Patents

Literature

49results about How to "Simplify the surface treatment process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

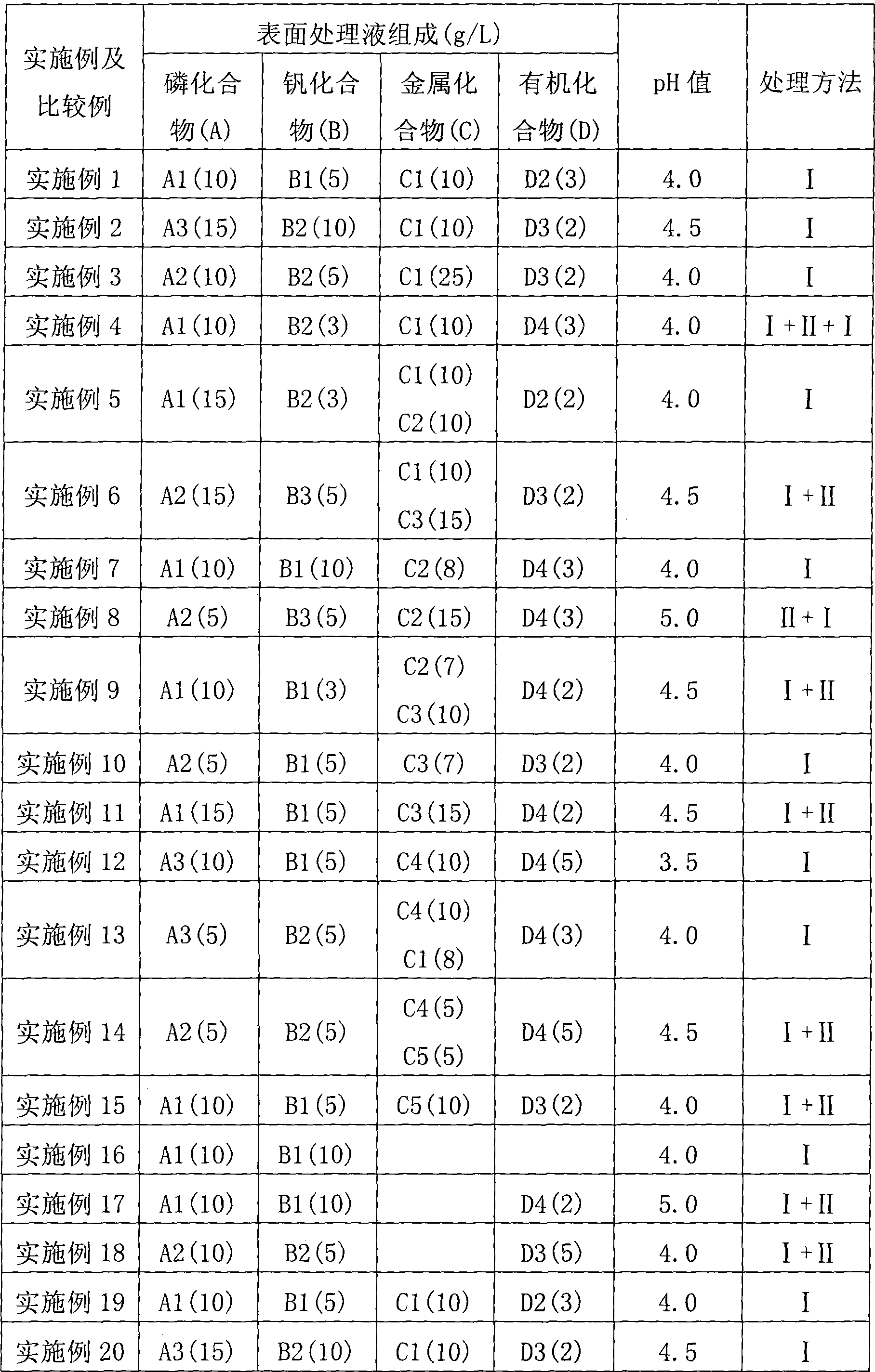

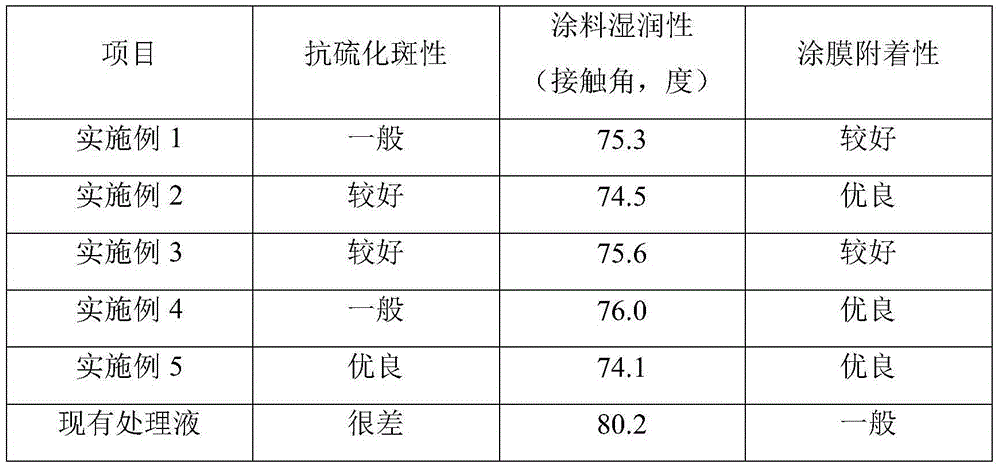

Surface treatment liquid, surface treatment method and tin-plated steel sheet by surface treatment

ActiveCN101545107AExcellent resistance to sulfur spotsExcellent paint wettingMetallic material coating processesPhosphateManganese

The invention provides a surface treatment liquid used for tin-plated steel sheets, which contains 1 to 50 g / L of phosphorus compound, 1 to 20 g / L of vanadium compound, 1 to 30 g / L of compound selected from one or more of molybdenum, zirconium, titanium, manganese and tungsten metal compounds, and 1 to 10 g / L of one or more compounds with at least one functional group of hydroxyl, carbonyl, carboxyl and phosphate. The invention also provides a surface treatment method using the surface treatment liquid, and a tin-plated steel sheet treated by the surface treatment liquid. By using the surface treatment liquid and the surface treatment method of the invention, chromium which is unfavorable for the environment is not contained in the process of producing the tin-plated steel sheets, and the cost is low. The tin-plated steel sheet has favorable sulfide spot resistance, paint wetting performance, coating adhesion and processing performance.

Owner:BAOSHAN IRON & STEEL CO LTD

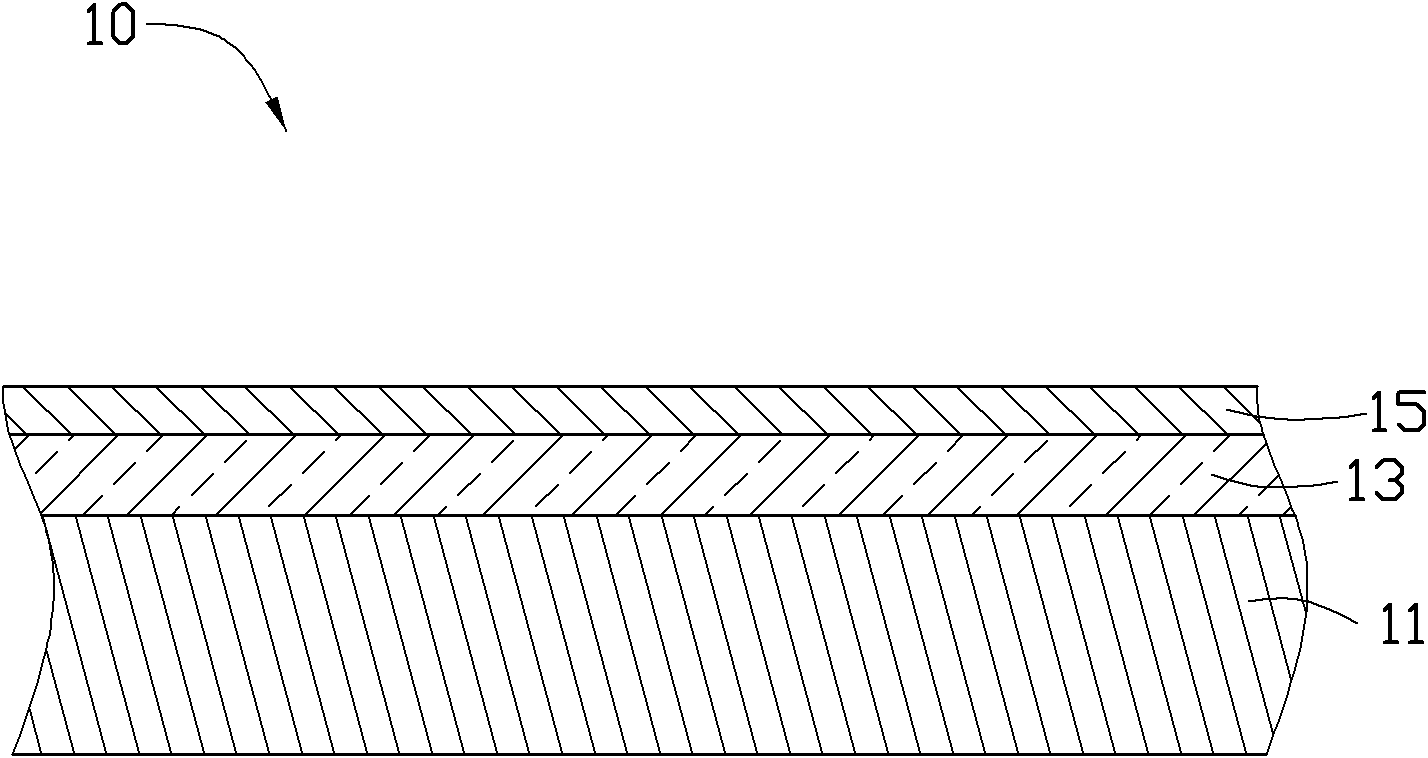

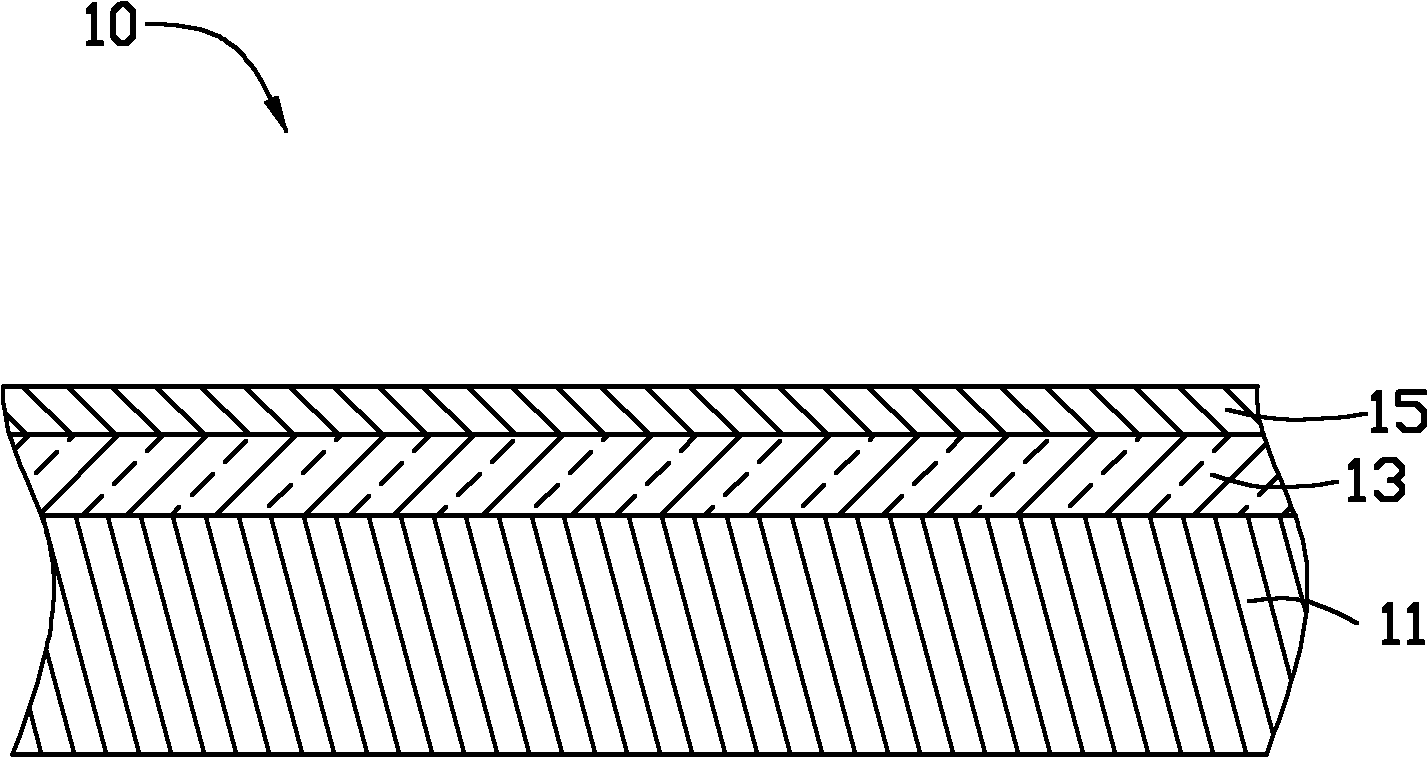

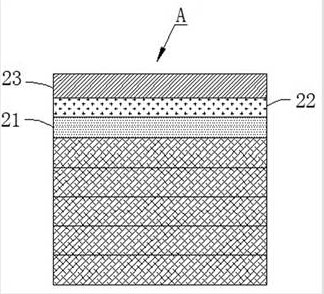

Electronic product shell material laminating structure and manufacture method thereof

InactiveCN102615888ASimplify the surface treatment processReduce surface treatment costsLamination ancillary operationsSynthetic resin layered productsPlastic filmSurface cover

The invention discloses an electronic product shell material laminating structure and a manufacture method thereof. One layer of plastic film covers on the laminating structure of the composite material; and the composite material covered with the plastic film is laminated, solidified and shaped by pressurizing and heating a die to form the electronic product shell material laminating structure composed of the composite material part and the plastic film so as to simplify the subsequent surface treatment process. The surface of the electronic product shell material laminating structure only needs to be polished once, supplemented with soil or sprayed, or the product can achieve a final finished product effect without polishing, supplementing with oil and spraying, and the surface treatment cost is lowered.

