Quartz Crucible Grinding Device

A technology of quartz crucible and slide rail, which is applied to grinding drive devices, grinding machines, and parts of grinding machine tools, etc., can solve the problems of low transmission precision and high mechanical failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

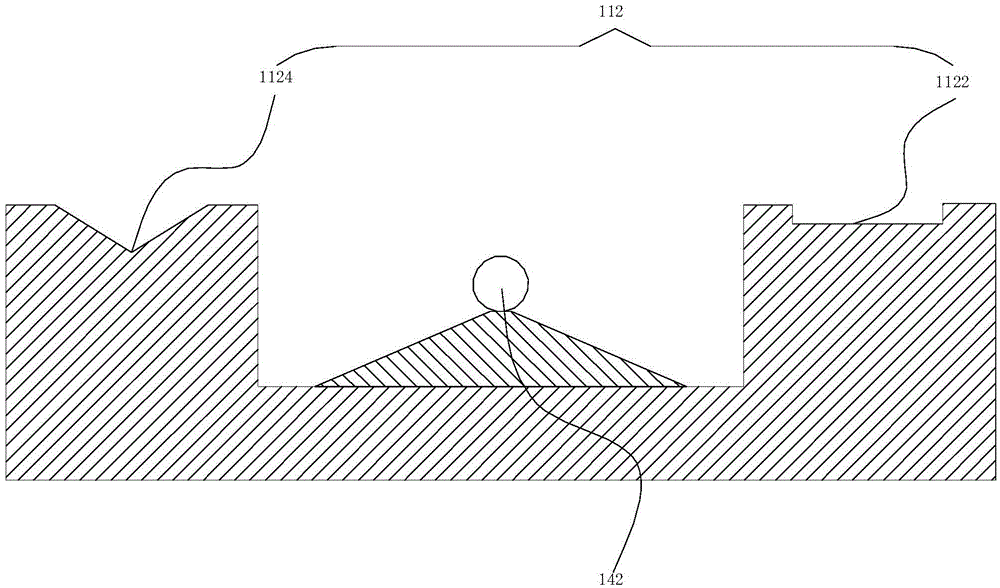

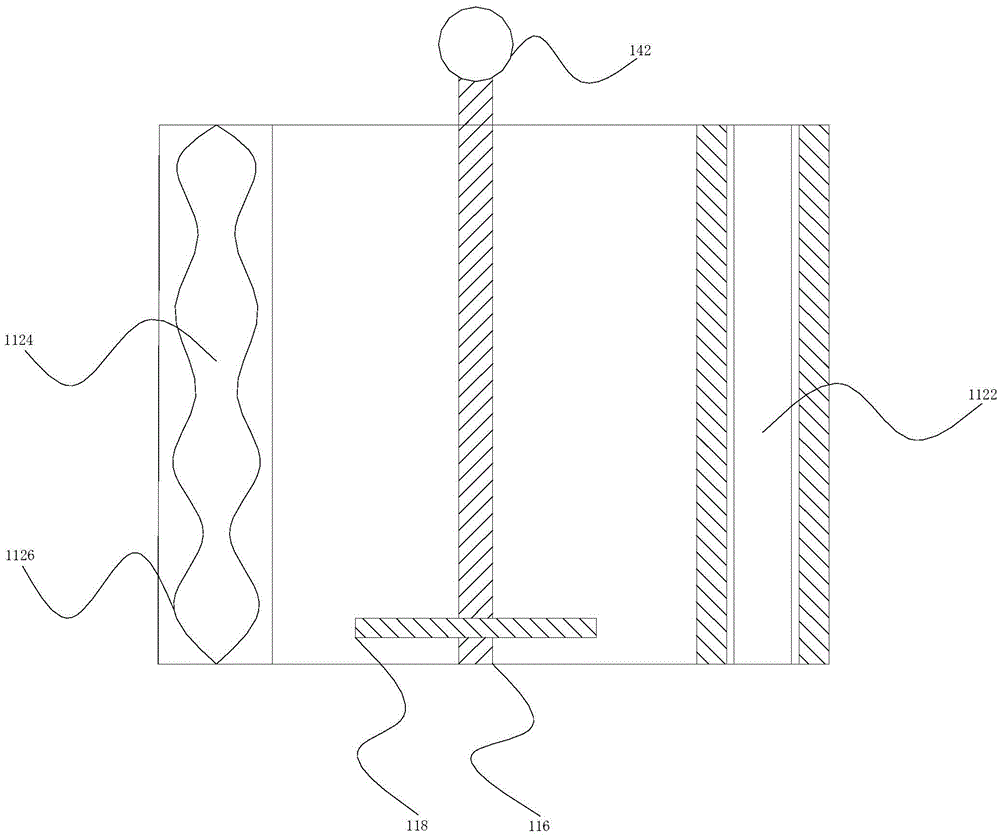

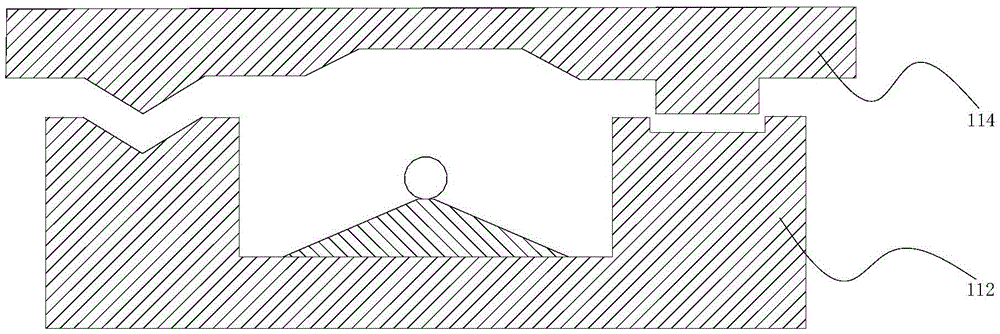

[0026] Such as figure 1 , image 3 , Figure 4 with Figure 6 As shown, a quartz crucible grinding device includes a main movement mechanism, a feeding mechanism, a grinding mechanism and a servo control mechanism.

[0027] The active mechanism includes a base 112 and a worktable 114, and the base 112 is fixedly placed on the ground or a placement surface to maintain a certain level and stability. Both sides of the base 112 are oppositely provided with a first slide rail 1122 and a second slide rail 1124, the feed direction of the slide rail is the feed direction of the main motion mechanism, the cross-sectional shape of the first slide rail 1122 is rectangular, and the second slide rail 1124 The cross-sectional shape of the rail 1124 is triangular, and the bottom of the workbench 114 is provided with a slide block matched with the first slide rail 1122 and the second slide rail 1124, so that the workbench 114 is slidably connected to the first slide rail 1122 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com