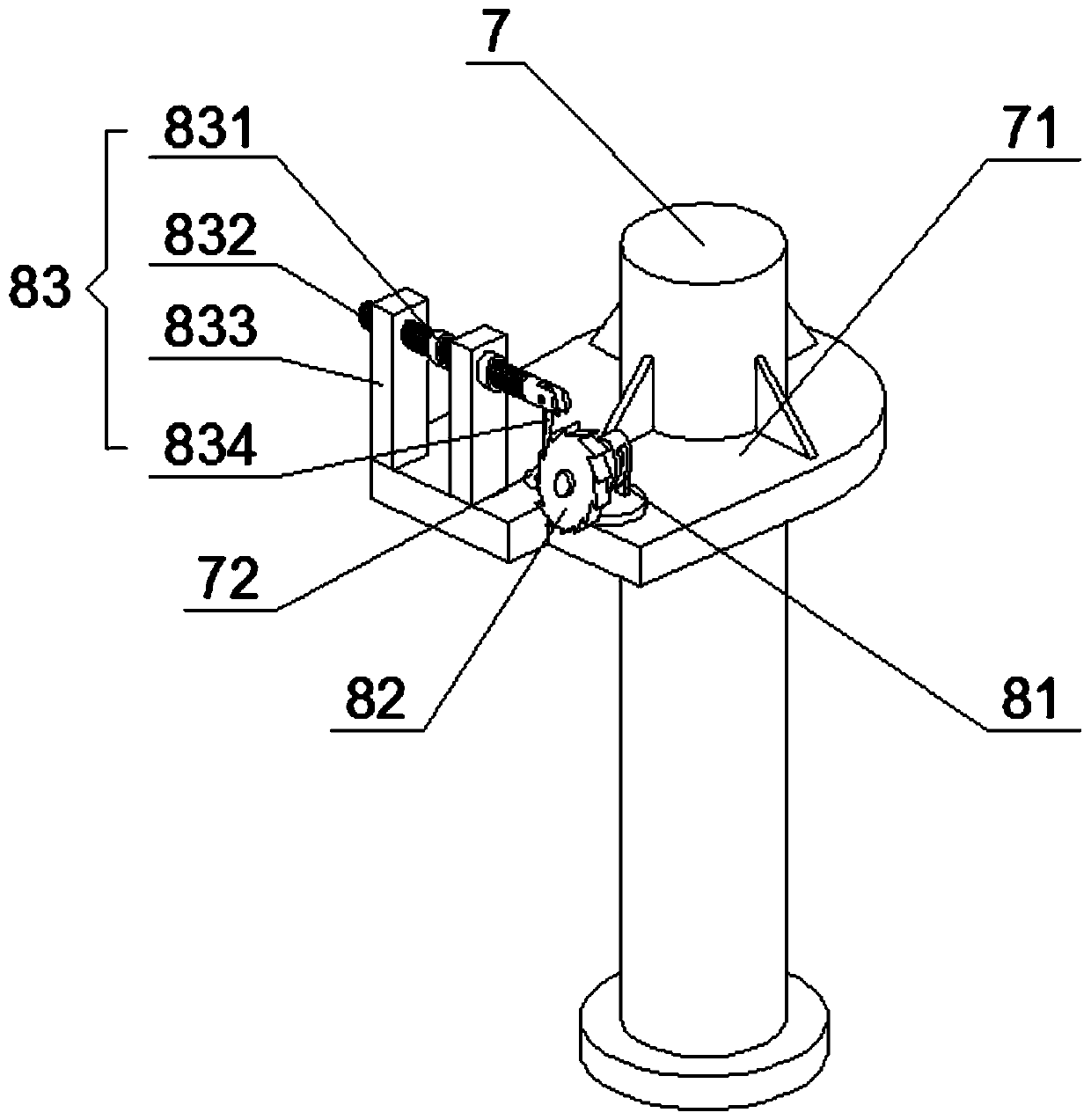

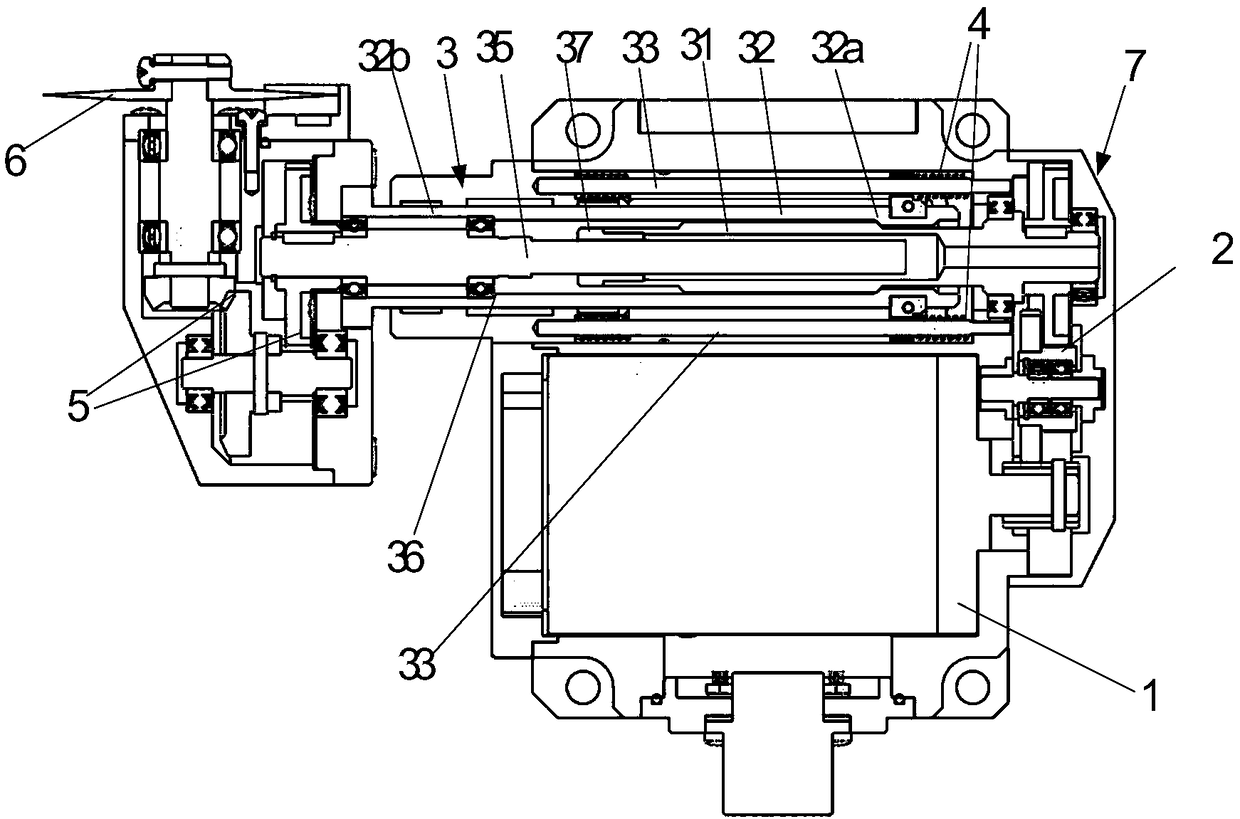

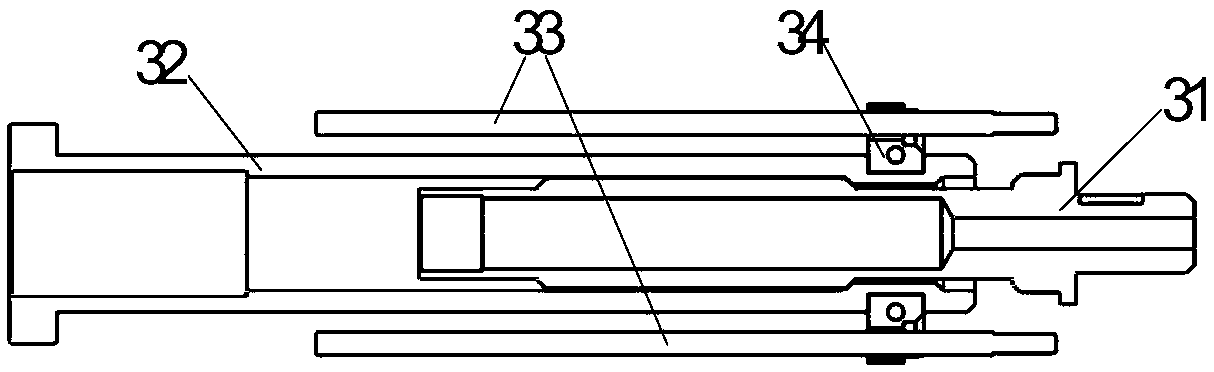

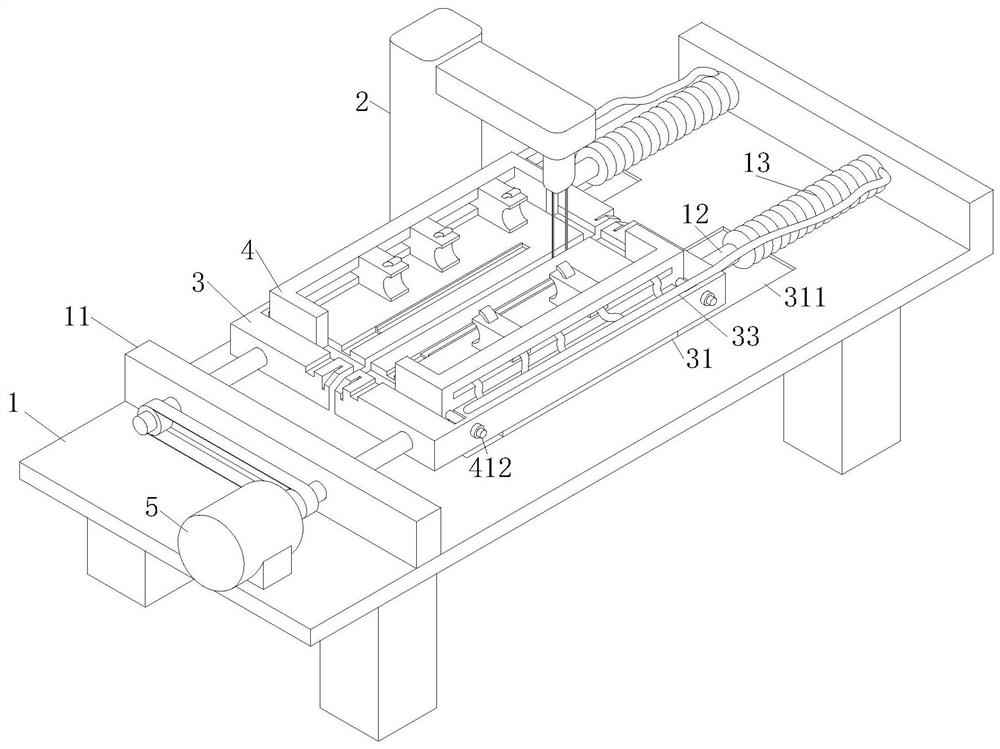

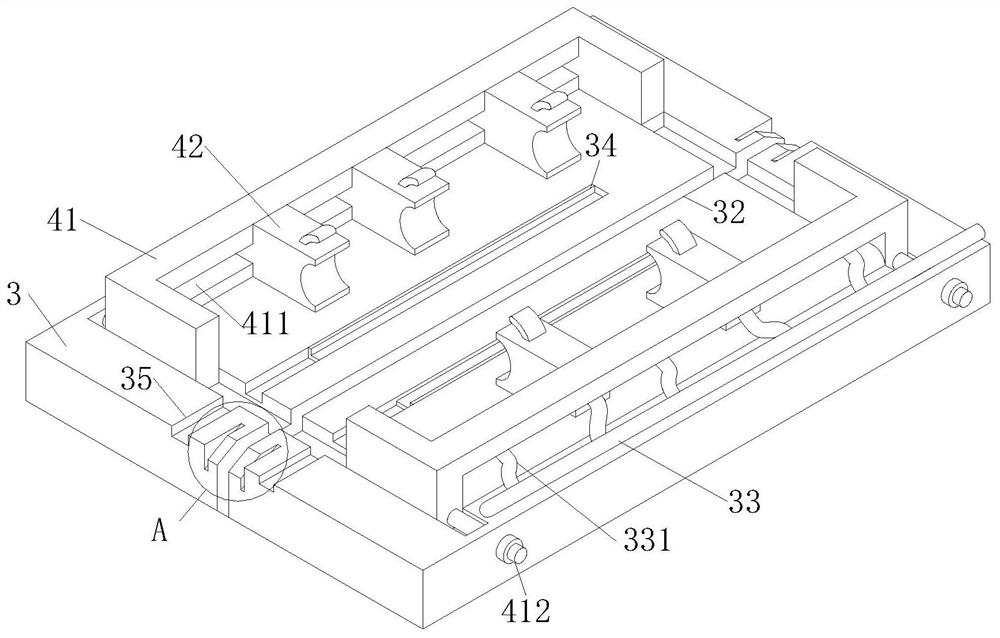

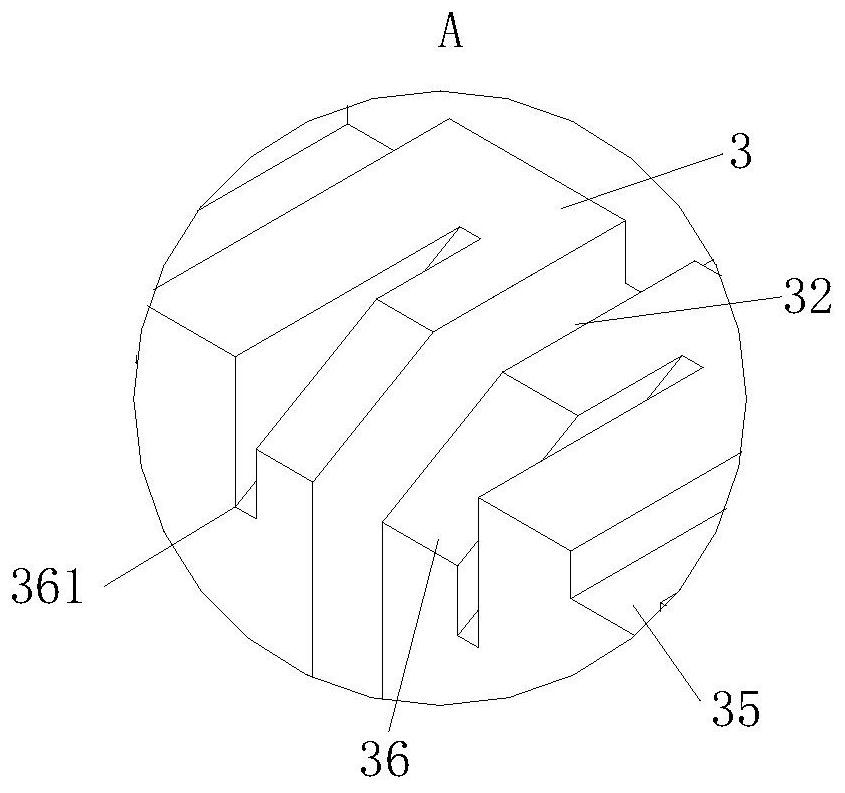

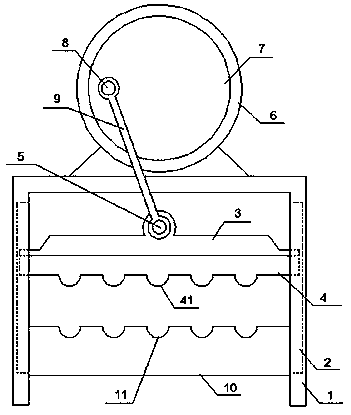

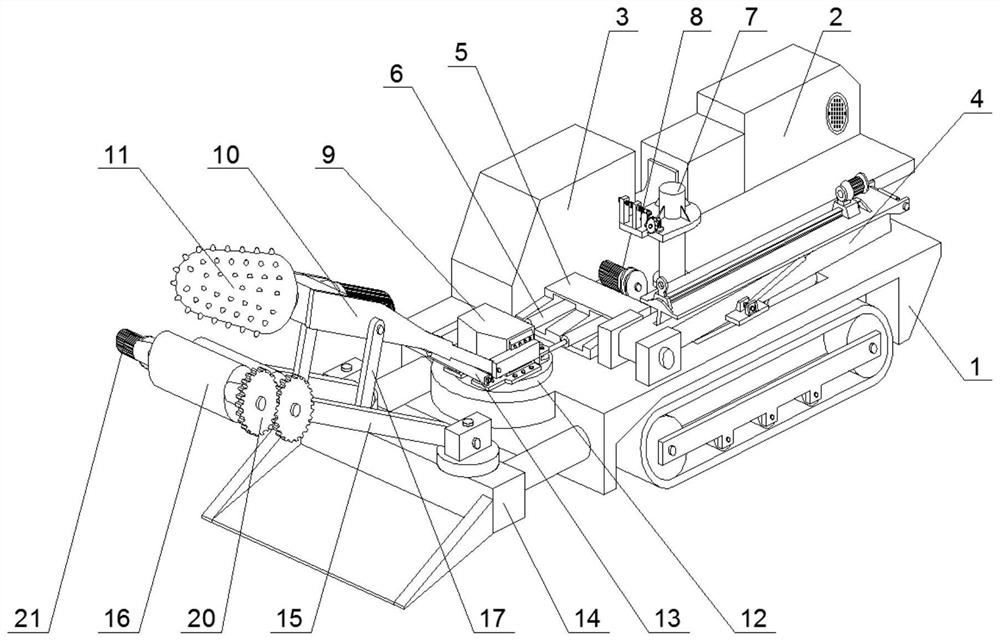

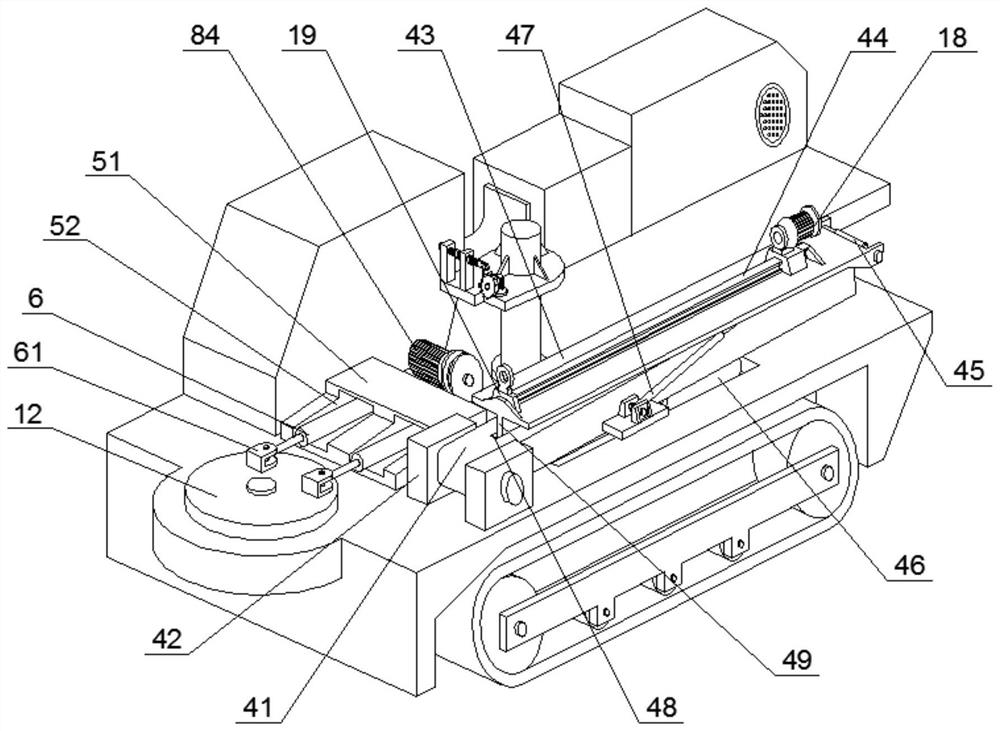

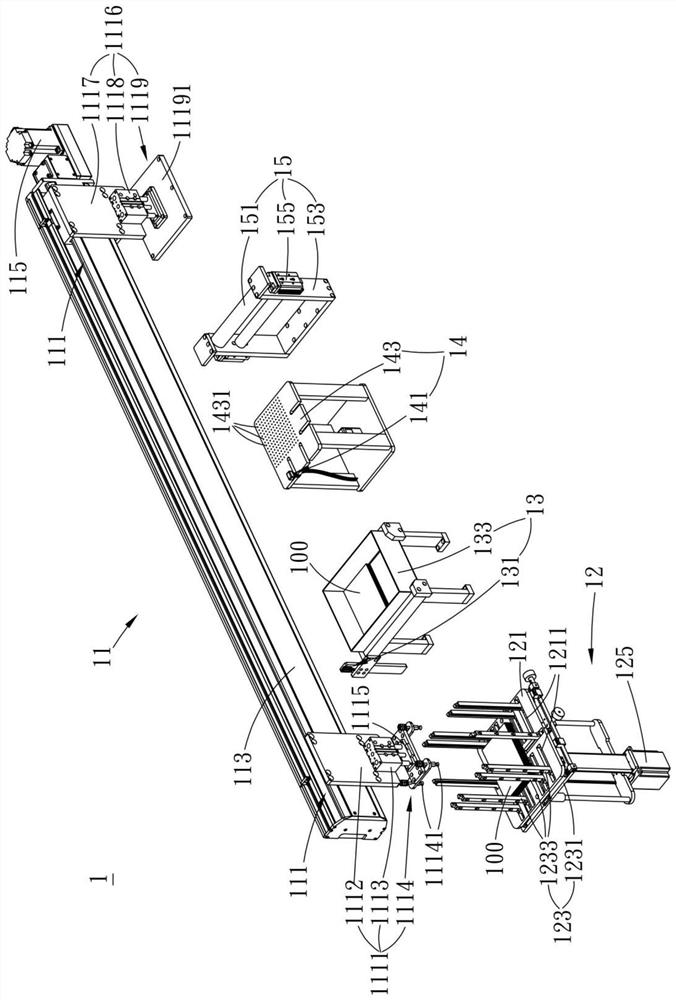

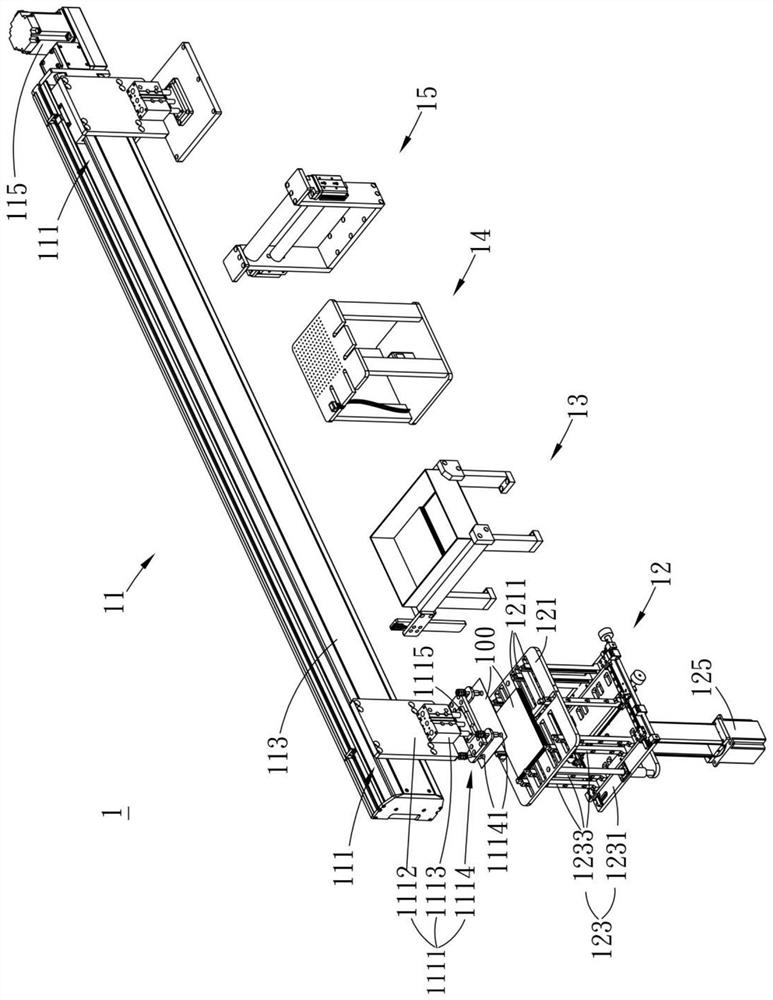

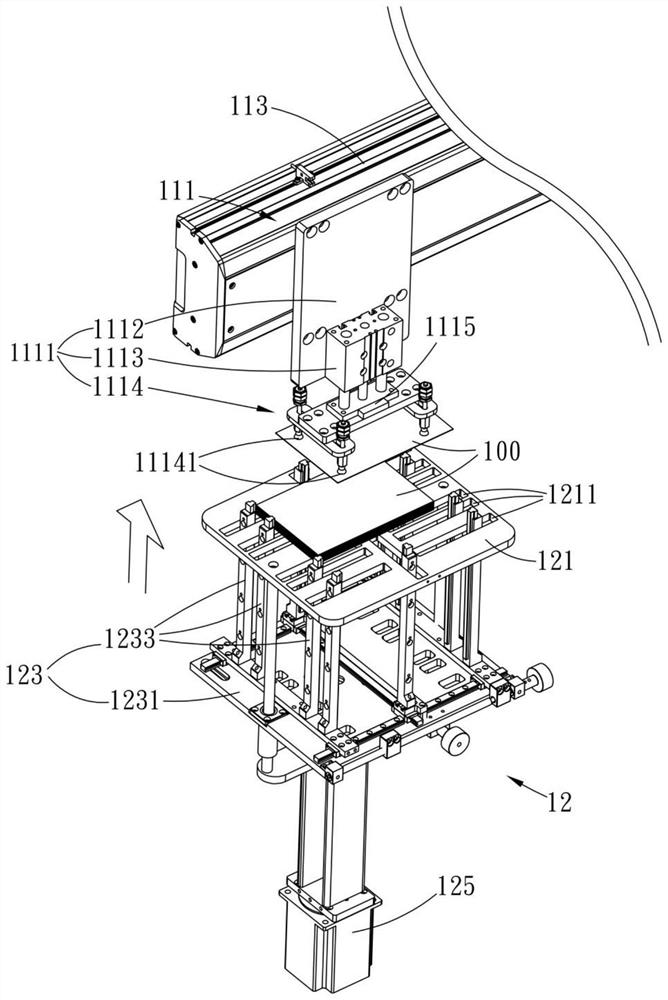

Automatic feeding saw for building aluminum formwork

InactiveCN109773266ASolve unqualifiedPlay a role in material breakingMetal sawing devicesMetal working apparatusLoop controlClosed loop

The invention discloses an automatic feeding saw for a building aluminum formwork. The automatic feeding saw comprises a feeding mechanism and a sawing mechanism. The feeding mechanism comprises a feeding frame mounted at the bottom, and a feeding machine head is mounted on the upper side of one end of the feeding frame. The feeding machine head is driven by a servo motor and subjected to closed-loop control through a magnetic railing ruler. The sawing mechanism is mounted at the other end of the feeding frame, and a dust collector is mounted beside the sawing mechanism. A discharging frame ismounted at the discharging end of the sawing mechanism, and an electric control cabinet is mounted beside the discharging frame. The feeding mechanism, the sawing mechanism and the dust collector areelectrically connected with the electric control cabinet. The automatic feeding saw for the building aluminum formwork is sawing equipment for the building aluminum formwork, a cut-off function is achieved, the automatic feeding mechanism is arranged, and the automatic feeding size is precise. The problem that original workpieces sawn by manual operation are unqualified is solved, the feeding speed is high, and the machining efficiency is high.

