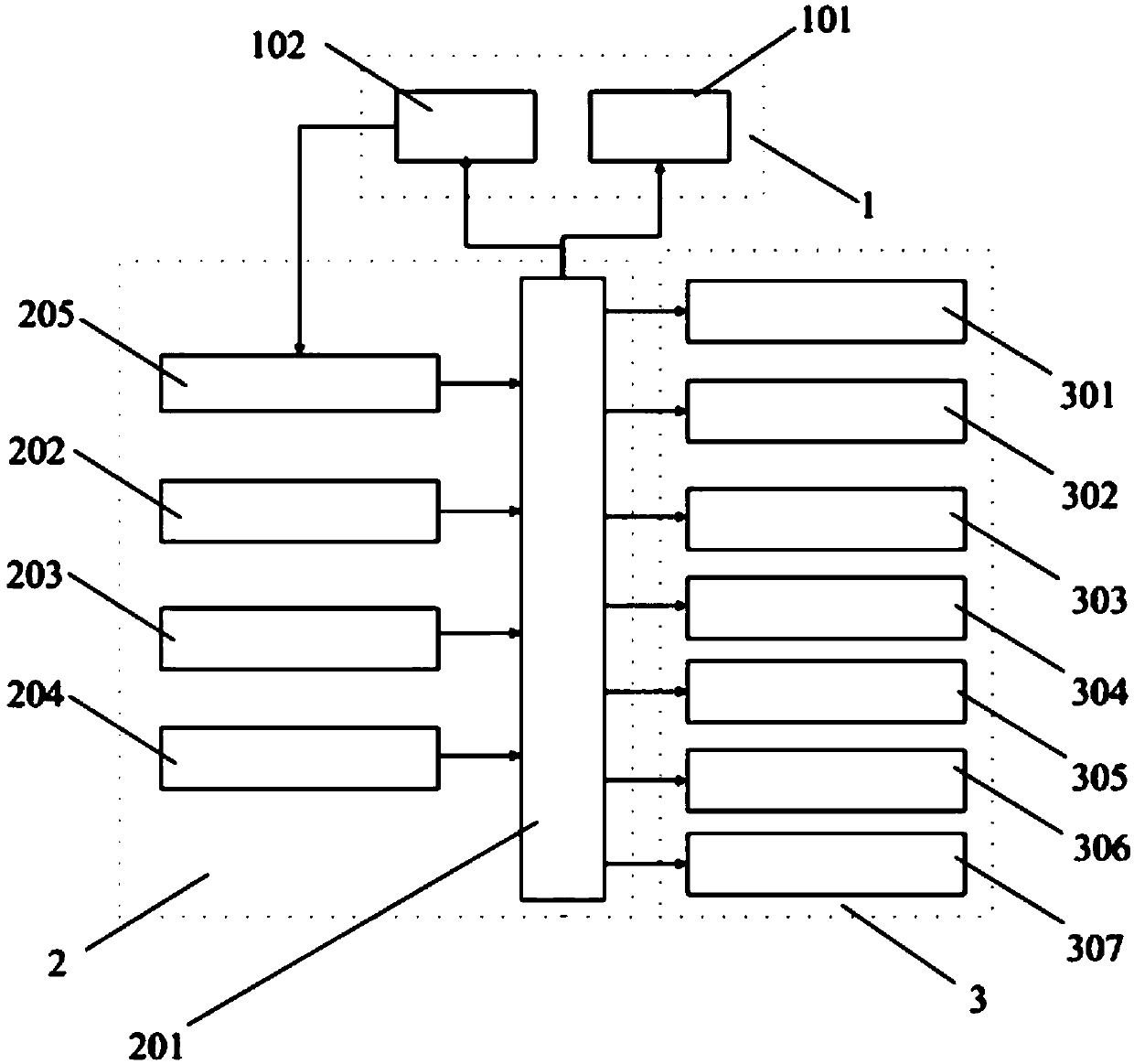

Patents

Literature

32results about How to "Error-free installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

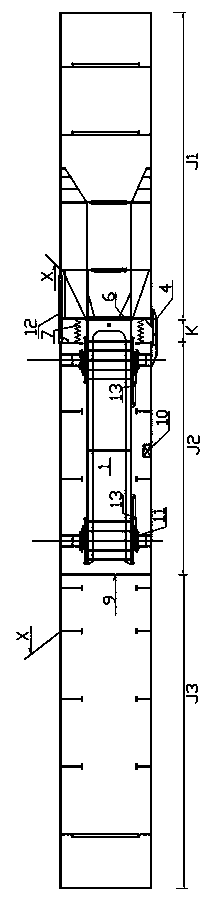

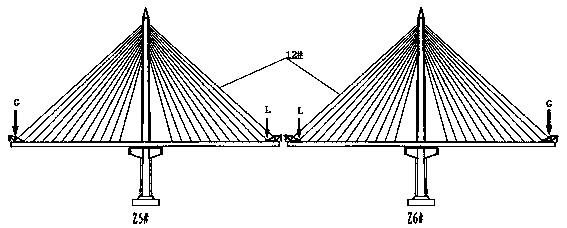

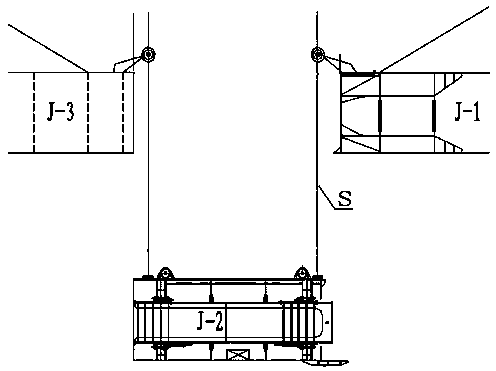

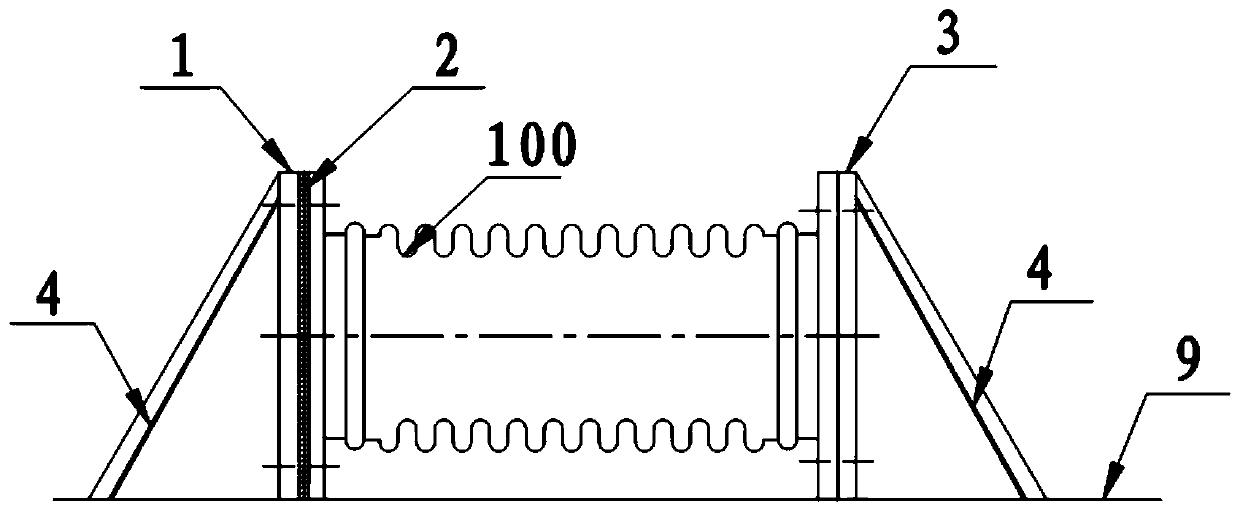

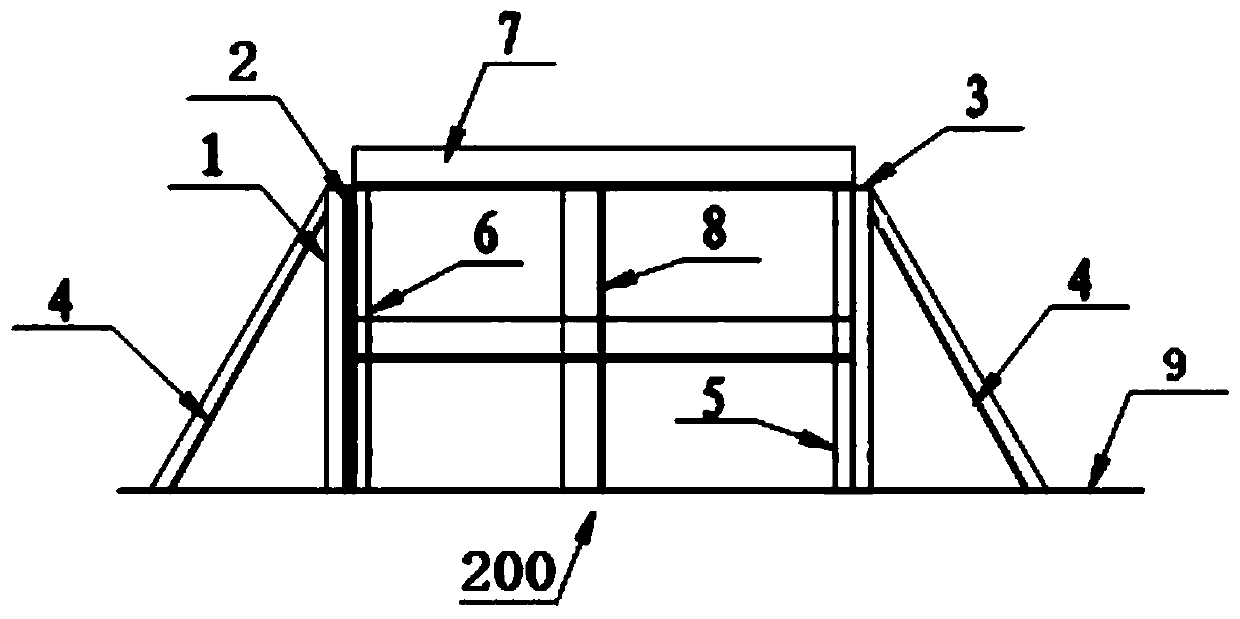

Installation construction method for bridge rigid hinge

InactiveCN103410094ASimple and fast operationReduce construction difficultyBridge erection/assemblyBox girderBuilding construction

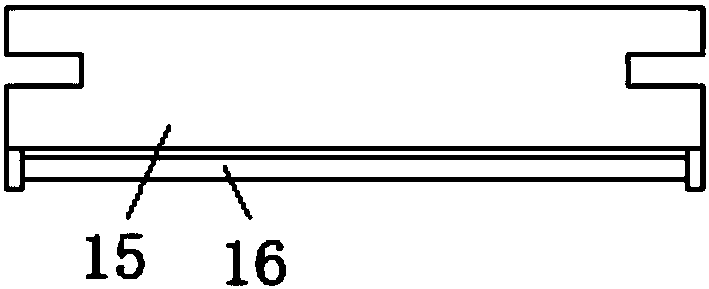

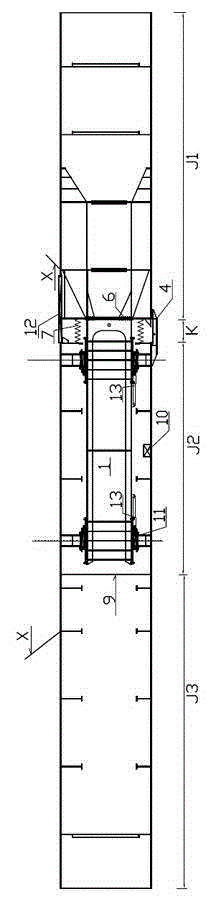

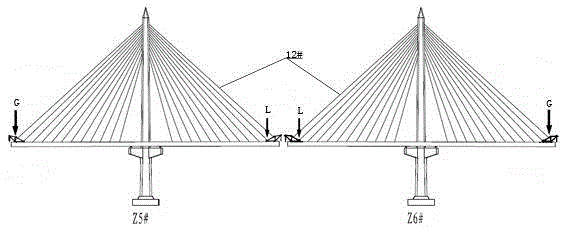

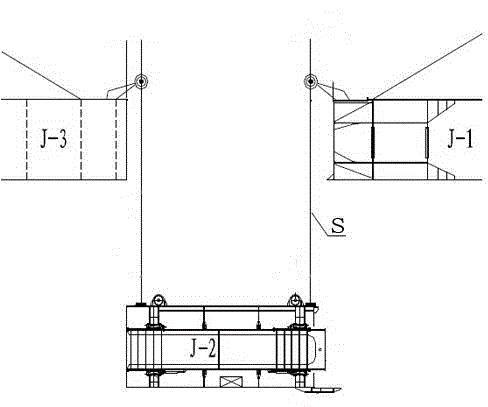

The invention discloses an installation method for a bridge rigid hinge and belongs to the technical field of bridge construction. The installation construction method for the bridge rigid hinge includes the steps that firstly, combination and assembling are performed in advance, a running-in test is performed, and accessories are installed; secondly, preparation is performed before hoisting; thirdly, a small box girder is temporarily locked into a J2 kind end beam; fourthly, synchronous hoisting is in place, entering a preset closure gap position is achieved, and adjustment is performed properly; fifthly, a temporary locking device is installed, temporary locking is relieved, the small box girder is moved close to a J1 beam segment fixing end, and a bolt is used for connection; sixthly, a closure seam of a J2 beam segment and a J3 beam segment is forcefully adjusted, temporary fixing accessories are temporarily fixedly combined and installed, construction site connection of the J2 beam segment and the J3 beam segment is finished, and a beam is installed on the J2 beam segment; seventhly, remained facilities are installed, temporary facilities are detached, and rigid hinge supports on the periphery of the small box girder are adjusted. According to the installation method for the bridge rigid hinge, the rigid hinge and parts of the rigid hinge can be accurately and inerrably installed, the rigid hinge and a bridge are stable in structure, and safety and reliability in using the rigid hinge and the bridge are ensured.