Owner:KUSN TONG YIN INDAL ELECTRONICS MAKING

Tinned steel plate surface treatment solution and preparation method thereof

ActiveCN104357825AGuaranteed corrosion resistanceGood adhesionMetallic material coating processesChromium freePhosphate

The invention discloses a tinned steel plate surface treatment solution and a preparation method thereof. The surface treatment solution contains 2-25 g / L disodium hydrogen phosphate, 2-13 g / L sodium pyrophosphate, 1-15 g / L ammonium hydrofluotitanate, 1-10 g / L potassium fluosilicate, 2-14 g / L nickel nitrate, 1-12 g / L zirconium titanate, 1-10 g / L sodium metaaluminate, 5-12 g / L manganese dihydrogen phosphate, 2-5 g / L sodium phytate and 1-7 g / L oxalic acid. The preparation method comprises the following steps: a. adding the disodium hydrogen phosphate and sodium pyrophosphate into deionized water, and stirring; b. adding the ammonium hydrofluotitanate, potassium fluosilicate, nickel nitrate, zirconium titanate, sodium metaaluminate and manganese dihydrogen phosphate; and c. regulating the pH value of the solution to 3-5 with phosphoric acid. On the basis of chromium-free passivation, the surface treatment solution ensures the corrosion resistance of the tinned plate without degrading the sulfur resistance, and also has excellent paint adhesiveness.

Owner:深圳市九久电子科技有限公司

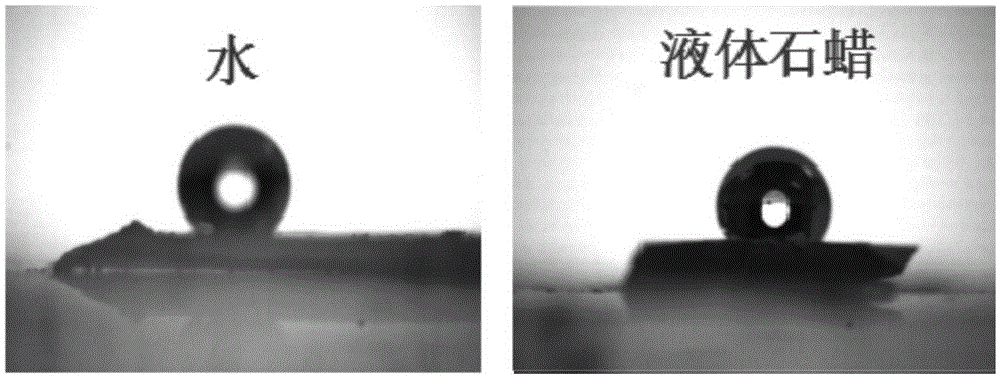

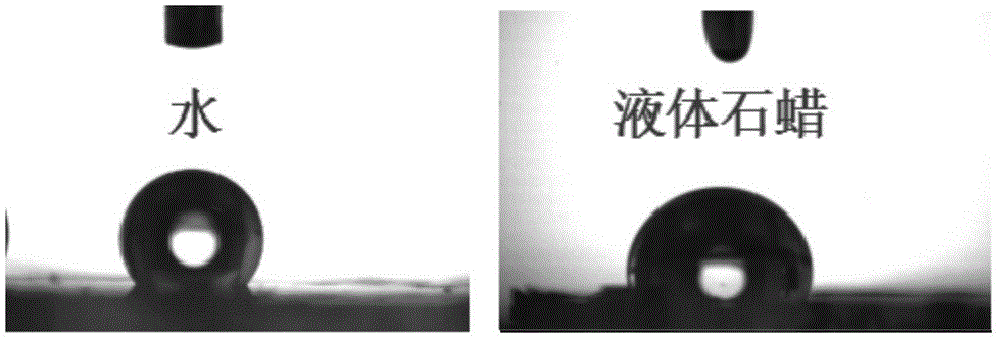

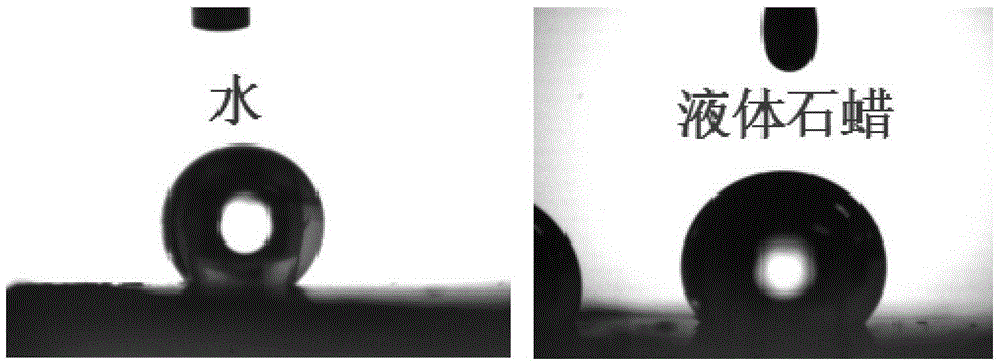

Preparing method for hydrophobic and oleophobic cosmetic pigment powder

ActiveCN105456048AHydrophobic and oleophobicSoft touchCosmetic preparationsMake-upNano siliconAlcohol

The invention discloses a preparing method for hydrophobic and oleophobic cosmetic pigment powder. The preparing method includes the following steps that 1, nano-silicon sol is sprayed to the surface of inorganic powder under the high-speed stirring condition; 2, first-time heat treatment is carried out; 3, fluorine containing silane is dispersed through ethyl alcohol or isopropanol, and then the fluorine containing silane is sprayed to the surface of the treated inorganic powder under the high-speed stirring condition; 4, second-time heat treatment is carried out; 5, airflow smashing is carried out. The powder prepared with the preparing method has the advantages that the hydrophobic performance and the oleophobic performance are achieved, soft and smooth hand feeling is achieved, and the skin fitting performance is good; as various kinds of toner are added into an emulsification system at the same time, the color floating problem can be solved, the color floating problem of the pigment powder treated through the fluorine containing silane in the cosmetic formula is fundamentally solved, and quite large convenience is provided for production and quality control of fluorated liquid foundation (cream) products.

Owner:SHANGHAI CO FUN BIOTECH

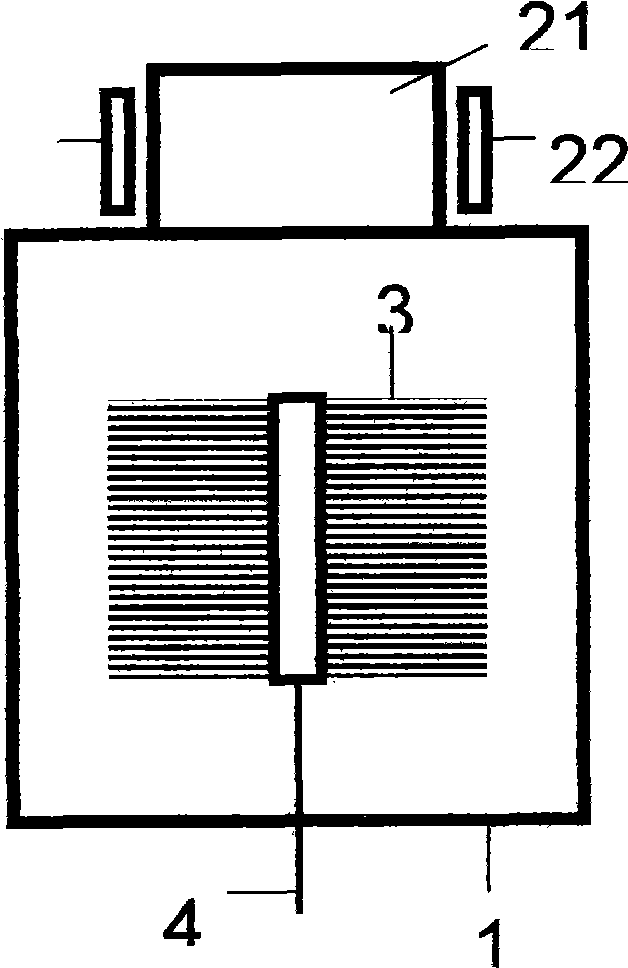

Plasma treatment method for corrosion-proof turbine molecular pump blade

InactiveCN101497982ASimplify the surface treatment processImprove compactnessPump componentsSolid state diffusion coatingNitrationVolumetric Mass Density

The invention relates to the technical field of vane surface treatment of a turbo molecular pump, in particular to a plasma treatment method of a corrosion-resistant turbo molecular pump vane. The method comprises the following step that firstly, a plasma is cleaned: the vane is put into a vacuum chamber of a plasma treatment device, the vacuum chamber is vacuumized, and the plasma is cleaned by injecting Ar and adding radio frequency; secondly, the plasma is oxidized or nitridized: O2, N2 or NH3 is injected into the vacuum chamber with atmospheric pressure of 1Pa-1KPa and treated for 1-5 hours with the radio frequency power of 100-5000W, the temperature of 200-400 DEG C and the power density of 1-60W / cm. Compared with the prior art, the invention has simple and environmental-friendly surface processing technology, and an oxidation layer or a nitration layer formed on the surface of the aluminum alloy vane treated by the process has high compactness and strong corrosion resisting capacity.

Owner:SUZHOU SUNLIGHTS TECH

Carbon fiber/polyphenylene sulfide composite material and preparation method and application thereof

ActiveCN113527885ASimplify the surface treatment processEasy to prepareAdditive manufacturing apparatusIncreasing energy efficiencyFiberCarbon fibers

The invention discloses a carbon fiber / polyphenylene sulfide composite material and a preparation method and application thereof. The preparation method comprises the following steps: carrying out surface pretreatment on carbon fibers to obtain pretreated carbon fibers; uniformly mixing the pretreated carbon fibers, a carrier, a dispersing agent and a solvent, and performing granulation treatment to obtain carbon fiber master batches; and uniformly mixing the carbon fiber master batch, polyphenylene sulfide, a flexibilizer and an antioxidant, and performing granulation treatment to obtain the carbon fiber / polyphenylene sulfide composite material. The carbon fiber content in the prepared carbon fiber / polyphenylene sulfide composite material is controllable, the carbon fibers can be uniformly dispersed after being doped into polyphenylene sulfide, and the mechanical property of the composite material can be greatly improved; meanwhile, the carbon fiber / polyphenylene sulfide composite material 3D printing wire is low in water absorption, easy to store and low in shrinkage rate, and a prepared printing piece is not prone to edge warping and high in Young modulus.

