Patents

Literature

31results about How to "The electroplating process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

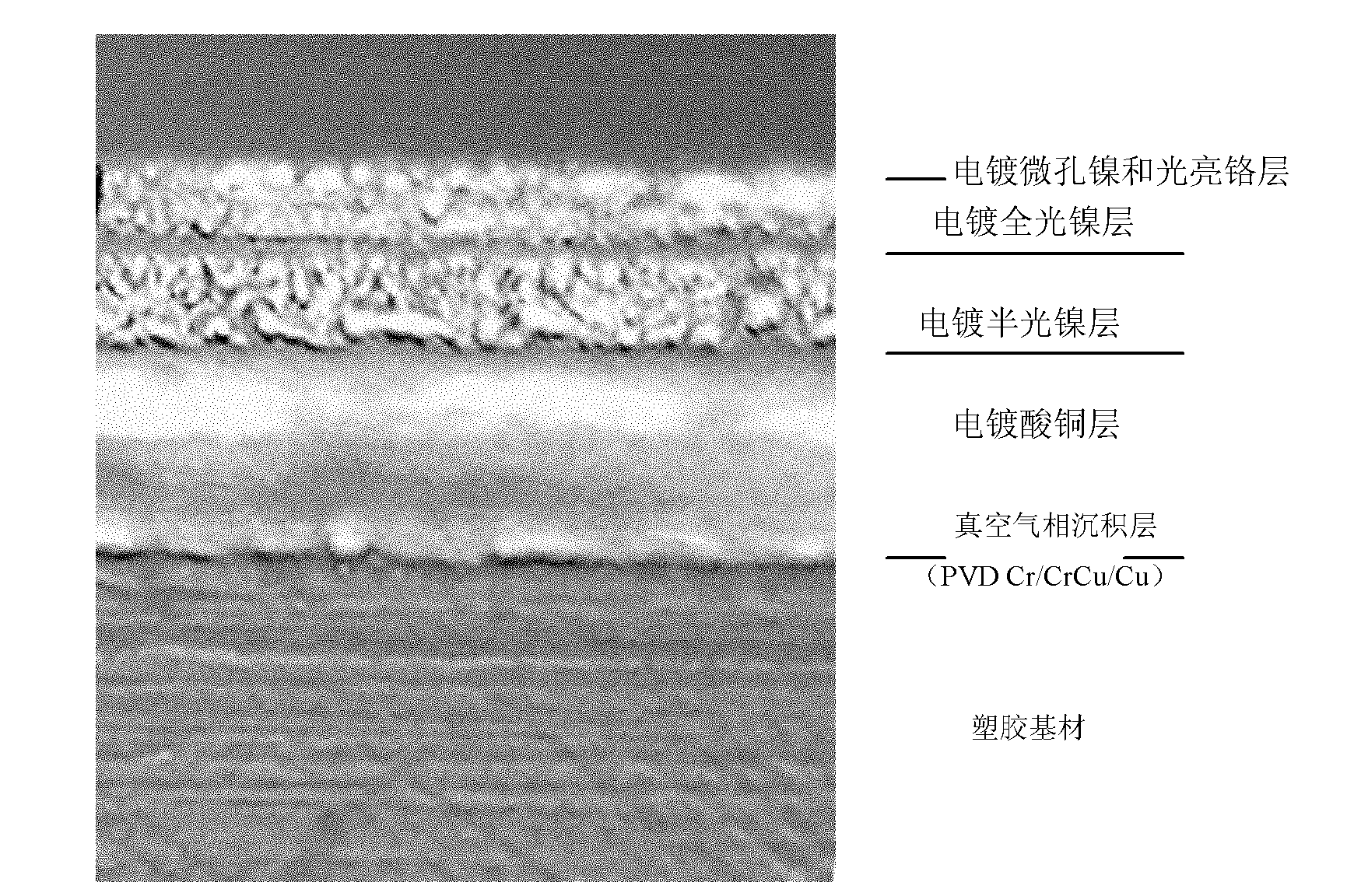

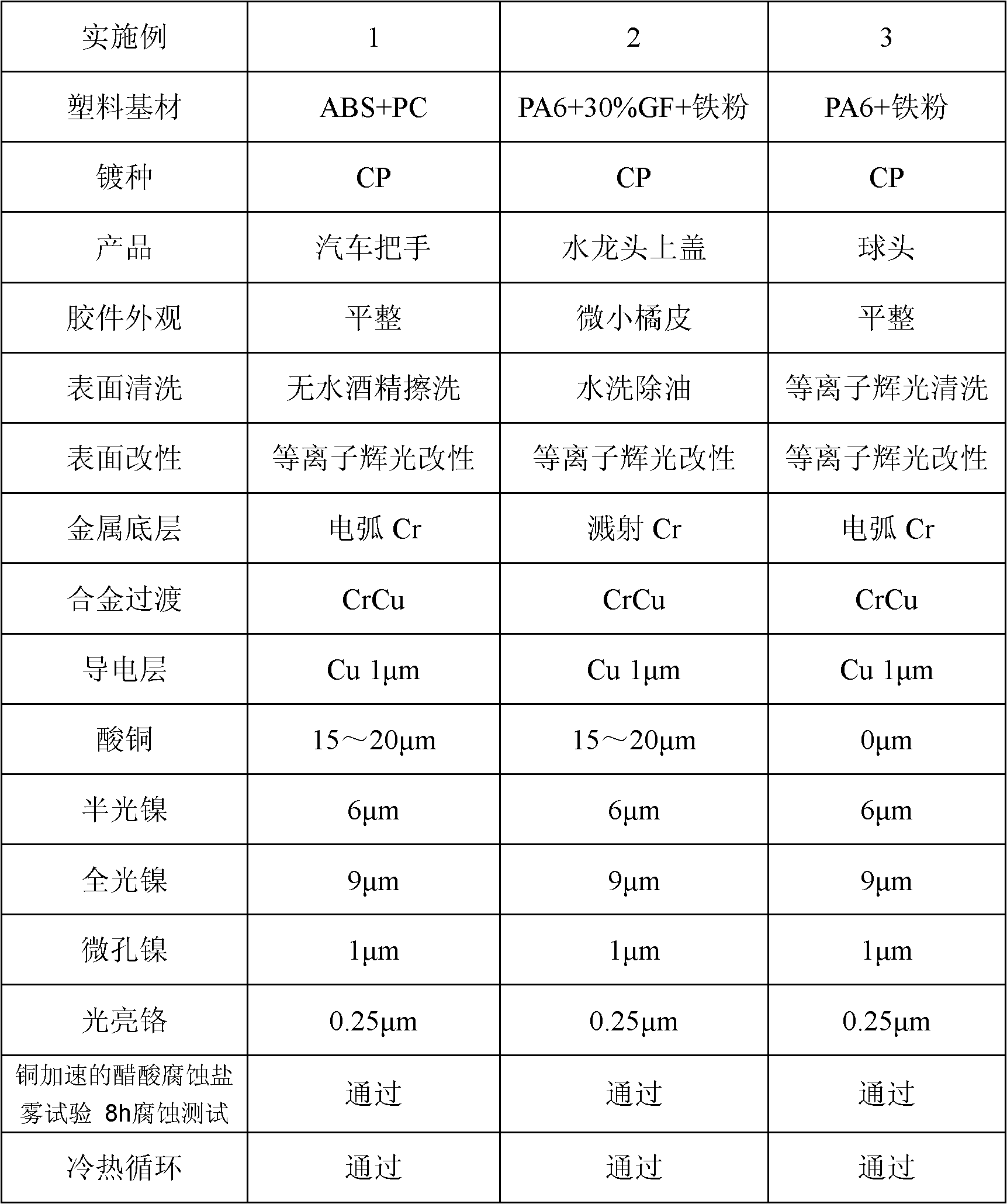

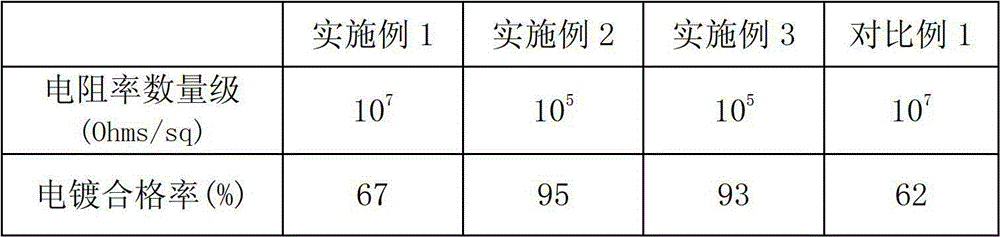

Method for implementing semi-dry plating on surface of plastic substrate

ActiveCN102127764AAchieve surface metallizationReduce pollutionVacuum evaporation coatingSputtering coatingPlastic materialsWastewater

Owner:XIAMEN RUNNER IND CORP

Electroplating poly carbonate (PC)/acrylonitrile butadiene styrene (ABS) alloy composition and preparation method thereof

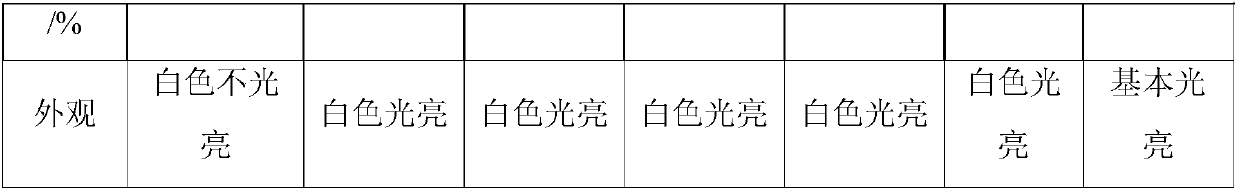

The invention relates to an electroplating poly carbonate (PC) / acrylonitrile butadiene styrene (ABS) alloy composition and a preparation method thereof. The PC and ABS alloy composition comprises the following components in part by weight: 30 to 80 parts of PC resin, 20 to 70 parts of ABS resin, 0.1 to 5 parts of carbon nano tube, 0.5 to 5 parts of compatilizer, 0.1 to 1 part of antioxidant, and 0.1 to 1 part of lubricating agent. The preparation method comprises the following steps of: adding all the components into a mixing and stirring machine in a ratio and mixing; and blending and pelletizing the obtained mixture by using a twin-screw extruder. The method is simple and feasible; due to the introducing of the compatilizer, the dispersing of the carbon nano tube in a PC / ABS base body is promoted; the PC / ABS alloy composition is endowed with excellent electric conduction performance by using a small amount of the carbon nano tube; and the alloy composition can be directly used for an electrocoppering process, the roughening, activating and chemical plating processes are eliminated, and an electroplating process is simplified.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Nickel-nanodiamond composite plating solution and preparation thereof

InactiveCN101280452ASoluble in waterGood dispersionElectrolytic coatingsSurface-active agentsSize ratio

The invention discloses a nickel-nano-diamond composite plating solution, which is in blend composition with the size ratio 0.1-2:22 through the modified nano-diamond water or dilute sulfuric acid solution and the water solution of nickel sulfate, nickel chloride, boric acid, saccharin and butynediol. The invention also discloses the preparation method of the composite plating solution. The composite plating solution of the invention has a high degree of stability, in which the key issues existed in the composite plating technique of nano-diamond that the nano-diamond is easy to be in agglomeration and settlement and the plating solution is unstable are resolved. Moreover the composite plating solution is in favor of the stable control of the structure and properties of the composite coating. During the preparation process, the ultrasound technology and the organic surface-active agent are not required to use, which is not only help reduce the plating cost, but also the environmental problems resulted from the adoption of the organic surface-active agents comprising sulfur, phosphorous and other elements are avoided. The composite coating obtained from the plating solution through a simple plating process is bright and smooth. Compared with the coating that the nano-diamond is not comprised and obtained under the same conditions, the micro-hardness of the composite coating can be increased at most by 38%, and the coefficient of friction can be reduced by 29%.

Owner:浣石

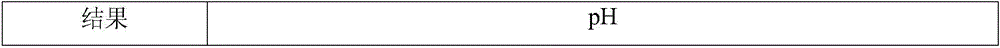

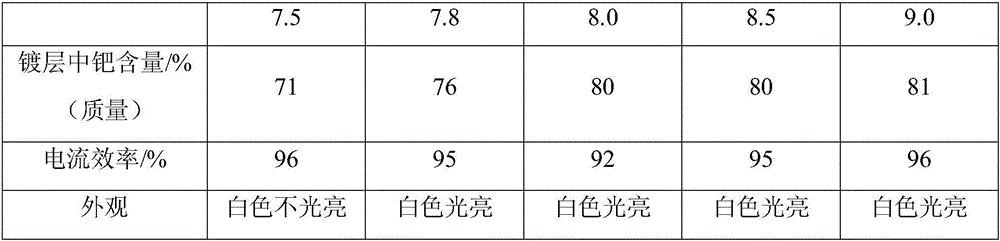

Au-Pd alloy electroplating solution as well as preparation method and electroplating process thereof

The embodiment of the invention discloses an Au-Pd alloy electroplating solution which comprises an Au salt, a Pd salt, a chelating agent and conducting salts. The Au-Pd alloy electroplating solution comprises the following components: 0.1-20g / l of Au salt based on the content of a single substance Au, 0.1-15 g / L of Pd salt based on the content of a single substance Pd, 30-300 g / L of chelating agent and10-30 g / L of conducting salt, wherein based on the content of metal substance, the mass ratio of gold salt to palladium salt is (0.5-20):1. In addition, the invention also discloses the preparation method and the electroplating process of the Au-Pd alloy electroplating solution. By using the Au-Pd alloy electroplating solution and electroplating process thereof, the process is simple, and an obtained Au-Pd alloy electroplating layer has the advantages of high electrical conductivity, strong wear resistance and corrosion resistance, metal white or light golden yellow appearance, and the like.

