Patents

Literature

713 results about "Potassium Pyrophosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tetrapotassium Pyrophosphate is a potassium salt of phosphoric acid widely used as buffering agent, emulsifier, dispersing agent and thickening agent in food production.

Potassium pyrophosphate pet food palatability enhancers

InactiveUS20050170067A1High degree of palatabilityAnimal feeding stuffAccessory food factorsAnimal scienceAdditive ingredient

A palatability enhancing composition for extruded pet food containing at least one potassium pyrophosphate salt in an amount effective to enhance palatability and at least one ingredient selected from animal products, animal by-products, fish products, fish by-products, dairy products, dairy by-products, sources of microbial proteins, vegetable proteins, carbohydrates and amino acids. Methods for enhancing pet food palatability with the disclosed palatability enhancing compositions and extruded pet food compositions coated therewith are also disclosed.

Owner:NUSCI LAB

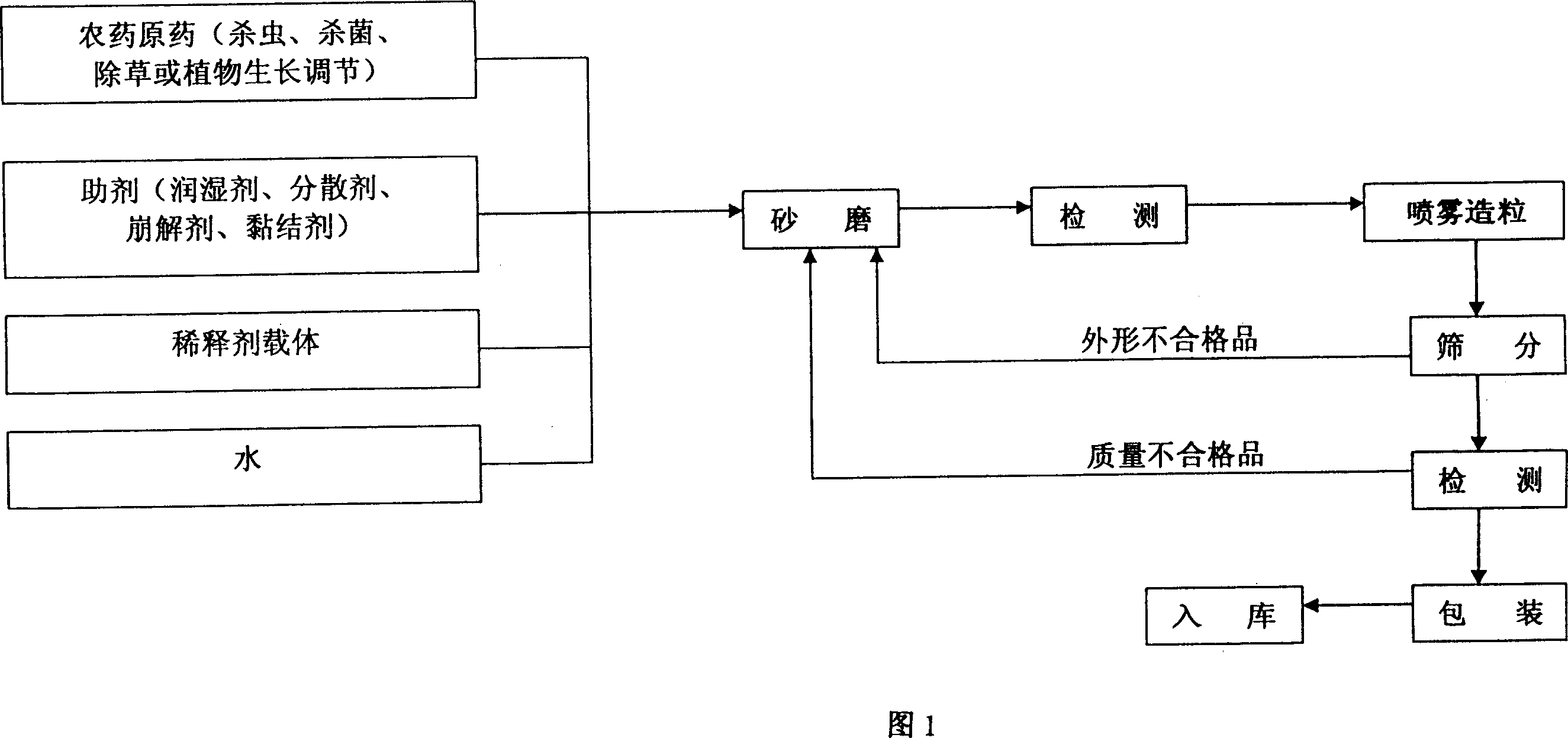

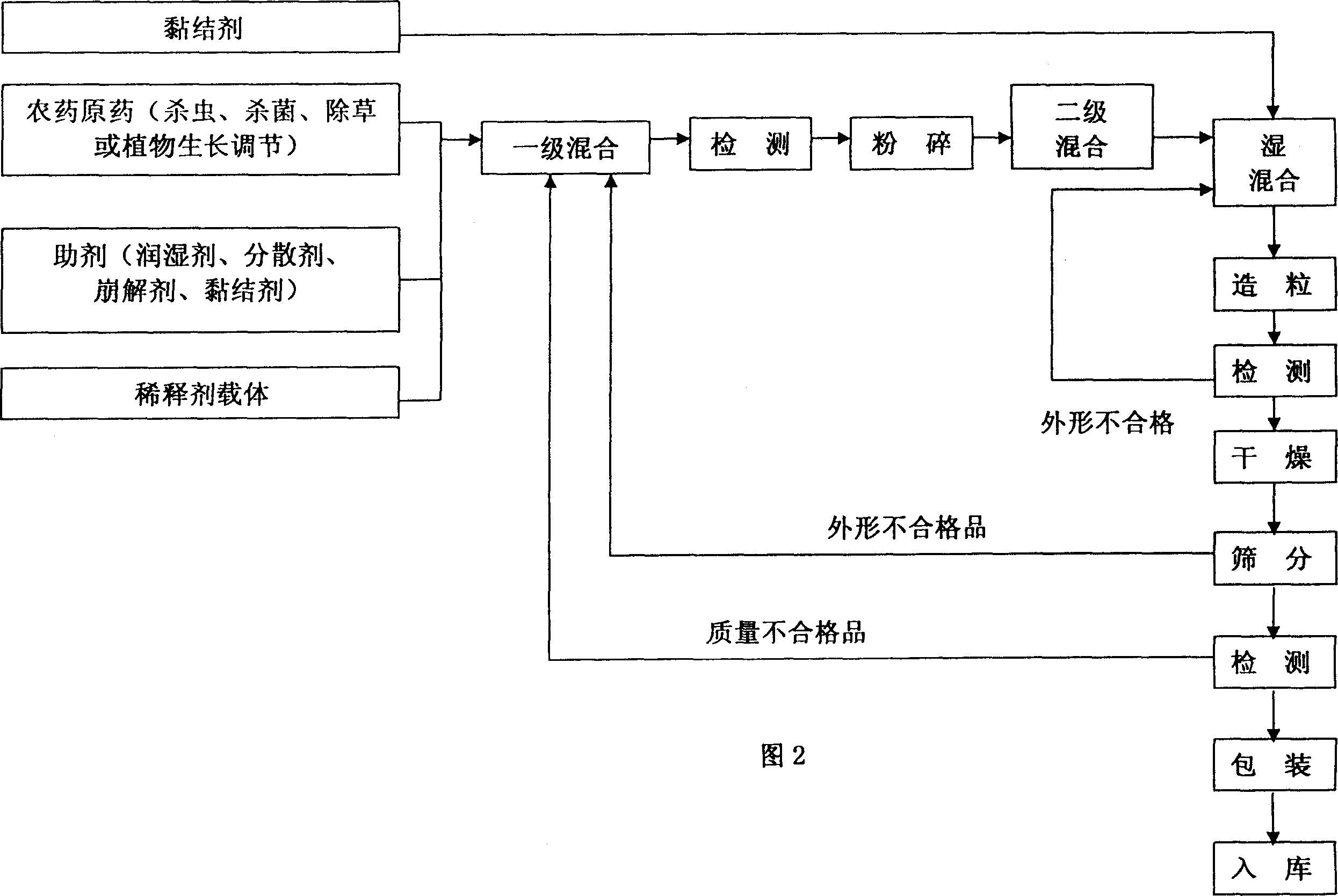

Water dispersion granules of pesticide, and preparation method

A water-dispersing particle of agricultural chemical contains active component, wetting agent, disperser, disintegrant chosen from sodium pyrophosphate, potassium pyrophosphate, sodium tripolyphosphate, sodium bihydrogen phosphate and polyose, adhesive, and diluent. Its preparing process is also disclosed.

Owner:新沂市中港农用化工有限公司

Preparation method of western yak steak

Owner:SHANGHAI FOOD RES INST +1

Alkaline fertilizer

InactiveCN104761322AGood characterPrevent acidificationFertilizer mixturesPotassium hydroxideManganese

The invention discloses an alkaline fertilizer composed of the following components in percentage by weight: 31-99.4% of macroelements, 0.5-50% of medium elements, 0.1-15% of microelements and 0-50% of synergic components, wherein the macroelements include two and even more selected from urea, diammonium phosphate, ammonium polyphosphate, dipotassium phosphate, tripotassium phosphate, potassium pyrophosphate, potassium tripolyphosphate, potassium nitrate, potassium carbonate, potassium sulfate, potassium chloride, potassium formate, potassium silicate and potassium hydroxide; the medium elements are one or more selected from calcium nitrate, calcium chloride, magnesium chloride, magnesium sulfate, EDTA calcium and EDTA magnesium; the microelements are one or more selected from ferrous sulfate, zinc sulfate, manganese sulfate, copper sulfate or an EDTA chelate of iron, zinc, manganese and copper, EDDHA iron, borax, disodium octaborate tetrahydrate and sodium molybdate; and the synergic components include one or more selected from sodium humate, potassium humate, sodium fulvate, potassium fulvate, sodium alginate, potassium alginate and a plant growth regulator.

Owner:于书强

High-concentration major element liquid water-soluble fertilizer and preparation method thereof

ActiveCN104151006AImprove stabilityNo crystallizationFertilizer mixturesDipotassium hydrogen phosphateHigh concentration

The invention discloses a high-concentration major element liquid water-soluble fertilizer and a preparation method thereof. The fertilizer comprises the materials in parts by weight: 7-10 parts of dipotassium hydrogen phosphate, 18-20 parts of urea, 8-11 parts of potassium dihydrogen phosphate, 5-8 parts of potassium permangenate, 24-28 parts of potassium formate, 1-3 parts of EDTA-Zn, 0.5-2 parts of instant boron, and the balance water. The method comprises the steps: under the ordinary pressure and in a reaction kettle, firstly stirring potassium permangenate, potassium formate and potassium dihydrogen phosphate for 2 h according to the formula ratio under the condition of the temperature of 80 DEG C, adjusting the temperature to 45 DEG C, stirring for 0.5 h, then dissolving dipotassium hydrogen phosphate and urea in the solution according to the set formula, after the materials are dissolved completely, adding a proper amount of instant boron and EDTA-Zn, heating to dissolve, after reaction dissolution of the materials according to the formula ratio is completed, cooling to the room temperature, packaging, and thus obtaining the major element liquid water-soluble fertilizer product. The process is simple, the raw material cost is low, and the product is suitable for requirements of current dropper devices and can be widely popularized.