Owner:CCCC HIGHWAY CONSULTANTS

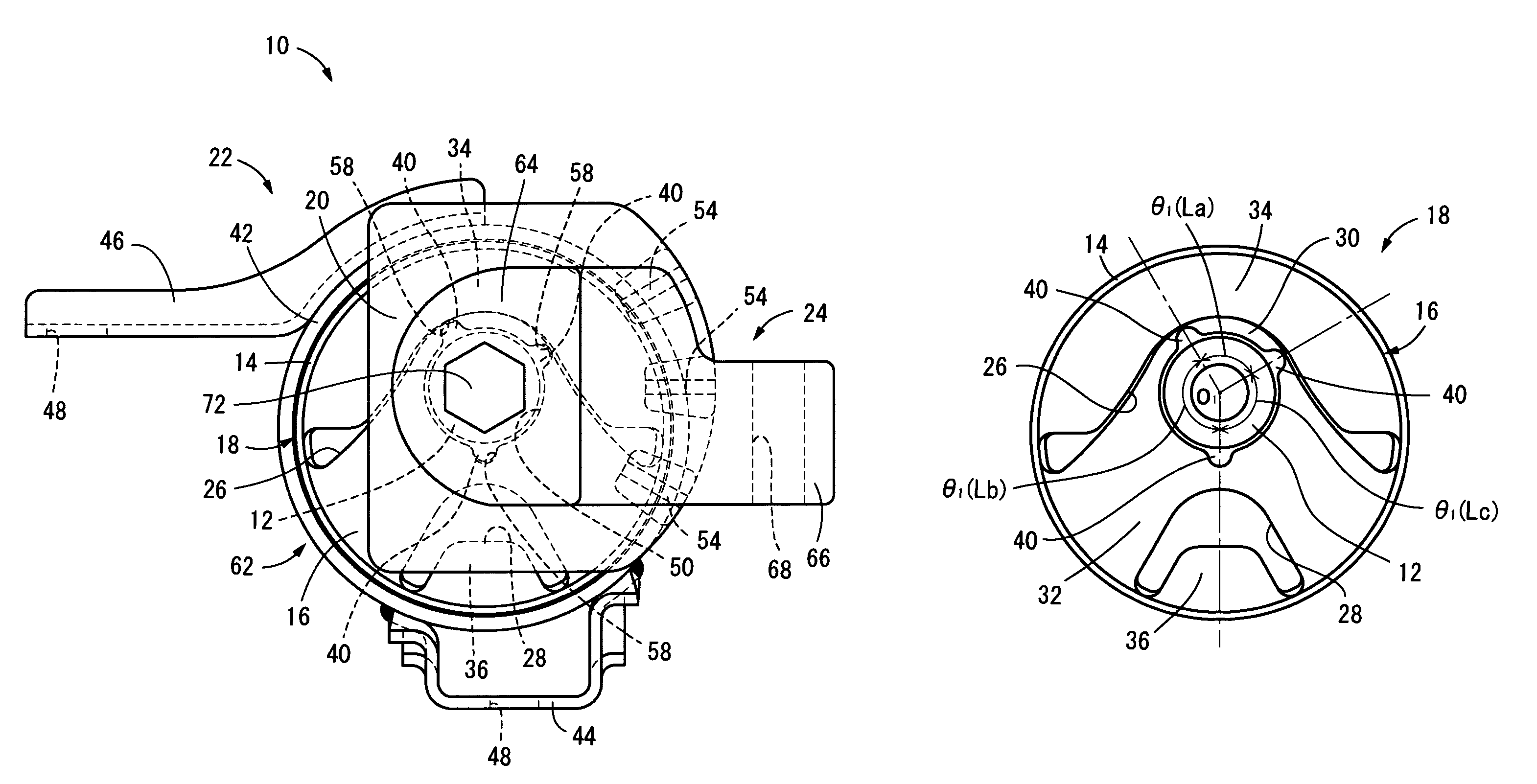

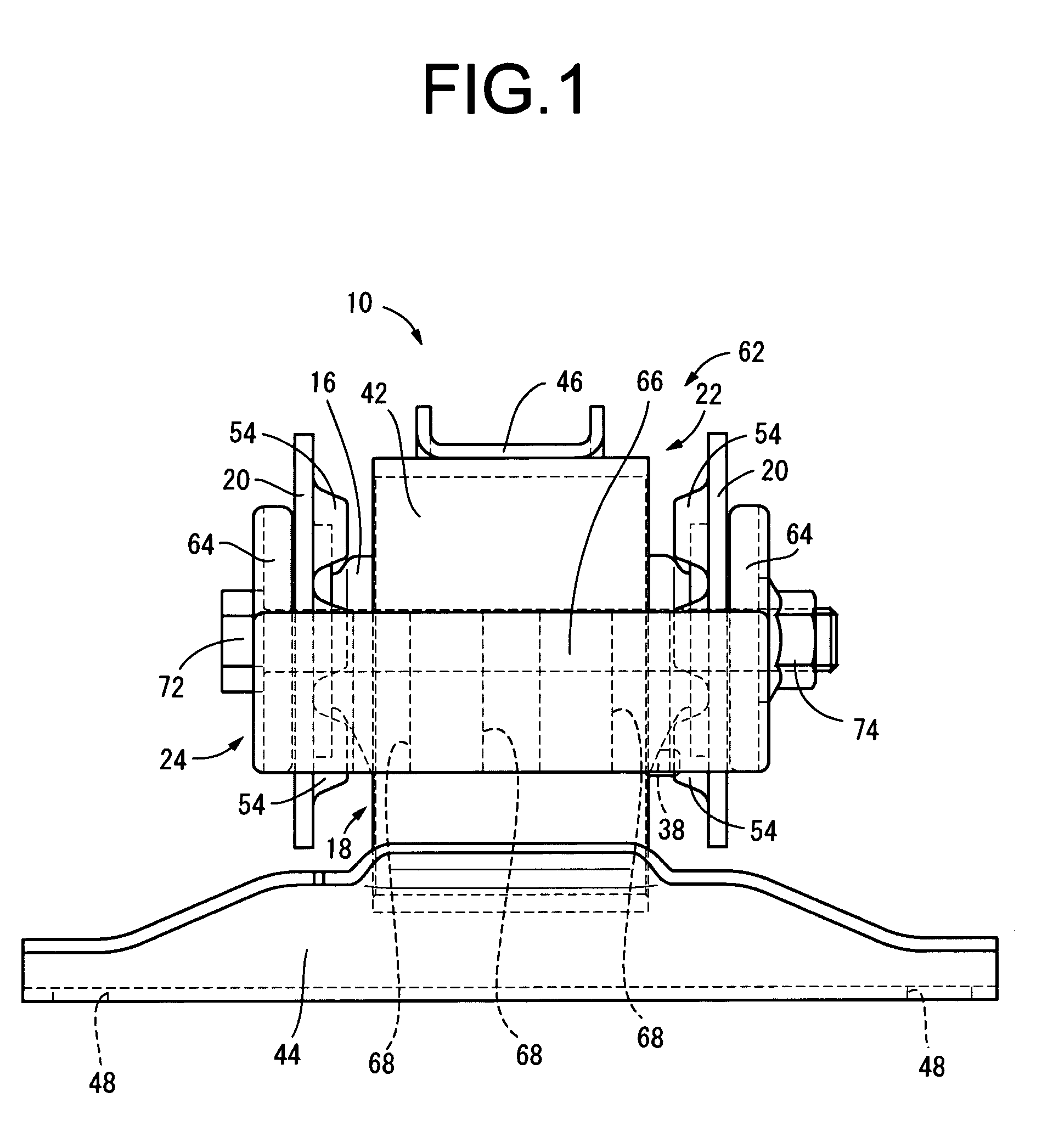

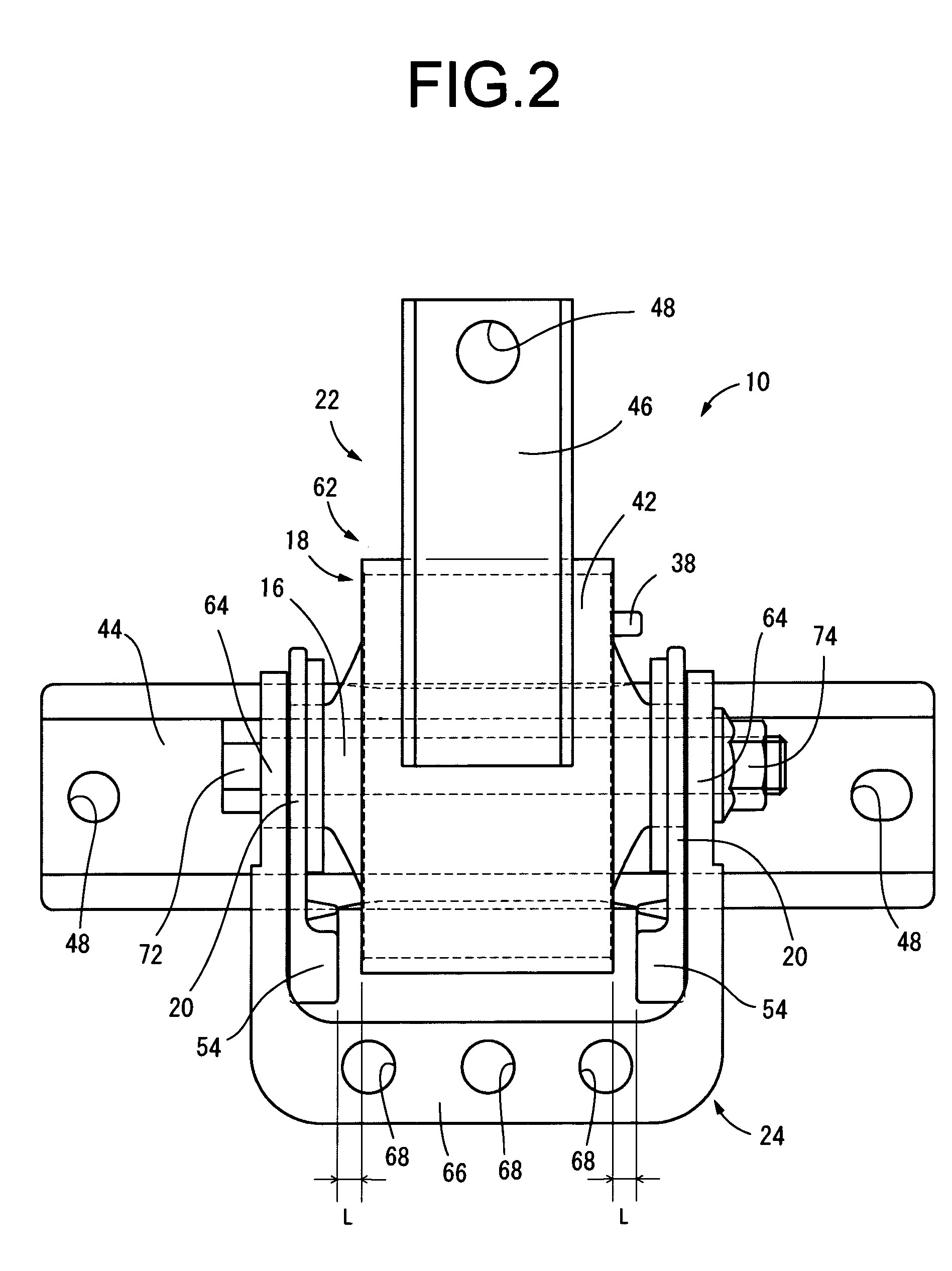

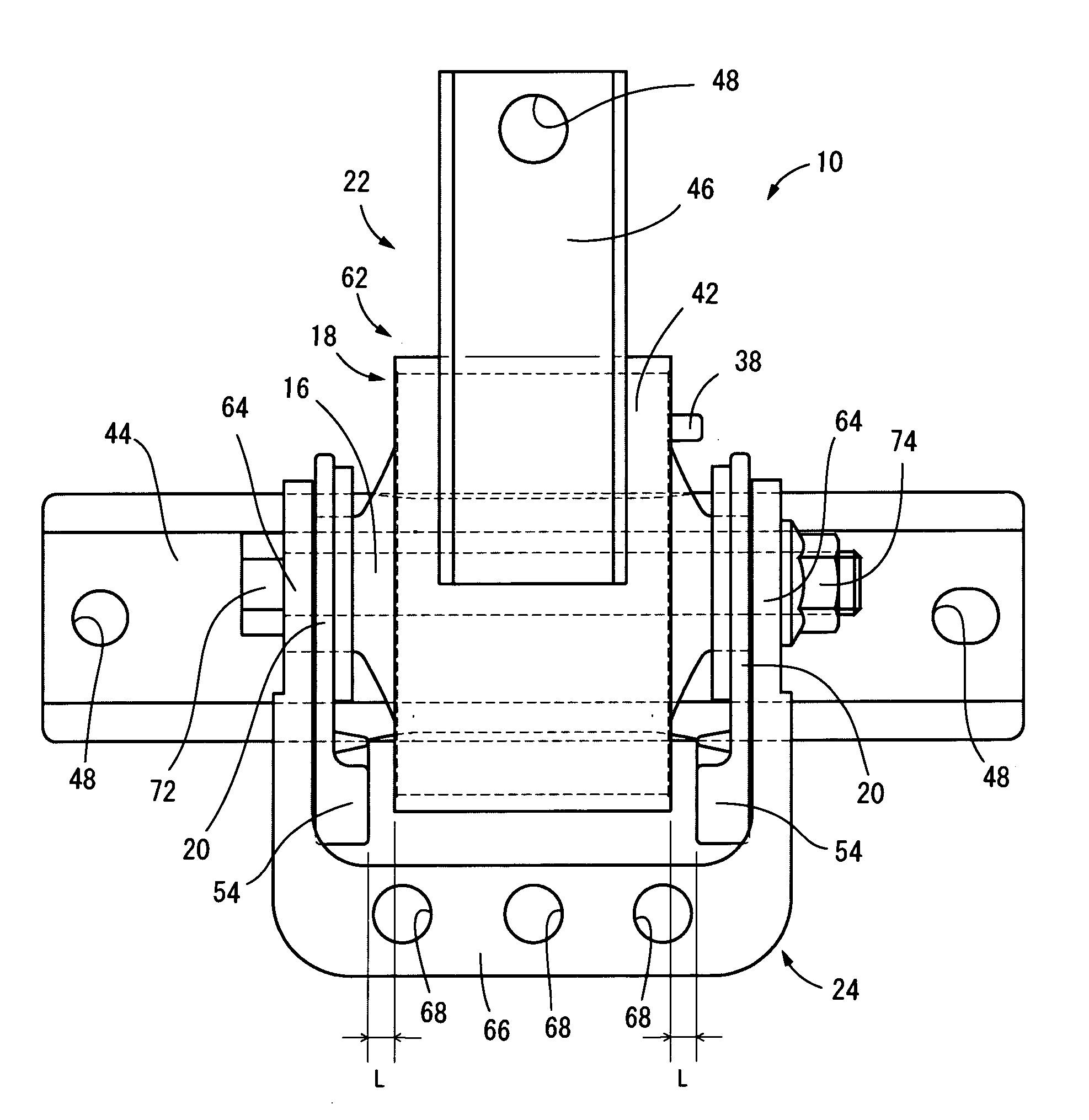

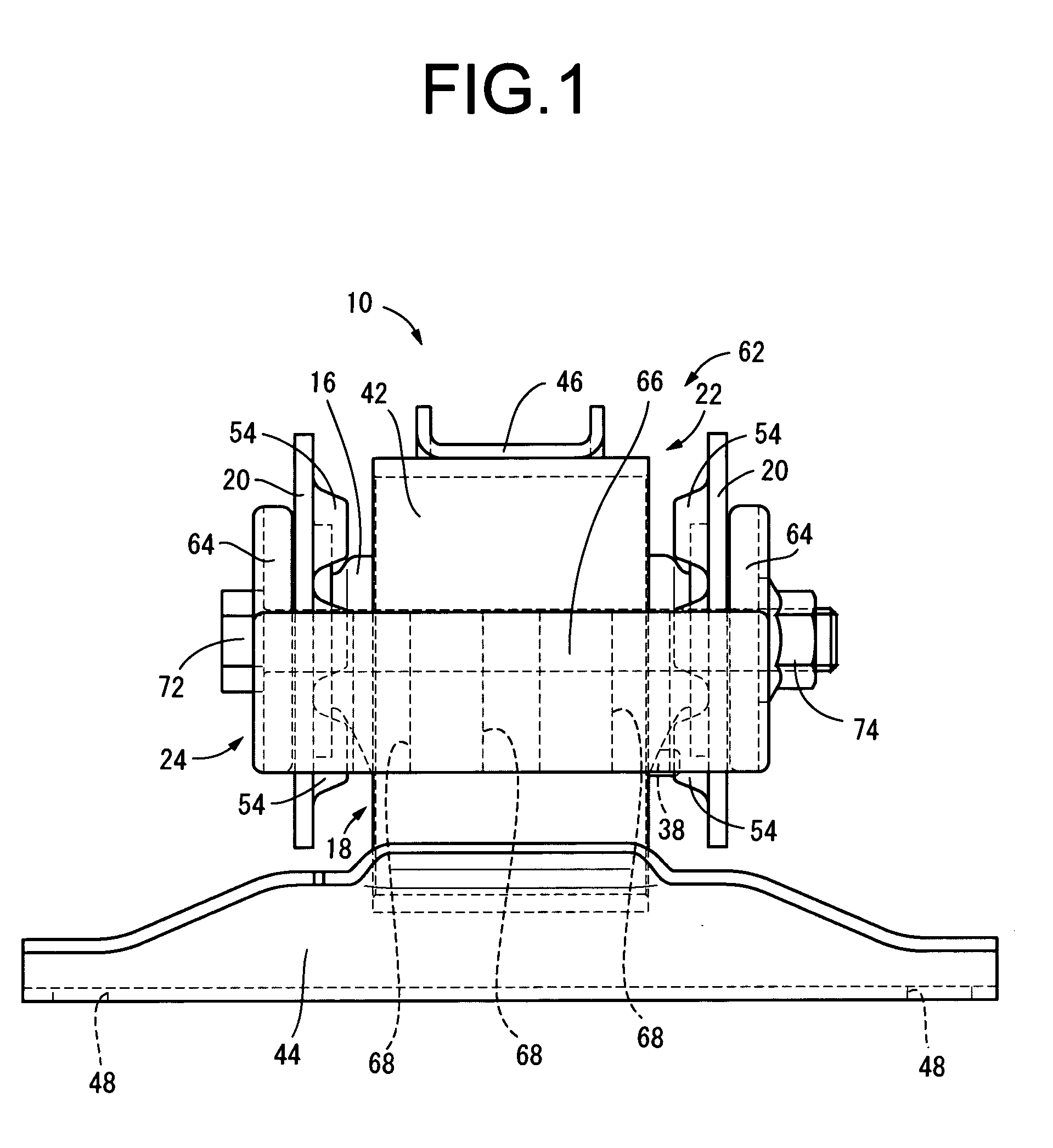

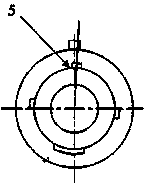

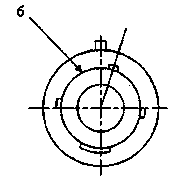

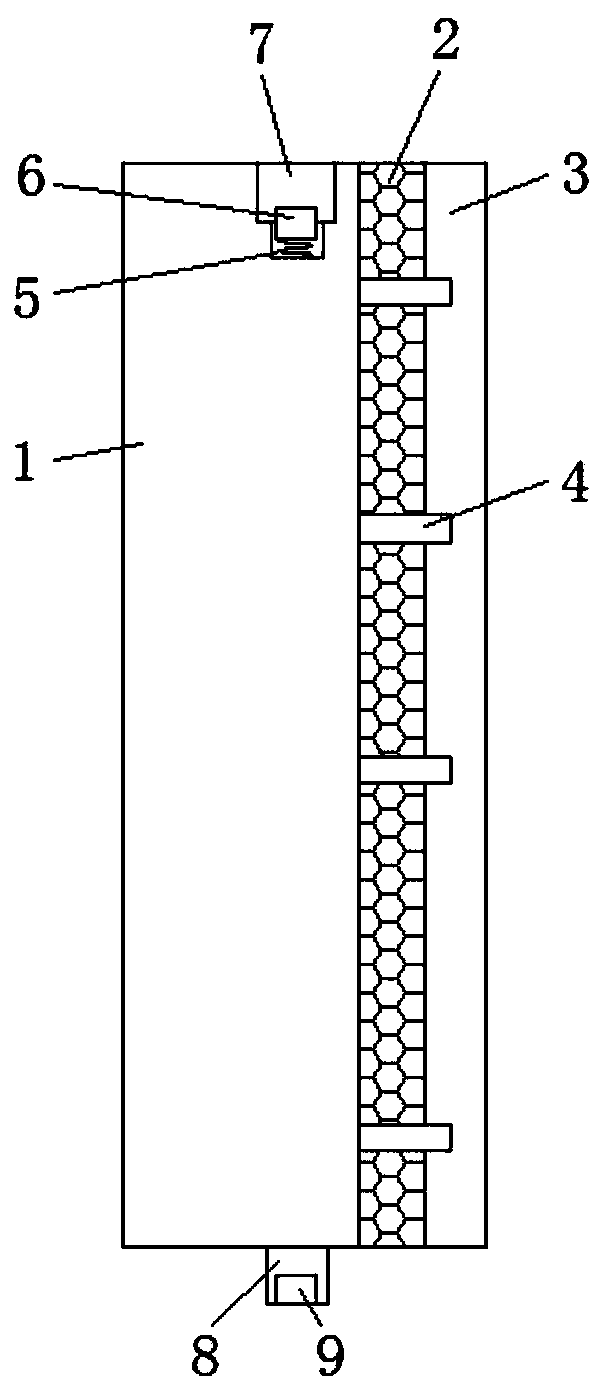

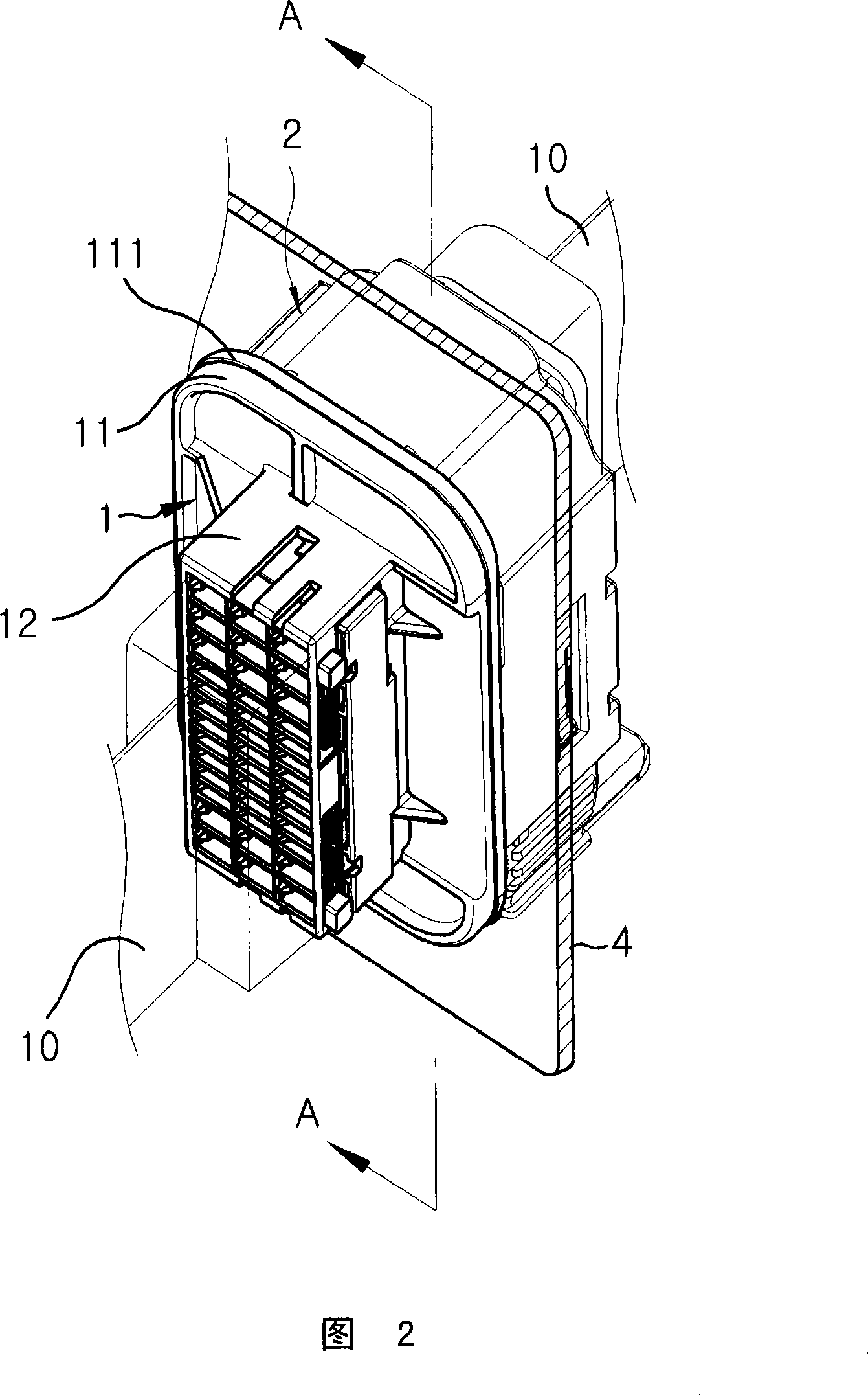

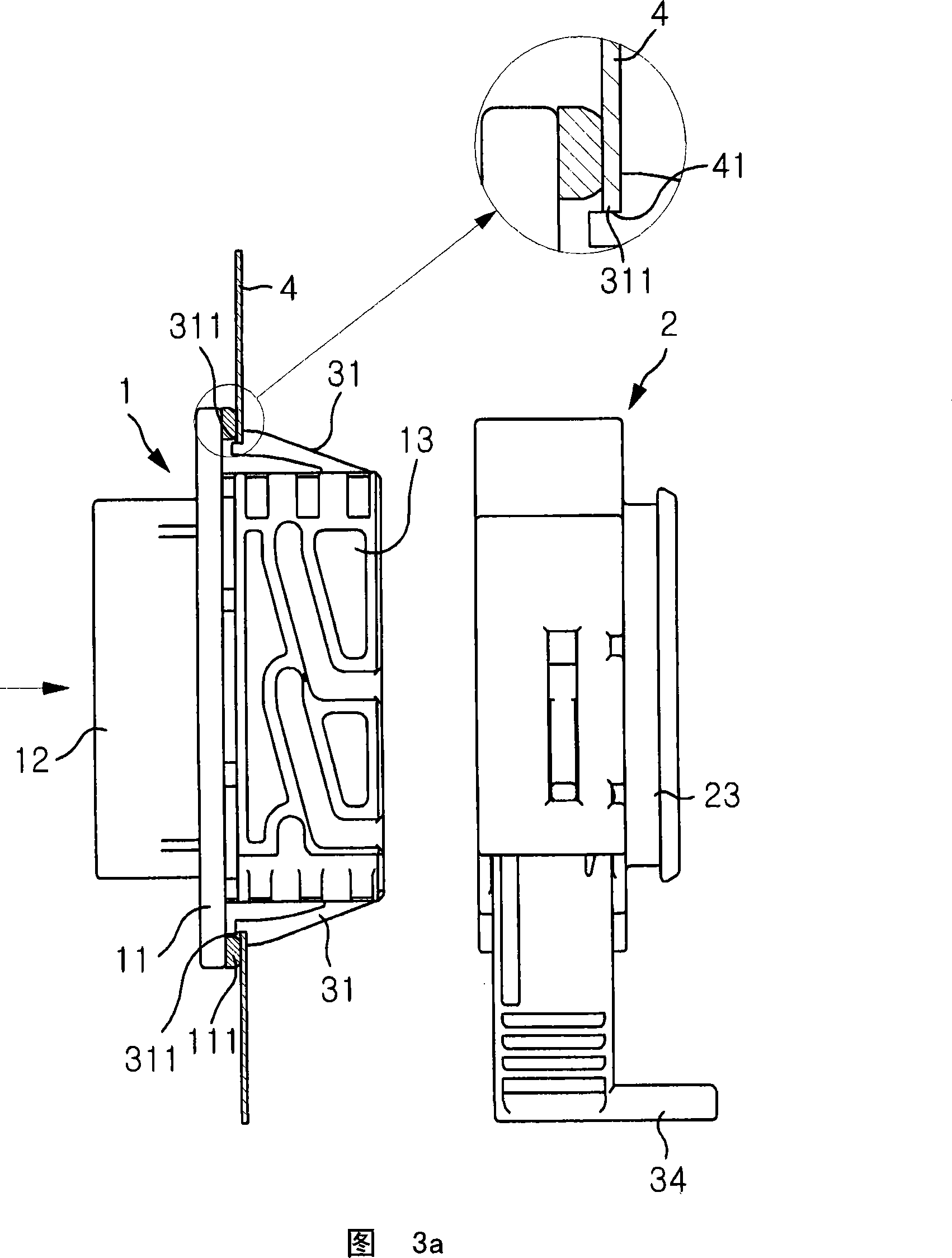

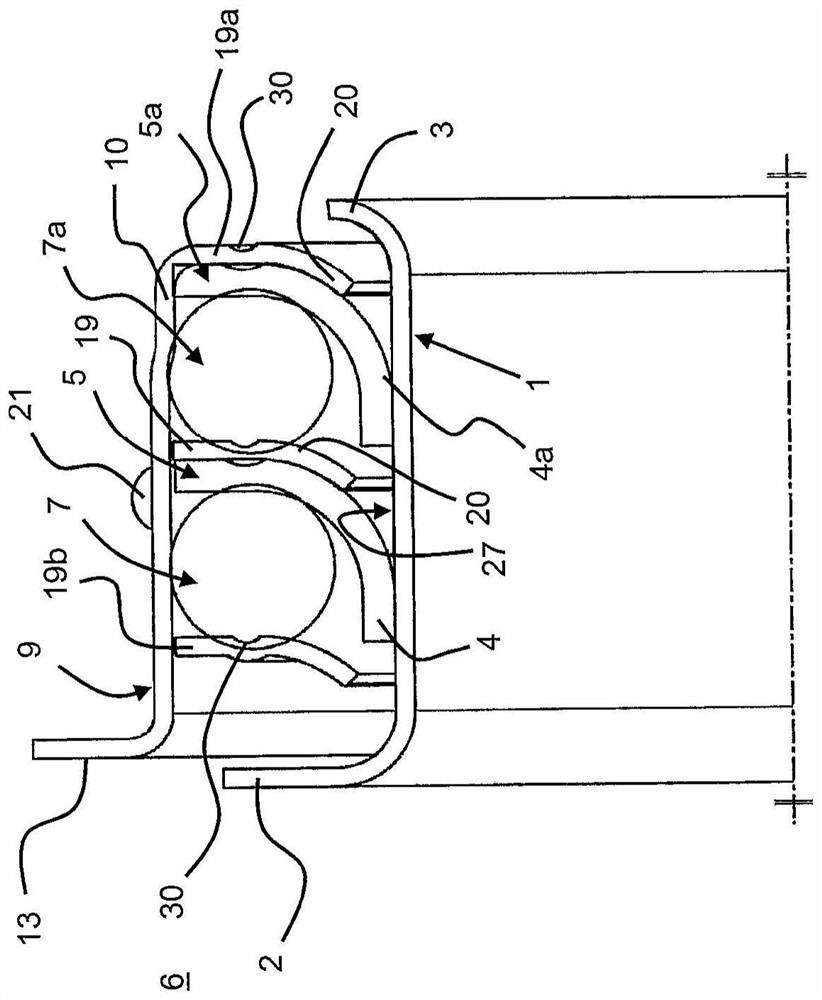

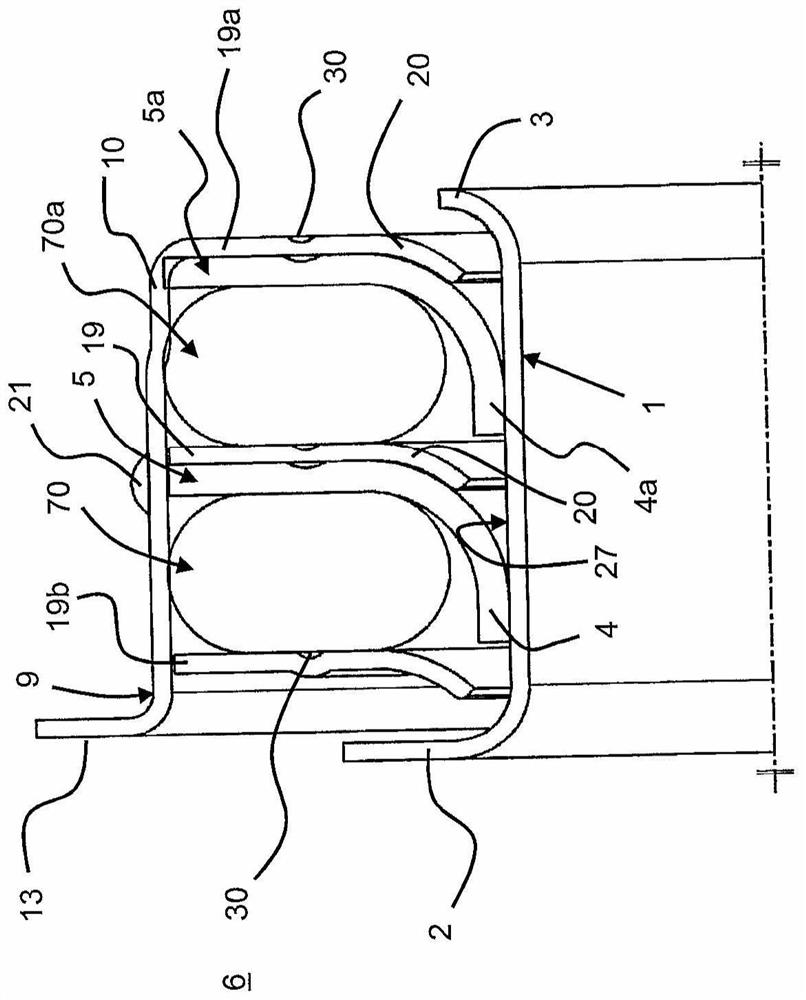

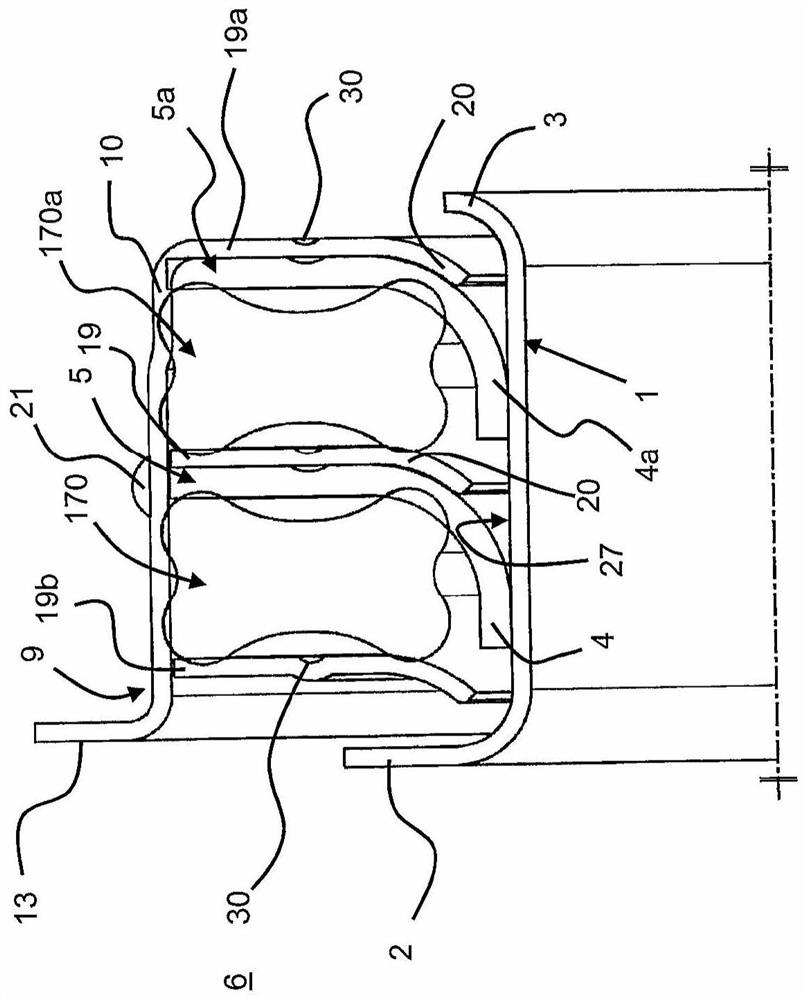

Cylindrical vibration damping apparatus and method of manufacturing the same

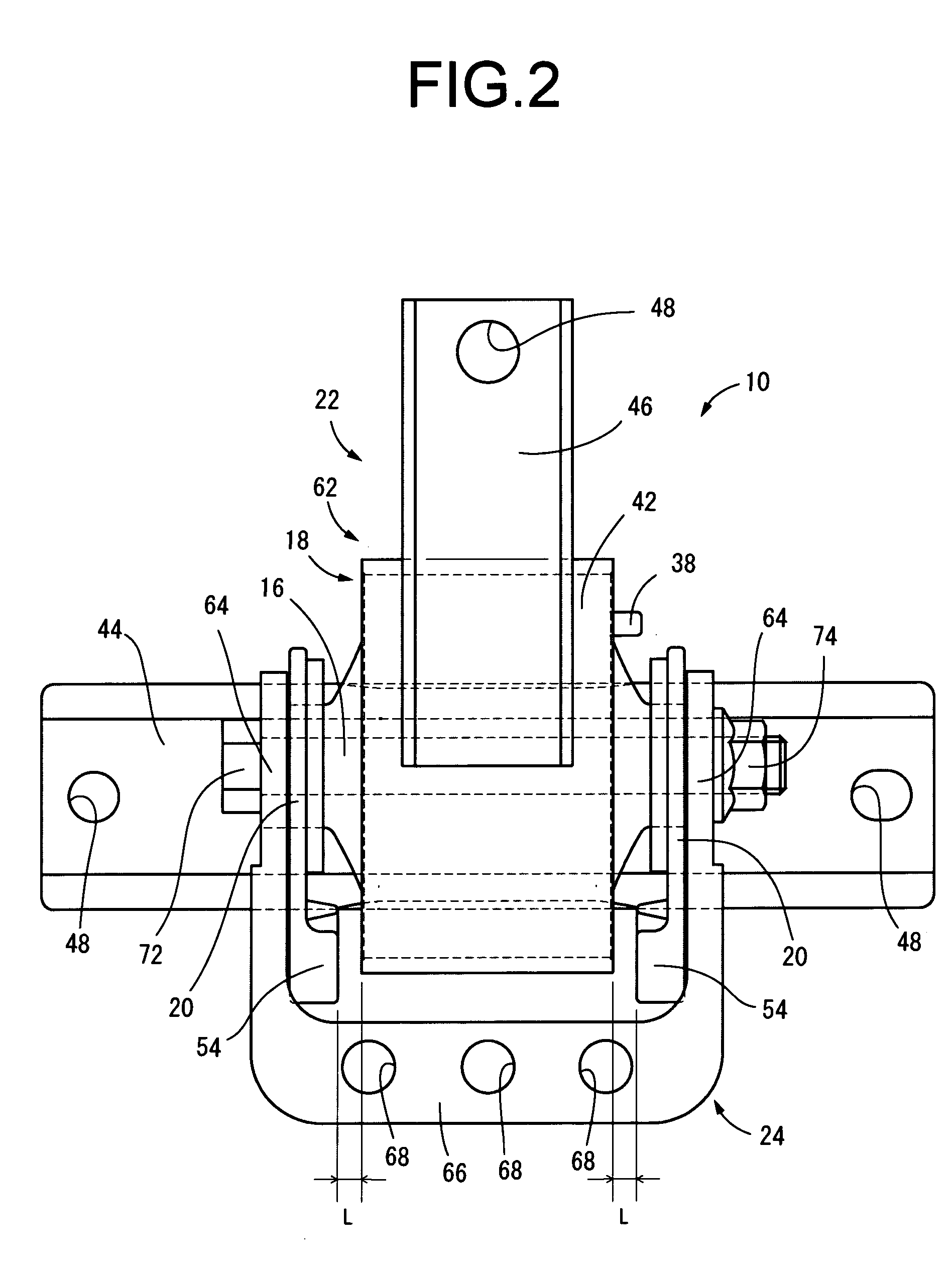

InactiveUS7354031B2Drawback can be obviatedError-free installationMachine framesNon-rotating vibration suppressionMechanical engineeringEngineering

A cylindrical vibration damping apparatus having an elastic body connecting an inner shaft and an outer cylinder member, and a pair of rubber stop plates disposed at axial ends of the inner shaft member. Each rubber stop plate has a mount hole that fits about the outside of the inner shaft member. Pairs of mating projections and mating recesses are provided to an interface between an inner circumferential surface of the mount hole of the each rubber stop plate and an outer circumferential surface of the corresponding axial end of the inner shaft member at three or more different intervals in a circumferential direction so that the pair of rubber stop plates are installed onto the axial ends of the inner shaft member with correct identification of a front and back and a circumferential position about the inner shaft member. A method of manufacturing the same is also disclosed.

Owner:SUMITOMO RIKO CO LTD

Cylindrical vibration damping apparatus and method of manufacturing the same

InactiveUS20050179181A1Improve production efficiencyConvenient ArrangementMachine framesNon-rotating vibration suppressionElastomerMechanical engineering

A cylindrical vibration damping apparatus having an elastic body connecting an inner shaft and an outer cylinder member, and a pair of rubber stop plates disposed at axial ends of the inner shaft member. Each rubber stop plate has a mount hole that fits about the outside of the inner shaft member. Pairs of mating projections and mating recesses are provided to an interface between an inner circumferential surface of the mount hole of the each rubber stop plate and an outer circumferential surface of the corresponding axial end of the inner shaft member at three or more different intervals in a circumferential direction so that the pair of rubber stop plates are installed onto the axial ends of the inner shaft member with correct identification of a front and back and a circumferential position about the inner shaft member. A method of manufacturing the same is also disclosed.

Owner:SUMITOMO RIKO CO LTD

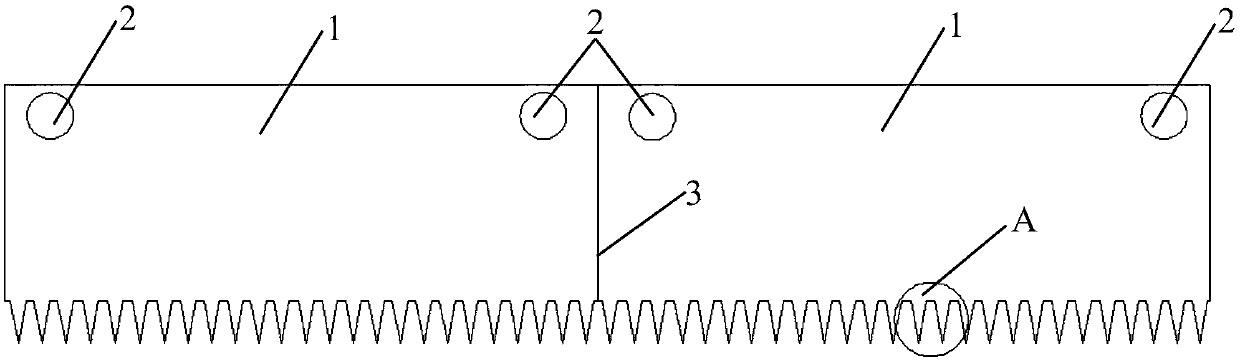

Serrated knife for high-speed carpet textile machine and machining method thereof

The invention discloses a serrated knife for a high-speed carpet textile machine. The serrated knife comprises a knife rest and a blade component, wherein the blade component comprises a plurality ofblade bodies; a plurality of sawteeth are arranged on one side of each blade body; the plurality of sawteeth are arranged at equal intervals; a plurality of mounting holes are formed in one side, farfrom the sawteeth, of each blade body; the plurality of blade bodies are detachably connected with the knife rest through the plurality of mounting holes; the end parts of the plurality of blade bodies are correspondingly spliced with one another; splicing lines are formed in spliced positions; the splicing lines are positioned at the roots of the sawteeth, so that the phenomena that the splicinglines have cracks at cutting edges of the splicing lines and the shearing quality of carpet fabric is reduced are avoided; meanwhile, the invention further discloses a machining method of the serratedknife. The serrated knife machined through the method is high in quality, sharp in cutting edges and long in service life, and improves the shearing efficiency of the carpet fabric.

