Cable winding machine cable feeding device

A wire feeding device and winding machine technology, which is applied in the directions of transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problem of no labor saving, etc., and achieve the effect of stable speed and large friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

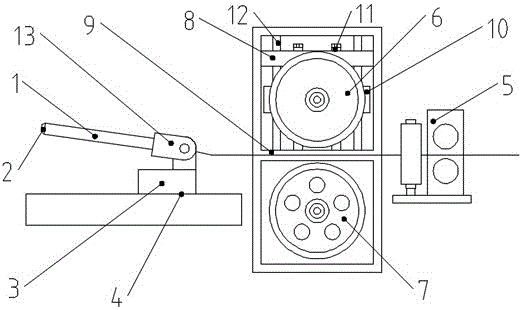

[0013] according to figure 1 Describe the specific embodiment of the present invention, including the main body of the winding machine, the wire feeding device is connected to the winding machine, the wire feeding device includes a wire feeding roller set and a wire feeding guide device, and the wire feeding guide The device is connected to the front end of the wire feeding roller group in the wire feeding direction. The wire feeding guide device includes a wire feeding guide 1, a wire feeding chuck 2 and a sliding push structure, and the cable passes through the wire feeding guide 1 , the wire feeding chuck 2 is connected to the front end of the wire feeding catheter 1, and the wire feeding catheter 1 is connected to a sliding push structure, and the sliding push structure includes a sliding base 3, a sliding groove 4 and a driving structure, the sliding groove 4 is fixed on the platform in front of the winding machine, the length direction of the notch of the sliding groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com