Owner:中化(临沂)作物营养有限公司

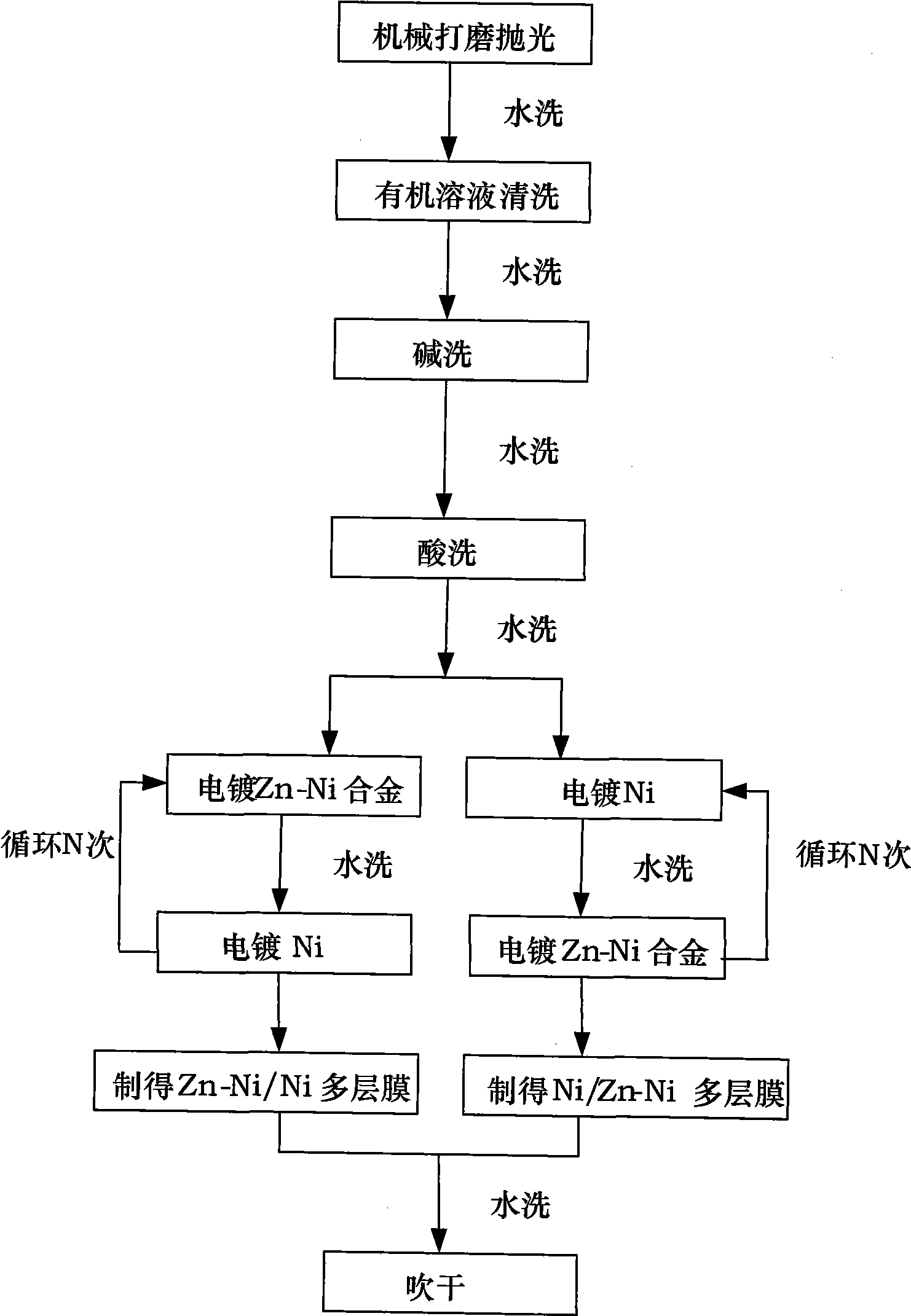

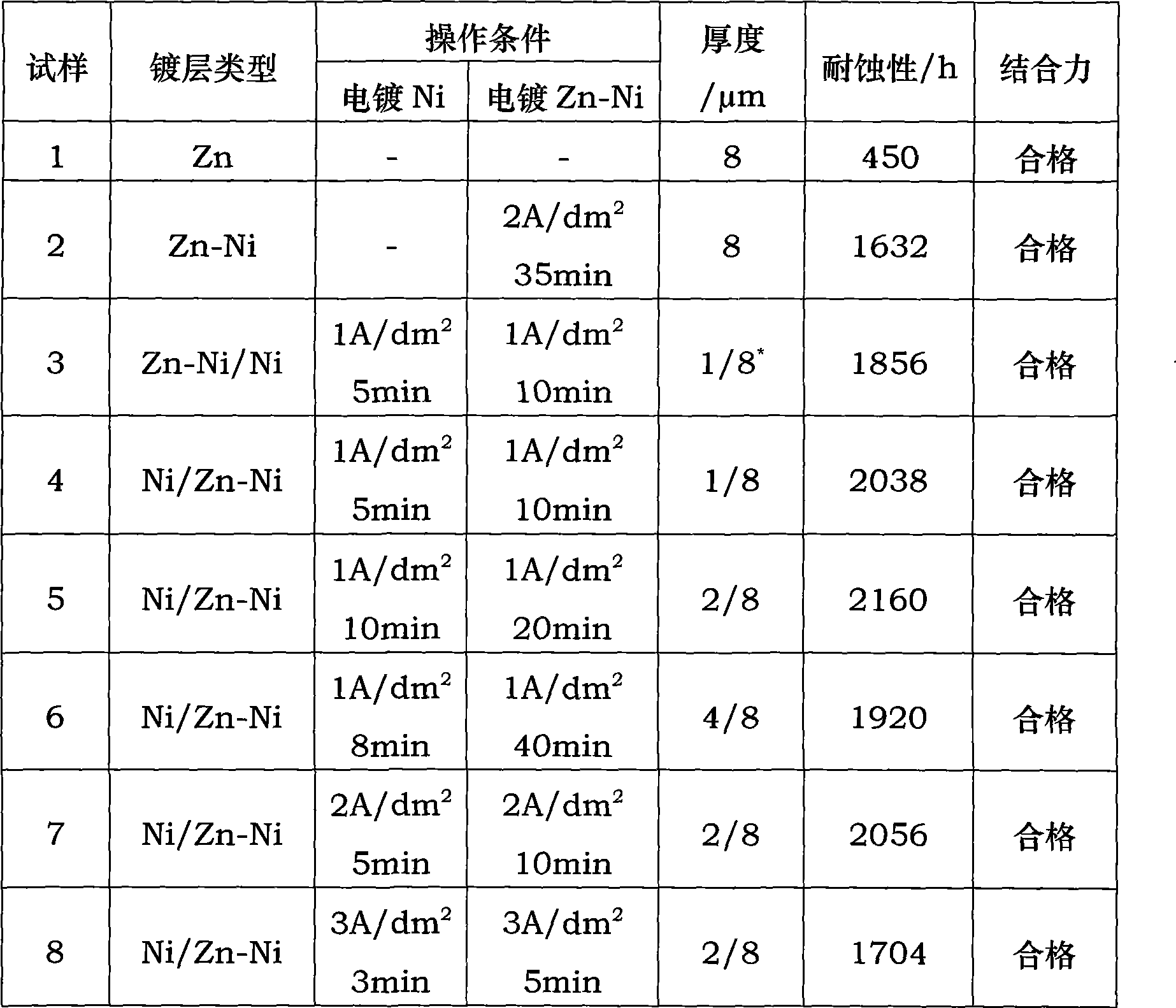

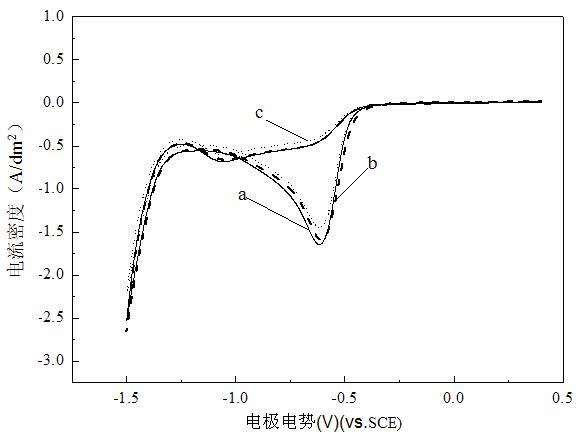

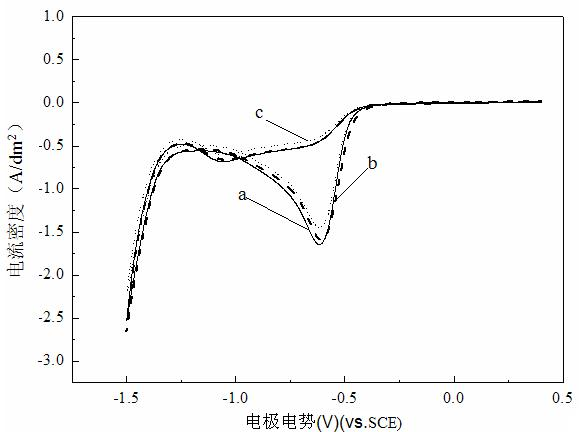

Method for modulating zinc-nickel alloy and nickel combined multi-layer membranous by electrochemical deposition component

InactiveCN101487134ASolve the problem of large compositional changesImprove current efficiencyPyrophosphateElectrochemistry

The invention provides a method for modulating a multilayer film consisting of Zn-Ni alloy and Ni by electro-chemically depositing compositions, comprising five steps as follows: preparing alkaline liquor, pickling liquor and electroplating solution, mechanical grinding and cleaning plating articles, alkaline washing, pickling and electroplating, wherein, the electroplating solution comprises alkaline electroplating solution with electroplated Zn-Ni alloy and neutral and alkaline electroplating solution with electroplated Ni; the electroplating solution of Ni consists essentially of a main salt and a complexing agent; the main salt is one or two compositions out of NiSO4 and NiCl2; and the complexing agent consists of two or more substances as follows: ammonium citrate, sodium citrate, citric acid, ammonia, sodium pyrophosphate, potassium pyrophosphate and triethanolamine. The Zn-Ni / Ni or Ni / Zn-Ni multilayer film electroplated by the method has smooth plating layer surface, better corrosion resistance and higher current efficiency and plating layer adhesion.

Owner:BEIHANG UNIV

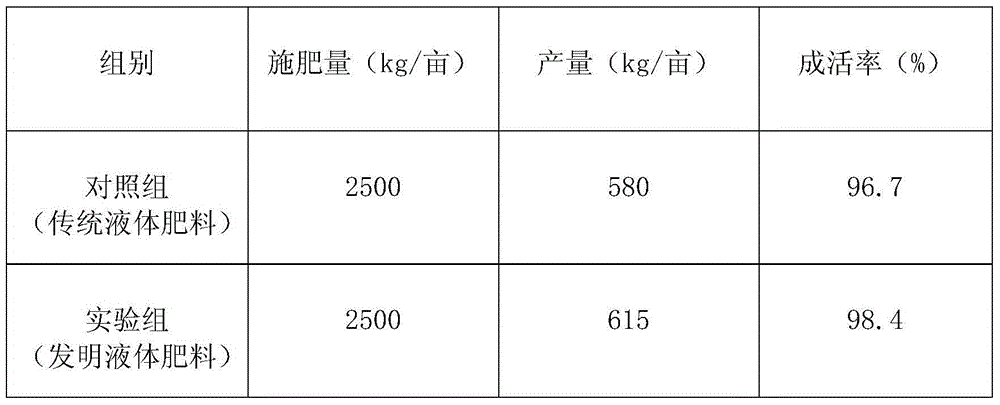

Root-promoting liquid fertilizer and preparation method thereof

The invention discloses a root-promoting liquid fertilizer, which is prepared from the following raw materials in parts by weight: 2-4 parts of ferrous sulfate, 2-3 parts of ammonium molybdate tetrahydrate, 1-3 parts of potassium pyrophosphate, 5-7 parts of short rhizome of spathiphyllum, 6-9 parts of castor cake, 15-20 parts of bran, 5-8 parts of potassium sulfate, 7-10 parts of urea, 2-4 parts of matrine, 2-3 parts of zinc sulphate heptahydrate, 0.1-0.2 part of 6-benzylaminopurine, 0.1-0.2 part of triiodobenzoic acid, 4-8 parts of rose, 10-14 parts of brewer's grains and 8-12 parts of an ingredient. Due to the addition of the 6-benzylaminopurine, the triiodobenzoic acid and the like, the liquid fertilizer disclosed by the invention has the function of adjusting the raw materials with a crop growth function, and is capable of effectively promoting rooting and formation of flower buds of the crops; the nutrient components of a microelement fertilizer can be increased by extract liquids such as chaff and brewer's grains; and the root-promoting liquid fertilizer is convenient to use, and obvious in yield-increasing effect, and has a good application prospect.