Owner:昆山立达纺织实业有限公司

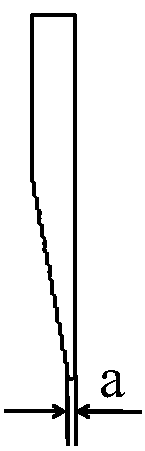

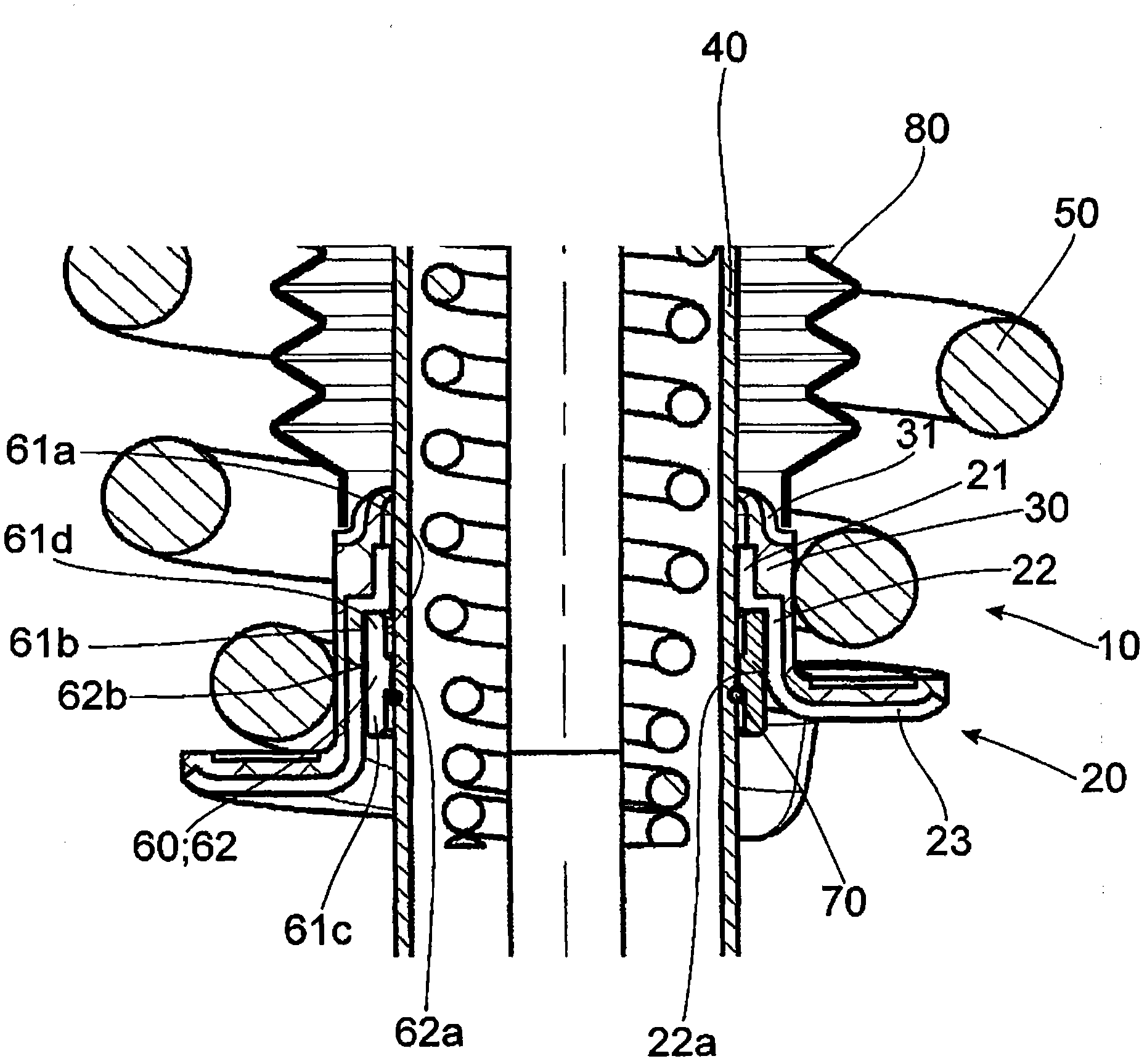

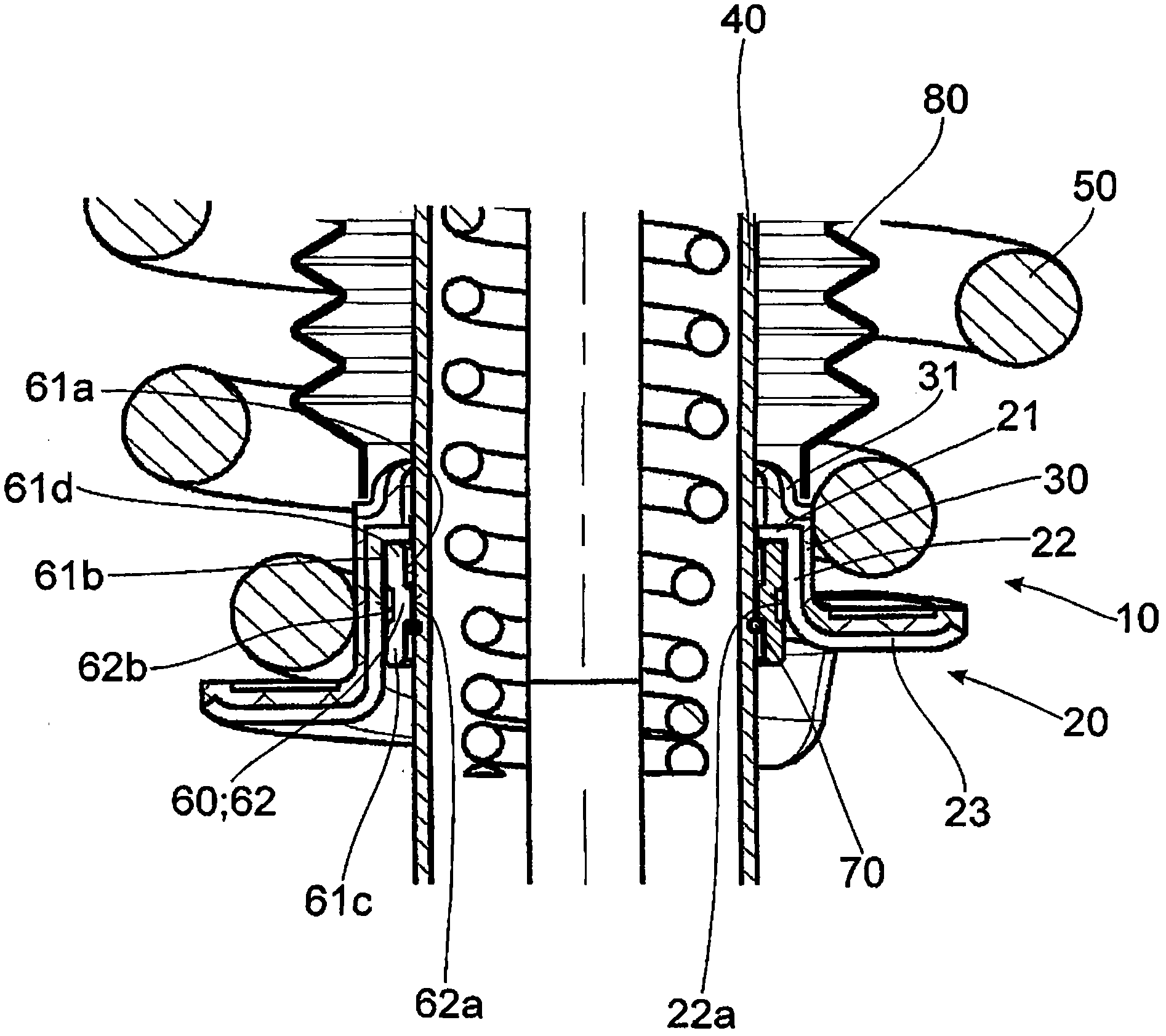

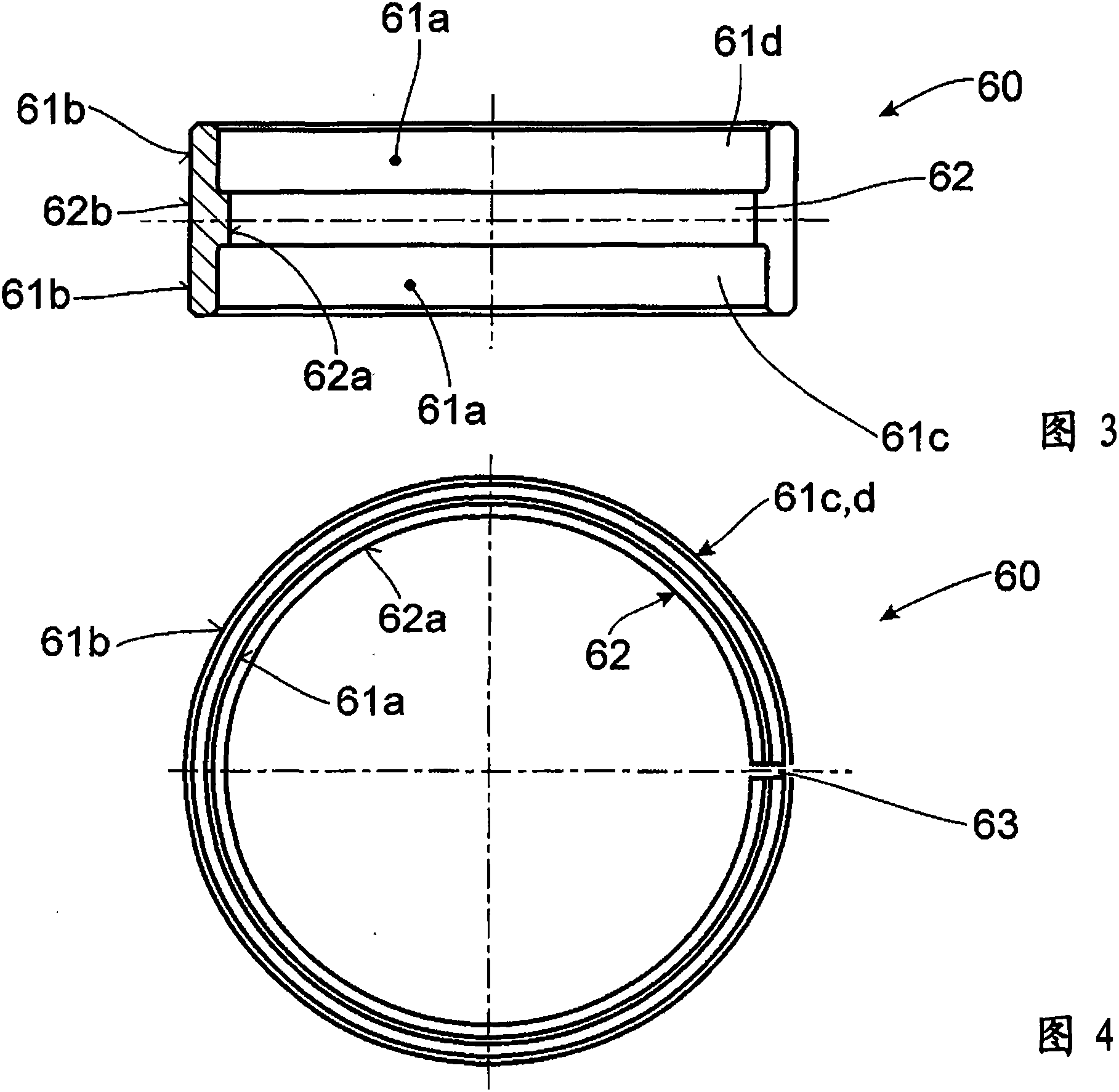

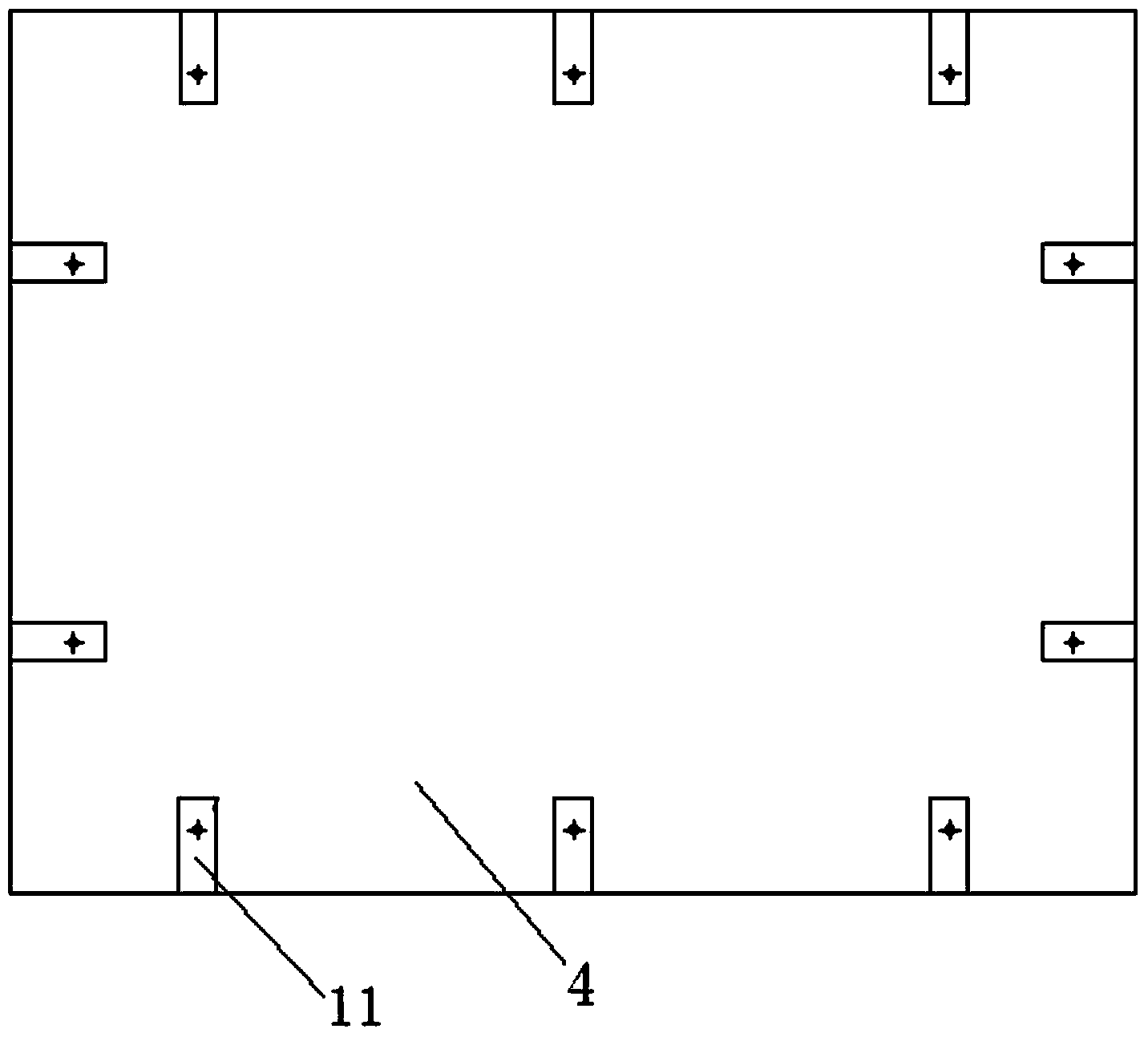

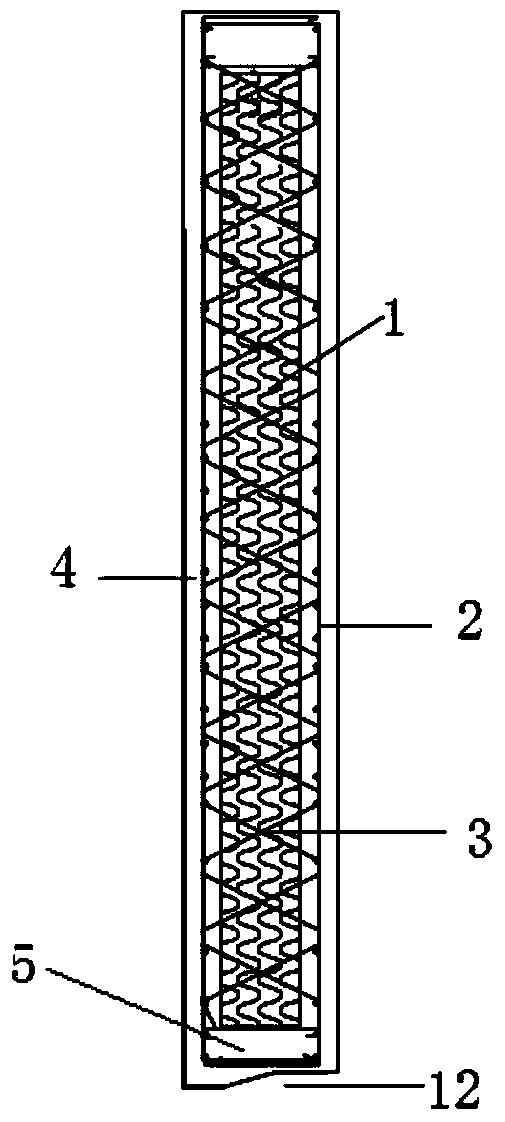

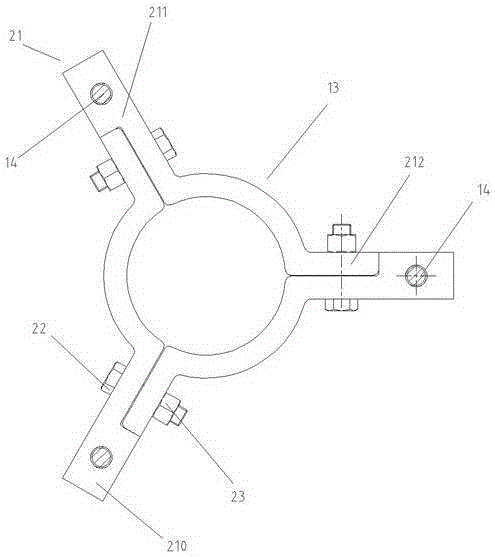

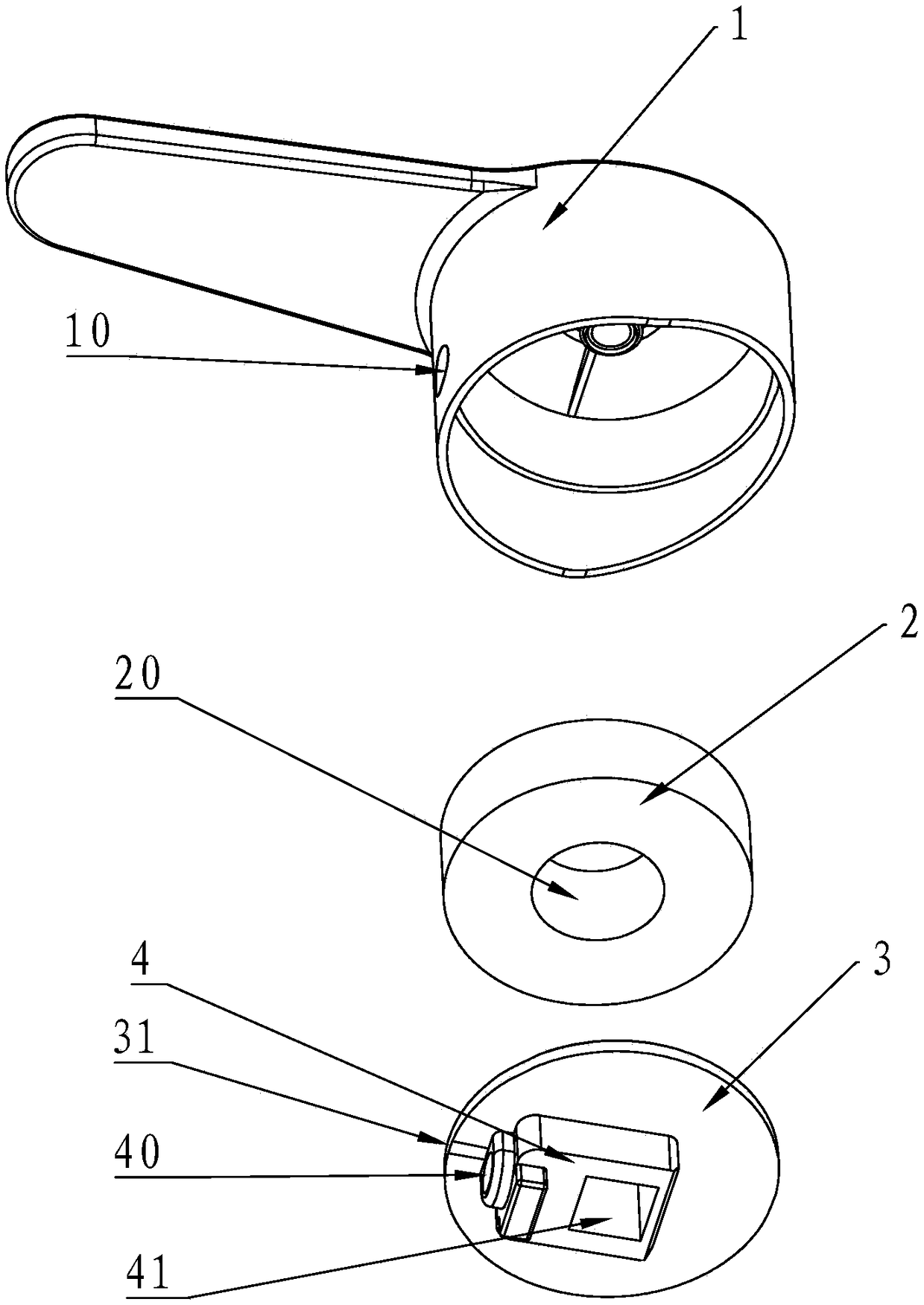

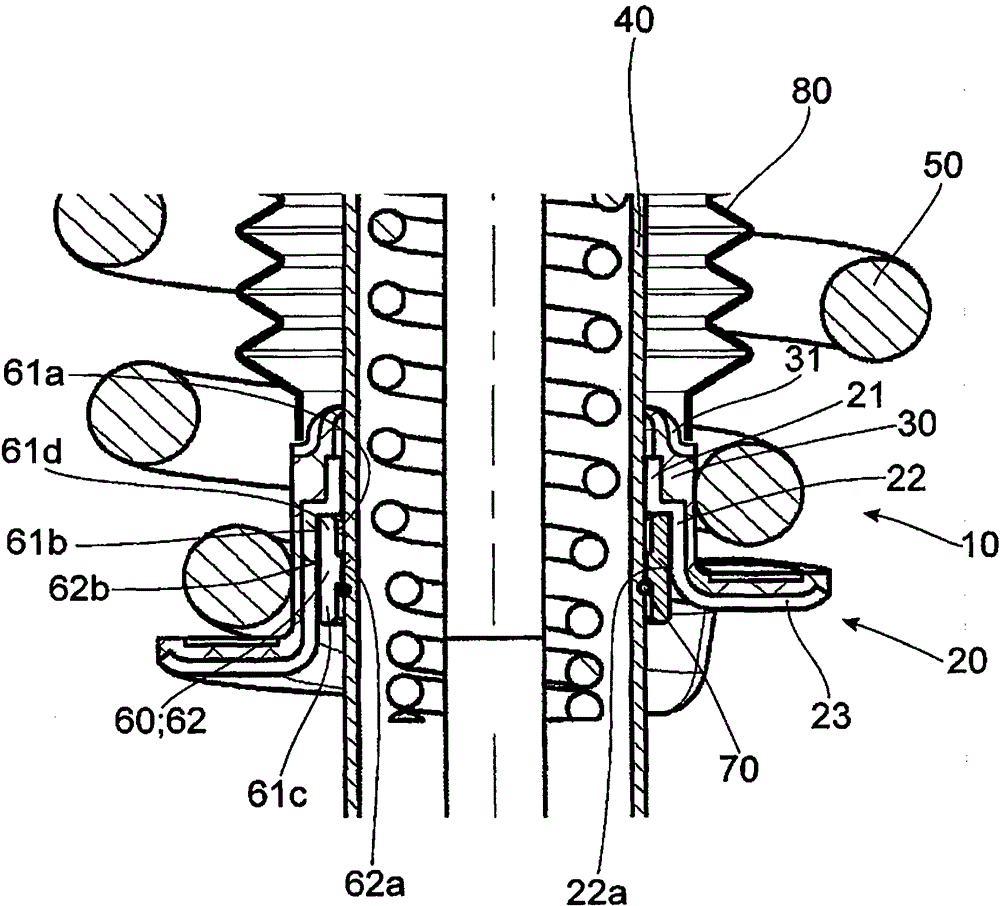

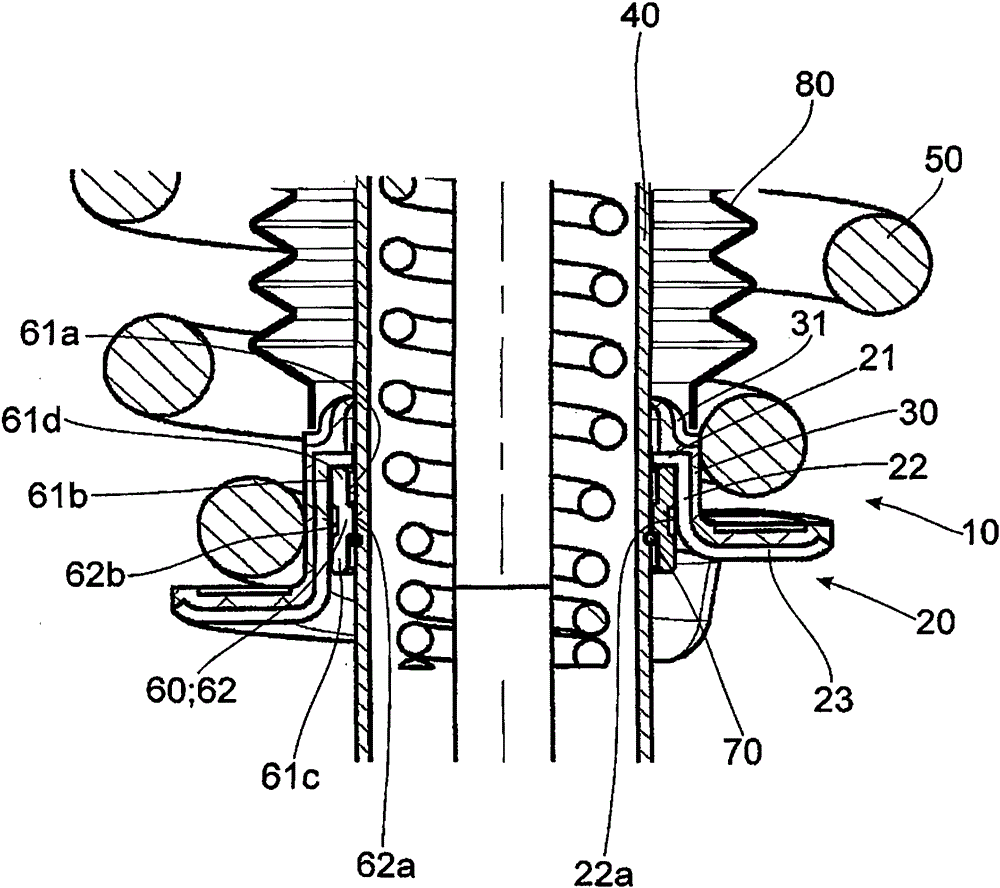

Spring Base Fixing Device For Vibration Damper

InactiveCN102562913AIt is impossible to change the spring tensionAvoid leaningSpringsSprings/dampers design characteristicsMechanical engineeringVibration damper

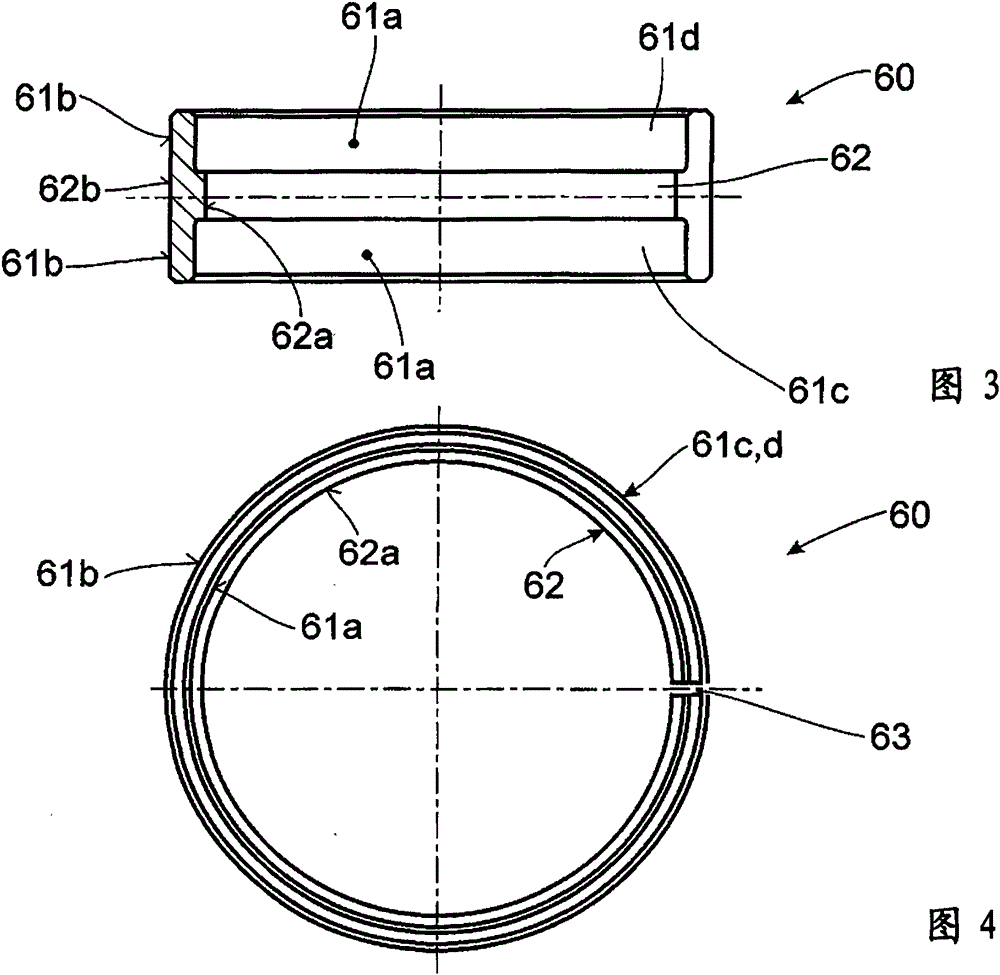

The present invention relates to a spring base fixing device (10) for a vibration damper, which comprises a spring base (20). The spring base is provided with the following components: a contact segment (21) which warps a vibration damping tube (40) along a circumferential direction, an accommodating segment (22) which is spaced from the contact segment (21) in an axial direction and a radial direction, and a supporting segment (23) which is spaced from the contact segment (21) in the axial direction, wherein, the supporting segment (23) axially supports a suspension spring (50) through a radial extension part that is basically disc-shaped. Furthermore the spring base fixing device (10) comprises an insulating component (60). The insulating component warps the vibration damping tube (40) and is equipped in the accommodating segment (22) of the spring base (20). Furthermore the insulating component is provided with a first outer segment (61c), a second outer segment (61d) and an intermediate segment (62), wherein, the outer segments (61c,61d) at least partially contact a radial inner surface (21a) of the spring base (20) in the contact segment (21) of the spring base through a radial outer surface (61b). The intermediate segment (62) is equipped between the two outer segments (61c,61d) along the axial direction and the intermediate segment (62) of the insulating component (60) at least partially contacts with the vibration damping tube (40) through a radial inner surface (62a). Furthermore the spring base fixing device (10) is provided with a locking component (70) which coils on the vibration damping tube (40). Furthermore the locking component (70) is radially equipped between the vibration damping tube (40) and a radial inner surface (61a) of one selected from the outer segments (61c,61d) of the insulating component (60) and causes the spring base fixing device (10) to resist the axial load and be locked.