Owner:RAMBO NANOTECH SHENZHEN

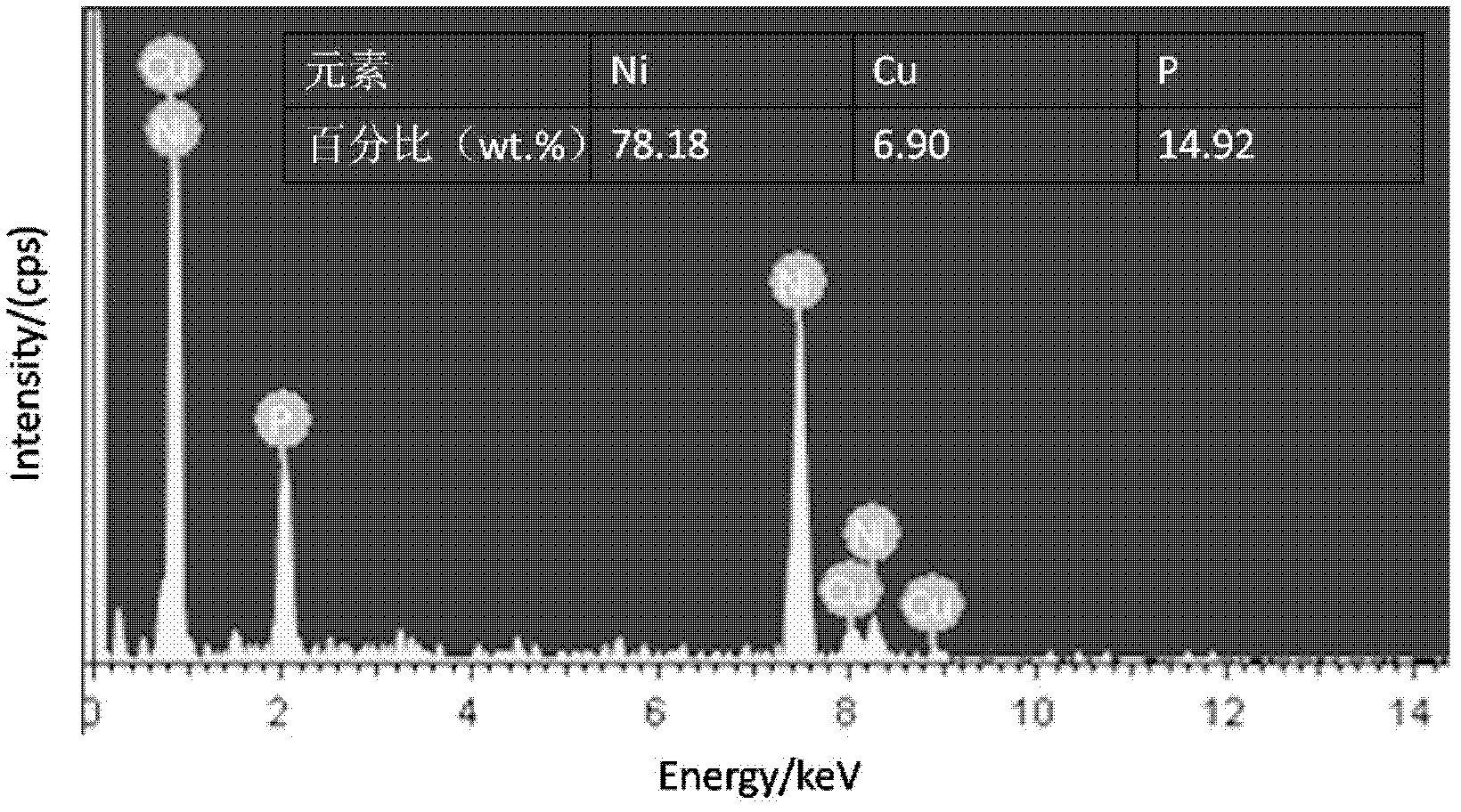

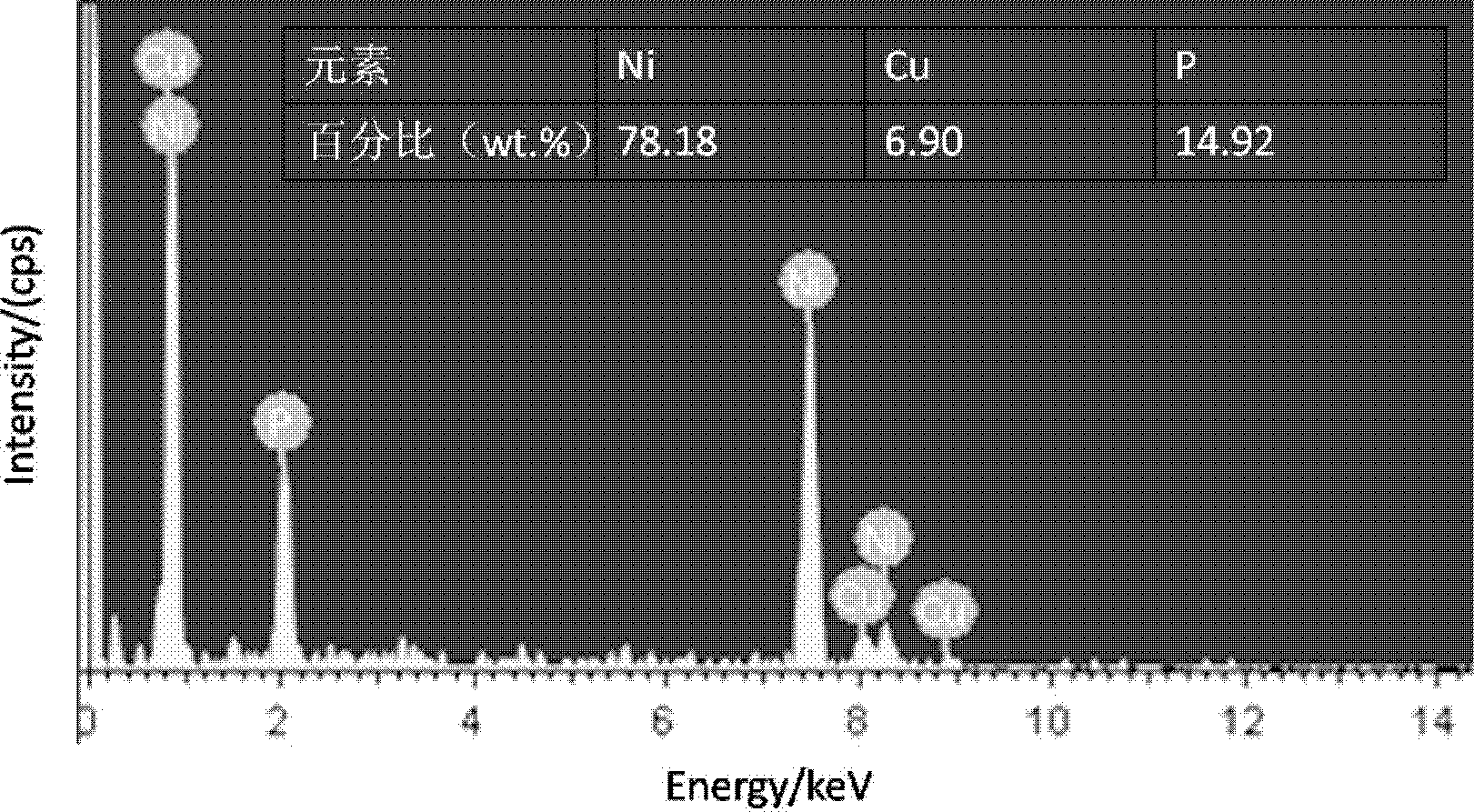

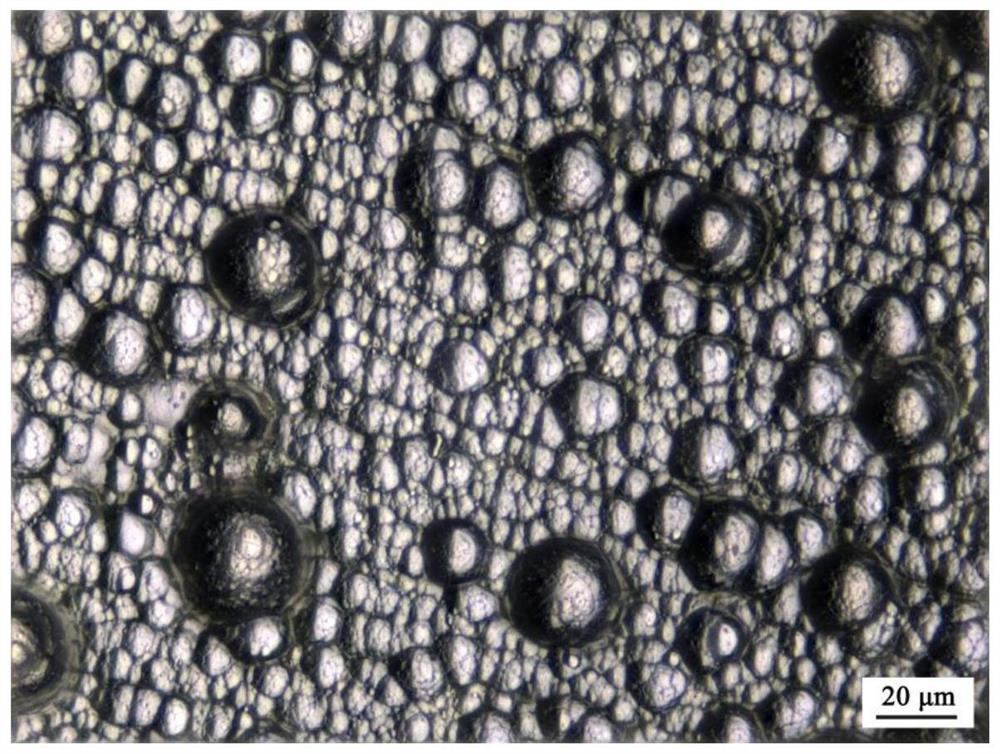

Ni-Cu-P ternary alloy coating serving as welding spot reaction barrier layer and electroplating preparation technology thereof

InactiveCN102560576AReduce energy consumptionHigh bath stabilitySoldering apparatusInterconnectionAlloy coating

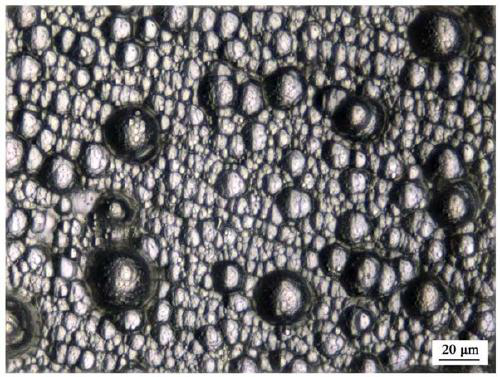

The invention discloses a Ni-Cu-P ternary alloy coating serving as a welding spot reaction barrier layer and an electroplating preparation technology thereof. The Ni-Cu-P ternary alloy coating serving as the welding spot reaction barrier layer comprises the following components in percentage by weight: 70-90% of Ni, 3-10% of Cu and 7-20% of P. The thickness of the coating is 2-15mu m. The preparation method comprises the following steps of: putting an electroplated cathode piece (metallized Si chip or Cu piece) and an electroplated anode sheet (Pt piece) into electroplate liquid; introducing dipulse current for dipulse electroplating; and forming an Ni-Cu-P alloy coating on the surface of the cathode piece. The components of the Ni-Cu-P alloy coating prepared by using the electroplating preparation technology conform to the use requirement of a welding spot reaction barrier layer for electronic packaging and interconnection, the coating and the cathode piece substrate (metallized Si chip or Cu piece) are tightly combined, a plating layer is flat, and the Ni-Cu-P ternary alloy coating is fine in cellular tissue, even in thickness, and compact in structure and is basically free from holes.