Owner:江西省纳米技术研究院

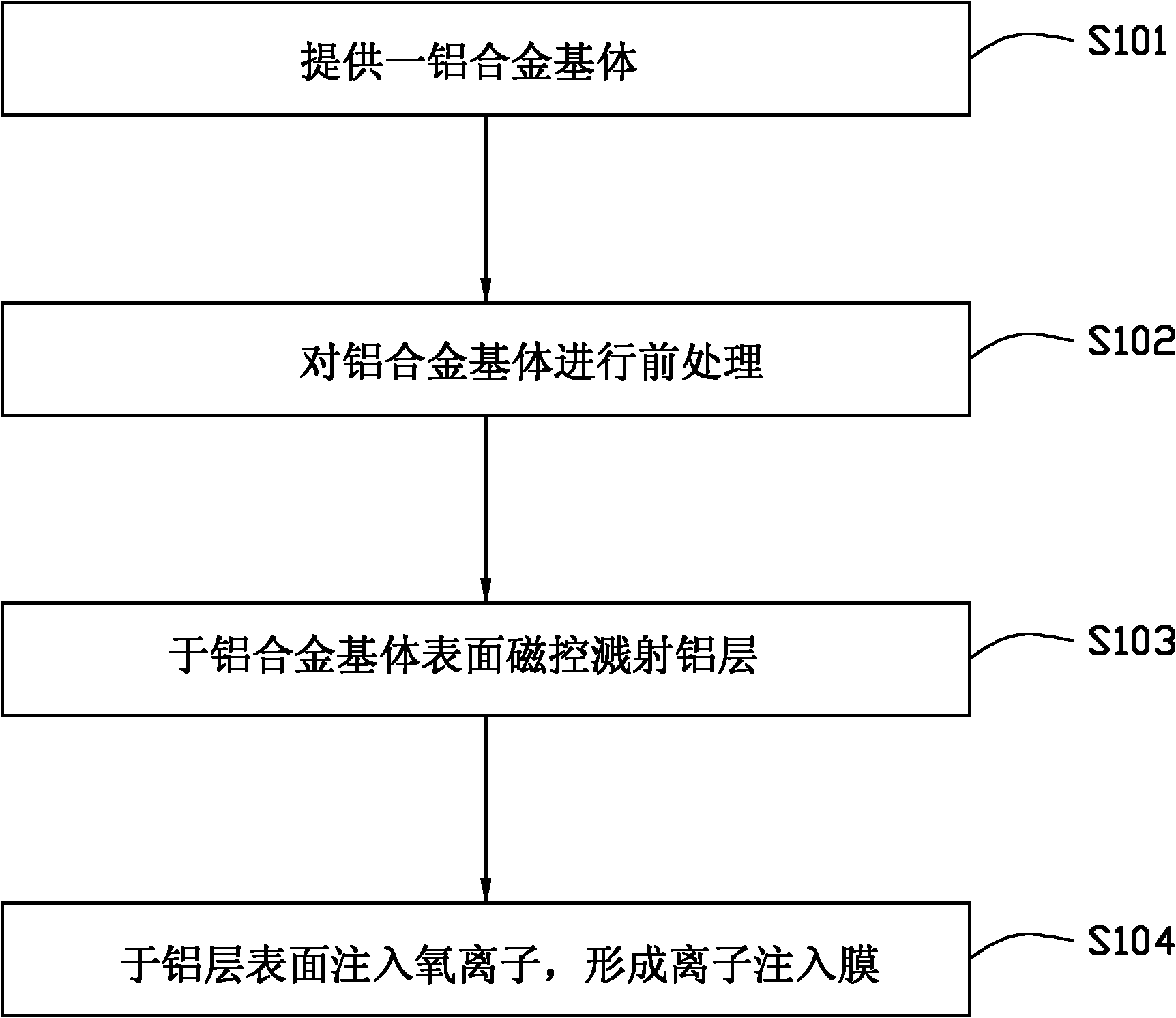

Surface treatment method for aluminum alloy and housing prepared from aluminum alloy

InactiveCN102400091AImprove corrosion resistanceNo pollution in the processVacuum evaporation coatingSputtering coatingSputteringSolid solution

The invention provides a surface treatment method for aluminum alloy. According to the method, an aluminum layer is formed on the surface of a matrix of the aluminum alloy through magnetron sputtering, and an ion implantation film is formed on the aluminum layer; the ion implantation film mainly contains solid solution phases of Al2O3 and AlO. A composite membrane layer composed of the aluminum layer and the ion implantation film substantially improves corrosion resistance of the matrix of the aluminum alloy. The invention also provides housing prepared from the aluminum alloy.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

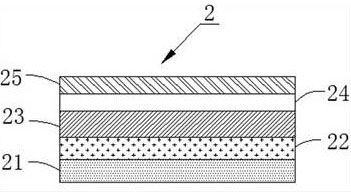

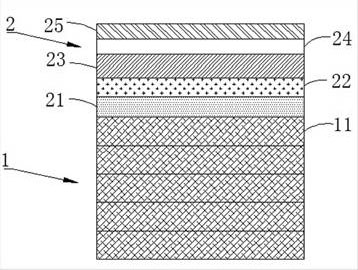

Composite appearance product with patterns and production method thereof

ActiveCN102615882ASimplify the surface treatment processAchieve the appearanceSynthetic resin layered productsGlass/slag layered productsPolyethylene glycolMaterials science

The invention discloses a composite appearance product with patterns and a production method thereof, which are manly characterized in that a composite stack and a decorative formed film are placed in a mould simultaneously, the decorative formed film is composed of a back glue layer, an ink layer, a production surface UV (ultraviolet) material layer, a release layer and a PET(polyethylene glycol terephthalate) layer, the decorative formed film is integrally joined with composite while the composite is formed, and accordingly the surface UV material layer, the ink layer and the back glue layer of the product with the decorative formed film are joined to the composite. The composite appearance product with patterns composed of a composite part, the back glue layer, the ink layer and the product surface UV material layer is produced by tearing the decorative formed film after mould opening, so that surface treatment process for the composite appearance product is simplified, and the appearance effect that the traditional composite cannot reach is realized.

Owner:KUSN TONG YIN INDAL ELECTRONICS MAKING

Surface treatment process of magnesium alloy product

InactiveCN104032294AThe surface treatment process is safe and environmentally friendlySimplify the surface treatment processElectrophoretic coatingsMetallic material coating processesSolderabilitySediment

The invention relates to the technical field of metal material surface treatment, and particularly relates to a surface treatment process of a magnesium alloy product. The surface treatment process comprises the following processing steps: (1) removing greasy dirt on the surface of a magnesium alloy workpiece; (2) removing an oxide on the surface of the magnesium alloy workpiece; (3) processing the magnesium alloy workpiece in a surface treating agent solution; (4) carrying out cathode electrophoretic painting on the magnesium alloy workpiece; (5) solidifying and baking the workpiece after electrophoretic painting. The component formula of the treating agent in the surface treatment process of the magnesium alloy product provided by the technical scheme disclosed by the invention is wide in raw material source, low in cost, stable in bath solution, not easy in generation of sediments, safe and environment-friendly in component in the use procedure, the late solderability of the magnesium alloy metal product is not affected, and the surface treatment process of the magnesium alloy product is simple, applicable to treatment of the surface of the magnesium alloy metal product, convenient and practical, and applicable to popularization and application.

Owner:张家港沙龙精密管业有限公司

Surface treatment liquid for iron and steel

The invention discloses surface treatment liquid for iron and steel. The surface treatment liquid comprises the following components: titanium salt of which the mass concentration is 0.1-1.5%, vanadium compounds of which the mass concentration is 2-15%, fluoride of which the mass concentration is 5-20%, water-soluble resin of which the mass concentration is 1-2%, an acid which is used for adjusting the pH value of the surface treatment liquid to 3-4, oxalic acid of which the mass concentration is 2-5%, citric acid of which the mass concentration is 2-4%, and the balance of water and other inevitable impurities. The surface treatment liquid disclosed by the invention does not contain carcinogen hexavalent chromium (chromate) or toxic metal ions, so that environmental pollution is greatly alleviated, and the cost is substantially reduced. Phosphoric acid which is an acid with medium strength is not as strong as a hydrochloric acid, a sulphuric acid and a nitric acid, so that when the phosphoric acid, an oxalic acid and a citric acid are jointly used, the total acidity and the free acidity can be improved, the effects of removing rust and removing scales can be achieved, and moreover, the citric acid not only enhances the acidity but also can have a complexing effect on iron ions.

Owner:WUXI EPIC TECH

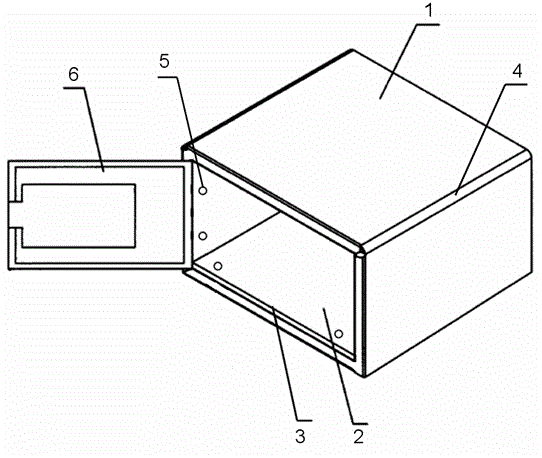

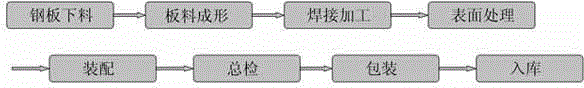

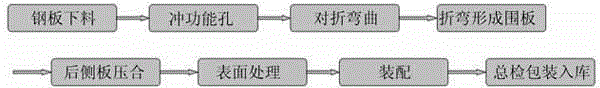

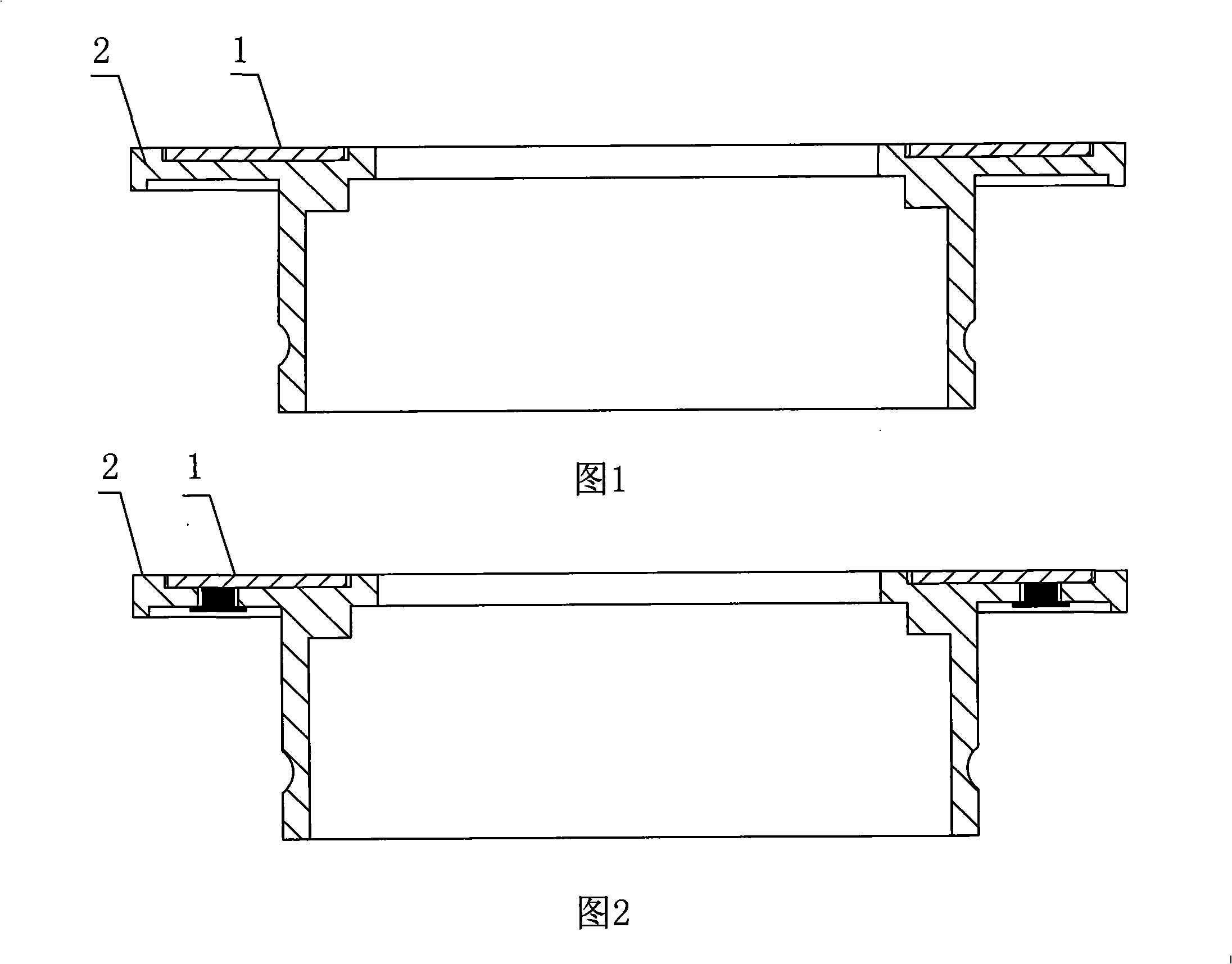

Semi-integral safety box and manufacturing method thereof

InactiveCN104790805AProblems affecting service lifeHigh dimensional accuracySafesPunchingMechanical strength

The invention discloses a semi-integral safety box and a manufacturing method thereof. The semi-integral safety box comprises a box body, a box door, a door lock component and a hinge component. The hinge component is arranged on one side edge of the box door, and the box door is connected with the box body through the hinge component. The door lock component is arranged on the box door and matched with a lockhole in the box body. The box body comprises a left side plate, a right side plate, an upper side plate and a lower side plate which are formed integrally in a punching mode. The box body further comprises a rear side plate which is connected with the left side plate, the right side plate, the upper side plate and the lower side plate in a press fit mode. The semi-integral safety box is high in mechanical strength and security. Continuous punch forming is adopted for the manufacturing method, so that production efficiency is greatly improved, production cost is reduced, and surface quality is good.