Owner:ZF FRIEDRICHSHAFEN AG

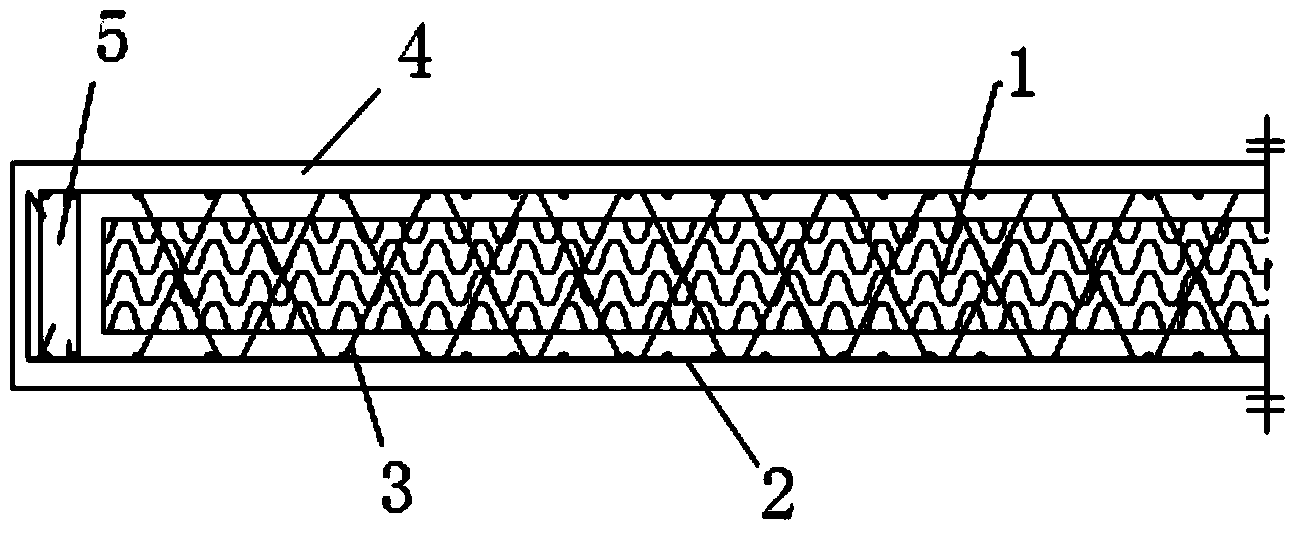

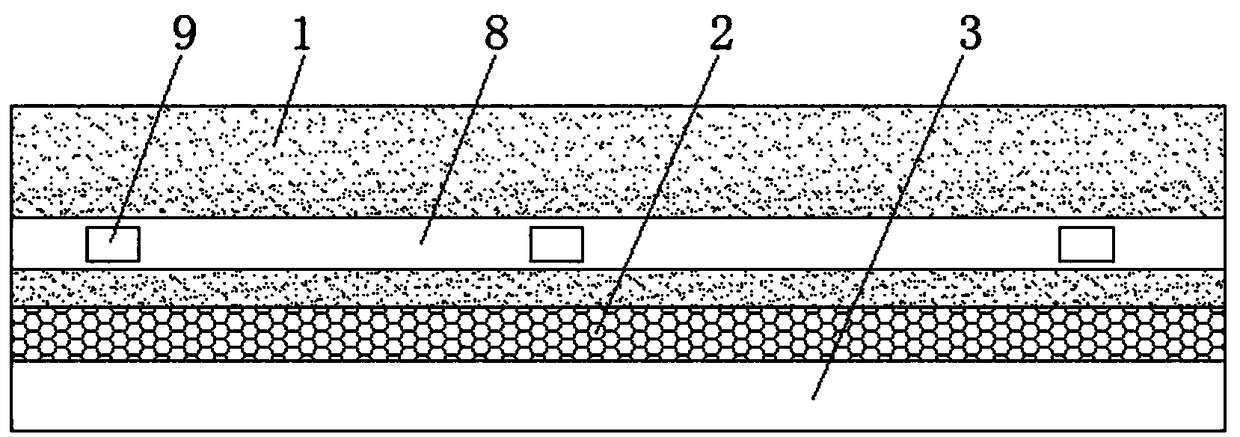

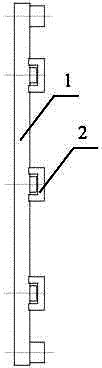

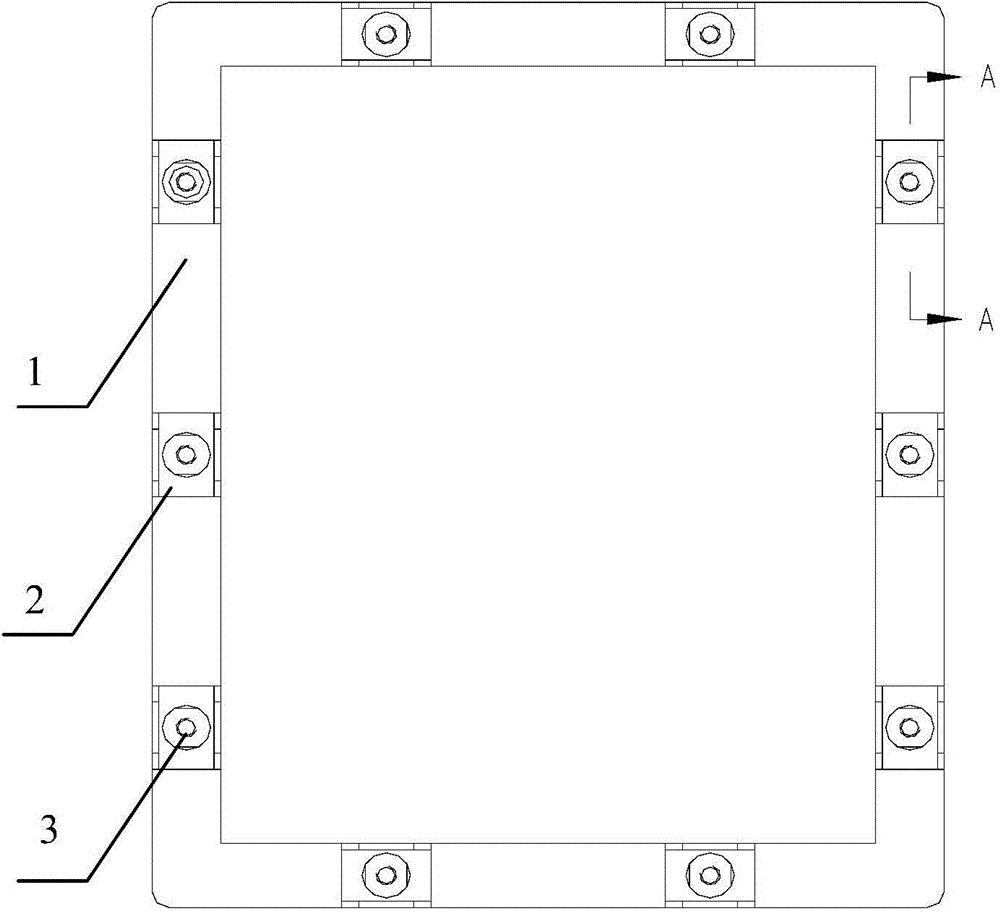

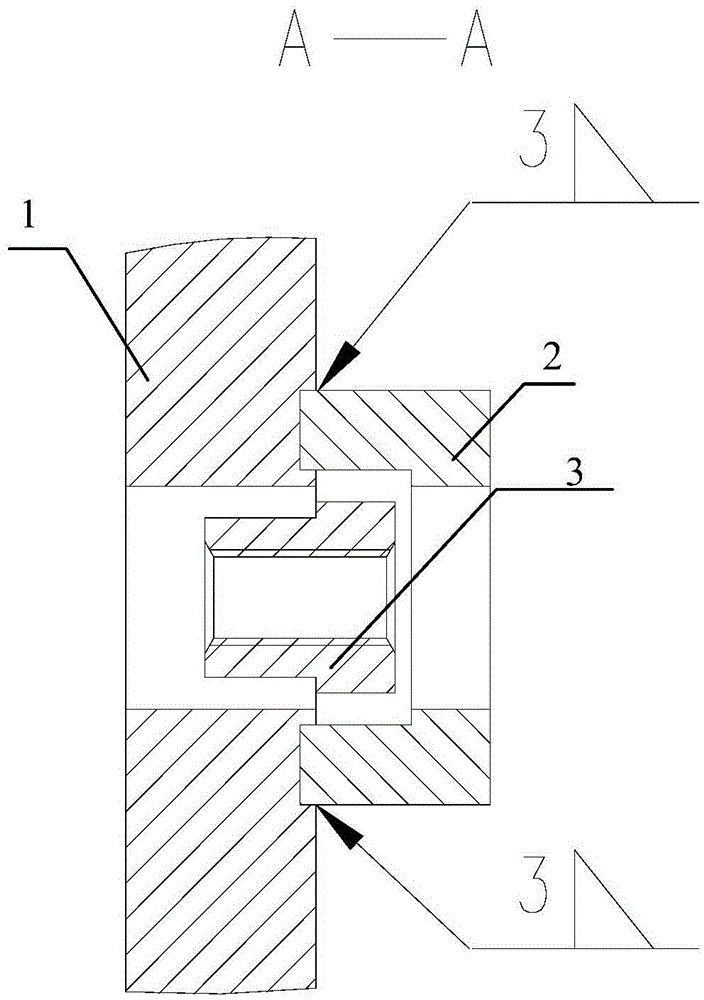

Self-heat-preservation prefabricated outer wall board with frame net rack

InactiveCN104234302AReduce the workload of insulationFast constructionBuilding componentsEngineeringSelf weight

The invention discloses a self-heat-preservation prefabricated outer wall board with a frame net rack. The prefabricated outer wall board comprises a heat-preservation sandwich board, steel wire net sheets and inclined inserting bars, wherein a space steel wire net rack is formed by the upper and lower steel wire net sheets and the heat-preservation sandwich board is arranged in the space steel wire net rack; the upper and lower steel wire net sheets are arranged at the peripheral edges along with the heat-preservation sandwich board, are bent inwards by two rows and are additionally provided with tie bars to form a frame steel bar cage; and lightweight concrete wall bodies are arranged on the upper and lower surfaces, and the peripheries of the space steel wire net rack. According to the self-heat-preservation prefabricated outer wall board, industrial prefabrication can be realized and the self weight is light; the periphery can be in flexible connection with a main body so that the anti-seismic effect is better; and meanwhile, the self-heat-preservation prefabricated outer wall board has the characteristics of rapid construction speed, low construction cost, energy conservation and environmental friendliness, safety and reliability and good heat preservation effect.

Owner:ANHUI YUTAI BUILDING TECH GRP

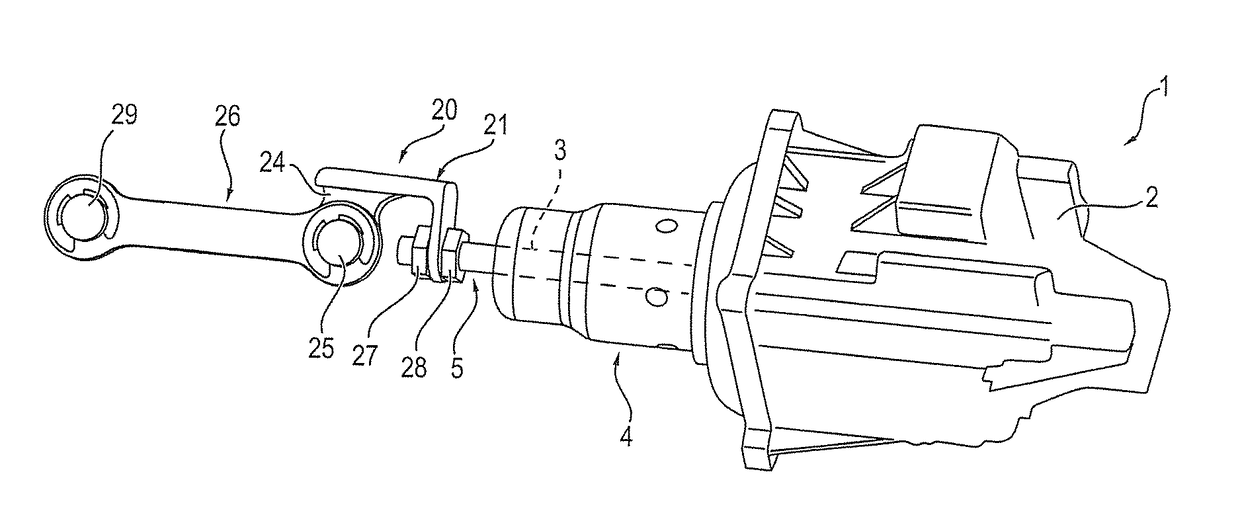

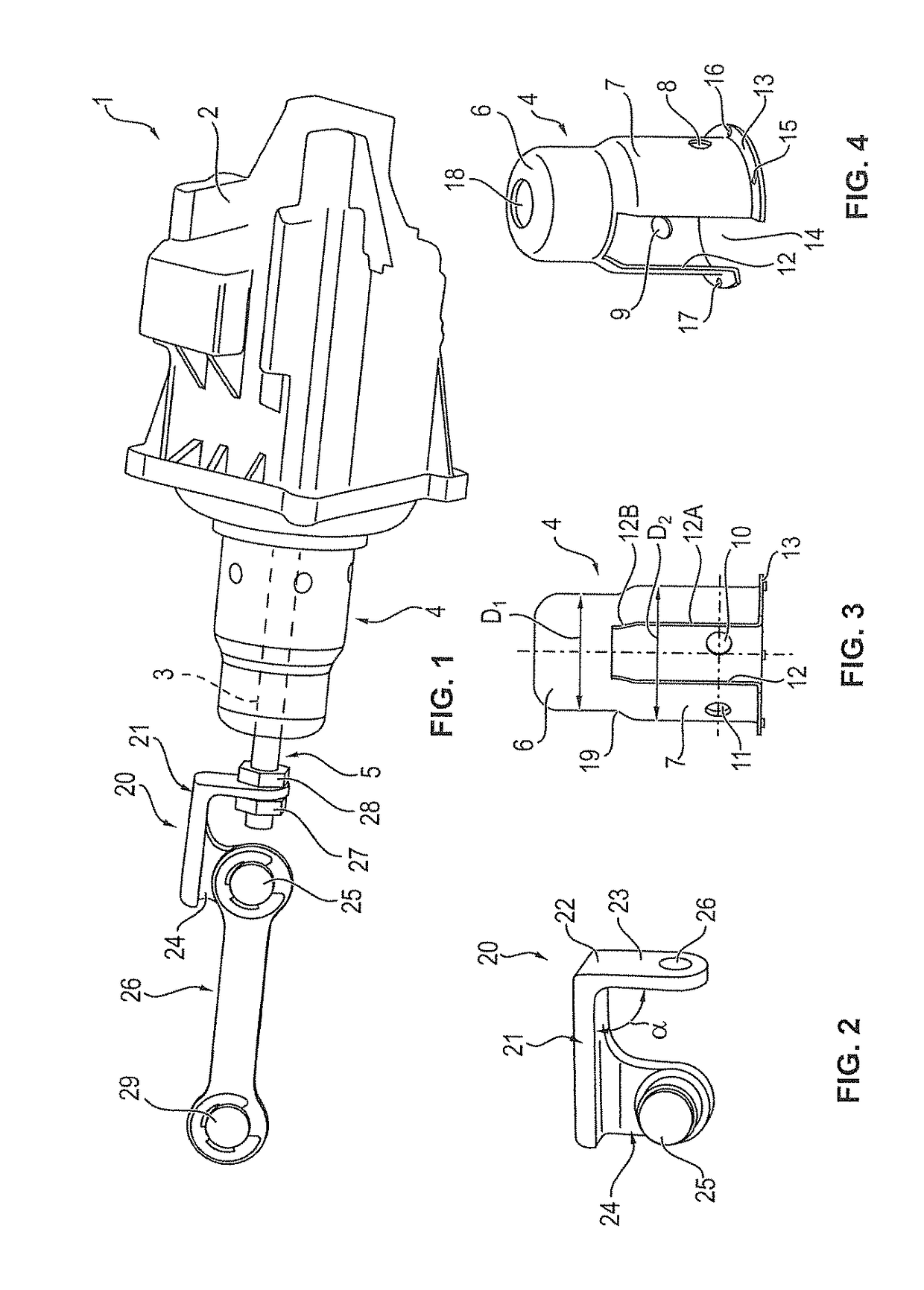

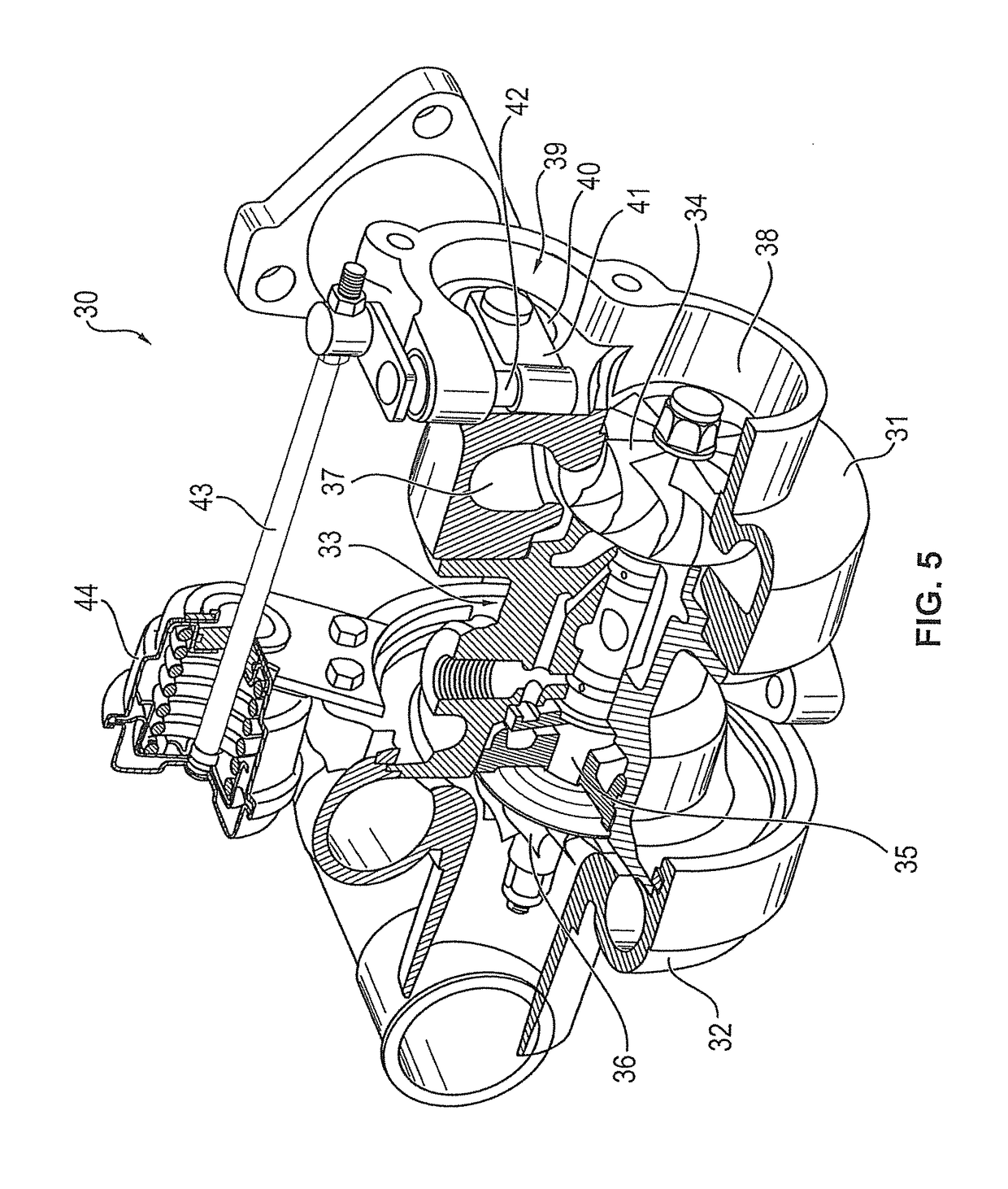

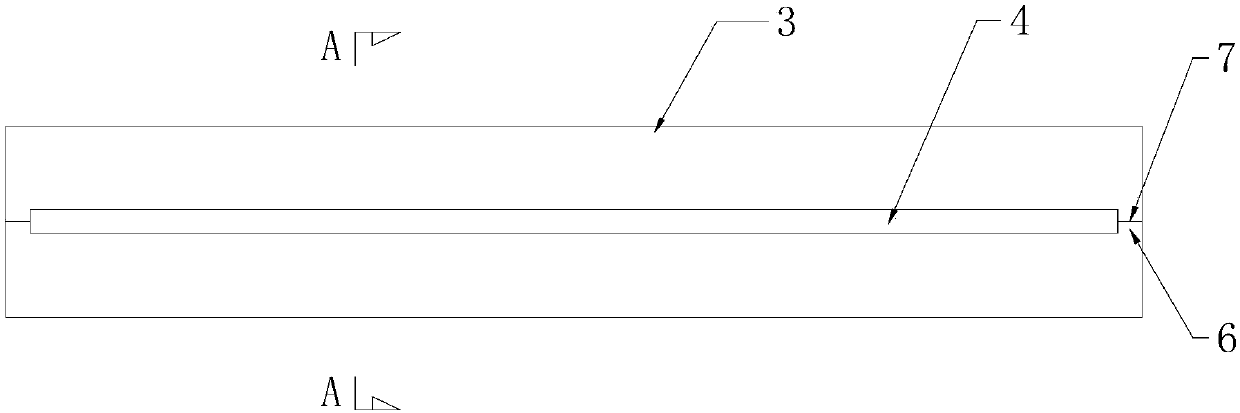

Actuation device, in particular electronic actuator

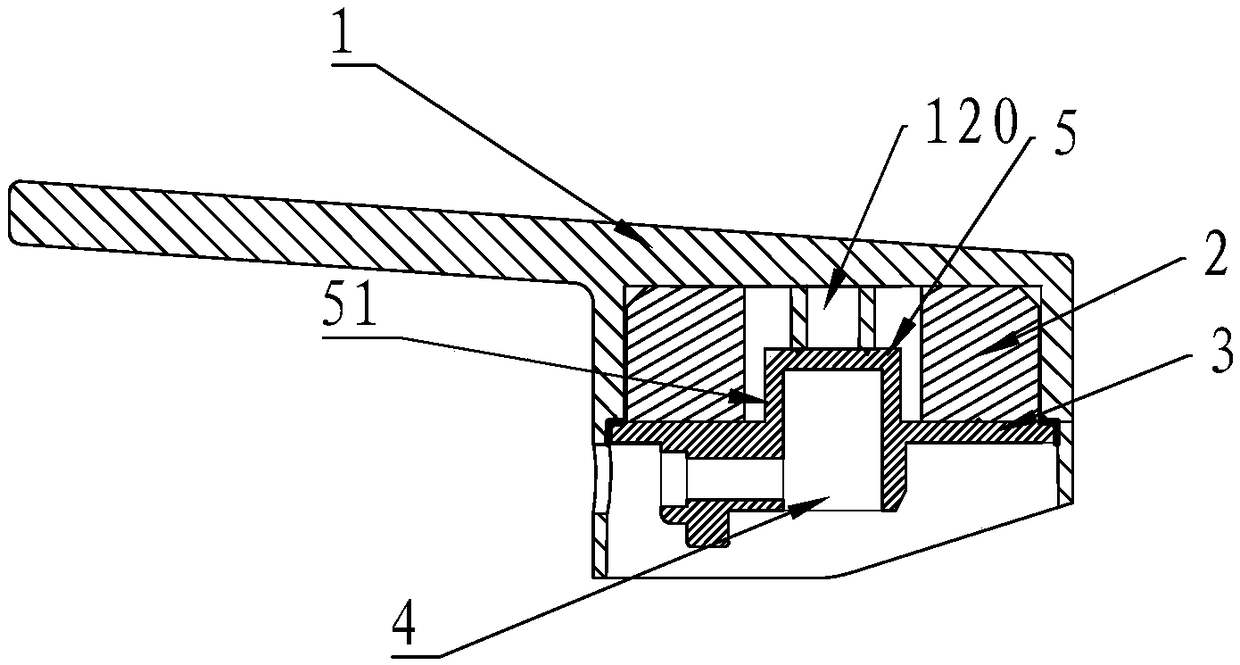

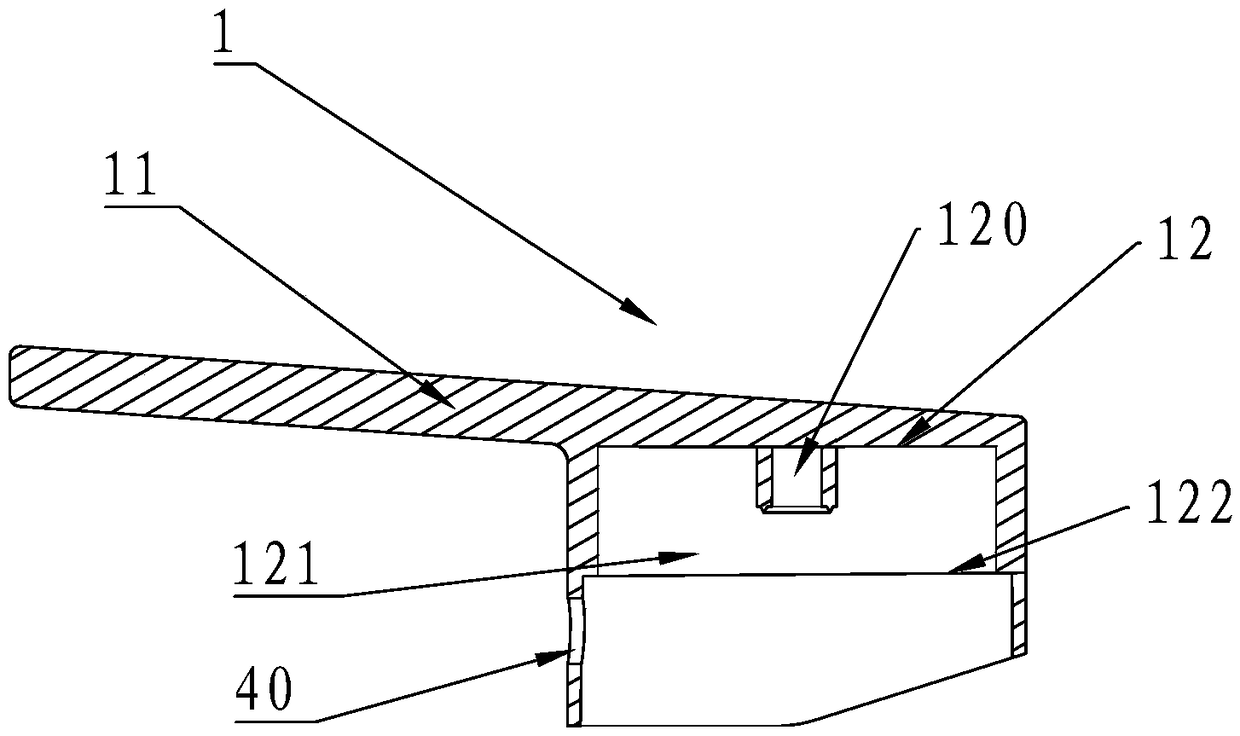

ActiveUS9822695B2Prevent scalingError-free installationInternal combustion piston enginesMagnetsEngineeringActuator

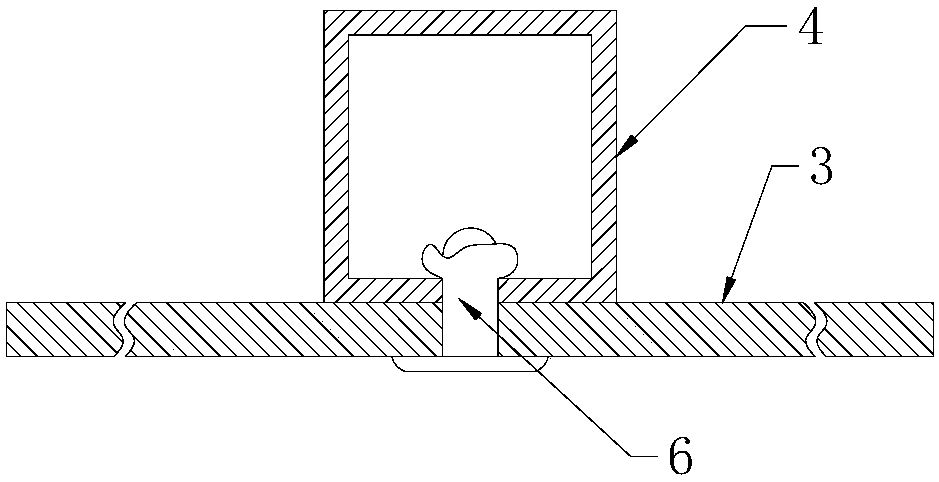

An actuation device (1), in particular electronic actuator, having a housing (2); and having an actuation shank which has a first shank portion guided in the housing (2), and which has a second shank portion (3) projecting out of the housing (2), wherein a shielding cap (4) is provided which is fastened to the housing (2) and which surrounds the second shank portion (3) with the exception of a fastening region (5).

Owner:BORGWARNER INC

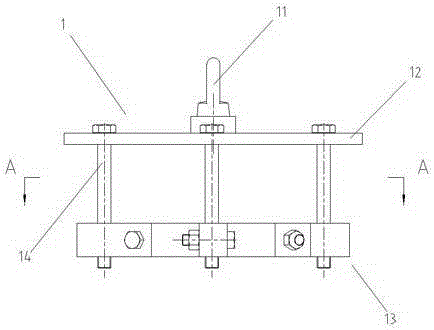

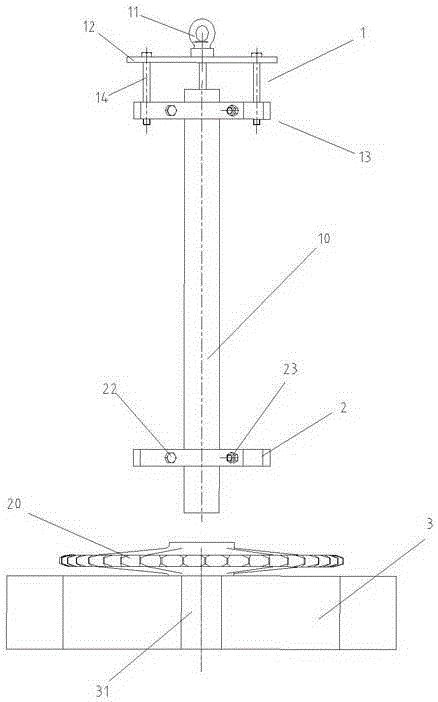

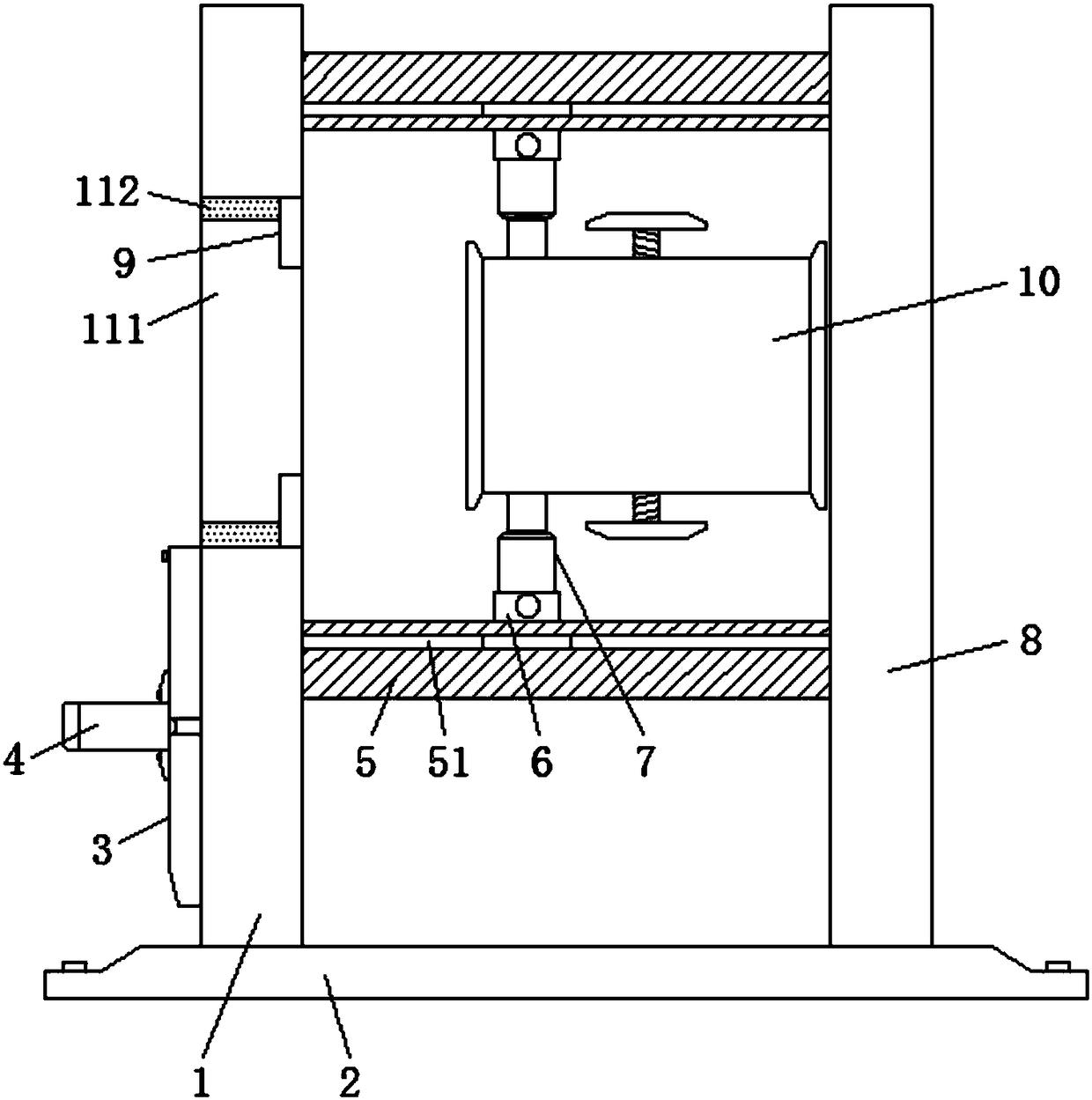

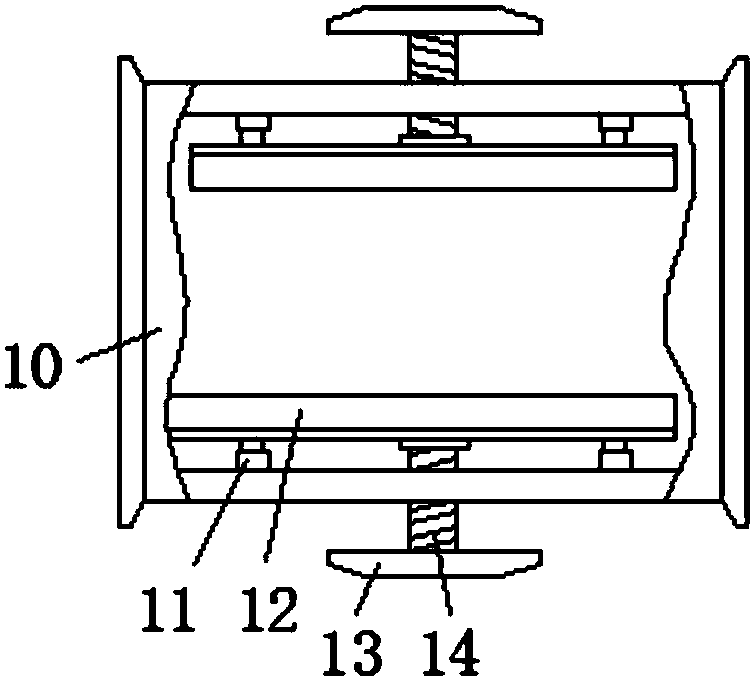

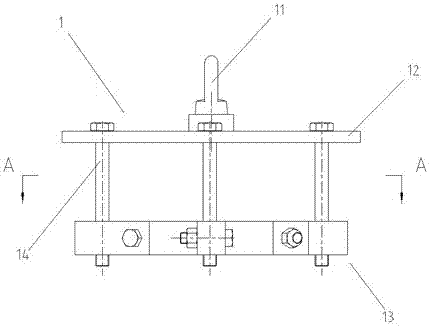

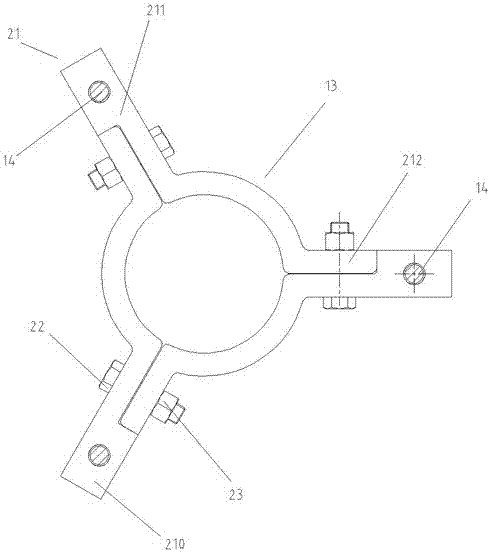

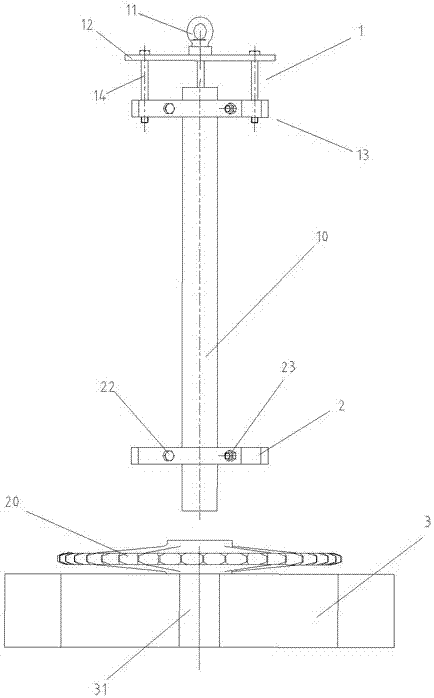

Tooling and method used for fixedly connecting camshaft with camshaft sprocket

ActiveCN105195978ASimple structureResolve Perpendicularity ToleranceMetal working apparatusEngineeringSprocket

The invention discloses a tooling used for fixedly connecting a camshaft with a camshaft sprocket. The tooling comprises a upper lifting appliance, a lower clamp hoop and a camshaft sprocket bracket, wherein the upper lifting appliance comprises a lifting bolt, an upper hanger plate, an upper clamp hoop and a plurality of connection screws; the upper clamp hoop is arranged below the upper hanger plate; the upper hanger plate and the upper clamp hoop are fixedly connected into a whole through the connection screws. The connection method of the tooling is that the upper clamp hoop and the lower clamp hoop are radially clamped and fixed on the vertical positioning benchmarks at the upper and lower ends of the camshaft respectively, and then the camshaft sprocket is horizontally supported by the camshaft sprocket bracket after being heated. The camshaft is lifted up vertically, the perpendicularity of the camshaft and the levelness of the camshaft sprocket are adjusted respectively, and finally, the lower end of the camshaft enters a central hole in the camshaft sprocket to fulfill assembling. The tooling and the method have the advantages that the perpendicularity tolerance of the camshaft is controlled; the axial positioning of the camshaft sprocket is accurate; the mounting accuracy and the mounting efficiency of a diesel engine are improved; the mounting cost is reduced.

