Prefabricated sandwich heat-preservation heat insulation concrete external wall panel and fabrication method

A technology of thermal insulation and manufacturing methods, which is applied in the direction of manufacturing tools, building components, ceramic molding machines, etc., can solve problems such as poor thermal insulation performance, cumbersome procedures, and difficulty in ensuring construction quality, so as to improve construction efficiency, reduce environmental pollution, Easy-to-control effects on build quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

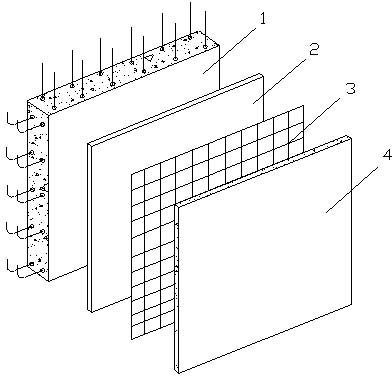

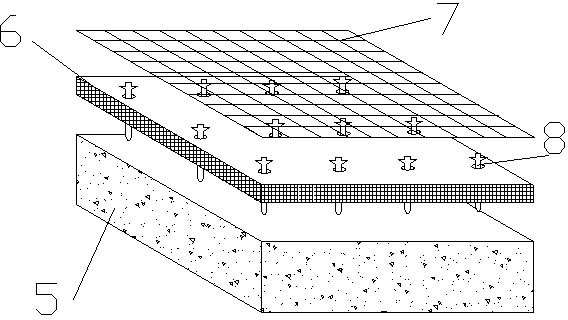

[0042] The prefabricated sandwich thermal insulation concrete exterior wall panel of the present invention adopts a composite wall panel integrating wall body, thermal insulation and architectural decoration from the inside to the outside. The wall 1 is a load-bearing concrete structure layer, the middle is a thermal insulation board 2, and the outermost is a building decoration external hanging board 4. The three layers are connected into a whole through thermal insulation connectors, and it is used in the assembly of integral shear wall structures or assembly A composite exterior wall panel with an integral frame-shear wall structure and meeting building energy-saving requirements.

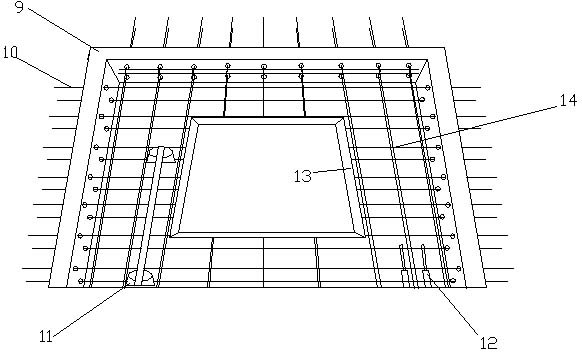

[0043] The wall body 1 of the prefabricated sandwich heat-insulating and heat-insulating concrete exterior wall panel has a thickness of 150-200mm, and a reinforcement cage 14 is pre-embedded in the wall body.

[0044] Water and electricity pipelines, metal embedded parts and switch sockets can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com