Owner:广东斯丹诺智能装备有限公司

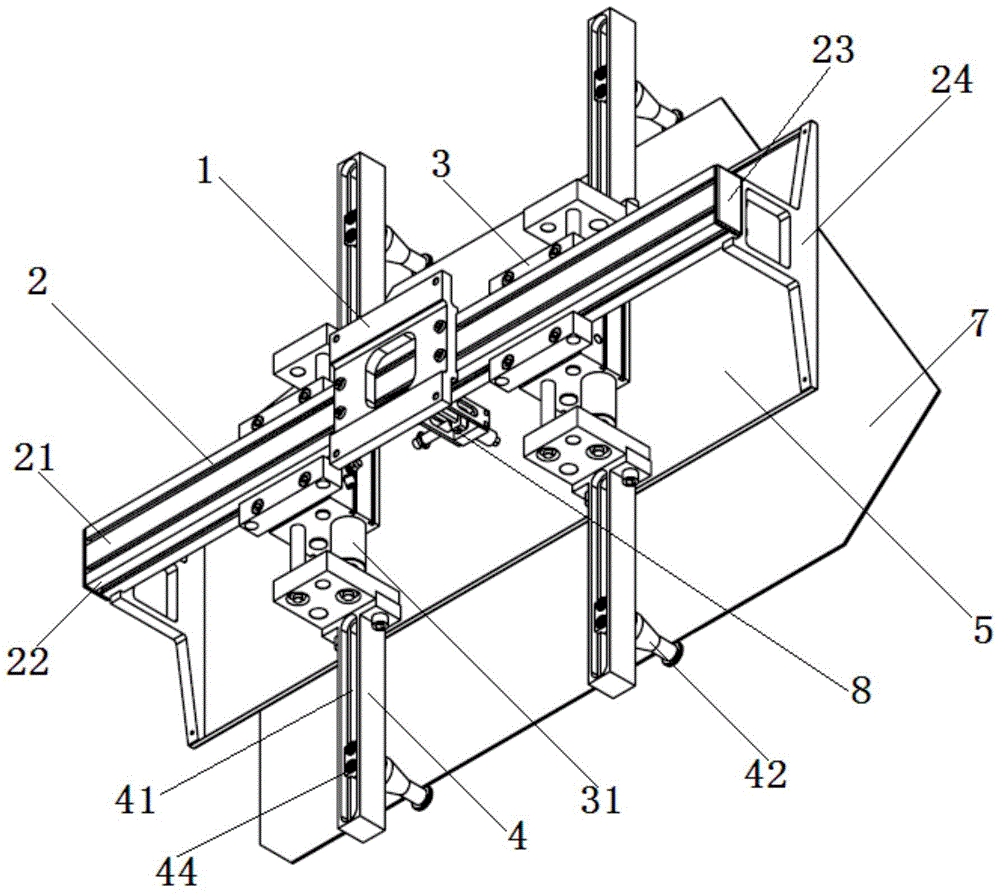

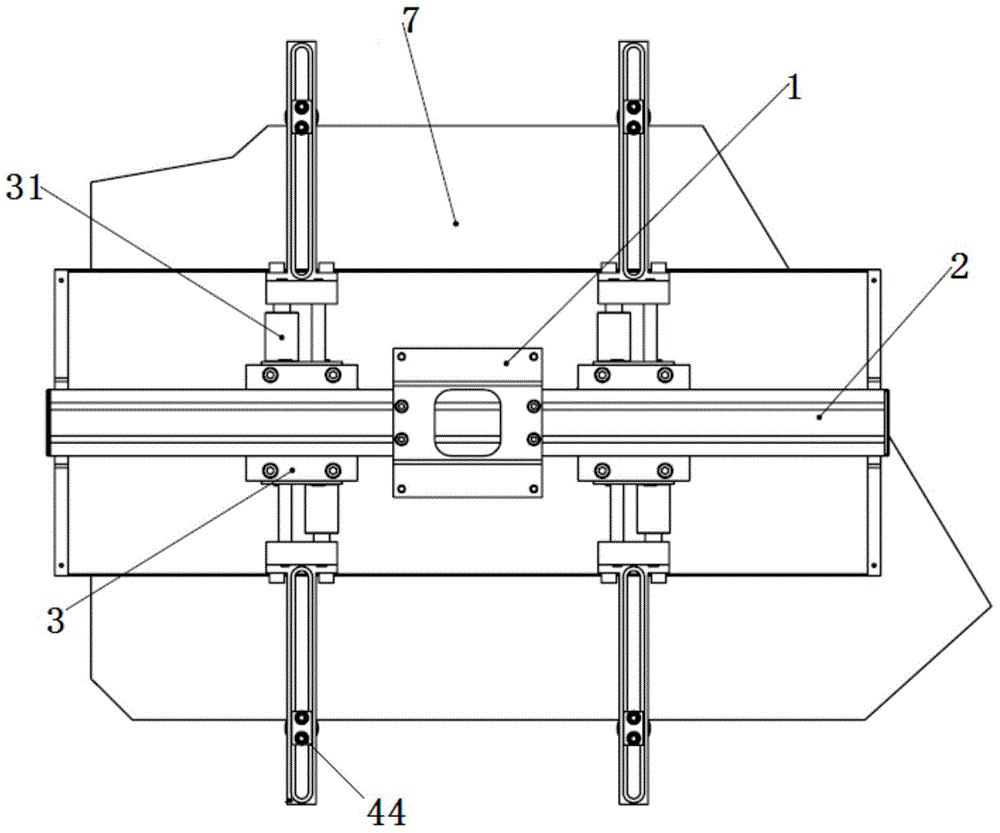

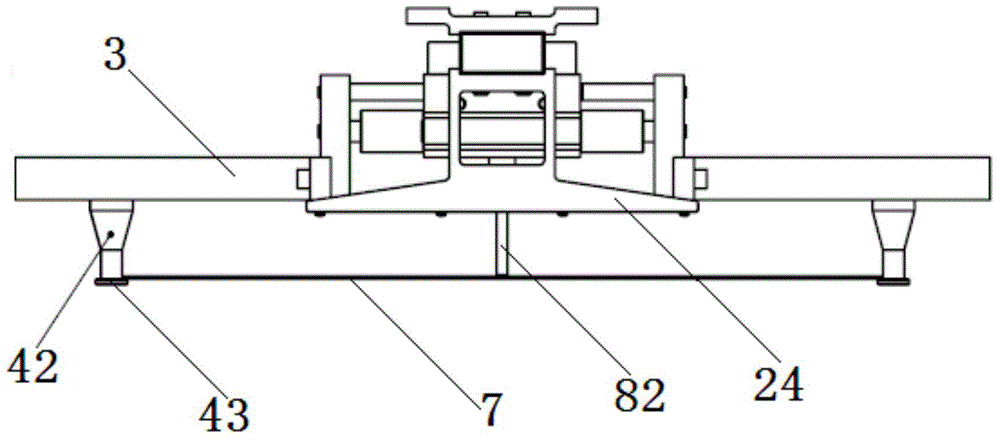

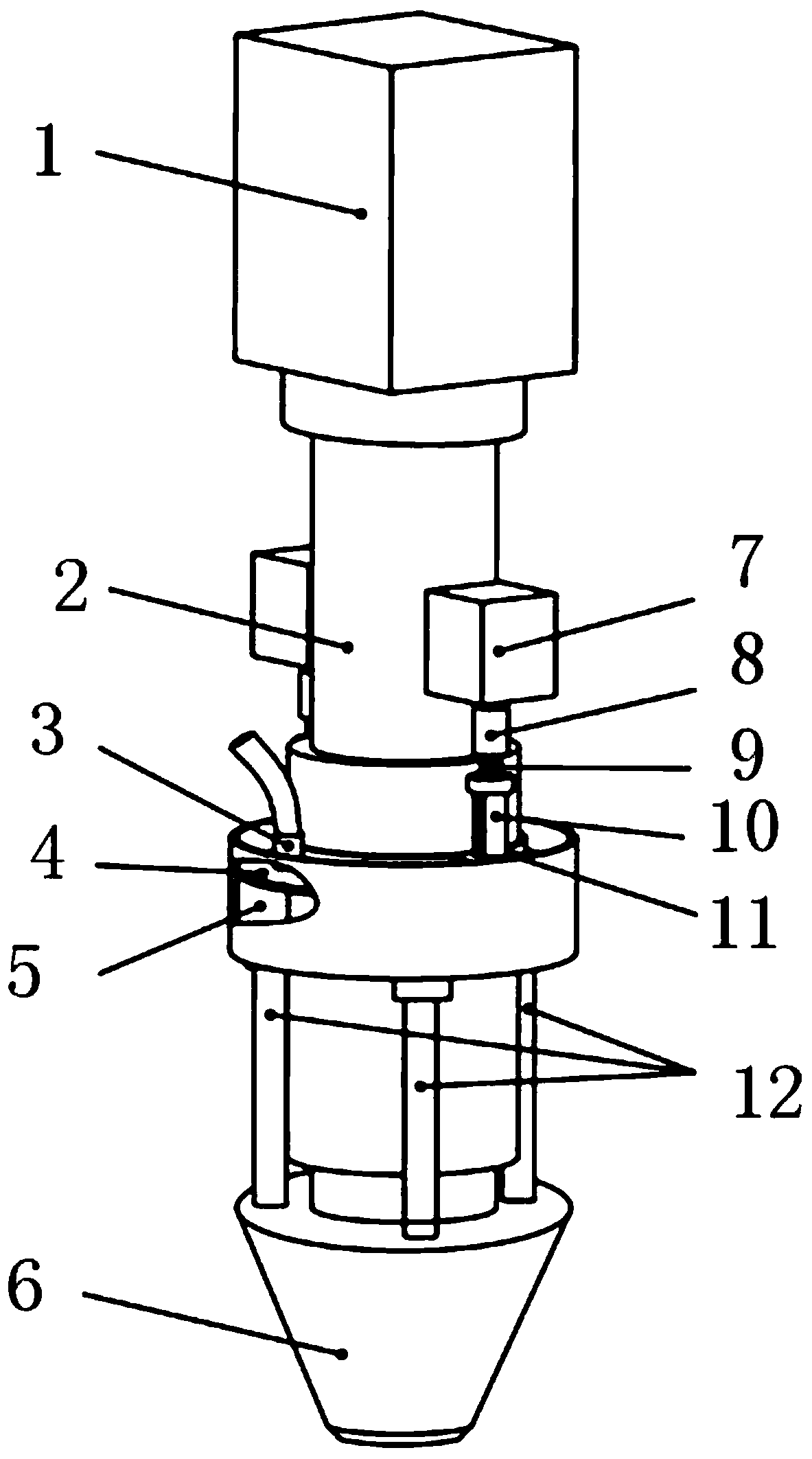

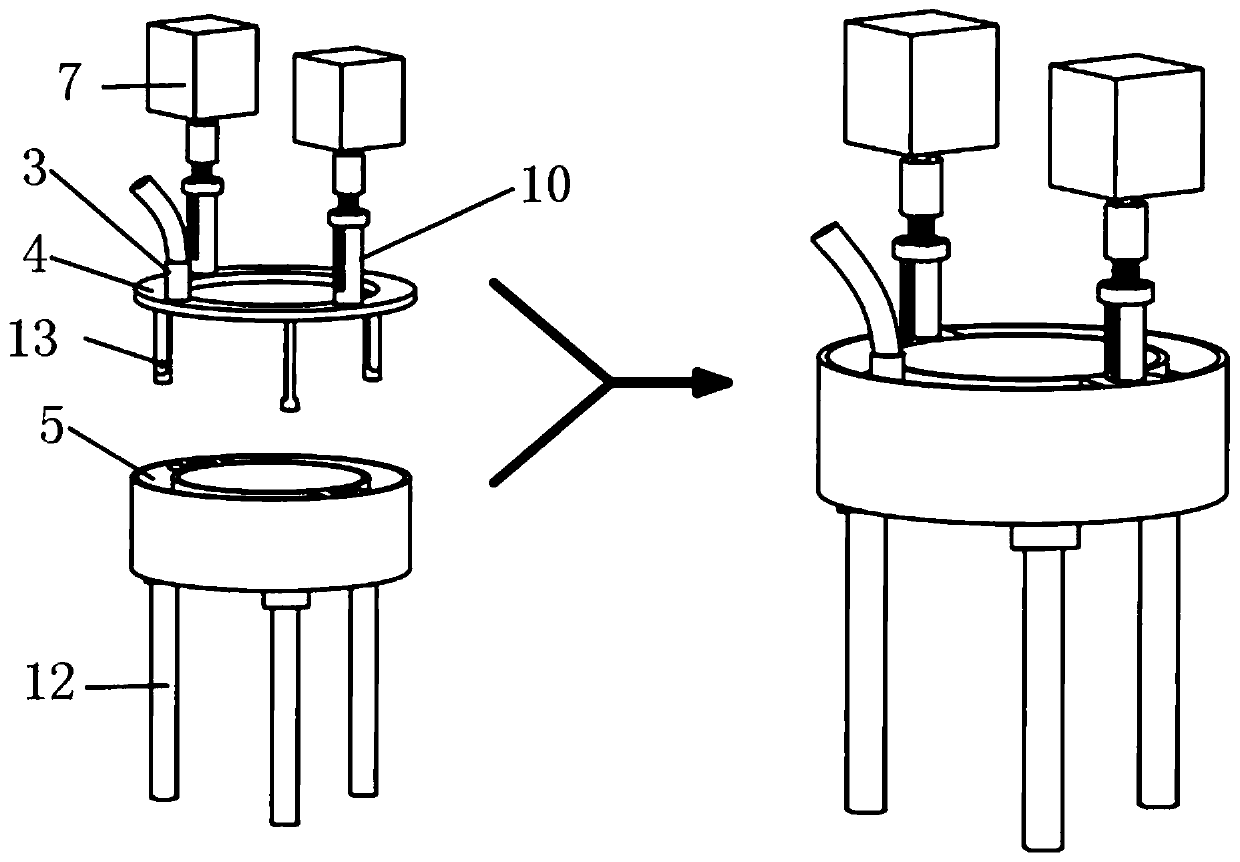

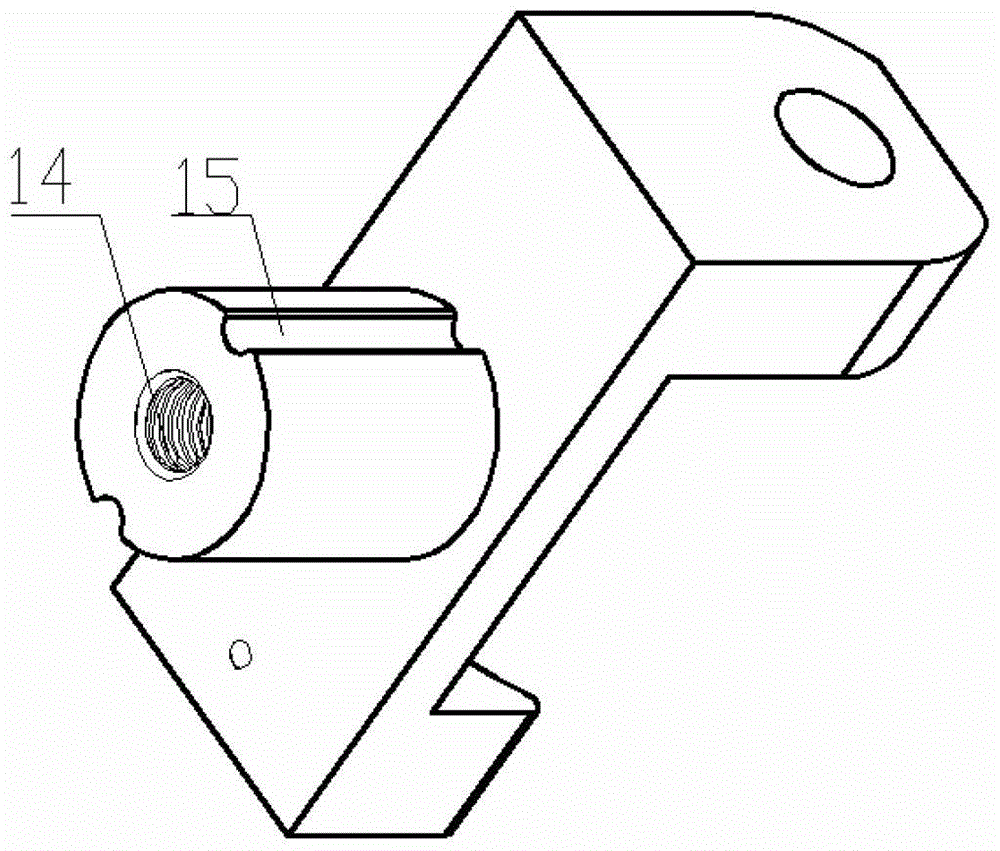

A high temperature pickup manipulator

InactiveCN105364920AWon't burnImprove reliabilityProgramme-controlled manipulatorGripping headsEngineeringManipulator

The invention provides a high temperature pickup manipulator with fingers. The positions of the fingers are adjustable; the finger feed is controlled by air cylinders. The fingers are used for clamping and fetching work pieces. The fingers are provided with gaskets used for lifting the work pieces. A baffle plate is arranged between the work pieces and the air cylinders and the like. The baffle plate isolates the work pieces and the air cylinders and the like above the work pieces, so that high-temperature work pieces are prevented from burning upper members. The high temperature pickup manipulator is arranged on a telescopic arm which drives the manipulator to perform feed movement; the telescopic arm is a two-stage telescopic arm, wherein the first-stage telescopic arm drives the second-stage telescopic arm to move at higher speed via a belt. The telescopic arm is simple in structure, small in size and high in moving speed.

