Plating solution for the process of plating stainless steel surface with palladium and application thereof

A stainless steel and liquid-passing technology, which is applied in the field of palladium-plating on the surface of stainless steel, can solve the problems of difficult to obtain thick palladium coating, high internal stress of palladium coating, poor ductility, etc., and achieve easy expansion of production, good adhesion, palladium layers of detailed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The composition of the electroplating solution is as follows:

[0021] Dichlorotetraammine palladium 0.3mol / L, diammonium hydrogen phosphate 0.001mol / L, potassium pyrophosphate 0.001mol / L, sodium sulfate 0.003mol / L, arginine 0.002mol / L, sodium hydroxide 0.003mol / L , aspartic acid 0.004mol / L, glutamic acid 0.004mol / L, dihydroxyacetone phosphate 0.0002mol / L, hydroxyethyldiaminetetraacetic acid 0.02~0.03mol / L, ethylenediamine 0.01~0.02mol / L , Hydroxyethylaminoacetic acid 0.03~0.05mol / L, pH 7.8~8.2, solvent is water.

[0022] Plating method:

[0023] Put the cleaned stainless steel into the palladium ferry solution, the current density is 0.1~0.5.A / dm 2 , the temperature of the liquid is 28°C, and the tank pressure is 4V.

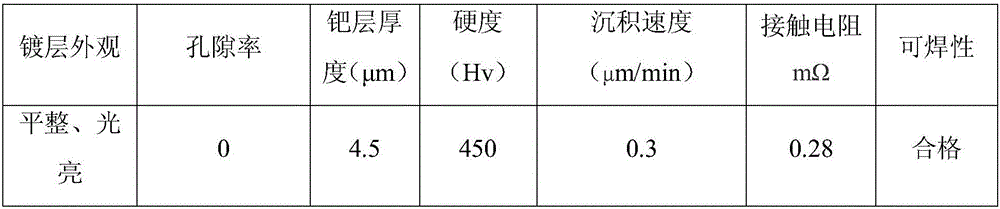

[0024] Plating effect:

[0025] The palladium-coated layer was observed under a microscope, and the palladium layer was fine, without cracks, and uniform in color; after baking for 5 minutes at a temperature of 200°C, the coating had no peeling or bu...

Embodiment 2

[0029] The composition of the electroplating solution is as follows:

[0030] Dichlorotetraammine palladium 0.5mol / L, diammonium hydrogen phosphate 0.002mol / L, potassium pyrophosphate 0.0015mol / L, sodium sulfate 0.004mol / L, arginine 0.001mol / L, sodium hydroxide 0.0035mol / L , aspartic acid 0.003mol / L, glutamic acid 0.004mol / L, dihydroxyacetone phosphate 0.00025mol / L, hydroxyethyldiaminetetraacetic acid 0.02~0.03mol / L, ethylenediamine 0.01~0.02mol / L , Hydroxyethylaminoacetic acid 0.03~0.05mol / L, pH 7.8~8.2, solvent is water.

[0031] Plating method:

[0032] Put the cleaned stainless steel into the palladium ferry solution, the current density is 0.1~0.5.A / dm 2 , The temperature of the liquid is 35°C, and the tank pressure is 4V.

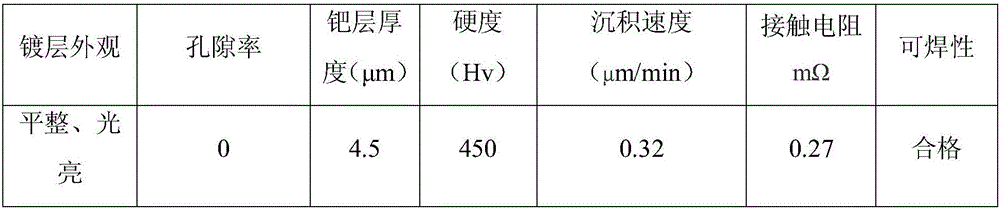

[0033] Plating effect:

[0034] The palladium-coated layer was observed under a microscope, and the palladium layer was fine, without cracks, and uniform in color; after baking for 5 minutes at a temperature of 200°C, the coating had no peeling or...

Embodiment 3

[0038] The composition of the electroplating solution is as follows:

[0039] Dichlorotetraammine palladium 0.4mol / L, diammonium hydrogen phosphate 0.002mol / L, potassium pyrophosphate 0.002mol / L, sodium sulfate 0.0035mol / L, arginine 0.0025mol / L, sodium hydroxide 0.003mol / L , aspartic acid 0.004mol / L, glutamic acid 0.0035mol / L, dihydroxyacetone phosphate 0.00025mol / L, hydroxyethyldiaminetetraacetic acid 0.025mol / L, ethylenediamine 0.02mol / L, hydroxyethyl Glycine 0.035mol / L, pH 7.8~8.2, solvent is water.

[0040] Plating method:

[0041] Put the cleaned stainless steel into the palladium ferry solution, the current density is 0.1~0.5.A / dm 2 , The temperature of the liquid is 35°C, and the tank pressure is 4V.

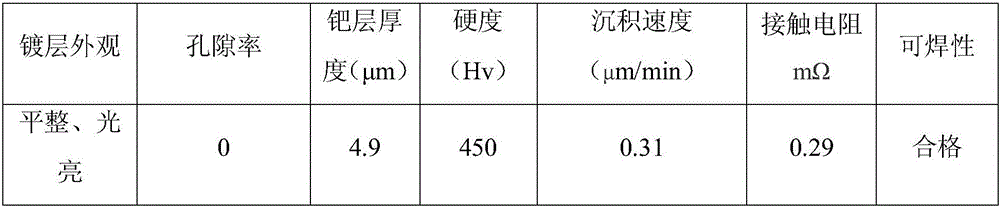

[0042] Plating effect:

[0043] The palladium-coated layer was observed under a microscope, and the palladium layer was fine, without cracks, and uniform in color; after baking for 5 minutes at a temperature of 200°C, the coating had no peeling or bubbling phenomenon,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com