Spring Base Fixing Device For Vibration Damper

A technology of fixing device and spring seat, applied in the direction of shock absorber, spring, spring/shock absorber design characteristics, etc., can solve problems such as failure to meet safety requirements, traffic accidents, loss of car control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

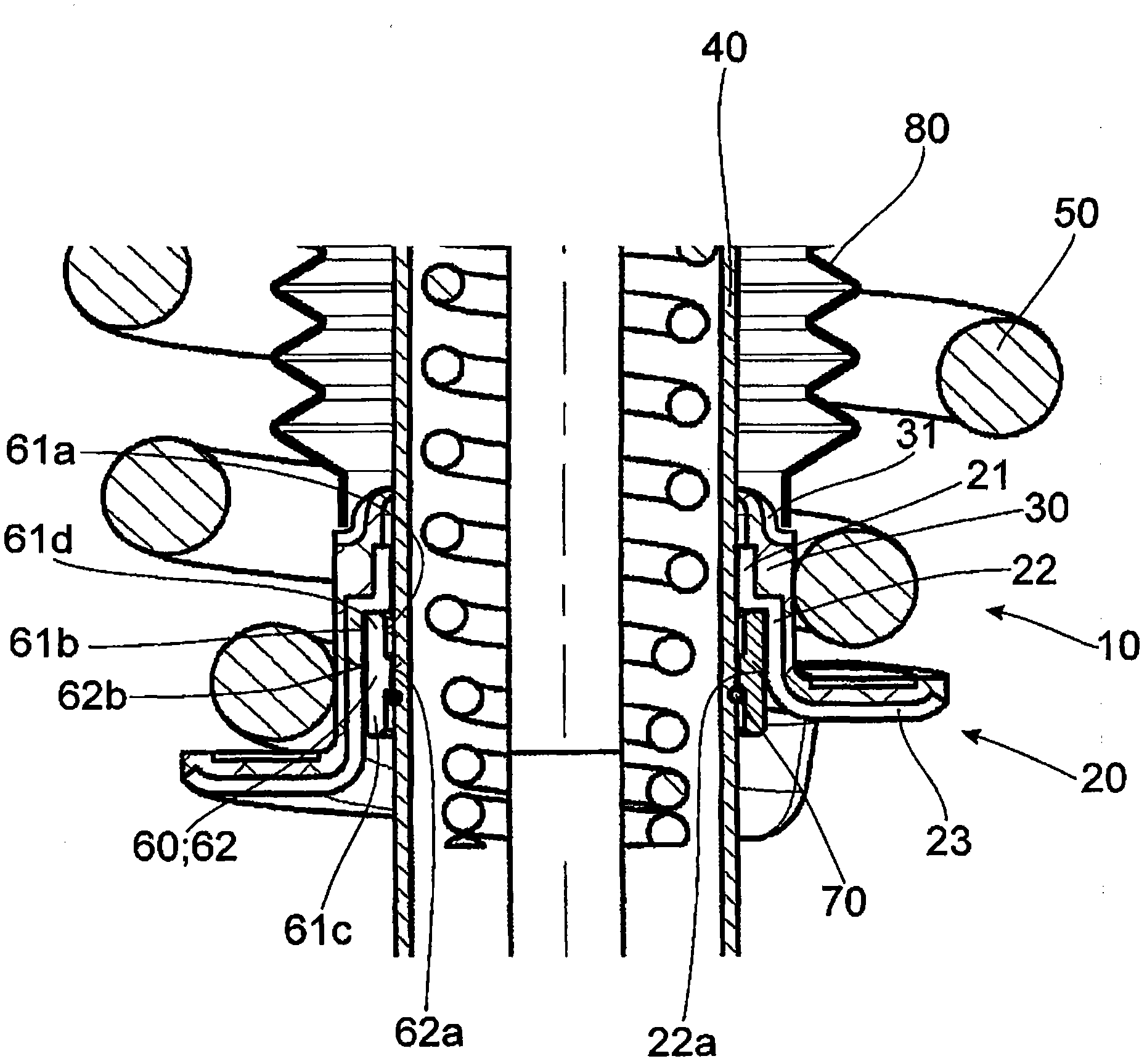

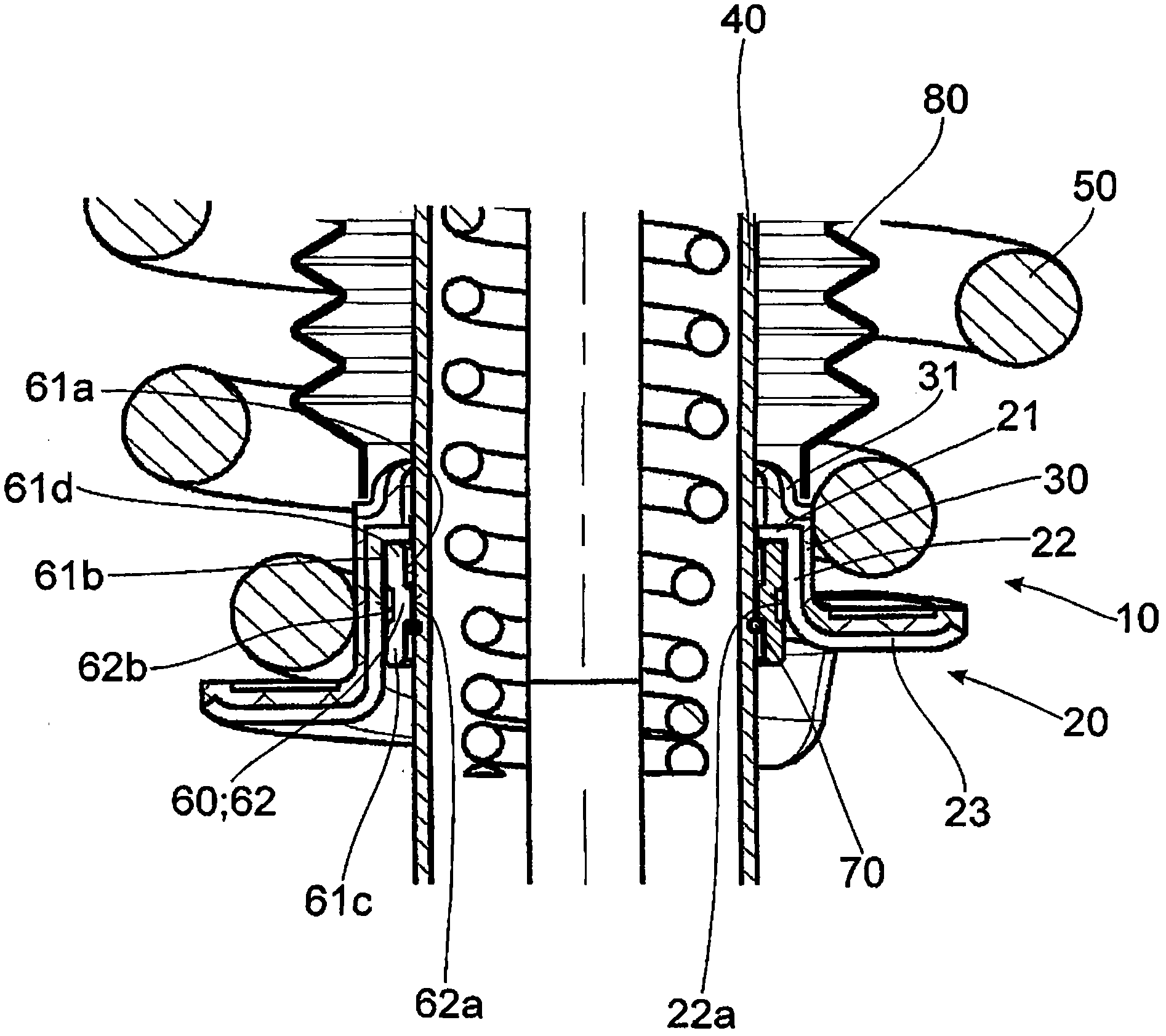

[0028] figure 1 A spring seat fastening device 10 for a shock absorber according to the invention is shown. The spring seat fastening device comprises a spring seat 20 which has a contact section 21 surrounding the damper tube 40 in the circumferential direction. Furthermore, the spring seat 20 has a receiving section 22 axially and radially spaced from the contact section 21 , and a supporting section 23 axially spaced from the contact section 21 . The support section 23 supports the suspension spring 50 in the axial direction by its substantially disk-shaped radial extension. In addition, in figure 1 as well as figure 2 FIG. 3 shows a one-piece spacer element 60 which likewise surrounds the damper tube 40 and is arranged inside the receiving section 22 of the spring seat 20 . figure 2 and Figure 5 The shown separating element 60 is embodied as a sheet metal profile.