Owner:周作艳

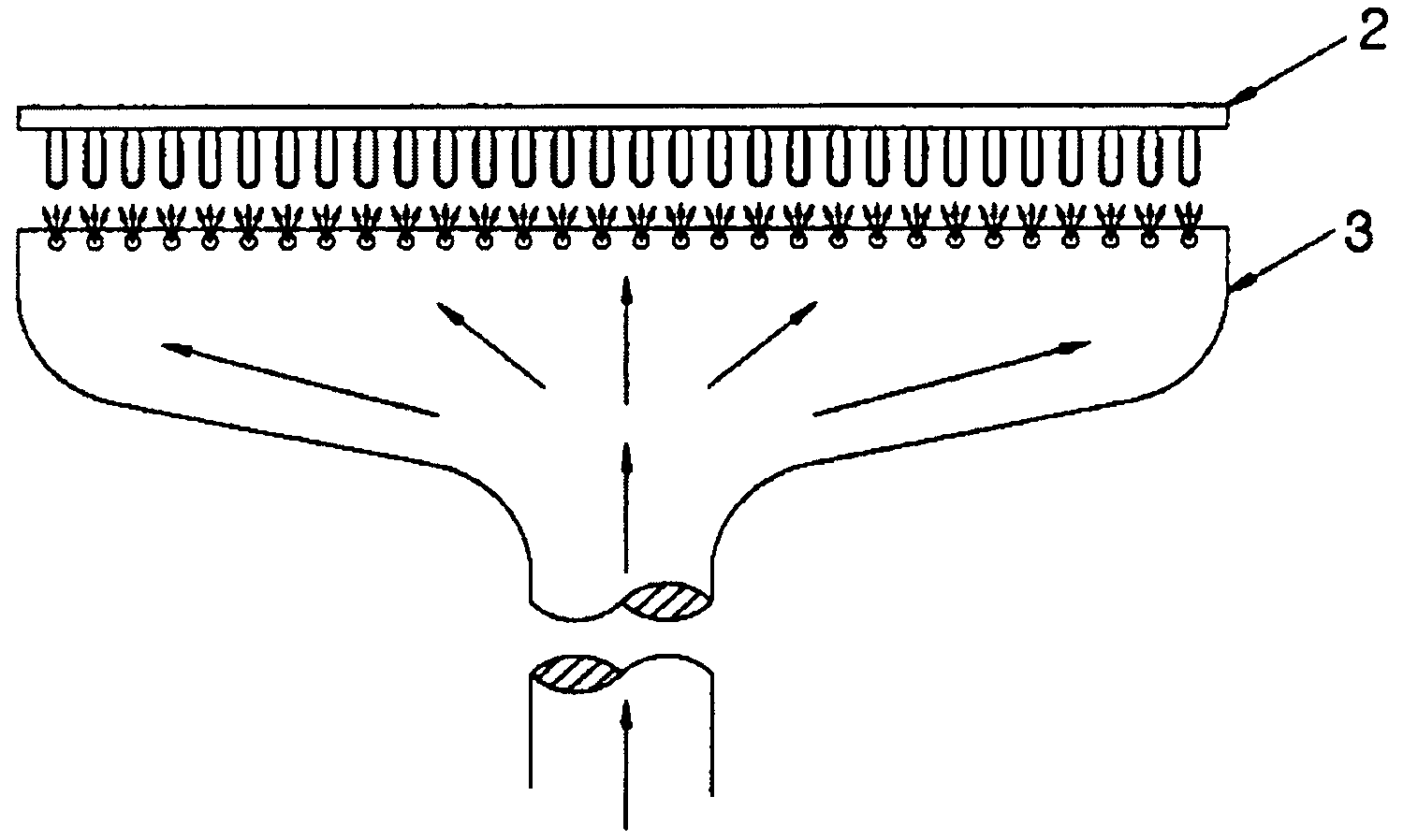

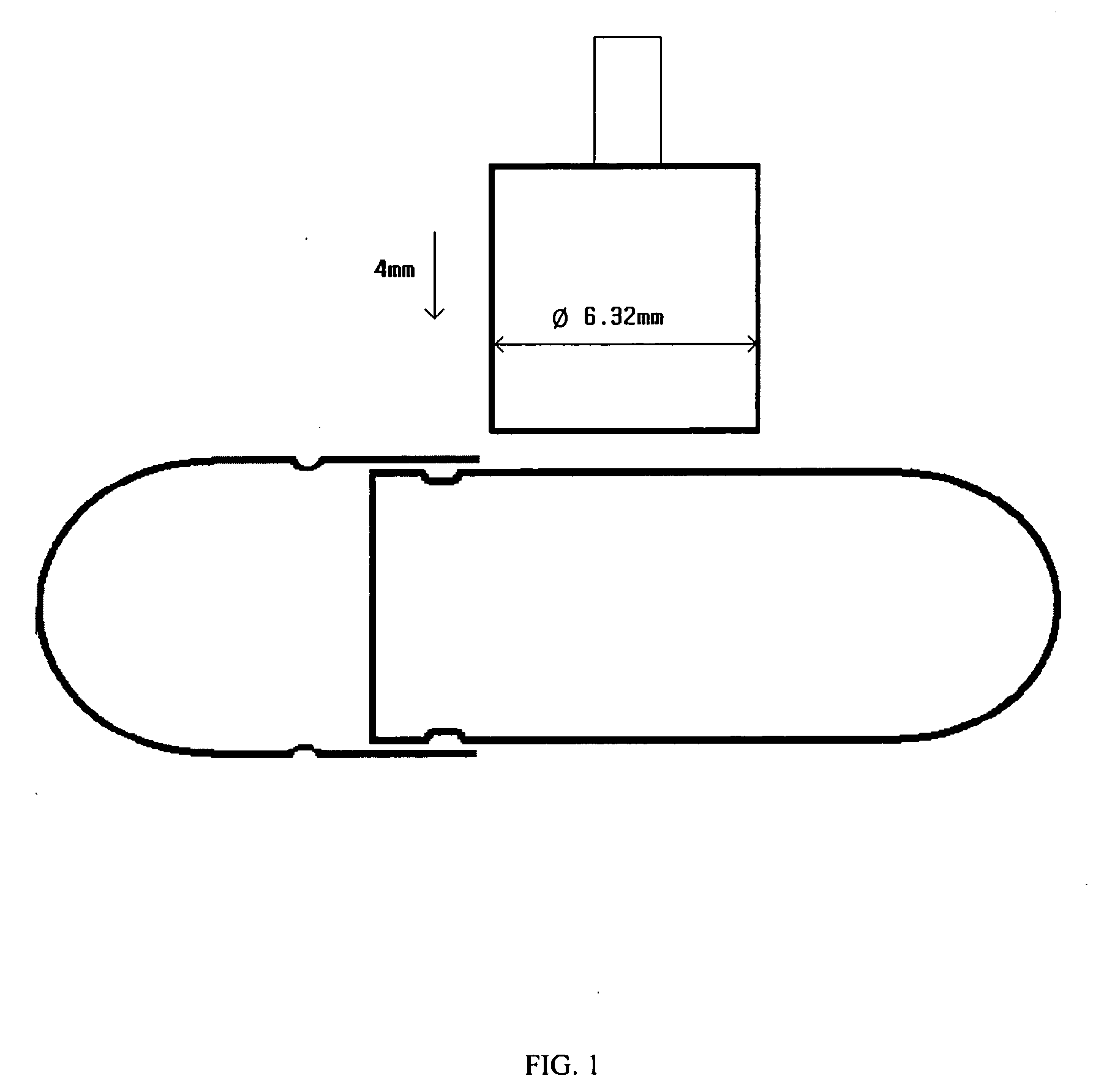

Cellulose hard capsule enhancing mechanical film strength

InactiveUS20080134937A1Enhancing mechanical film strengthCapsule deliveryCellulose adhesivesAcetic acidCellulose

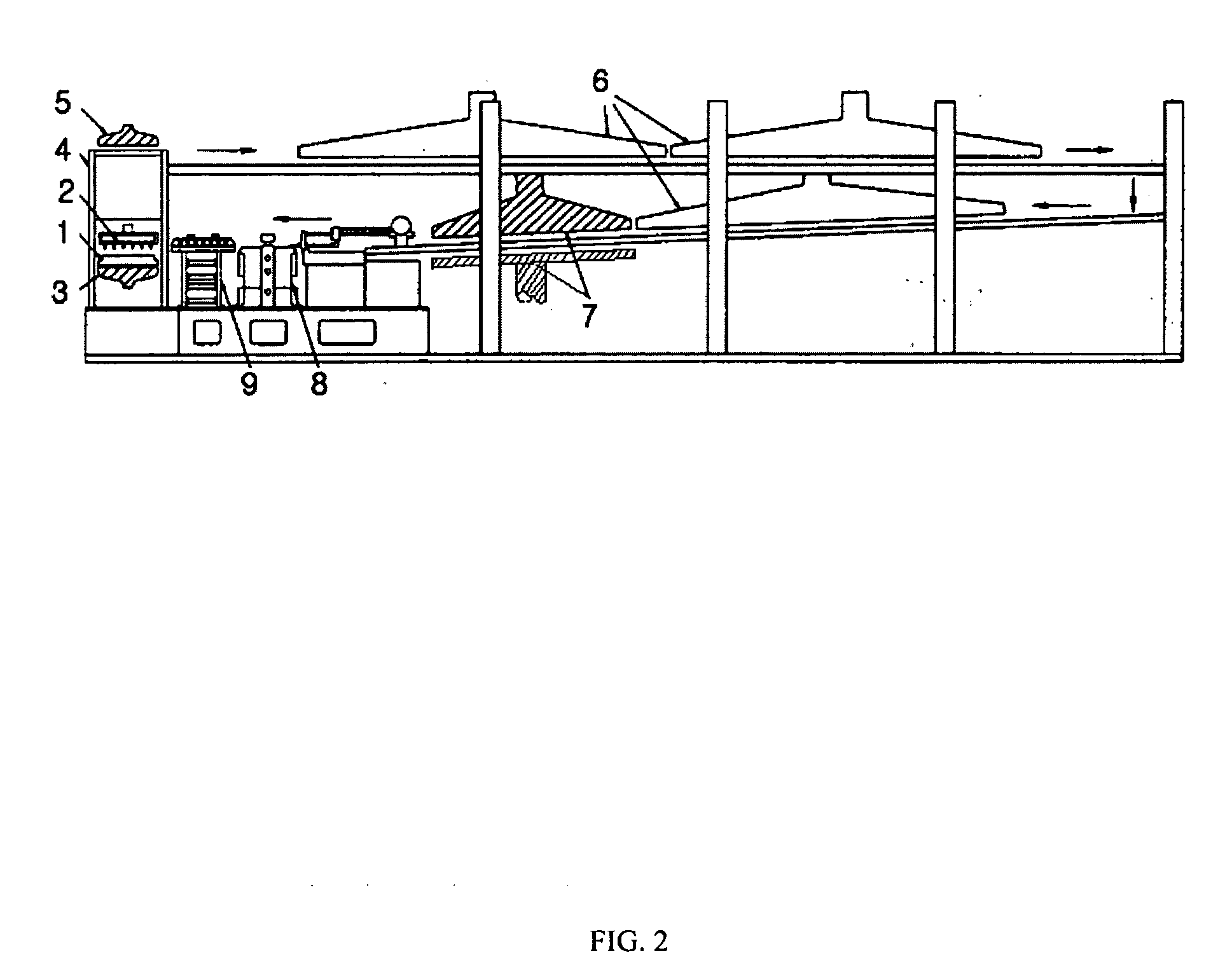

This invention provides a process for preparing a cellulose capsule enhancing mechanical film strength comprising the steps of: i) preparing 100 wt part of an aqueous solution containing 18˜21 wt part of solubilized cellulose; ii) adding 0.1˜0.5 wt part of sucrose fatty acid ester, 0.05˜0.3 wt part of potassium pyrophosphate and 0.01˜0.2 wt part of glacial acetic acid to 100 wt part of an aqueous solution of solubilized cellulose; iii) adding a mixed solution of 0.1˜1.0 wt part of iota-carageenan and 0.02˜0.5 wt part of agar to the resulting admixutre; and iv) allowing obtained product to stand, adjusting its viscosity and forming a capsule from it, wherein said forming step comprises i) dipping the mold pin into the obtained cellulose mixture at the dipping pan, ii) molding the film of the cellulose capsule, iii) cooling said film of the cellulose capsule using 15˜18° C. cooling air for 10˜20 seconds at the bottom film cooling device, iv) cooling said film of the cellulose capsule again using 15˜18° C. cooling air for 70˜100 seconds at the upper film cooling device in order to control the flow of film.

Owner:SUHEUNG CAPSULE CO LTD

Antibacterial natural latex product based on quaternary ammonium salt antibacterial agent and preparation technology of antibacterial natural latex product

