Tri-spindle synchronizer

A synchronization device and spindle technology, applied in the direction of fluid pressure actuators, servo motors, mechanical equipment, etc., can solve the problems of difficult operation and difficulty in ensuring synchronization, so as to improve precision and production efficiency, high synchronization accuracy, The effect of stable and consistent feed speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

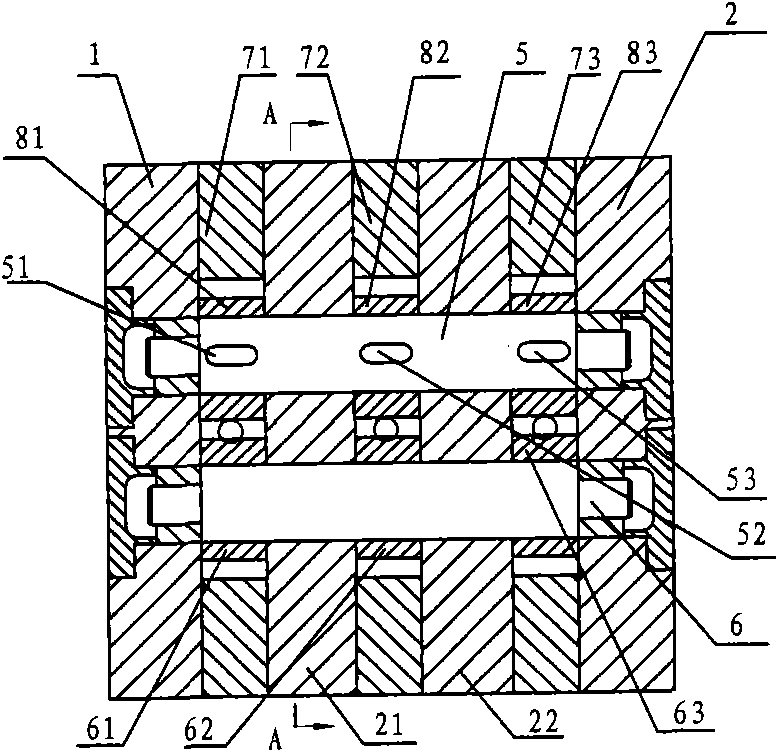

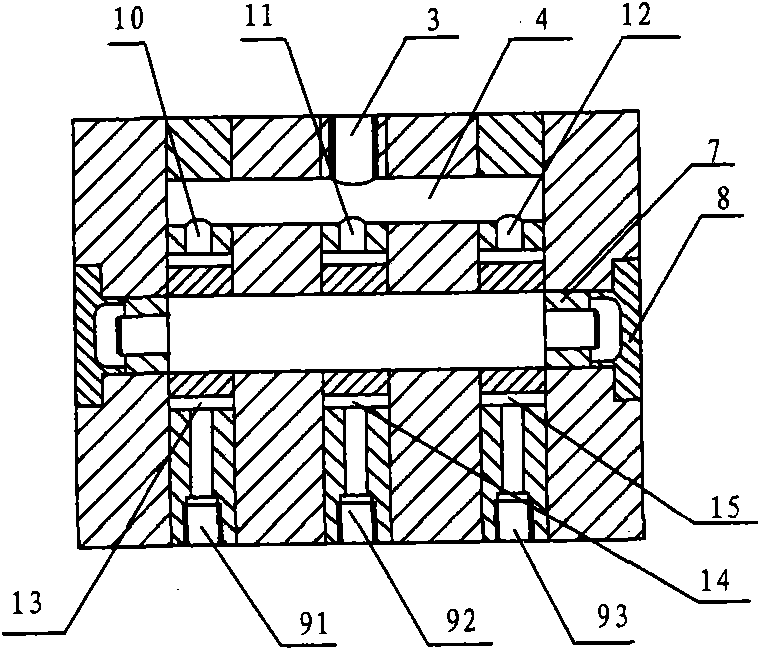

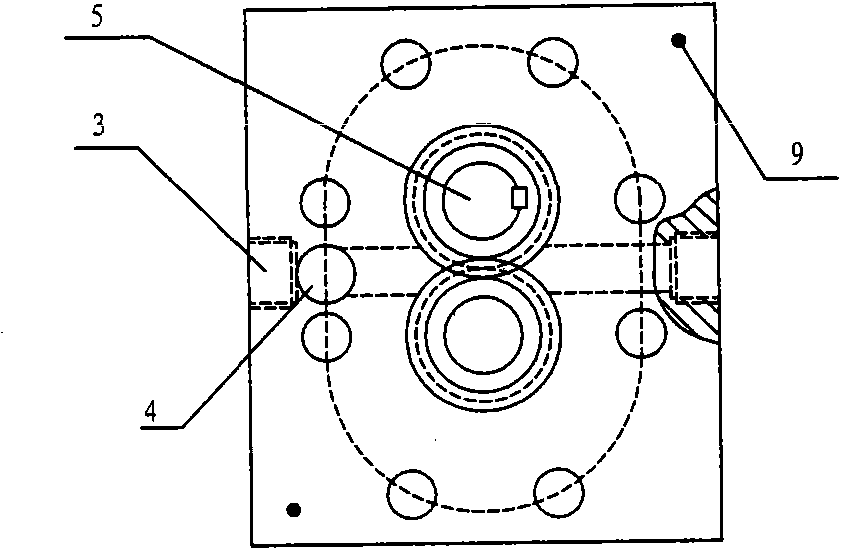

[0013] Such as figure 1 , 2 As shown, the three-axis synchronizing device includes a front end cover 1 and a rear end cover 2, two holes are arranged at the corresponding positions of the front end cover 1 and the rear end cover 2, and sliding bearings 7 are arranged in the holes; the driving shaft 5 and the The two ends of the driven shaft 6 are arranged in the inner holes of the corresponding sliding bearings 7; three oil cavities 71, 72, 73 and two partitions 21, 22 are fixedly arranged between the front end cover 1 and the rear end cover 2 , the separators 21, 22 are set between the three oil chambers 71, 72, 73; the oil inlet 3 is placed on the middle oil chamber 72, and the other end of the oil chamber 71, 72, 73 is provided with an oil outlet Ports 91, 92, 93; on the side close to the oil inlet 3, an oil chamber 4 is arranged parallel to the direction of the driving shaft 5, and the oil chamber 4 runs through all the oil chambers 71, 72, 73 and the partitions 21, 22 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com