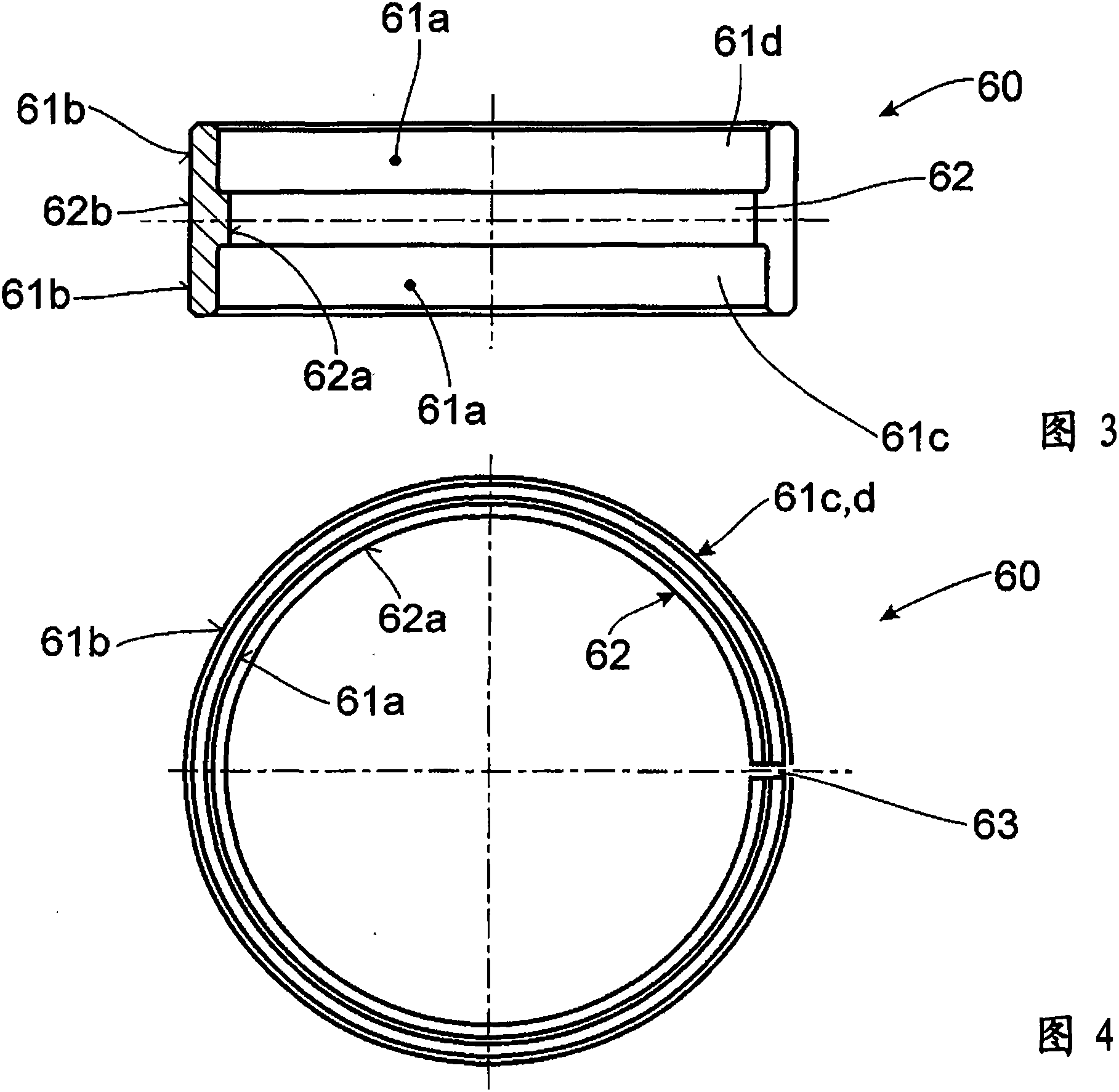

[0029] exist Figure 3 to Figure 5 As can be seen particularly clearly in FIG. 2 , the spacer elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com