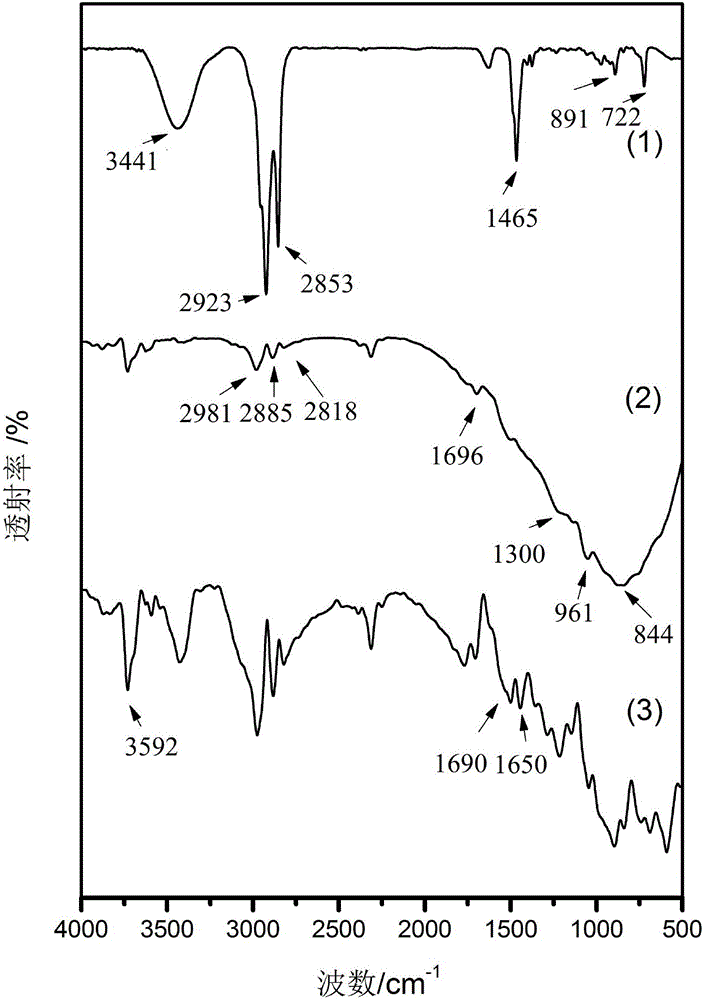

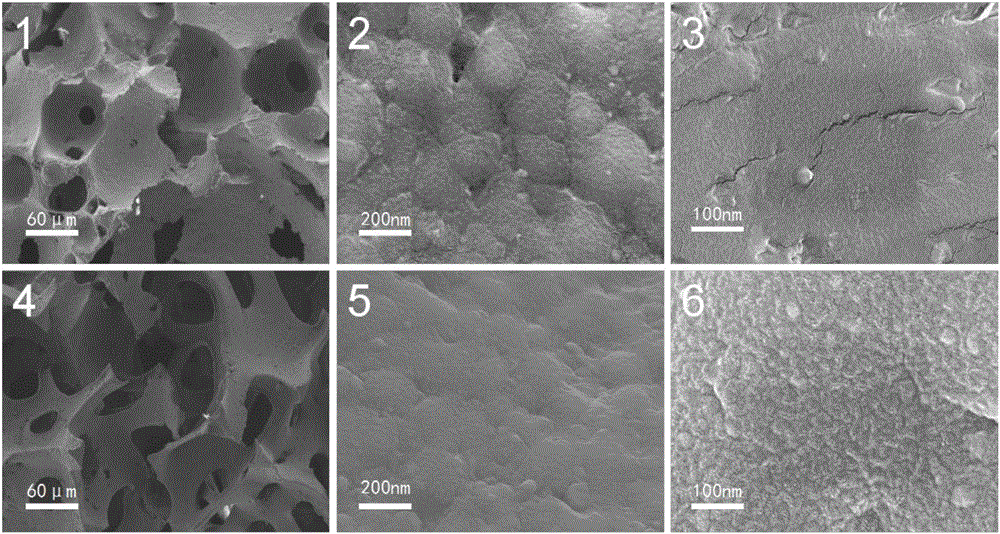

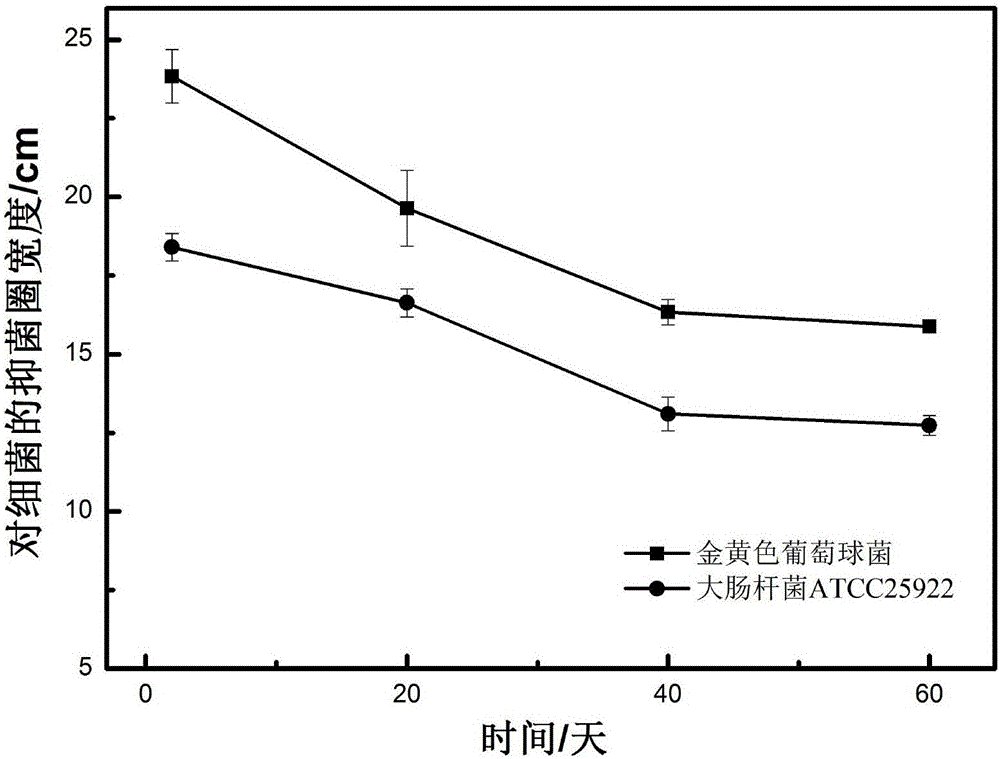

The invention discloses an antibacterial natural latex product based on a quaternary ammonium salt antibacterial agent and a preparation technology of the antibacterial natural latex product, and belongs to the technical field of latex materials. The antibacterial natural latex product is prepared from the following components by weight: 90 to 100 parts of natural latex, 1 to 9 parts of sulfur, 1 to 5 parts of a vulcanization accelerator, 1.5 to 2 parts of an anti-aging agent, 1 to 6 parts of zinc oxide, 0.5 to 2 parts of sodium fluosilicate, 1 to 3 parts of potassium castorate, 0.1 to 2 parts of potassium oleate, 0.5 to 1 part of potassium permanganate and 0.1 to 3 parts of the quaternary ammonium salt antibacterial agent. The antibacterial natural latex product is based on the antibacterial characteristic of a low-concentration quaternary ammonium salt compound. The adopted quaternary ammonium salt compound has the advantage of stable performance, and the compound is tightly combined with latex polymer molecules and cannot permeate the skin of people or an animal by changing the physicochemical property of material surface. The latex product prepared in the invention has the advantages of high antibacterial property, hygiene, high practicability and the like, and has a broad market prospect.

Owner:江苏金世缘乳胶制品股份有限公司 +1

Cyanogens-free gold plating solution and method for plating gold by adopting same

The invention provides cyanogens-free gold plating solution and a method for plating gold by adopting the cyanogens-free gold plating solution, relating to a plating solution and a gold electroplating method. The invention solves the problems that cyanide is toxic and the stability of sulphite gold plating solution is poor. The cyanogens-free gold plating solution of the invention is composed of coordinating agent, auric chloride, potassium carbonate, potassium pyrophosphate and compound additive. The gold plating method of the invention includes the following steps: sodium hydroxide is used for regulating the pH value of cyanogens-free gold plating solution, then constant current mode is adopted, and plating is carried out under the conditions that the distance of cathode and anode is 5-20cm and the temperature is 30-60 DEG C. The cyanogens-free gold plating solution of the invention contains no highly toxic substance, and the stability of plating solution is good, the plating solution is not muddy or changed in colour when being used in 30 days (including plating and ingredient compensation). Meanwhile 10ml plating solution is used for continuous plating and 0.15Ah of electric quantity passes through, and a coating in good surface state still can be obtained.

Owner:WUXI HAITE NEW MATERIAL RES INST

Macroelement water soluble fertilizer having effect of improving crop growth environment and application thereof

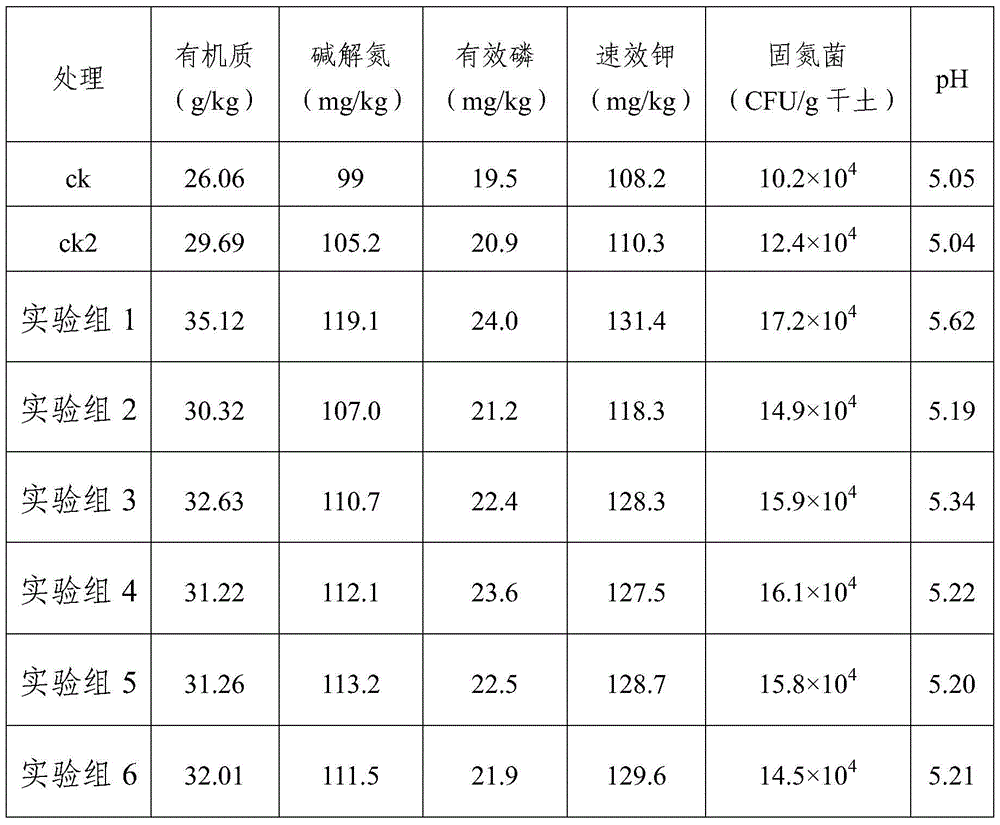

InactiveCN105669299AImprove the ecological environmentStimulate microscopic biological activityMagnesium fertilisersAlkali orthophosphate fertiliserEcological environmentSoil properties

The invention relates to the field of fertilizers, and in particular, relates to a macroelement water soluble fertilizer having an effect of improving a crop growth environment. The macroelement water soluble fertilizer comprises the following components in parts by weight: 50-100 parts of potassium fulvate, 1-15 parts of alga oligosaccharides, 1-15 parts of chitosan oligosaccharide, 100-300 parts of potassium nitrate, 300-500 parts of potassium dihydrogen phosphate, 100-300 parts of ammonium nitrate, 200-500 parts of urea, 10-30 parts of magnesium sulfate monohydrate, 5-25 parts of boric acid, 1-15 parts of EDTA chelated manganese, 1-15 parts of EDTA chelated iron, 1-15 parts of EDTA chelated copper, and 1-15 parts of EDTA chelated zinc. The fertilizer provided by the invention has comprehensive nutrients, has the effect of improving the soil micro ecological environment and soil property components, and has the advantages of rich content of medium-trace elements, high crop-absorbed utilization efficiency, high fertilizer efficiency and excellent water-saving effect.

Owner:HUNAN TAIGU BIOTECH

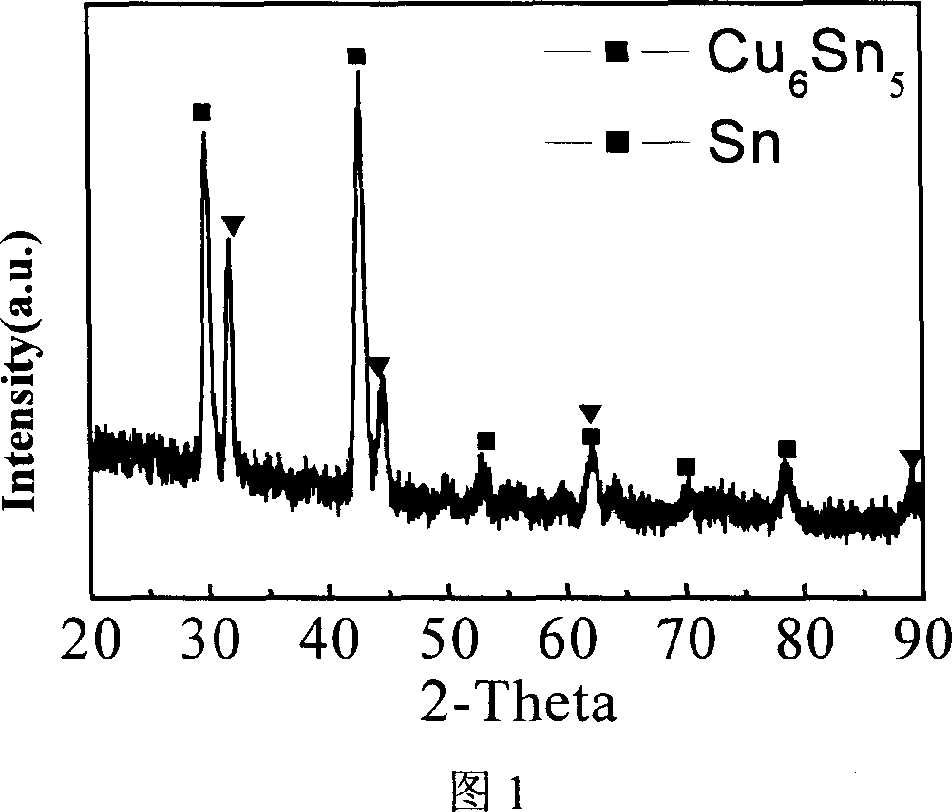

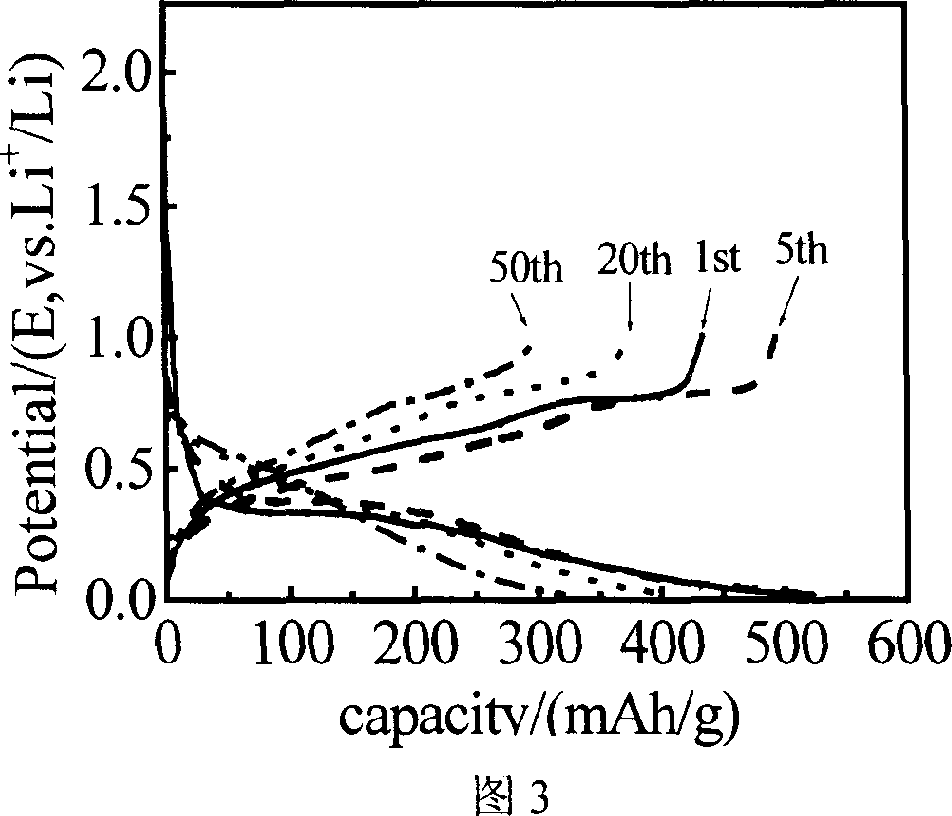

Prepn process of Sn-Cu alloy material for negative pole of lithium ion cell

InactiveCN1974869ARealize large-scale productionNo pollution in the processElectrode manufacturing processesDischarge efficiencyAlloy

The present invention relates to negative pole material for lithium ion cell, and is especially one no-cyanide electroplating process for preparing Sn-Cu alloy as negative pole material for lithium ion cell. The no-cyanide electroplating process includes the following steps: dissolving potassium pyrophosphate in water, adding stannous chloride and copper sulfate to obtain mixed solution, adding epoxy chloroalkane, triethanolamine, formaldehyde and gelatin to form electroplating solution; and electroplating on copper substrate to form silvery white bright Sn-Cu alloy. The process has low cost, no environmental pollution, and the lithium ion cell with negative pole of the Sn-Cu alloy has high initial capacity, high initial charging and discharging efficiency and good charging and discharging circulating performance.