Owner:HEFEI UNIV OF TECH

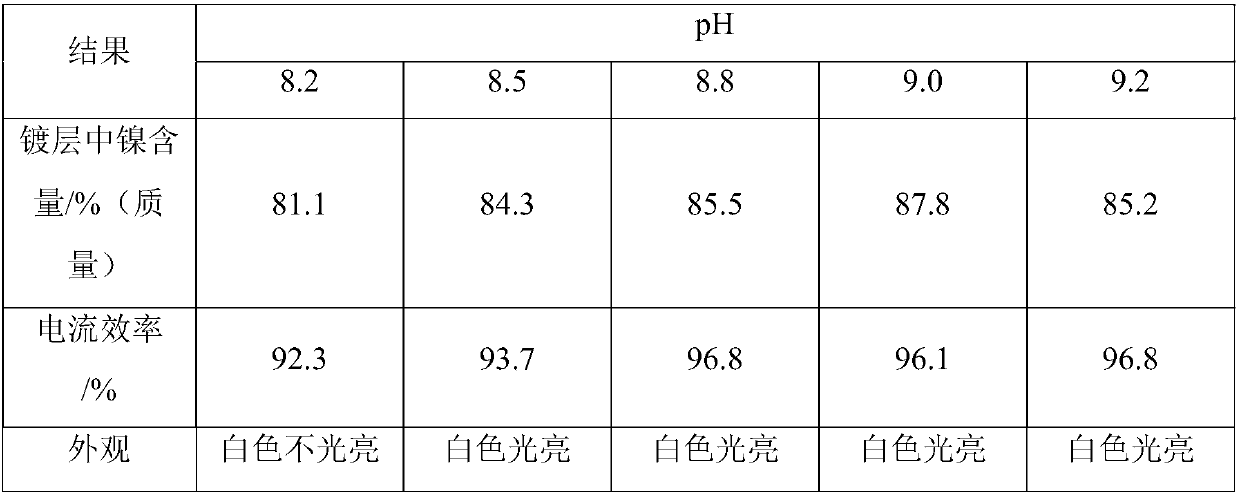

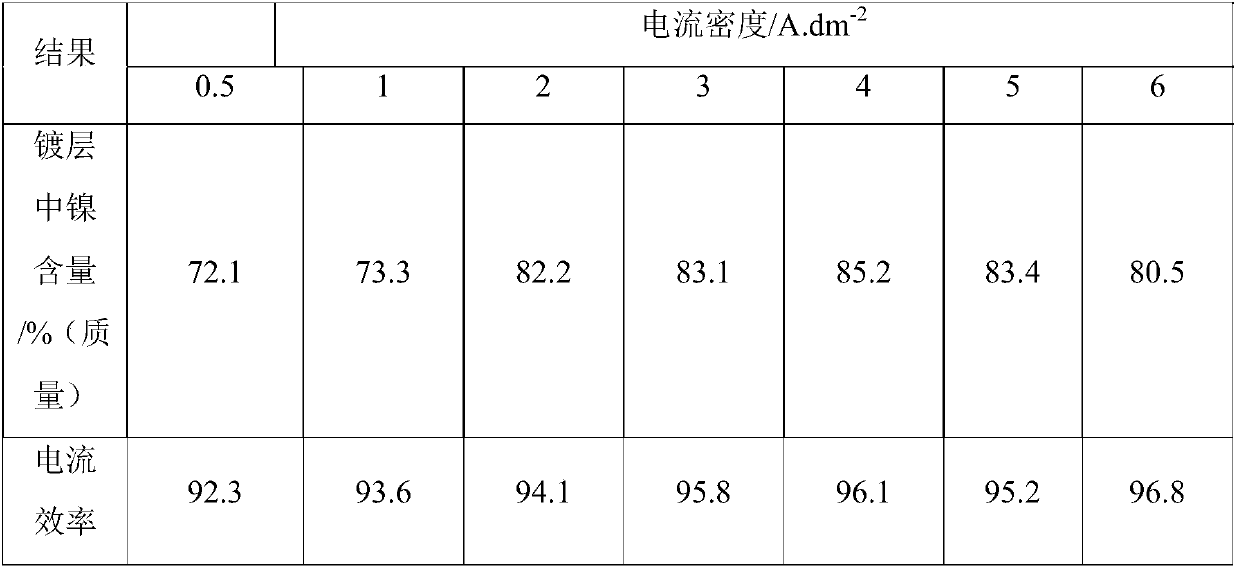

Zinc-nickel alloy plating liquid and application thereof

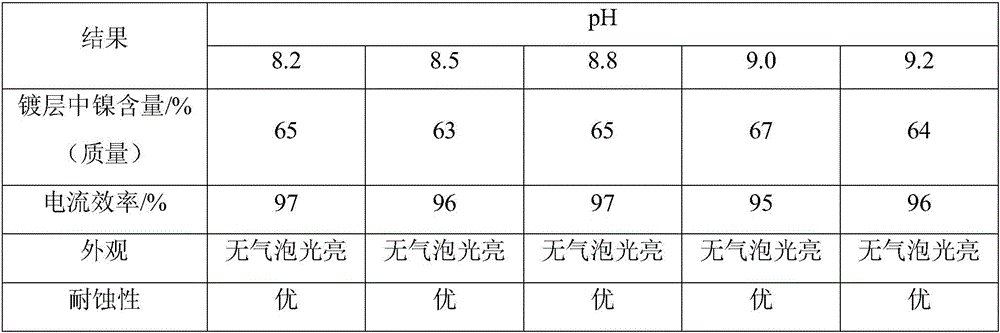

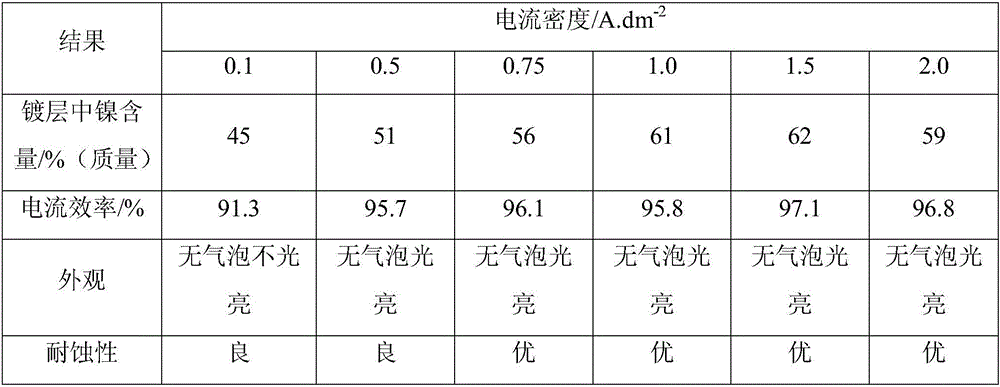

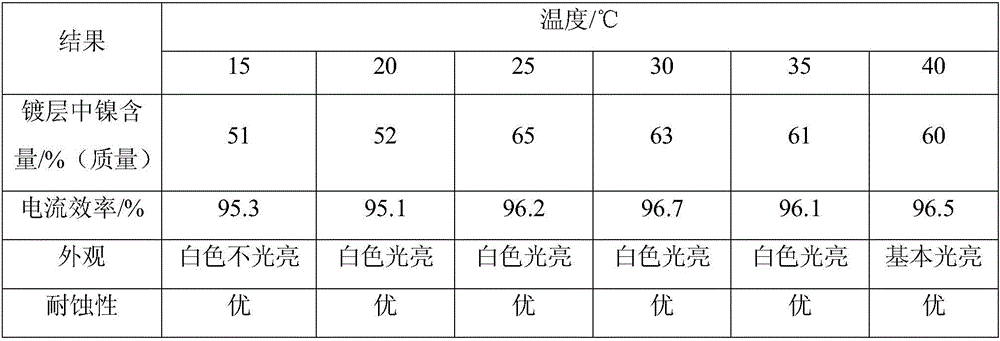

The invention discloses zinc-nickel alloy plating liquid. The zinc-nickel alloy plating liquid comprises 0.08-0.1mol / L of zinc sulfate, 0.1-0.2mol / L of nickel sulfamate, 0.01-0.05mol / L of sodium hydroxide, 0.01-0.03mol / L of ammonia chloride, 0.002-0.003mol / L of boric acid, 0.001-0.002mol / L of beta-sodium naphthenate, 0.0001-0.0002mol / L of leucine, 0.0001-0.0003mol / L of isoleucine, brightener and complexing agent, wherein pH is 8.8-9.2, and a solvent is water. The zinc-nickel alloy plating liquid has the advantages that an electroplating matrix using the plating liquid is good in corrosion resistance, and a plated layer is compact, even, and small in particle.

Owner:JIANGSU AOGUANG ELECTRONICS

Method for electroplating shaft bushing antifriction layer by metilsulfate plating bath

InactiveCN101503811AImprove performanceThe electroplating process is simpleBearing componentsTinningAlloy

The invention relates to a method for plating a bush antifriction coating through a methyl sulfonate bath. The method comprises the following steps: (1) cleaning a bush after ultrasonic degreasing, and cleaning a bush upper ring after cathode electroplating degreasing; (2) cleaning the bush after dilute hydrochloric acid activation for 1 to 2 minutes, placing the bush into the methyl sulfonate bath, taking a terne metal containing 10 percent of tin as an anode at a room temperature, carrying out the electroplating for 18 to 22 minutes when the cathode current density is 2 to 3 A / dm, and then cleaning the bush and obtaining a terne copper coating on the inner surface of the bush; and (3) placing the bush into a tinning bath, taking a steel plate as an anode at 75 to 80 DEG C, carrying out the electroplating for 3 to 8 minutes when the cathode current density is 1 to 1.5 A / dm, and obtaining a tin coating on the inner surface of the bush. The methyl sulfonate bath has stable performance and a simple process; the coating has fine crystallization, good hardness and good abrasion resistance; the bush coating has even thickness; as no strong complexing agent and F are contained, wastewater is easily processed; and the method is suitable for plating the bush antifriction coating on large and medium-size diesel engines and combustion engines.

Owner:JIAYING UNIV

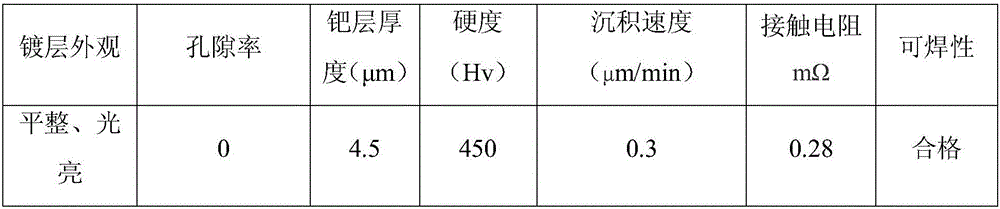

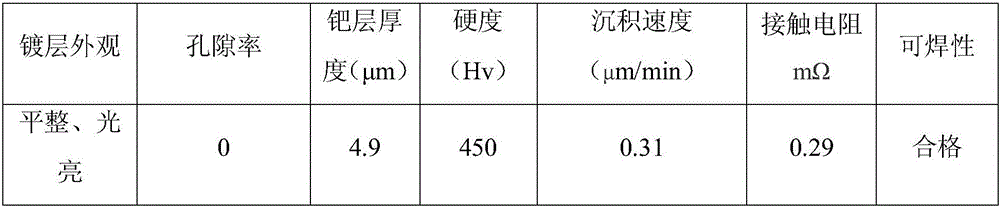

Terminal surface electroplating liquid and application thereof

The invention discloses terminal surface electroplating liquid. The terminal surface electroplating liquid comprises the following components of 0.1-0.2 mol / L of nickel acetate, 0.4-0.5 mol / L of nickel chloride, 0.1-0.5 mol / L of glycine, 0.01-0.03 mol / L of ammonium chloride, 0.001-0.003 mol / L of potassium sulfate, 0.001-0.002 mol / L of beta-naphthalene sulfonic acid, 0.002-0.003 mol / L of phenylalanine, a brightener, a complexing agent, the pH is 8.8-9.2, and a solvent is water. A palladium plating layer is observed under a microscope, the palladium plating layer is fine, no crack exists, and the color is uniform; and the palladium plating layer is baked for 5min at the temperature of 200 DEG C, the plating layer has no peeling and bubbling phenomenon, and the adhesion force is very good.