Owner:SHENYANG ZHONGTUO ROBOT EQUIP

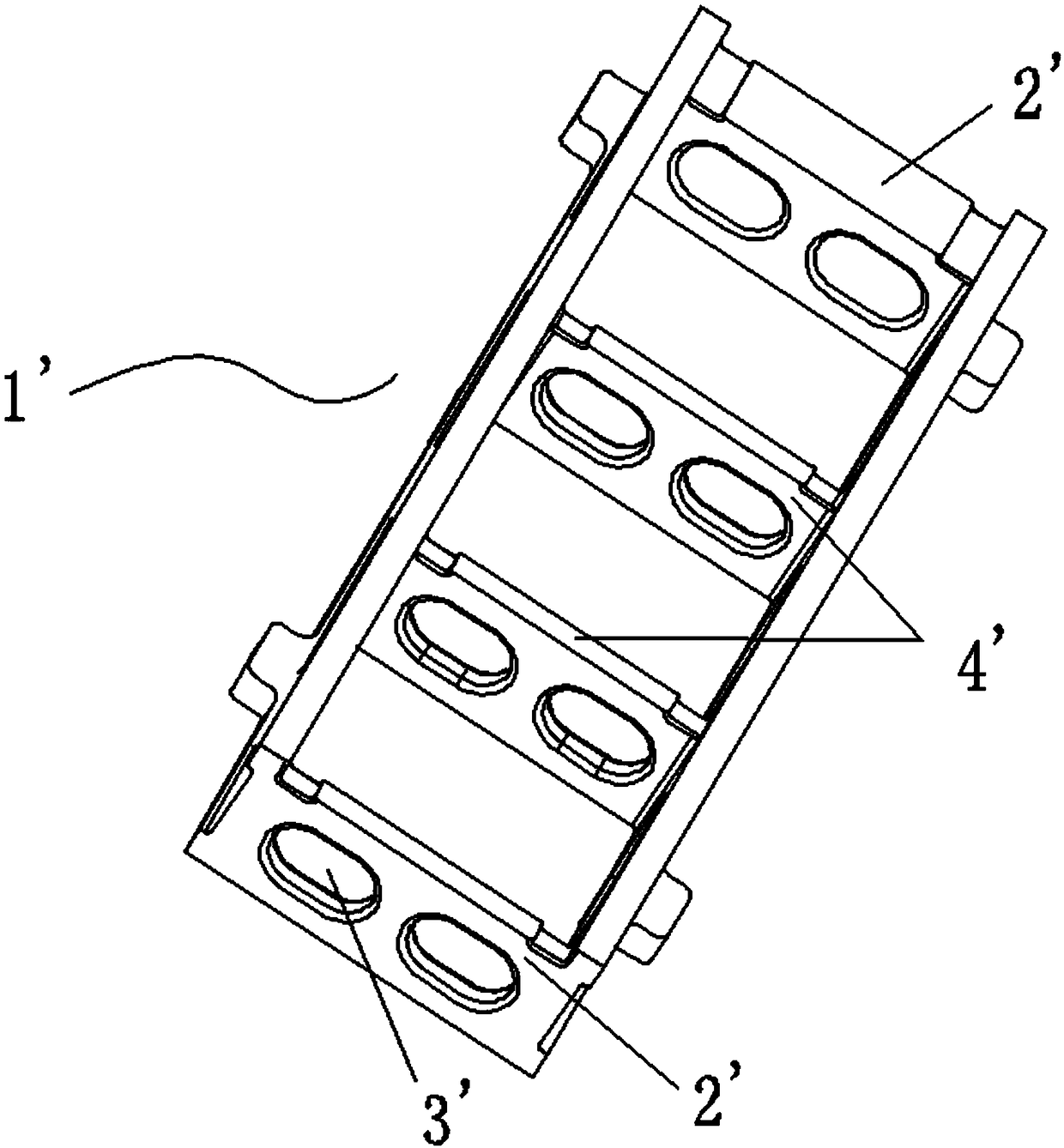

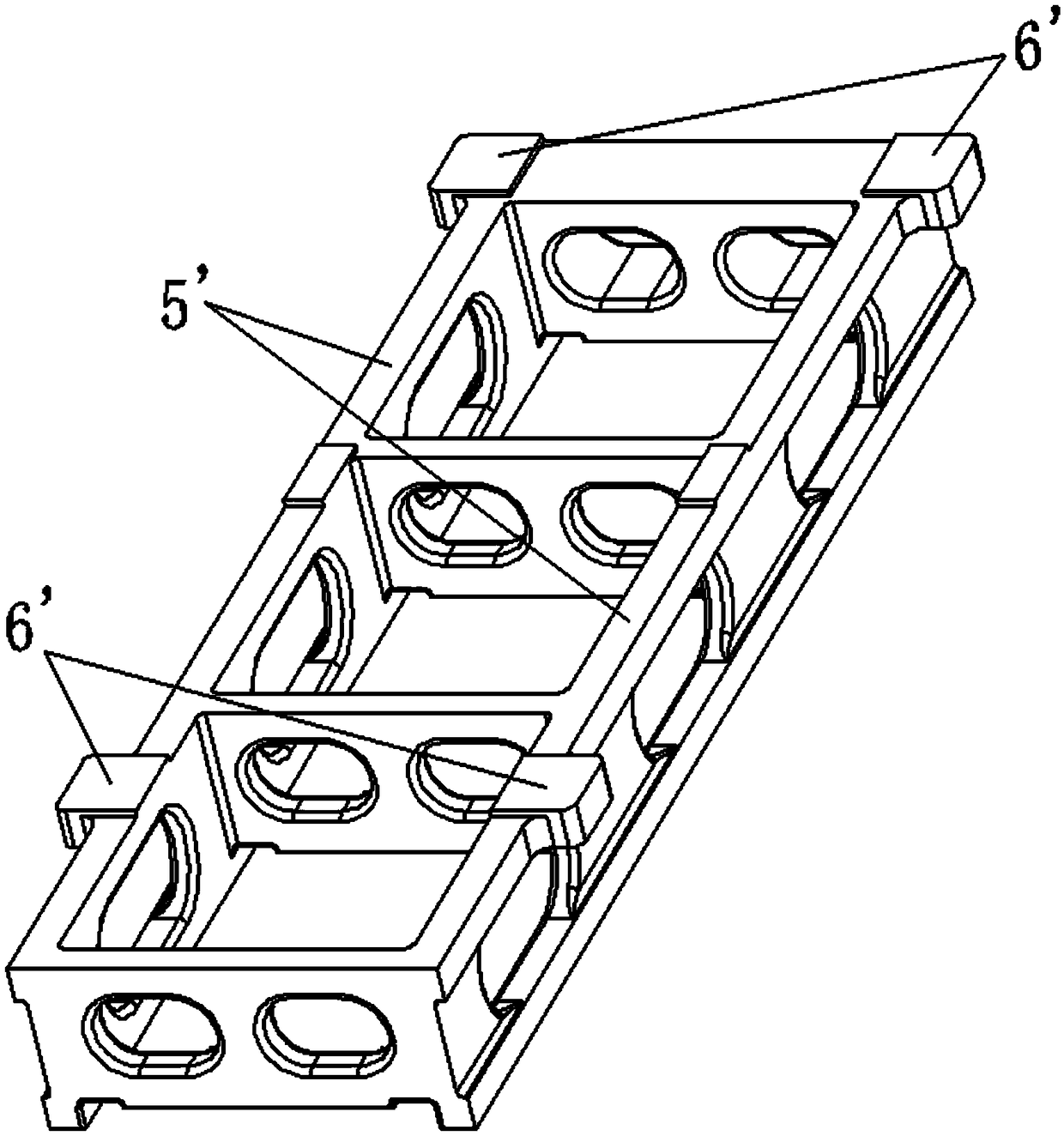

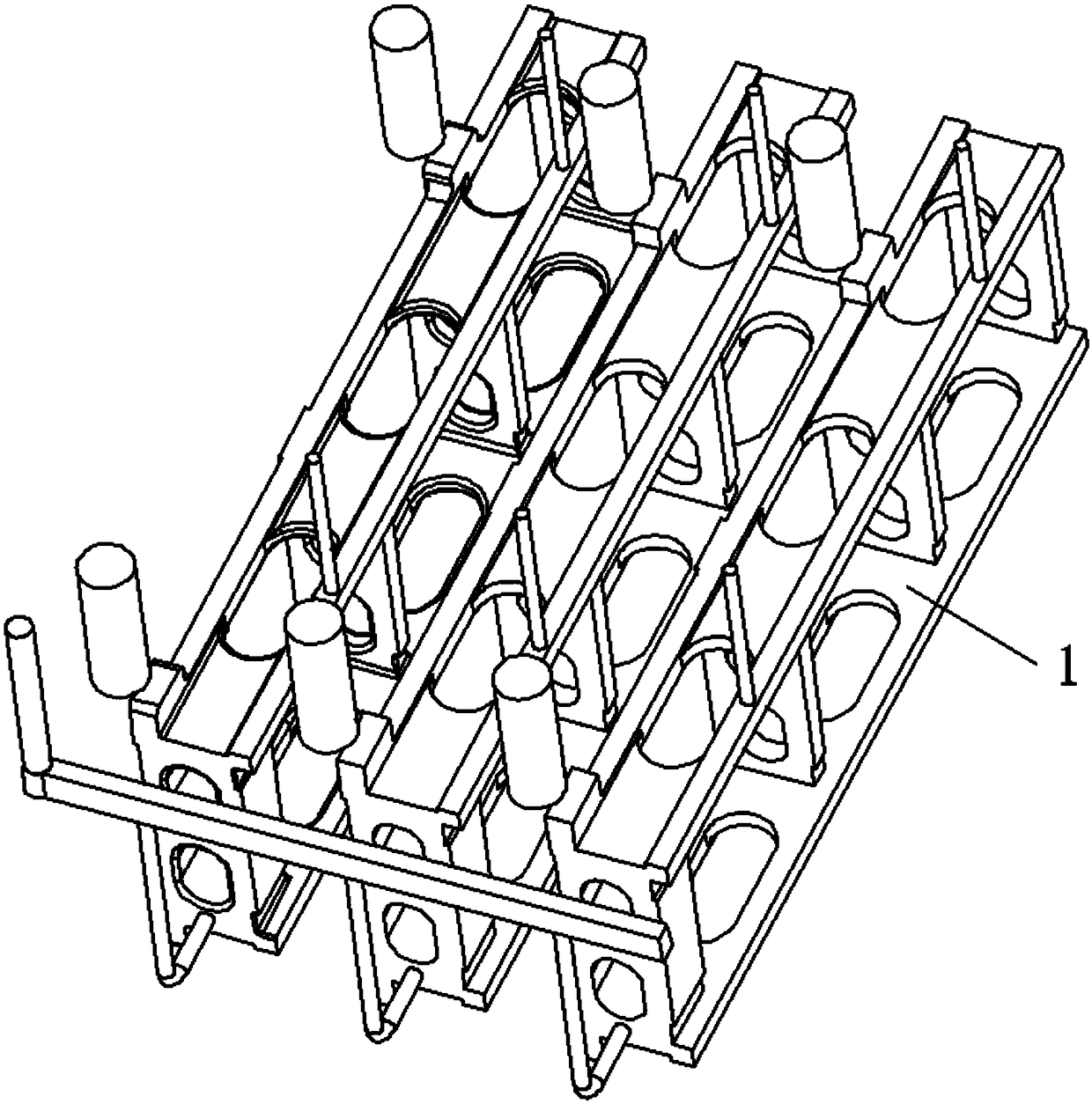

One-casting-multiple-yielding casting method of thin-walled framework castings

InactiveCN108817327AReduce cooling rateReduce problemsFoundry mouldsFoundry coresChemical compositionSlag

The invention relates to a one-casting-multiple-yielding casting method of thin-walled framework castings. The method comprises the steps: 1) die making; 2) sand core making; 3) sprue runner setting;4) casting forming, wherein the strength of a sand core is controlled to 0.8MPa to 0.9MPa in the step 2); the strength of external shape forming sand is controlled to 0.9MPa to 1.1MPa in the step 3);the requirements on casting fluid ingredient and casting fluid temperature during casting in the casting forming in the step 4) are as follows: casting fluid is prepared from chemical ingredients in percentage by weight: 3.65% to 3.80% of C, 2.20% to 2.65% of Si, less than or equal to 0.30% of Mn, less than or equal to 0.04% of P, less than or equal to 0.012% of S, 0.035% to 0.06% of Mg, less thanor equal to 0.02% of RE, 4.50% to 4.65% of CE and the balance of Fe; the addition of a nodulizer is 1.2% to 1.30%, and the addition of an inoculant is 0.8% to 1.0%; the temperature of the casting fluid is 1,350 DEG C to 1,380 DEG C. According to the method, the production efficiency of the thin-walled framework castings can be increased while the rate of finished products of the thin-walled framework castings is increased, and the castings are free of white microstructure and defects of shrinkage porosity, slag inclusion and the like.

Owner:宁波拓铁机械有限公司

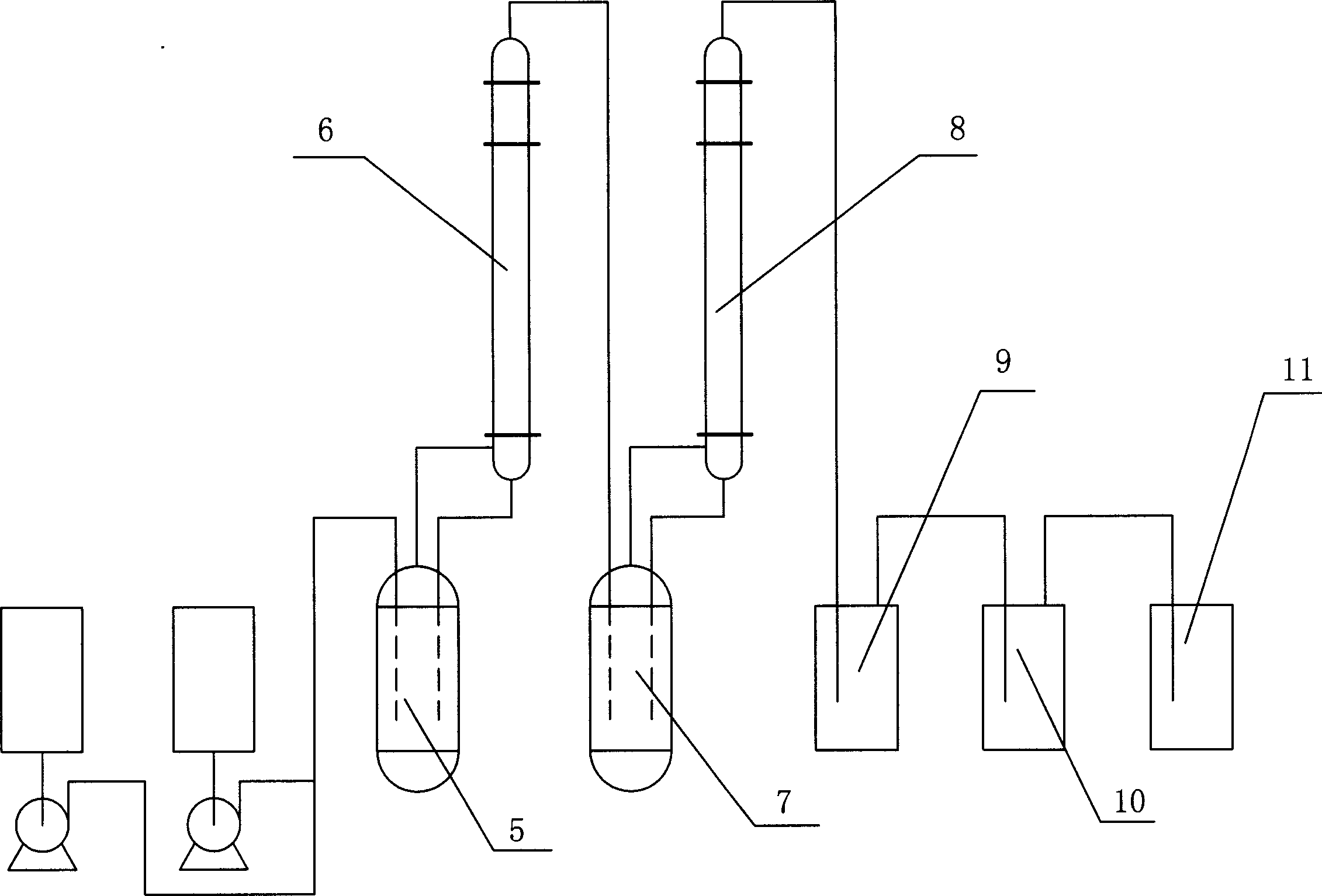

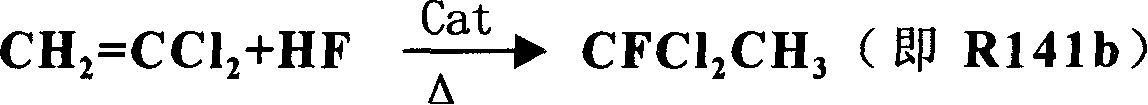

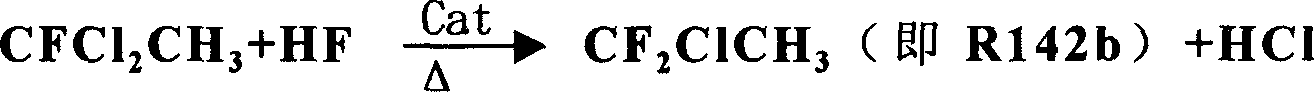

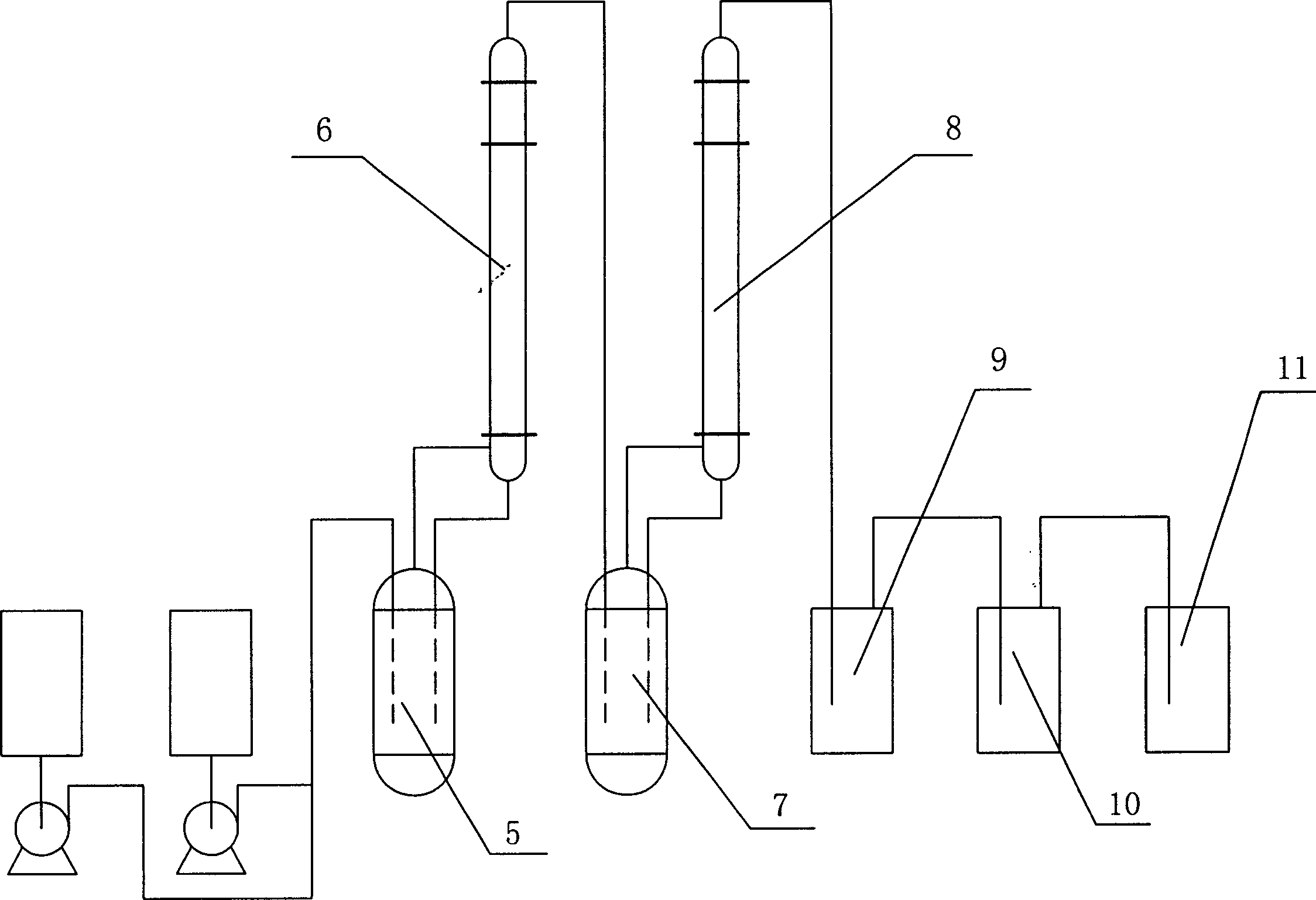

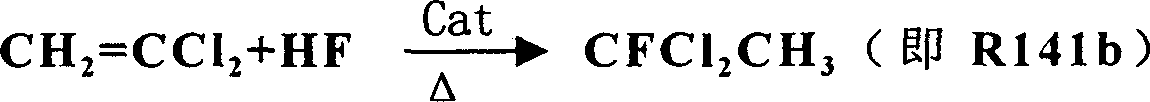

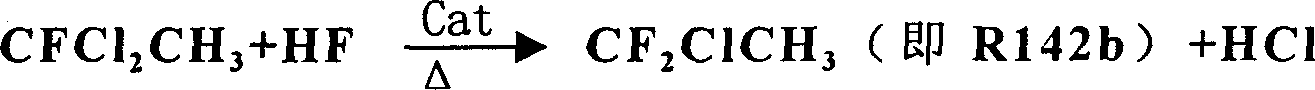

Process for preparing 1, 1, 1-trifluoroethane and 1, 1, 1-difluorochloroethane

InactiveCN1569784AIncrease profitHigh catalytic activityHalogenated hydrocarbon preparationHydrogen fluoridePolymer science

The invention discloses a process for preparing 1,1,1-trifluoroethane and 1,1,1-difluorochloroethane by using vinyl chloride and waterless hydrogen fluoride as the raw material, characterized in that, two liquid phase fluorine reaction kettles are employed for tandem reaction, the first reaction kettle uses one or two of SnCl4, TiCl4 as catalyst, while the second reaction kettle uses one or more from SbCl5, TaCl5, TaF5, NbCl5 as catalyst, which make the HF react completely.

Owner:苏州联氟化学有限公司

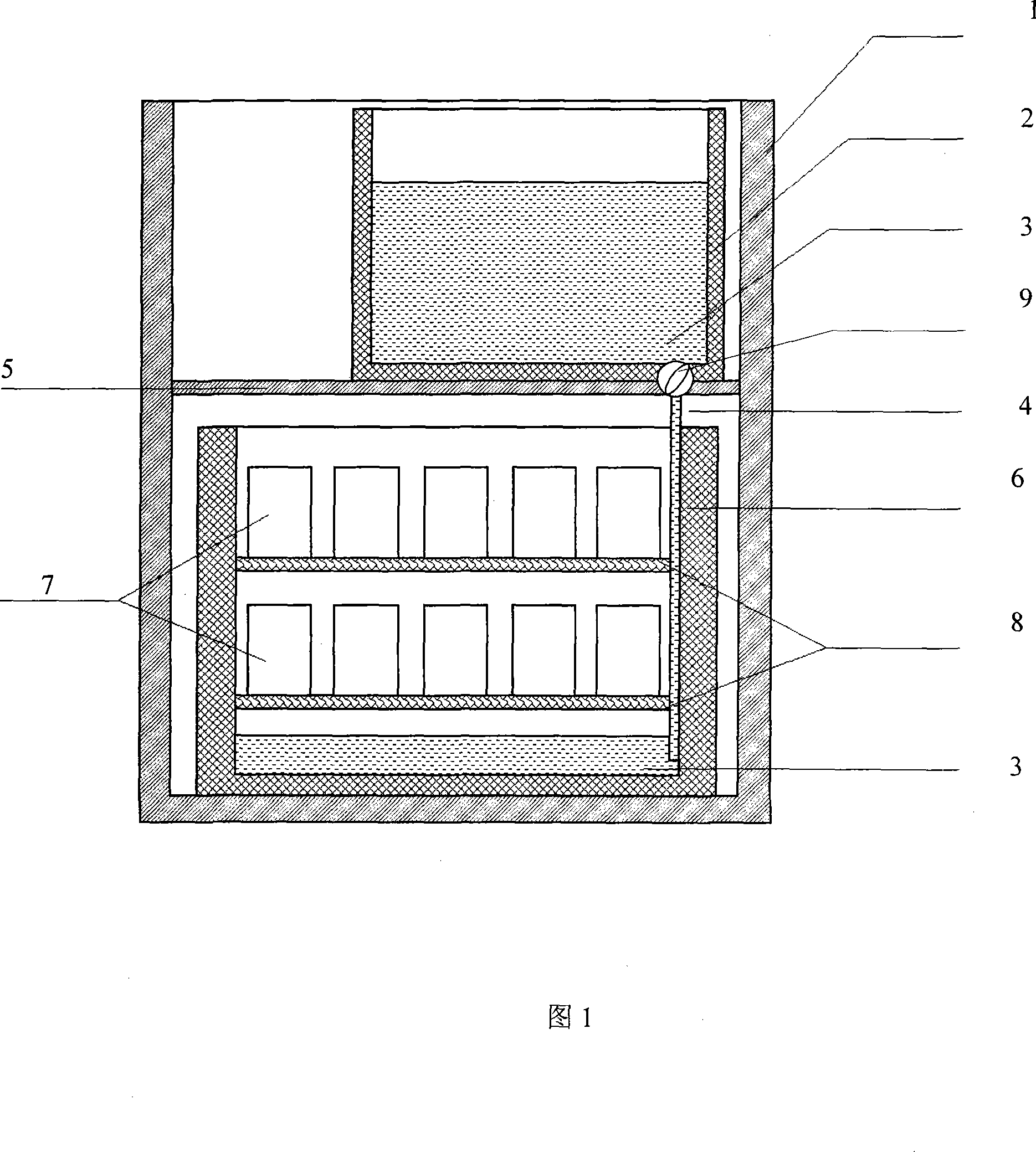

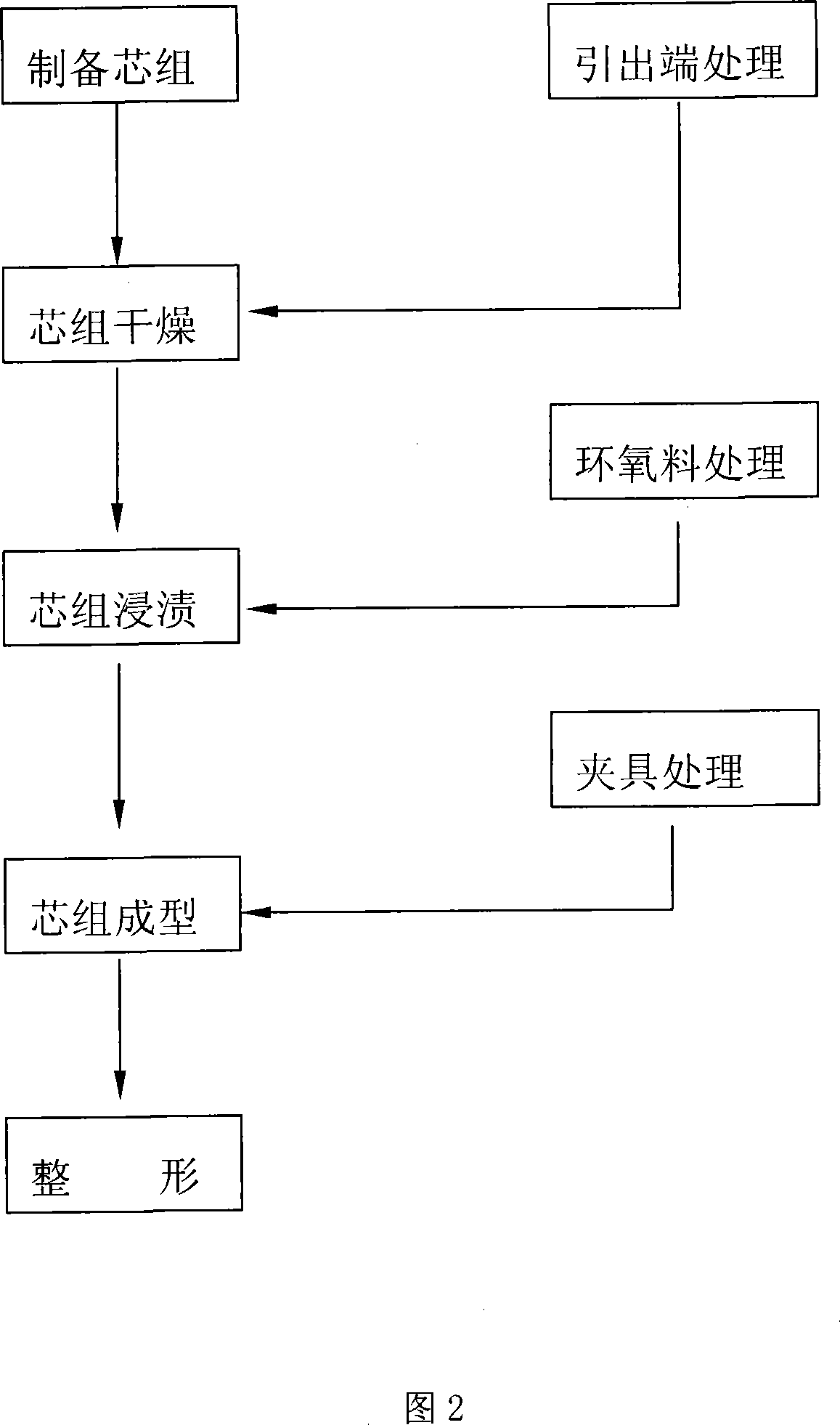

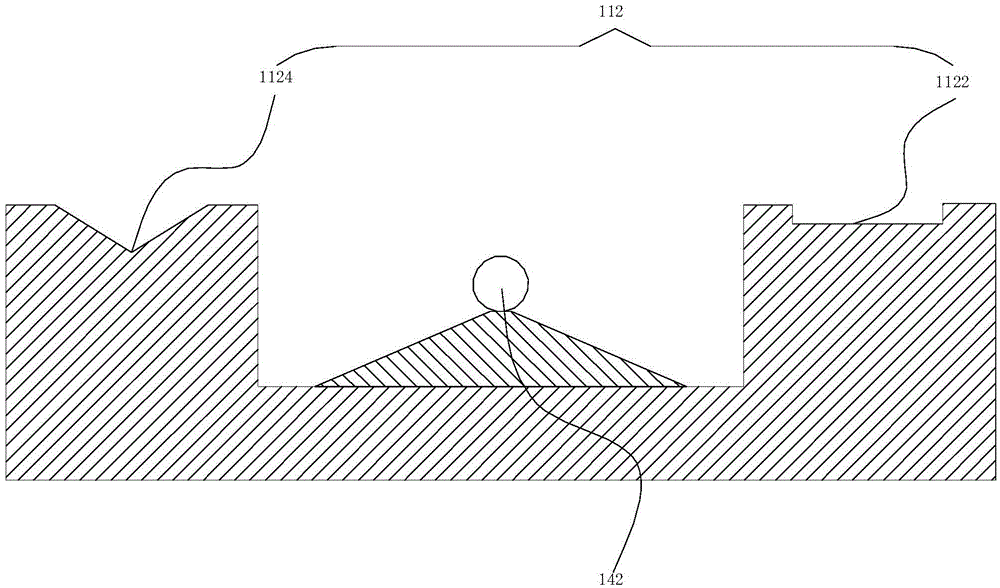

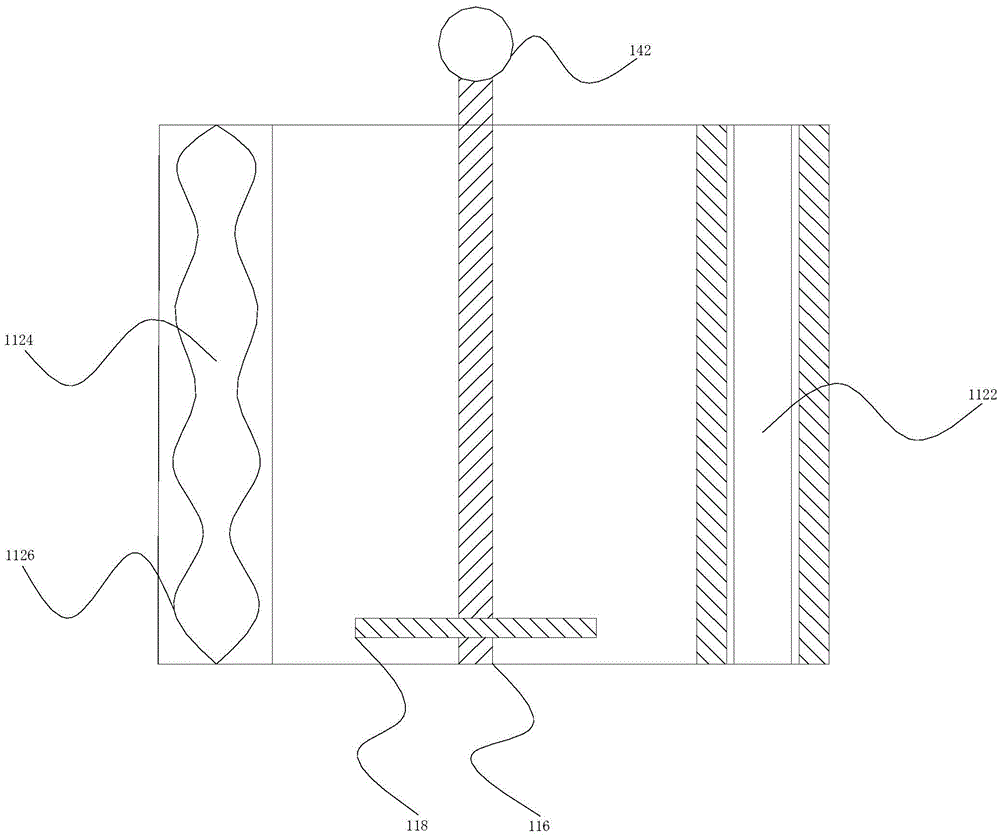

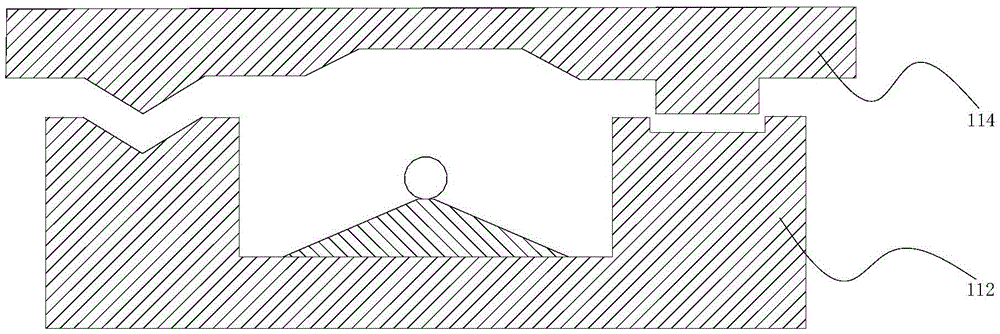

Impregnation forming method for capacitor core assembly

ActiveCN101121159AStable feed rateLower the surface tension of the liquidPretreated surfacesCoatingsAirplaneEngineering