Owner:XIAMEN UNIV

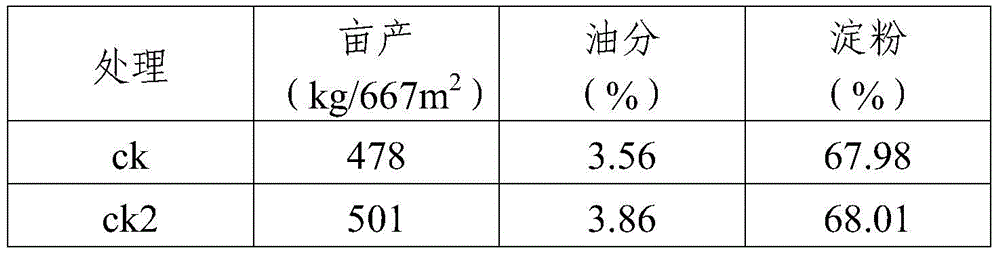

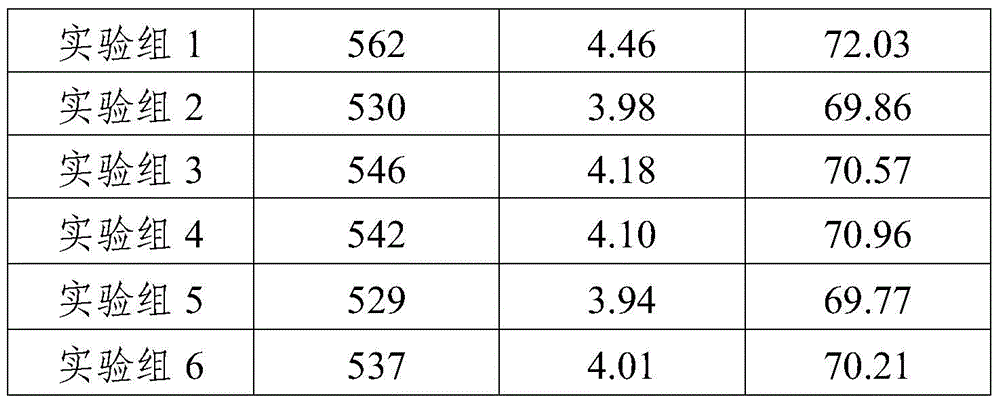

Potassium polyphosphate strawberry slow release fertilizer and production method thereof

InactiveCN107056438ARich varietyPromote growthAlkali orthophosphate fertiliserExcrement fertilisersPotassiumLong acting

The invention relates to potassium polyphosphate strawberry slow release fertilizer and a production method thereof. The potassium polyphosphate strawberry slow release fertilizer is prepared from the following raw materials in parts by weight: 50 to 60 parts of urea, 70 to 80 parts of potassium polyphosphate, 0.5 to 0.8 part of magnesium nitrate, 0.5 to 0.7 part of calcium nitrate, 1.8 to 2.2 parts of microelement, 8 to 10 parts of bone meal, 6 to 10 parts of ammonium humate, 10 to 15 parts of matured chicken manure, 2 to 4 parts of alcohol waste liquid, 10 to 15 parts of medicine powder and 15 to 20 parts of slow release agent. The potassium polyphosphate strawberry slow release fertilizer produced by the invention can be prepared according to fertilizer requiring characteristics of strawberry growth; the produced potassium polyphosphate strawberry slow release fertilizer has rich and balance nutrition, contains rich nutrients and medium-trace element and can quickly supplement nutrients required by strawberry in a long-acting mode; furthermore, nutritional ingredients in the fertilizer can be slowly released, so that fertilizer efficiency is long, utilization rate of the fertilizer is beneficial to being improved, and effects of increasing yield and revenue and improving strawberry quality are achieved.

Owner:广西东林食品化工有限公司

Pyrophosphate copper plating used as grounding electroplate liquid for cyanogen-free copper plating

The invention discloses a strike bath solution with pyrophosphate plating copper as the cyanide-free copper, which contains a make-up agent and rehydration salt; the make-up agent contains the following raw materials: potassium pyrophosphate, copper pyrophosphate, ammonium citrate, sorbol, sulfosalt, phenyl carboxylate, dextrin, alkyl thiourea and nitrogen heterocyclic; the rehydration salt is as supplementation of all raw materials in the make-up agent during the plating process; the invention does not contain harmful substances, such as cyanidum, heavey metal, etc and is in compliance with EU RoHS Directive (2002 / 95 / EC) with stable bath solution and wide cathode current density range, and the plating layer prepared by the invention is fine, even and in a semi-bright state; and the make-up is conducted with original solution, supplementation is conducted with single rehydration salt, which is convenient in operation and simple in management; the plating layer is well adhesive to the matrix, with good straggling capability and covering capability. The invention is applicable in pre-plating of iron materials, zinc alloys, aluminum alloys and copper alloys, as well as barrel plating and suspension plating, with the waste water easy to dispose, which will not bring the secondary pollution.

Owner:江门市瑞期精细化学工程有限公司

Organic-inorganic compound fertilizer for high-yield paddy rice

InactiveCN105384527AIncrease productionProduct environmental protectionFertilizer mixturesSeabirdPesticide residue

The invention discloses an organic-inorganic compound fertilizer for high-yield paddy rice. The organic-inorganic compound fertilizer is prepared from the following raw materials in parts by weight: 20 to 50 parts of urea, 5 to 20 parts of monoammonium phosphate, 30 to 50 parts of potassium polyphosphate, 30 to 50 parts of seabird droppings, 15 to 35 parts of fermented paddy rice straws, 5 to 18 parts of fermented cow dung, 15 to 30 parts of bone dregs, 5 to 15 parts of humic acid, 2 to 8 parts of modified turf, 1 to 7 parts of paddy rice straws, 15 to 19 parts of coal ash, 5 to 12 parts of attapulgite, 1 to 6 parts of kaolin, 1 to 3 parts of manganese sulfate, 1 to 2 parts of ferrous sulfate, 1 to 4 parts of carbonic lime, 0.01 to 0.07 part of compound enzyme and 0.01 to 0.05 part of compound bacteria. A product of the organic-inorganic compound fertilizer is environment-friendly, less in pesticide residue, balanced in nutrition and high in yield of paddy rice.

Owner:高青山

Papermaking pulping cooking auxiliary

InactiveCN1611672AImprove and protect strengthGood dispersionPulping with inorganic basesFiltrationDistillation

This invention is a pulping digestion auxiliary agent of paper making. It is prepared by the feed of fatty alcohol-polyexythelene ether, alkyl sodium sulfate, the putylnaphthalene monosulfonic acid, the sodium pyrophosphate, carboxyme-thylcellulose sodium, sodium sulfate, sulfuric acid and the deionized water. It can be gauging canned after the uniform mixing. This invention is strong acid, strong alkali and high temperature fastness, and it has good dispersion and filtration in water. It can reduce the amount of alkali usage, shorten the time of distillation. The production of this invention is sanitary.