Owner:CSSC MARINE POWER

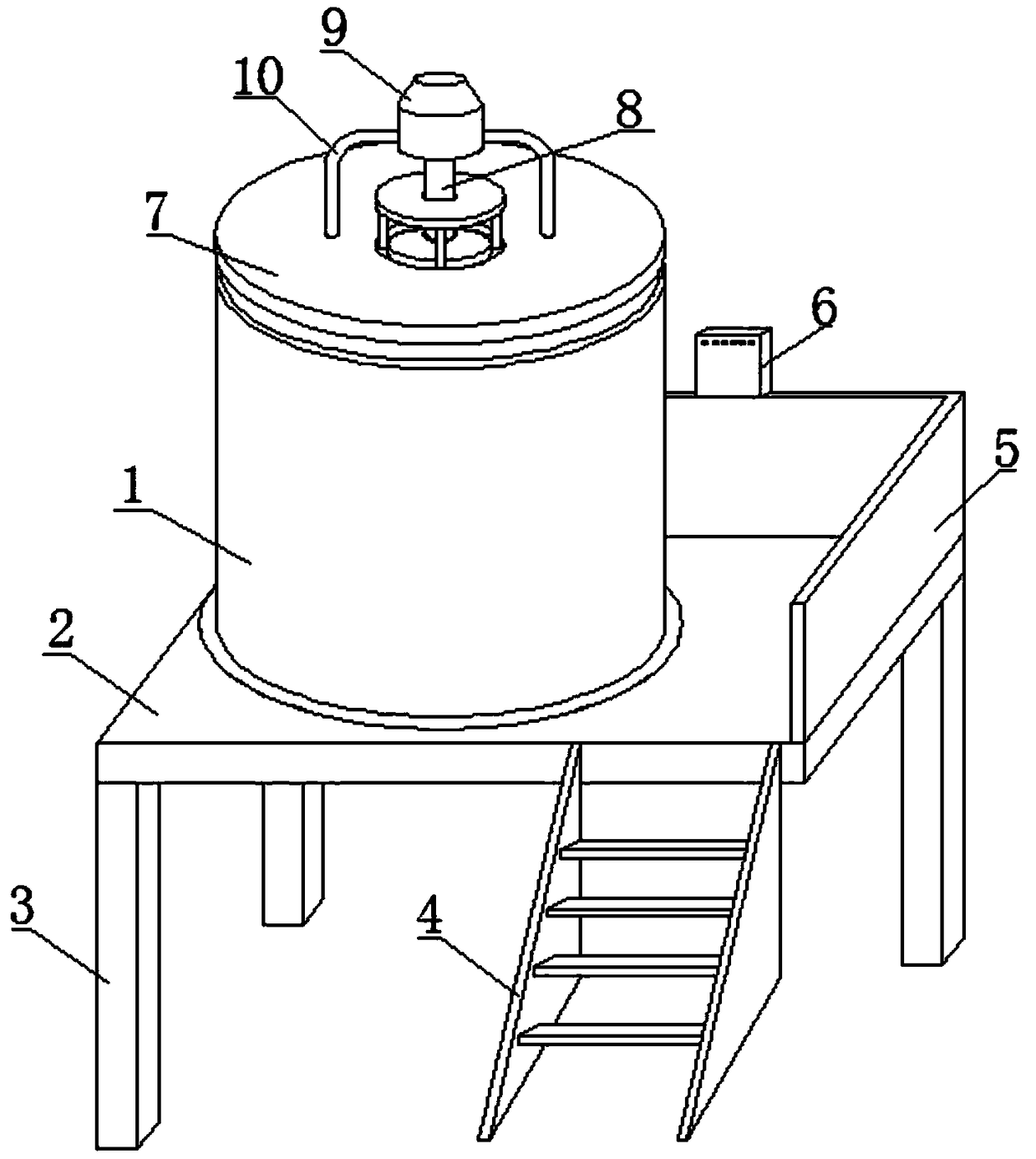

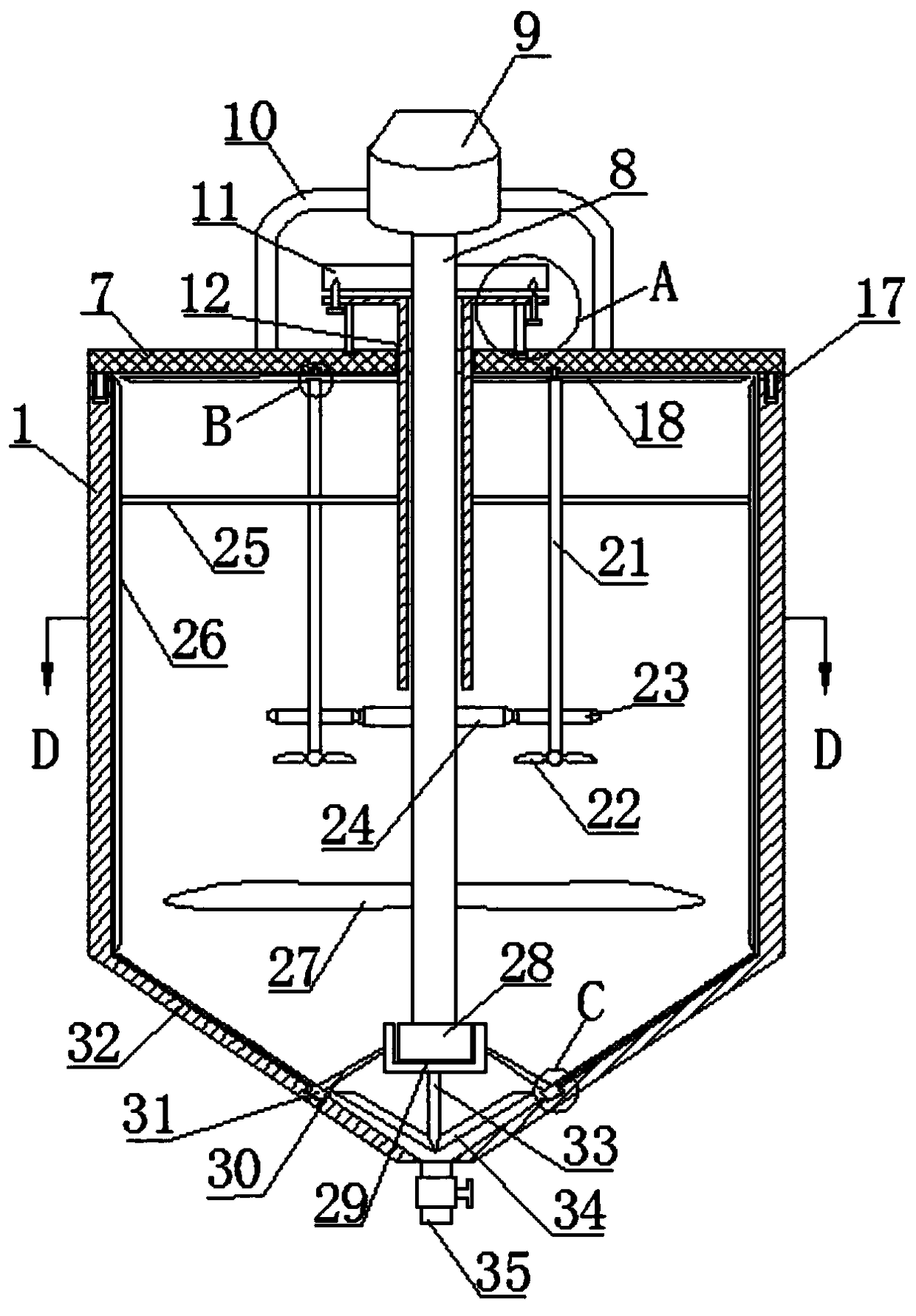

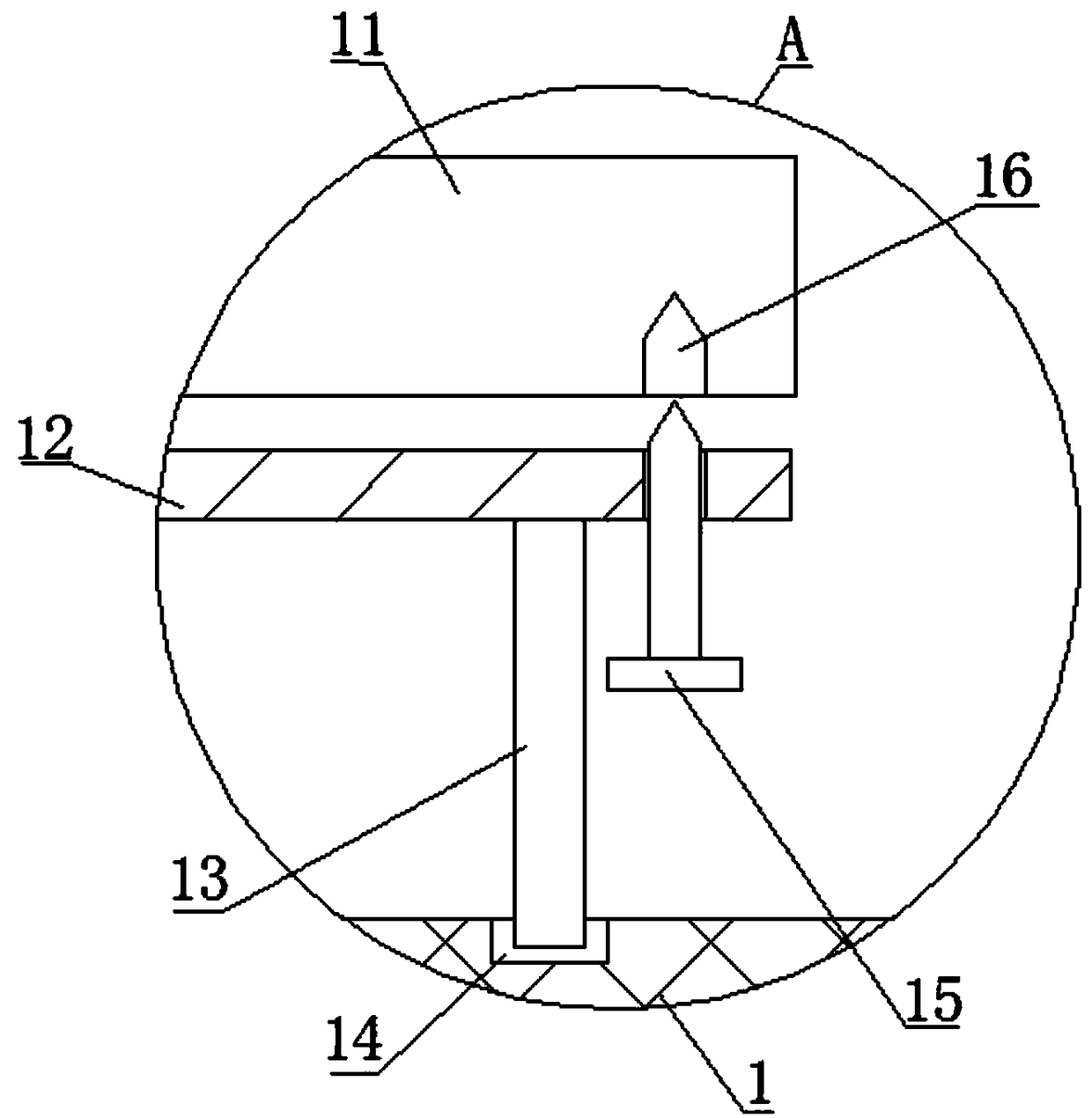

Novel epoxy resin encapsulation and stirring tank

InactiveCN109012278APlay a protective effectEasy to cleanRotary stirring mixersTransportation and packagingEpoxyEngineering

The invention discloses a novel epoxy resin encapsulation stirring tank. A tank cover is arranged at one end of an opening of the stirring tank; a first transfer rod is movably inserted and connectedon the tank cover; the lower end of the first transfer rod extends to the stirring tank; a plurality of second stirring claws are fixedly connected onto one section, positioned in the stirring tank, of the first transfer rod. The novel epoxy resin encapsulation stirring tank has the advantages that an upper scrapping plate and a bottom scrapping plate are added, so that during the cleaning, the effect of scrapping residues can be achieved at the tank cover and the stirring tank bottom; a better cleaning effect can be achieved; a plurality of first stirring claws are added, so that during the stirring, the stirring speed can be accelerated; the work efficiency is improved; a protection plate is added, so that when the scrapping plate works, the adhered residues can be firstly cleared through the protection plate; then, the scrapping plate is used for scrapping, so that the effects of convenience, high speed and efficient cleaning are achieved; meanwhile, the protection effect can also be achieved on the scrapping plate.

Owner:安徽菲扬新材料有限公司

Faucet handle and machining and electroplating method thereof

InactiveCN108930833ASimple structureThe electroplating process is simpleOperating means/releasing devices for valvesEngineeringInjection moulding

The invention relates to a faucet handle. The faucet handle comprises a handle shell, a balance weight block and a fixed piece, wherein injection molding is adopted for the handle shell and the fixedpiece; the handle shell is provided with an installing hole, and comprises a handle and a faucet connection portion; the faucet connection portion is provided with a hollow containing portion; the balance weight block is arranged in the containing portion; a valve element connection head is arranged on the outer side of the fixed piece, and a positioning boss is arranged on the inner side; and thefixed piece is arranged in the containing portion on the outer side of the balance weight block and is welded to the handle shell in an interference manner. The faucet shell has the following beneficial effects that firstly, the structure is simplified, the electroplating process is simple, and cost is lower; secondly, the appearance face comprises a visible portion in the handle shell, and bothof them are very bright and clean, and the nearly perfect metal texture is achieved; thirdly, the fixed piece and the handle shell are in interference welding, so that gas tightness between the fixedpiece and the handle shell is better, and connection is more stable and reliable; and fourthly, the fixed piece is provided with an alignment groove, in the process of installing the fixed piece, thealignment groove is aligned with the installing hole, and the fixed piece can be accurately installed in place.