Owner:江西金钱豹保险设备集团有限公司

High-temperature alloy mould and casting and demoulding method thereof

InactiveCN105855519AExtended service lifeSolve the industry problems with high cost of useFoundry mouldsFoundry coresUltrasonic assistedSuperalloy

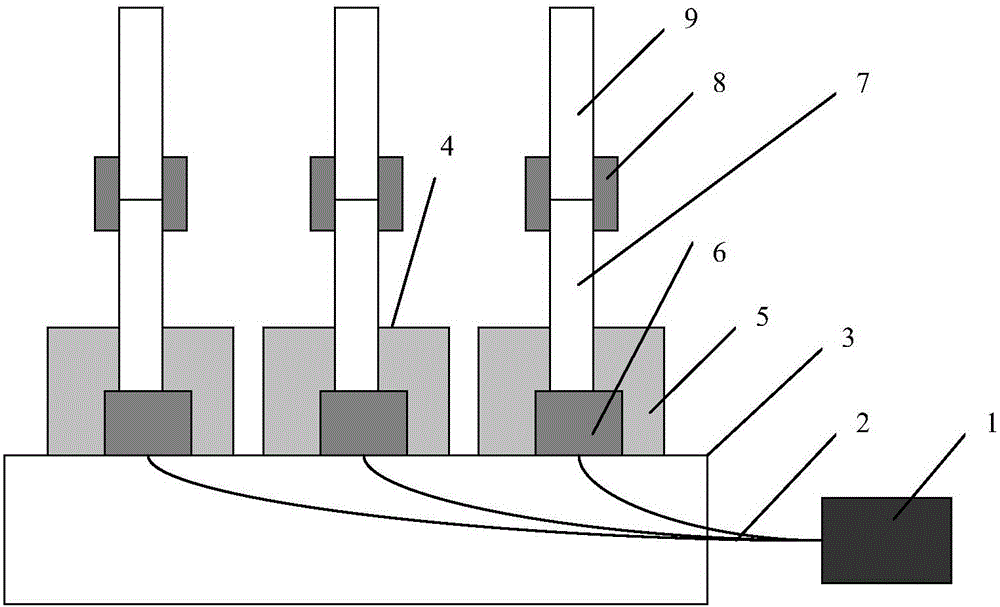

The invention discloses a high-temperature alloy mould and a casting and demoulding method of the high-temperature alloy mould. The high-temperature alloy mould comprises an ultrasonic controller, wires, a base and a plurality of mould components, wherein each mould component comprises a mould, an upper mould and a lower mould; a bottom fixed seat and an ultrasonic probe are arranged in the mould, the mould is vertically fixed on the upper surface of the base, the ultrasonic probe is connected with the ultrasonic controller through the wire, and fastened on the upper surface of the base, the bottom fixed seat is further fastened on the upper surface of the base and the ultrasonic probe is wrapped inside the bottom fixed seat, and a hole of which the surface area is smaller than that of the ultrasonic probe is opened at the upper part of the ultrasonic probe, the lower mould is vertically inserted into the internal part of the bottom fixed seat through the hole, and the upper mould is arranged above the lower mould and connected with the lower mould through a clamping buckle. According to the invention, the existing process is improved by adopting an ultrasonic assisted high-temperature casting and double-node mould technology, and the high-temperature alloy mould and the casting and demoulding method of the high-temperature alloy mould are low in cost, simple in process and suitable for industrial production.

Owner:HOHAI UNIV

Surface treatment method for compound semiconductor substrate and epitaxial structure

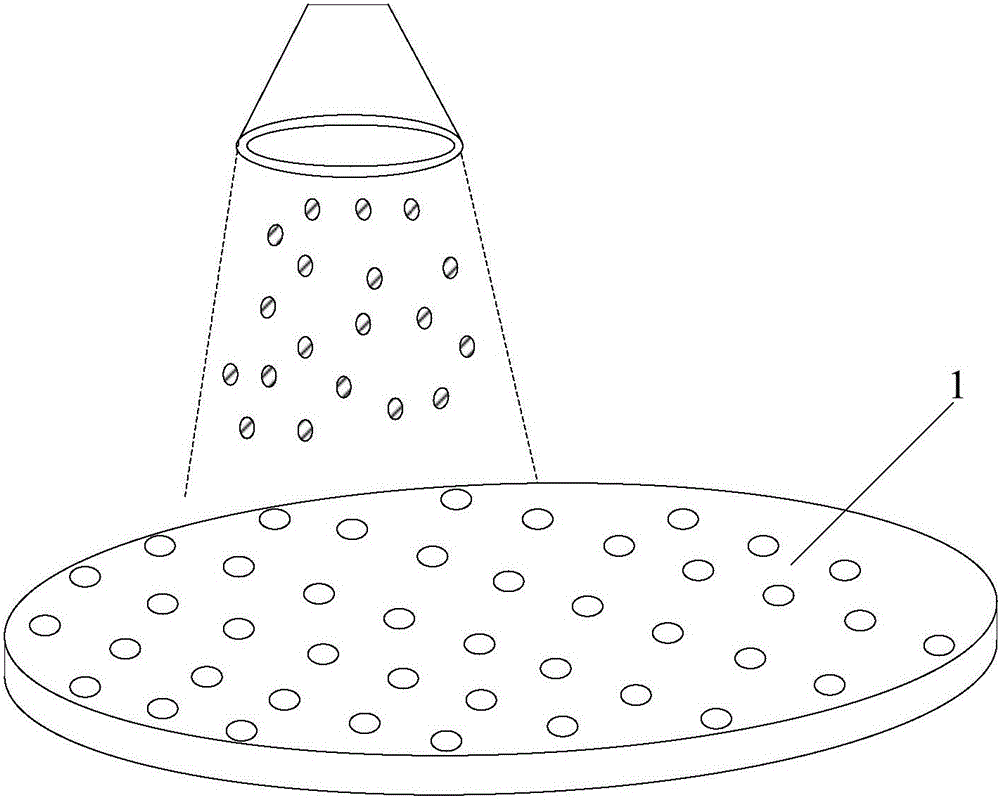

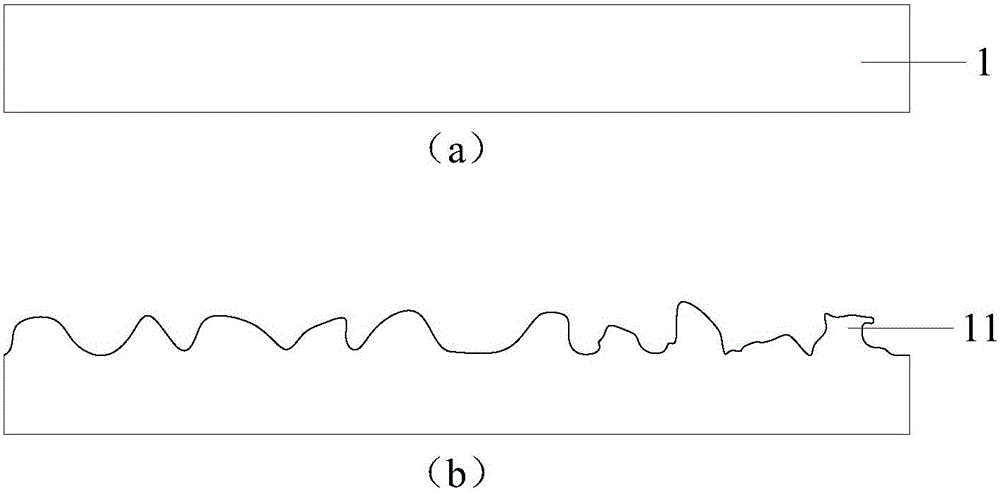

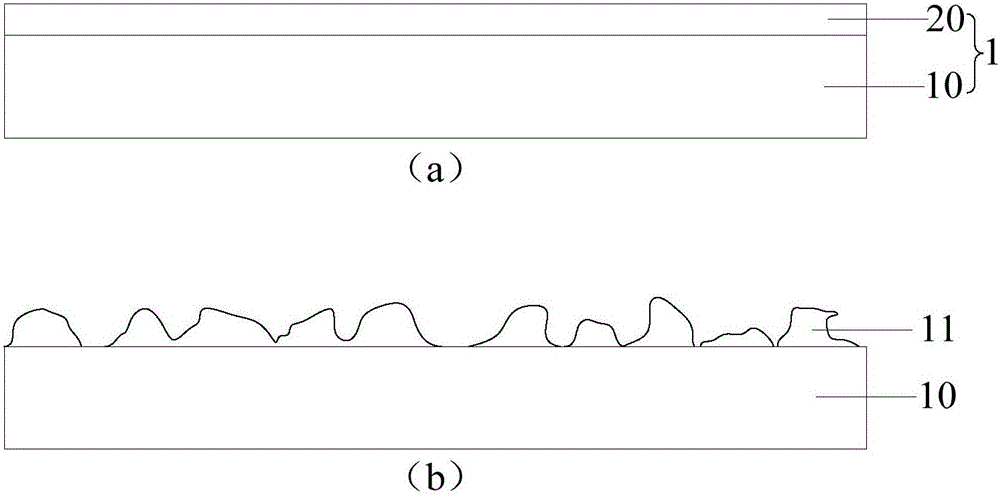

ActiveCN105810578ASimplify the surface treatment processImprove surface roughnessSemiconductor/solid-state device manufacturingConvex structureHigh pressure

The invention provides a surface treatment method for a compound semiconductor substrate and an epitaxial structure. The surface treatment method comprises the following step of spraying slurry containing an abrasive material towards the surface of the compound semiconductor substrate at high pressure to form an irregular concave-convex structure on the surface of the compound semiconductor substrate. The epitaxial structure comprises the compound semiconductor substrate obtained by the surface treatment method and a compound semiconductor thin film; the compound semiconductor thin film transversely grows on the concave-convex structure of the compound semiconductor substrate; and the compound semiconductor substrate and the compound semiconductor thin film are in heterostructure. By the above method, the surface treatment technology can be simplified.

Owner:CHENGDU HIWAFER SEMICON CO LTD

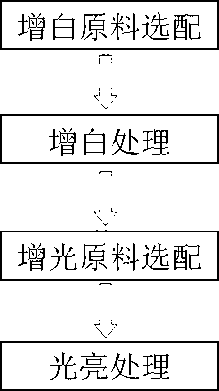

Technology for surface treatment of double-layered stainless steel product

InactiveCN102995038ASimplify the surface treatment processClean surfaceChemical treatmentRaw material

The invention discloses a technology for surface treatment of a double-layered stainless steel product. The technology for the surface treatment comprises the following steps: a, whitening raw material selecting and blending; b, whitening treating; c, brightening raw material selecting and blending; and d, brightening treating. The invention discloses the technology for the surface treatment of the double-layered stainless steel product. The technology for the surface treatment adopts a chemical treatment method and is simple in technological method, the selected chemical raw materials are prepared reasonably and are low in cost, and the double-layered stainless steel product after surface treatment not only has a clean, white and bright surface and but also has the original vacuum degree which is not damaged at all.

Owner:昆山浦力真空科技有限公司

Steel surface treatment liquid

The invention discloses a steel surface treatment liquid comprising titanium salt with the mass concentration of 0.1-1.5%, vanadium compound with the mass concentration of 2-15%, fluoride with the mass concentration of 5-20%, water soluble resin with the mass concentration of 1-2%, acid used for adjusting the pH value of a passive solution to be 3-4, phosphorus compound with the mass concentration of 5-25%, molybdenum, zirconium, manganese or tungsten metallic compound or the combination thereof with the mass concentration of 0.1-1.5%, and water and other inevitable impurities. The surface treatment process has the advantages of simple method, easy implementation and low cost. Only a small number of auxiliary instruments or equipment are required to completely perform the chrome free surface treatment on the traditional chrome treatment production line of steel plates, thereby simplifying wastewater treatment, lowering cost and achieving remarkable economic benefits.