Owner:曾国奇

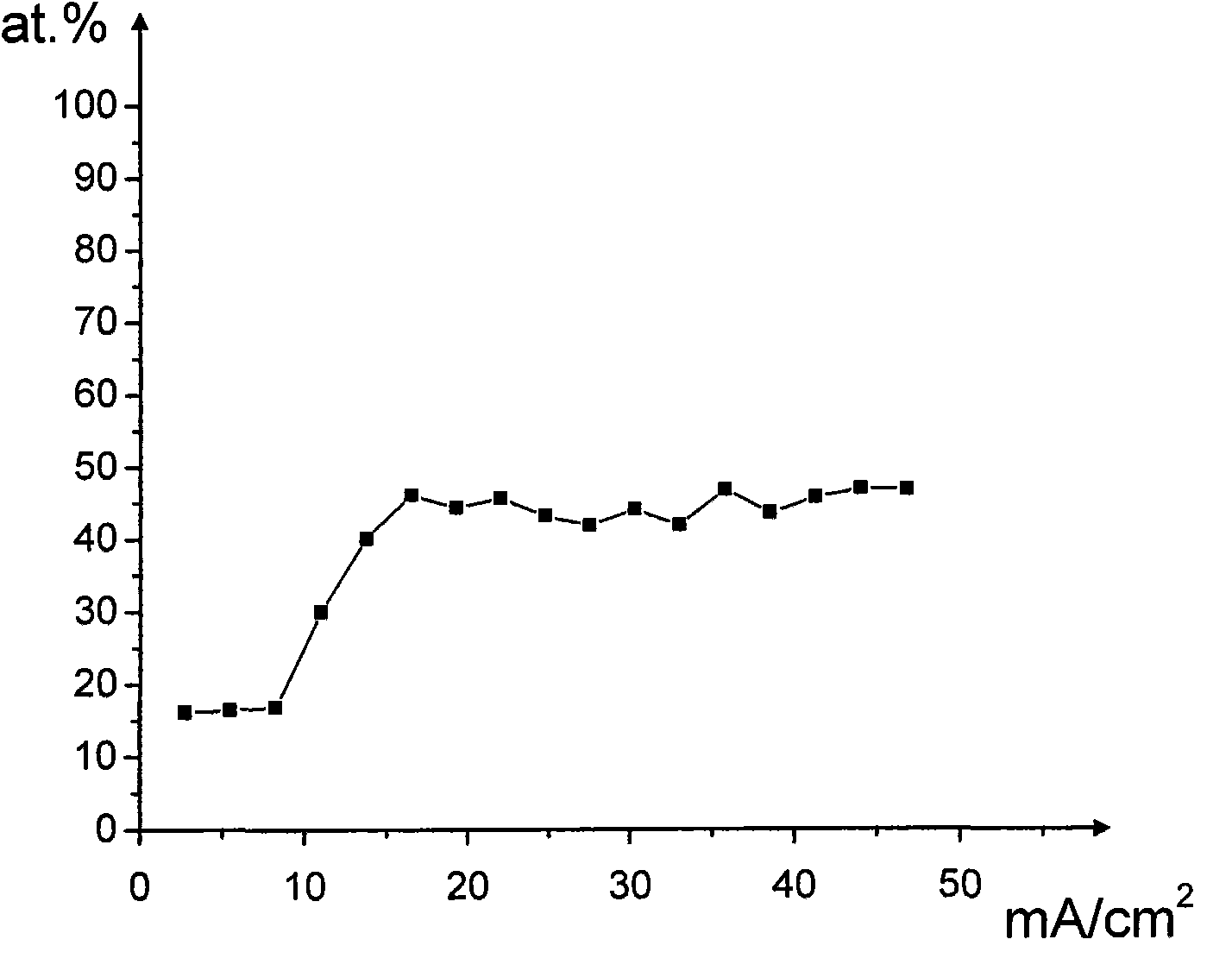

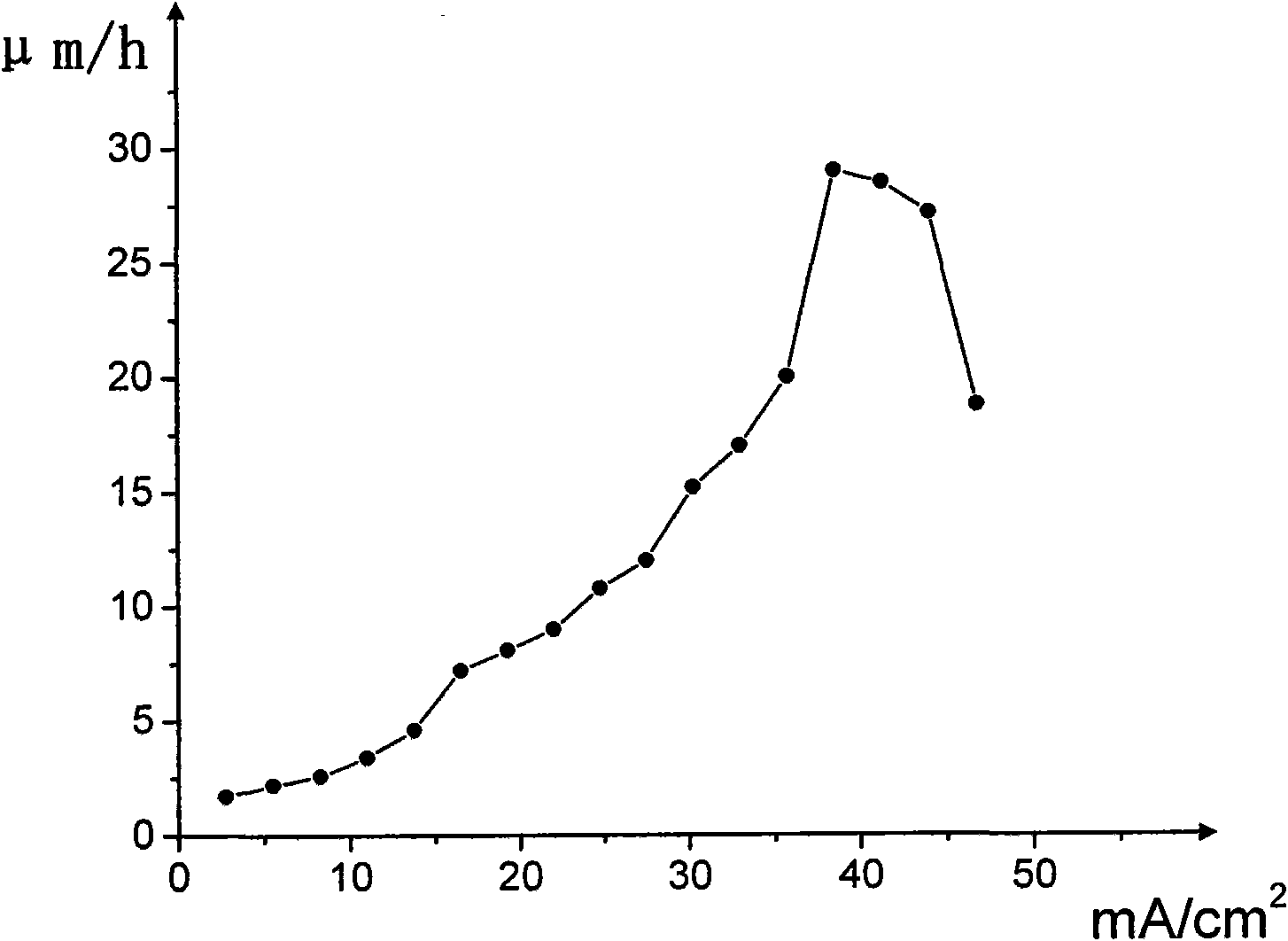

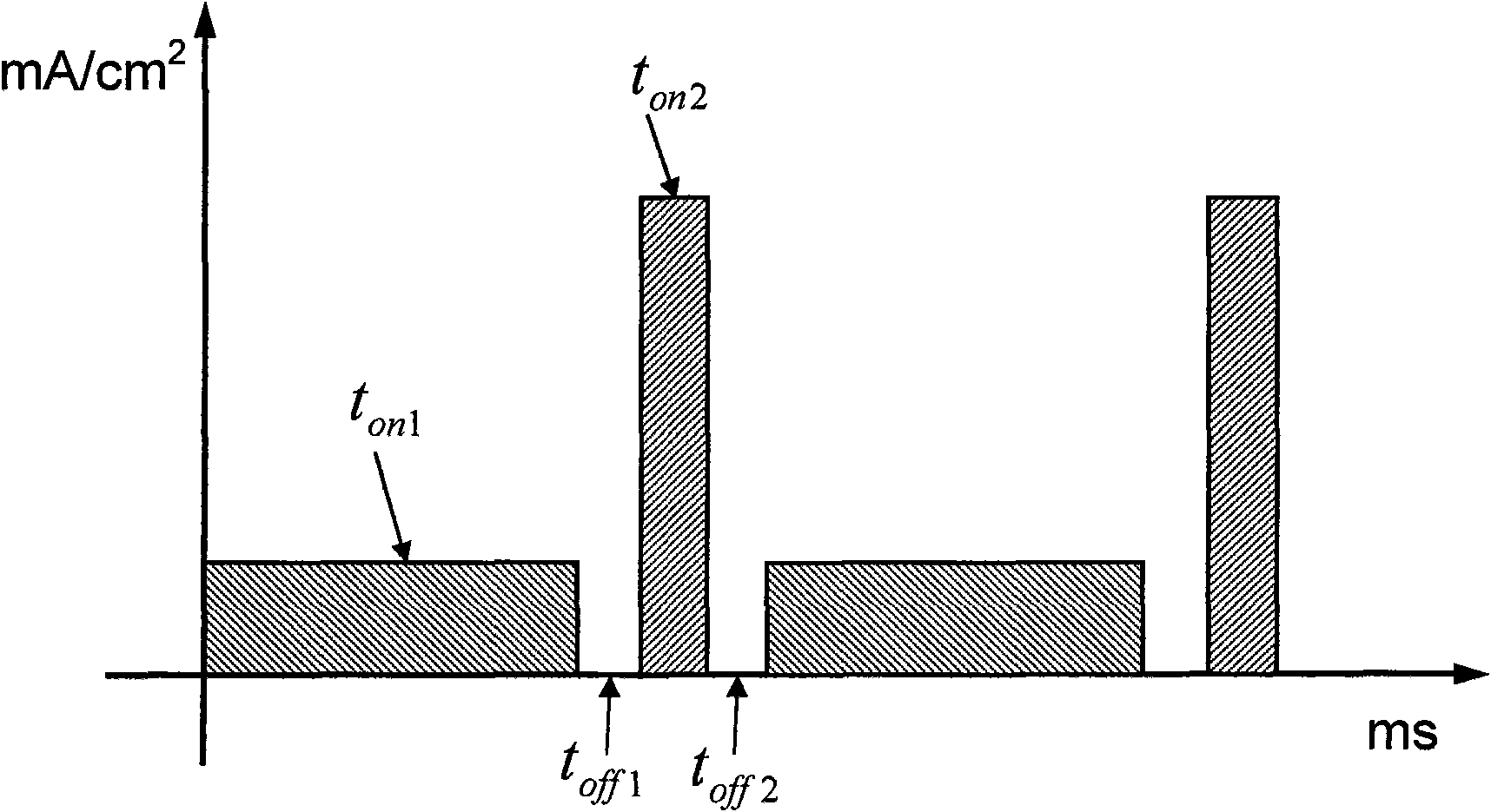

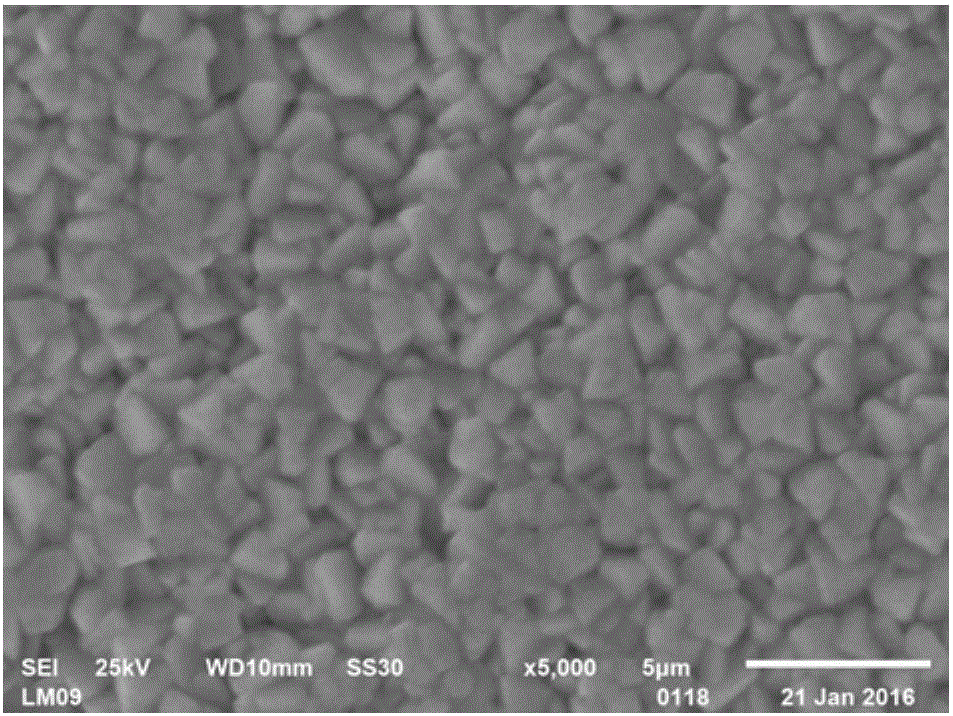

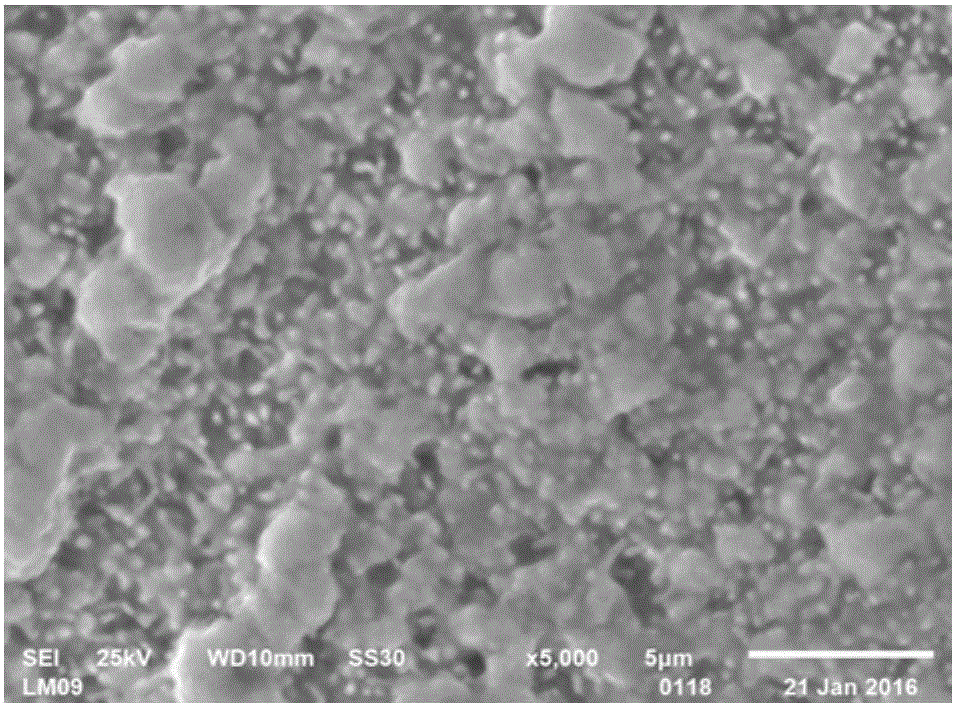

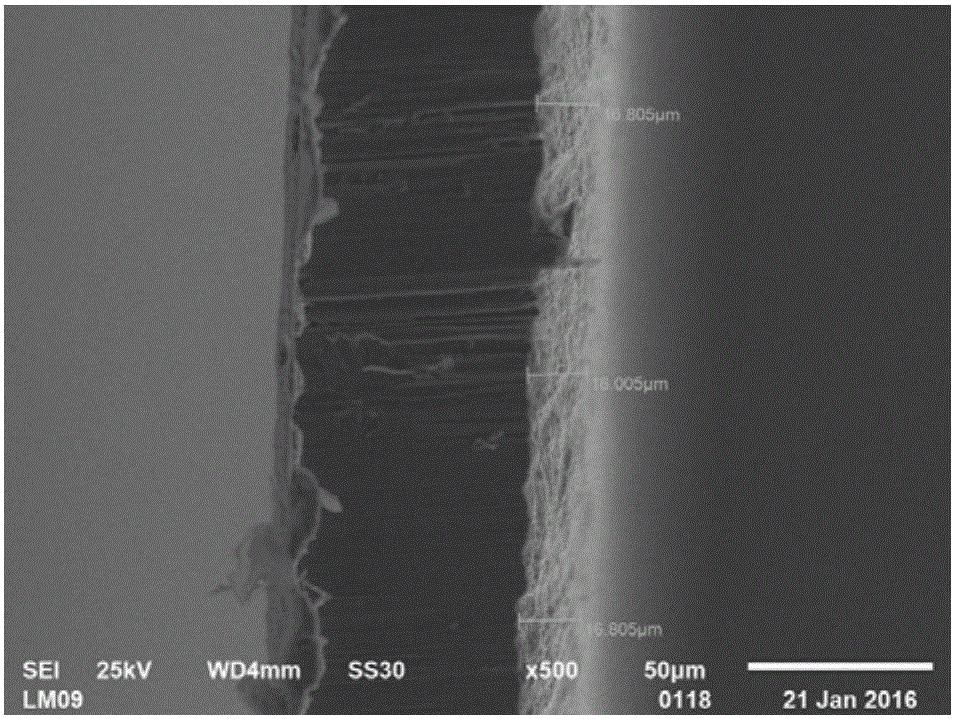

Co-deposition electroplating method with cyanogen-free Au-Sn alloy electrolyte

The invention relates to a co-deposition electroplating method for preparing Au-Sn alloy on an electroplating substrate and a cyanogen-free Au-Sn alloy electrolyte. The wave forms of electroplating current pulses are forward variable-amplitude pulses, namely that two different forward square wave pulses exist in one period, and the peak values and the conducting time of the electroplating current pulses respectively correspond to peak value current density and time which are required for generating Au5Sn and an Au-Sn alloy phase in a plating layer. In the electrolyte, sodium sulfite is adopted as a main complexing agent and ethylene diamine tetraacetic acid is adopted as an auxiliary complexing agent for the gold ion complexing agent, potassium pyrophosphate is used as a tin ion complexing agent, hydroquinone is used as an antioxidant, and the pH value of the electrolyte is from 8 to 9. When the method is used for preparing Au-30at.%Sn eutectic plated layer through electroplating, the plating speed reaches 13 mum / hour, the electrolyte is stable, the operation is simple, and the gold and tin content in the plated layer is easy to control. The method can be applied in microelectronics and photoelectron industry for connecting and encapsulating LED chips, connecting flip chips, forming welding pads or patterns on the surface of semiconductor devices or similar devices, etc.

Owner:DALIAN UNIV OF TECH

Rare earth modified brushing electroplating silver plating solution and preparing technology and use method of solution

ActiveCN106283134AUniform and dense appearanceBright appearanceN dimethylformamideHexamethylenetetramine

The invention provides a rare earth modified brushing electroplating silver plating solution. The rare earth modified brushing electroplating silver plating solution comprises following components including, by mass concentration, 10 g / L to 30 g / L of silver salt, 0.1 g / L to 2 g / L of modifying agent rare earth cerous nitrate, 50 g / L to 200 g / L of coordination agent sulfosalicylic acid, 50 g / L to 200 g / L of imidazole, 0.01 g / L to 1 g / L of protection agent hexamethylenetetramine, 0.01 g / L to 1 g / L of addition agent N,N-dimethylformamide, 1 g / L to 30 g / L of polyethylene glycol, 10 g / L to 50 g / L of ammonium hydroxide, 10 g / L to 40 g / L of stabilizing agent ammonium acetate and 5 g / L to 30 g / L of potassium pyrophosphate. The pH value of the solution is adjusted to range from 6.8 to 7.2 through dilute nitric acid or dilute sodium hydroxide. The invention further provides a preparing technology and use method of the rare earth modified brushing electroplating silver plating solution. The harmfulless silver salt, a rare earth modification agent, a coordination agent, a protection agent and the like are mixed for forming the solution, the solution is a neutral cyanide-free silver plating solution, raw materials are easily obtained, and the preparing technology is simple. A product is applied to a copper or copper alloy surface to be subject to brushing electroplating, the method is simple and easy to operate, and a plating is stable.

Owner:STATE GRID CORP OF CHINA +1

Cyanide-free silver plating solution additive

The invention relates to a cyanide-free silver plating solution additive which comprises the following components by ratio: 0.1-10g / l of brightener, 5-10g / l of leveling agent, 100-600g / l of complexing agent and the balance of plasma water, wherein the brightener is one or mixture of more in nitrogen-containing compound, triazole, benzotriazole, 2-hydroxypyridine, pyridine, 22 dipyridyl, 1, 10-phenanthroline, triethylene tetramine and diethylene triamine according to any ratio; the leveling agent is one or mixture of more in aromatic hydrocarbon compounds, naphthalene, 1-methylnaphthalene, 1, 4-naphthoquinone and 1-naphthol according to any ratio; the complexing agent is one or mixture of more in disodium ethylenediamine tetraacetate, niacin, aminosulfonic acid and potassium pyrophosphate according to any ratio. The cyanide-free silver plating solution additive has the beneficial effects that the plating solution is stable, low in toxicity and good in dispersing ability; the obtained plating layer is bright and fine as well as good in binding force; the technology adopts the environment-friendly organic additive which does not contain heavy metal and sulfide; the plating layer is good in corrosion resistance. Furthermore, the cyanide-free silver plating solution additive can be directly used for parts such as brass, copper, chemical nickel and the like, preplating is not needed, and the binding force is also guaranteed.