Owner:XIAMEN LIYE IND & TRADE CO LTD

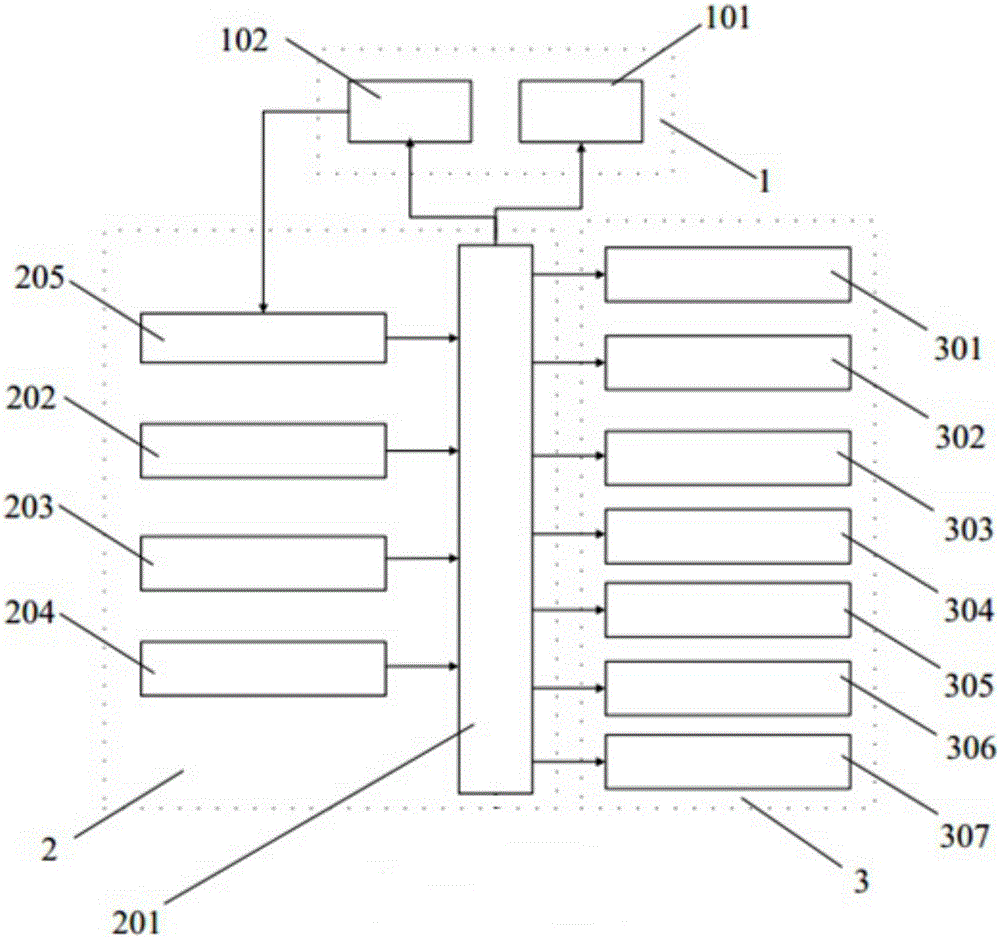

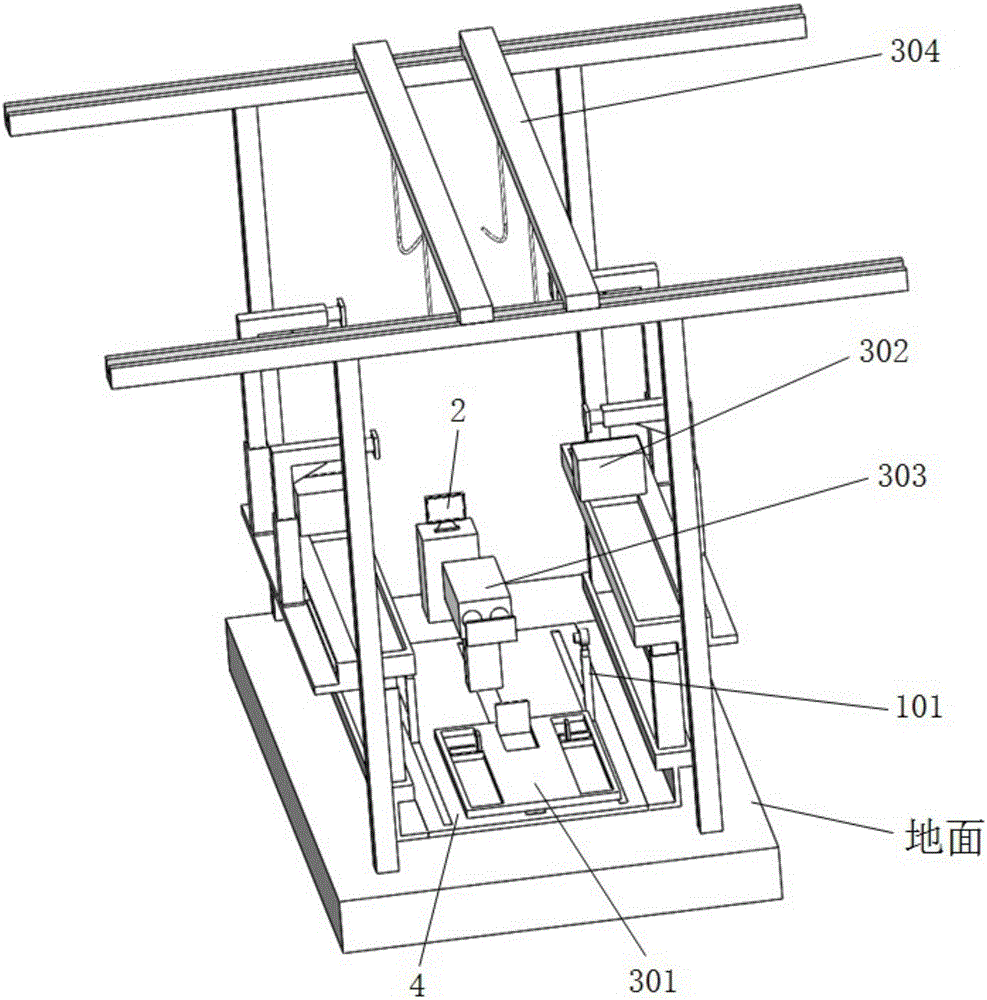

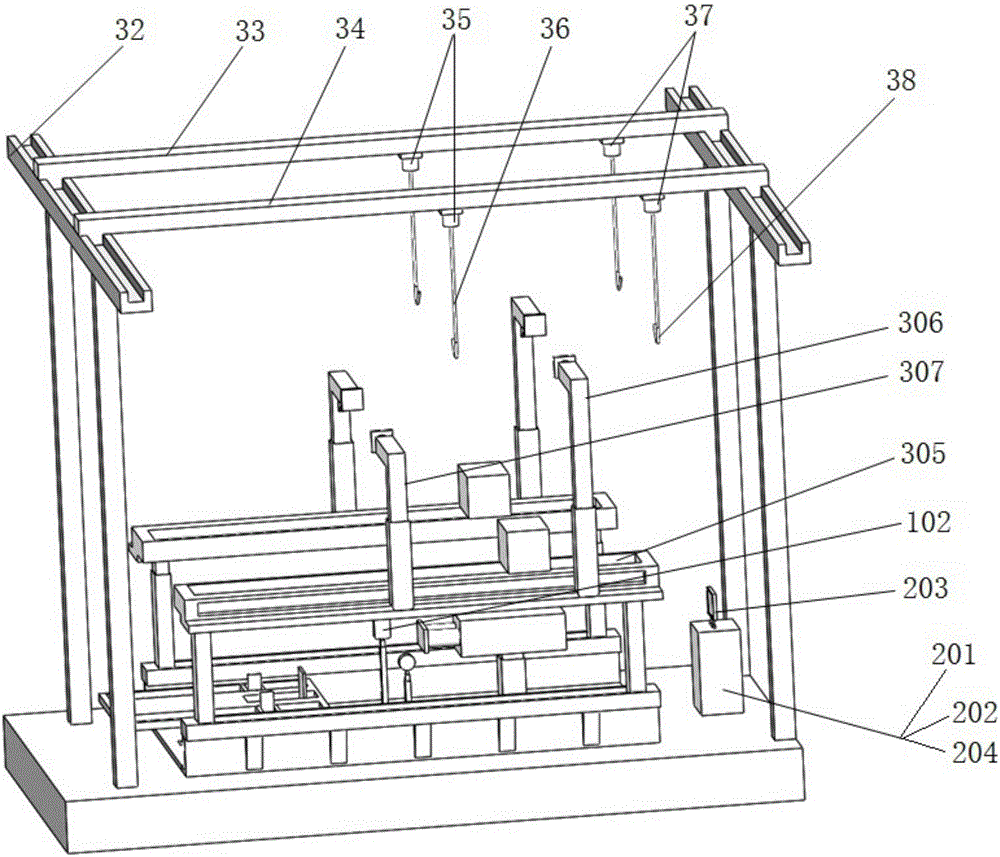

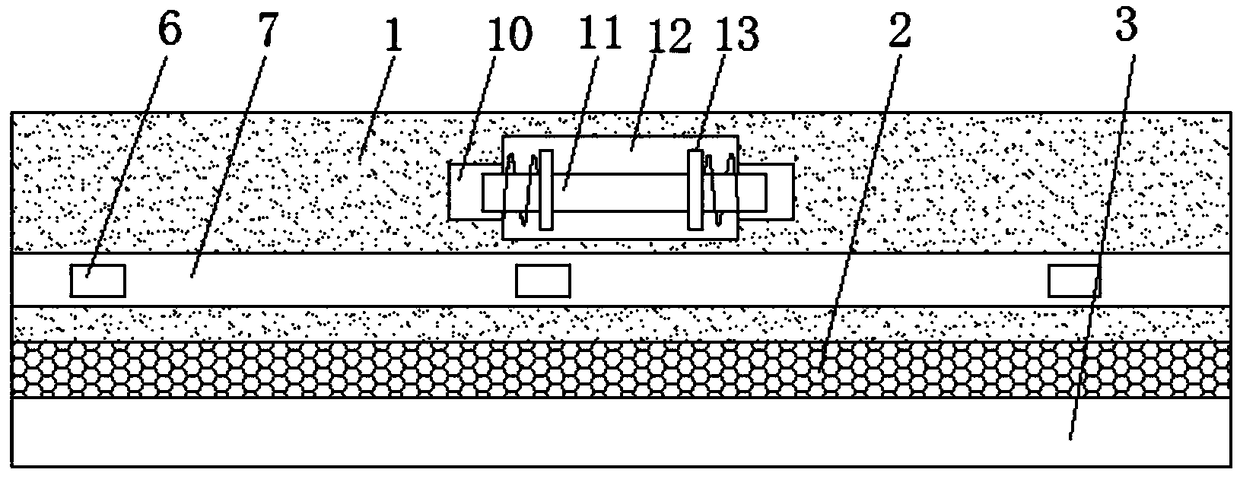

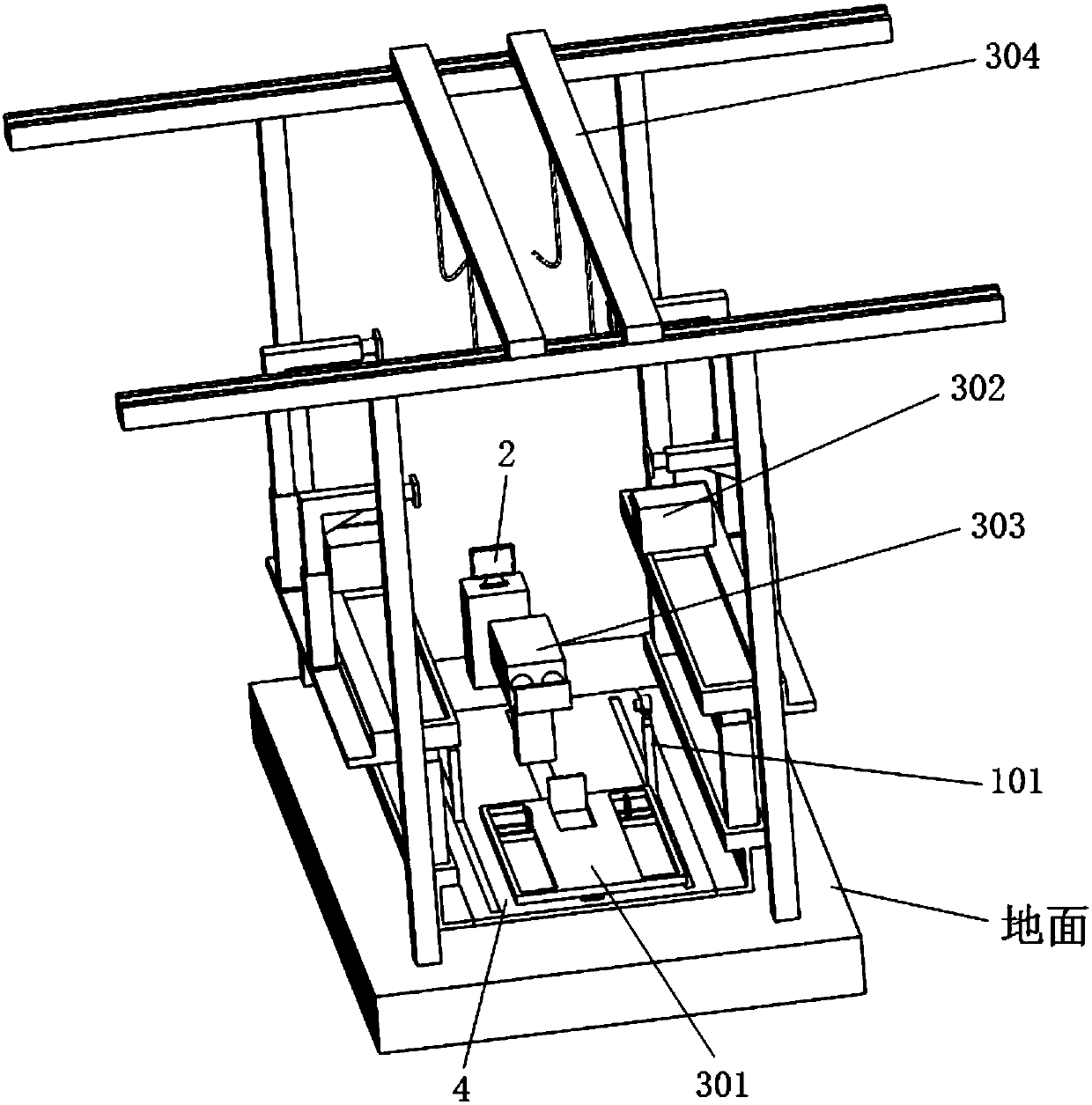

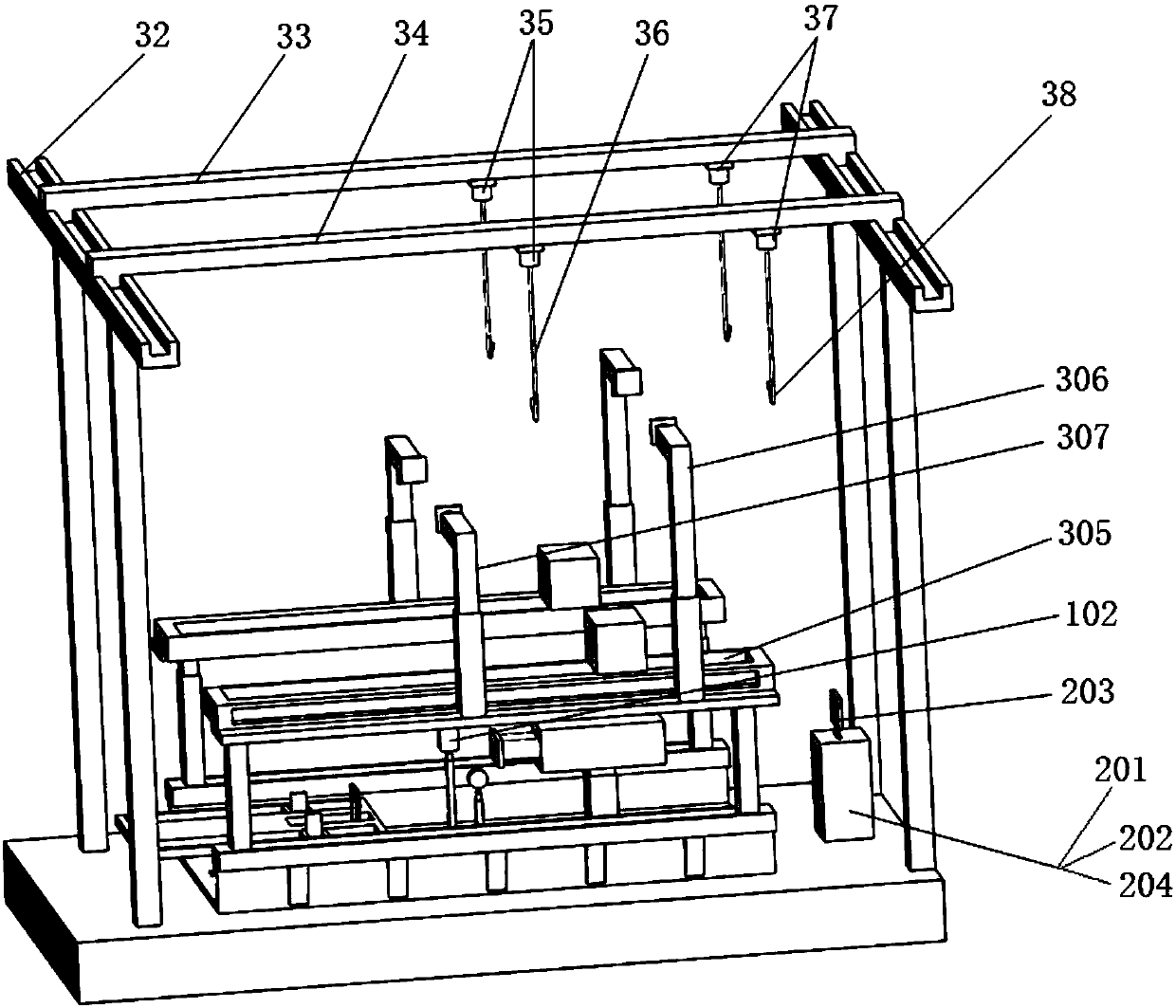

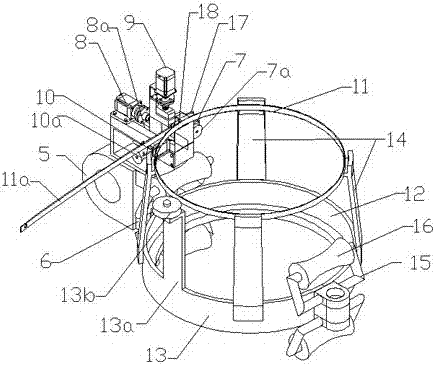

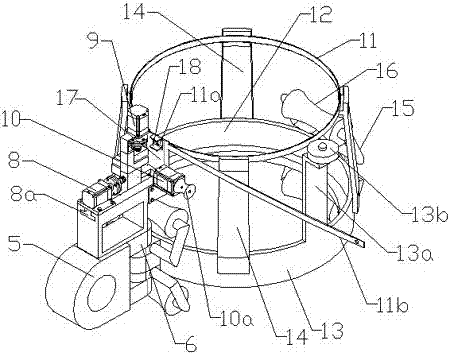

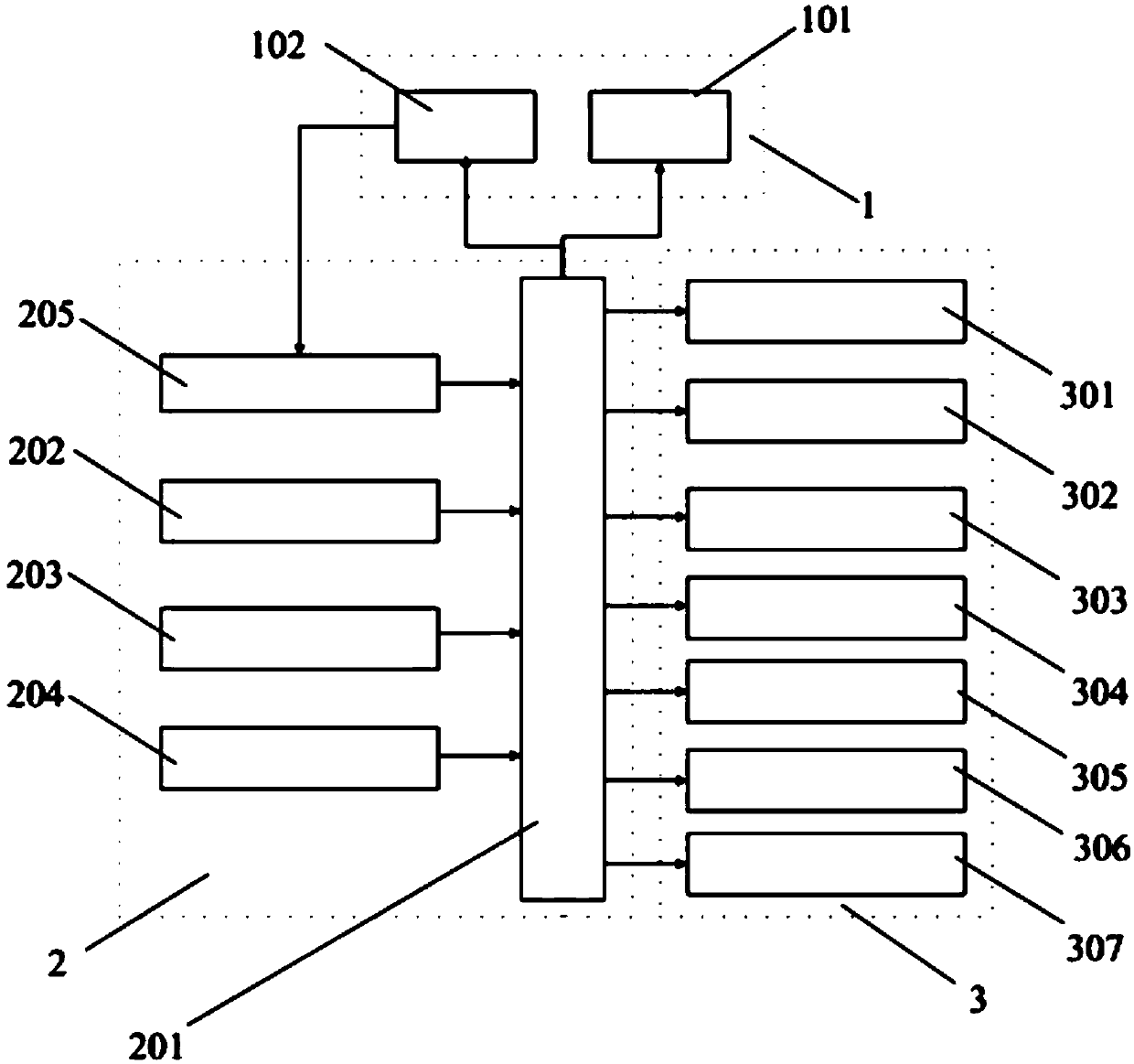

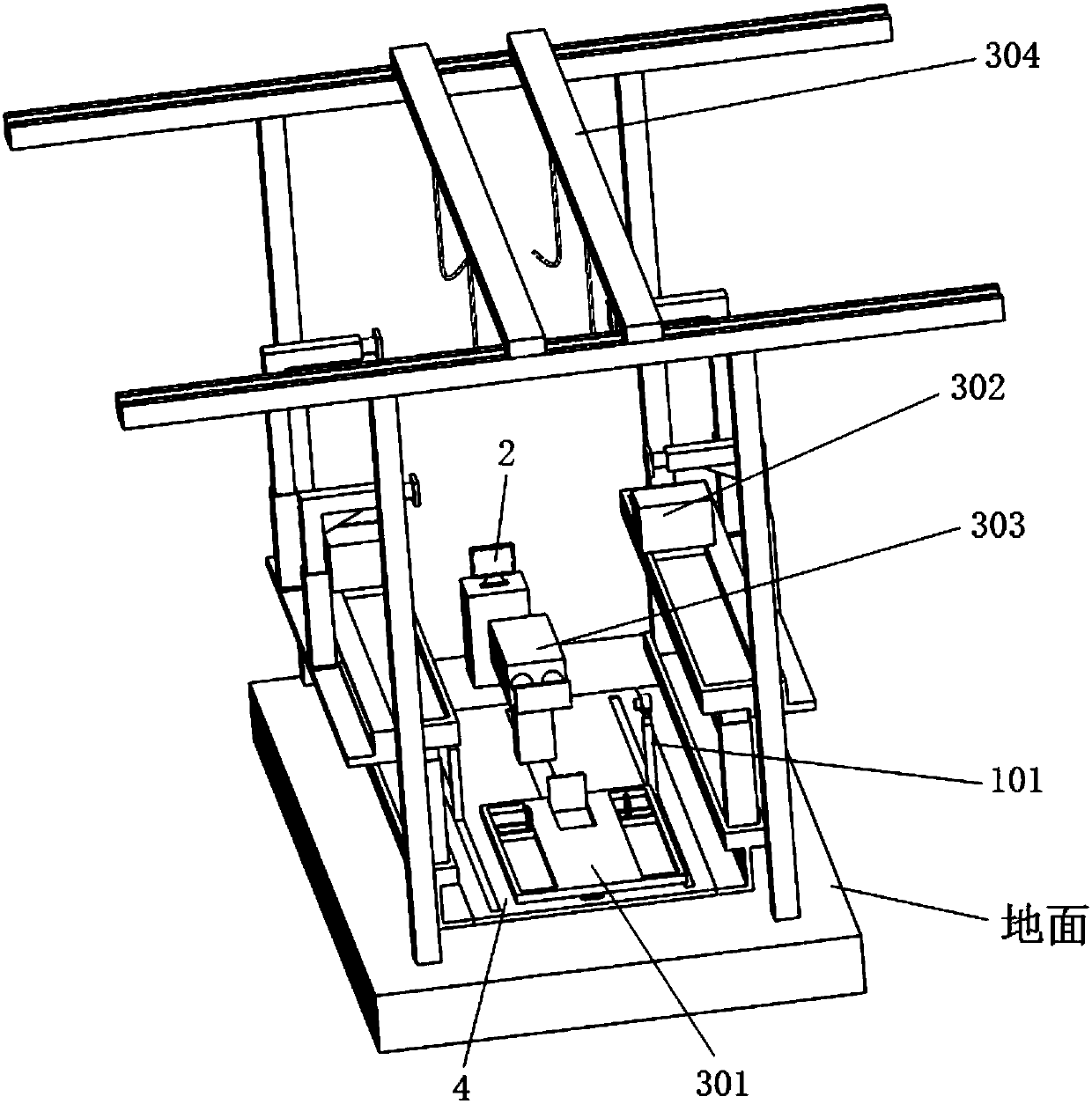

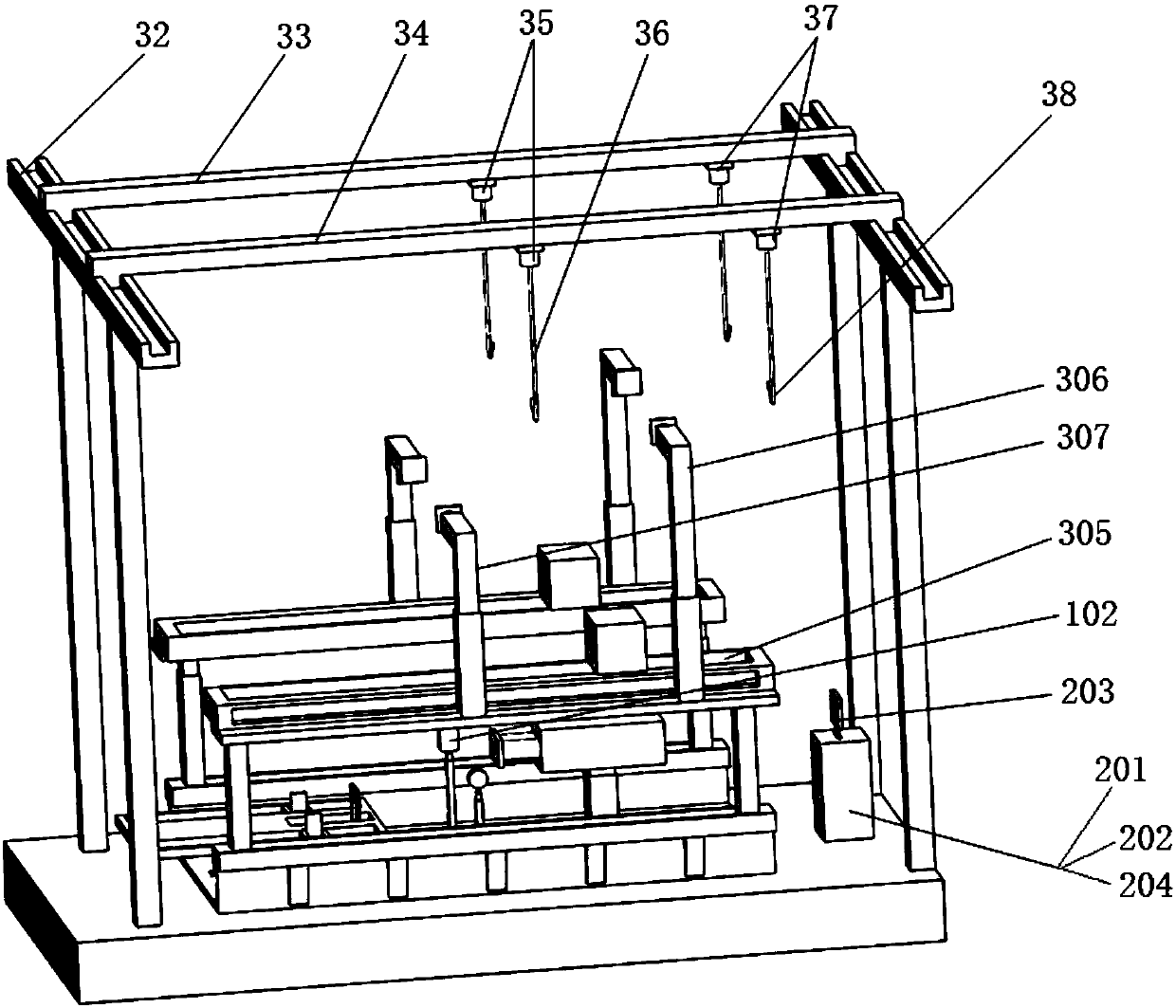

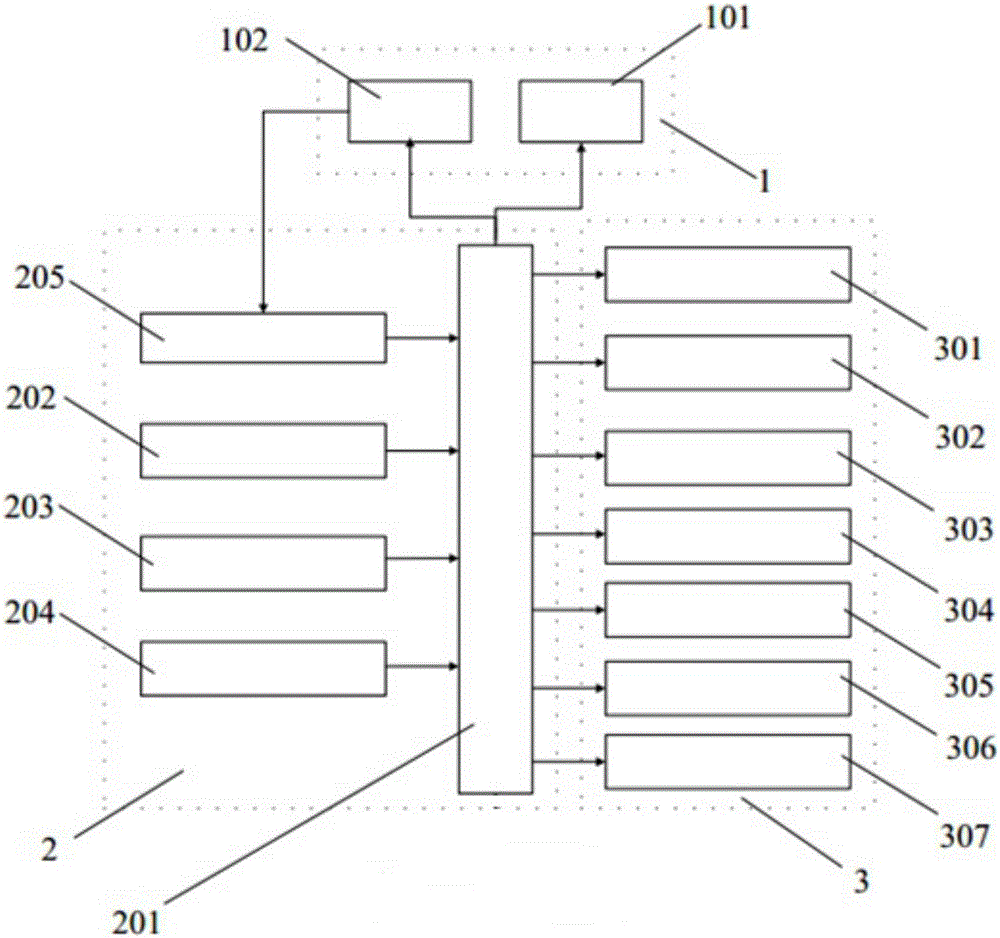

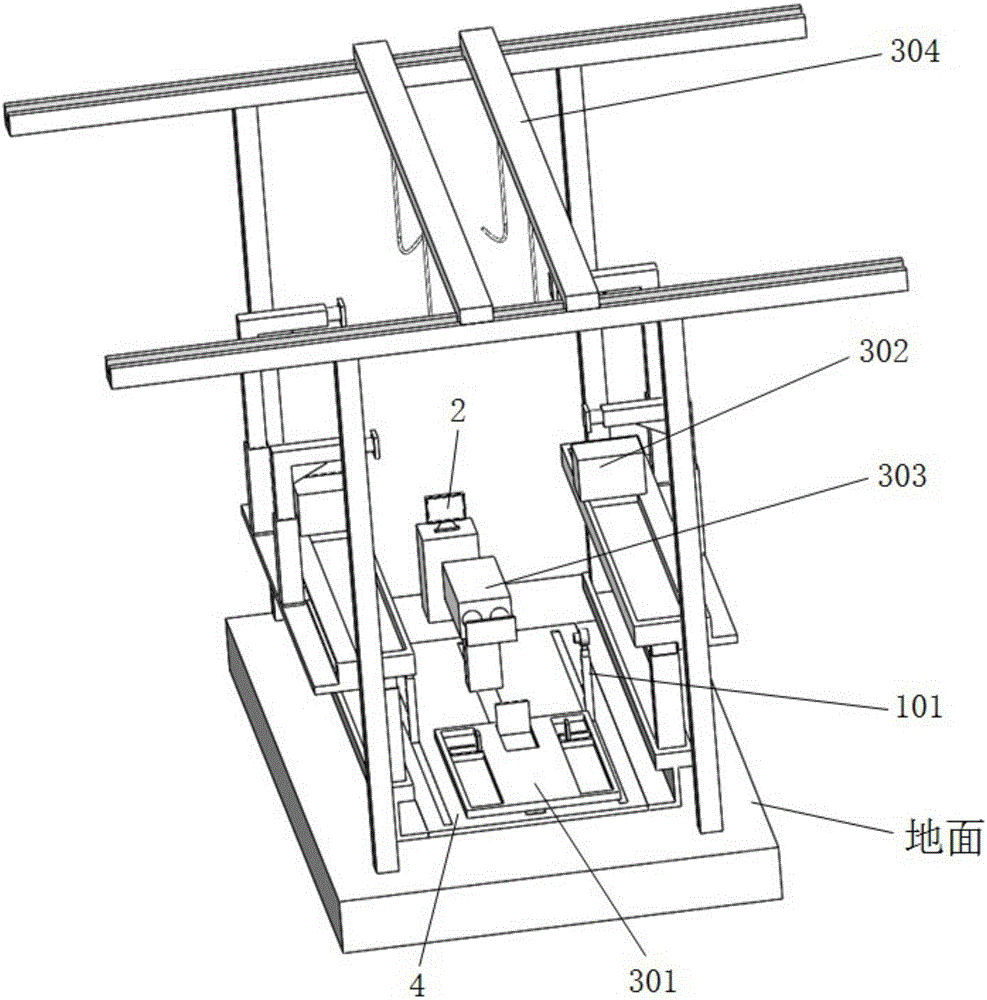

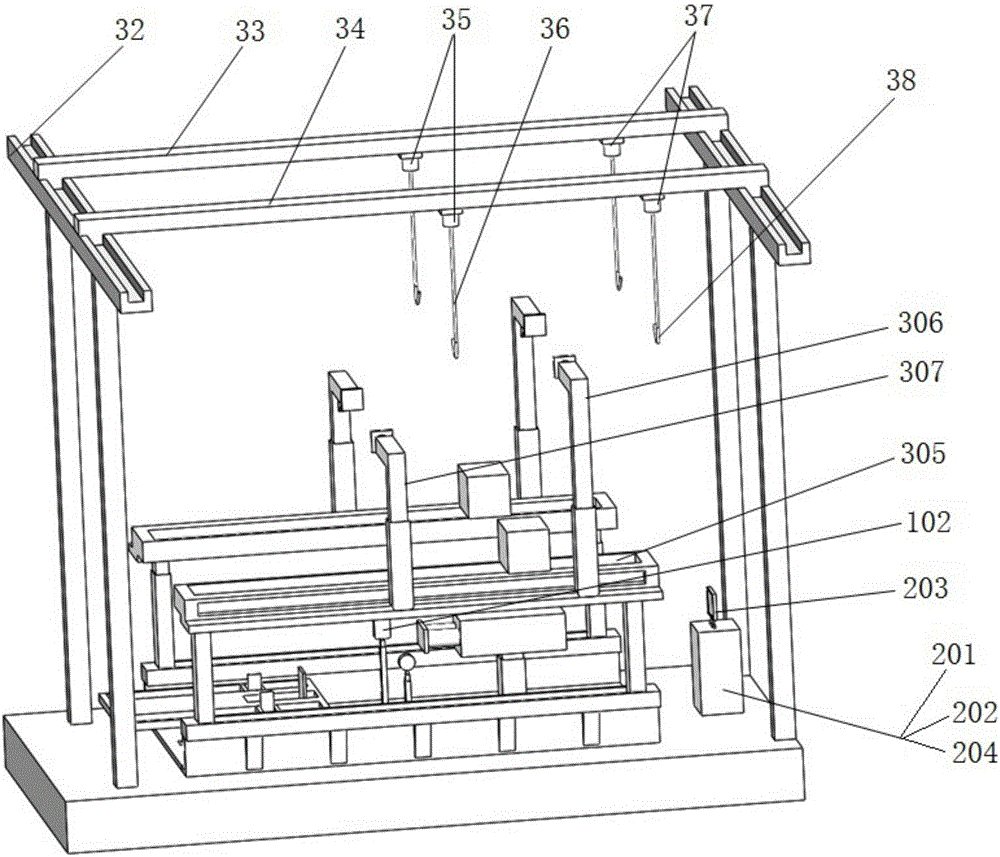

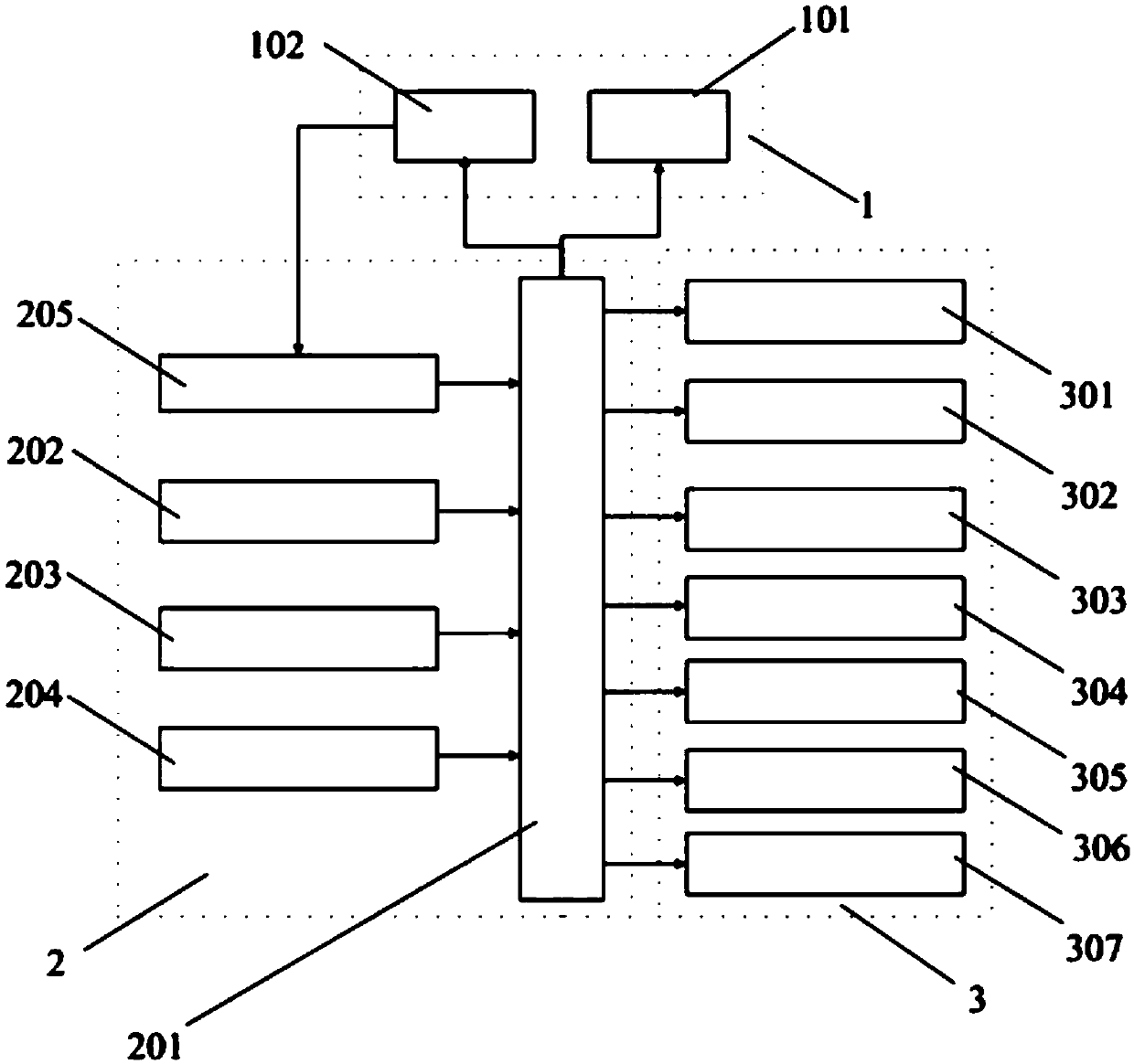

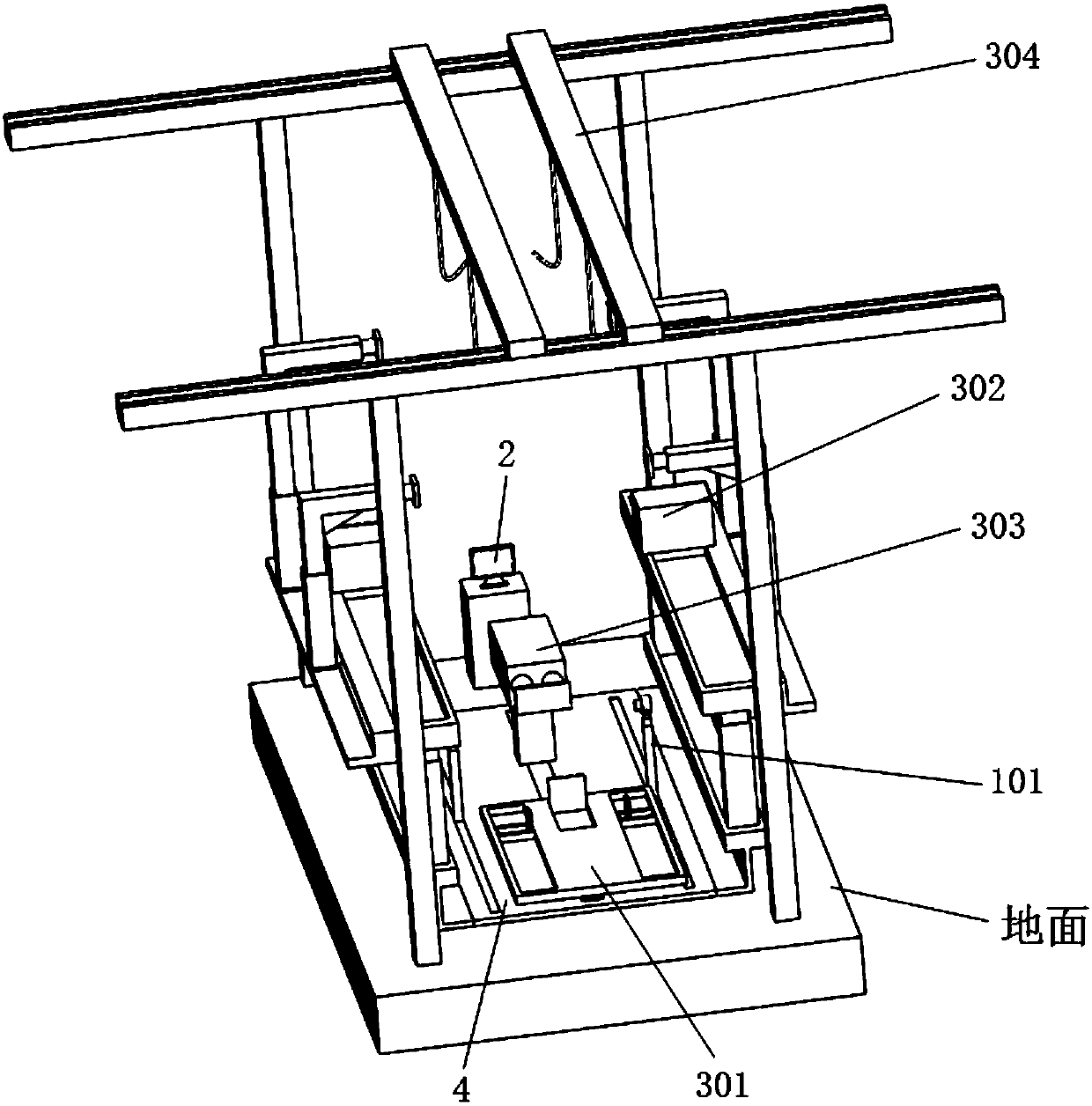

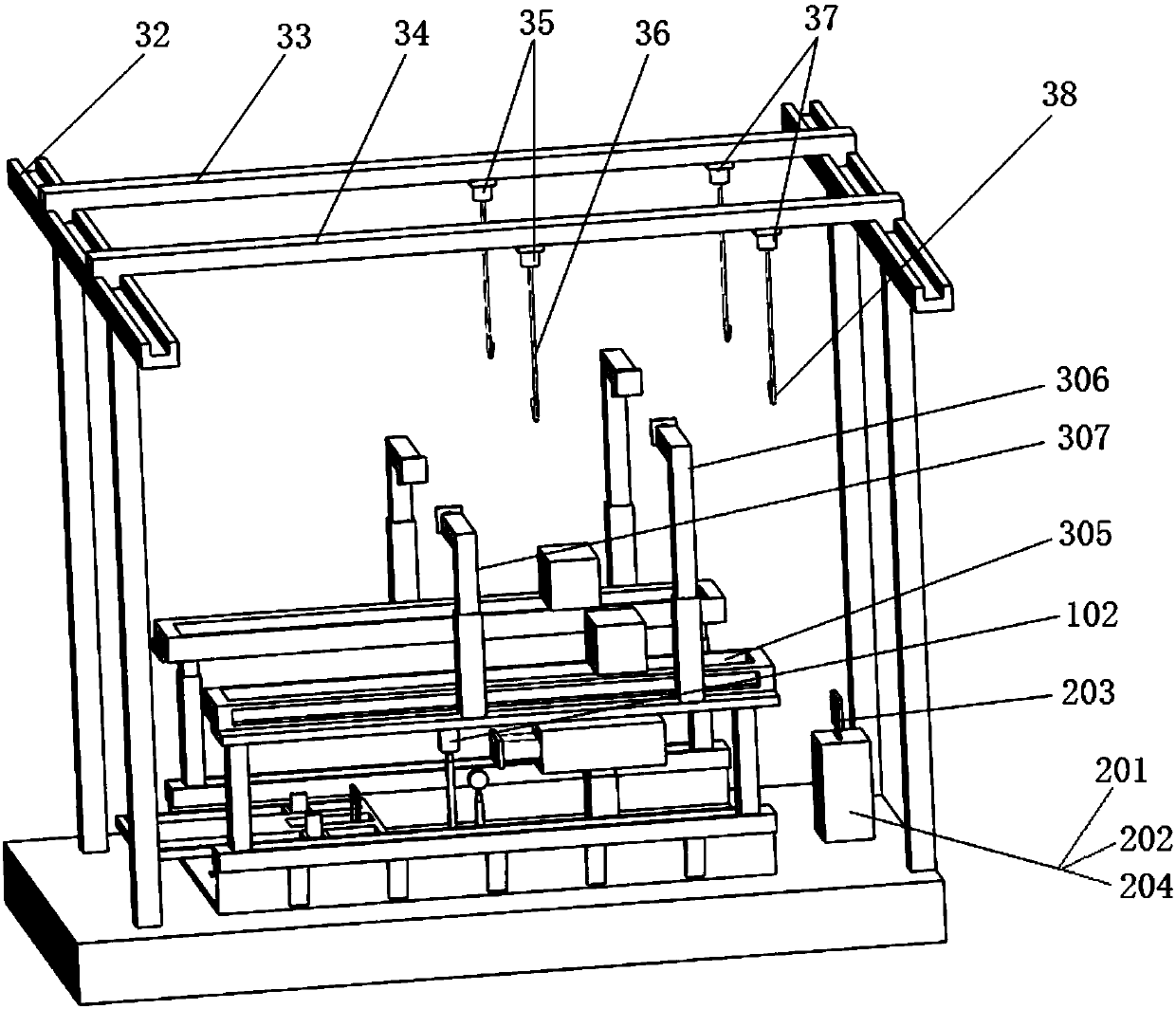

Intelligent installation machine for hydraulic support and application method of intelligent installation machine

The invention relates to an intelligent installation machine for a hydraulic support and an application method of the intelligent installation machine. The intelligent installation machine comprises an installation implementation system, a hinge pin hole locating assembly and a control system. The control system is electrically connected with the installation implementation system and the hinge pin hole locating assembly and used for intelligently controlling operation of the installation implementation system and the hinge pin hole locating assembly. According to the intelligent installation machine for the hydraulic support and the application method of the intelligent installation machine, coordinate information of hinge-joint holes in a hydraulic support base, a front connection rod and a rear connection rod is obtained through a laser lamp module in the hinge pin hole locating assembly; centering of hinge-joint holes is completed by completing movement of the front connection rod and the rear connection rod in a preset coordinate system through the control system; and after hinge pins at specific positions are grabbed through mechanical arms in the installation implementation system, the hinge pins are inserted into the hinge-joint holes, so that installation of the front connection rod, the rear connection rod and the base as well as installation of a top beam and a shield beam are completed. By means of the intelligent installation machine, traditional hydraulic support installation modes are changed; manpower and material resources are saved; intelligentized control is achieved; installation precision is high; and installation efficiency is improved.

Owner:SHANDONG UNIV OF SCI & TECH

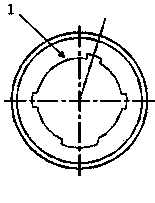

Structure for preventing bulbs from being mistakenly arranged for automobile lamp

InactiveCN104033857AAvoid functional clutterError-free installationRoad vehiclesLight fasteningsFogElectrical and Electronics engineering

A structure for preventing bulbs from being mistakenly arranged for an automobile lamp is composed of bulb seats of three states and a lamp housing. The bulb seats of the three states comprise the rear fog lamp bulb seat, the position lamp bulb seat and the steering lamp bulb seat, the bulb seats of the three states are provided with bulbs of different specifications respectively, and the lamp housing is provided with bulb seat mounting holes. The structure for preventing the bulbs from being mistakenly arranged for the automobile lamp is characterized in that each bulb seat is provided with four clamping legs, each bulb seat is in the first state after each clamping leg is rotated anticlockwise by 14 degrees and is in the second state after each clamping leg is rotated clockwise by 14 degrees, the original state of each bulb seat is the third state, the structures of the bulb seat mounting holes in the lamp housing correspond to the three bulb seats, and therefore the bulb seats which are provided with the bulbs with different functions are mounted in the mounting holes corresponding to the bulb seats in the lamp housing. The structure for preventing the bulbs from being mistakenly arranged for the automobile lamp is simple in structure, it is guaranteed that the position lamp bulb, the steering lamp bulb and the rear fog lamp bulb in a rear lamp can be accurately mounted, and the condition that the functions of the rear lamp are chaotic is avoided.

Owner:DANYANG DEQUAN AUTOMOTIVE ORNAMENTS

Composite thermal insulation plate for building

PendingCN109440967AFix security issuesResolution cycleWallsHeat proofingThermal insulationEconomic benefits

The invention discloses a composite thermal insulation plate for a building. As for the problems that existing composite thermal insulation plates have low safety performance and long installation period, according to the following scheme, the composite thermal insulation plate comprises an inner blade concrete layer, a thermal insulation plate, and an outer blade light panel, one side of the thermal insulation plate is fixedly connected with one side of the inner blade concrete layer, the other side of the thermal insulation plate is fixedly connected with one side of the outer blade light panel, the inner blade concrete layer, the thermal insulation plate and the outer blade light panel are fixedly connected through a plurality of tie parts, a connecting groove and a groove are formed inone side of the inner blade concrete layer, the groove is located in the side, away from the thermal insulation plate, of the connecting groove, and a plurality of spring holes are formed in the bottom of the connecting groove at equal distances. According to the composite thermal insulation plate for the building, the structure is simple, design is ingenious, the attractive degree of an outer wall is improved, the construction speed is high, the construction period is short, the security risks are lowered, construction safety is ensured, and the economic benefits of construction engineeringare improved.

Owner:TIANJIN INDZATION CONSTR CO LTD

A hydraulic support intelligent installation machine and its use method

The invention relates to an intelligent installation machine for a hydraulic support and an application method of the intelligent installation machine. The intelligent installation machine comprises an installation implementation system, a hinge pin hole locating assembly and a control system. The control system is electrically connected with the installation implementation system and the hinge pin hole locating assembly and used for intelligently controlling operation of the installation implementation system and the hinge pin hole locating assembly. According to the intelligent installation machine for the hydraulic support and the application method of the intelligent installation machine, coordinate information of hinge-joint holes in a hydraulic support base, a front connection rod and a rear connection rod is obtained through a laser lamp module in the hinge pin hole locating assembly; centering of hinge-joint holes is completed by completing movement of the front connection rod and the rear connection rod in a preset coordinate system through the control system; and after hinge pins at specific positions are grabbed through mechanical arms in the installation implementation system, the hinge pins are inserted into the hinge-joint holes, so that installation of the front connection rod, the rear connection rod and the base as well as installation of a top beam and a shield beam are completed. By means of the intelligent installation machine, traditional hydraulic support installation modes are changed; manpower and material resources are saved; intelligentized control is achieved; installation precision is high; and installation efficiency is improved.

Owner:SHANDONG UNIV OF SCI & TECH

Slider insert to control positional degree of gear mounting shaft

InactiveCN108555850AError-free installationImprove installation accuracyWork holdersWork benchesLaser transmitterGear wheel