Owner:JIANGSU AOGUANG ELECTRONICS

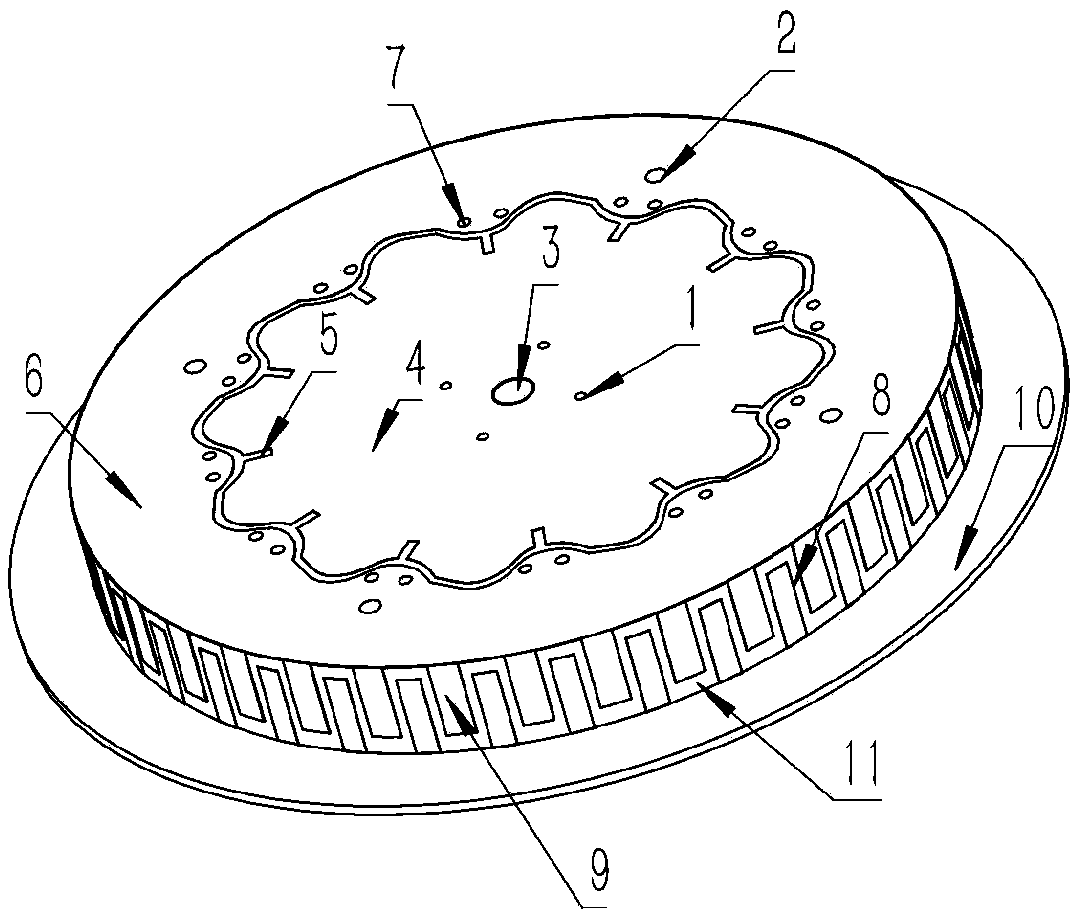

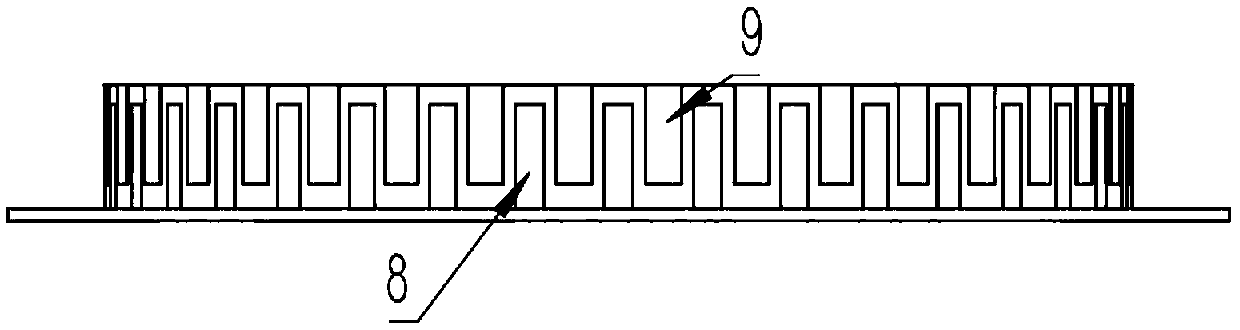

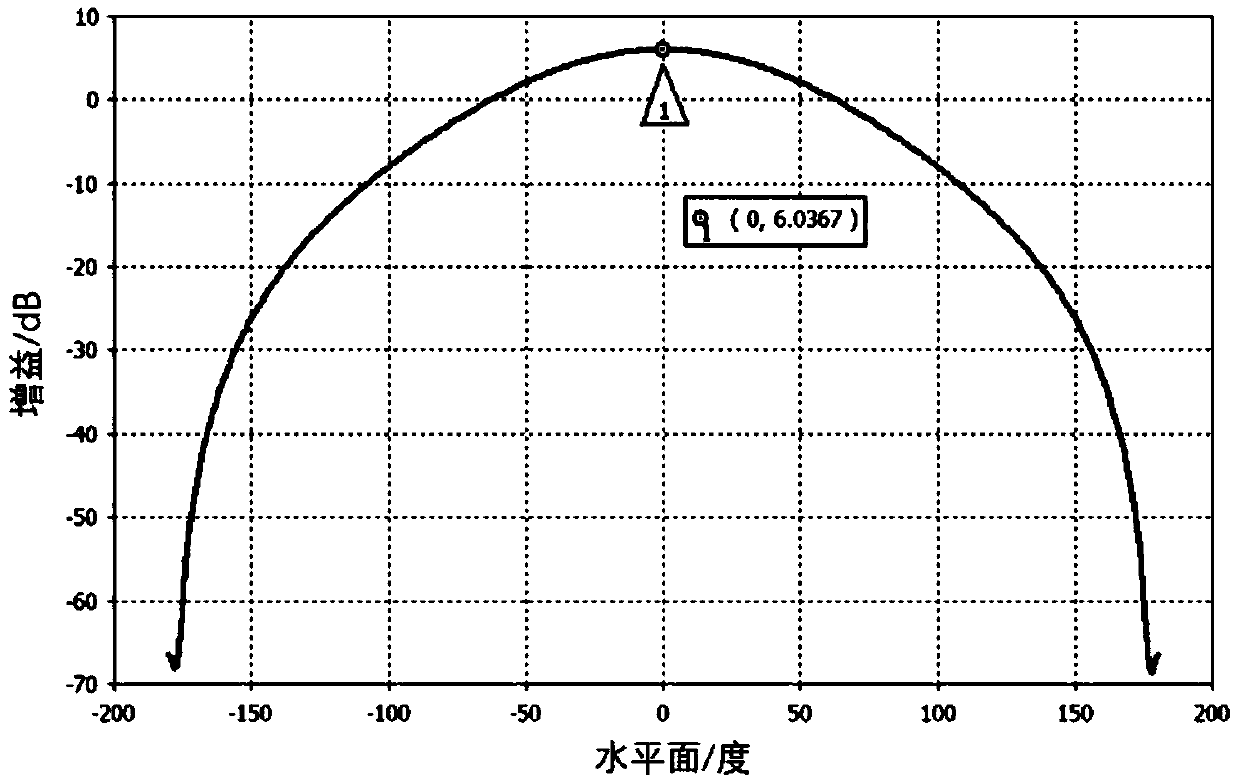

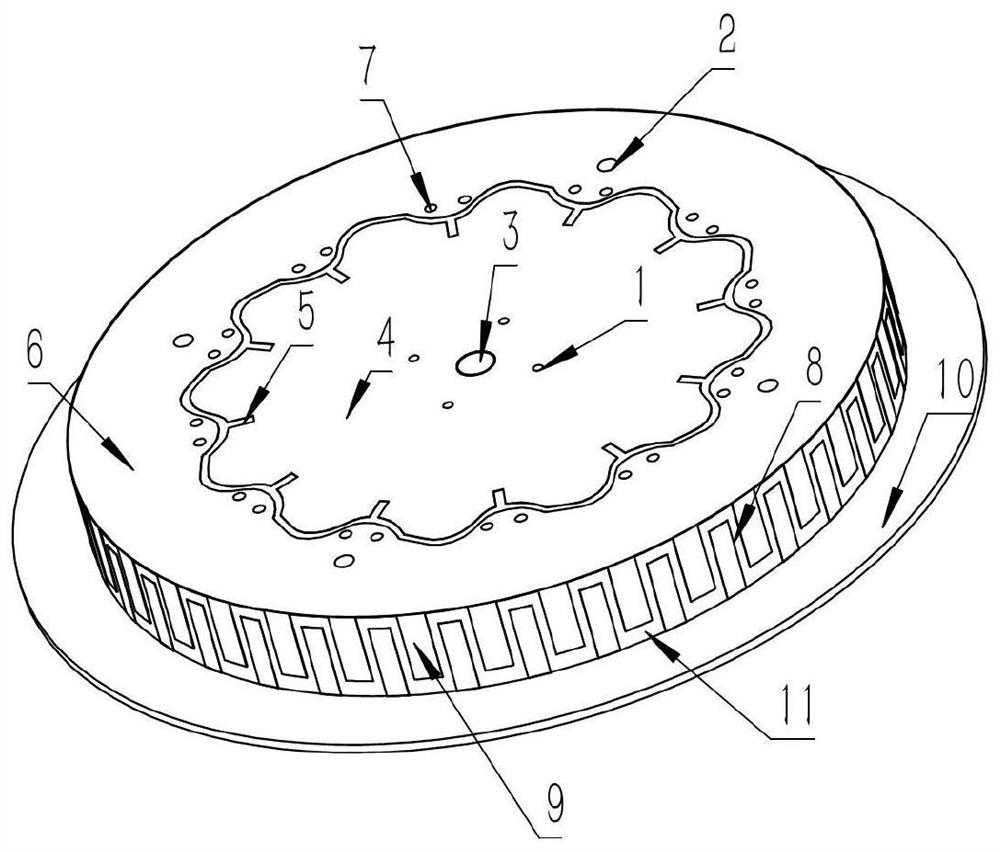

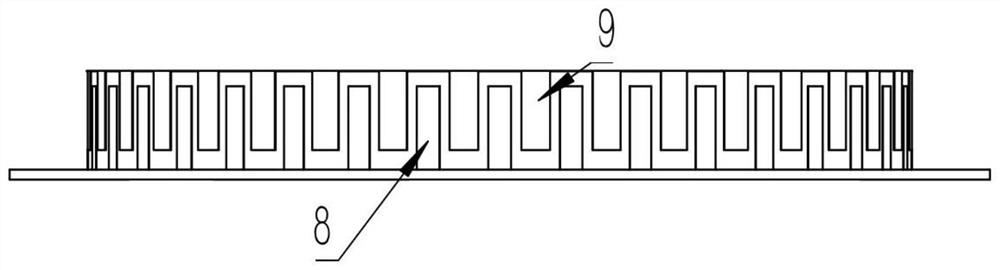

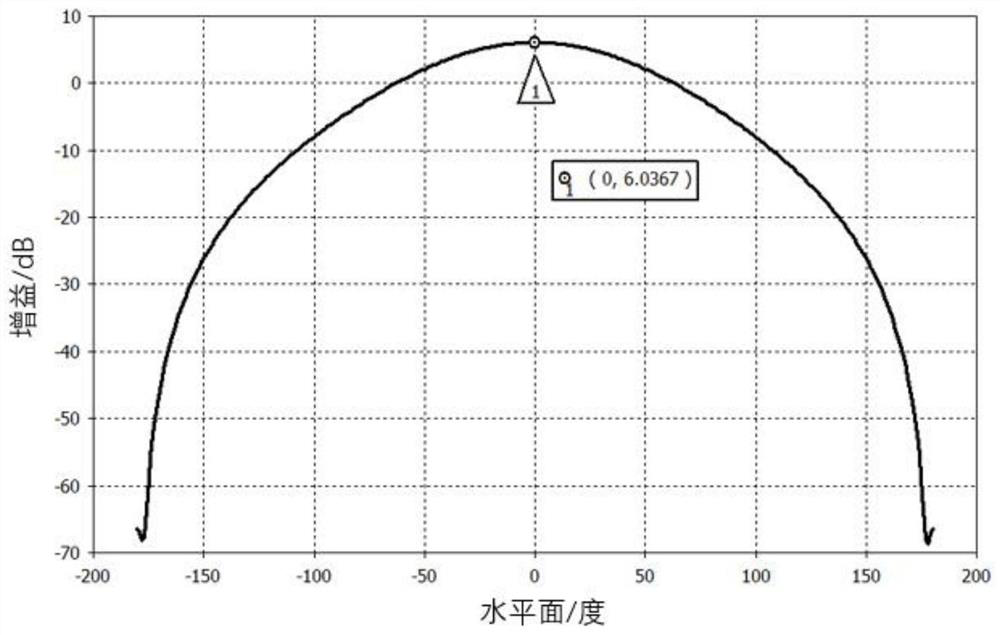

Miniature planar dual-frequency-band high precision satellite navigation antenna

ActiveCN109546331AOptimize volumeReduce volumeSimultaneous aerial operationsRadiating elements structural formsDual frequencyDielectric plate

The invention provides a miniature planar dual-frequency-band high precision satellite navigation antenna. The miniature planar dual-frequency-band high precision satellite navigation antenna includesa dielectric plate and a printed circuit base plate, wherein the dielectric plate includes a plurality of high frequency feeding points, a high frequency radiating surface, a plurality of low frequency feeding points, and a low frequency radiating surface; short circuit pins are distributed in the inner ring of the low frequency radiating surface; upward branch knots and downward branch knots aredistributed around the dielectric plate; the upward branch knots contact the printed circuit base plate; the downward branch knots are connected to the low frequency radiating surface; and coupling slits are formed between the upward branch knots and the downward branch knots. The miniature planar dual-frequency-band high precision satellite navigation antenna preferably solves the problems of antenna miniaturization, dual-frequency-band, antenna phase center elevation and the like, provides a design scheme for the miniature planar dual-frequency-band of the high precision satellite navigation antenna, effectively reduces the volume of the antenna, and effectively reduces the weight of the antenna at the same time.

