A working method for intelligent installation of heavy hydraulic supports

A technology of hydraulic support and working method, which is applied to pillars/supports, earth-moving drilling, mining equipment, etc., can solve the problems of inability to meet the requirements of rapid operation, unreliable installation accuracy, cumbersome installation process, etc., and achieve the requirements of fast and efficient work, Save manpower and achieve the effect of intelligent installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

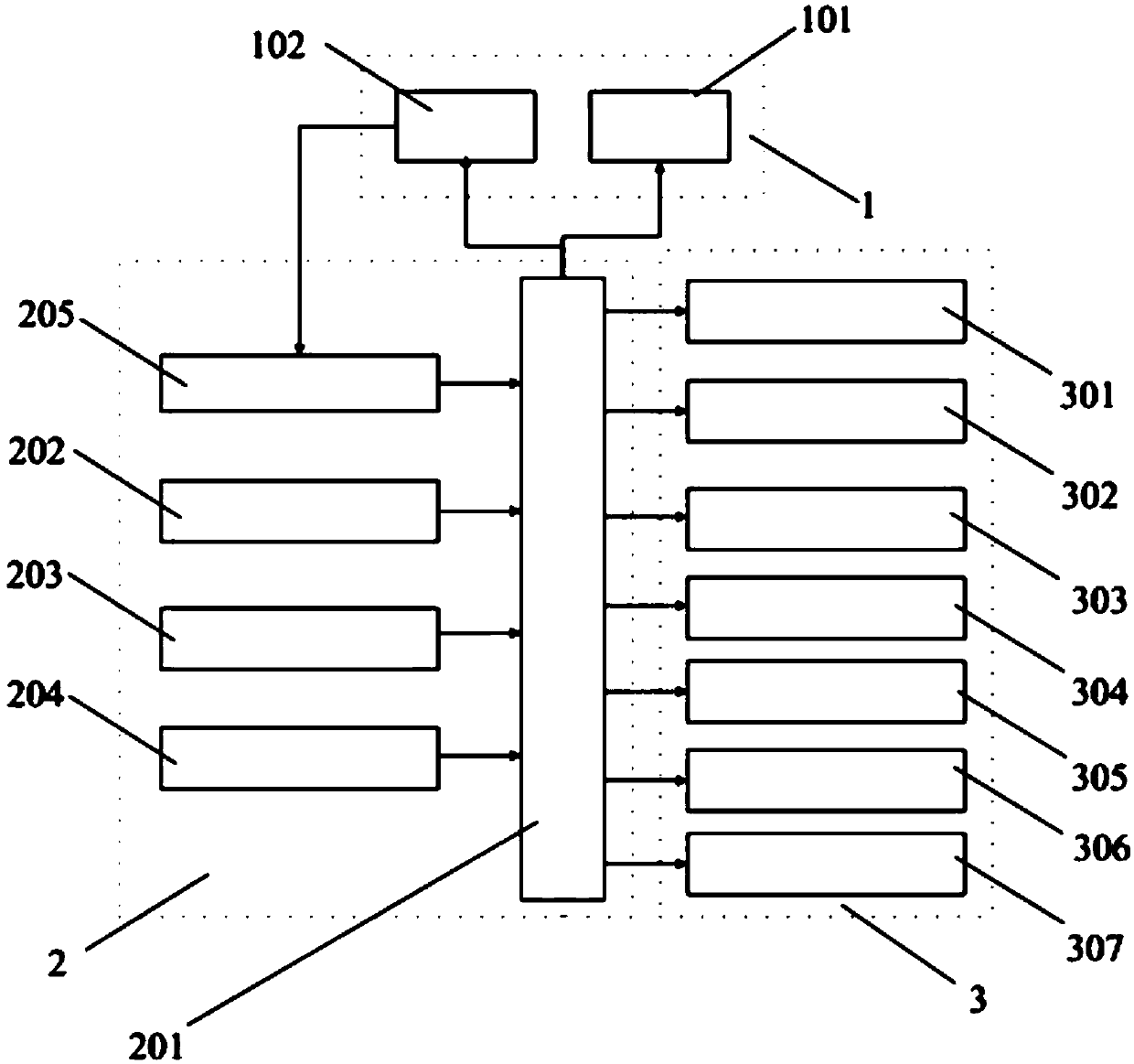

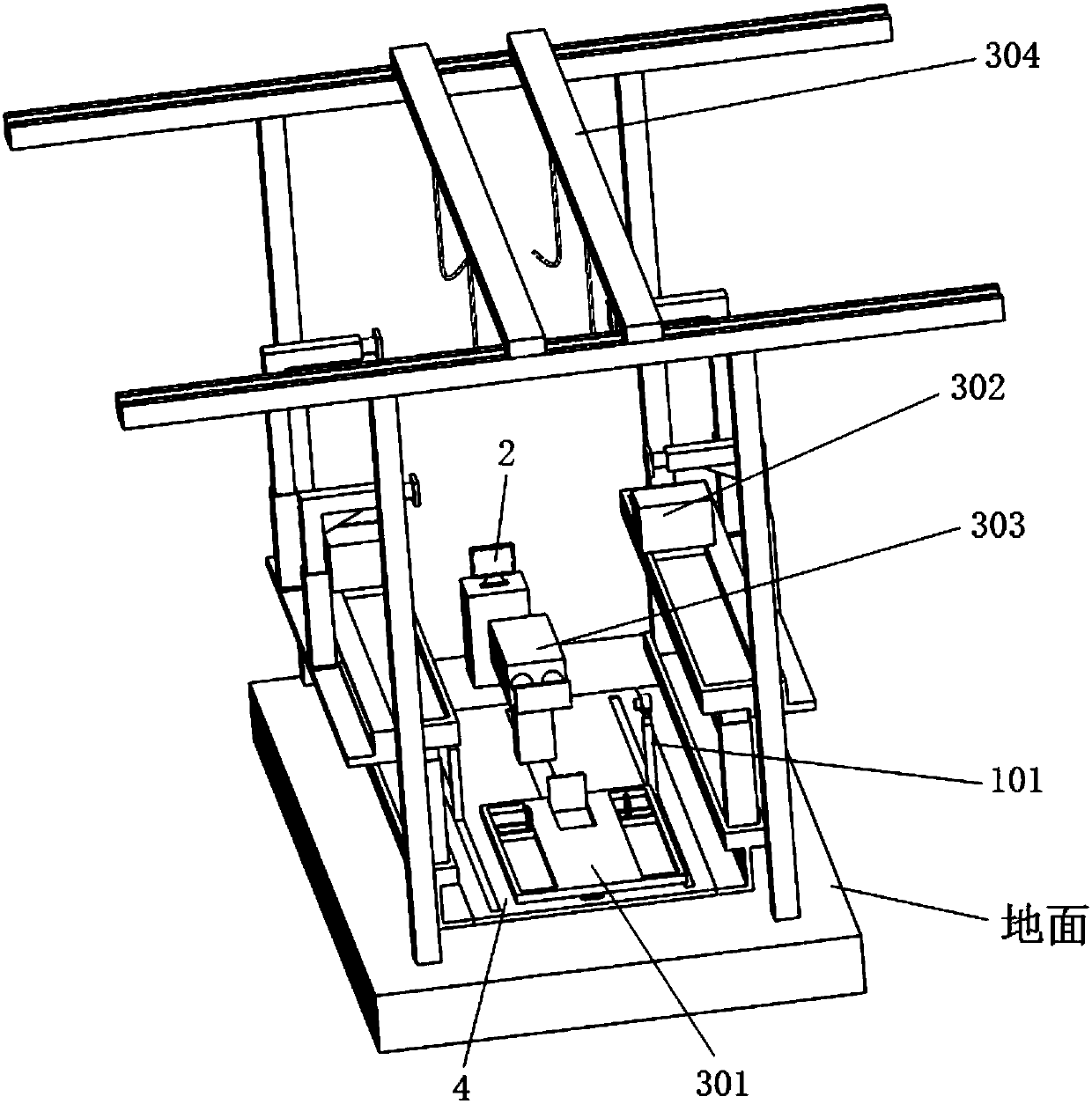

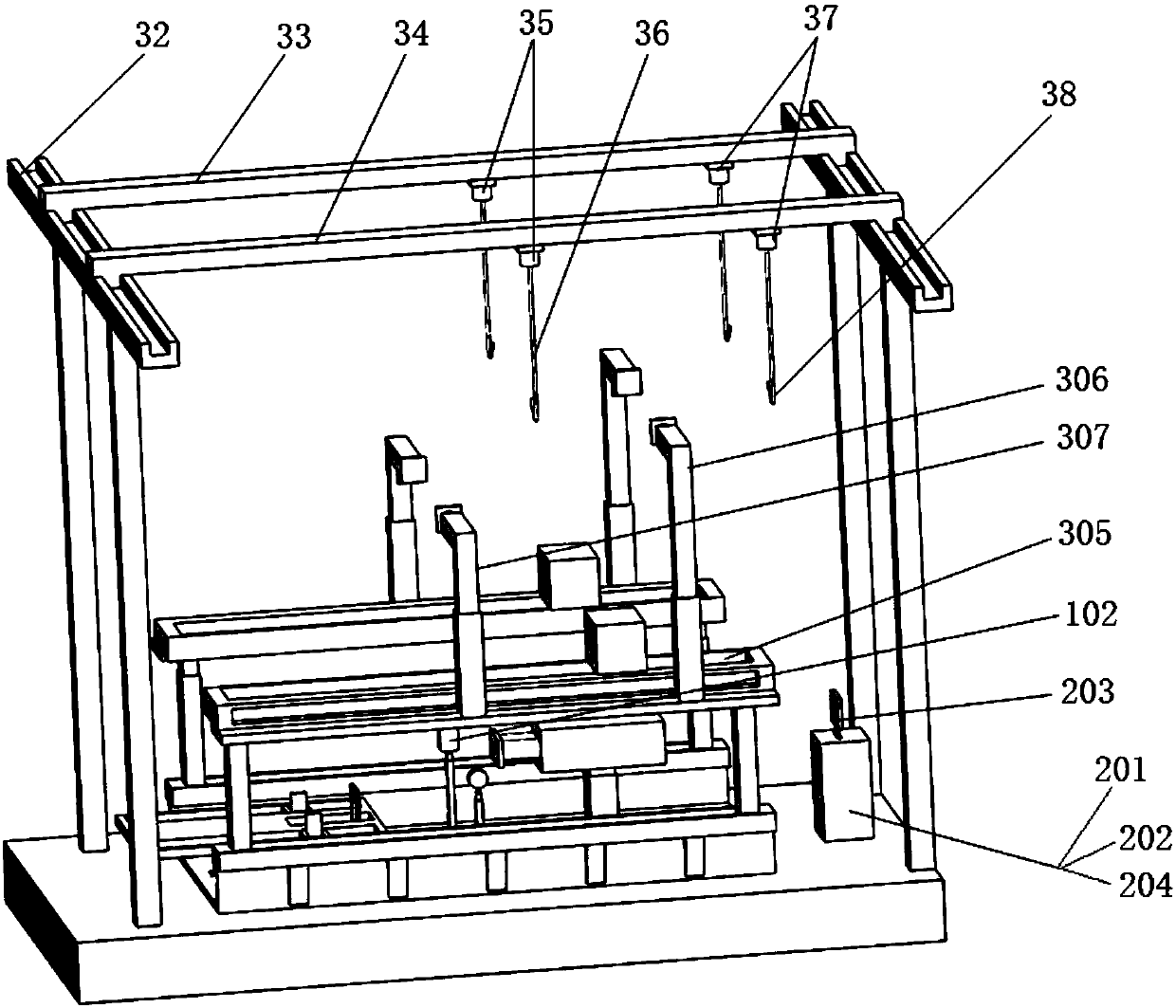

[0067] Such as Figure 1 to Figure 6b As shown, this embodiment provides a working method for intelligently installing heavy-duty hydraulic supports. The working method is based on an intelligent installation device. The intelligent installation