Owner:WUXI EPIC TECH

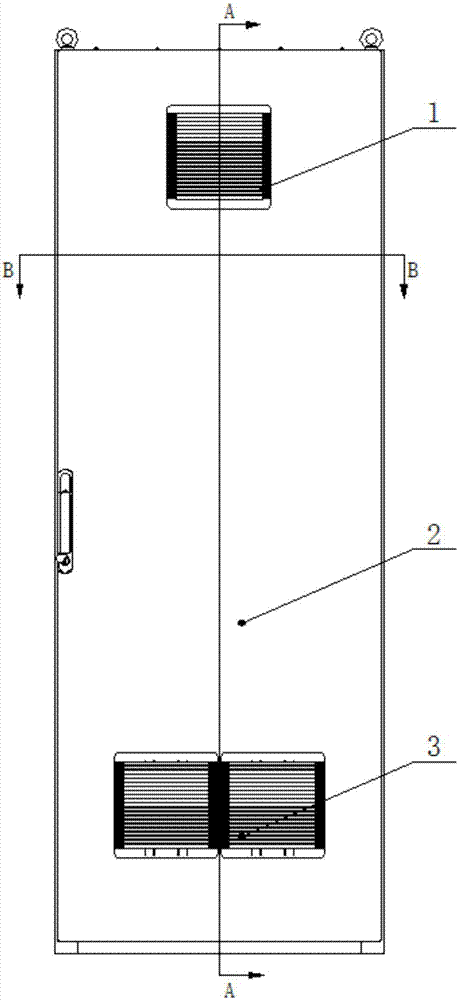

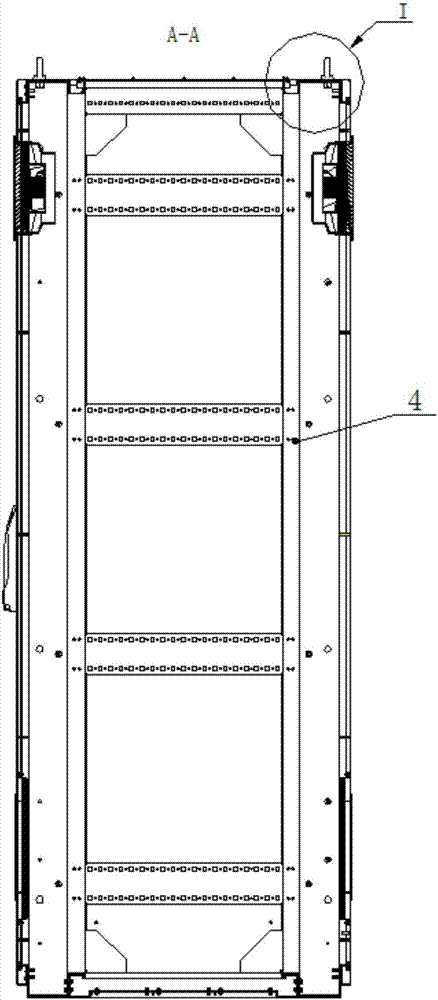

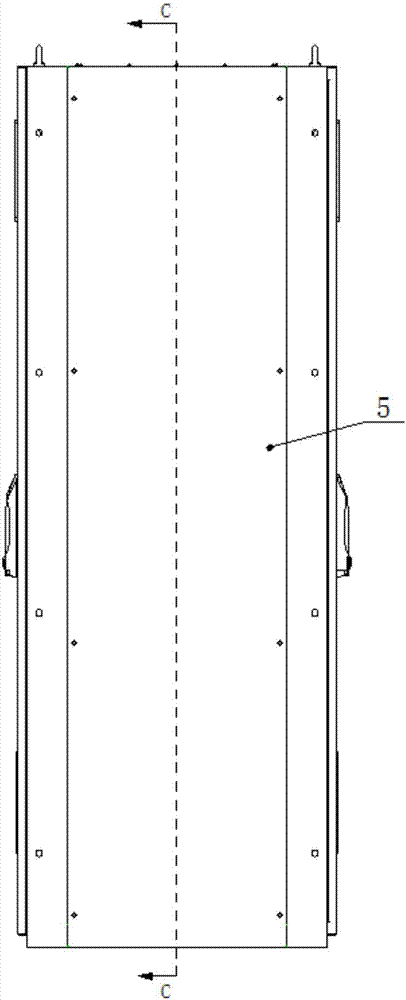

Cabinet having IP*6 protection capability

InactiveCN107466181AMeet the needs of useGood IP protection effectCasings/cabinets/drawers detailsHermetically-sealed casingsEngineeringInstrument control

The invention belongs to the technical field of nuclear power non-safety instrument control, and particularly relates to a cabinet having IP*6 protection capability. The cabinet integratedly employs a cold-roll steel sheet to be bent and is formed by assembling a front / rear door plate, a cabinet frame, a left / right side plate, a bottom plate and a top cover, a door plate horizontal shielding sealing strip and a door plate vertical shielding sealing strip are arranged between the front / rear door plate and the cabinet frame, a fan and a dustproof net are arranged on the front / rear door plate, a side plate horizontal shielding sealing strip and a side plate vertical shielding sealing strip are arranged between the left / right side plate and the cabinet frame, and a shielding sealing strip is pasted between the top cover and the cabinet frame. The cabinet has a relatively good IP protection effect and is less in welding, the surface processing process is simpler than that of integrated welding type cabinet, the manufacturing and processing cost is greatly reduced, and meanwhile, the application demand of a nuclear power plant is satisfied.

Owner:CHINA NUCLEAR CONTROL SYST ENG

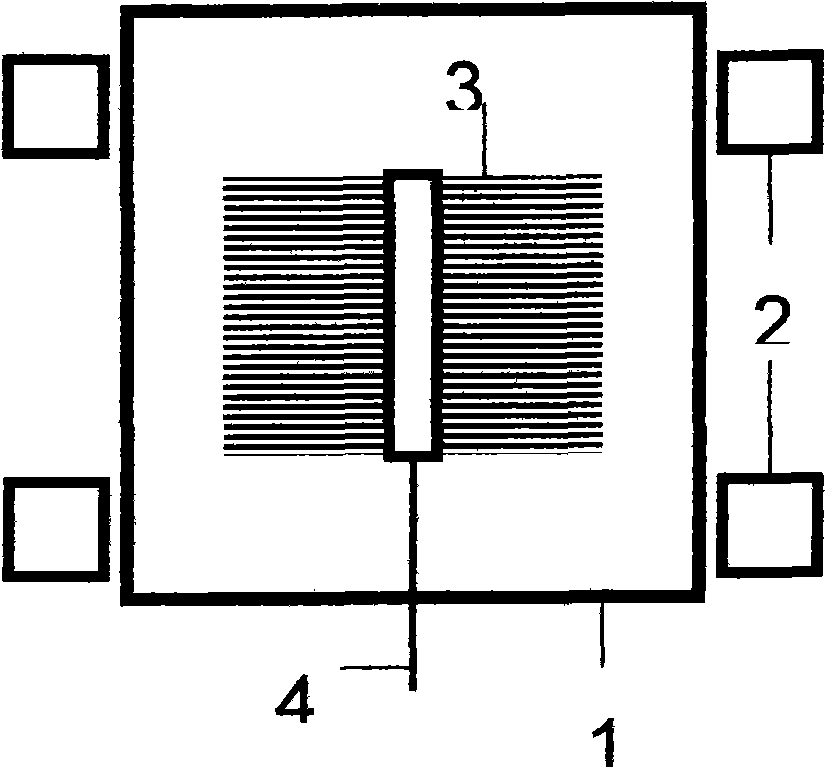

Transformer

InactiveCN104505232APromote withdrawalDraw downTransformers/inductances coolingTransformers/inductances coils/windings/connectionsFerrite layerTransformer

The invention discloses a transformer, which comprises a coil former, a magnetic core and a replaceable insulation mat assembly, wherein the magnetic core is arranged in the center through hole of the coil former; the replaceable insulation mat assembly is arranged between the magnetic core and the coiler former; the coiler former is provided with a placement groove used for containing a coil; the insulation mat assembly comprises two opposite insulation mats; each insulation mat is provided with an insulation mat body and a handle, wherein the insulation mat body is used for isolating the magnetic core from the coil former; the handle is arranged on the end part of the insulation mat body and is clamped on the inner side of the coil former; the handle extends to the outer side of the coil former; the handle is provided with a groove where a hand is put; and the magnetic core comprises a first magnetic core and a second magnetic core, wherein the first magnetic core and the second magnetic core are independently combined by an alloy material layer and a ferrite layer, the shape of the alloy material layer is not completely same with the shape of the ferrite layer, the integral magnetic core is formed after the alloy material layer and the ferrite layer are combined, and the main body surfaces of the first magnetic core and the second magnetic core respectively form a first magnetic pillar and a second magnetic pillar, wherein the first magnetic pillar and the second magnetic pillar externally extend. The transformer has the advantages of being convenient in use, good in cooling effect and high in stability.

Owner:江苏辰宇电气有限公司

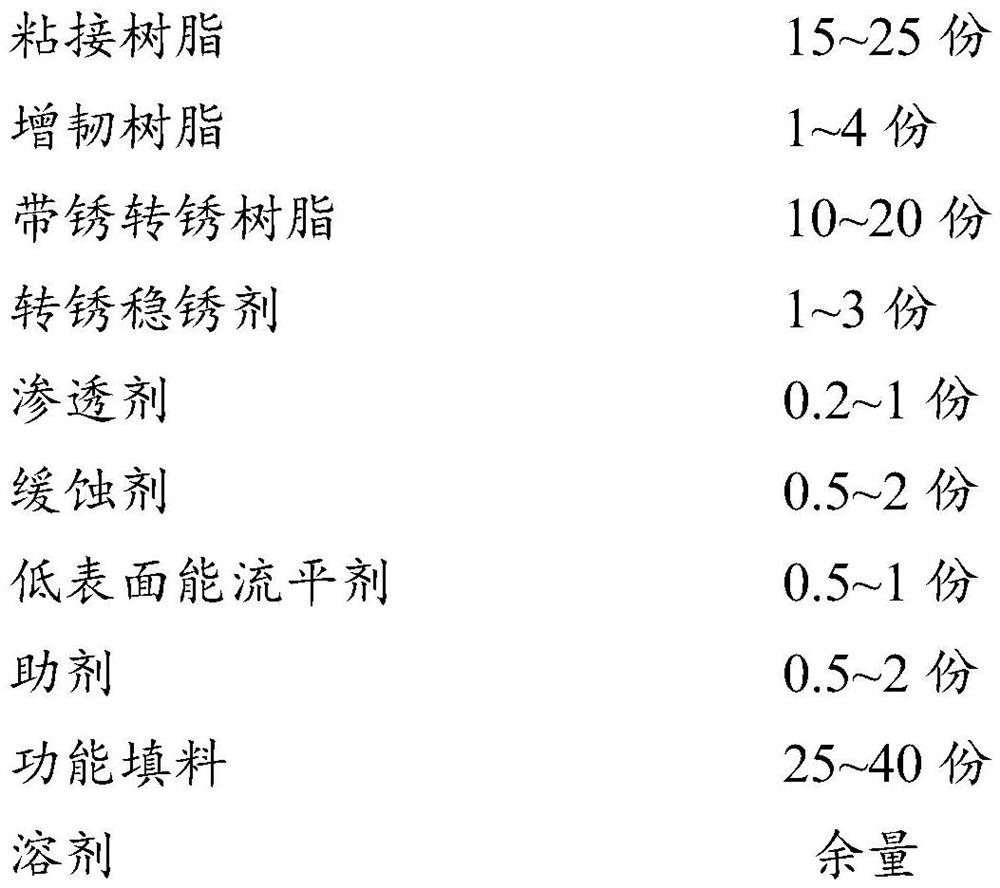

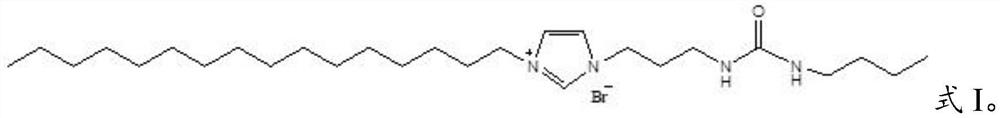

Permeation corrosion inhibition type rusty antirust primer and preparation method and application thereof

InactiveCN111826060AImprove toughnessImprove impact resistanceAnti-corrosive paintsEpoxy resin coatingsCoated surfaceHigh surface

The invention belongs to the technical field of corrosion prevention, and provides a permeation corrosion inhibition type rusty antirust primer and a preparation method and application thereof. The toughness and impact resistance of a paint film are improved through the toughening resin, the coating performance of the primer under the damp working condition is enhanced through the low-surface-energy leveling agent, moisture in a rust layer can be replaced, moisture on the surface of a base material is promoted to migrate to the surface of the coating from the bottom of the coating, and the continuity of the coating and the adhesive force between the coating and the base material are improved. The permeability of the primer is improved through the penetrating agent, the primer is promoted to fully infiltrate and permeate into the porous rust layer, and the rust conversion performance is improved. Rust is converted into stable and useful filler through rust conversion resin with rust anda rust conversion agent, the attachment area of the primer and the metal base material is further increased, and the compactness of a paint film is improved. The permeation corrosion inhibition typerusty antirust primer provided by the invention can be coated on the surface of a wet rusty base material, and has the characteristics of good permeability, strong corrosion inhibition capability, high rust conversion capability, low surface treatment grade and synergistic long-acting protection.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Decorative lamp tinting processing method

InactiveCN101260986ASimplify the surface treatment processShorten the processing cycleNon-electric lightingPoint-like light sourceSurface finishingEngineering

The invention relates to the decoration lamp production technical field, in particular to a method for color coated treatment to a decoration lamp. In the method, firstly, a lamp bracket and a decorative surface sheet are manufactured in split mode; then, the lamp bracket and the decorative surface sheet undergo color coated treatment with different colors; finally, the lamp bracket and the decorative surface sheet are correspondingly assembled. The invention designs the lamp bracket and the decorative surface sheet into two separate parts which undergo surface treatment such as plating and spray finishing and then assembled together. In the way, the method adopted can greatly simplify the technology of the surface treatment, shorten processing cycle, largely reduce the cost and improve the quality of the surface treatment.