Owner:HANGZHOU WIN WIN TECH CO LTD

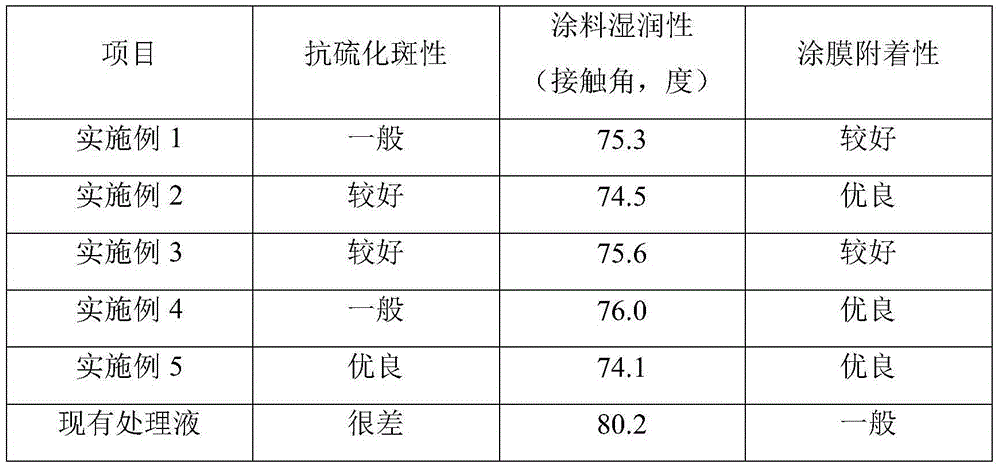

Tinned steel plate surface treatment solution and preparation method thereof

ActiveCN104357825AGuaranteed corrosion resistanceGood adhesionMetallic material coating processesChromium freePhosphate

The invention discloses a tinned steel plate surface treatment solution and a preparation method thereof. The surface treatment solution contains 2-25 g / L disodium hydrogen phosphate, 2-13 g / L sodium pyrophosphate, 1-15 g / L ammonium hydrofluotitanate, 1-10 g / L potassium fluosilicate, 2-14 g / L nickel nitrate, 1-12 g / L zirconium titanate, 1-10 g / L sodium metaaluminate, 5-12 g / L manganese dihydrogen phosphate, 2-5 g / L sodium phytate and 1-7 g / L oxalic acid. The preparation method comprises the following steps: a. adding the disodium hydrogen phosphate and sodium pyrophosphate into deionized water, and stirring; b. adding the ammonium hydrofluotitanate, potassium fluosilicate, nickel nitrate, zirconium titanate, sodium metaaluminate and manganese dihydrogen phosphate; and c. regulating the pH value of the solution to 3-5 with phosphoric acid. On the basis of chromium-free passivation, the surface treatment solution ensures the corrosion resistance of the tinned plate without degrading the sulfur resistance, and also has excellent paint adhesiveness.

Owner:深圳市九久电子科技有限公司

Cleaning agent for stainless steel-aluminum alloy plate combined electric kettle and preparation method

The invention discloses a bright cleaning agent for a stainless steel-aluminum alloy plate combined electric kettle, which is generally used for spraying and ultrasonic washing, and can simultaneously remove oil, wax and other pollutants on the surface of stainless steel and aluminum alloy of the electric kettle to achieve strong polishing and oxidation resistance and other effects, and a preparation method. The bright cleaning agent is prepared from the following raw materials in percentage by weight: 0.1-0.5% of sodium hydroxide, 1-5% of sodium carbonate, 1-4% of potassium metasilicate pentahydrate, 1-3% of potassium pyrophosphate, 1-3% of borax decahydrate, 1-4% of sodium tripolyphosphate, 0.1-1.8% of penetrant, 0.5-2% of special low-foaming surfactant for spray degreasing, 0.5-3% of special surfactant for removing molten wax, 0.5-2% of Y-73 low-foaming surfactant for ultrasonic washing, 0.5-3% of Y-75 low-foaming surfactant for ultrasonic washing, 1-3% of defoaming agent and the balance of water.

Owner:DALIAN SANDAAOKE CHEM

Rice special fertilizer for improving soil

InactiveCN107266234APromote production and incomeReduce manufacturing costCalcareous fertilisersAlkali orthophosphate fertiliserDiseaseSodium Bentonite

The invention discloses a rice special fertilizer for improving soil, the rice special fertilizer for improving the soil comprises the following raw materials by weight: 20-26 parts of plant ash, 10-20 parts of potassium magnesium salt, 30-40 parts of potassium polyphosphate, 50-60 parts of ammonium nitrate, 70-80 parts of an urea complex, 180-200 parts of an organic fertilizer, 4-8 parts of zeolite powder, 3-5 parts of bentonite, 1-2 parts of brassinolide, 4-8 parts of trace elements and 2-4 parts of a bioinsecticide. The rice special fertilizer for improving the soil is rich in components and balanced in nutrients, can effectively inhibit pest growth in weeds in a paddy field, enhances disease resistance, improves rice quality, can effectively improve the soil, and can promote rice growth.

Owner:WANGJIANG NONGWANG AGRI SPECIALIZED COOP

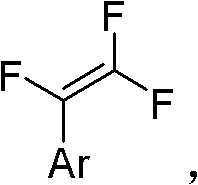

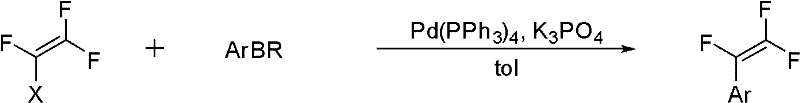

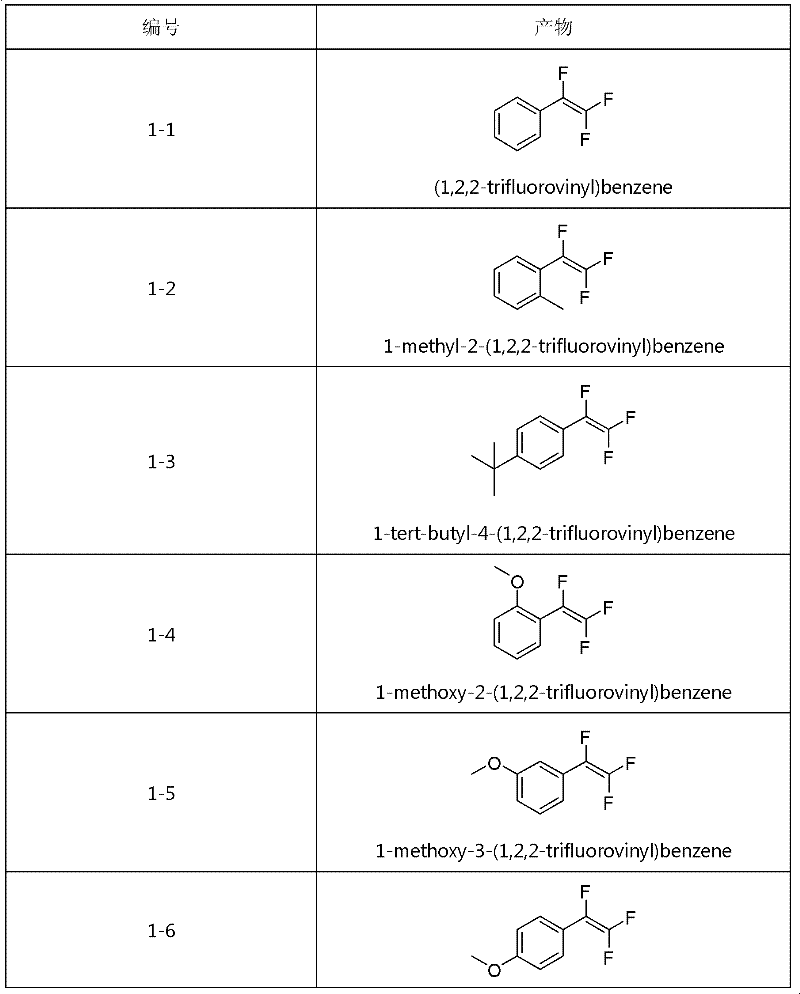

Method for synthesizing trifluorostyrene fluorine-containing monomer

InactiveCN102241554ARaw materials are easy to getSimple methodCarboxylic acid nitrile preparationAmino preparation from aminesRefluxTriphenylphosphine

The invention relates to a method for synthesizing a trifluorostyrene fluorine-containing monomer. The monomer is obtained by making halogenated trichloroethylene react with ArBR under the catalytic actions of tetra(triphenylphosphine) palladium and potassium phosphate at reflux temperature. Raw materials are readily available, and the method is easy and convenient, and is a method suitable for industrial production.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

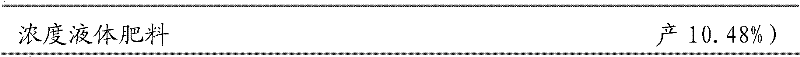

Anti-hard water composite water-soluble fertilizer and preparation method thereof

InactiveCN102584470AHigh nutrient contentStrong resistance to hard waterFertilizer mixturesCarrageenanCopper sulfate

The invention discloses an anti-hard water composite water-soluble fertilizer and a preparation method of the anti-hard water composite water-soluble fertilizer. The existing composite water-soluble fertilizer is low in hard water resistance and cannot be used in saline-alkali areas. The anti-hard water composite water-soluble fertilizer contains the following components: 30-50% of nitrogen, phosphorus and potassium, 0.5-2% of microelements including iron, manganese, copper, zinc, molybdenum and boron, 3-8% of humic acid, and water for the rest. The preparation method of the anti-hard water composite water-soluble fertilizer comprises the following steps: taking weathered coal, sulfuric acid, phosphoric acid, nitric acid, ammonium nitrate, potassium hydroxide and potassium nitrate as main materials; taking potassium pyrophosphate, polyvinylpyrrolidone, polyacrylamide, ammonium polyphosphate, sodium dodecyl sulfate, methylsilane, xanthan gum, carrageenan and konjac gum mixture as an auxiliary anti-hard water slow release agent; taking ferrous sulfate, zinc sulfate, potassium borate, copper sulfate, manganese sulfate and ammonium molybdate as microelement additives; degrading, modifying, chelating, stabilizing and the like to obtain the anti-hard water composite water-soluble fertilizer. The anti-hard water composite water-soluble fertilizer is high in utilization rate, stable in product shape, convenient to use, resistant to hard water and the like, and is suitable for saline-alkali areas with harder water.