The present invention relates to a novel dip forming method of a specific dry-type capacitor. An isolation screen is added. A core group, which dips the dipping material from bottom to upside, is adopted, and a glass rod is used in a diversion step. The core group is thoroughly solidified by the heat preservation of a multi-temperature zone. The purpose of the present invention is to solve the problems of dipping and an encapsulation of the specific capacitors and the relevant electronic equipments. With a strong technical generality, less implementation difficulty, little investment and stable and reliable quality, the dip forming can satisfy the requirements of the electronic equipment of miniaturization, dry-type (solidification), large span of working temperature-zones and strong environmental applicability. The present invention can be used for manufacturing specific capacitors which are applied to high current with high temperature and high voltage, such as a filter capacitor which is used for high-voltage electrical source of airplane, an engine-igniting capacitor, a deep-well pulse sound wave exploration etc. The present invention can also be used in the encapsulation field of high-performance electronic equipment.

Owner:CHENGDU HONGMING ELECTRONICS CO LTD

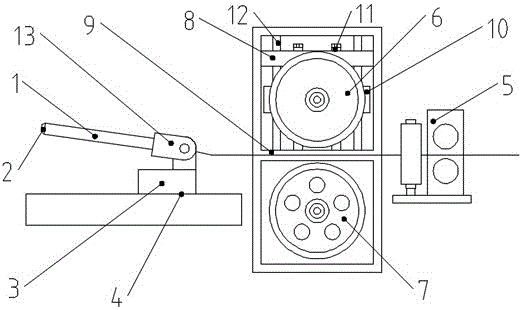

Cable winding machine cable feeding device

The invention discloses a cable winding machine cable feeding device. The cable feeding device is connected to a winding machine. The cable feeding device comprises a cable feeding roller set and a cable feeding guiding device. The cable feeding guiding device is connected with the front end of the cable feeding direction of the cable feeding roller set. The cable feeding guiding device comprises a cable feeding guide pipe, a cable feeding clamp and a sliding and pushing structure. A cable penetrates through the cable feeding guide pipe, the cable feeding clamp is connected to the front end of the cable feeding guide pipe, and the cable feeding guide pipe is connected to the sliding and pushing structure. The sliding and pushing structure comprises a sliding base, a sliding groove and a driving structure, the sliding base is connected into the sliding groove in a sliding mode, the cable feeding guide pipe is connected to the sliding base, and the driving structure is connected with the sliding base. The cable feeding guide pipe can directly convey the cable to a required position in a directed mode, the cable feeding clamp can clamp the cable to prevent falling, the sliding and pushing structure is a whole so that the cable feeding clamp cannot become loose during feeding, accordingly the cable is kept clamped in the cable conveying process and is prevented from being loosened midway, and machining efficiency is not influenced.

Owner:德清凯斯达线缆有限公司

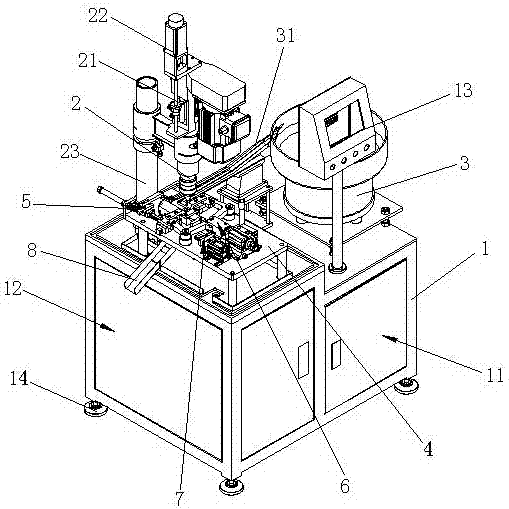

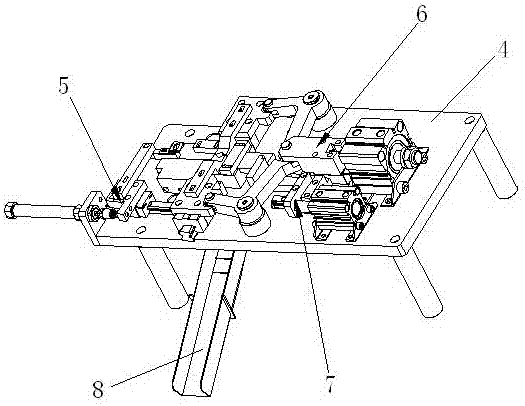

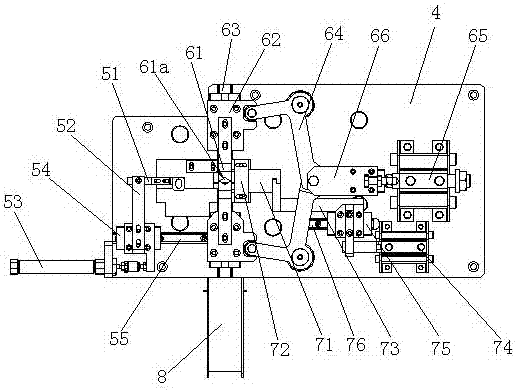

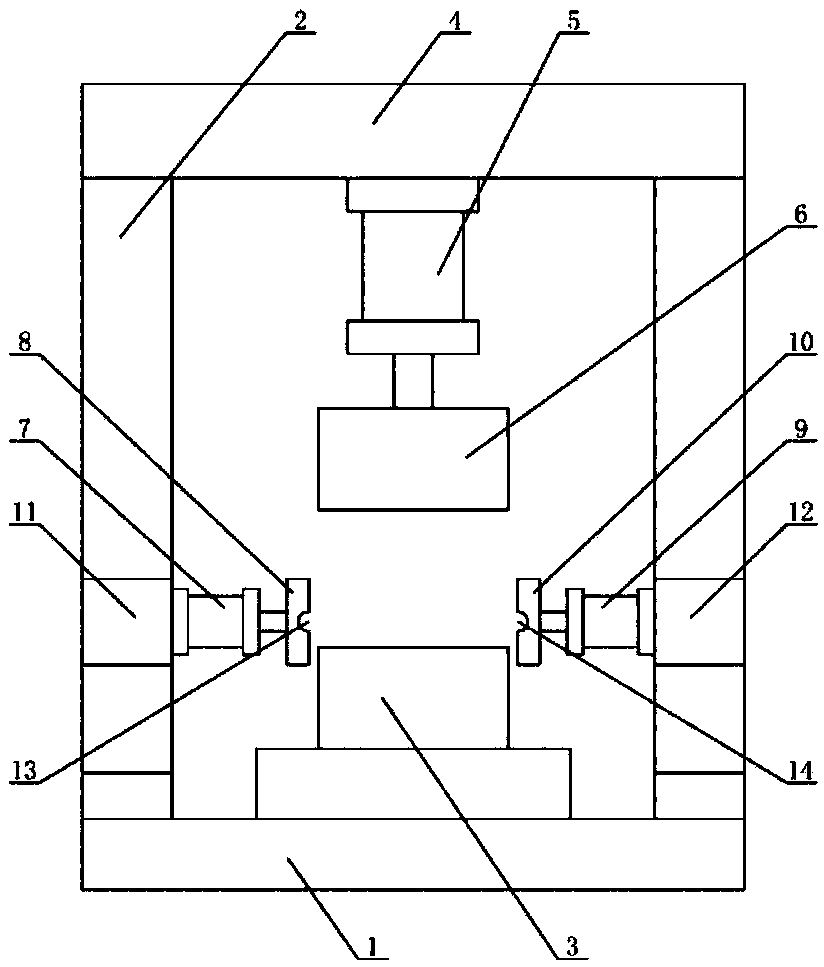

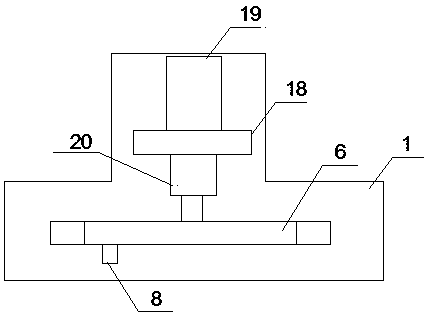

Automatic magnetic steel drilling machine

PendingCN107877244AReasonable structureImprove processing efficiencyMetal working apparatusBoring/drilling machinesBall screwDrilling machines

The invention discloses an automatic magnetic steel drilling machine. The automatic magnetic steel drilling machine is characterized in that a distribution cabinet and a water tank cabinet are arranged in a rack; a console and a drilling machine are arranged on the rack; a vibration disc is arranged on the rack; the vibration disc is connected with an inlet of a straight vibration slide; a bracketis fixed to the rack; a feeding mechanism, a workpiece clamping mechanism and a discharge mechanism are arranged on the bracket; a feeding push block of the feeding mechanism is arranged at an outletof the straight vibration slide; two clamping blocks of the workpiece clamping mechanism are arranged below the drilling machine; V-shaped grooves are formed in the end parts of the clamping blocks;a sliding plate of the discharge mechanism is arranged below the clamping blocks; a baffle plate is fixed to the bracket; the end part of the sliding plate penetrates through the baffle plate and stretches to the position below the clamping blocks; a discharge opening is formed in the position, below the clamping blocks, on the bracket; a discharge slide is fixed to the rack; an inlet of the discharge slide is positioned below the discharge opening; and the drilling machine is connected with a servo motor through a ball screw. The automatic magnetic steel drilling machine has the advantages that the structure is reasonable, and automatic centering for magnetic steel and automatic cleaning of chips can be achieved.

Owner:宁波市涵鹏机械制造有限公司

Packaging box production equipment

The invention belongs to machines for manufacturing paper boxes, cartons, envelopes or paper bags, and particularly discloses packaging box production equipment which comprises a machine frame. A diecutting rule, a driving mechanism used for driving the die cutting rule and a placing table for placing materials are arranged on the machine frame, the die cutting rule is located above the placing table, the upper end face of the placing table is provided with a groove matched with the die cutting rule in shape, a filling portion is connected to the interior of the groove in a sliding mode, theshape and size of the filling portion are the same as those of the die cutting rule, a pressing spring is arranged between the filling portion and the bottom face of the groove, an a paper scrap collection mechanism is arranged in the placing table and driven by the filling portion. The problem that when paper boards are subjected die cutting in the prior art, the paper boards cannot be completelycut off is solved.

Owner:重庆漱心斋文化产业发展有限公司

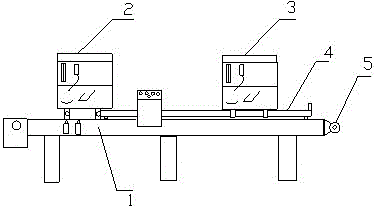

Numerically-controlled double-end saw

The invention discloses a numerically-controlled double-end saw which comprises a saw body, a fixed sawing mechanism, a movable sawing mechanism and a servo motor. The servo motor drives the movable sawing mechanism to move along a transverse linear guide rail arranged on the saw body. A longitudinal linear guide rail, a cutting saw blade, a spindle motor and a feeding mechanism are arranged on the fixed sawing mechanism, wherein the spindle motor drives the cutting saw blade to rotate, and the feeding mechanism drives the fixed sawing mechanism to move along the longitudinal linear guide rail. A gas-liquid damping cylinder is adopted as the feeding mechanism. As the gas-liquid damping cylinder having the advantages of pneumatic and hydraulic ways is adopted as the feeding mechanism, damping oil fluid can be adjusted to enable the moving speed of a cylinder piston rod to change stably so that the piston rod can adapt to fast advancing and retreating and slow advancing and retreating, the speed adjustment range is large, operation is convenient, the feeding speed of the cutting saw blade can be more stable, and the service life of the saw blade is prolonged to a certain degree.