Owner:SHANGHAI HUACE NAVIGATION TECH

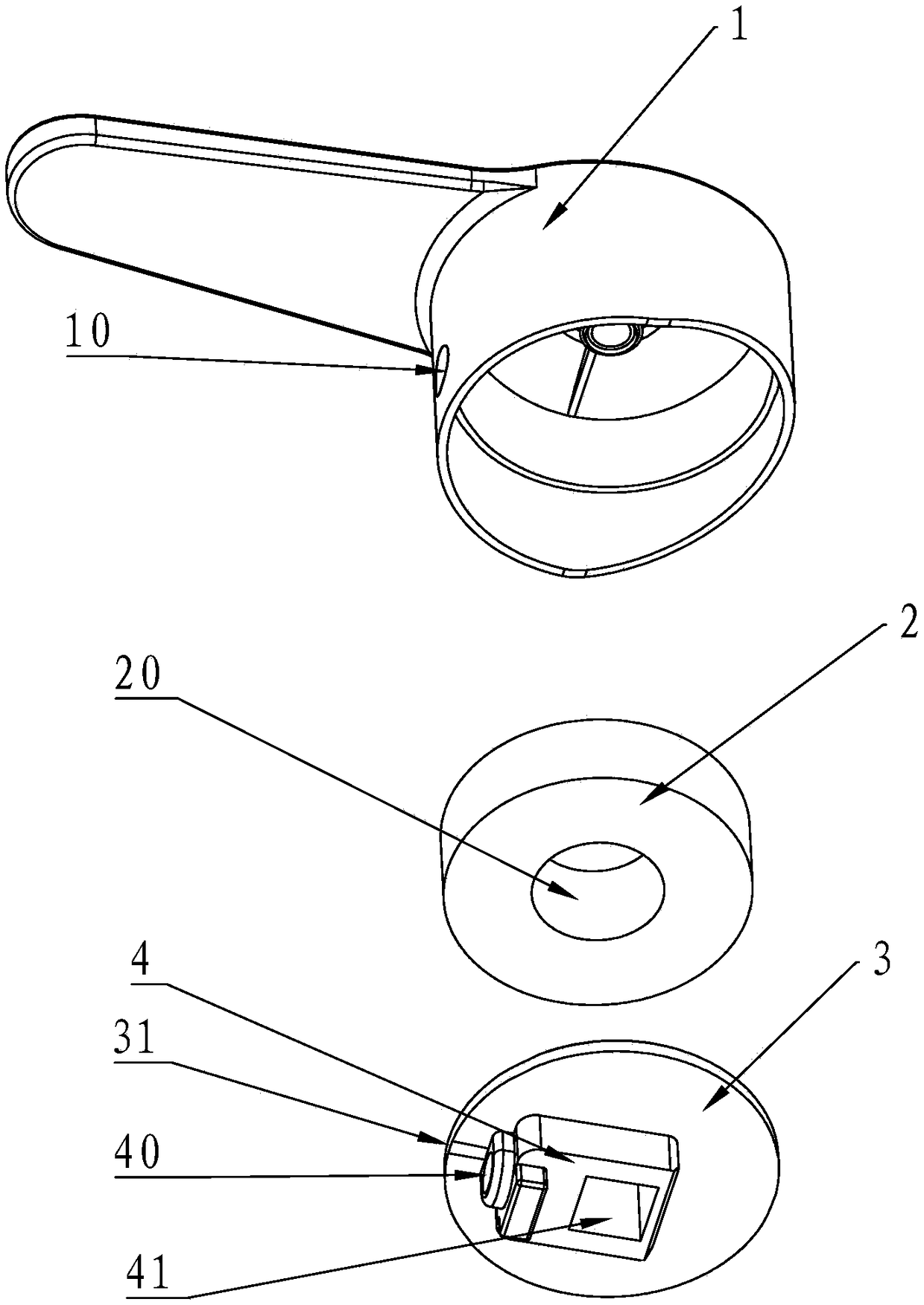

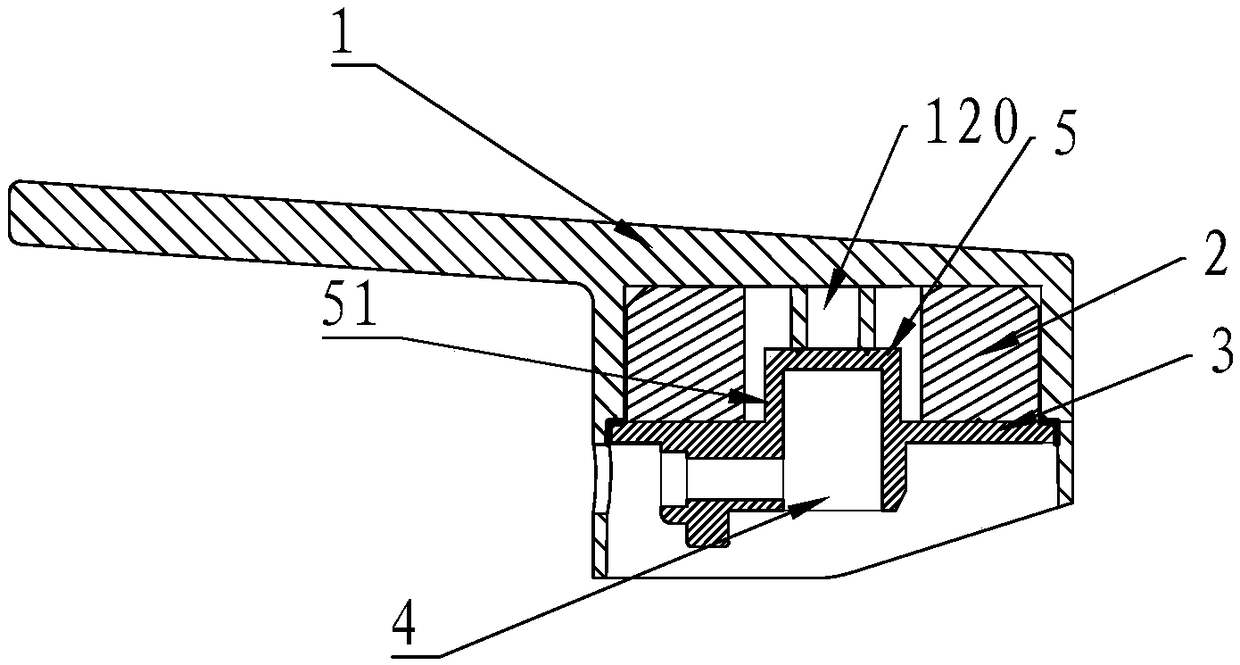

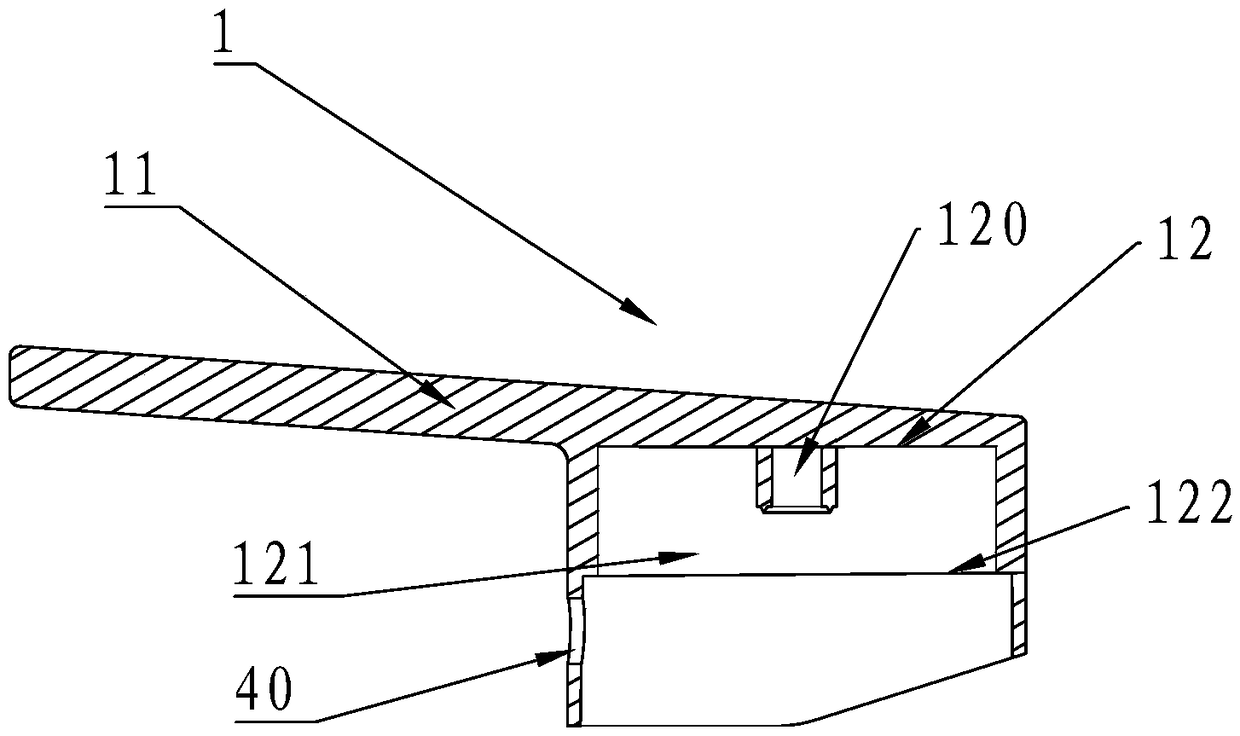

Faucet handle and machining and electroplating method thereof

InactiveCN108930833ASimple structureThe electroplating process is simpleOperating means/releasing devices for valvesEngineeringInjection moulding

The invention relates to a faucet handle. The faucet handle comprises a handle shell, a balance weight block and a fixed piece, wherein injection molding is adopted for the handle shell and the fixedpiece; the handle shell is provided with an installing hole, and comprises a handle and a faucet connection portion; the faucet connection portion is provided with a hollow containing portion; the balance weight block is arranged in the containing portion; a valve element connection head is arranged on the outer side of the fixed piece, and a positioning boss is arranged on the inner side; and thefixed piece is arranged in the containing portion on the outer side of the balance weight block and is welded to the handle shell in an interference manner. The faucet shell has the following beneficial effects that firstly, the structure is simplified, the electroplating process is simple, and cost is lower; secondly, the appearance face comprises a visible portion in the handle shell, and bothof them are very bright and clean, and the nearly perfect metal texture is achieved; thirdly, the fixed piece and the handle shell are in interference welding, so that gas tightness between the fixedpiece and the handle shell is better, and connection is more stable and reliable; and fourthly, the fixed piece is provided with an alignment groove, in the process of installing the fixed piece, thealignment groove is aligned with the installing hole, and the fixed piece can be accurately installed in place.

Owner:XIAMEN LIYE IND & TRADE CO LTD

Nickel-nanodiamond composite plating solution and preparation thereof

InactiveCN101280452BSoluble in waterGood dispersionElectrolytic coatingsSurface-active agentsSaccharin

Owner:浣石

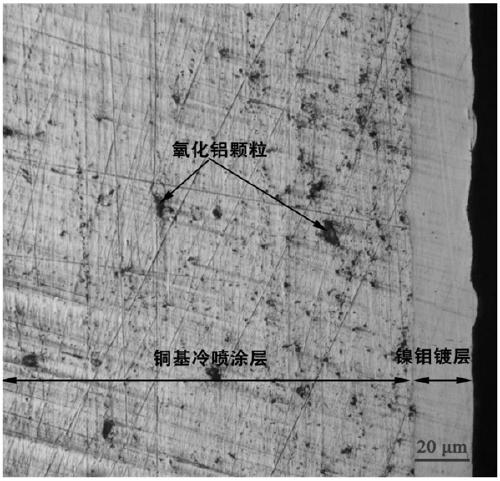

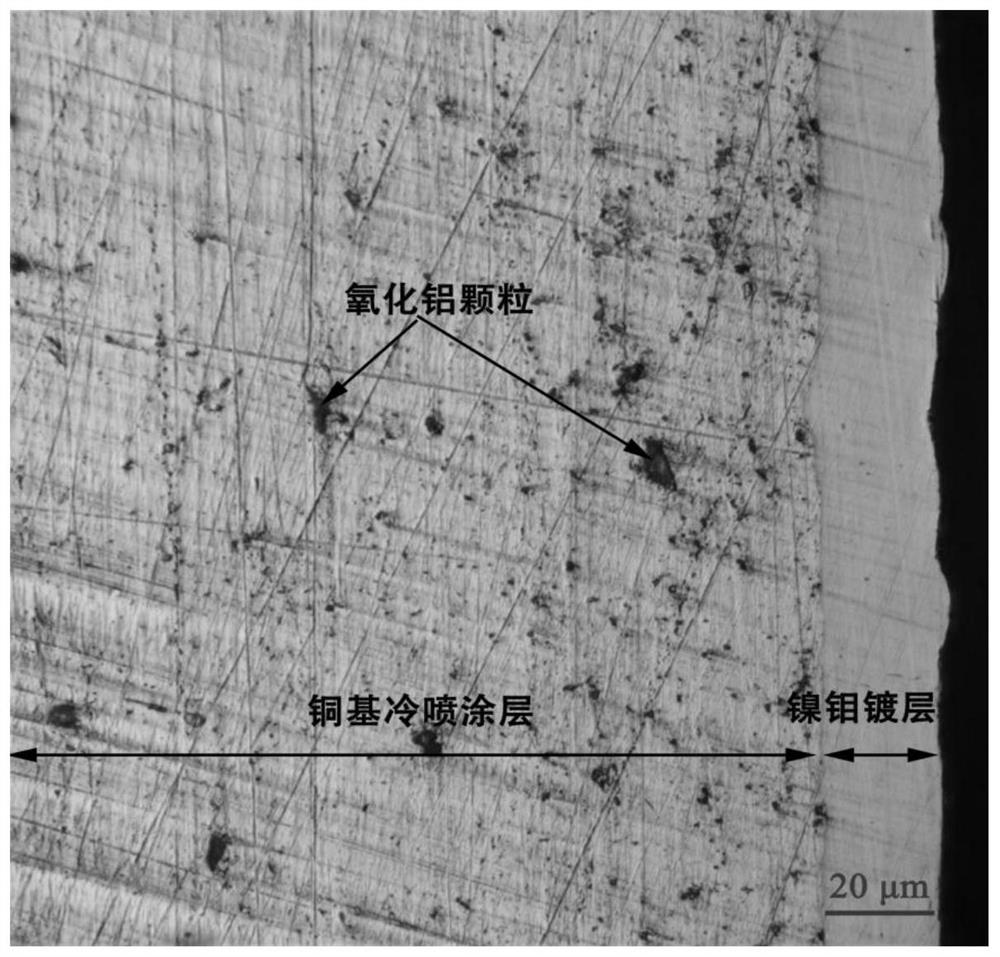

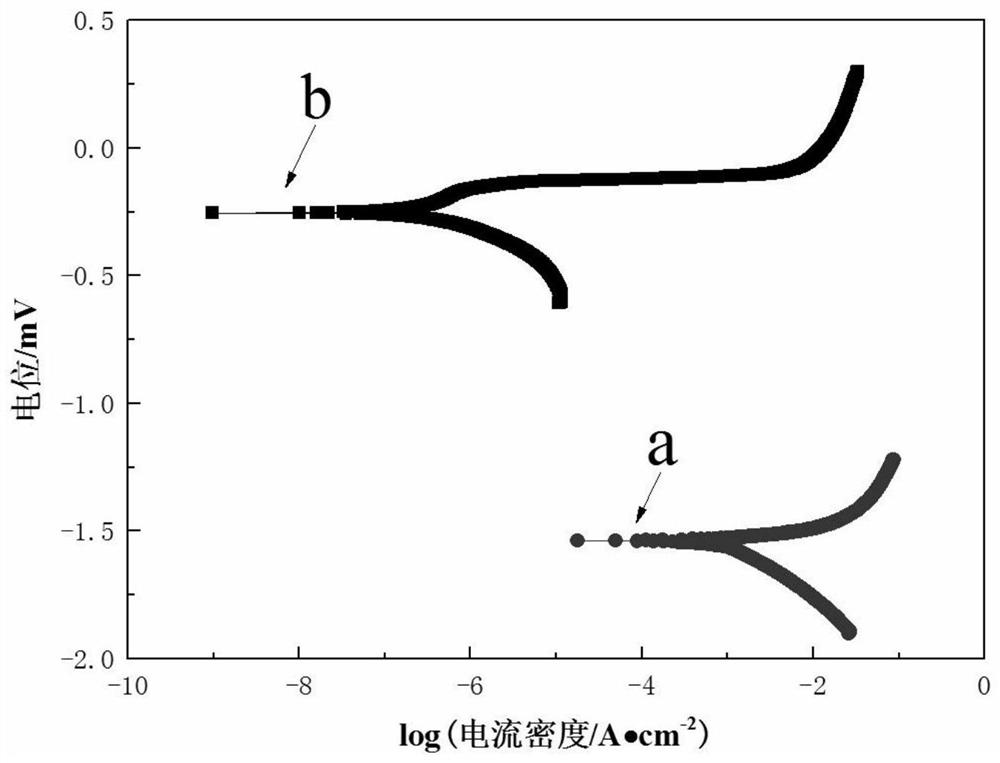

Method for rapid electrolytic-deposition of coating on surface of magnesium alloy

ActiveCN109487261AImprove the protective effectSimple and efficient processSuperimposed coating processHeat inorganic powder coatingSpray coatingPollution

The invention belongs to the technical field of metal surface treatment, and discloses a method for rapid electrolytic-deposition of a coating on a surface of a magnesium alloy. According to the method, sand blasting equipment is adopted for carrying out sand blasting treatment on the surface of the magnesium alloy, then ultrasonic cleaning is carried out on the surface of the magnesium alloy, anda coating material is sprayed on the surface of the magnesium alloy which is subjected to the sand blasting treatment by adopting a cold spraying method; the working gas of the cold spraying is compressed air, wherein the pressure is 0.6 MPa to 0.8 MPa, the preheating temperature of the cold spraying gas is 400-600 DEG C, the powder feeding distance is 10 mm, the relative moving speed of a nozzleis 600-2000 mm / min, and a cold-sprayed copper-based coating is prepared; and the cold-sprayed copper-based coating is placed in an electroplating solution, electroplating parameters are set, and a composite coating of a copper base and an electroplating layer is prepared through electroplating. The composite coating is good in microstructure and stable in physical property, the bonding strength of the cold-sprayed coating and the base material is high, the thickness of the cold spraying layer and the base material is controllable, and the composite coating has excellent corrosion resistance and wear resistance. According to the method, the electroplating process of the magnesium alloy is simplified, and the pollution to the environment is reduced.