device includes an installation execution system 3, a pin hole positioning component 1 and a control system 2. The control system 2 is electrically connected with the installation execution system 3 and the pin hole positioning component 1 for intelligently controlling the installation execution system 3 and the pin hole positioning component 1;

[0068] The installation execution system 3 includes a mobile platform assembly 301, a hoisting device 304, a clamping device, a manipulator assembly and a rear connecting rod push cylinder assembly; the mobile platform assembly 301 is used to move the hydraulic support base to the target position, and the hoisting device 304 is used to move the hydraulic The front connecting rod, rear connect...

Embodiment 2

[0081] A working method for intelligently installing a heavy-duty hydraulic support, the working method is based on the intelligent installation device described in Embodiment 1, and the working method specifically includes the following steps,

[0082] (1) First, connect the cover beam ZJ4, the front connecting rod ZJ3 and the rear connecting rod ZJ2 of the hydraulic support to form an assembly for standby; install the column on the base of the hydraulic support for standby;

[0083] (2) Turn on the heavy-duty hydraulic support intelligent installation equipment, the reference coordinate system is determined by the control system 2, the intelligent installation equipment is in the initial position, that is, the mobile platform assembly 301 is located at the forefront of the middle chute, and the laser light assembly 101 is located at the extreme end of the right chute The front end and the projection board assembly 102 are located at the front end of the left chute, at this ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com