Owner:马宗刚

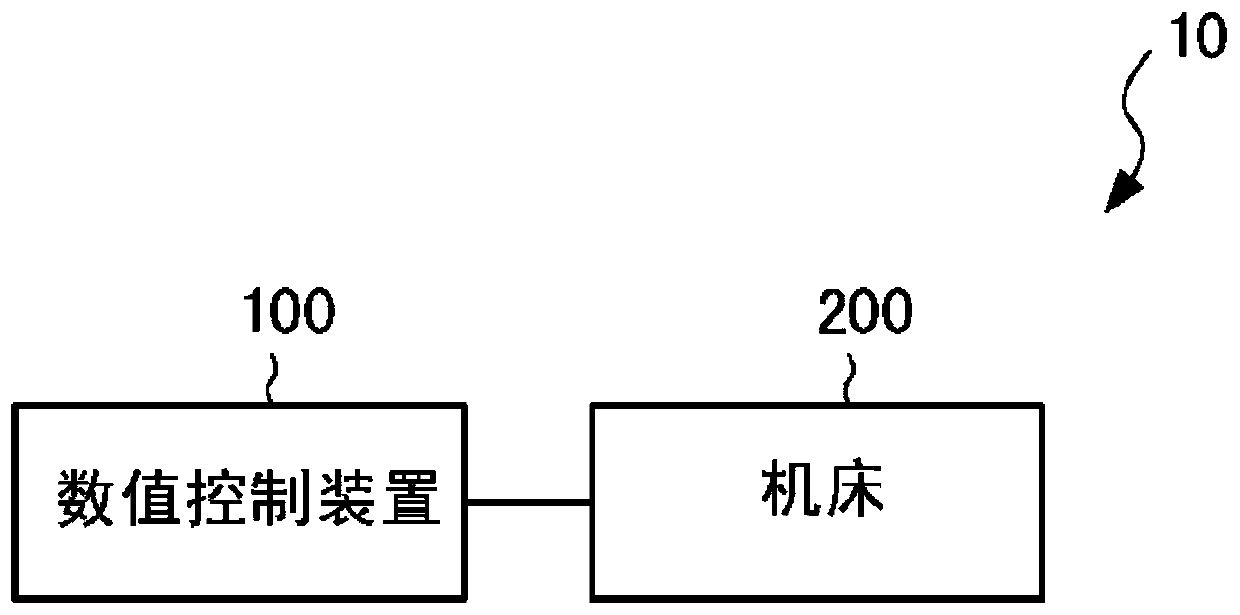

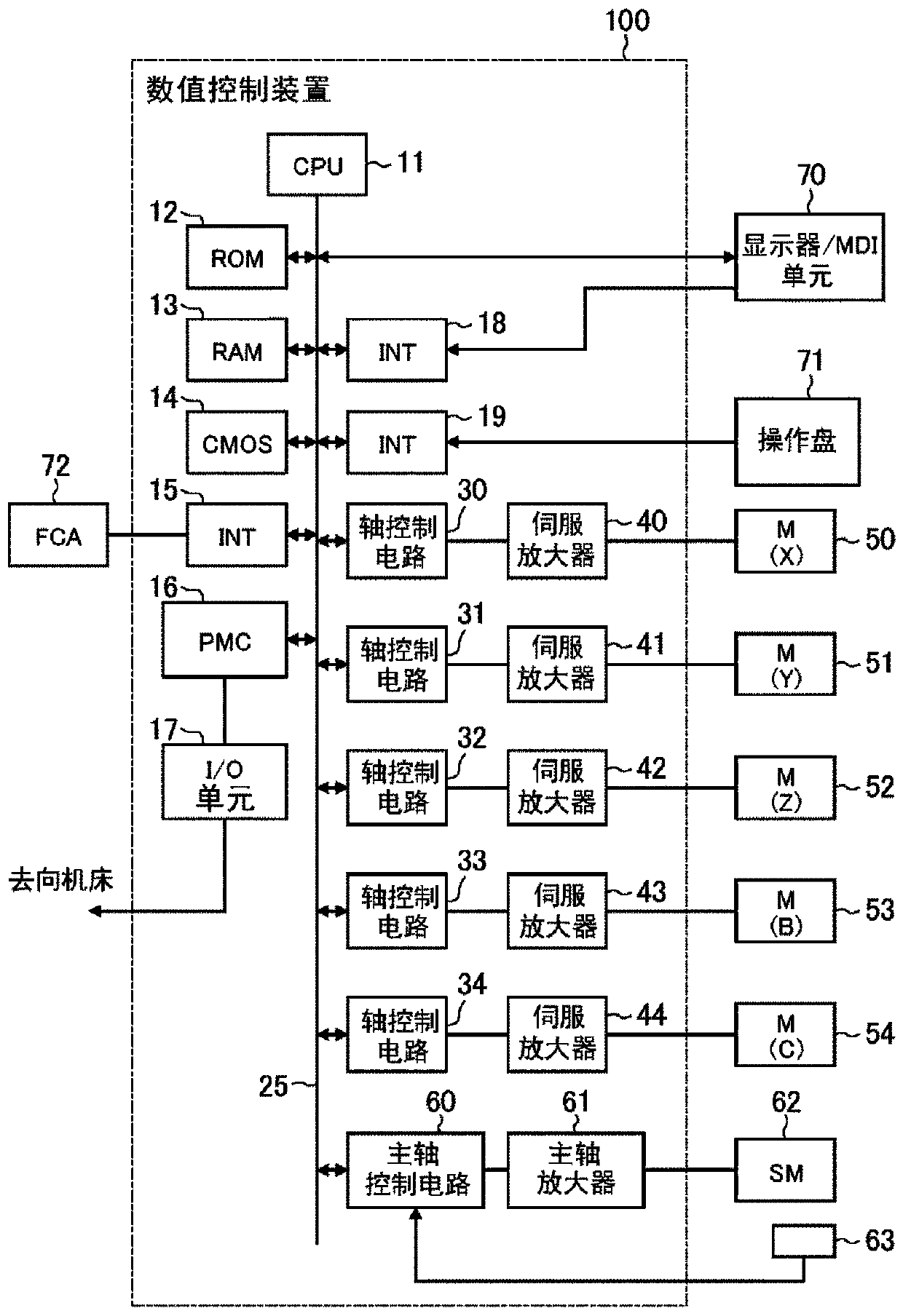

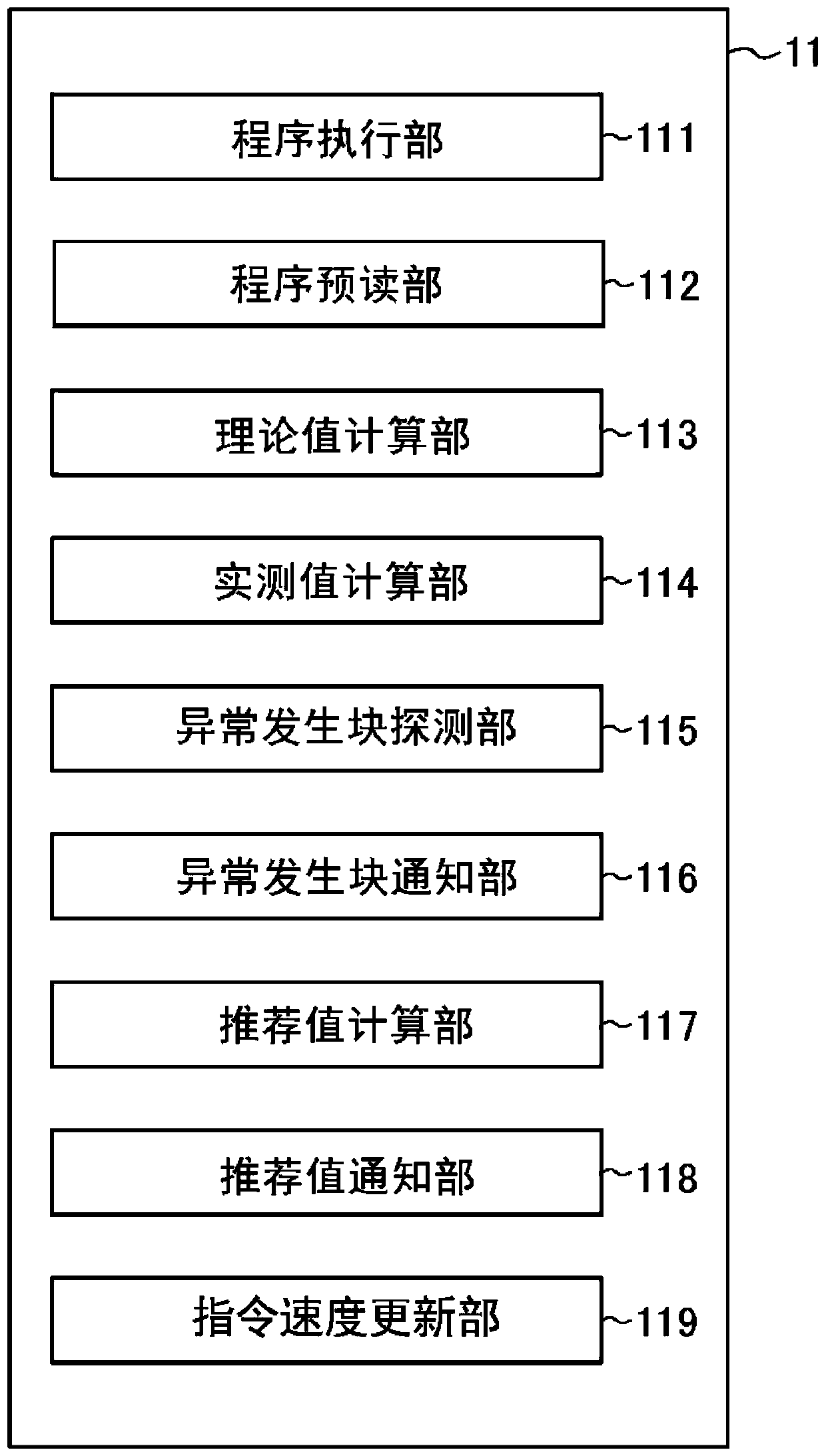

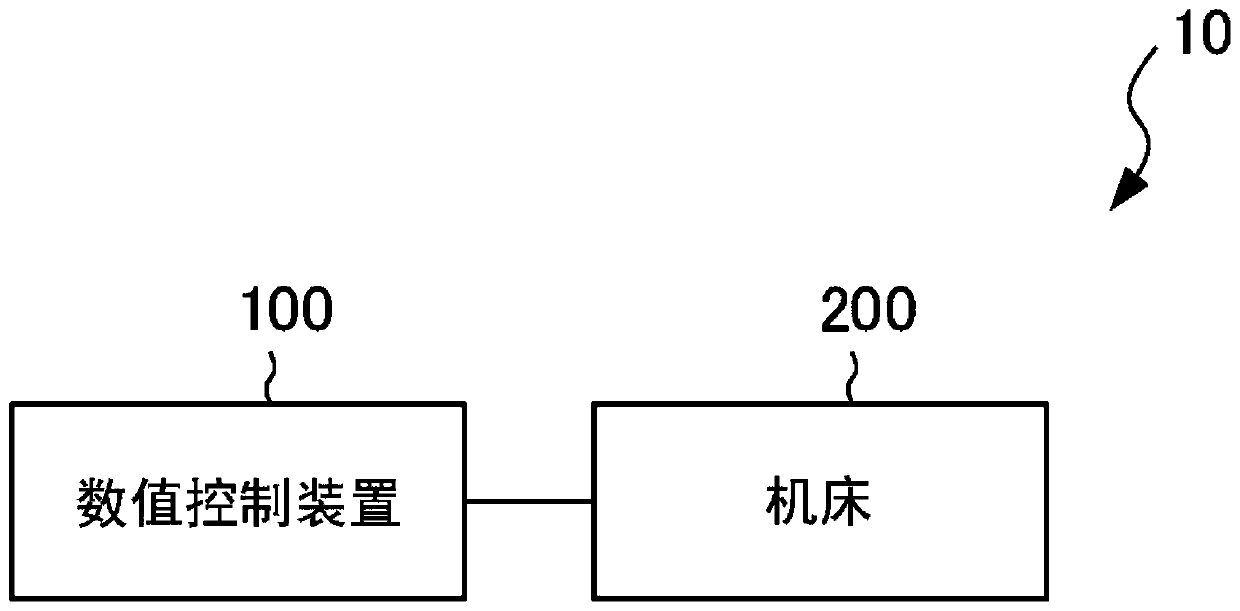

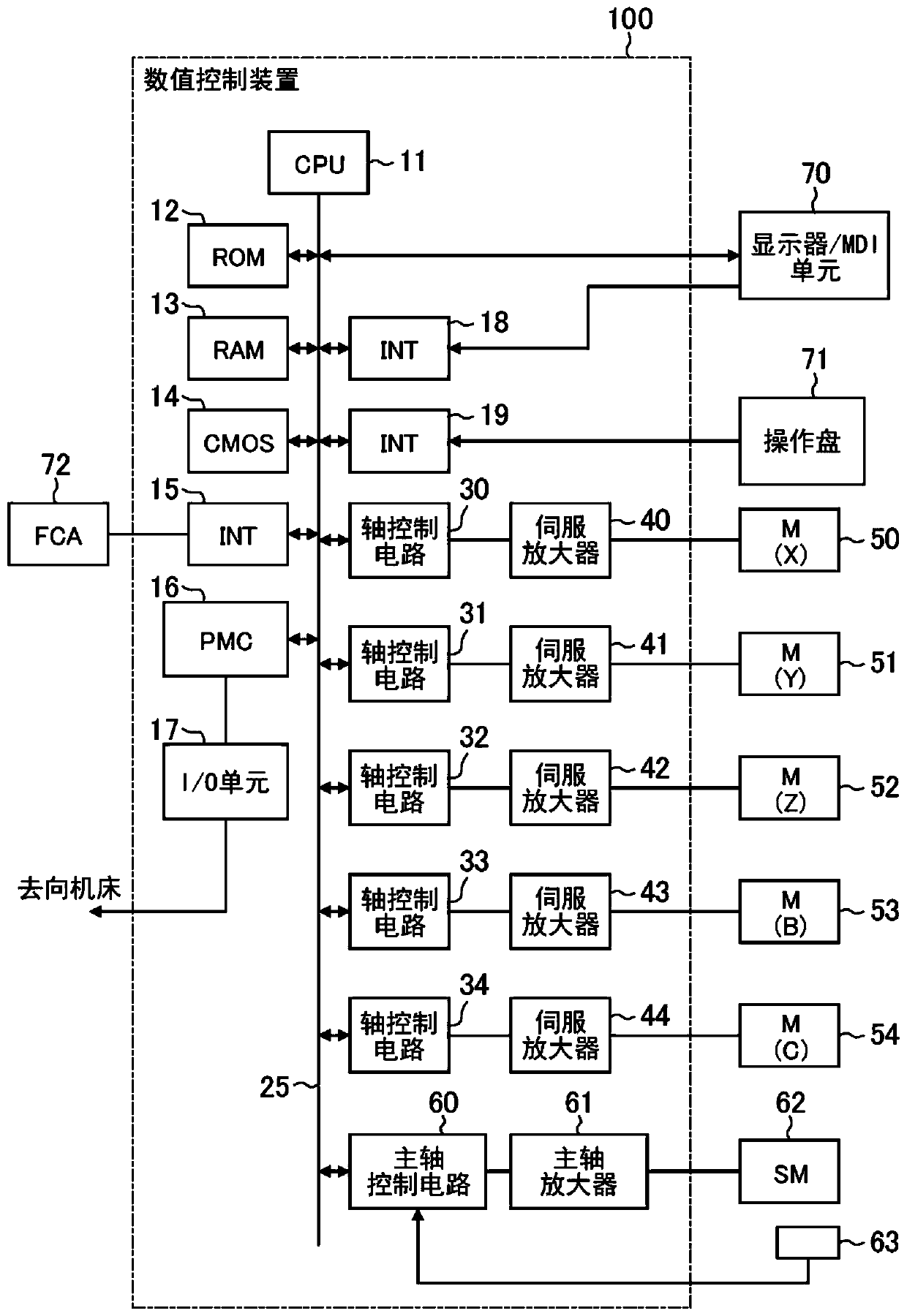

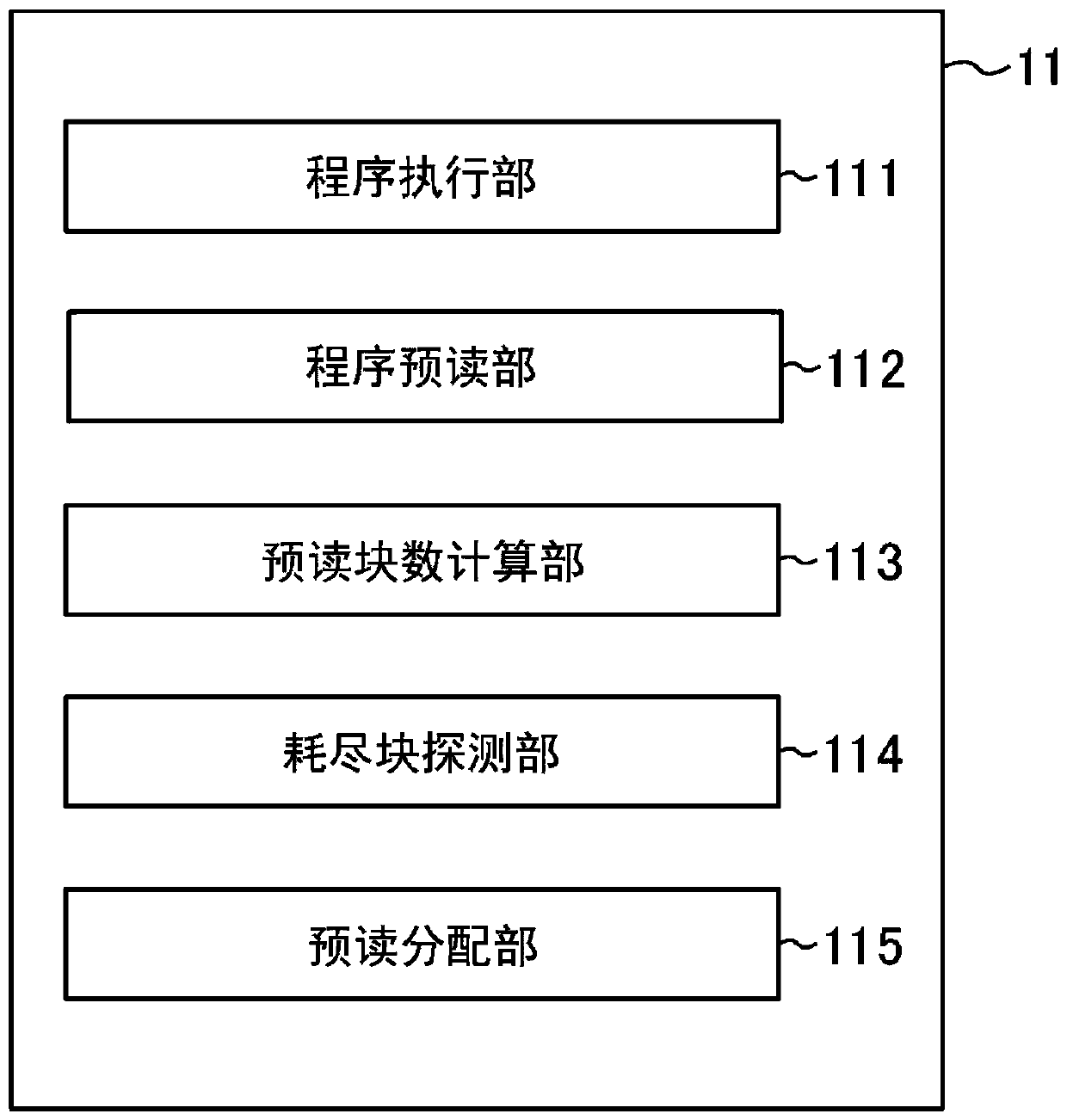

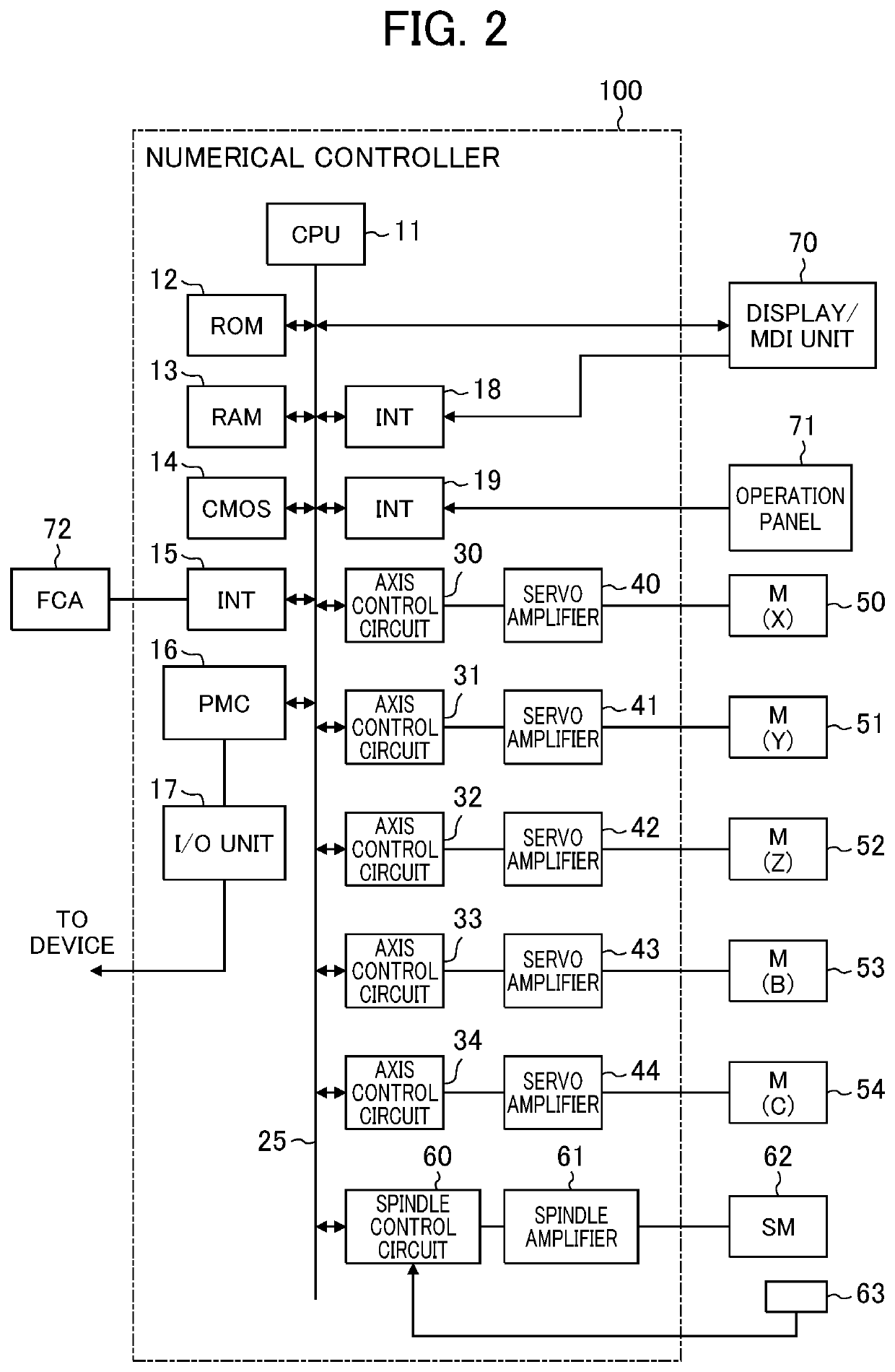

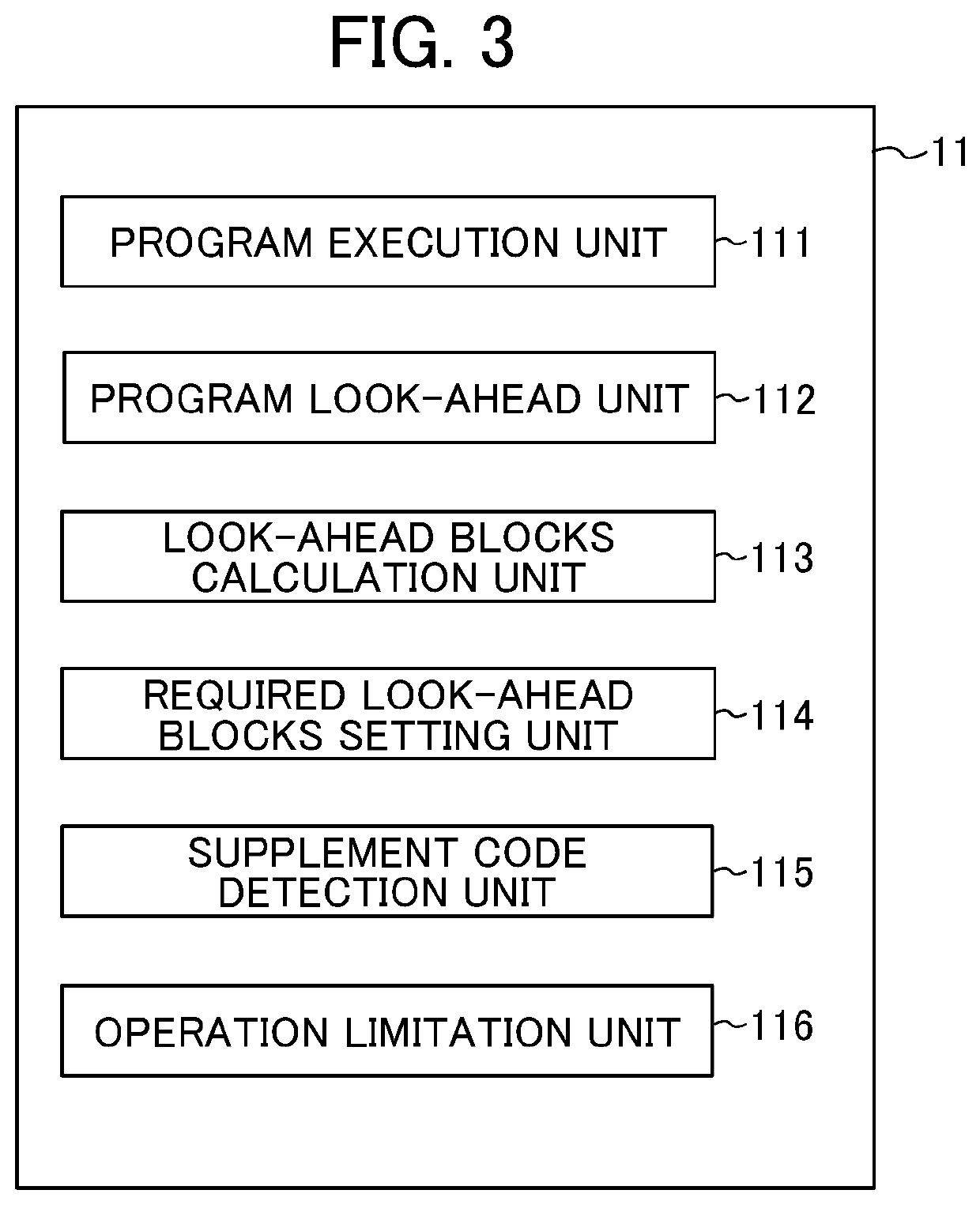

Numerical control device

ActiveCN111123840AStable feed rateStabilization of cutting speedNumerical controlNumerical controlSoftware engineering

A numerical control device is provided, which can detect the position where the number of pre read blocks used to determine acceleration and deceleration actions is insufficient in the processing program, so as to stabilize the feed speed, cutting speed, etc. The numerical control device (100) is provided with a program execution unit (111), which executes a processing program, a program pre reading unit (112), which reads a processing program in parallel with the execution of a processing program, and a theoretical value calculation unit (113), which calculates a processing program accordingto the length of a tiny straight line forming a processing path of the machine tool (200) and the feed speed of the machine tool. During the execution of the processing program, the measured value calculation unit (114) calculates the measured value of the pre reading time of the program and the processing time of the processing program for each block; and the abnormal occurrence block detection unit (115), the difference between the accumulated theoretical value and the measured value exceeds the specified value at the time point The block at is the exception block.

Owner:FANUC LTD

Process for preparing 1,1,1-trifluoroethane and 1,1,1-difluorochloroethane

InactiveCN1246273CIncrease profitHigh catalytic activityHalogenated hydrocarbon preparationHydrogen fluorideChloride vinyl

The invention discloses a process for preparing 1,1,1-trifluoroethane and 1,1,1-difluorochloroethane by using vinyl chloride and waterless hydrogen fluoride as the raw material, characterized in that, two liquid phase fluorine reaction kettles are employed for tandem reaction, the first reaction kettle uses one or two of SnCl4, TiCl4 as catalyst, while the second reaction kettle uses one or more from SbCl5, TaCl5, TaF5, NbCl5 as catalyst, which make the HF react completely.

Owner:苏州联氟化学有限公司

A single tower reaction industrial preparation process of alkoxyhydrogensilane

The invention relates to an alkoxy hydrosilane single-tower reaction industrial preparing technology and belongs to the technical field of fine chemical engineering. The alkoxy hydrosilane single-tower reaction industrial preparing technology comprises the steps that hydrogen-containing monomers and alcohol serve as the raw materials, and a reaction is carried out under the gas and liquid alcohol bi-directional esterification condition to synthesize an alkoxy hydrosilane product. According to the alkoxy hydrosilane single-tower reaction industrial preparing technology, a single tower is adopted, the esterification technology of feeding gas alcohol in a lower tower body, feeding the hydrogen-containing monomers in a middle tower body and feeding liquid alcohol in an upper tower body is carried out, quasi-continuous production can be achieved through an overflow kettle, the mass ratio is strictly controlled in the production process, the equal mole reaction of the two reaction materials is ensured, and thus various side reactions are reduced to the maximum. The method overcomes many defects of an existing preparing method of alkoxy hydrosilane, the production efficiency is effectively improved, and the demand for alkoxy hydrosilane by the market is met.