Owner:东莞市先力得热处理有限公司

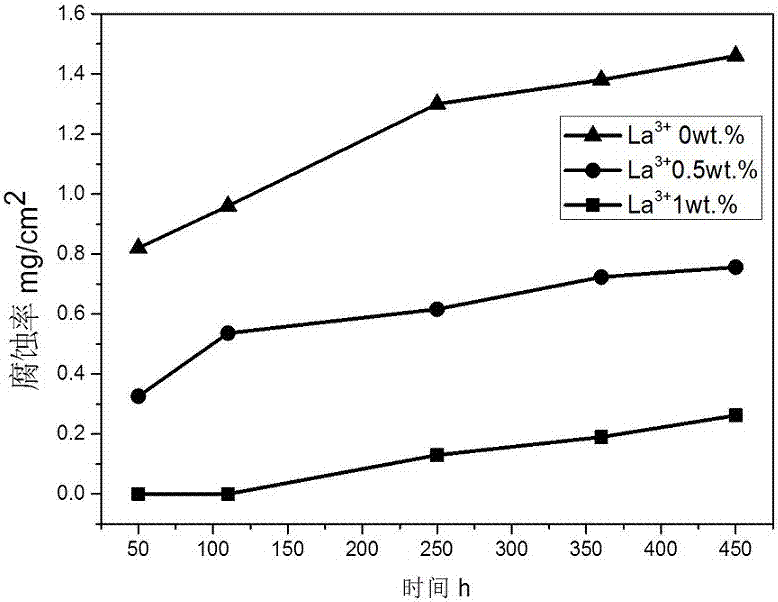

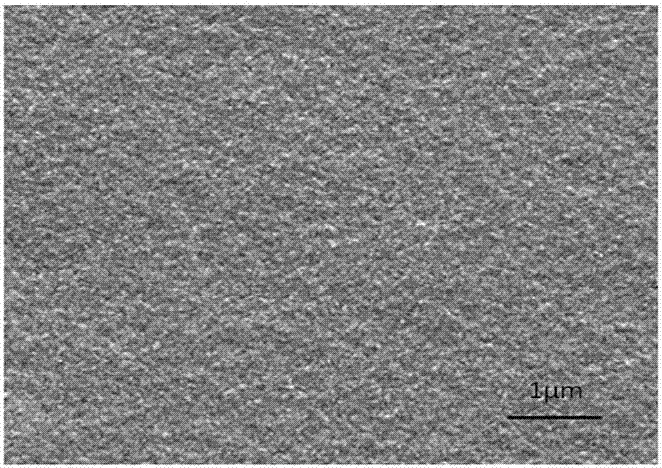

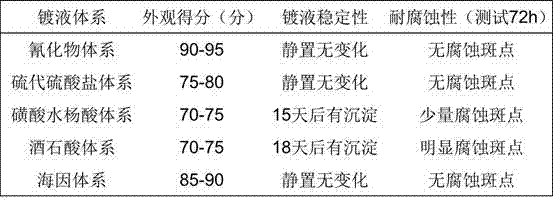

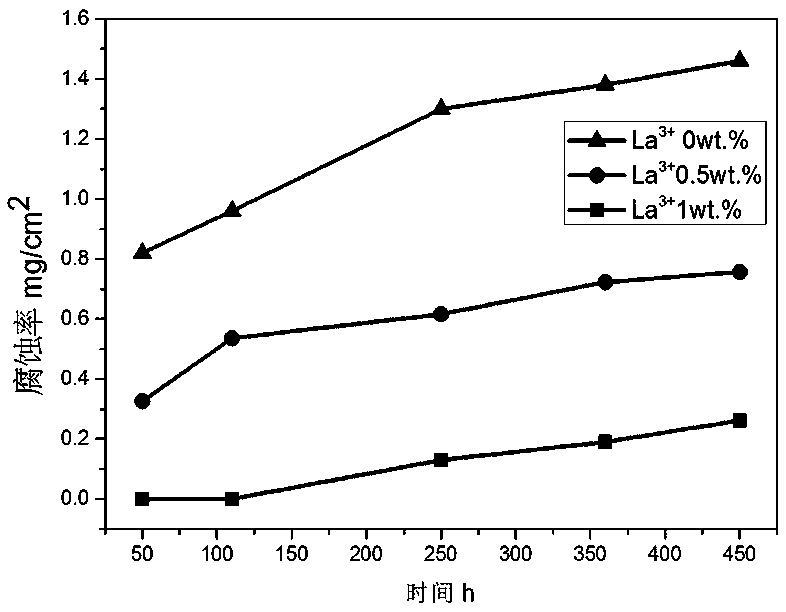

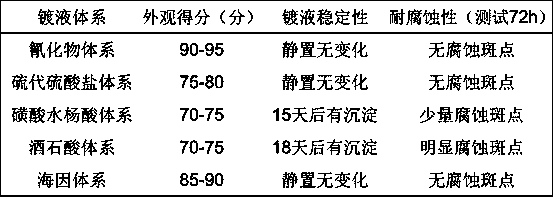

Electroplating method of carrying out La-TiO2-Ag layer cyanide-free composite electroplating on surface of steel base material

ActiveCN107385440AHomogeneous tissue compositionImprove surface qualityLiquid/solution decomposition chemical coatingSuperimposed coating processEnvironmental resistanceCyanide

The invention provides an electroplating method of carrying out La-TiO2-Ag layer cyanide-free composite electroplating on the surface of a steel base material. The electroplating method is safe and environment-friendly, a preparation technology is simple, a La-TiO2-Ag layer is flat and smooth in surface, a coating is compact, is uniform in structural components and good in surface quality and presents metallic luster, the effect of the coating using a hydantoin series electroplating solution is far higher than that of a coating using a similar cyanide-free electroplating solution system, the stability of the electroplating solution is high, the corrosion resistance and the oxidation resistance are high, and the La-TiO2-Ag layer has better antibacterial and bactericidal performance.

Owner:五莲县展鹏制造有限公司

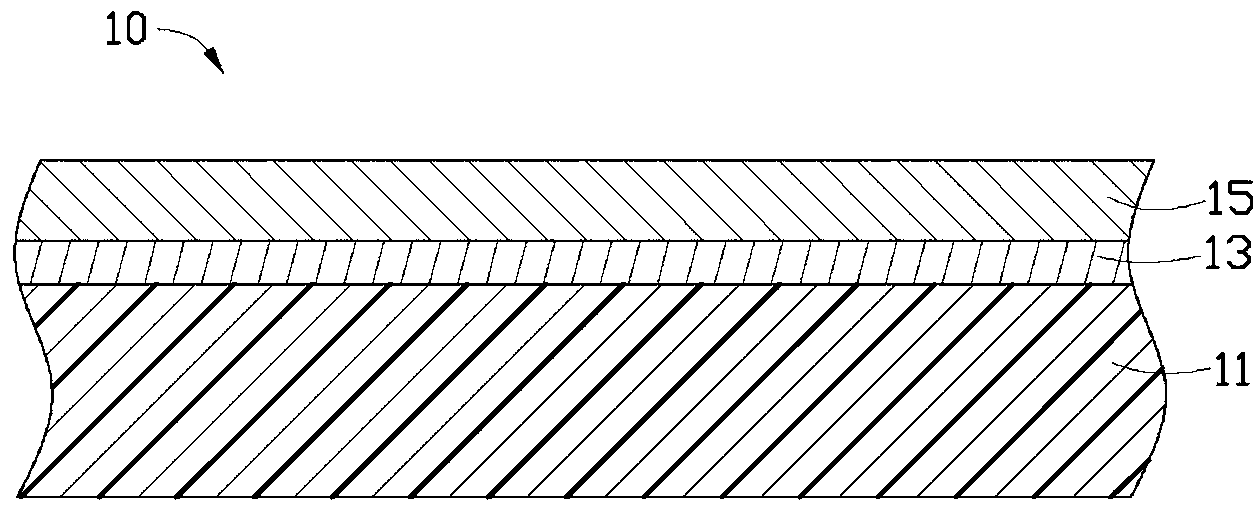

Electroplating process and electroplated part prepared by applying electroplating process

InactiveCN103184495AThe material is not particularly limitedReduce coarseningPretreated surfacesCoatingsMetal powderIrradiation

The invention discloses an electroplating process. The electroplating process comprises the following steps of: providing a plastic matrix; forming a paint layer containing a metal powder and a paint on the surface of the plastic matrix by spraying; performing laser irradiation treatment on the paint layer to change the paint layer into a combined coating; and performing electroplating on the surface of the combined layer to form an electroplated layer. The electroplating process is simple, the manufacturing procedures of coarsening and activating of the conventional electroplating process are reduced, and special limits on the material of the plastic matrix are not required. Additionally, the invention further provides an electroplated part prepared by the process aforementioned.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

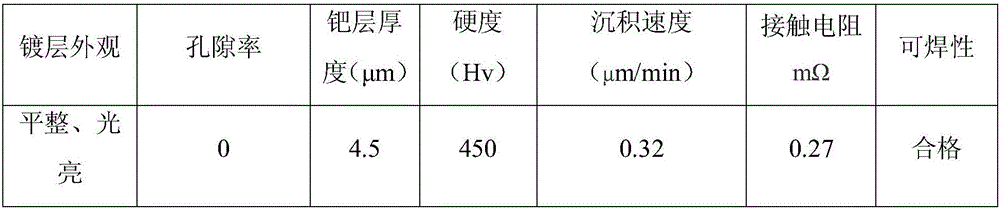

Plating solution for the process of plating stainless steel surface with palladium and application thereof

The invention discloses a plating solution for the process of plating a stainless steel surface with palladium. The plating solution comprises the following components of 0.3-0.5 mol / L of Palladium tetrammine chloride, 0.001-0.003 mol / L of diammonium phosphate, 0.001-0.003 mol / L of potassium pyrophosphate, 0.003-0.004 mol / L of sodium sulfate, 0.002-0.003 mol / L of arginine, 0.003-0.004 mol / L of sodium hydroxide, 0.001-0.005 mol / L of aspartic acid, 0.003-0.005 mol / L of glutamic acid, 0.0002-0.0003 mol / L of dihydroxyacetone phosphate and complexing agents. The potential of hydrogen is 7.8-8.2. Water serves as a solvent. When observed under a microscope, a palladium plating layer is compact, no crack exists, and the color is uniform; and after baked at the temperature of 200 DEG C for 5 min, the plating layer is free from peeling and bubbling phenomena, and adhesive force is quite good.

Owner:JIANGSU AOGUANG ELECTRONICS

Composite electroplating solution with good rust protection function for scaffolds

InactiveCN106048675AImprove wear reduction performanceImprove the lubrication effectElectrolytic coatingsSodium acetateSurface-active agents

The invention discloses a composite electroplating solution with a good rust protection function for scaffolds. The composite electroplating solution is composed of, by weight, 6.8-9 parts of aniline, 0.1-0.2 part of ammonium persulfate, 50-60 parts of boric acid, 2-3 parts of sodium acetate, 220-250 parts of nickel sulfate, 40-50 parts of nickel chloride, 0.2-0.3 part of lauryl sodium sulfate, 50-60 parts of polytetrafluoroethylene emulsion, 3-4 parts of cationic surface active agents FC134, 2.2-3 parts of cerous nitrate, 1.4-1.8 parts of neodymium nitrate, 4.6-5 parts of aluminium nitride, an appropriate amount of concentrated ammonia water, an appropriate amount of absolute ethyl alcohol and an appropriate amount of deionized water. According to the electroplating solution, the electroplating technology is simple, the strength, the corrosion resistance, the toughness and the abrasive resistance of the scaffolds are improved, plating layers do not fall off easily, the cost is lowered, and the service life is long. Thus, the composite electroplating solution is worthy of popularization.

Owner:王世群

Method for electroplating shaft bushing antifriction layer by metilsulfate plating bath

InactiveCN101503811BImprove performanceThe electroplating process is simpleBearing componentsTinningAlloy

The invention relates to a method for plating a bush antifriction coating through a methyl sulfonate bath. The method comprises the following steps: (1) cleaning a bush after ultrasonic degreasing, and cleaning a bush upper ring after cathode electroplating degreasing; (2) cleaning the bush after dilute hydrochloric acid activation for 1 to 2 minutes, placing the bush into the methyl sulfonate bath, taking a terne metal containing 10 percent of tin as an anode at a room temperature, carrying out the electroplating for 18 to 22 minutes when the cathode current density is 2 to 3 A / dm<2>, and then cleaning the bush and obtaining a terne copper coating on the inner surface of the bush; and (3) placing the bush into a tinning bath, taking a steel plate as an anode at 75 to 80 DEG C, carrying out the electroplating for 3 to 8 minutes when the cathode current density is 1 to 1.5 A / dm<2>, and obtaining a tin coating on the inner surface of the bush. The methyl sulfonate bath has stable performance and a simple process; the coating has fine crystallization, good hardness and good abrasion resistance; the bush coating has even thickness; as no strong complexing agent and F<-> are contained,wastewater is easily processed; and the method is suitable for plating the bush antifriction coating on large and medium-size diesel engines and combustion engines.

Owner:JIAYING UNIV

A kind of gold-palladium alloy electroplating solution and its preparation method and electroplating process

The embodiment of the invention discloses an Au-Pd alloy electroplating solution which comprises an Au salt, a Pd salt, a chelating agent and conducting salts. The Au-Pd alloy electroplating solution comprises the following components: 0.1-20g / l of Au salt based on the content of a single substance Au, 0.1-15 g / L of Pd salt based on the content of a single substance Pd, 30-300 g / L of chelating agent and10-30 g / L of conducting salt, wherein based on the content of metal substance, the mass ratio of gold salt to palladium salt is (0.5-20):1. In addition, the invention also discloses the preparation method and the electroplating process of the Au-Pd alloy electroplating solution. By using the Au-Pd alloy electroplating solution and electroplating process thereof, the process is simple, and an obtained Au-Pd alloy electroplating layer has the advantages of high electrical conductivity, strong wear resistance and corrosion resistance, metal white or light golden yellow appearance, and the like.

Owner:RAMBO NANOTECH SHENZHEN

Formation method of nickel-tungsten alloy coating

The invention relates to a method for forming a nickel-tungsten alloy coating, comprising the following steps: placing a workpiece to be plated and an anode material into an electroplating solution for electroplating, so as to form a nickel-tungsten alloy coating on the surface of the workpiece; the electroplating solution includes the following components: nickel Salt, tungstate, complexing agent and anode stabilizer; the complexing agent is selected from citric acid and / or citrate; the anode stabilizer is an enamine compound. The invention discloses a method for forming a nickel-tungsten alloy coating that can not only prolong the service life of an electroplating solution, but also form a dense and bright coating on a workpiece.

Owner:SUZHOU UNIV

A kind of cyanide-free composite plating la-tio on the surface of steel substrate 2 -The electroplating method of the ag layer

ActiveCN107385440BHomogeneous tissue compositionImprove surface qualityLiquid/solution decomposition chemical coatingSuperimposed coating processCyanideComposite plate

The invention provides an electroplating method of carrying out La-TiO2-Ag layer cyanide-free composite electroplating on the surface of a steel base material. The electroplating method is safe and environment-friendly, a preparation technology is simple, a La-TiO2-Ag layer is flat and smooth in surface, a coating is compact, is uniform in structural components and good in surface quality and presents metallic luster, the effect of the coating using a hydantoin series electroplating solution is far higher than that of a coating using a similar cyanide-free electroplating solution system, the stability of the electroplating solution is high, the corrosion resistance and the oxidation resistance are high, and the La-TiO2-Ag layer has better antibacterial and bactericidal performance.

Owner:五莲县展鹏制造有限公司

A miniaturized planar dual-band high-precision satellite navigation antenna

ActiveCN109546331BOptimize volumeReduce volumeSimultaneous aerial operationsRadiating elements structural formsDielectric plateEngineering

The invention provides a miniature planar dual-frequency-band high precision satellite navigation antenna. The miniature planar dual-frequency-band high precision satellite navigation antenna includesa dielectric plate and a printed circuit base plate, wherein the dielectric plate includes a plurality of high frequency feeding points, a high frequency radiating surface, a plurality of low frequency feeding points, and a low frequency radiating surface; short circuit pins are distributed in the inner ring of the low frequency radiating surface; upward branch knots and downward branch knots aredistributed around the dielectric plate; the upward branch knots contact the printed circuit base plate; the downward branch knots are connected to the low frequency radiating surface; and coupling slits are formed between the upward branch knots and the downward branch knots. The miniature planar dual-frequency-band high precision satellite navigation antenna preferably solves the problems of antenna miniaturization, dual-frequency-band, antenna phase center elevation and the like, provides a design scheme for the miniature planar dual-frequency-band of the high precision satellite navigation antenna, effectively reduces the volume of the antenna, and effectively reduces the weight of the antenna at the same time.