Owner:HANGZHOU QIUSHI INTPROP CONSULTATION & SERVICE

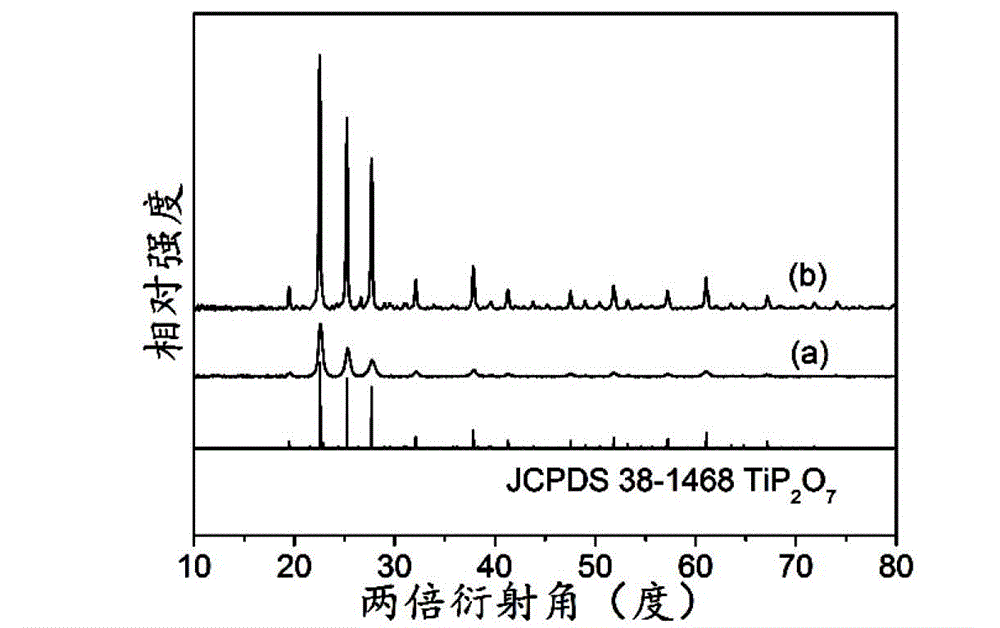

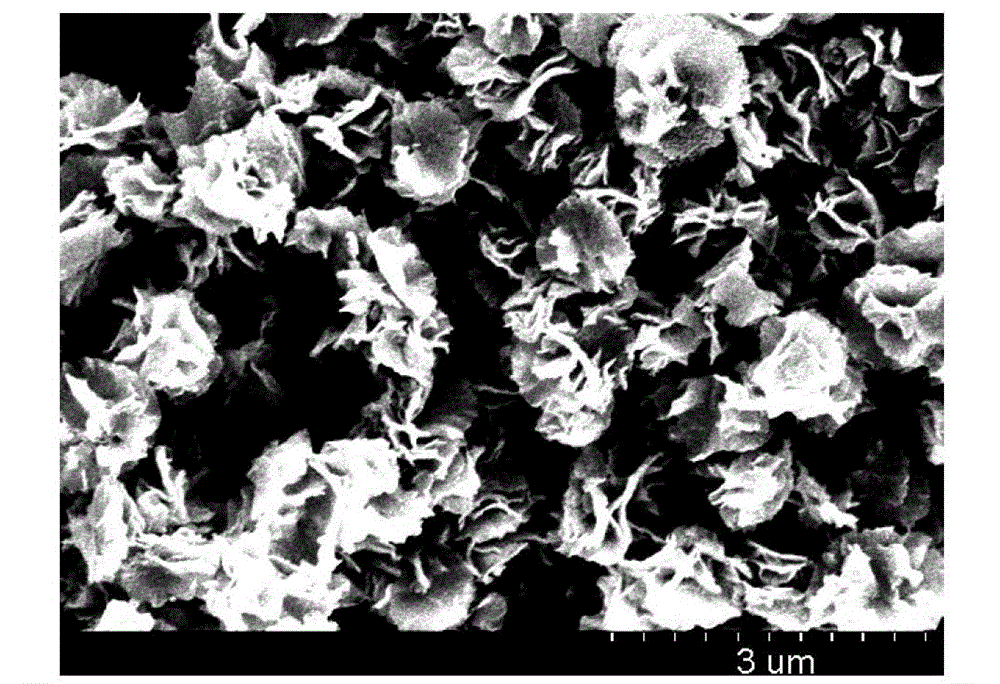

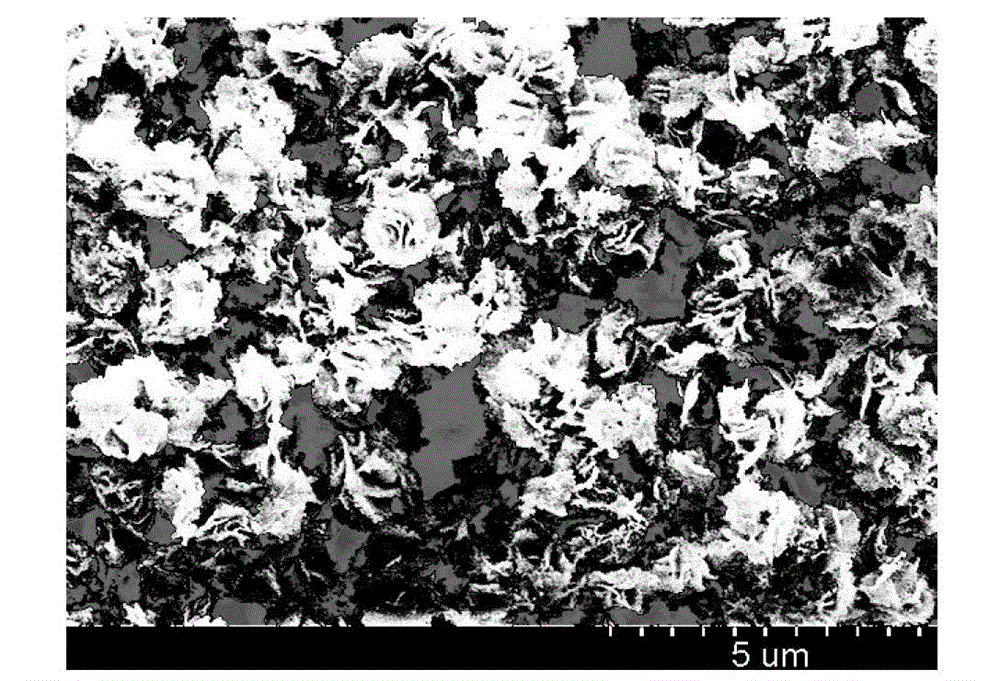

Preparation method for titanium pyrophosphate with flower-like micron/nanometre structure

InactiveCN102976301AReduce manufacturing costSimple processNanotechnologyPhosphorus compoundsIon exchangePhytic acid

The invention relates to a preparation method for titanium pyrophosphate with a flower-like micron / nanometre structure, comprising the following steps of: a, adding phytic acid and a titanium source in absolute ethyl alcohol to prepare a mixed solution, and performing heat-insulating reaction on the mixed solution to obtain reaction solution; b, performing solid-liquid separation on the reaction solution, and washing and drying solids to prepare a target product precursor; and c, calcining the target product precursor to prepare the titanium pyrophosphate with the flower-like micron / nanometre structure. Via the preparation method disclosed by the invention, the titanium pyrophosphate with the flower-like micron / nanometre structure is prepared for the first time; and the titanium pyrophosphate with the flower-like micron / nanometre structure has many potential purposes in the fields of bionics, ion exchange, catalysis and lithium battery materials.

Owner:QILU UNIV OF TECH

Environment-friendly multifunctional sustained-release fertilizer

The invention pertains to an environment-friendly multifunctional sustained-release fertilizer. The environment-friendly multifunctional sustained-release fertilizer is prepared from the following components in parts by mass: 40-90 parts of SA (sodium alginate), 20-70 parts of AA (acrylic acid), 30-90 parts of APS (ammonium persulfate), 70-120 parts of copper sulfate pentahydrate, 30-80 parts of potassium pyrophosphate trihydrate, 20-60 parts of urea and 60-90 parts of NNMBA (N,N-methylene bisacrylamide), wherein the viscosity of the 2% aqueous solution of SA at the temperature of 25 DEG C is 3,200mPa.s.

Owner:QINGDAO WATER WORLD ENVIRONMENTAL PROTECTION TECH

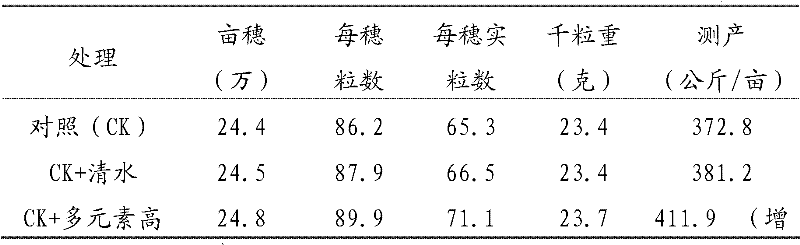

Preparation method of multi-element high-concentration liquid fertilizer with stable performance

ActiveCN102442855AStable in natureGood water solubilityFertilizer mixturesHigh concentrationChemical reaction

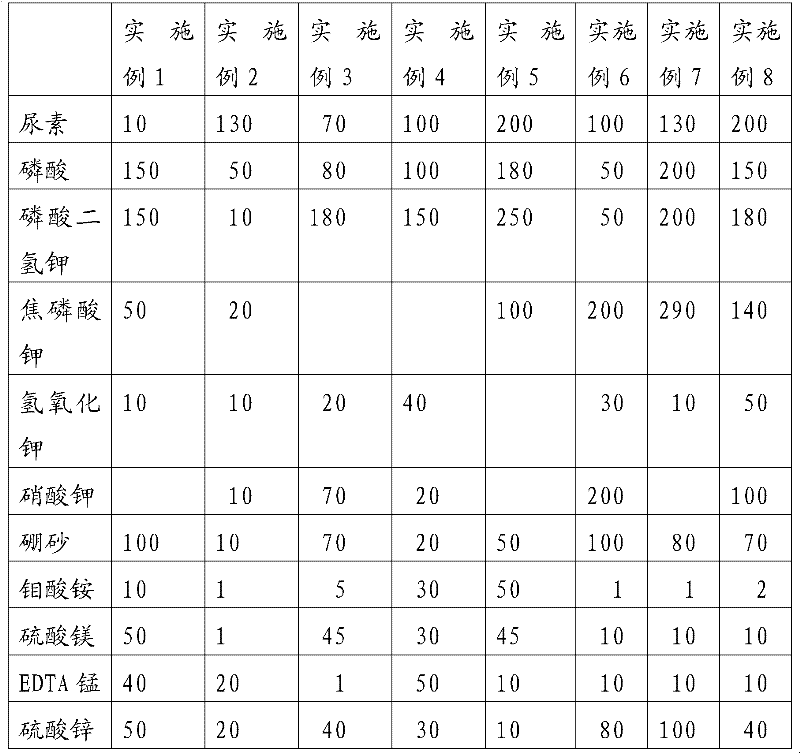

The invention relates to a preparation method of a multi-element high-concentration liquid fertilizer with the stable performance, aiming at solving the problems of fewer kinds, low element content and poor adhesive power of a traditional multi-element high-concentration liquid fertilizer. In the technical scheme, the multi-element high-concentration liquid fertilizer comprises 100-200 parts of urea, 50-200 parts of phosphoric acid, 50-500 parts of at least one of monopotassium phosphate, potassium pyrophosphate, potassium hydroxide or potassium nitrate, 10-100 parts of borax, 1-50 parts of ammonium molybdate, 1-50 parts of magnesium sulfate, 1-50 parts of EDTA (Ethylene Diamine Tetraacetic Acid) manganese and 10-100 parts of zinc sulfate, wherein the ratio of the weight of water to the total weight of the raw materials is 3:4. The multi-element high-concentration liquid fertilizer is prepared from the raw materials through a chemical reaction and has the advantages of great specific weight, favorable adhesive power and stable performance.

Owner:武汉富强科技发展有限责任公司

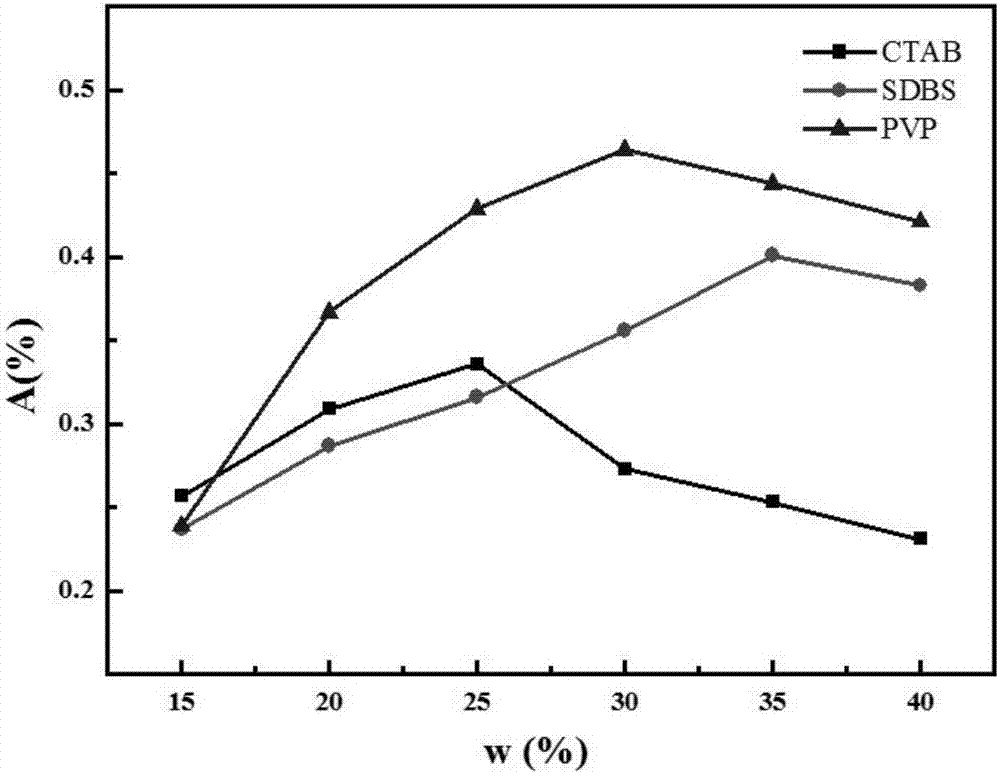

Composite silver plating solution as well as preparation method thereof and electrodeposition process

InactiveCN107345307AGood dispersionAddress technical flaws that underperformElectrolytic coatingsWater solubleCvd graphene

The invention belongs to the field of electroplating, and in particular relates to a composite silver plating solution, a preparation method thereof and an electrodeposition process. The invention provides a composite silver plating solution, which comprises: a water-soluble silver-containing compound, succinimide, potassium pyrophosphate, graphene and polyvinylpyrrolidone. The invention also discloses an electrodeposition process. The composite silver plating solution disclosed by the present invention and its preparation method and electrodeposition process can effectively solve the problem of poor graphene dispersion, easy interface reaction and the performance of the prepared silver-graphene composite coating when graphene is used to prepare new silver plating solutions. Poor technical flaws.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Magnesium-lithium alloy surface electrocoppering solution and magnesium-lithium alloy surface electrocoppering treatment method

InactiveCN102776535AImprove manufacturing speedImprove corrosion resistanceCopper platingPhytic acid

The invention provides magnesium-lithium alloy surface electrocoppering solution and a magnesium-lithium alloy surface electrocoppering treatment method. The method comprises the following steps that (1) the magnesium-lithium alloy surface is subjected to pretreatment; (2) the activation is carried out under the room temperature and ultrasonic conditions; (3) the zinc galvanizing is carried out at the temperature being 40 to 60 DEG C; and (4) the electrocoppering is carried out in copper plating solution; the electrocoppering solution consists of 50 to 70g / L of cupric pyrophosphate, 300g / L of potassium pyrophosphate, 40g / L of dipotassium phosphate, 40g / L of potassium sodium tartrate, 0.1 g / L of citric acid, 0.1g / L of phytic acid, 0.02 g / L of vanillin and the balance water; and the electrocoppering comprises the following conditions that the pH is 8 to 9, the temperature is 30 to 50 DEG C, the voltage is 2 to 4V, the current is 0.02 to 0.04 A, and the time is 20 to 40 minutes. The plating layer has the performance which is not reached by the existing magnesium-lithium alloy surface treatment method, meanwhile, the plating layer forming is fast, the plating layer forming speed is accelerated, the surface treatment efficiency is improved, the operation is simple and convenient, the production efficiency is high, and the large-scale popularization and the application are favorably realized.

Owner:HARBIN ENG UNIV

Polydopamine coated controlled-release fertilizer

The invention relates to preparation of a polydopamine coated controlled-release fertilizer, and in particular relates to a polydopamine coated slow-release fertilizer which is prepared by coating a substrate which is copper potassium pyrophosphate trihydrate by dopamine; the slow-release fertilizer consists of phosphorus, potassium, copper and nitrogen, and is a fertilizer which integrates a great amount of elements and trace elements and has a controlled-release function, wherein contents of various nutrient elements of the fertilizer are as follows: 38.0% of phosphorus, 6.5% of potassium and 26.45% of copper; and accumulative release amount of the fertilizer in 30days just includes 10% of phosphorus, 3.2% of potassium and 7.1% of copper.

Owner:SHIHEZI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com