Owner:JINGZHOU JIANGHAN FINE CHEM

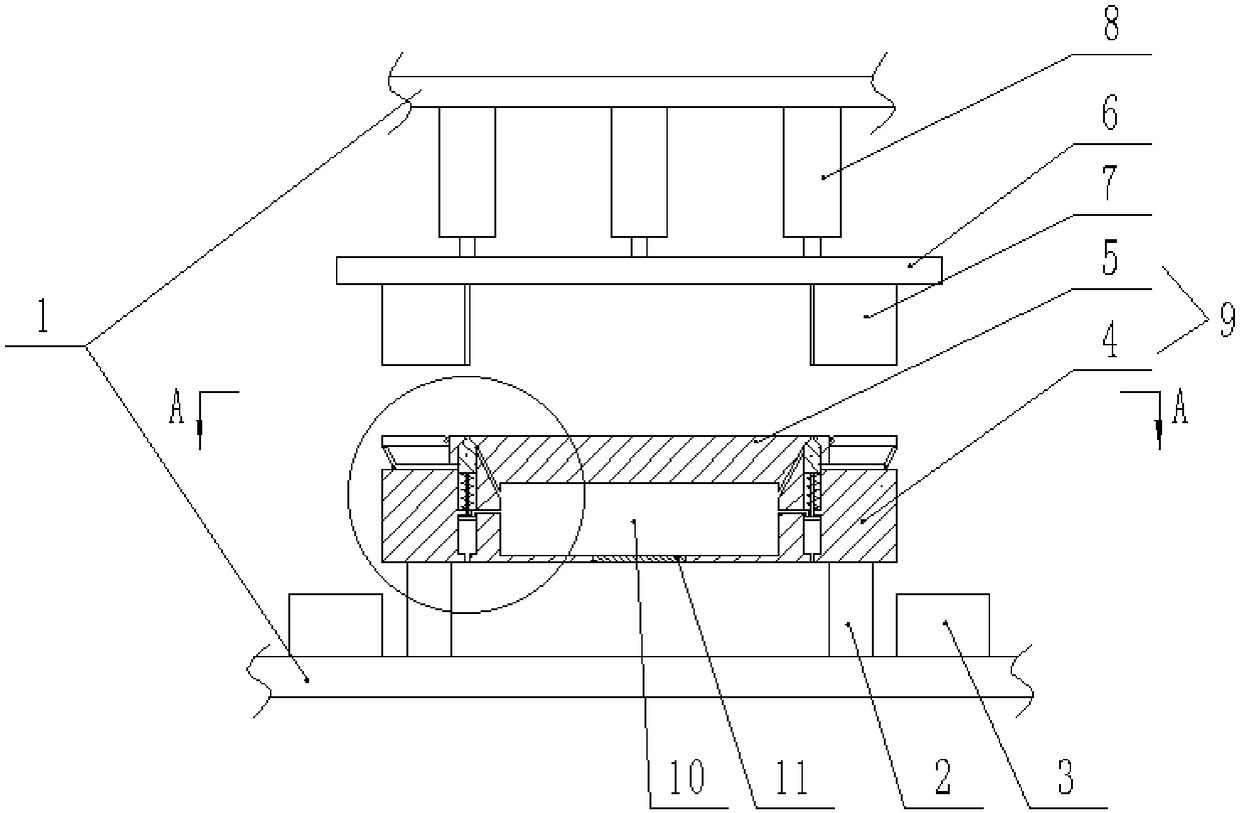

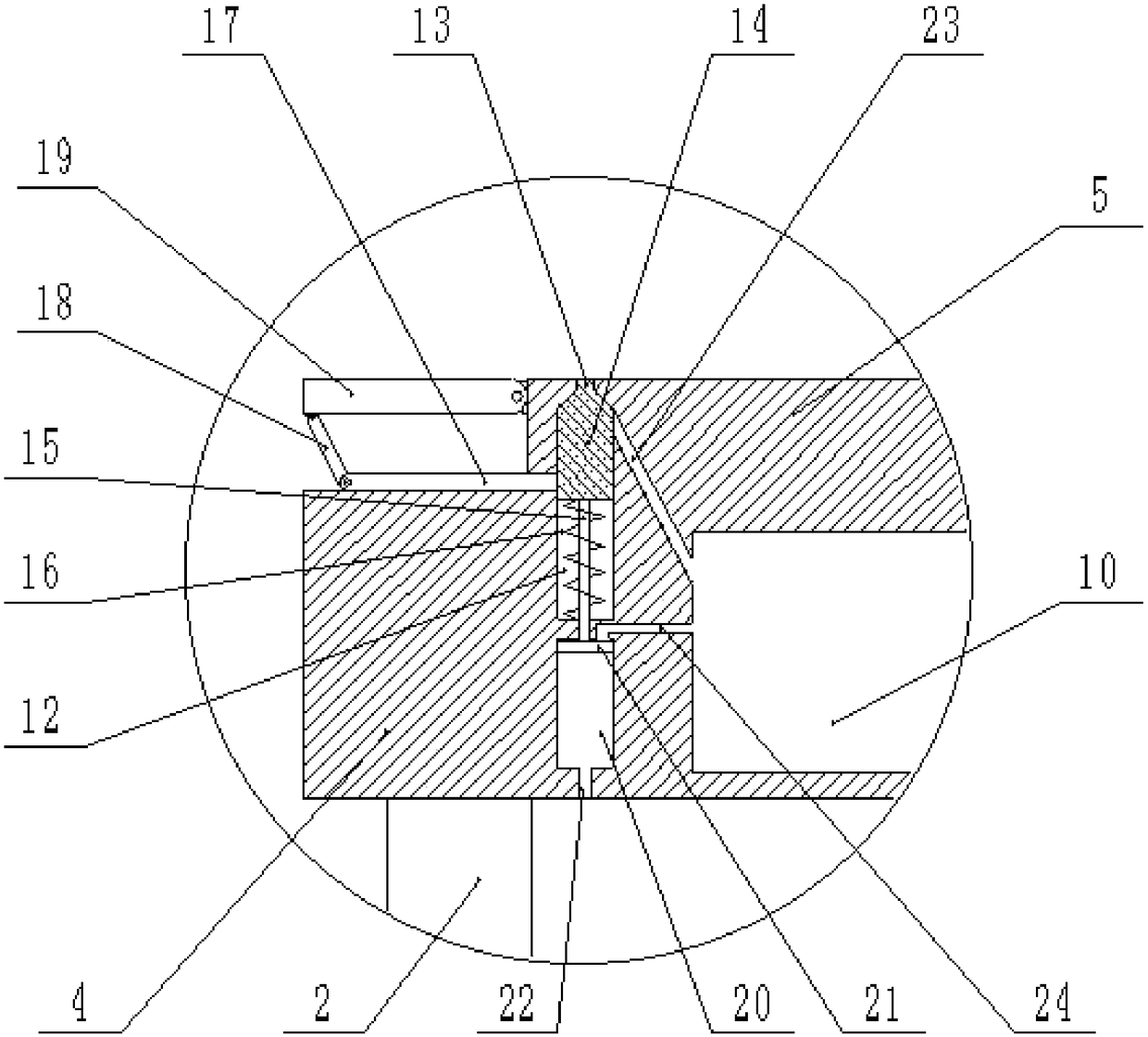

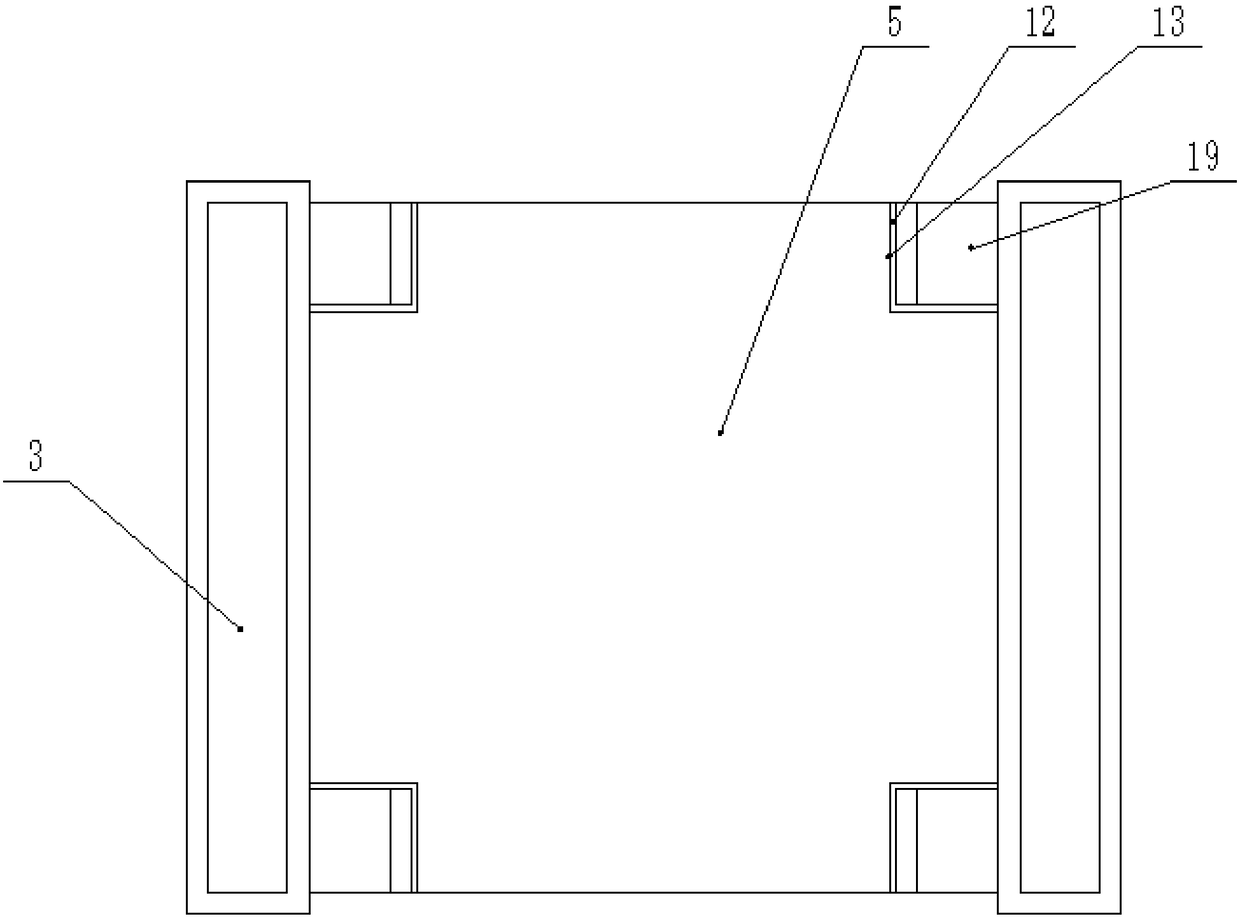

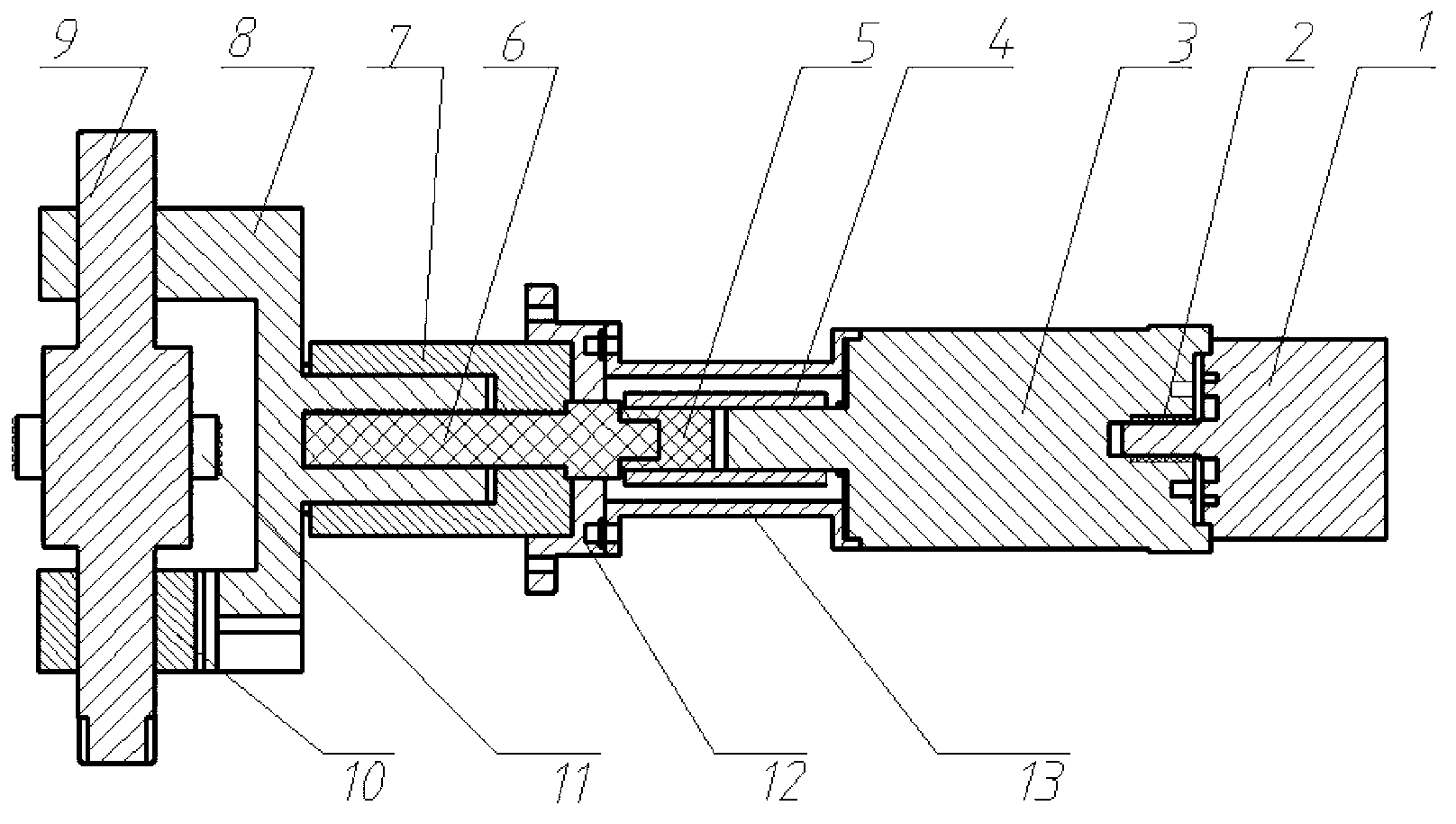

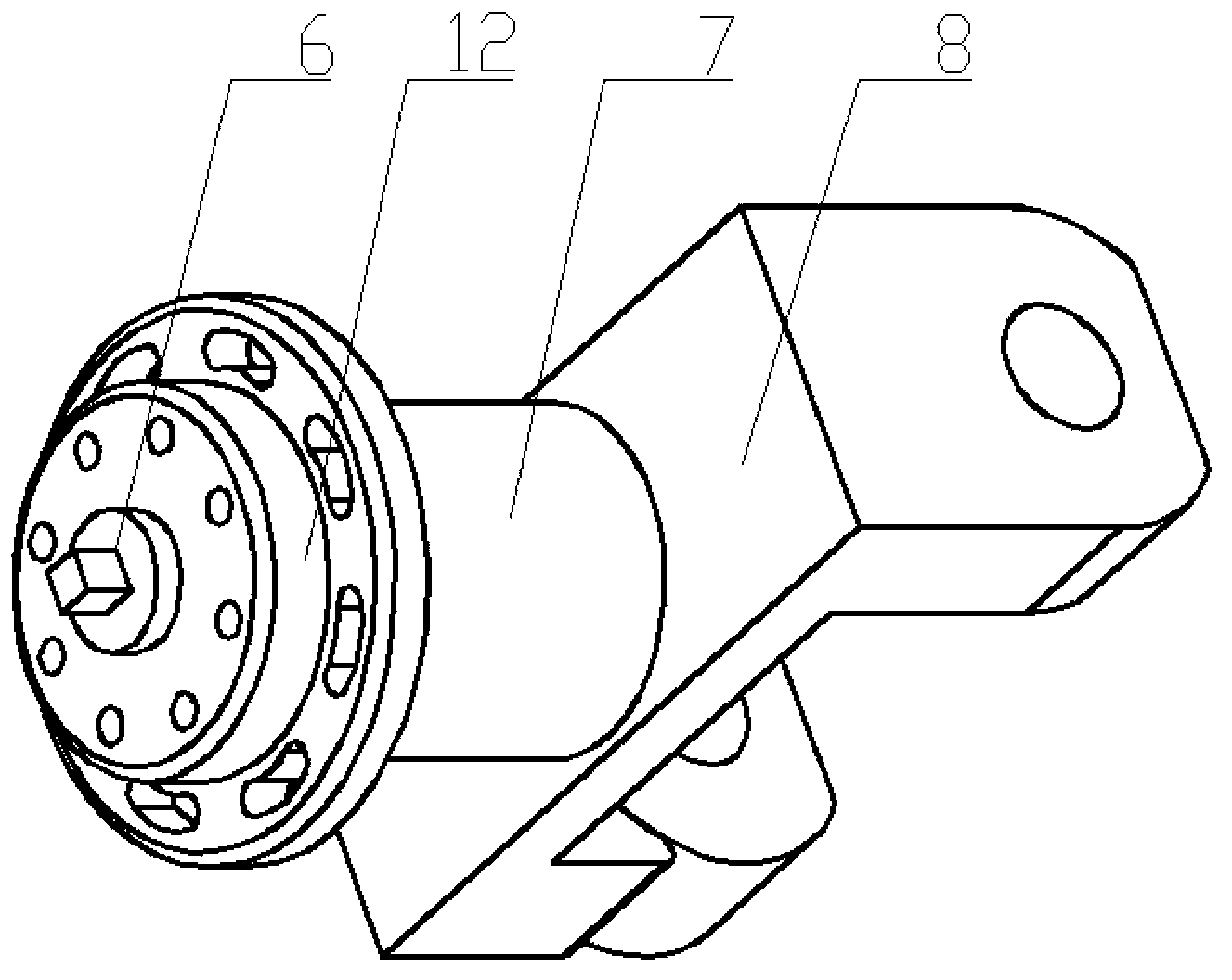

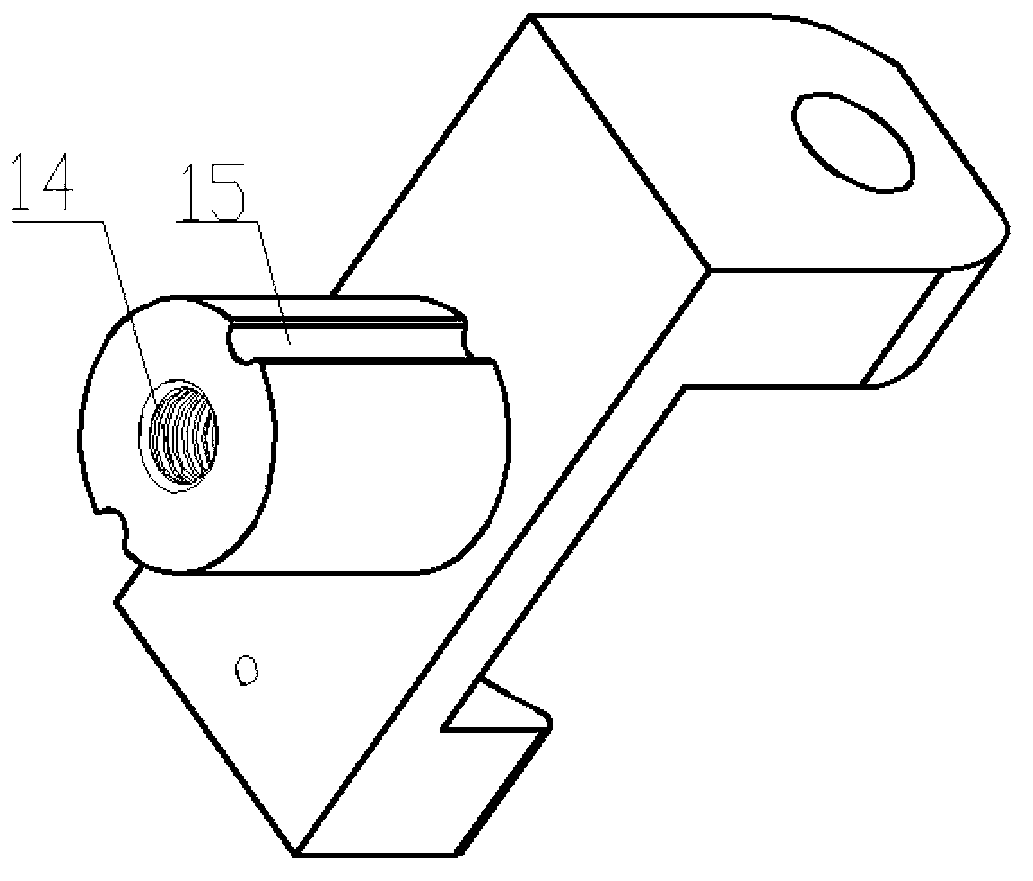

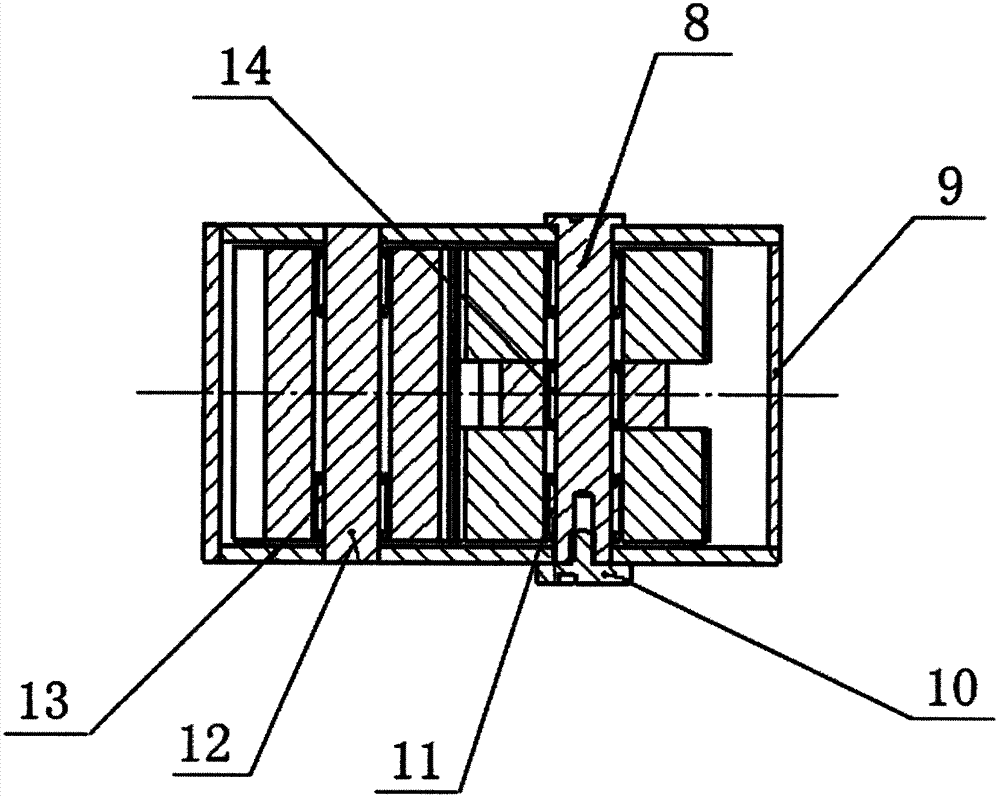

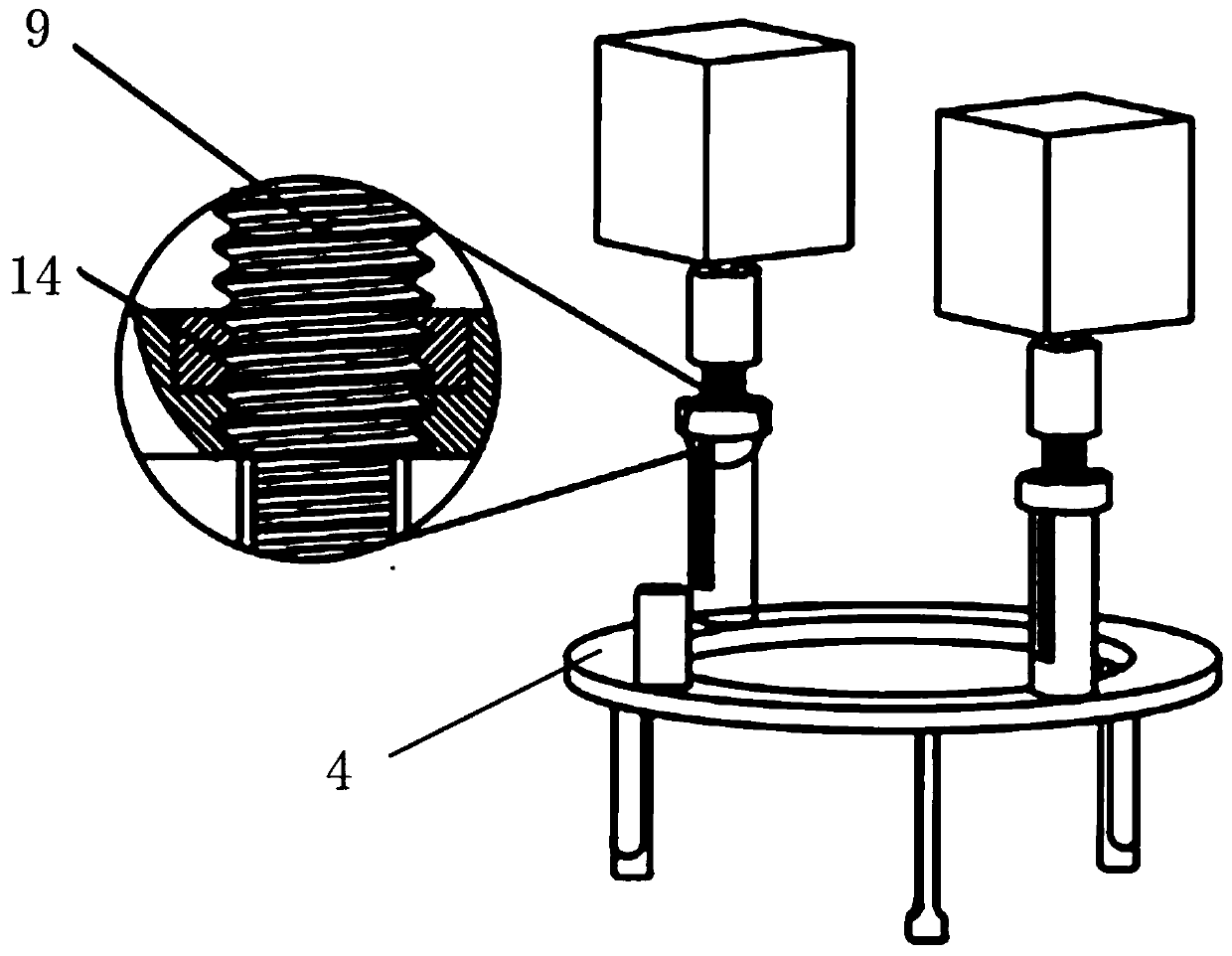

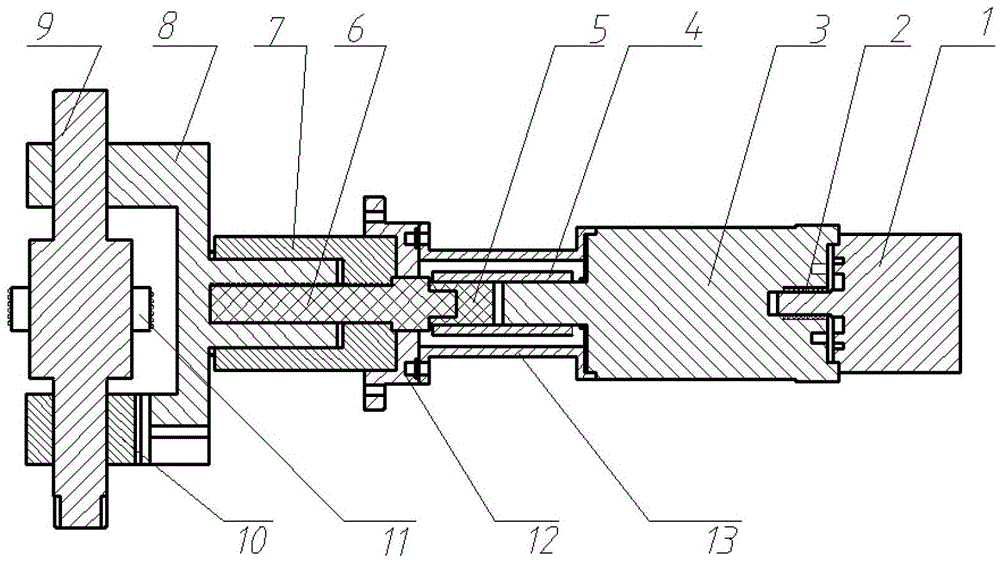

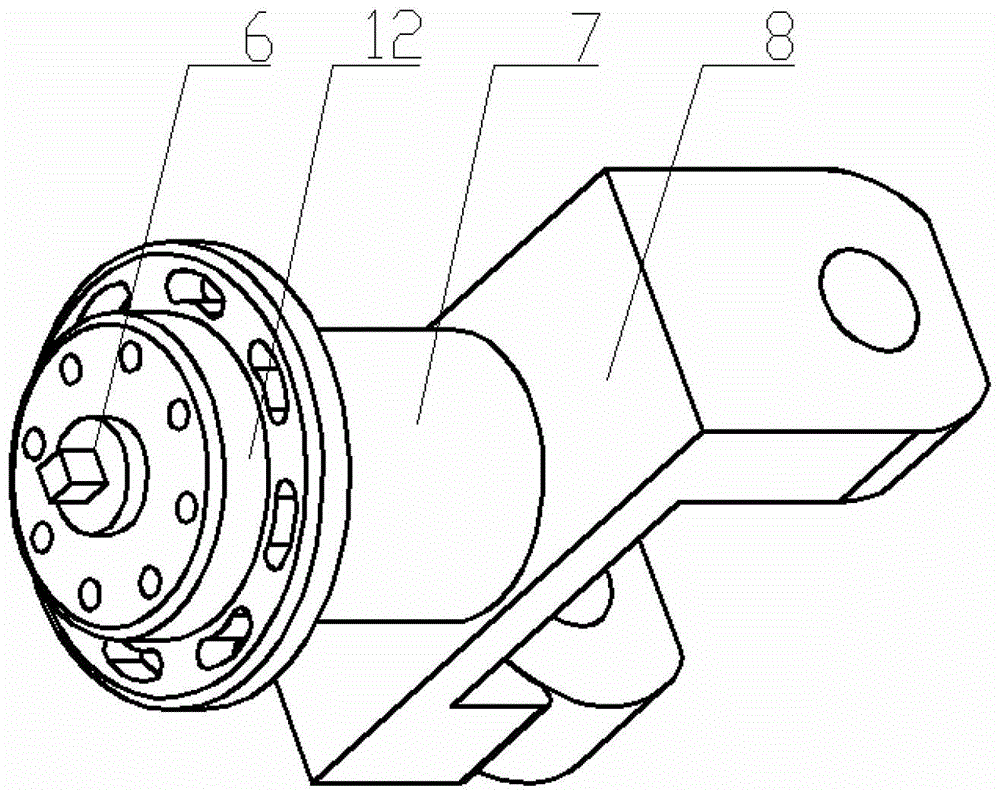

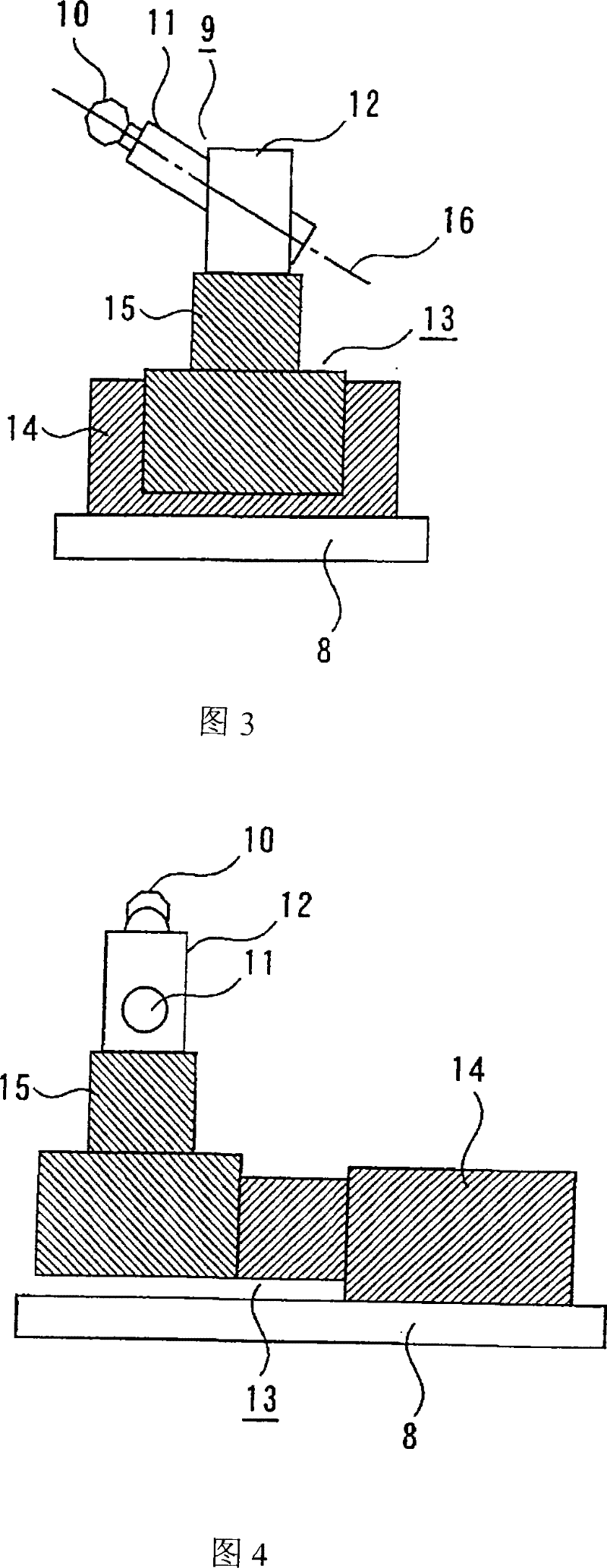

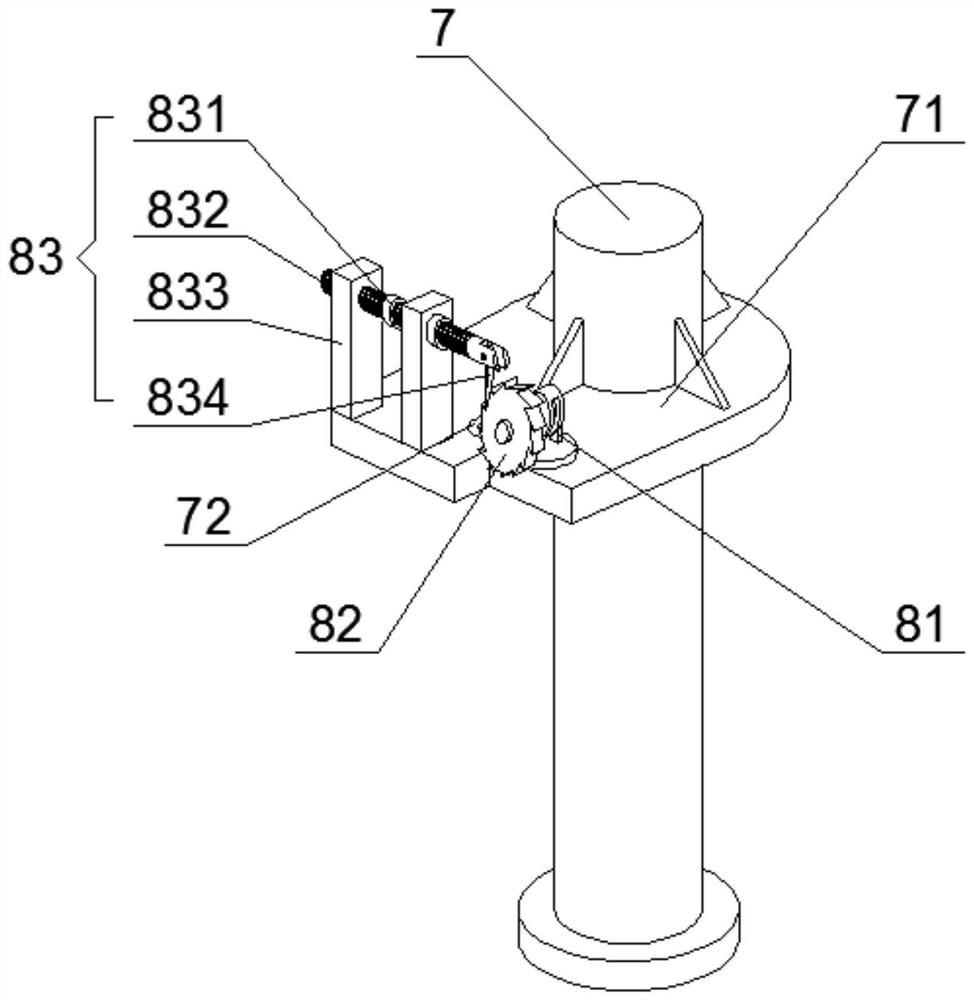

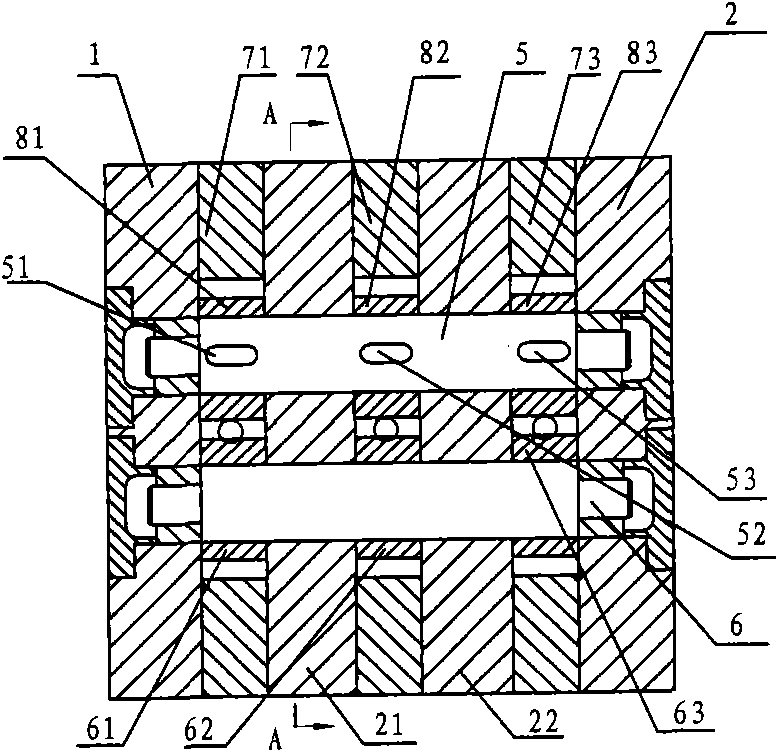

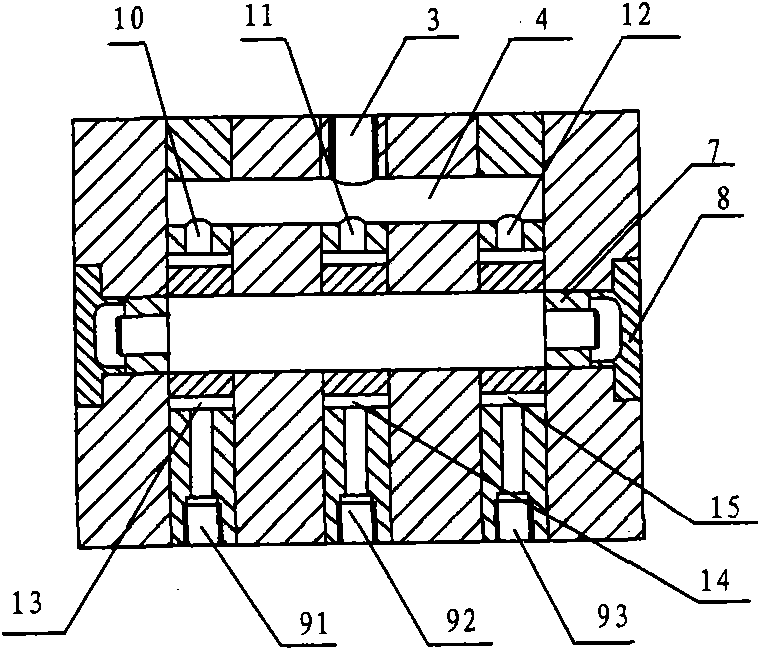

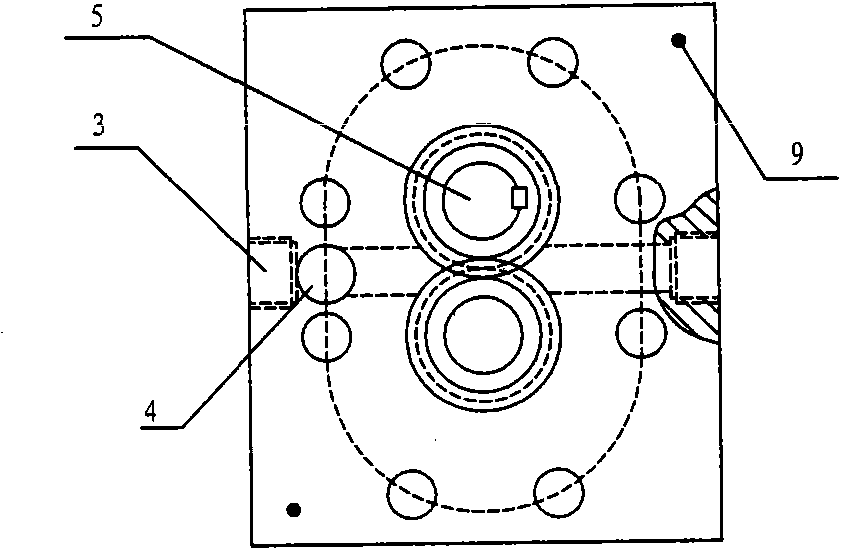

Cutter feeding mechanism of high-efficiency heat exchange tube processing equipment

ActiveCN103264064APrecise position controlControl speedExtrusion control devicesPower apparatusFlange

The invention relates to a cutter feeding mechanism of high-efficiency heat exchange tube processing equipment. The cutter feeding mechanism is characterized by comprising a cutter mounting shaft (9), a cutter connecting piece (8), a sleeve (7), a screw rod (6), a connecting flange (12), a screw rod connecting block (5) and a sleeve connector (4), wherein one end of the sleeve connector (4) is connected with an output shaft of a power device, and the other end of the sleeve connector (4) is connected with the screw rod connecting block (5); one end of the screw rod (6) is connected with the screw rod connecting block (5), and the other end of the screw rod (6) is screwed into a threaded end (14) of the cutter connecting piece (8) by a thread (17) at the end of the sleeve (7); the threaded end of the cutter connecting piece (8) is inserted into the sleeve (7) and only axially moves in a straight line in the sleeve (7); the cutter mounting shaft (9) is arranged on the end, outside the sleeve (7), of the cutter connecting piece (8); a cutter (11) is arranged on the cutter mounting shaft (9); and the connecting flange (12) is fixed on the sleeve (7) and is connected with the power device by a fixed flange (13). The cutter feeding mechanism is simple in structure and convenient to adjust, and can be used for adjusting and processing high-efficiency heat exchange tubes such as a corrugated tube in a full-automatic way so as to obtain high-accuracy and high-efficiency heat exchange tubes.

Owner:江苏中圣压力容器装备制造有限公司

Shaping machine

ActiveCN111347093AImprove processing effectExpand the range of changesPlaning/slotting machinesServoEngineering