Owner:SHANGHAI HUACE NAVIGATION TECH

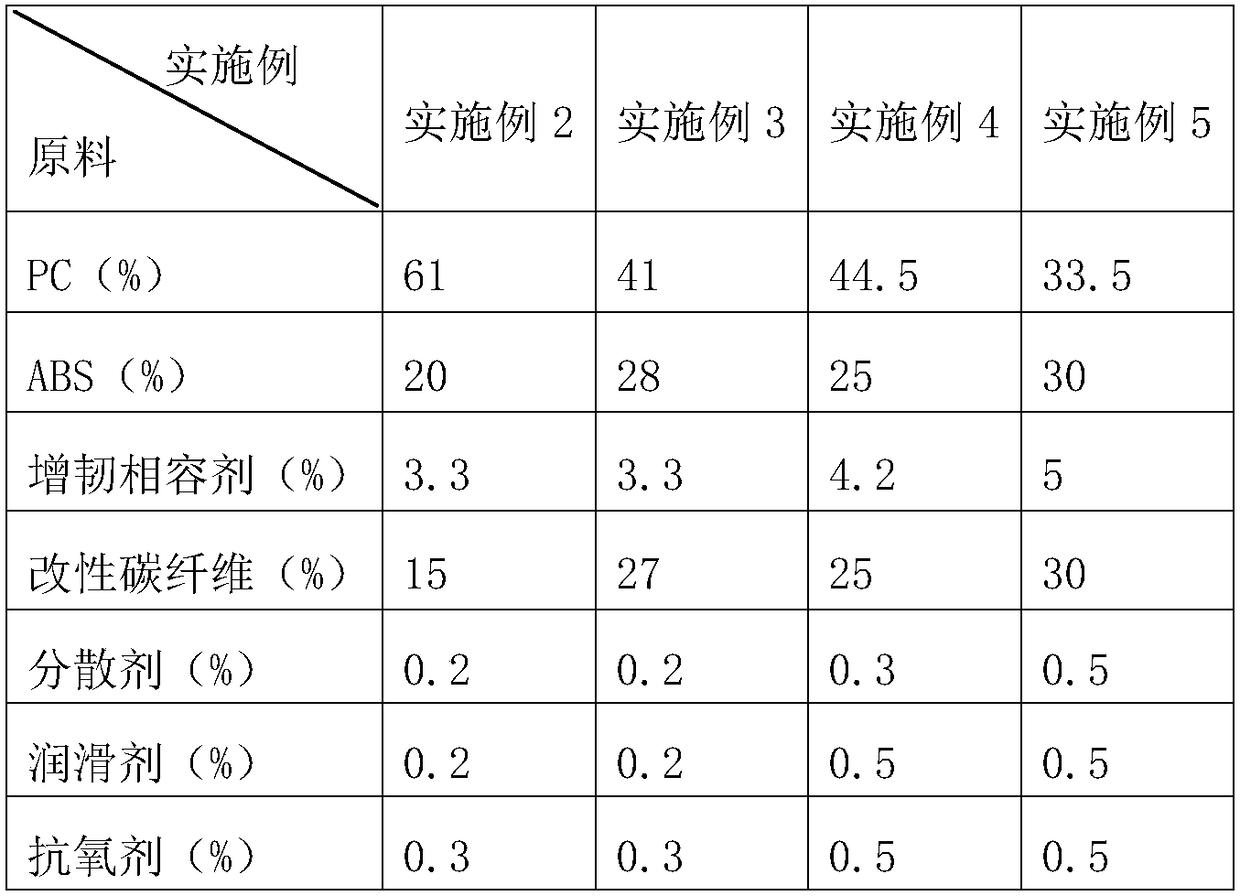

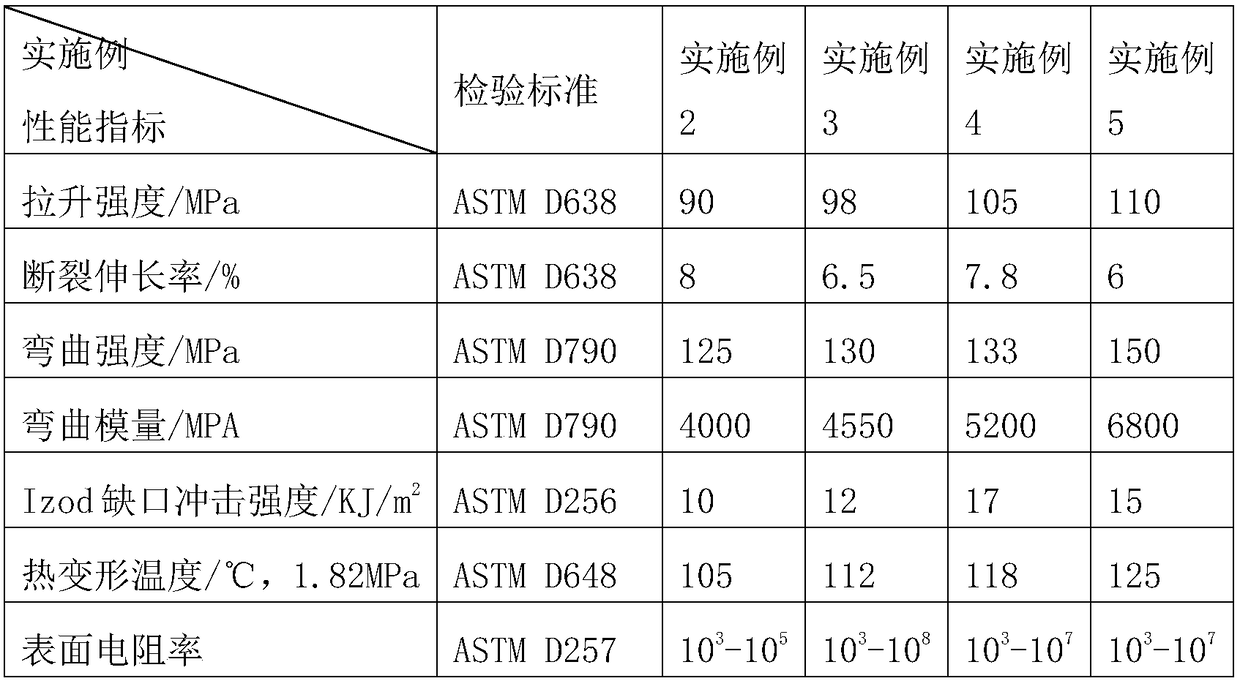

A pc/abs material with high binding force and easy electroplating and its preparation method

The invention relates to a PC / ABS material with high binding force and easy to electroplate and a preparation method thereof. The PC / ABS material is prepared from the following components by a weight ratio: 33.4 to 61.3 percent of PC, 20 to 30 percent of ABS, 15 to 30 percent of modified carbon fiber, 3 to 5 percent of compatilizer, 0.2 to 0.5 percent of dispersant, 0.3 to 1 percent of antioxidant and 0.2 to 0.5 percent of lubricant. The preparation method of the PC / ABS material comprises the following steps of mixing all the components into a mixing agitator according to a proportion to carry out mixing; blending and granulating an obtained mixture through a twin screw extruder. The method provided by the invention is simple, easy and feasible; the dispersion, in a PC / ABS matrix, of the carbon fiber is promoted through the introduction of the compatilizer, so that the excellent electric conduction performance can be given to a PC / ABS alloy composition through a minute quantity of the carbon fiber; the linear expansion coefficient of the composition is decreased; an electroplating procedure can be directly carried out; coarsening, activating and chemical plating procedures are omitted; the electroplating procedure is simplified; a product composition provided by the invention has high mechanical strength; further, the dimensional stability is good.

Owner:广东道生科技股份有限公司

Nano conductive carbon paste for surface electroplating of non-metal insulating materials and preparation method thereof

ActiveCN105741908BReduce pollutionEliminate sensitizationNon-conductive material with dispersed conductive materialMaterials processingReducing agent

Owner:YANTAI XIAXIN NEW MATERIAL CO LTD

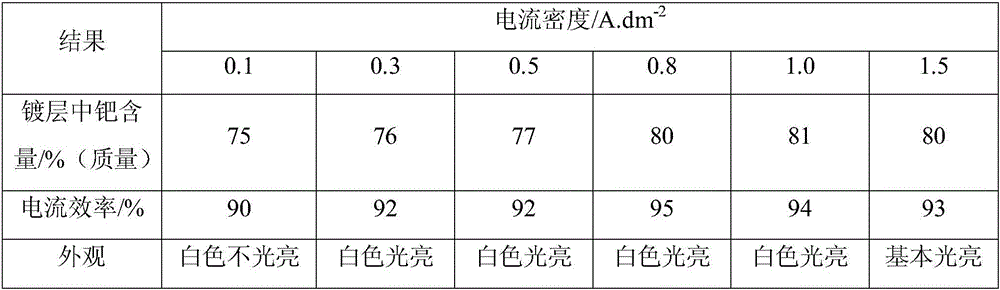

Method for chemically plating nickel-palladium alloy on PCB board

InactiveCN106757207AThe electroplating process is simpleEasy to expand productionJewelleryAdhesion forceEtching

The invention discloses a method for chemically plating a nickel-palladium alloy on a PCB board. The method is characterized by comprising the following steps of: (1) removing oil: putting the PCB board into an oil removing agent, and performing ultrasonic treatment for 10-15 minutes; (2) performing micro-etching: putting the PCB board into a micro-etching solution, and standing for 1-2 hours; (3) activating: putting the PCB board into an activating solution to activate at an activating temperature being 25-30 DEG C; (4) chemically plating nickel and palladium; and (5) performing washing and drying: washing the surface of a circuit board with water, and drying at a temperature from 55 DEG C to 65 DEG C. Content of palladium in the coating is about 80%, and the coating is fine in texture, is free of cracks, is uniform in color, is free of peeling and bubbling phenomena, and is good in adhesion force.

Owner:JIANGSU AOGUANG ELECTRONICS

Ni-Cu-P ternary alloy coating serving as welding spot reaction barrier layer and electroplating preparation technology thereof

InactiveCN102560576BReduce energy consumptionHigh bath stabilitySoldering apparatusInterconnectionAlloy coating

The invention discloses a Ni-Cu-P ternary alloy coating serving as a welding spot reaction barrier layer and an electroplating preparation technology thereof. The Ni-Cu-P ternary alloy coating serving as the welding spot reaction barrier layer comprises the following components in percentage by weight: 70-90% of Ni, 3-10% of Cu and 7-20% of P. The thickness of the coating is 2-15mu m. The preparation method comprises the following steps of: putting an electroplated cathode piece (metallized Si chip or Cu piece) and an electroplated anode sheet (Pt piece) into electroplate liquid; introducing dipulse current for dipulse electroplating; and forming an Ni-Cu-P alloy coating on the surface of the cathode piece. The components of the Ni-Cu-P alloy coating prepared by using the electroplating preparation technology conform to the use requirement of a welding spot reaction barrier layer for electronic packaging and interconnection, the coating and the cathode piece substrate (metallized Si chip or Cu piece) are tightly combined, a plating layer is flat, and the Ni-Cu-P ternary alloy coating is fine in cellular tissue, even in thickness, and compact in structure and is basically free from holes.

Owner:HEFEI UNIV OF TECH

A method for rapid electrodeposition coating on the surface of magnesium alloy

ActiveCN109487261BImprove the protective effectSimple and efficient processSuperimposed coating processHeat inorganic powder coatingSand blastingSpray coating

The invention belongs to the technical field of metal surface treatment, and discloses a method for rapid electrolytic-deposition of a coating on a surface of a magnesium alloy. According to the method, sand blasting equipment is adopted for carrying out sand blasting treatment on the surface of the magnesium alloy, then ultrasonic cleaning is carried out on the surface of the magnesium alloy, anda coating material is sprayed on the surface of the magnesium alloy which is subjected to the sand blasting treatment by adopting a cold spraying method; the working gas of the cold spraying is compressed air, wherein the pressure is 0.6 MPa to 0.8 MPa, the preheating temperature of the cold spraying gas is 400-600 DEG C, the powder feeding distance is 10 mm, the relative moving speed of a nozzleis 600-2000 mm / min, and a cold-sprayed copper-based coating is prepared; and the cold-sprayed copper-based coating is placed in an electroplating solution, electroplating parameters are set, and a composite coating of a copper base and an electroplating layer is prepared through electroplating. The composite coating is good in microstructure and stable in physical property, the bonding strength of the cold-sprayed coating and the base material is high, the thickness of the cold spraying layer and the base material is controllable, and the composite coating has excellent corrosion resistance and wear resistance. According to the method, the electroplating process of the magnesium alloy is simplified, and the pollution to the environment is reduced.