The invention discloses a slider insert to control positional degree of a gear mounting shaft. The slider insert comprises a first fixing plate, a second fixing plate and an I-shaped slider; the firstfixing plate and the second fixing plate are perpendicularly arranged on the two sides of the top of the base respectively; the first fixing plate is horizontally provided with a gear holding channelin penetrating manner. The slider insert has the advantages that the horizontal height of the mounting shaft can be adjusted under telescoping action of a first telescoping rod, the vertical and horizontal position of the mounting shaft can be adjusted until the axis of the mounting shaft and an emitting red point of a laser emitter overlap under sliding action of a sliding sleeve on a limiting sliding rod, the mounting shaft is finally inserted into a gear under the horizontal sliding action of the I-shaped slider on a transverse plate, and mounting is precisely finished; the cooperation ofthe structures enables the axis of the mounting shaft and the center of the gear to be set in a same horizontal line such that the mounting shaft is mounted accurately with no error, and mounting efficiency is effectively improved.

Owner:CHENGDU YANXINGGUO TECH CO LTD

Installation construction method for bridge rigid hinge

InactiveCN103410094BSimple and fast operationReduce construction difficultyBridge erection/assemblyEngineeringBox girder

The invention discloses an installation method for a bridge rigid hinge and belongs to the technical field of bridge construction. The installation construction method for the bridge rigid hinge includes the steps that firstly, combination and assembling are performed in advance, a running-in test is performed, and accessories are installed; secondly, preparation is performed before hoisting; thirdly, a small box girder is temporarily locked into a J2 kind end beam; fourthly, synchronous hoisting is in place, entering a preset closure gap position is achieved, and adjustment is performed properly; fifthly, a temporary locking device is installed, temporary locking is relieved, the small box girder is moved close to a J1 beam segment fixing end, and a bolt is used for connection; sixthly, a closure seam of a J2 beam segment and a J3 beam segment is forcefully adjusted, temporary fixing accessories are temporarily fixedly combined and installed, construction site connection of the J2 beam segment and the J3 beam segment is finished, and a beam is installed on the J2 beam segment; seventhly, remained facilities are installed, temporary facilities are detached, and rigid hinge supports on the periphery of the small box girder are adjusted. According to the installation method for the bridge rigid hinge, the rigid hinge and parts of the rigid hinge can be accurately and inerrably installed, the rigid hinge and a bridge are stable in structure, and safety and reliability in using the rigid hinge and the bridge are ensured.

Owner:CCCC HIGHWAY CONSULTANTS

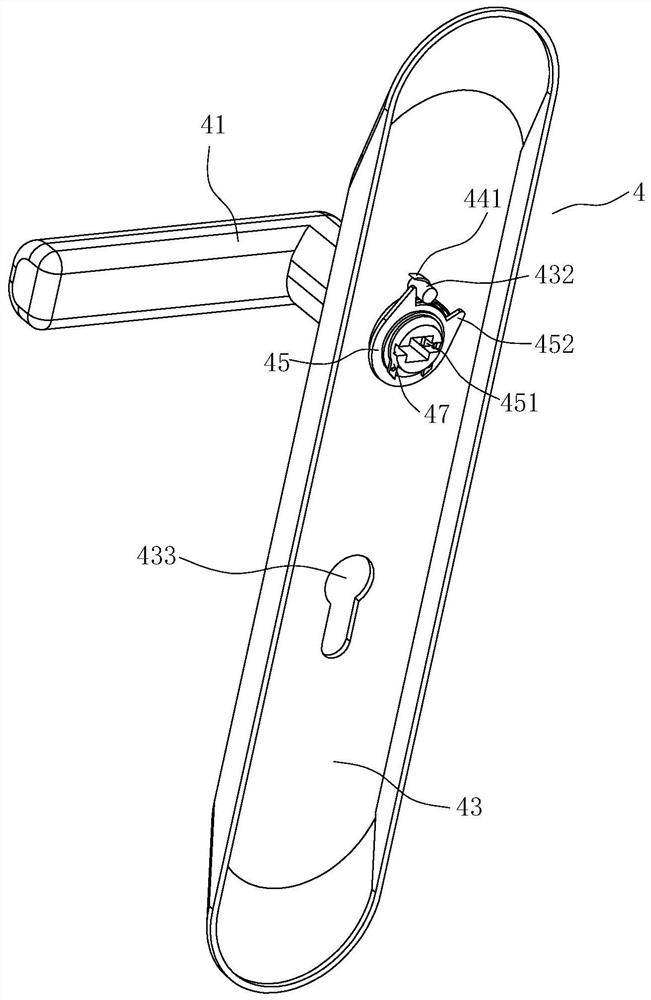

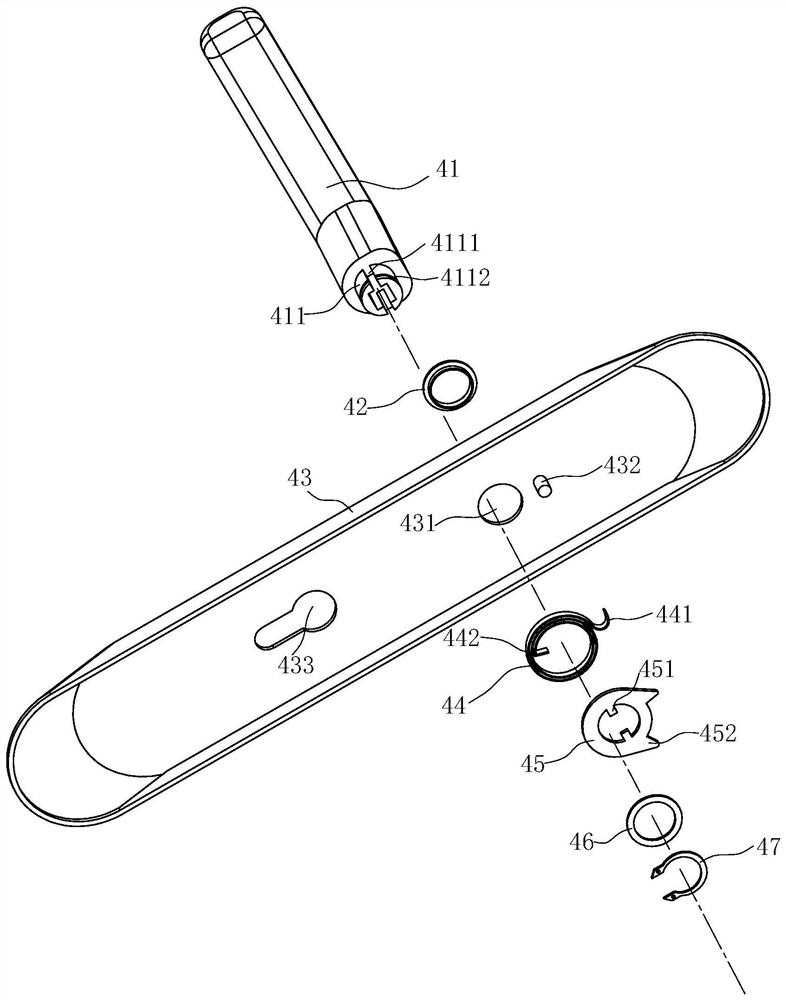

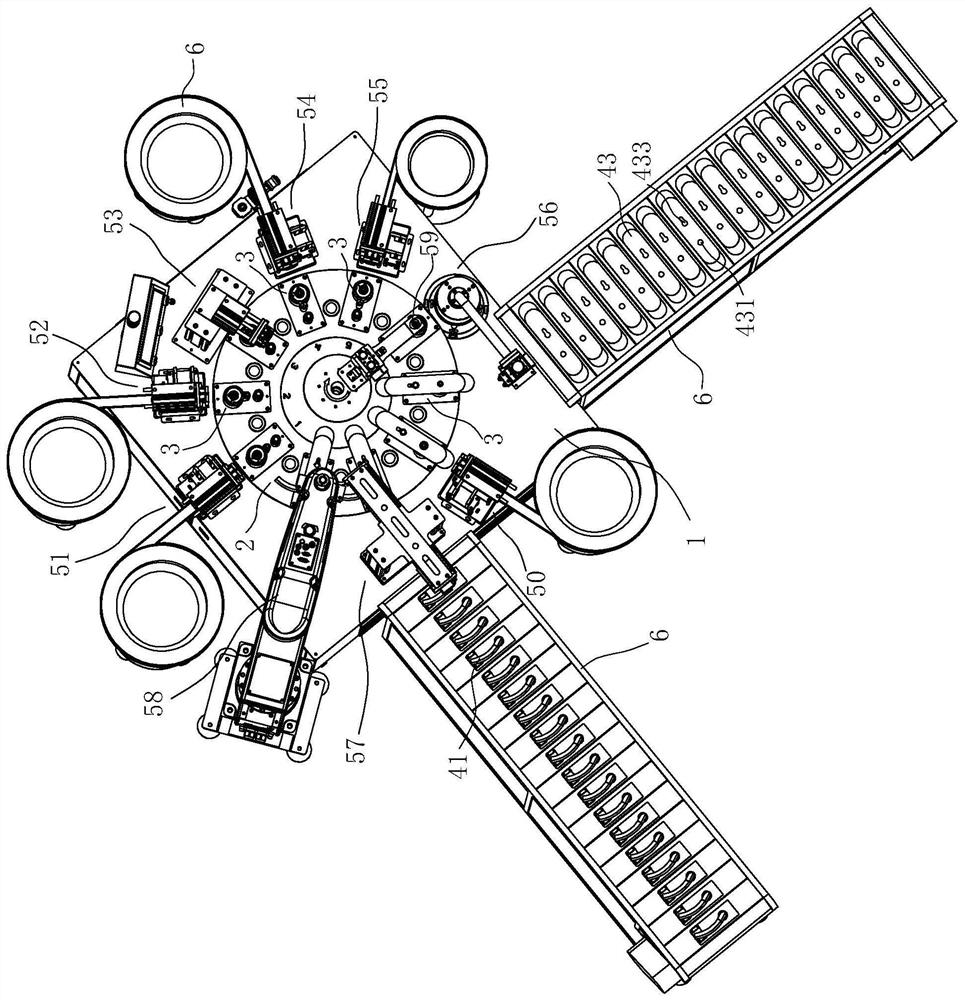

An automatic assembly method for a handle lock

ActiveCN109176005BEasy to assembleAssembly is easily achievedAssembly machinesControl engineeringMotion control

The invention relates to an automatic assembly method of a handle lock. The handle lock is assembled through handle lock automatic assembly equipment. The handle lock automatic assembly equipment comprises a controller and an assembly platform; a rotary plate is arranged on the assembly platform; a plurality of working mechanisms are sequentially arranged at the positions, close to the edge, of the rotary plate in the rotating direction of the rotary plate; a feeding mechanism is arranged on each working mechanism correspondingly; and the multiple working mechanisms and the rotary plate collect working data and feed the working data back to the controller, and complete action control is conducted through the controller. At present, manual assembly is adopted, and no relevant automatic assembly equipment exists on the market; handle lock automatic assembly equipment developed by the project fills the gap in the market; and the automation degree is high. Through the automatic assembly method, the whole handle lock is conveniently assembled, the assembly efficiency is greatly improved, due to the fact that the whole process is automatically controlled and operated through a master control program, the influence of human factors are reduced, and the profits of enterprises are increased

Owner:浙江理工大学瓯海研究院有限公司 +1

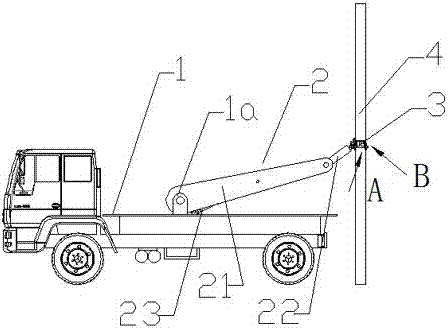

A vehicle-mounted telegraph pole information board semi-automatic installation device

InactiveCN105619059BImprove installation efficiencyAvoiding the Hazards of Falling from HeightsMetal working apparatusCranesElectricitySemi automatic

The invention relates to a vehicle-mounted semi-automatic installation device for telegraph pole information signs. The vehicle-mounted semi-automatic installation device comprises a vehicle chassis, a lifting device and a semi-automatic installation device body; by adopting the semi-automatic installation device body for installing the telegraph pole information signs, installation saves the time and the labor, the installation process is simple, the installation efficiency of the telegraph pole information signs is greatly improved, workers do not need to climb for installation in the installation process of the telegraph pole information signs, and the risk that the workers fall from the high altitude is avoided in the installation process; in addition, the telegraph pole information signs can be firmly installed on telegraph poles, and the potential safety hazards caused by falling off of the telegraph pole information signs are avoided.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO SHOUGUANG POWER SUPPLY CO +2

Spring seat mounts for shock absorbers

InactiveCN102562913BAvoid leaningPrevent axial movementSpringsSprings/dampers design characteristicsEngineeringMechanical engineering

The arrangement (10) has a spacer element (60) with a middle section (62) axially arranged between outer sections (61c, 61d) of the spacer element. The middle section partially contacts a damper tube (40) with its radial inner surface (62a). A fuse element (70) encloses the damper tube, and is radially arranged between the damper tube and a radial inner surface (61a) of one of the outer sections of the spacer element. The arrangement is securely arranged against axial loading, and the spacer element is designed as sheet shaped-metal.

Owner:ZF FRIEDRICHSHAFEN AG

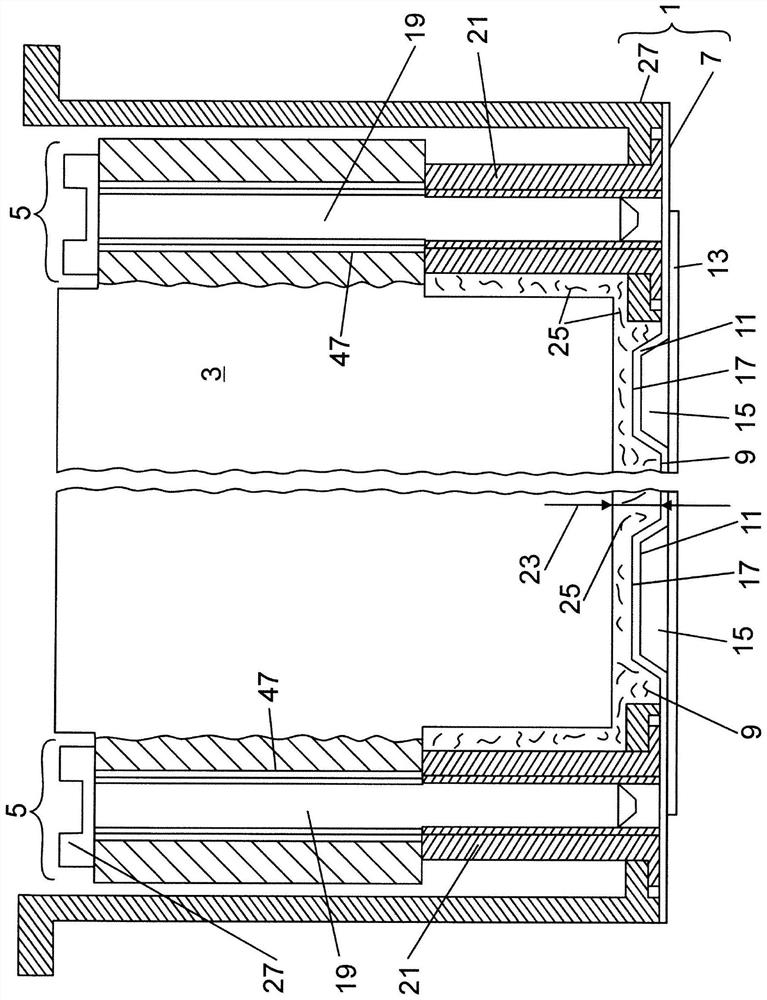

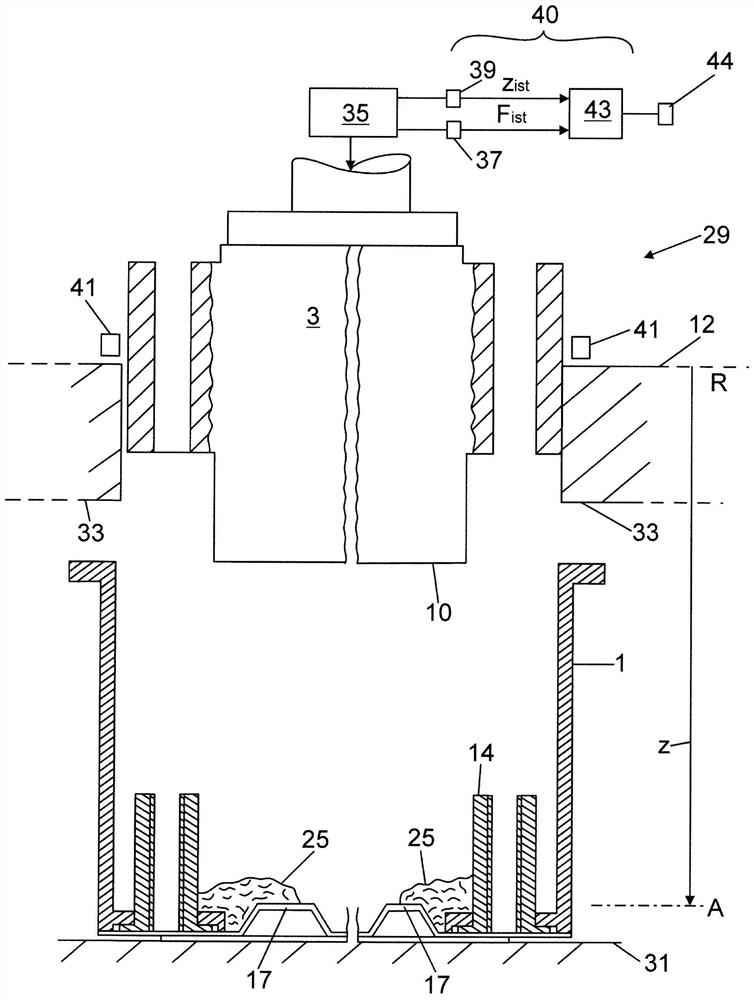

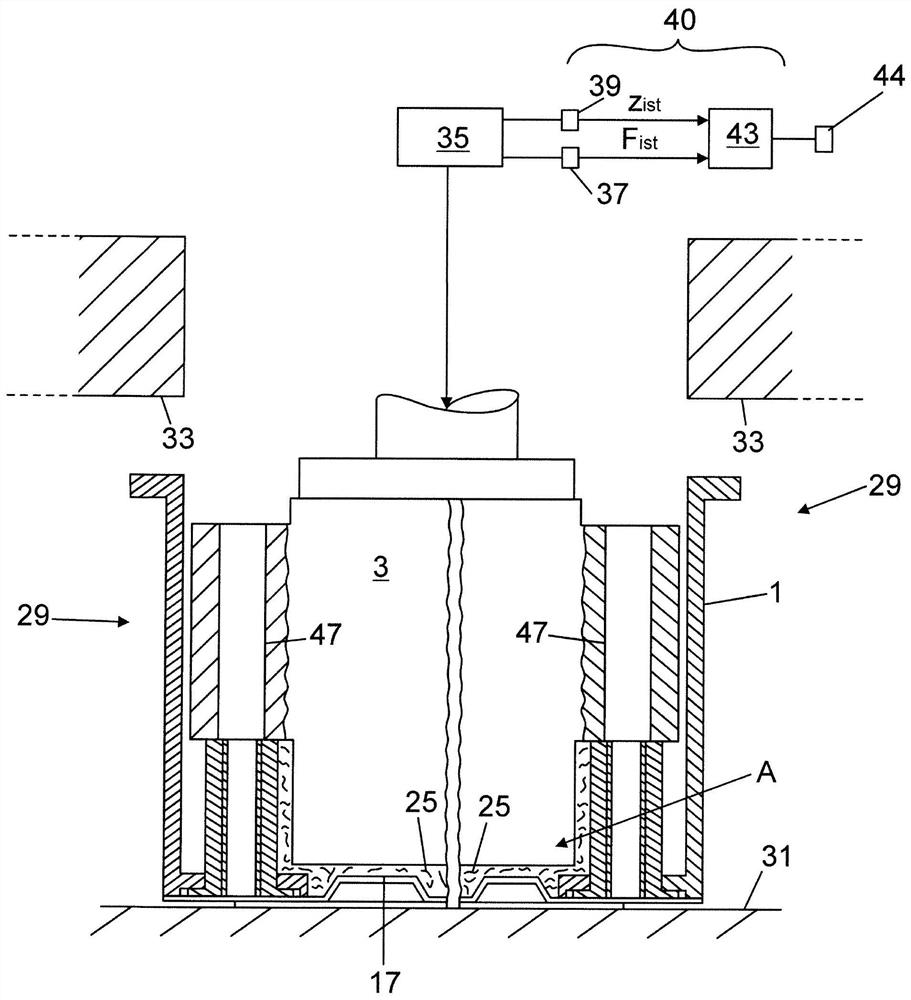

Method for producing a vehicle traction battery

ActiveCN112272888AError-free installationEasy to operateProgramme-controlled manipulatorFinal product manufacturePower batteryRobot control

The invention relates to a method for fitting at least one battery module (3) into a battery housing (1) of a traction battery of a vehicle, in which, in a delivery process step, the battery module (3) is introduced into the battery housing (1) in a robot-controlled manner via a delivery path and by means of a delivery force (F), and until reaching an assembled position (A) in which the battery module (3) is in the correct position on a contact contour (17) of a housing base (7) of the battery housing (1), and in a securing process step, the correctly positioned battery module (3) is secured in the battery housing (1). According to the invention, the delivery process step is monitored by a monitoring unit (40), which detects an actual delivery path (zist) and an actual delivery force (Fist) during the delivery process step, and evaluates whether the delivery process step is being carried out error-free or not on this basis.