The invention relates to the technical field of machine tool machining and mechanical transmission, in particular to a shaping machine. The shaping machine comprises a lathe bed, a workbench, a ram, atool post and a controller; the lower portion of the lathe bed is provided with a base, the outer side of the lathe bed is provided with the workbench, the upper portion of the lathe bed is providedwith the ram, and the end, facing towards the workbench, of the ram is provided with the tool post; in the working process of the shaping machine, the feeding speed of the tool post is unbalanced dueto driving of a connection rod mechanism, the low output power of a servo motor is hardly to directly drive the shaping machine to move, then, the machining effect of the shaping machine on a workpiece is influenced, thus, through a strut arranged in the connection rod mechanism, the torque of acting force of a driving rod to a swing rod is improved, a strut rotationally connected to the servo motor serves as supporting to operation of the connection rod, driving control of the servo motor at low power on power input of the connection mechanism is achieved, then, the feed rate of the tool postis stabilized, and accordingly the machining effect of the shaping machine is improved.

Owner:ZHEJIANG ZHIHENG MACHINE TOOLS CO LTD

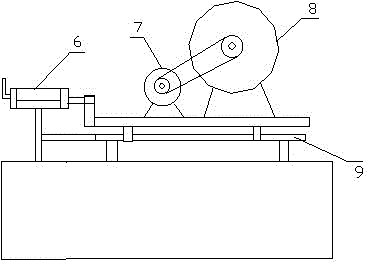

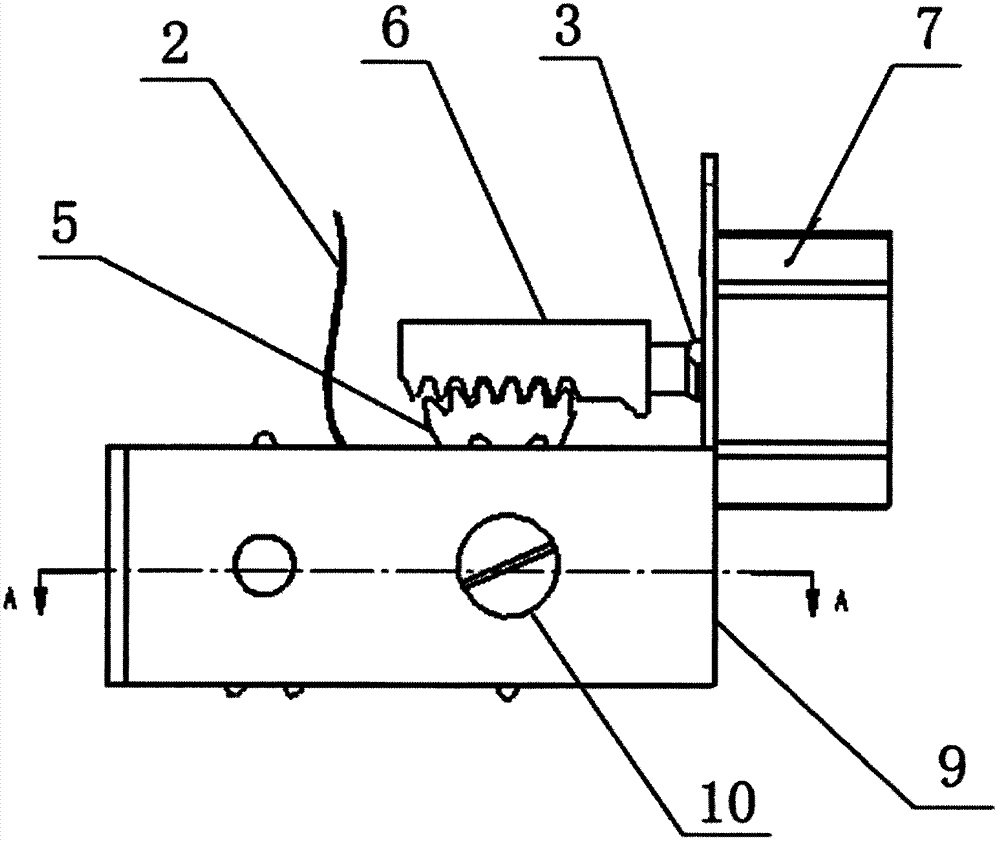

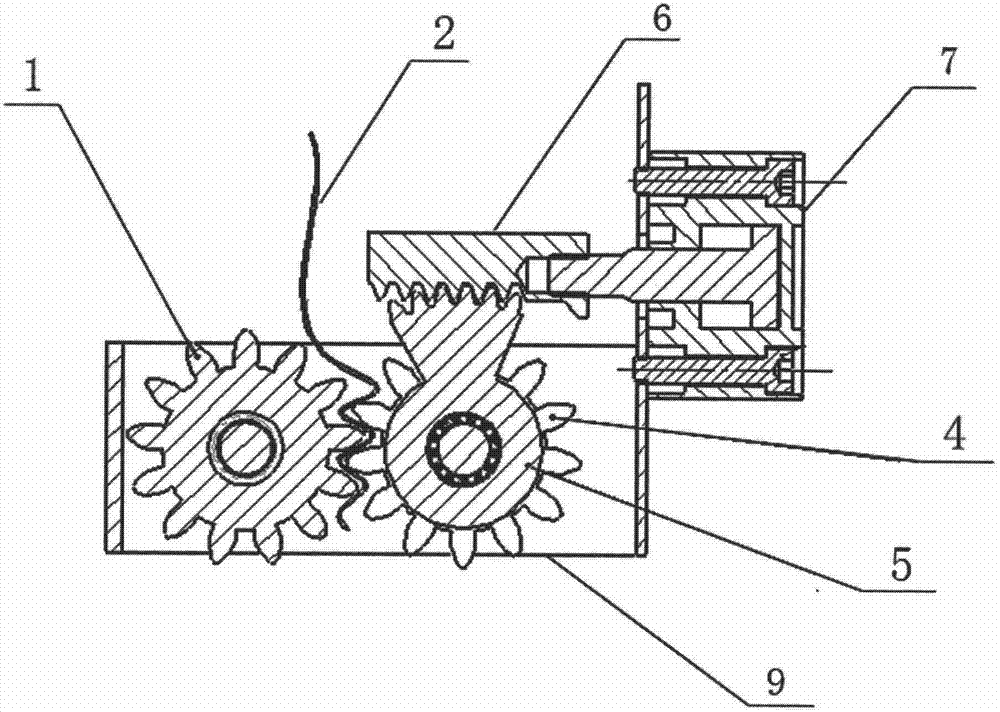

Abrasive belt automatic feeding mechanism

ActiveCN103158065BRealize manual feedingEasy to operateGrinding drivesBelt grinding machinesGear wheelConductor Coil

Owner:潍坊天润曲轴有限公司

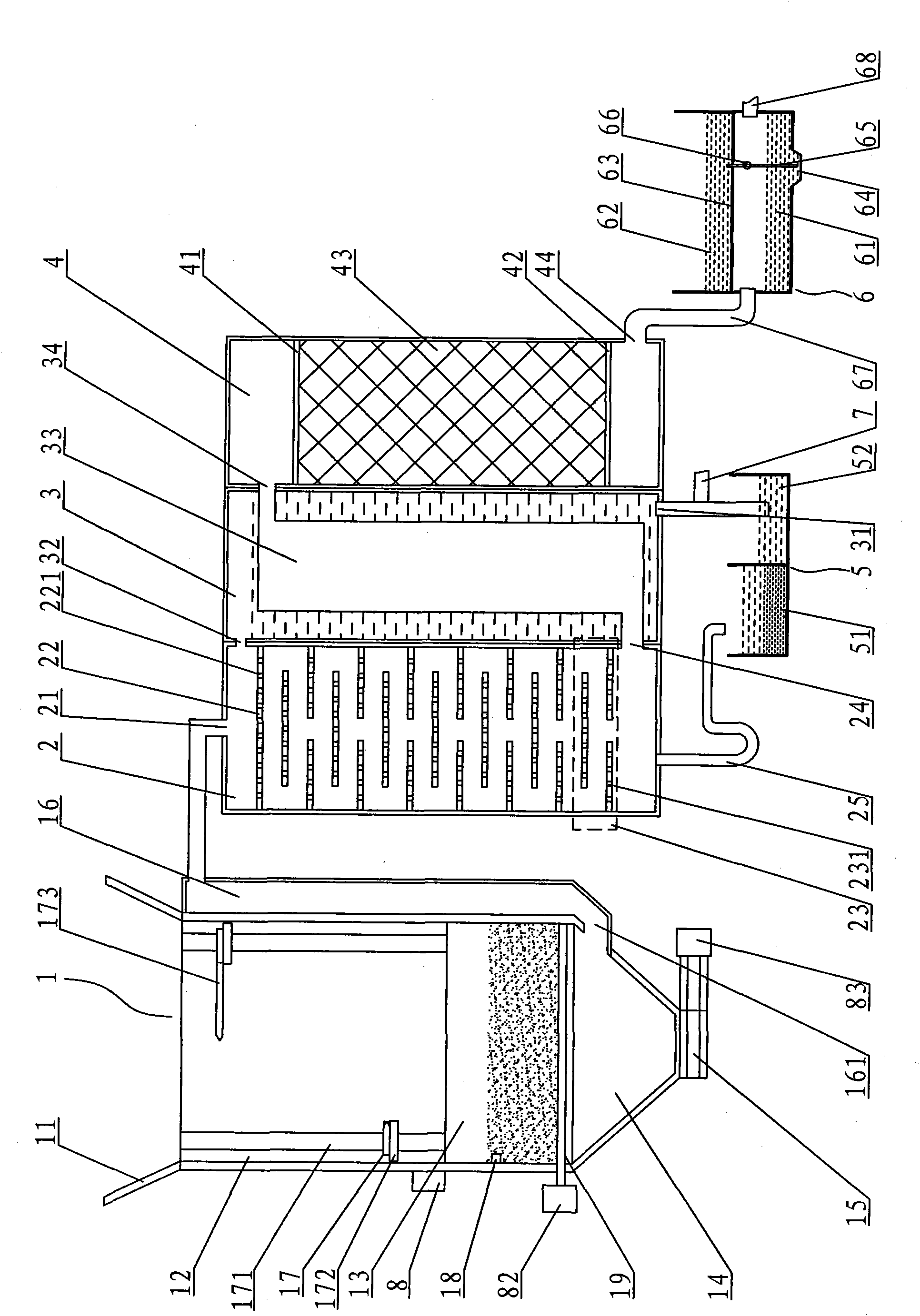

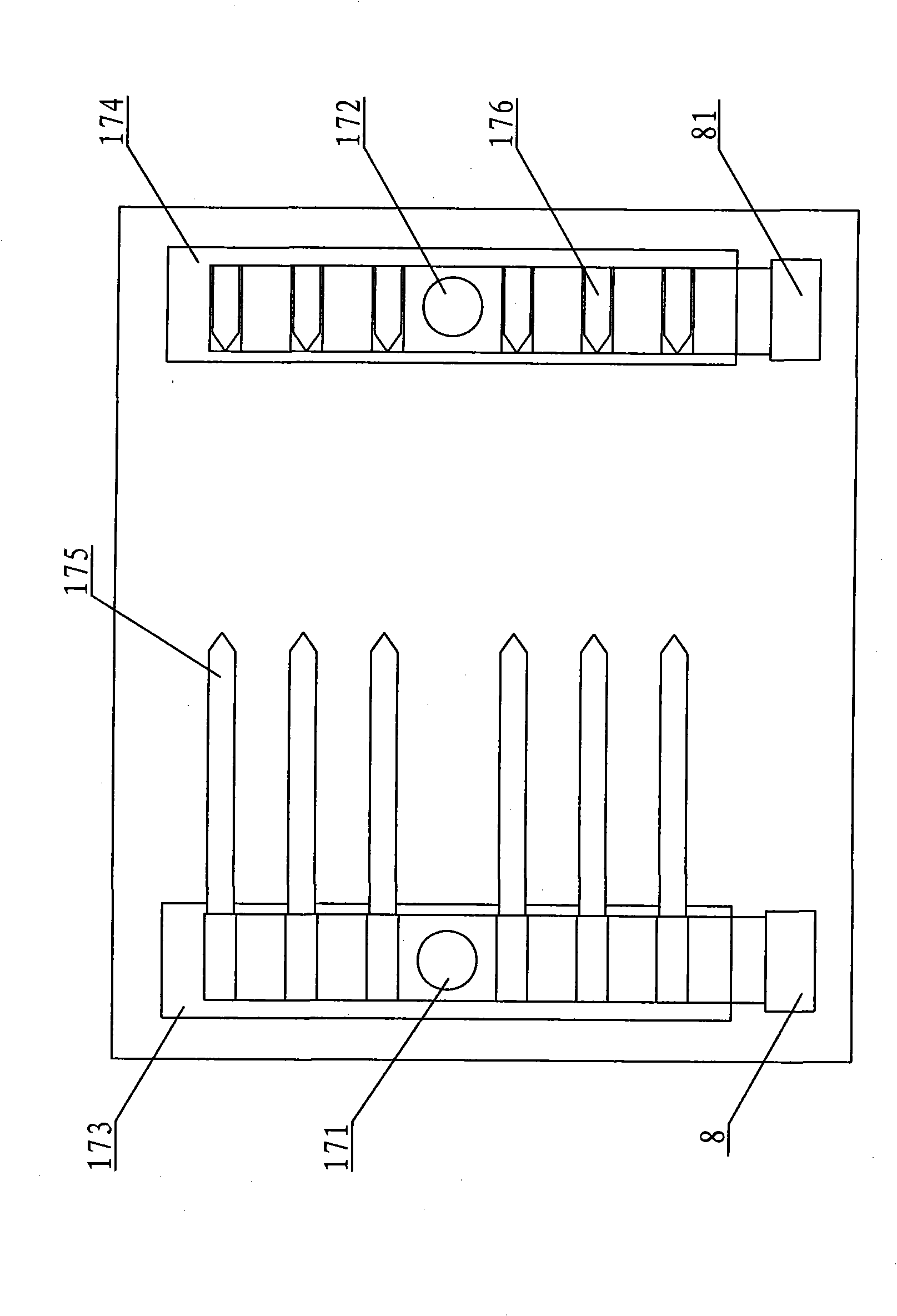

Biomass gasification equipment

ActiveCN102010752BImprove gasification effectImproved continuous performanceCombustible gas productionResource utilizationEngineering

The invention relates to biomass gasification equipment mainly comprising a gasification furnace, a spray washing chamber, a condensing chamber, a filtering chamber, a liquid separating pool and a gas storage pool. The biomass gasification equipment is used for carrying out the purification treatment on a gasified gas of the gasification furnace by adopting spraying, washing, condensing and filtering integral type equipment, stably and continuously pressing the materials by matching with a material pressing mechanism inside the gasification furnace, emitting the carbon in time by matching with upper and lower water-cooling dischargers and upper and lower carbon emission strobes inside the gasification furnace, effectively eliminating the tar contained in the gas by matching with multi-layer labyrinth type washing inside the spray washing chamber, filtering the gas by matching with a biomass filter core inside the filtering chamber, finally collecting the side products through the liquid separating pool and storing the gas through the gas storage pool, can continuously and stably supply the gas and effectively utilize various biomass resources, has high purity of the supplied gas, high yield of the biomass gasification gas and the side products and high resource utilization rate and is suitable for centralized gas supply within a regional range with sufficient biomass resources.

