Faucet handle and machining and electroplating method thereof

A faucet handle and handle technology, applied in the field of bathroom, can solve the problems of handle breakage, light weight of plastic handle, complicated process, etc., and achieve the effect of enhancing airtightness and airtightness, good airtightness and airtightness, and simple electroplating process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

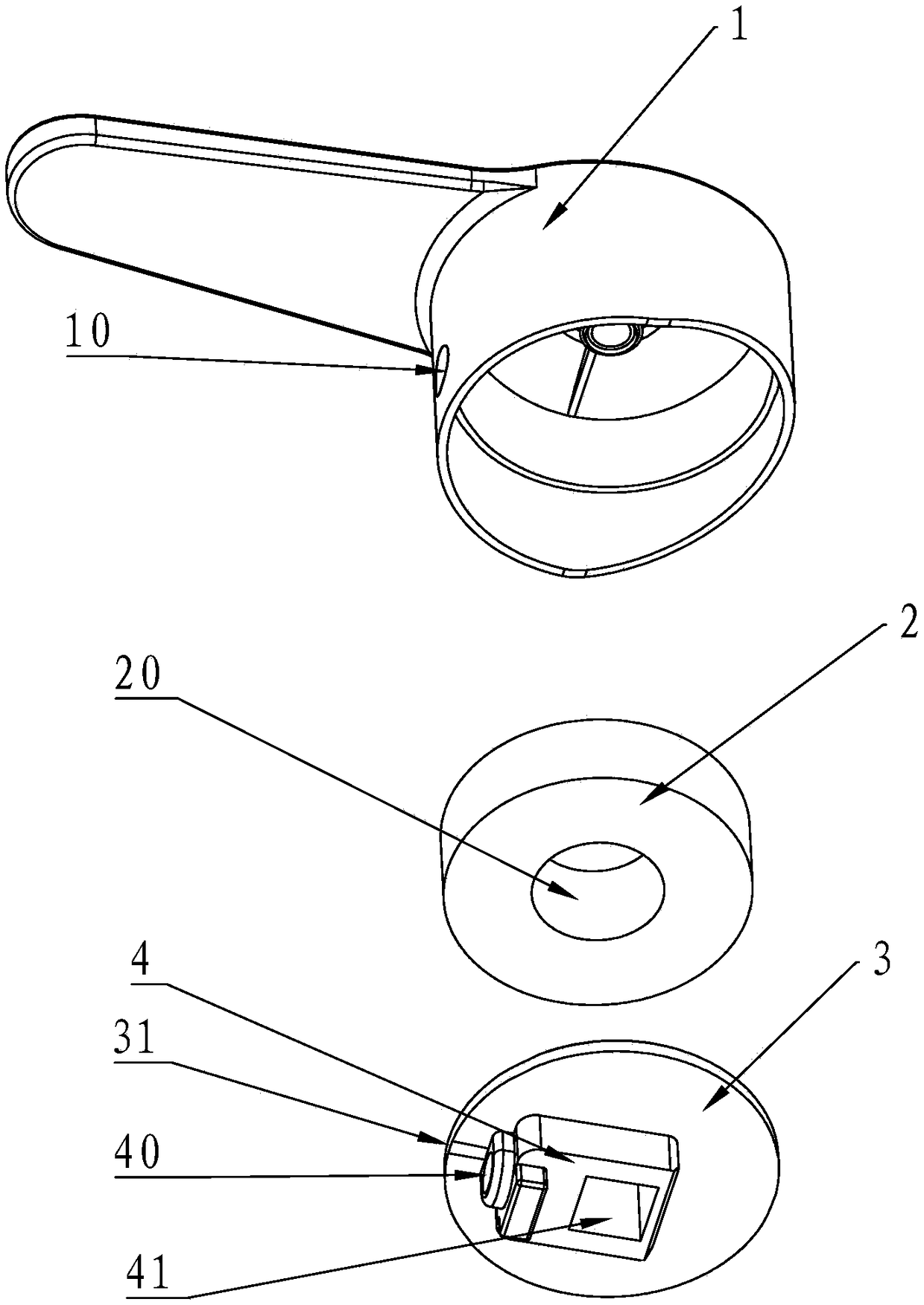

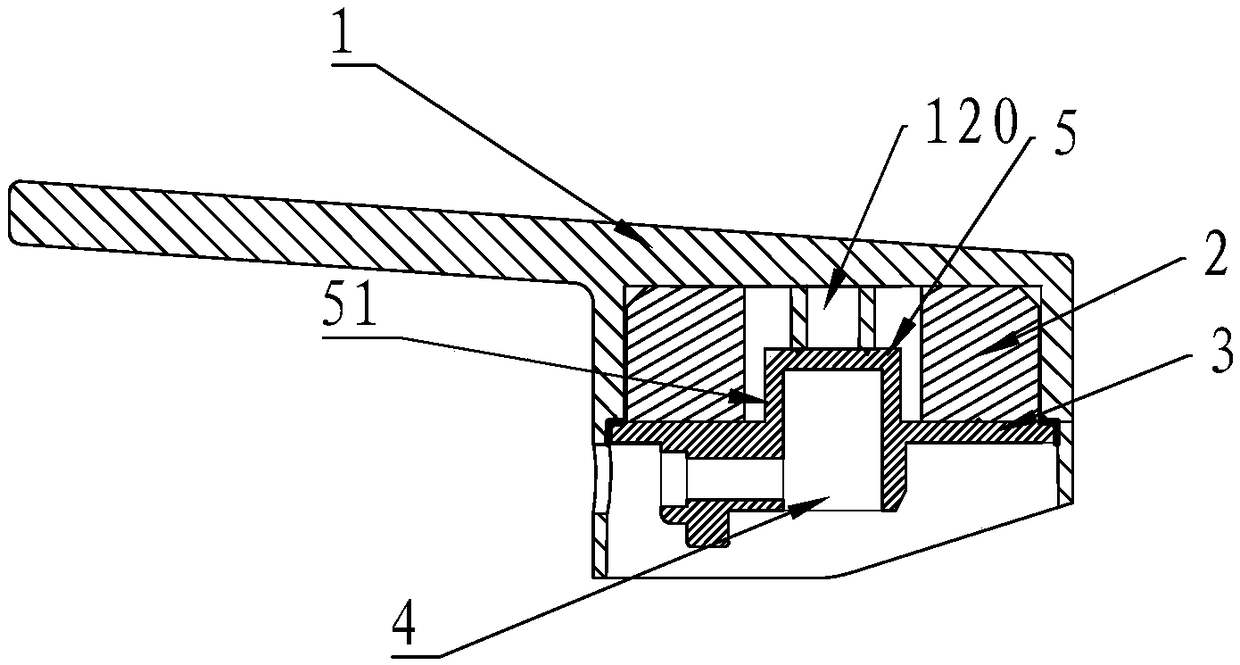

[0025] Such as Figure 1 to Figure 3 As shown, a faucet handle includes a handle housing 1 , a counterweight 2 and a fixing piece 3 .

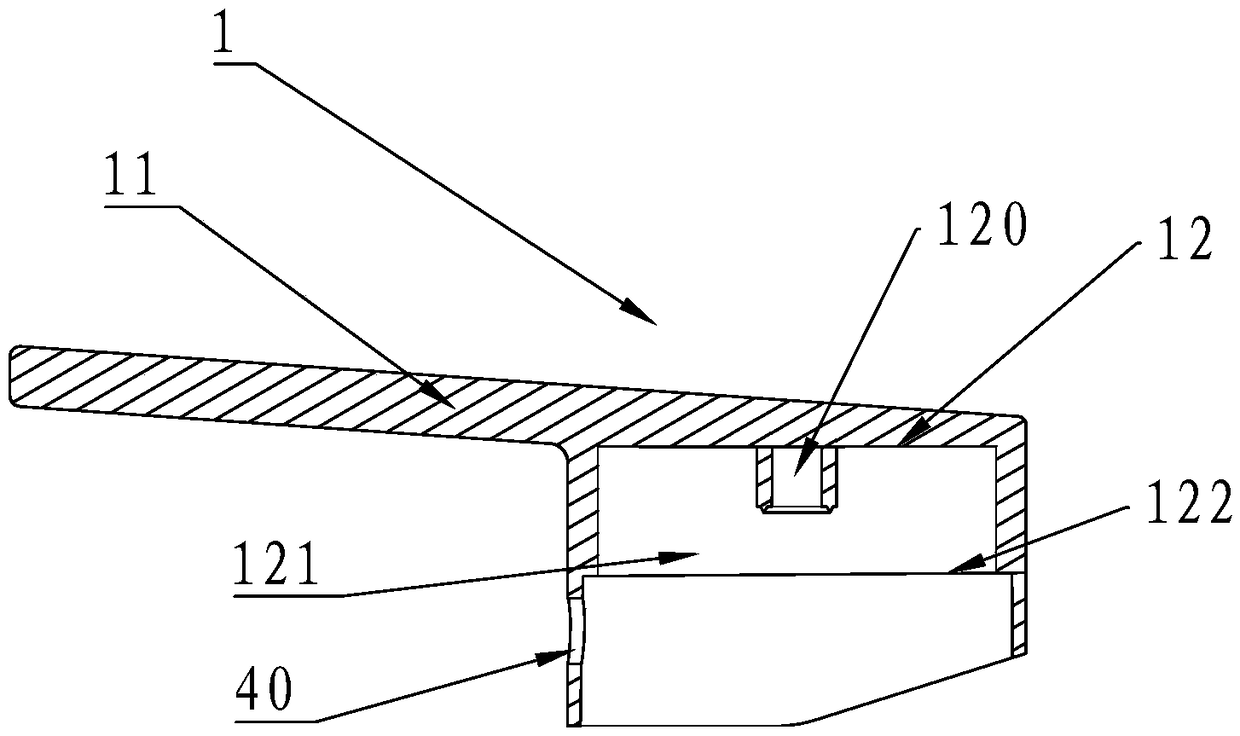

[0026] Wherein, the handle shell 1 and the fixing piece 3 are injection molded. The handle housing 1 is provided with an installation hole 10 , and the handle housing 1 includes a handle 11 and a faucet connecting portion 12 , and the faucet connecting portion 12 has a hollow accommodating portion 121 . A hollow column 120 is disposed at the center of the accommodating portion 121 , and an annular positioning step 122 is disposed on the inner wall of the accommodating portion 121 .

[0027] The counterweight 2 is disposed in the accommodating portion 121 , and the counterweight 2 is a cylinder, and a circular through hole 20 is formed in the center of the cylinder.

[0028] A square spool joint 4 is provided on the outside of the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com