Owner:肖志蓝

Surface treatment process for aluminum products

InactiveCN107460519AReduce process stepsReduce job manufacturing costsAnodisationSilica particleSilicon dioxide

The invention discloses a surface treatment process for aluminum products. The surface treatment process comprises the following steps: 1, oil removing procedure, wherein an aluminum product is put into an alkaline solution to remove oil for 20-30 seconds, and then clean water is used for cleaning the aluminum product for one time; and 2, grinding procedure, wherein a plurality of silica particles are poured into the grinding chamber of an industrial vibration grinding machine, a silica particle pile is formed, clear water is poured into the grinding chamber of the industrial vibration grinding machine, the poured clear water submerges the silica particle pile, and the aluminum product after being treated in the oil removing procedure is poured into the grinding chamber of the industrial vibration grinding machine. According to the surface treatment process for the aluminum products, the aluminum product after being treated in the oil removing procedure is poured into the industrial vibration grinding machine with the plurality of silica particles to be subjected to grinding, on one hand, the silica particles can grind burrs on the surface of the aluminum product, on the other hand, silicon dioxides in the silica particles can neutralize the alkaline solution, and therefore, the aluminum product does not need to be added with an acidic solution for neutralization after being subjected to the oil removing procedure in the alkaline solution.

Owner:泰州亚泰金属有限公司

Board lamination process

InactiveCN104802490ASimplify the surface treatment processImprove environmental performanceLamination ancillary operationsLaminationEngineeringMechanical engineering

The invention discloses a board lamination process which comprises the following steps: dust removing, painting, photocuring, sanding, rolling pressing, laminating and drying. The paint surface of a finished board product is full, smooth and clean, and UV (ultraviolet) paint is the most environment-friendly, so that the environment-friendliness of the board is improved.

Owner:ANHUI GUOTAI PACKING PRINTING

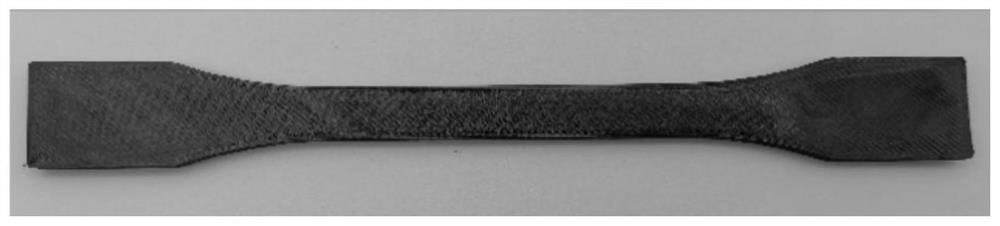

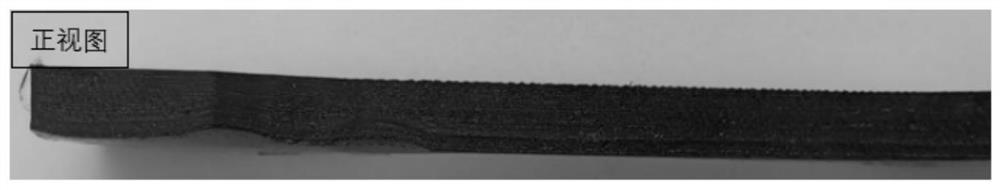

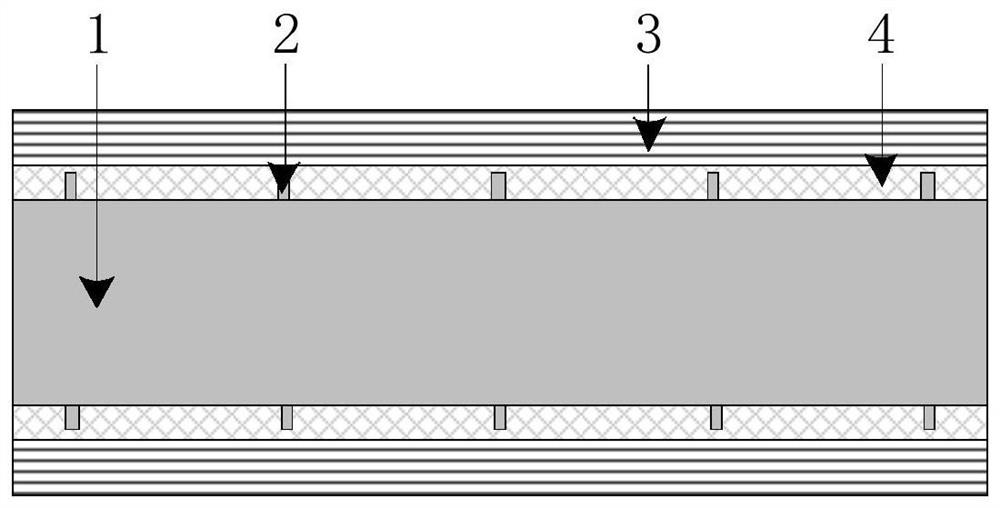

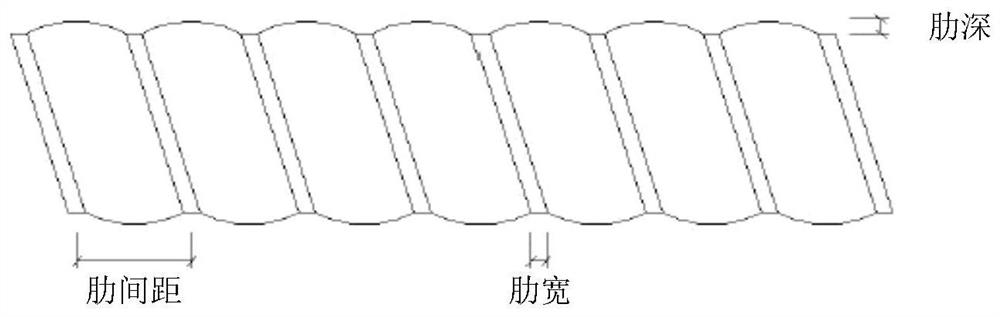

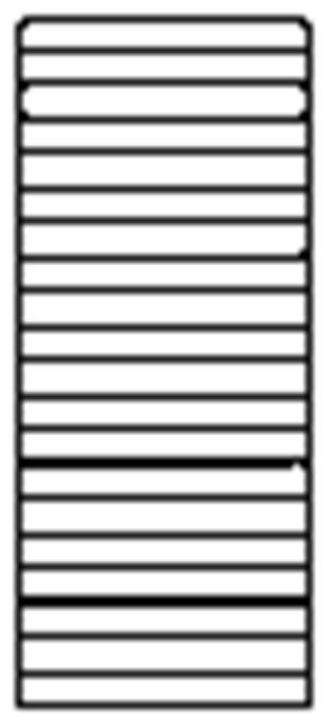

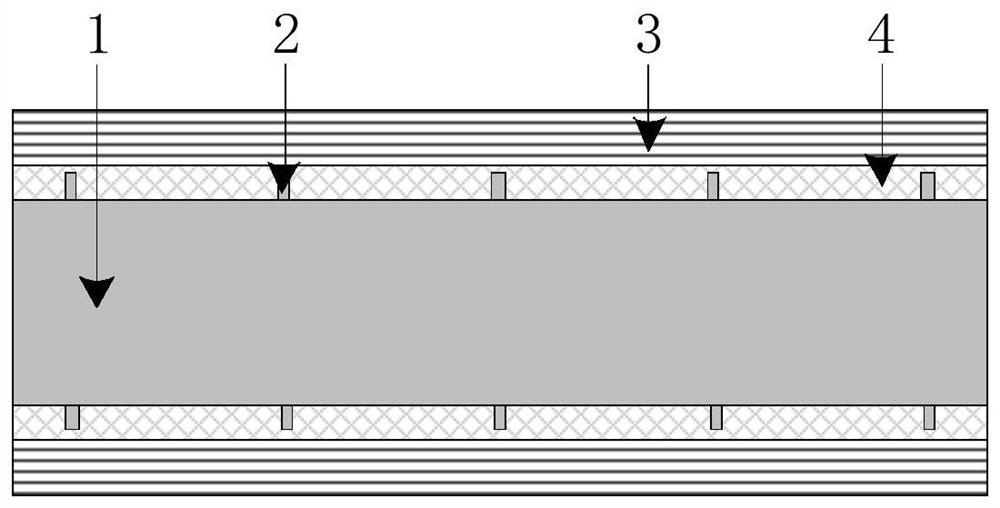

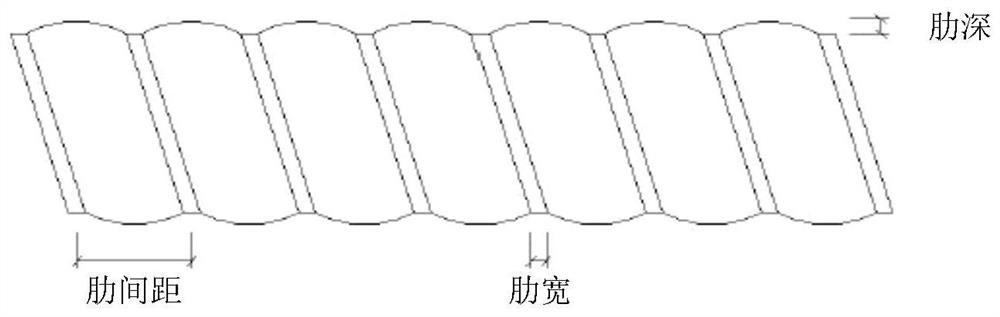

Steel-continuous fiber composite bar and preparation method

ActiveCN112324054AIncrease free energyImprove interfacial adhesionBuilding reinforcementsRebarFiber volume ratio

The invention discloses a steel-continuous fiber composite bar and a preparation method. The steel-continuous fiber composite bar comprises a steel bar inner core, a continuous fiber layer and steel bar reinforced ribs, wherein the continuous fiber layer is arranged outside the steel bar inner core, the steel bar reinforced ribs are arranged on the outer surface of steel bars, and a bridging layercomposed of chopped fiber and resin is arranged between the steel bar inner core and the continuous fiber layer. The spacing of steel bar reinforced ribs is 1.5 times of the diameter of the bars, therib width is 23% to 25% of the diameter, and the rib depth is 0.07 to 0.08 of the diameter. According to the steel-continuous fiber composite bar, the resin is reinforced by the chopped fiber, the obtained modified resin is used for manufacturing the bridging layer, on one hand, the cooperative work performance of the steel bars and the fiber is improved, and on the other hand, the production efficiency of the bars is improved. The surface form of the bars is optimized, controllable sliding between the composite bar and concrete is achieved, and the breaking risk of the continuous fiber is reduced; and additionally, the volume ratio of the steel bars to the fiber is reasonably designed, so that the secondary rigidity of the composite bar after the steel bars are yielded is guaranteed, thedecline amount of the strength of the steel bars after the fiber is broken is reduced, and the safety performance of the structure is further improved.