Owner:JIANGSU YUNJIANG BIOLOGICAL ENERGY TECH

Multifunctional mining equipment for plaster stone

ActiveCN110374590AImprove mining progressGuaranteed stabilityDerricks/mastsDriving meansSlagEngineering

The invention discloses multifunctional mining equipment for plaster stone. The multifunctional mining equipment comprises a walking part, a power assembly and a control assembly, wherein the power assembly and the control assembly are arranged on the walking part; a mining part is arranged at the front end of the walking part; a work drilling mechanism used for hole drilling is arranged on the walking part; the mining part comprises a tunneling mechanism and a slag crushing mechanism; the tunneling mechanism comprises a tunneling support frame, a tunneling head arranged on the tunneling support frame and a tunneling motor used for providing power for the tunneling head; the slag crushing mechanism comprises a slag crushing support frame and two groups of crushing rollers arranged on the slag crushing support frame; a bucket is arranged on the front side wall of the walking part; one end of the slag crushing support frame is hinged onto the bucket; and at least one connecting arm is hinged between the middle parts of the slag crushing support frame and the tunneling support frame. The multifunctional mining equipment has the advantages that on the basis of tunneling functions of atraditional tunneling machine, hole drilling and timely crushing functions are added, so that the mining operation on rock stratums with different cross sections and hardness can be realized; and themineral product yield is ensured.

Owner:康定龙源穗城石膏有限责任公司

Quartz Crucible Grinding Device

ActiveCN103447921BImprove seismic performanceLow mechanical failure rateGrinding drivesGrinding machinesFriction lossSlide plate

A quartz crucible grinding device, the cross-sectional shape of the first sliding rail of the main movement mechanism is rectangular, and the cross-sectional shape of the second sliding rail is triangular; rail, the second direction slide plate can be slidably set on the second direction slide rail, the first direction slide rail is away from the base, the cross section of the slide rail is rectangular, the first direction slide rail is close to the base, the cross section shape of the slide rail is dovetail shape, the second direction slide rail The cross-sectional shape of the rails is all dovetail-shaped, the main shaft motor is installed on the second direction slide plate, the main shaft motor drives the flat grinding head, the servo motor assembly drives the worktable, the first direction carriage and the second direction slide plate through the ball screw; the servo motor passes through The ball screw drive mode has small friction loss, reduces the failure rate, and has high transmission efficiency; the mechanical slide rail has good rigidity, high shock resistance, stable feed, no crawling at slow speed, no vibration at high speed, and safety performance during operation High, low mechanical failure rate.

Owner:徐州协鑫太阳能材料有限公司

A Cutter Suitable for Straight Cutting Operations

The invention provides a cutter applicable to linear cutting operation. The cutter comprises a transmission mechanism which is in a shell and is driven by a motor to perform rotational motion and linear feeding motion, and a cutting assembly which is arranged on one side of the transmission mechanism and is driven by the transmission mechanism to rotate at a high speed. The cutter is characterized in that while an outer shaft and a rotating shaft on the inner and outer sides of a screw drive shaft arranged on the transmission mechanism cooperate to drive the cutting assembly arranged on one side of the transmission mechanism to rotate at a high speed, linear feeding motion is achieved. According to the cutter applicable to linear cutting operation, the structure is simple, different forms of cutting operation can be implemented, and safety is improved.

Owner:NAT UNIV OF DEFENSE TECH

Metal ceramic composite material additional material manufacturing device and production method thereof

PendingCN110238399AImprove liquidityStable feed rateAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankMolten bath

The invention provides a metal ceramic composite material additional material manufacturing device and a production method thereof. The manufacturing device comprises a wire feeding spraying head, a raw material extruding device and a laser generator. The raw material extruding device comprises a slurry groove and an extruding disc arranged in the slurry groove. The slurry groove is provided with a material guide pipe. The material extruding disc is provided with a material guide rod for the material guide pipe to penetrate. An extruding assembly used for pushing the extruding disc to move towards one side of the slurry groove is further connected to the extruding disc. After slurry enters the slurry groove, the extruding assembly pushes the extruding disc to move toward one side of the slurry groove, thus the slurry in the slurry groove enters the material guide pipe due to gravity and extruding force and flows out along the periphery side of the material guide rod, the situation that secondary particles are spontaneously gathered and formed on the surface of the slurry due to accumulated surface energy is avoided, the slurry shape and mobility of the slurry flowing out along the material guide rod meet the technology requirement, the wire feeding spraying head enables the particles to be collected to one point, the slurry forms a molten bath through a laser generator, and the slurry is piled up gradually in space to form an entity of the metal ceramic composite material.

Owner:昆山金甲虫机器人技术有限公司

A vertical sawing machine

ActiveCN111069697BStrengthen the effect of clamping forceLarge clamping forceMetal sawing devicesMetal sawing accessoriesElectric machineryEngineering

The invention relates to the technical field of sawing equipment, in particular to a vertical sawing machine, which includes a bed, a saw frame, a tooling table, a clamping unit, a motor and a controller; Saw frame; the left and right sides of the upper part of the bed are provided with mounting bases; two parallel lead screws are arranged between the mounting bases; the tooling table is driven by the lead screw to adjust the feeding position on the bed; Because during the sharp cutting process of clamping a long irregular workpiece, the feed movement of the tooling table and the vibration of the clamping block when sawing the workpiece will destroy the clamping effect, thereby affecting the machining accuracy of the sawing machine; therefore, The present invention strengthens the clamping effect on irregular long workpieces by setting the adjustable pressure block on the clamping block, and through the tooling table installed on the lead screw pair, cooperates with the precise control of the controller to stabilize the clamping force. The feed rate of the workpiece during sawing improves the machining accuracy of the sawing machine.

Owner:济南北方金锋锯业有限公司

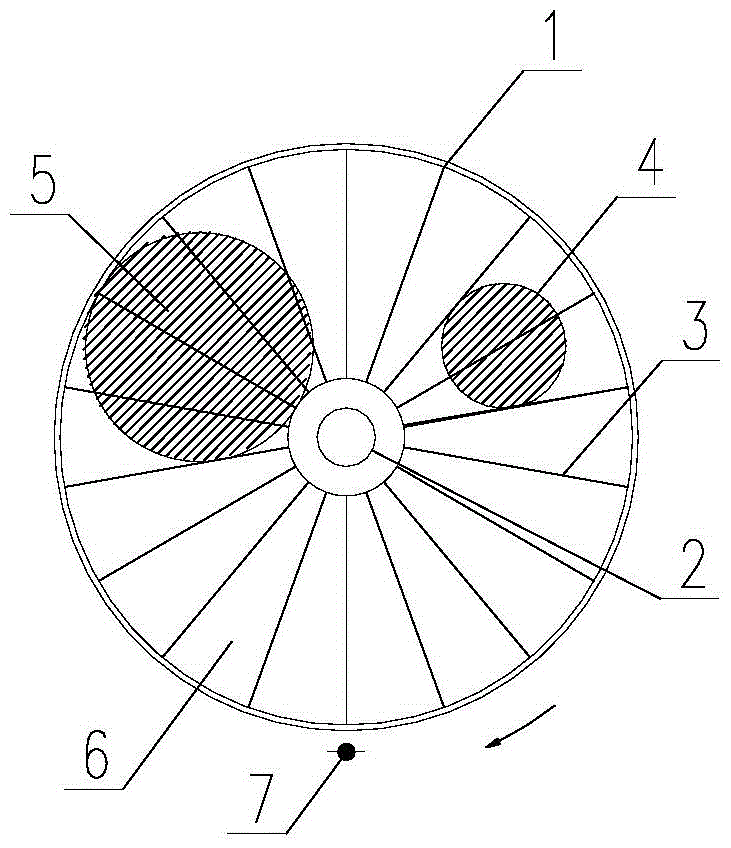

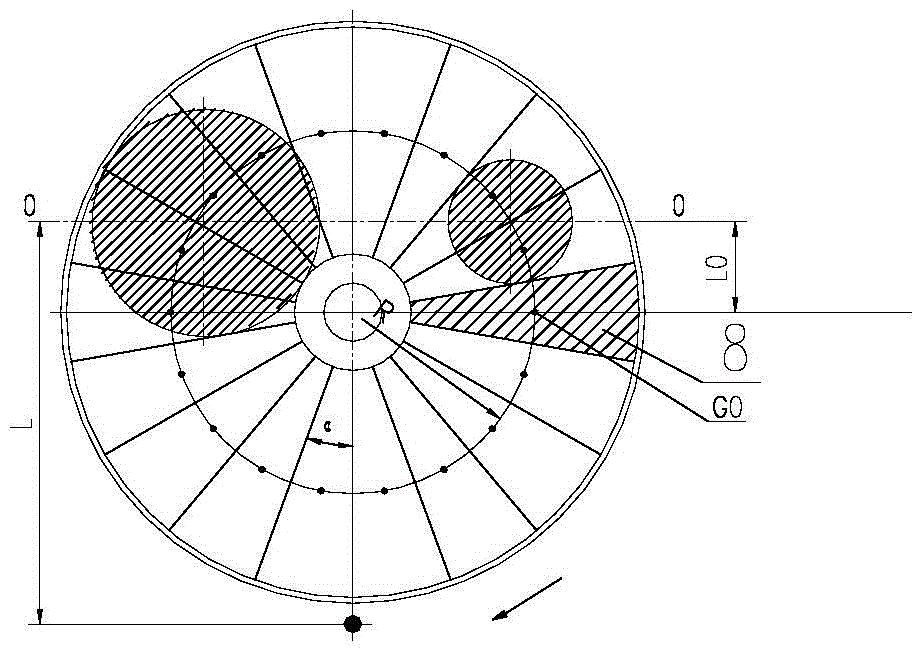

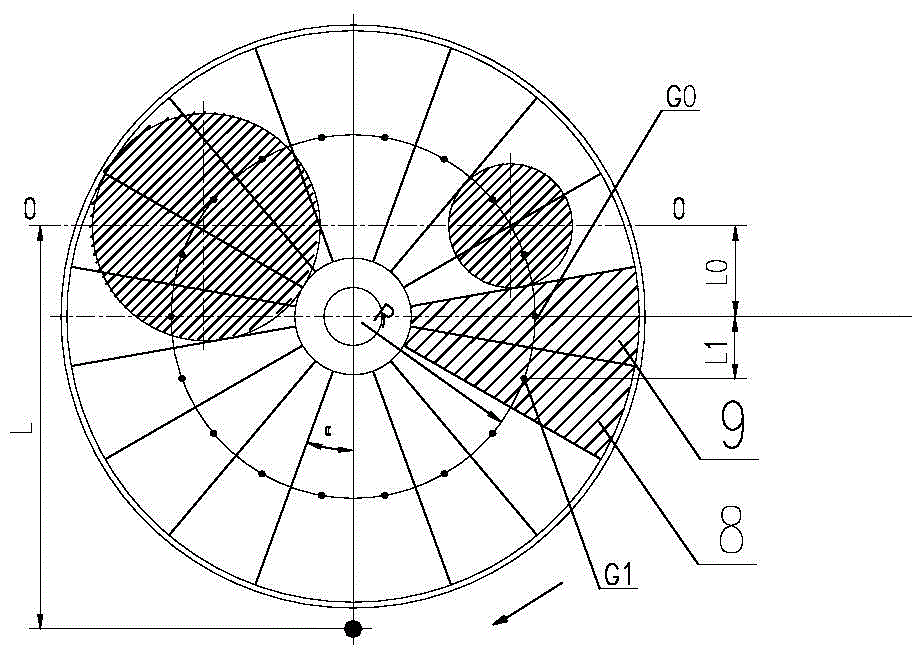

A rotary quantitative feeding device and its measuring method

ActiveCN103662680BHigh feed accuracyImprove metering accuracyWeighing apparatus for continuous material flowRotary conveyorsEngineeringSupport point

The invention relates to the technical field of feeding setting, in particular to a rotation rationing feed device and a metering method thereof. The rotation rationing feed device comprises an outer shell, a rotating wheel, a feed port and a discharge port, wherein the rotating wheel is arranged in the outer shell in a rotatable mode, the rotating wheel is provided with a plurality of blades arranged evenly, the feed port and the discharge port are formed in the outer shell, and sector spaces containing materials are formed between every two adjacent blades. The rotation rationing feed device further comprises a weighing device, the connecting lines of the supporting points of the feed device are located on one side of the center of equipment, the weighing device is arranged on the other side of the center of the equipment, and the weighing device is located on the central line of the connecting lines of the supporting points. According to the metering method of the rotation rationing feed device, weighing and calculation are carried out on the materials in each sector space, adjustment on the rotating speed of the rotating wheel is carried out aiming at the materials in each sector space, the metering accuracy of rotation type rationing feed equipment can be improved effectively, and the stability of the instant feeding rate is guaranteed.

Owner:CHENGDE DINGXIN AUTOMATION ENG

High-efficiency heat exchange tube processing equipment tool feed mechanism

ActiveCN103264064BPrecise position controlControl speedExtrusion control devicesPower apparatusHeat transfer tube

The invention relates to a cutter feeding mechanism of high-efficiency heat exchange tube processing equipment. The cutter feeding mechanism is characterized by comprising a cutter mounting shaft (9), a cutter connecting piece (8), a sleeve (7), a screw rod (6), a connecting flange (12), a screw rod connecting block (5) and a sleeve connector (4), wherein one end of the sleeve connector (4) is connected with an output shaft of a power device, and the other end of the sleeve connector (4) is connected with the screw rod connecting block (5); one end of the screw rod (6) is connected with the screw rod connecting block (5), and the other end of the screw rod (6) is screwed into a threaded end (14) of the cutter connecting piece (8) by a thread (17) at the end of the sleeve (7); the threaded end of the cutter connecting piece (8) is inserted into the sleeve (7) and only axially moves in a straight line in the sleeve (7); the cutter mounting shaft (9) is arranged on the end, outside the sleeve (7), of the cutter connecting piece (8); a cutter (11) is arranged on the cutter mounting shaft (9); and the connecting flange (12) is fixed on the sleeve (7) and is connected with the power device by a fixed flange (13). The cutter feeding mechanism is simple in structure and convenient to adjust, and can be used for adjusting and processing high-efficiency heat exchange tubes such as a corrugated tube in a full-automatic way so as to obtain high-accuracy and high-efficiency heat exchange tubes.

Owner:江苏中圣压力容器装备制造有限公司

Efficient plate shearing machine

InactiveCN109732134AIncrease flexibilityStable feed rateShearing machinesMaintainance and safety accessoriesEngineeringRotating disc

The invention relates to the technical field of plate shearing machines, in particular to an efficient plate shearing machine. Sliding chutes are arranged in the inner walls of the left side and the right side of the machine frame respectively, a knife rest are slidably connected in the sliding chutes; a blade are fixedly connected to the lower end of the knife rest, a plurality of knife edges areuniformly arranged at the lower end of the blade; a rotating shaft I is fixedly connected to the middle of the upper end of the knife rest; the upper end of the machine frame is fixedly connected with a rotating frame, the rotating frame is rotationally connected with a rotating disc; a rotating shaft II is fixedly connected to the front plane of the rotating disc, the rotating shaft I is rotationally connected with one end of the connecting rod, and the other end of the connecting rod is rotationally connected with the rotating shaft II; feeding plates are fixedly connected to the lower endsof the left inner wall and the right inner wall of the machine frame, a plurality of longitudinal feeding grooves are uniformly arranged in the feeding plate; transverse feeding grooves are arrangedin the feeding plates, the position of the feeding grooves are corresponded to blades position; and a plurality of feeding mechanisms are arranged on the feeding plates, a power mechanism is arrangedon the machine frame. The efficient plate shearing machine has the advantages of being high in cutting efficiency, convenient to use, high in flexibility and capable of improving the cutting stabilityand the like.

Owner:安徽省通快数控机床制造有限公司

Numerical controller

ActiveCN111123845AStable feed rateStabilization of cutting speedProgramme controlComputer controlControl engineeringExecution unit

To provide a numerical controller that can detect a position in a machining program at which a speed control abnormality is likely to occur due to an insufficient look-ahead blocks that are used to determine an acceleration / deceleration operation, and start a look-ahead processing function from the position in parallel with looking ahead at the machining program from the start of the machining program. The numerical controller (100) includes a program execution unit (111) that executes a machining program, a program look-ahead unit (112) that simultaneously looks ahead at the machining programfrom different blocks in the machining program in parallel with execution of the machining program and that includes a first program look-ahead unit (112a) and a second program look-ahead unit (112b), and a look-ahead allocation unit that divides a storage unit into at least a first region and a second region and instructs the first program look-ahead unit (112a) to perform a look-ahead action ofstoring look-ahead blocks in the first region and instructs the second program look-ahead unit (112b) to perform a look-ahead action of storing look-ahead blocks in the second region.

Owner:FANUC LTD

Numerical controller

ActiveUS20200133240A1Stable feed rateStabilize cutting speedComputer controlSimulator controlControl engineeringControl theory

To provide a numerical controller that can detect a position in a machining program at which a speed control abnormality is likely to occur due to an insufficient look-ahead blocks that are used to determine an acceleration / deceleration operation, and supplement the look-ahead blocks at that position in order to stabilize feed rate, cutting speed and other factors. A numerical controller includes a required look-ahead blocks setting unit that sets a required look-ahead blocks, which is a look-ahead blocks required to execute a machining program, and an operation limitation unit that compares a look-ahead blocks calculated by a look-ahead blocks calculation unit to the required look-ahead blocks and, if the look-ahead blocks is less than the required look-ahead blocks, limits execution of the machining program until the look-ahead blocks reach the required look-ahead blocks.

Owner:FANUC LTD

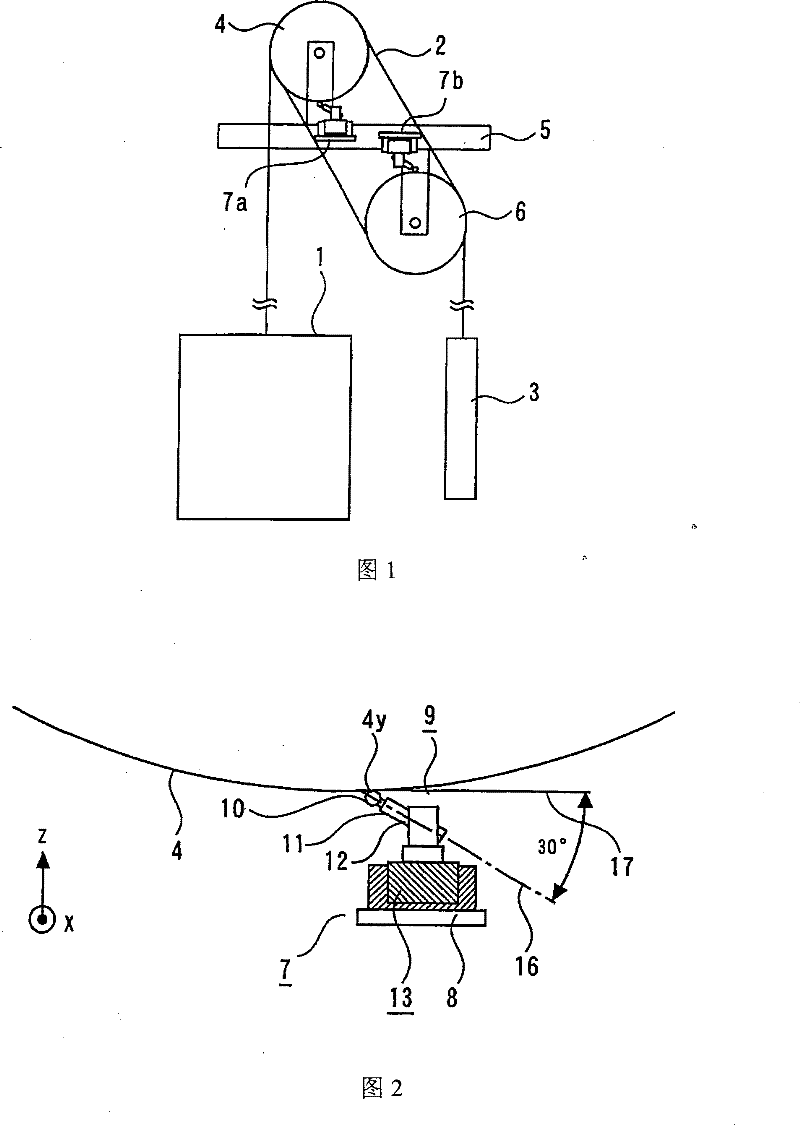

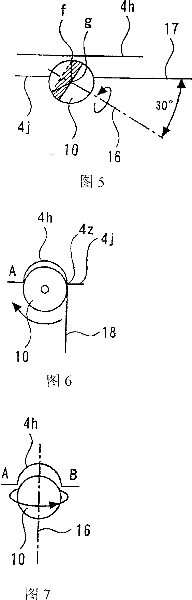

Apparatus and method for processing elevator wire rope groove

ActiveCN101157193BPrevent adhesionLower quality of serviceGrinding feed controlBuilding liftsGrinding wheelRADIUS

The invention provides a processing device for an elevator steel cable groove which can renovate and process the steel cable groove used for driving a steel cable wheel in a short time, and can prevent the service quality of the elevator from decreasing. The invention is provided with a mounting part (8) which is demountably arranged on a fixing rack (5) of the elevator, a processing part (9) which is arranged at the opposite position of the steel cable groove part of a main steel cable (2) being used for suspension hanging the case of the elevator and being positioned inside the steel cable groove (4a) of a driving steel cable wheel (4), and a movable bearing part (13) which is arranged on the mounting part and used for bearing the processing part and which can move along the rotating axle direction and the radius direction of the driving steel cable wheel. The processing part is provided with a rotary grinding wheel (10) which is used for grinding and processing the steel cable groove. The rotary axle (16) of grinding wheel forms an angle of about 30 degrees with a tangent (17) starting from the processing point of the driving steel cable wheel.

Owner:MITSUBISHI ELECTRIC BUILDING SOLUTIONS CORP

Multifunctional mining equipment for gypsum rock

ActiveCN110374590BImprove mining progressGuaranteed stabilityDerricks/mastsDriving meansSlagElectric machinery

The invention discloses multifunctional mining equipment for plaster stone. The multifunctional mining equipment comprises a walking part, a power assembly and a control assembly, wherein the power assembly and the control assembly are arranged on the walking part; a mining part is arranged at the front end of the walking part; a work drilling mechanism used for hole drilling is arranged on the walking part; the mining part comprises a tunneling mechanism and a slag crushing mechanism; the tunneling mechanism comprises a tunneling support frame, a tunneling head arranged on the tunneling support frame and a tunneling motor used for providing power for the tunneling head; the slag crushing mechanism comprises a slag crushing support frame and two groups of crushing rollers arranged on the slag crushing support frame; a bucket is arranged on the front side wall of the walking part; one end of the slag crushing support frame is hinged onto the bucket; and at least one connecting arm is hinged between the middle parts of the slag crushing support frame and the tunneling support frame. The multifunctional mining equipment has the advantages that on the basis of tunneling functions of atraditional tunneling machine, hole drilling and timely crushing functions are added, so that the mining operation on rock stratums with different cross sections and hardness can be realized; and themineral product yield is ensured.

Owner:康定龙源穗城石膏有限责任公司

Tri-spindle synchronizer

The invention provides a tri-spindle synchronizer, which is characterized in that sliding bearings are respectively arranged on positions corresponding to a front end cover and a rear end cover; two ends of a drive shaft and a driven shaft which are arranged in parallel are arranged in the holes of the sliding bearing; three oil cavities and two clapboards are fixedly arranged between the front end cover and the rear end cover, and the clapboard is arranged between the oil cavities; an oil inlet is arranged in the middle oil cavity, and an oil outlet is respectively arranged on the other end of each of the oil cavity; an oil cavity passes through all the oil cavities and the clapboards and is communicated with the oil inlet; three drive wheels are arranged on the drive shaft, three driven wheels which are engaged with the drive wheels correspondingly are arranged on the driven shaft, and one pair of engaged gears are arranged in one oil cavity; and each oil cavity is provided with a high-pressure cavity and a low-pressure cavity.

Owner:山东省青岛生建机械厂

Automatic diaphragm feeding device and automatic diaphragm feeding method

PendingCN114249151AReduce labor costsStable feed rateArticle feedersCleaning processes and apparatusEngineeringStructural engineering

The invention discloses an automatic diaphragm feeding device and an automatic diaphragm feeding method. The automatic diaphragm feeding device comprises a taking mechanism, a feeding mechanism, a detecting mechanism and a discharging mechanism. The material taking mechanism is provided with a material taking assembly and a rail, the material taking assembly is movably arranged on the rail, and the material taking driving piece drives the material taking assembly to move along the rail. The feeding mechanism is arranged on one side of the track and used for providing a plurality of diaphragms, and the taking assembly takes out the diaphragms. The detection mechanism is arranged on one side of the feeding mechanism, and the material taking assembly carries the membrane to the detection mechanism for detection. The discharging mechanism is arranged on one side of the detection mechanism, and the material taking assembly carries the membrane to the discharging mechanism for discharging. The cleaning mechanism is arranged on one side of the discharging mechanism, and the material taking assembly carries the membrane to the cleaning mechanism for cleaning. According to the automatic diaphragm feeding device, through the modes of automatic diaphragm feeding, diaphragm discharging and diaphragm cleaning, a large amount of labor cost is saved, the stable feeding speed is provided, and the production requirement is met.

Owner:TRANSCEND OPTRONICS (YANGZHOU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com