Owner:东莞市先力得热处理有限公司

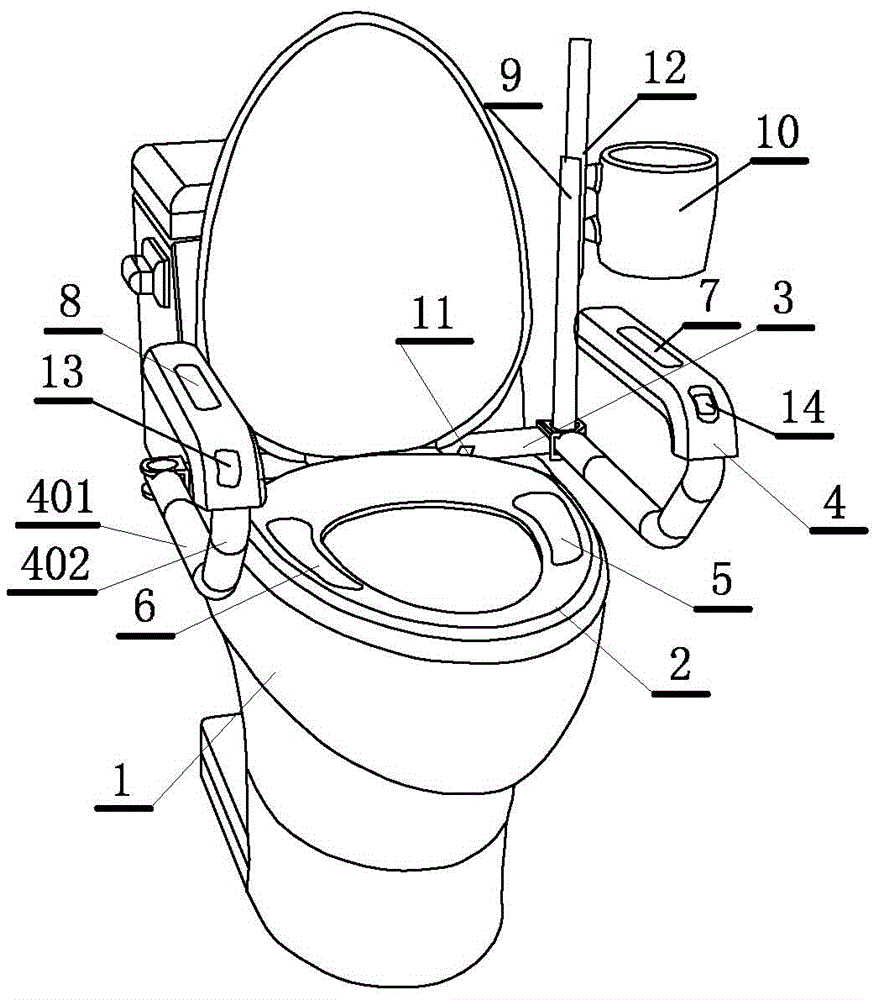

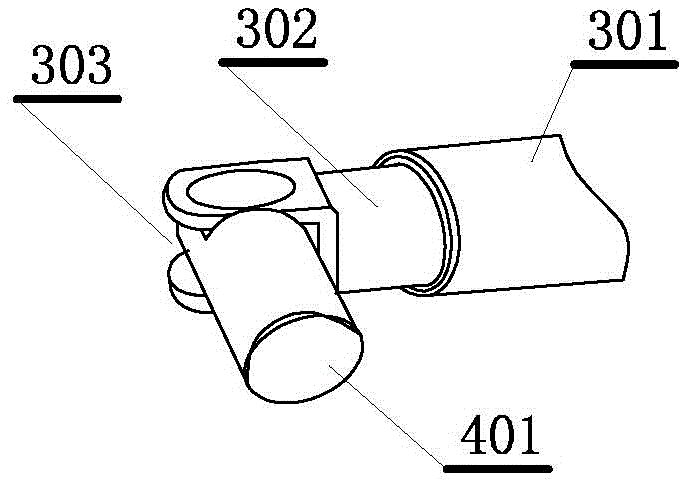

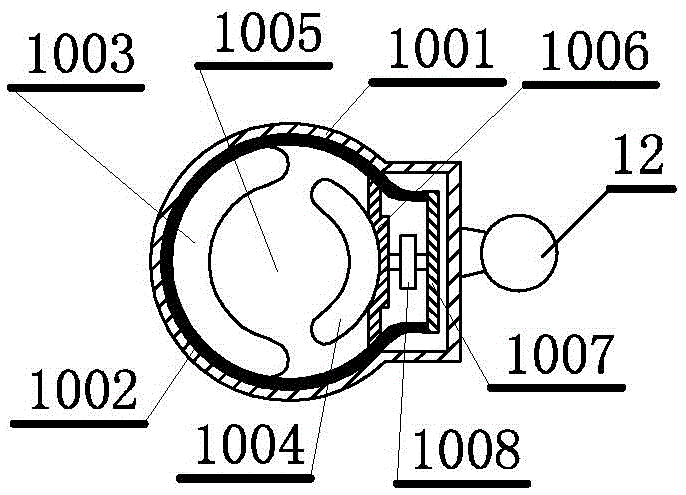

A toilet type rapid physical examination device

ActiveCN104323770BReduce usageHighly integratedSurgeryVaccination/ovulation diagnosticsBlood pressure cuffsBlood pressure cuff

The invention discloses a pedestal pan type quick physical examination device which comprises a pedestal pan main body and a pedestal pan ring at an upper opening of the pedestal pan main body, wherein the physical examination device further comprises a supporting connecting rod, handrails and a physical examination test device; a left leg electrode and a right leg electrode in the test device are arranged on left and right surfaces of the pedestal pan ring; the supporting connecting rod is arranged on the rear side of the pedestal pan ring and is fixedly connected with the pedestal pan main body; the handrails and the supporting connecting rod are connected with each other and are arranged on the two sides of the pedestal pan ring; left arm and right arm test electrodes in the test device are arranged on fore knuckle arm supporting surfaces of the two handrails; a supporting rod is arranged at one end of the supporting connecting rod; a blood pressure cuff of the test device is mounted on the supporting rod. According to the invention, the test devices for various physiological parameters, such as electrocardio, blood pressure and blood oxygen, are integrated into a pedestal pan structure, so that the usage of various accessories is reduced, the system integration degree is high, the fault rate is reduced, the daily physiological parameter test is convenient and the device is specially fit for the aged and disabled people.

Owner:CONTEC MEDICAL SYST

Method for electroplating environment-friendly chromium on aluminum and aluminum alloy parts

PendingCN113445049AHarm reductionImprove corrosion resistanceLiquid/solution decomposition chemical coatingSuperimposed coating processCyanideChromium coating

The invention discloses a method for electroplating environment-friendly chromium on aluminum and aluminum alloy parts. The method comprises the step: performing oil removal, alkali washing, acid pickling, primary zinc dipping, zinc stripping, secondary zinc dipping, cyanide-free alkali copper plating, nickel pre-plating, acid copper plating, activation, semi-bright nickel plating, full-bright nickel plating, nickel sealing and trivalent chromium treatment on the aluminum or aluminum alloy parts sequentially. By adopting the method, the environment-friendly chromium coating with super corrosion resistance and high binding force can be formed on the surface of the aluminum or aluminum alloy part, the method is simple and convenient to implement, the requirement on the technical capability of operators is not high, and the quality of the produced product is very stable.

Owner:JOMOO KITCHEN & BATHROOM

Steel casing electroplating technology

The invention discloses a steel casing electroplating technology. The technology comprises 1, roller burnishing degreasing, 2, alkaline degreasing, 3, pickling rust removal, 4, electronickelling and 5, water washing and recovery. The technology has simple processes, is free of repeated processes and improves work efficiency. The technology improves steel casing surface electroplating quality and has good electroplating effects.

Owner:CHONGQING YONGLIN MACHINERY EQUIP

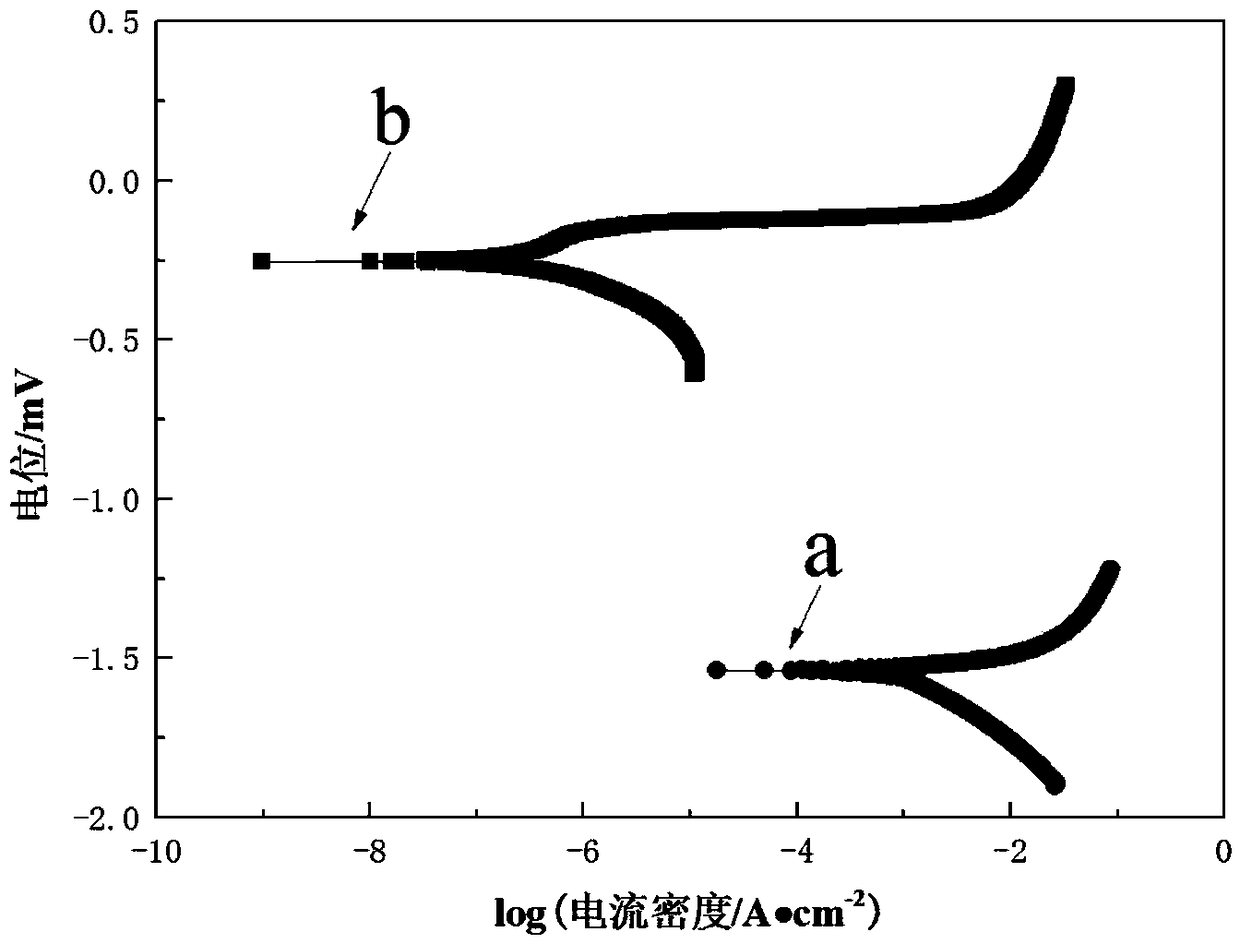

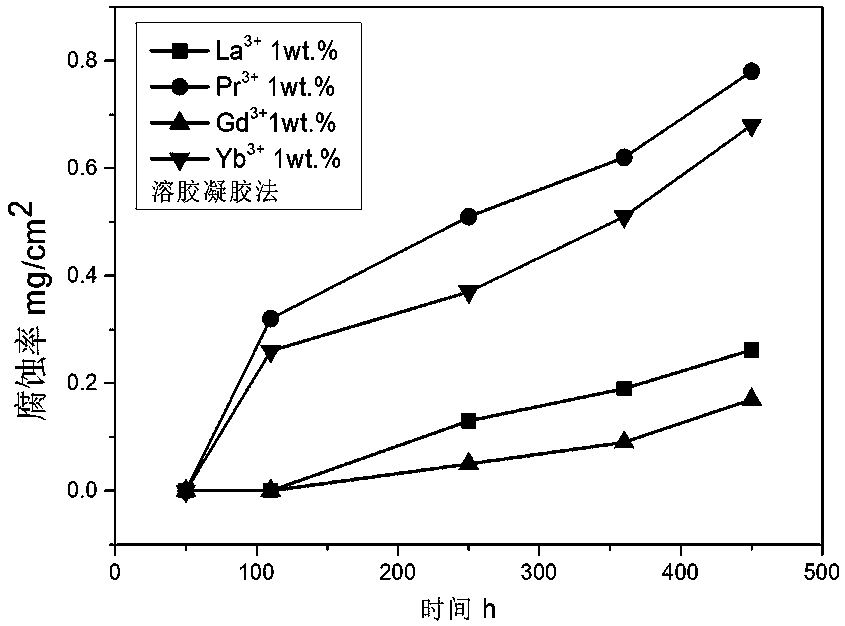

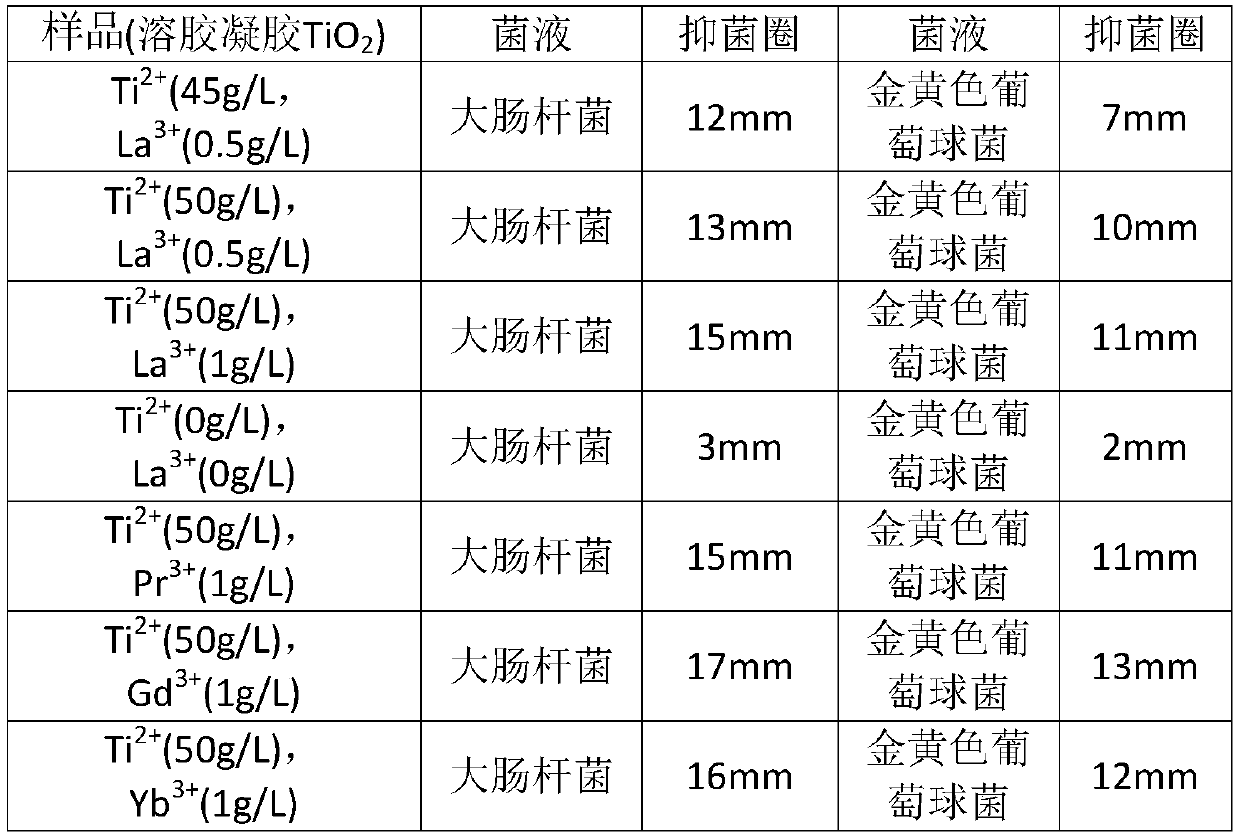

A cyanide-free composite plating re-tio on the surface of steel substrate 2 - Plating method of ag layer

ActiveCN107299368BFlat surfaceHomogeneous tissue compositionElectrolytic coatingsRare-earth elementCyanide

The invention provides a cyanide-free composite electroplating method for plating a RE-TiO2-Ag layer on the surface of a steel substrate. RE rare earth element is selected from La<3+>, Pr<3+>, Gd<3+> or Yb<3+>, and titanium oxide is from titanium oxide powder with the size of 20-100nm or a titanium oxide sol solution. The electroplating method is safe and environment-friendly, the preparation process is simple, and an obtained electroplated layer is uniform, compact, strong in corrosion resistance and strong in oxidation resistance and has relatively good antibacterial and bactericidal properties.

Owner:长江润发(江苏)薄板镀层有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com