Tooling and method used for fixedly connecting camshaft with camshaft sprocket

A technology for camshafts and sprockets, which is applied in the tooling field where the diesel engine camshaft and the red sleeve of the sprocket after heating are connected by interference fit, can solve the problems of sprocket scrapping, rework, heavy workload, etc., and achieve reliable clamping and method Ease of use and reduced installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

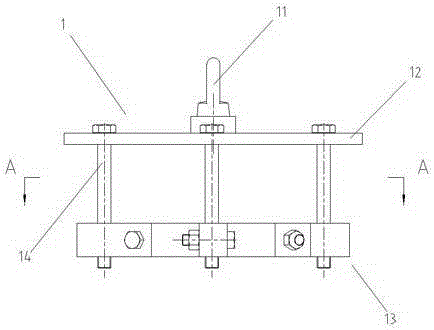

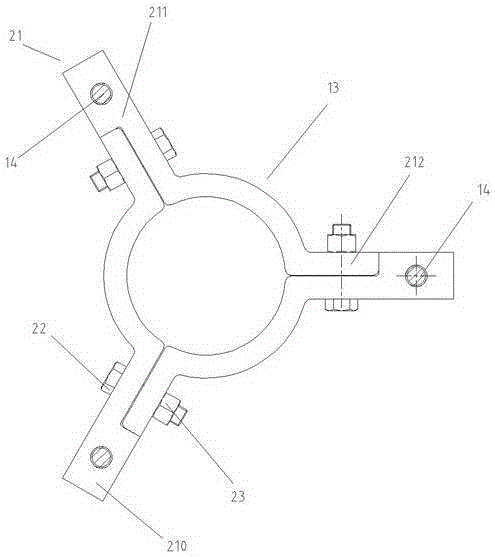

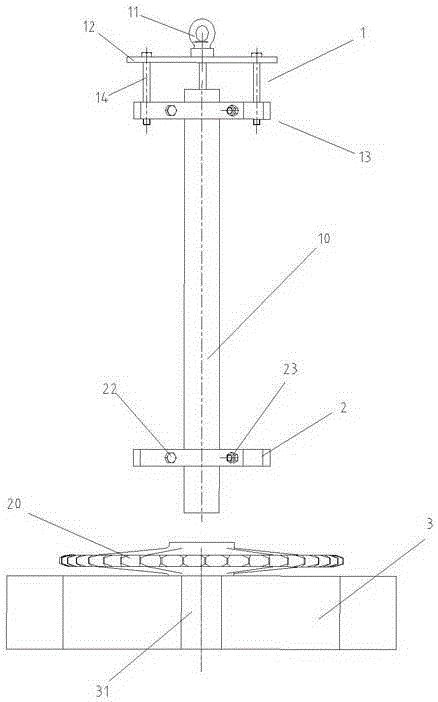

[0027] Such as figure 1 and figure 2 As shown, the present invention includes an upper sling 1, a lower clamp 2 and a camshaft sprocket bracket 3, and the upper sling 1 includes an eyebolt screw 11, an upper hanging plate 12, an upper clamp 13 and three connecting screws 14. The upper hanging plate 12 is circular, the screw at the lower end of the hanging ring screw 11 is screwed into and fixed in the center of the upper hanging plate 12, the upper clamp 13 is arranged on the lower side of the upper hanging plate 12, and the upper hanging plate 12 and the upper clamp 13 are connected by three vertically arranged The screws 14 are fixedly connected into one body. Such as image 3 and Figure 4 As shown, when the camshaft 10 is connected to the camshaft sprocket 20, the upper clamp 13 and the lower clamp 2 are radially clamped and fixed on the upper end of the camsha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com