Owner:江苏绿材谷新材料科技发展有限公司

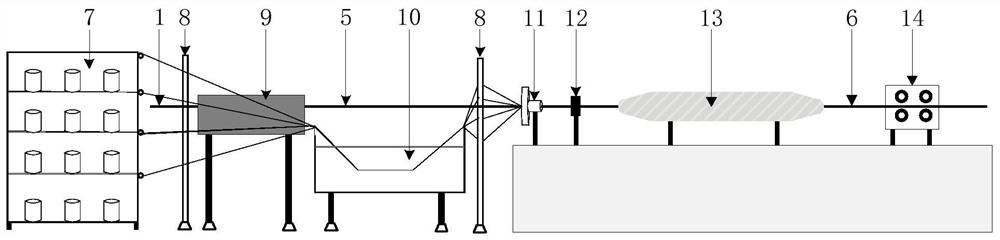

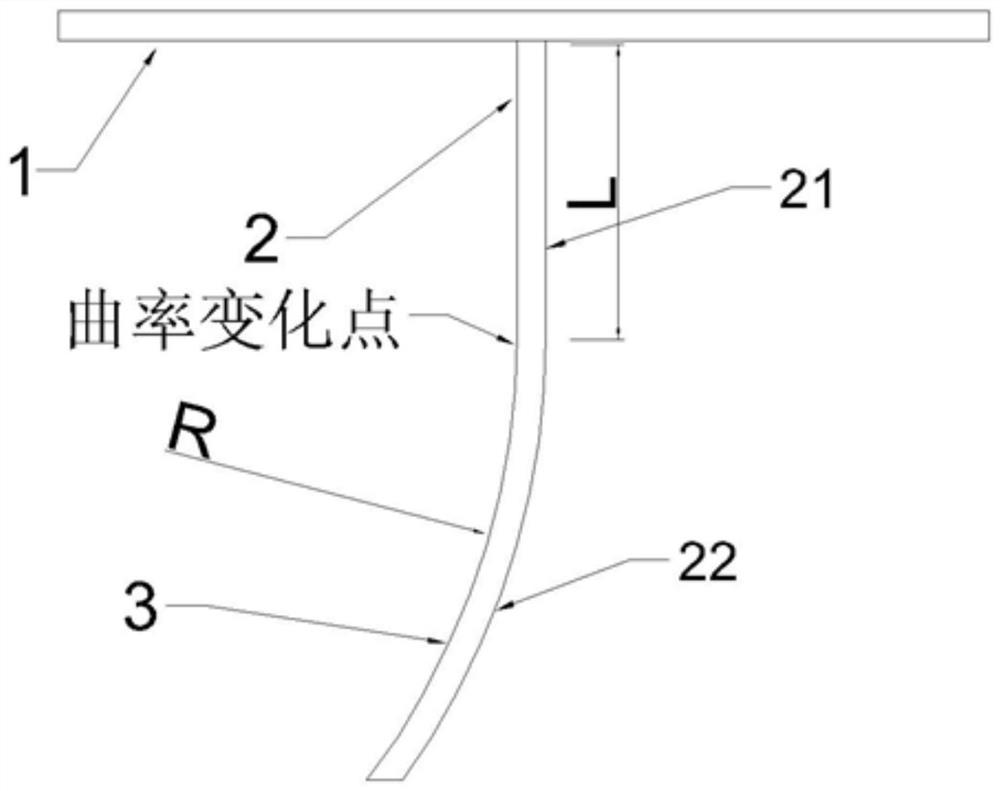

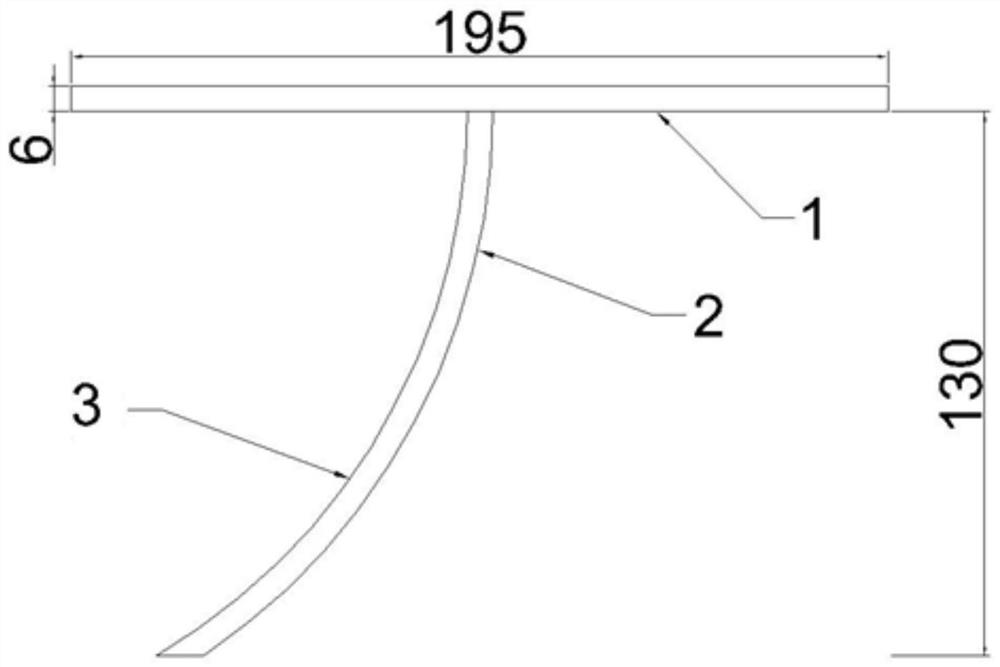

Underwater dredging and desilting vehicle track tooth and manufacturing method thereof

ActiveCN113309167AFirmly connectedCompact structureSoil-shifting machines/dredgersMarine engineeringWave shape

The invention discloses an underwater dredging and desilting vehicle track tooth and a manufacturing method thereof. The underwater dredging and desilting vehicle track tooth comprises a top plate and a track tooth, wherein the track tooth is provided with a vertical part and a bent part; the top end of the vertical part is fixedly connected with the lower surface of the top plate, and the bent part is bent towards the rear side of the crawler tooth; a layer of film is arranged on the surface of each crawler tooth, the film is provided with an uneven corrugated surface, the corrugated surface conforms to a waveform function Y = 2sin (X / 10), and the contact angle between sediment and the surface of the film is at least 150 degrees. According to the invention, the adhesive force between the crawler tooth and the deep-sea sediment can be minimum.

Owner:XIANGTAN UNIV

A kind of steel-continuous fiber composite bar and its preparation method

ActiveCN112324054BIncrease free energyImprove interfacial adhesionBuilding reinforcementsPhysical chemistryRebar

Owner:江苏绿材谷新材料科技发展有限公司

Process for treating surface of austenitic stainless steel equipment at normal temperature

PendingCN114108044AThe process is simpleLow requirements for production equipmentProcess efficiency improvementAustenitic stainless steelMetallurgy

The invention provides a process for treating the surface of austenitic stainless steel at normal temperature, which comprises the following steps: (1) brushing acidizing paste on the surface of an austenitic stainless steel workpiece to be treated, acidizing to eliminate residual martensite on the surface of the austenitic stainless steel workpiece, and then washing with water; (2) a brush plating pen connected with the positive electrode of a power source is adopted for brush plating of brush plating liquid to the surface of the austenitic stainless steel workpiece which is connected with the negative electrode of the power source and treated in the step (1), after brush plating is completed, residual liquid on the surface of equipment is cleaned up, and then washing is conducted; and (3) the austenitic stainless steel equipment treated in the step (2) is placed in the environment with the temperature being 50-60 DEG C and the humidity being 60-70% for hardening treatment.

Owner:SHENZHEN CANDORTECH INC CO

A kind of mixing tool surface treatment method

ActiveCN111001923BAvoid the disadvantages of poor processabilityGet high temperature resistanceCleaning using liquidsNon-electric welding apparatusChemical reactionWear resistance

The invention discloses a method for treating the surface of a stirring tool. The processed stirring tool is cleaned on the surface, coated with a layer of brazing flux, kept warm at the flux activation temperature for a period of time, and then immersed in molten brazing material. The stirring tool and the The brazing filler metal undergoes a brazing reaction, forming a layer of intermetallic compounds on the surface of the stirring tool. The invention enables the stirring tool to avoid the disadvantage of poor processing performance of the intermetallic compound stirring tool while obtaining the excellent properties of the intermetallic compound such as high temperature resistance, wear resistance, and no chemical reaction with the workpiece to be welded. The entire surface treatment process is simple, efficient, and low in cost, and is suitable for mass production.

Owner:AEROSPACE ENG EQUIP SUZHOU CO LTD

Calcium silicate board UV film pressure treatment process

InactiveCN103386800BSimplify the surface treatment processReduce processing timeLamination ancillary operationsCovering/liningsCalcium silicatePolyester

The invention relates to a calcium silicate board UV film pressure treatment process, and relates to a surface treatment process of a construction board material. According to the process, UV paint is used for carrying out surface treatment on the calcium silicate board; the surface of the calcium silicate board is subjected to UV film pressure treatment by using a mold prepared by using a polyester film and a cold-light ultraviolet curing machine. Specific steps comprise (1) dedusting, (2) UV paint rolling, (3) light curing, (4) sanding and dedusting, (5) UV film pressure treatment, (6) topcoat rolling, and (7) bake-drying and blanking. With the treatment provided by the invention, the calcium silicate board paint surface is full and smooth. The process is simple and environment-friendly.

Owner:SHANDONG GREEN CENT NEW BUILDING MATERIALS TECH CO LTD

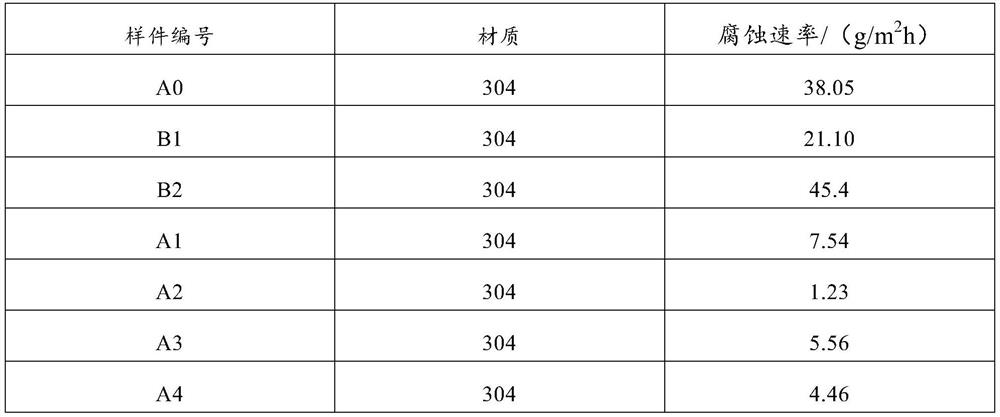

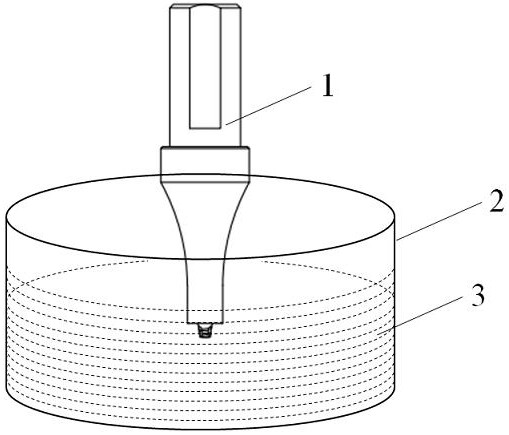

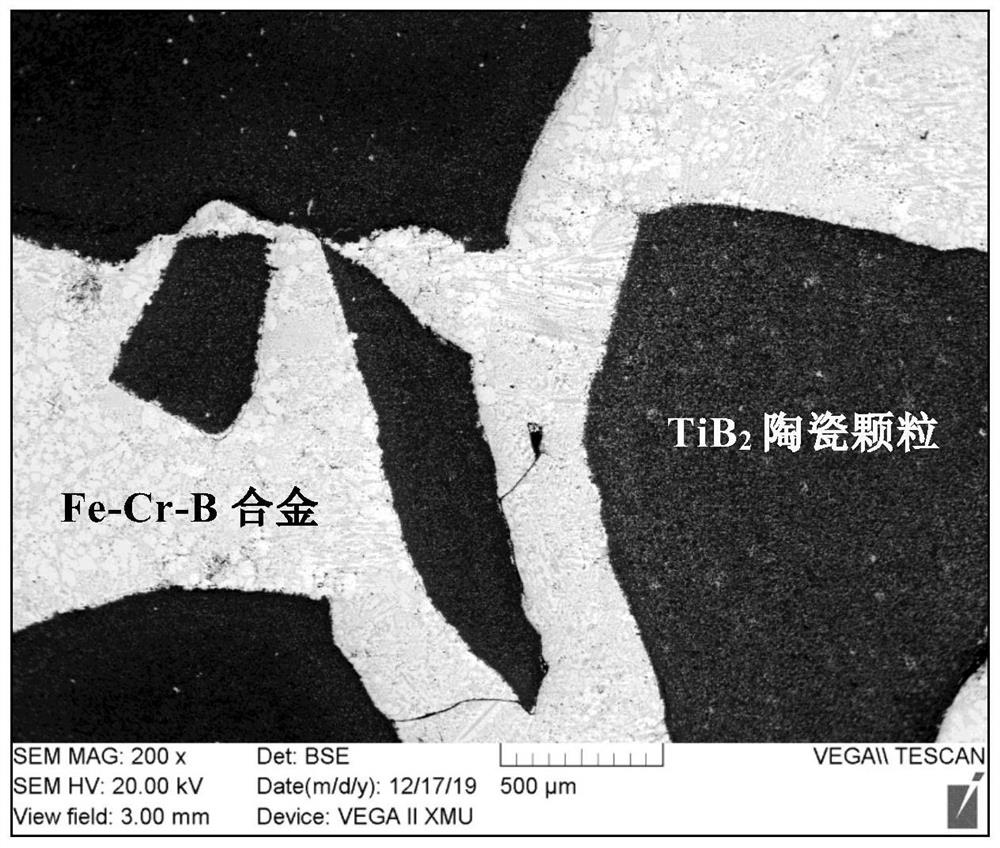

Preparation method of TiB2 reinforced Fe-Cr-B alloy-based composite lining plate

The invention discloses a preparation method of a TiB2 reinforced Fe-Cr-B alloy-based composite lining plate. The preparation method comprises the following steps that 1, TiB2 powder and Fe-Cr alloy powder are added into a polyvinyl alcohol solution, and the mixture is uniformly stirred to obtain a TiB2 ceramic blank; 2, pressing is conducted to obtain a TiB2 ceramic blank body; 3, vacuum sintering is conducted to obtain a TiB2 ceramic block; 4, the TiB2 ceramic block is crushed into TiB2 ceramic particles, then the TiB2 ceramic particles and Fe-Cr alloy powder are added into ethanol, uniformmixing is conducted, and vacuum sintering is conducted to obtain a prefabricated body; and 5, Fe-Cr-B alloy liquid is poured into the prefabricated body, and the composite lining plate is obtained. According to the preparation method, the bonding strength of the TiB2 ceramic particles and the internal interface of the Fe-Cr-B alloy-based composite lining plate is enhanced through the Fe-Cr alloy,the wear resistance of the composite lining plate is improved, the quality of the composite lining plate is improved, the surface treatment process is simplified, the preparation cost is reduced, andthe problem that the wear resistance of a material is affected due to poor bonding capacity of the ceramic particles and the interface of a matrix is solved.