Owner:AUDI AG

Fixing structure used for self-moving nut

Owner:BEIJING NORTH VEHICLE GROUP CORP

A working method for intelligent installation of heavy hydraulic supports

ActiveCN106640156BMeet fast and efficient work requirementsNo manipulationProps/chocksElectricityControl system

The invention relates to a working method for installing a heavy hydraulic support intelligently. The working method is based on intelligent installing equipment. The intelligent installing equipment comprises an installing execution system, a pin shaft hole positioning assembly and a control system; the control system is electrically connected with the installing execution system and the pin shaft hole positioning assembly to intelligently control operation of the installing execution system and pin shaft hole positioning assembly. According to the working method for installing the heavy hydraulic support intelligently, the coordinate information of hinge holes in a hydraulic support base, a front connecting rod and a back connecting rod are obtained through a laser lamp assembly in the pin shaft hole positioning assembly, centering of the hinge holes and moving of the front connecting rod and the back connecting rod in a preset coordinate system is completed, a mechanical arm in the installing execution system is used for grabbing a pin shaft in an appointed position and then inserting the pin shaft into the hinge holes, and intelligent installation of the heavy hydraulic support is completed. The working method replaces a traditional installing method of the hydraulic support, manpower and material resources are saved, intelligent control is achieved, meanwhile, installing precision is high, and installing efficiency can be improved.

Owner:SHANDONG UNIV OF SCI & TECH

Intelligent installation equipment for large-mining-height hydraulic support and application of intelligent installation equipment

ActiveCN106401633ARealize mechanized workSave human effortMine roof supportsElectricityControl system

The invention relates to intelligent installation equipment for a large-mining-height hydraulic support and application of the intelligent installation equipment. The intelligent installation equipment comprises an installation implementation system, a hinge pin hole locating assembly and a control system. The control system is electrically connected with the installation implementation system and the hinge pin hole locating assembly and used for intelligently controlling operation of the installation implementation system and the hinge pin hole locating assembly. According to the intelligent installation equipment for the large-mining-height hydraulic support and application of the intelligent installation equipment, coordinate information of hinge-joint holes in a hydraulic support base, a front connection rod and a rear connection rod is obtained through a laser lamp module in the hinge pin hole locating assembly; centering of hinge-joint holes is completed by completing movement of the front connection rod and the rear connection rod in a preset coordinate system through the control system; and after hinge pins at specific positions are grabbed through mechanical arms in the installation implementation system, the hinge pins are inserted into the hinge-joint holes, so that installation of the front connection rod, the rear connection rod and the base as well as installation of a top beam and a shield beam are completed. By means of the intelligent installation equipment for the large-mining-height hydraulic support and application of the intelligent installation equipment, traditional hydraulic support installation modes are changed; manpower and material resources are saved; intelligentized control is achieved; installation precision is high; and installation efficiency is improved.

Owner:SHANDONG UNIV OF SCI & TECH

Fixed connection tooling and method for camshaft and camshaft sprocket

ActiveCN105195978BSimple structureSolve the problem of precise axial positionMetal working apparatusSprocketEngineering

The invention discloses a tooling used for fixedly connecting a camshaft with a camshaft sprocket. The tooling comprises a upper lifting appliance, a lower clamp hoop and a camshaft sprocket bracket, wherein the upper lifting appliance comprises a lifting bolt, an upper hanger plate, an upper clamp hoop and a plurality of connection screws; the upper clamp hoop is arranged below the upper hanger plate; the upper hanger plate and the upper clamp hoop are fixedly connected into a whole through the connection screws. The connection method of the tooling is that the upper clamp hoop and the lower clamp hoop are radially clamped and fixed on the vertical positioning benchmarks at the upper and lower ends of the camshaft respectively, and then the camshaft sprocket is horizontally supported by the camshaft sprocket bracket after being heated. The camshaft is lifted up vertically, the perpendicularity of the camshaft and the levelness of the camshaft sprocket are adjusted respectively, and finally, the lower end of the camshaft enters a central hole in the camshaft sprocket to fulfill assembling. The tooling and the method have the advantages that the perpendicularity tolerance of the camshaft is controlled; the axial positioning of the camshaft sprocket is accurate; the mounting accuracy and the mounting efficiency of a diesel engine are improved; the mounting cost is reduced.

Owner:CSSC MARINE POWER

An intelligent installation device for large mining height hydraulic support and its application

ActiveCN106401633BRealize mechanized workSave human effortMine roof supportsElectricityControl system

Owner:SHANDONG UNIV OF SCI & TECH

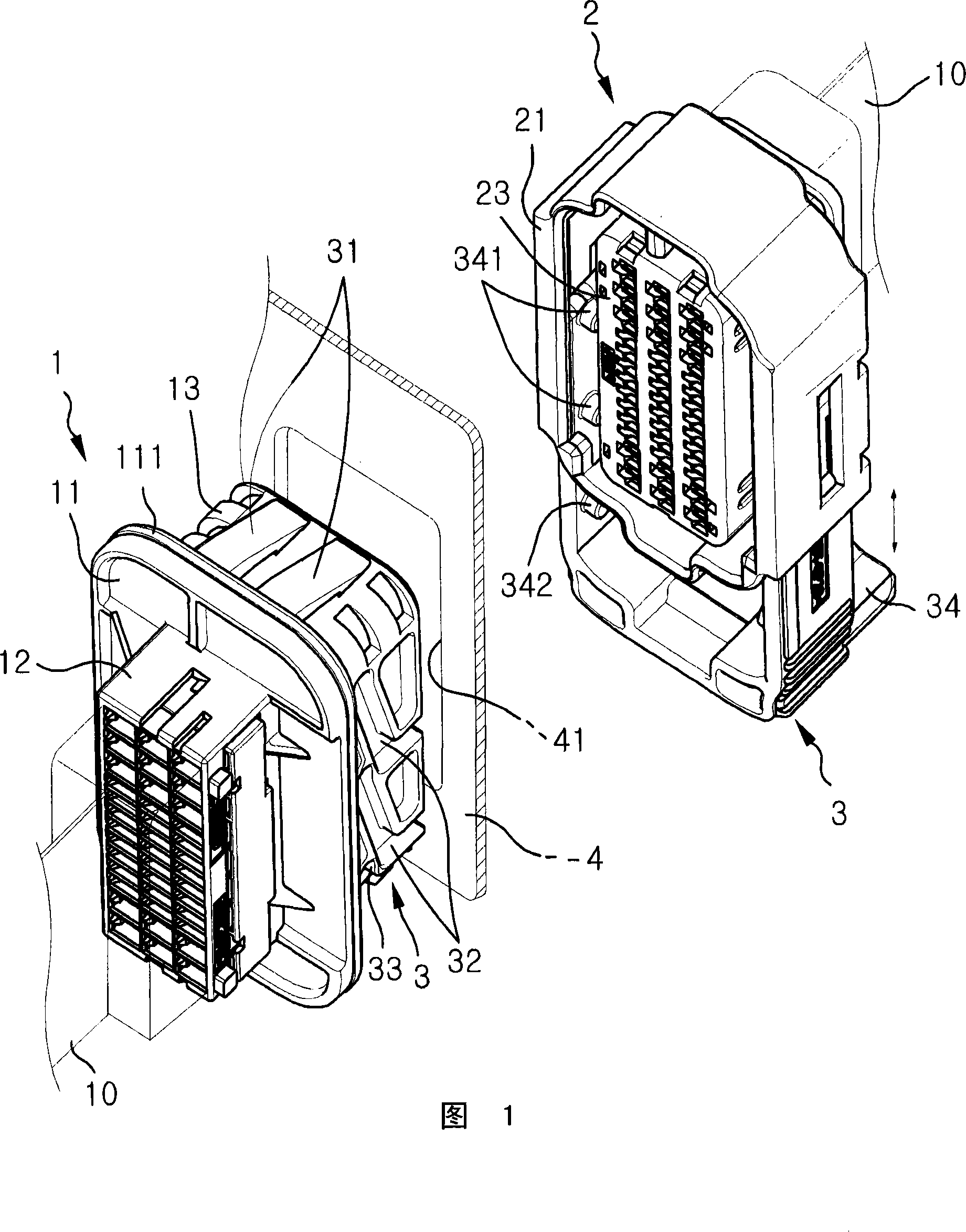

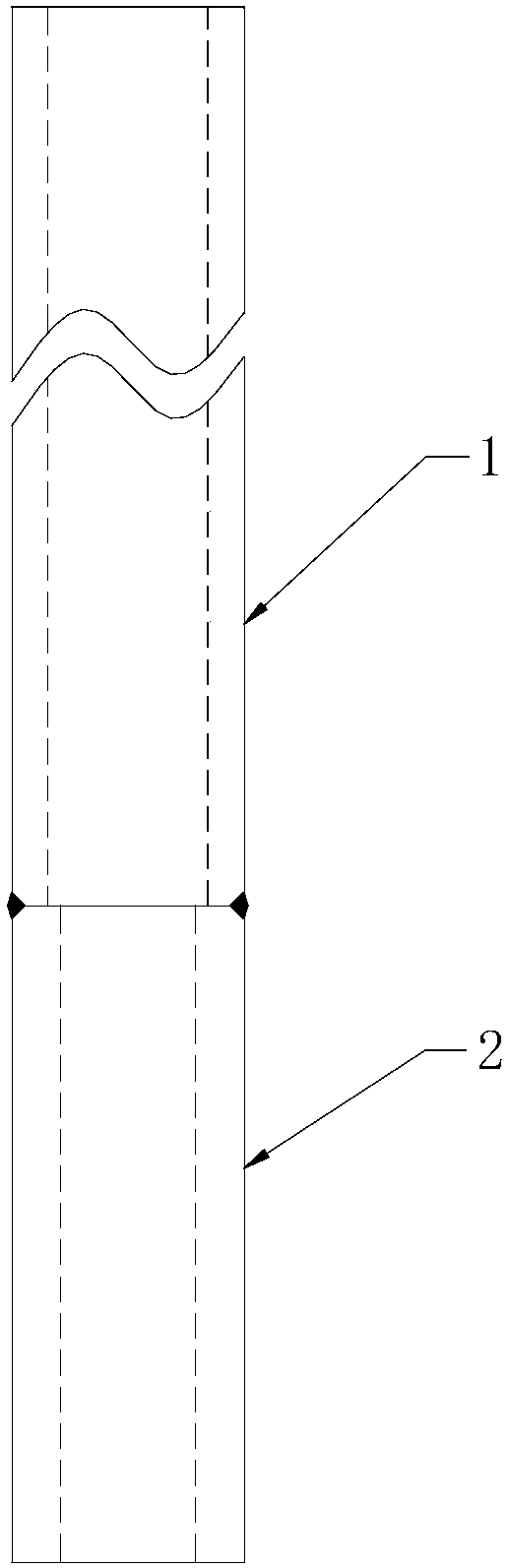

Cable connector for vehicle door

ActiveCN101286595BEasy to assembleError-free installationVehicle connectorsCoupling device detailsCouplingEngineering

A cable connector (1, 2) for a vehicle door which enables a worker to simply assemble a female connector (2) thereof and a male connector (1) thereof without using any coupling means such as a bolt and to install the male connector (1) to a panel (4) of a vehicle body without any mistake. The male connector (1) includes a flange (11) provided between a contact terminal (12) and a fitting part (13), and a waterproof seal (111). The female connector (2) is engaged with the fitting part (13), and includes a complementary contact terminal (23). A plurality of elastic members are formed on an outer surface of the fitting part (13), and include latching recesses in which an edge of a connecter mounting hole (41) of a panel (4) of a vehicle body is fitted. A guide connecting device means includes cam recesses (32) and locking recesses (33) formed on the outer surface of the fitting part (13), and a slide lever (34) slidably provided in the female connector (2). The slide lever (34) has guide protrusions (341) moveable along the cam recesses (32) and locking protrusions (342) lockable in the locking recesses (33).

Owner:TYCO ELECTRONICS AMP KOREA

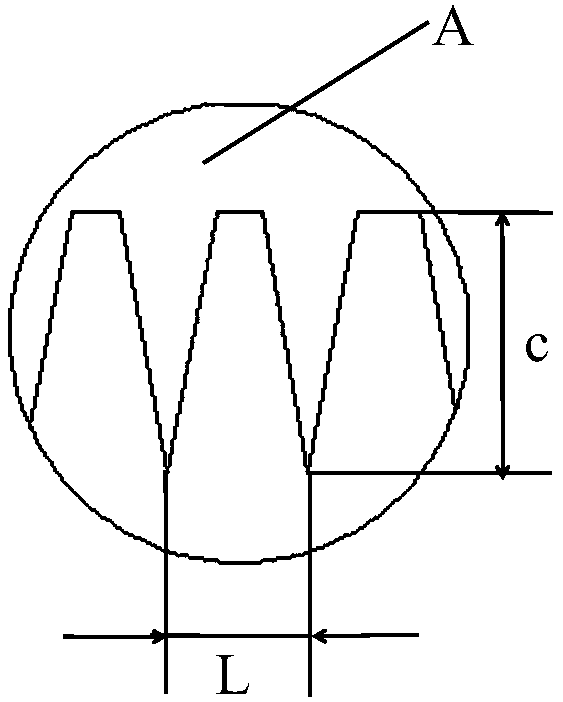

Method for installing rail steel backing plate by transplanting technique

ActiveCN107869095AError-free installationPrecise drillingRail fastenersRailway track constructionStructural engineeringMechanical engineering

The invention discloses a method for installing a rail steel backing plate by a transplanting technique. The method comprises the following steps of a, checking the verticality of an embedded bolt, and aligning; b, erecting a centerline of a rail groove; c, manufacturing a transplanting plate; d, putting the transplanting plate at the top part of the embedded bolt, adjusting the centerline of thetransplanting plate, and aligning with the centerline of the rail groove along the vertical direction; e, marking the center point of the embedded bolt at the front surface of the transplanting plate;f, transferring the transplanting plate with the marked centerline of the embedded bolt to a rail steel backing plate, mutually overlapping, aligning and fixing; g, drilling a hole in the marked center point on the transplanting plate, and forming drilling trace on the rail steel backing plate; h, detaching the transplanting plate, and drilling a hole in the rail steel backing plate with the drilling trace; I, installing the drilled rail steel backing plate to the embedded bolt, and repeating the steps, until the installation of all rail steel backing plates of the whole rail is completed. The method has the advantages that the steel backing plates can be accurately and correctly installed to the embedded bolts, and the working efficiency is obviously improved.

Owner:GANGSHENG BRANCH OF ZHANGJIAGANG PORT GRP

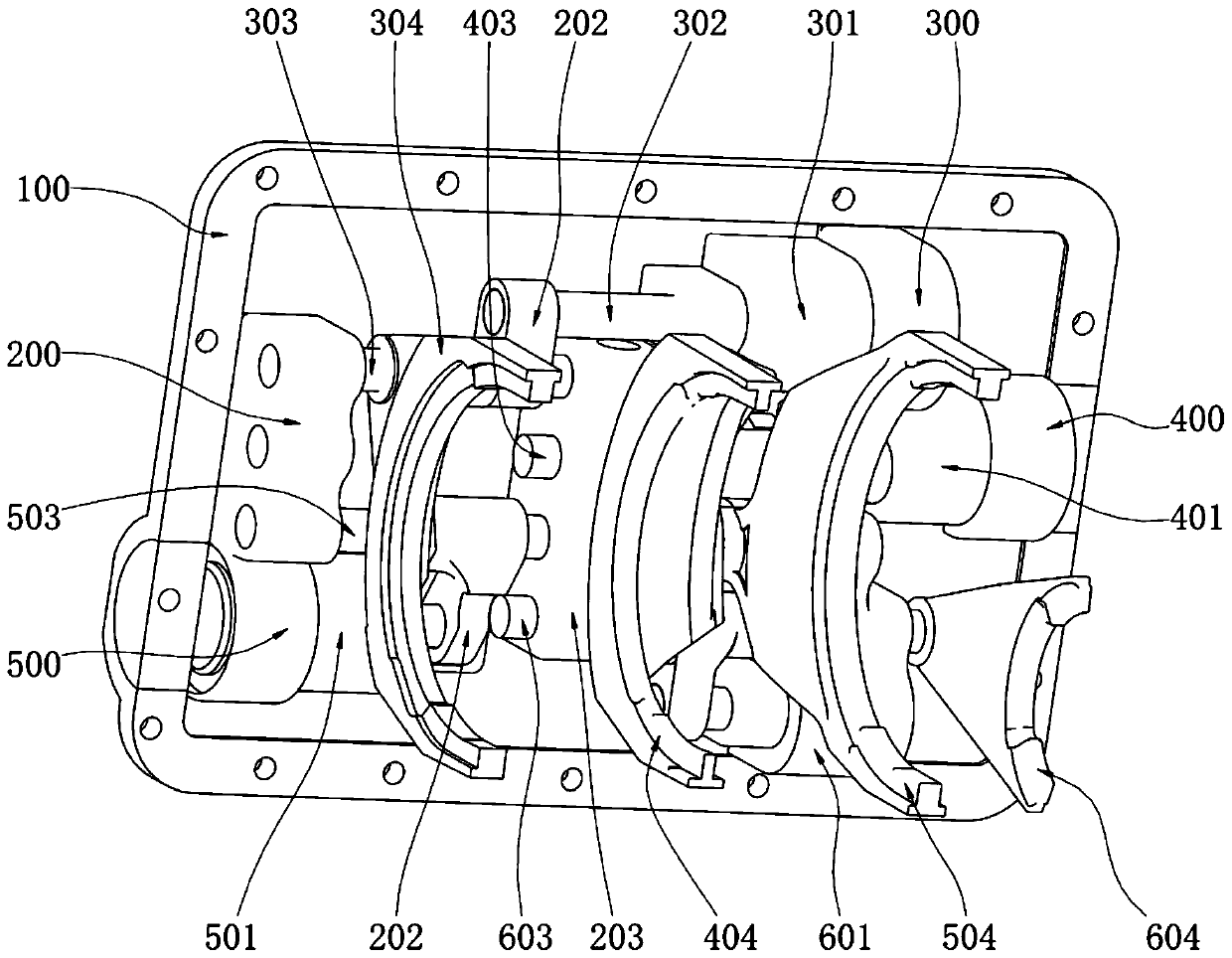

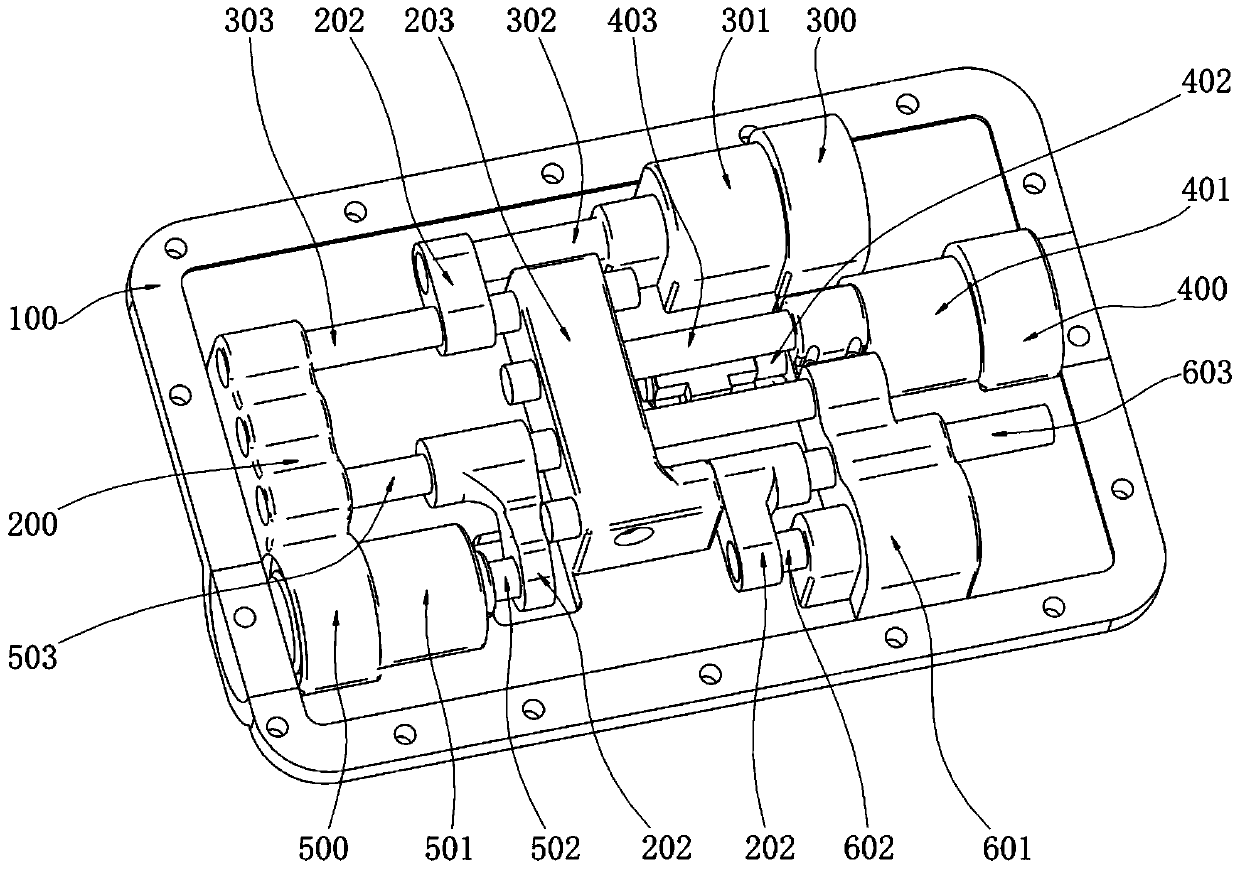

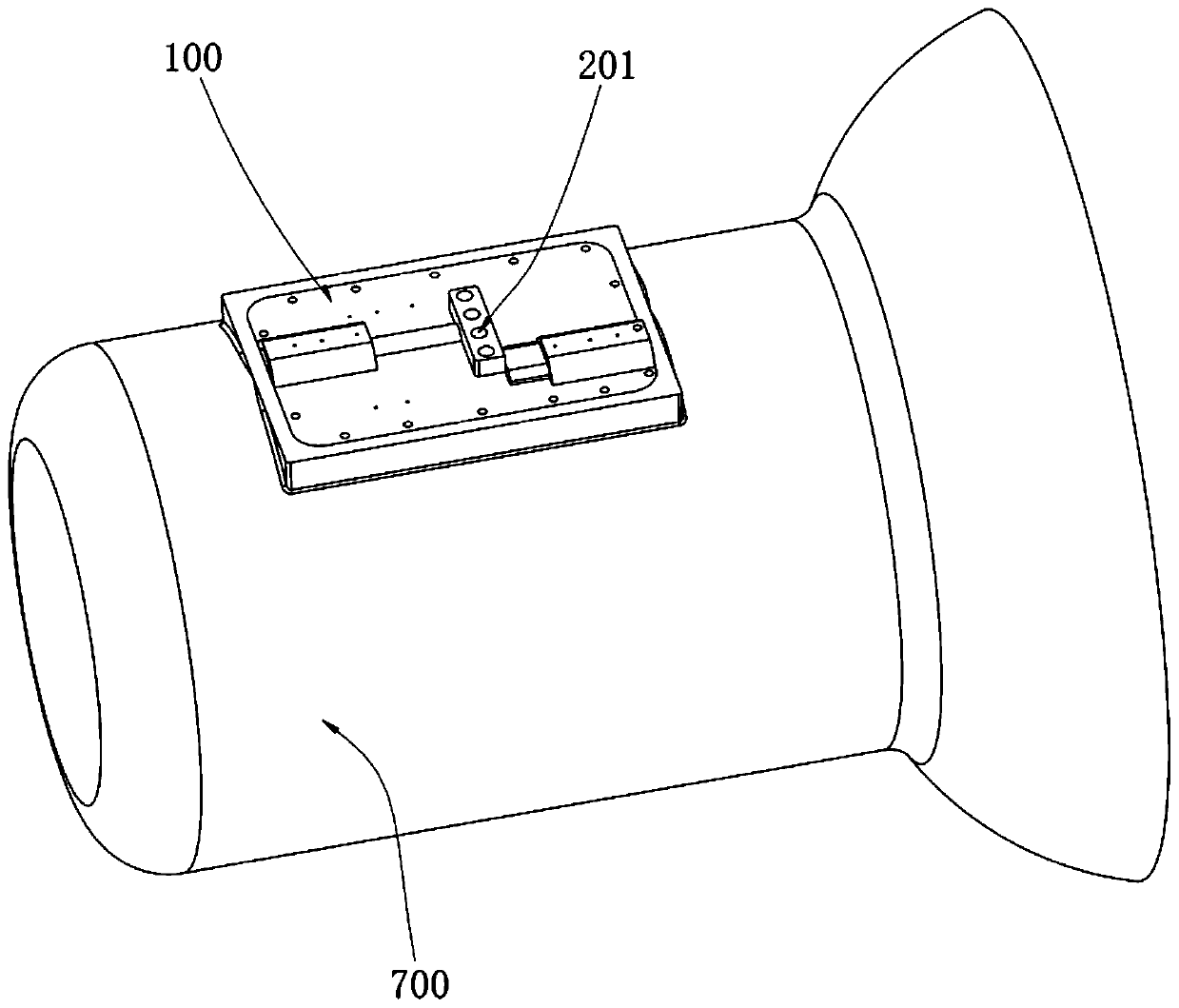

Novel gear-shifting speed-changing executing device and vehicle gearbox

InactiveCN110822079AGuaranteed accuracyAdvanced technologyControlled membersGearing controlAutomotive engineeringMechanical engineering

Owner:邢台威力汽车零部件有限公司

Shaft seal, in particular radial shaft seal, having at least one sealing element

PendingCN113090758APrevent creepReduce error rates and manufacturing costsEngine sealsChemistryPolytetrafluoroethylene

The invention relates to a shaft seal, in particular a radial shaft seal, having at least one sealing element (5, 5a) made of a polyfluorocarbon, preferably polytetrafluoroethylene. The sealing element (5, 5a) is provided with a sealing lip (4, 4a) which bears against the surface to be sealed under the action of a radial force. The sealing element (5, 5a) is supported by at least one elastomeric element which consists of a sealing ring (7, 7a).

Owner:KACO

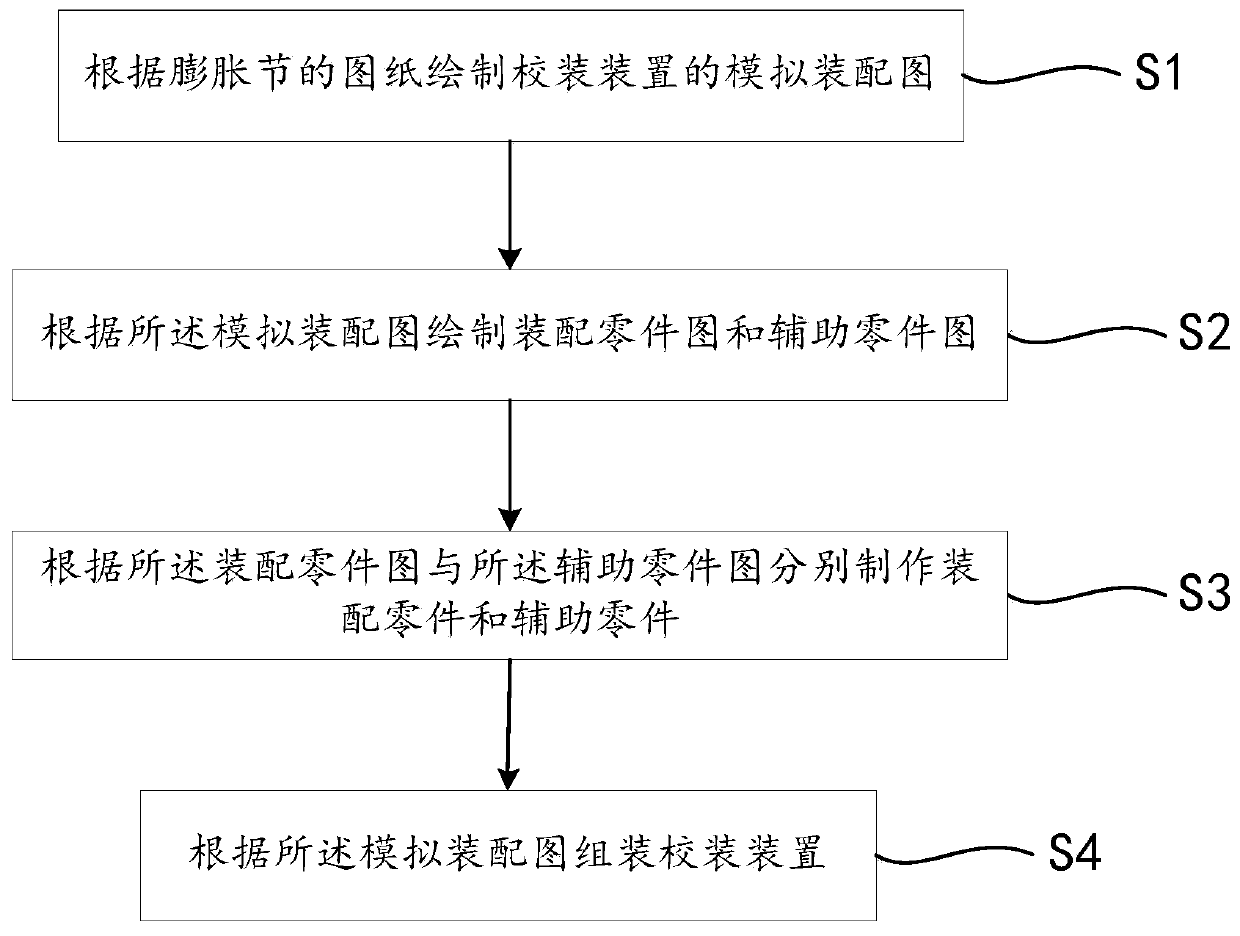

Calibration device, method of making calibration device, and method of using calibration device

ActiveCN107984187BError-free installationAvoid damageMetal working apparatusEngineeringExpansion joint

The invention discloses a manufacturing method of a correction device. The manufacturing method comprises the following steps that a simulated assembly drawing of the correction device is drawn according to a drawing of an expansion joint; an assembly part drawing and an auxiliary part drawing are drawn according to the simulated assembly drawing, wherein the assembly part drawing is the drawing of parts for forming the correction device, and the auxiliary part drawing is the drawing of temporary parts used when the correction device is assembled; according to the assembly part drawing and theauxiliary part drawing, assembly parts and auxiliary parts are manufactured respectively; and the correction device is assembled according to the simulated assembly drawing. The invention further discloses the correction device manufactured by the manufacturing method and a using method of the correction device. By means of the correction device, rainwater can be prevented from entering a dieselengine, a smoke exhaust pipe can be conveniently corrected, and the expansion joint can be prevented from being damaged.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com