Tinned steel plate surface treatment solution and preparation method thereof

A technology of surface treatment liquid and tin-plated steel plate, applied in the coating process of metal materials, etc., to achieve the effect of no reduction in sulfur resistance, simple surface treatment process, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

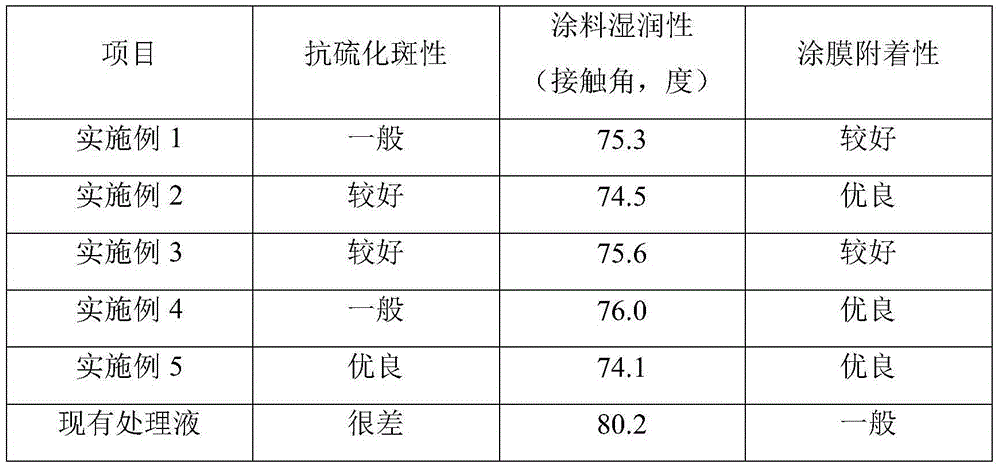

Examples

Embodiment 1

[0023] A tin-plated steel surface treatment solution contains: 2g / L disodium hydrogen phosphate, 2g / L sodium pyrophosphate, 1g / L ammonium fluorotitanate, 1g / L potassium fluorosilicate, 2g / L nickel nitrate, 1g / L Zirconyl titanate, 1g / L sodium metaaluminate, 5g / L manganese dihydrogen phosphate, 2g / L sodium phytate and 1g / L oxalic acid.

[0024] A preparation method for a tin-plated steel surface treatment solution, comprising the following steps:

[0025] a. Weigh the components respectively, first add disodium hydrogen phosphate and sodium pyrophosphate into deionized water for stirring, control the stirring speed at 60 rpm, until completely dissolved;

[0026] b. Add ammonium fluorotitanate, potassium fluorosilicate, nickel nitrate, zirconyl titanate, sodium metaaluminate and manganese dihydrogen phosphate to the solution obtained in step a, then stir, and control the stirring speed to 40 rpm min, until completely dissolved;

[0027] c. Finally, add sodium phytate and oxalic...

Embodiment 2

[0029] A tin-plated steel surface treatment solution contains: 25g / L disodium hydrogen phosphate, 13g / L sodium pyrophosphate, 15g / L ammonium fluorotitanate, 10g / L potassium fluorosilicate, 14g / L nickel nitrate, 12g / L Zirconyl titanate, 10g / L sodium metaaluminate, 12g / L manganese dihydrogen phosphate, 5g / L sodium phytate and 7g / L oxalic acid.

[0030] A preparation method for a tin-plated steel surface treatment solution, comprising the following steps:

[0031] a. Weigh the components respectively, first add disodium hydrogen phosphate and sodium pyrophosphate into deionized water for stirring, control the stirring speed at 65 rpm, until completely dissolved;

[0032] b. Add ammonium fluorotitanate, potassium fluorosilicate, nickel nitrate, zirconyl titanate, sodium metaaluminate and manganese dihydrogen phosphate to the solution obtained in step a, then stir, and control the stirring speed to 42 rpm min, until completely dissolved;

[0033] c. Finally, add sodium phytate an...

Embodiment 3

[0035] A tin-plated steel surface treatment solution contains: 5g / L disodium hydrogen phosphate, 4g / L sodium pyrophosphate, 3g / L ammonium fluorotitanate, 5g / L potassium fluorosilicate, 5g / L nickel nitrate, 4g / L Zirconyl titanate, 2g / L sodium metaaluminate, 7g / L manganese dihydrogen phosphate, 3g / L sodium phytate and 2g / L oxalic acid.

[0036] A preparation method for a tin-plated steel surface treatment solution, comprising the following steps:

[0037] a. Weigh the components respectively, first add disodium hydrogen phosphate and sodium pyrophosphate into deionized water for stirring, control the stirring speed at 75 rpm, until completely dissolved;

[0038] b. Add ammonium fluorotitanate, potassium fluorosilicate, nickel nitrate, zirconyl titanate, sodium metaaluminate and manganese dihydrogen phosphate to the solution obtained in step a, then stir, and control the stirring speed to 48 rpm min, until completely dissolved;

[0039] c. Finally, add sodium phytate and oxalic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com