Owner:XIAN UNIV OF SCI & TECH

Electronic product shell material laminating structure and manufacture method thereof

InactiveCN102615888BSimplify the surface treatment processReduce surface treatment costsLamination ancillary operationsSynthetic resin layered productsPlastic filmTreatment costs

Owner:KUSN TONG YIN INDAL ELECTRONICS MAKING

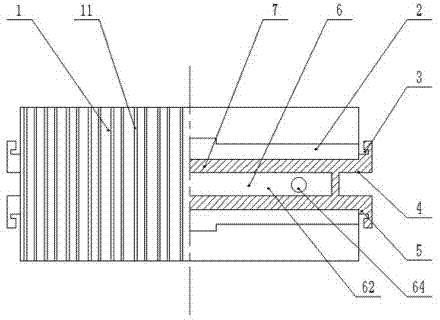

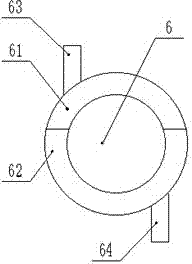

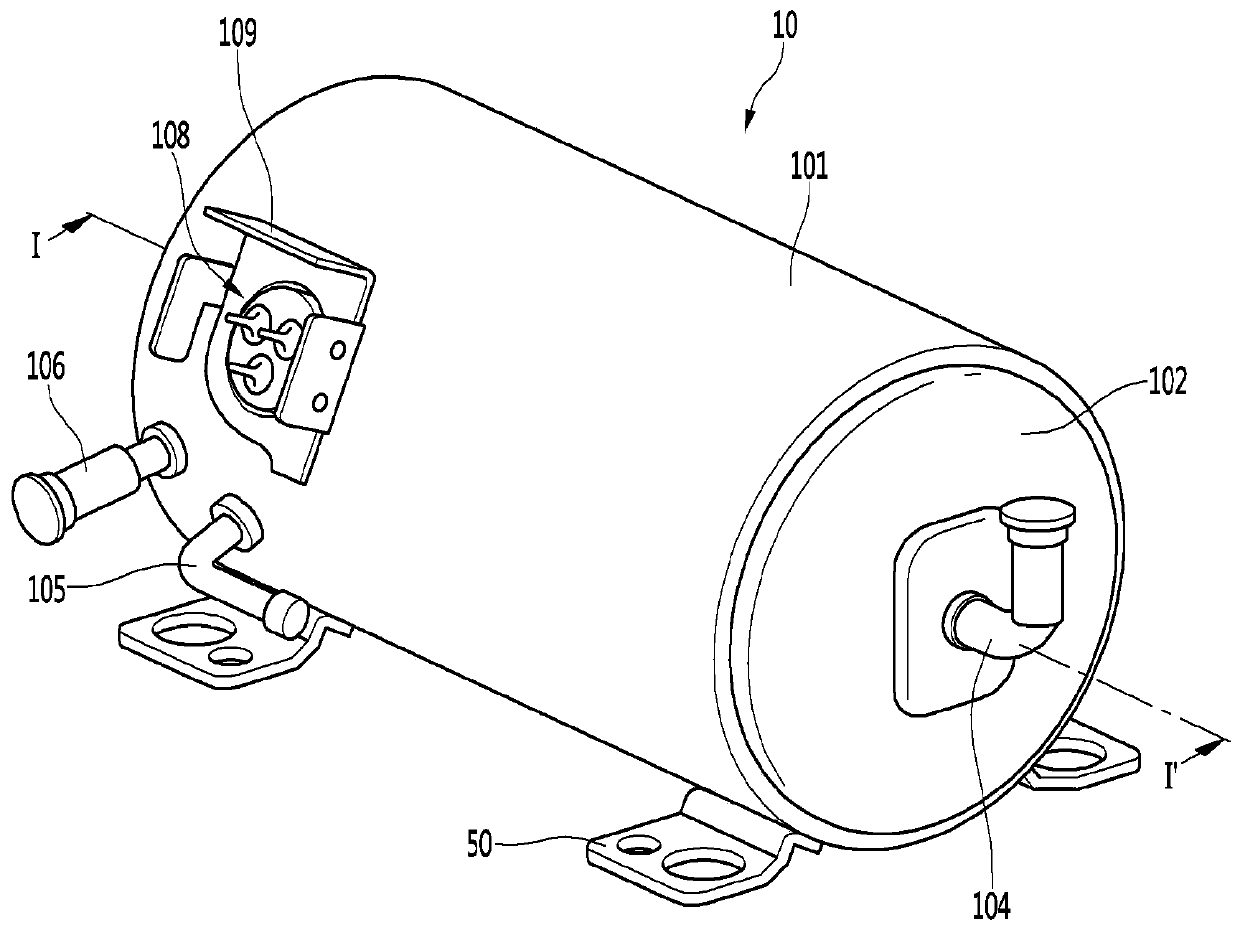

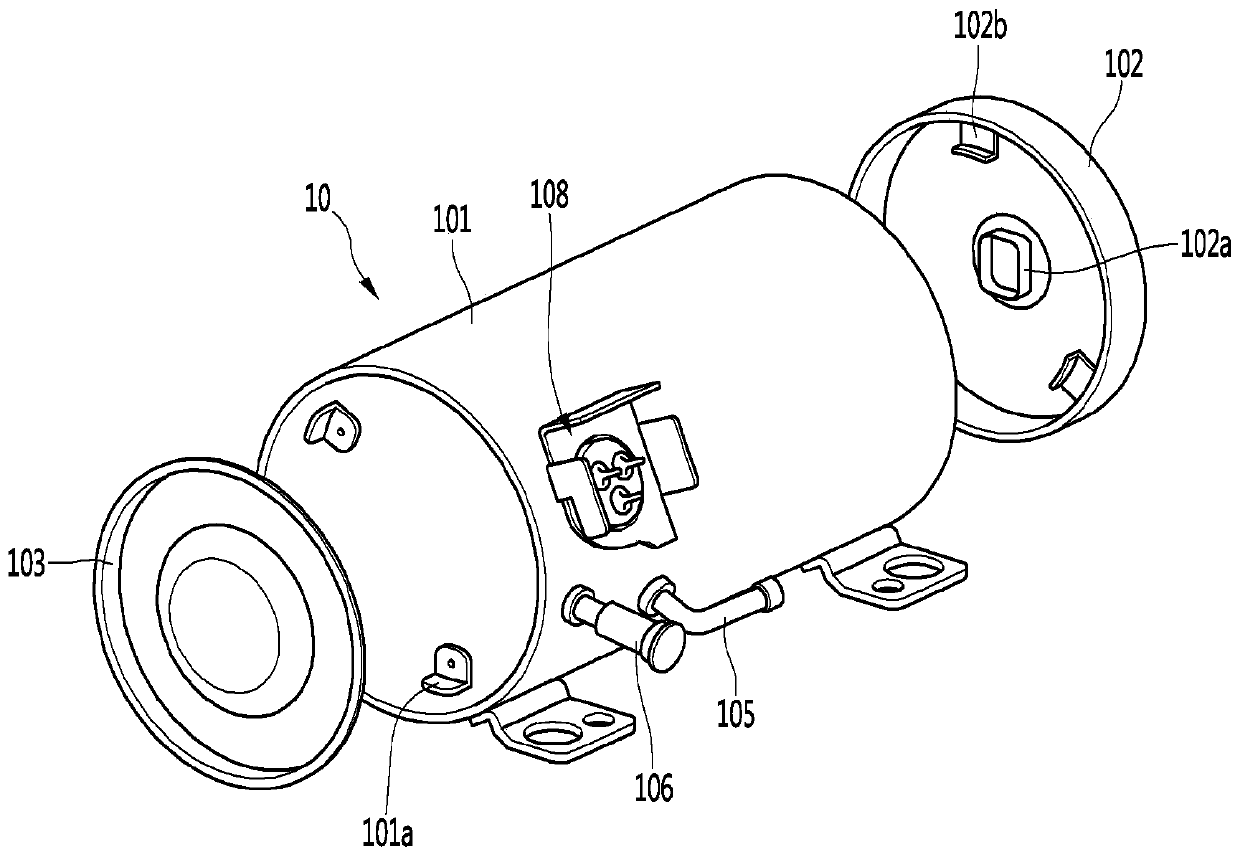

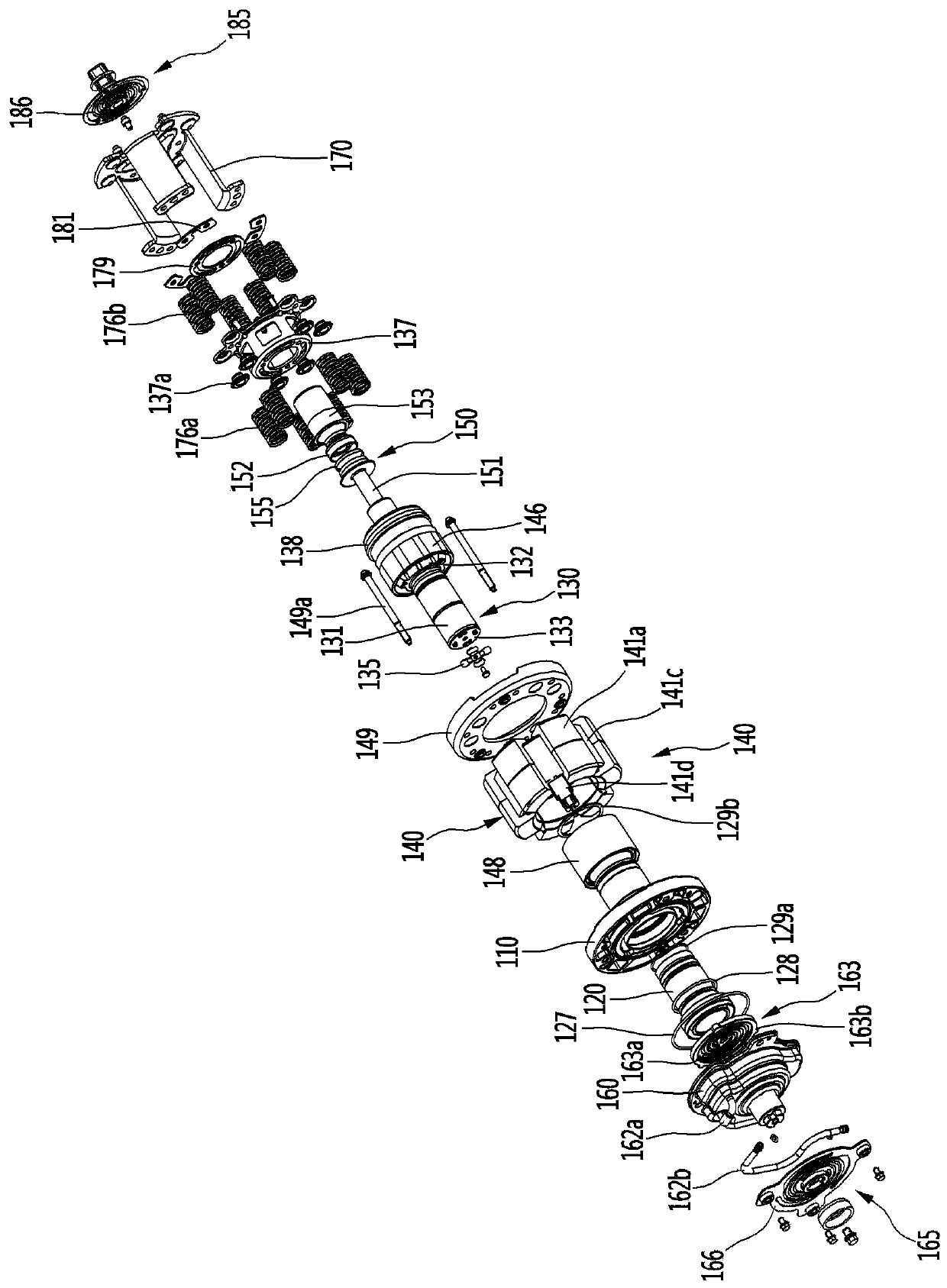

Linear compressor and manufacturing method thereof

ActiveCN107339214BReduce sizeIncrease internal storageAnodisationPlungersLinear compressorReciprocating motion

The present invention provides a linear compressor and a manufacturing method thereof. The linear compressor of the embodiment of the present invention includes: a piston inserted into a cylinder and reciprocating; the piston includes: a surface-treated body made of aluminum or an aluminum alloy; The first surface treatment part is arranged on the outside of the surface treatment body by a first vacuum evaporation method; and the second surface treatment part is arranged on the outside of the first surface treatment part by a second vacuum evaporation method.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com