Surface treatment method for aluminum alloy and housing prepared from aluminum alloy

A technology of surface treatment and aluminum alloy, which is applied in the field of surface treatment of aluminum alloy and shells made of aluminum alloy, can solve the problems of PVD coating corrosion resistance reduction, electrochemical corrosion, etc., achieve no environmental pollution, improve Corrosion resistance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

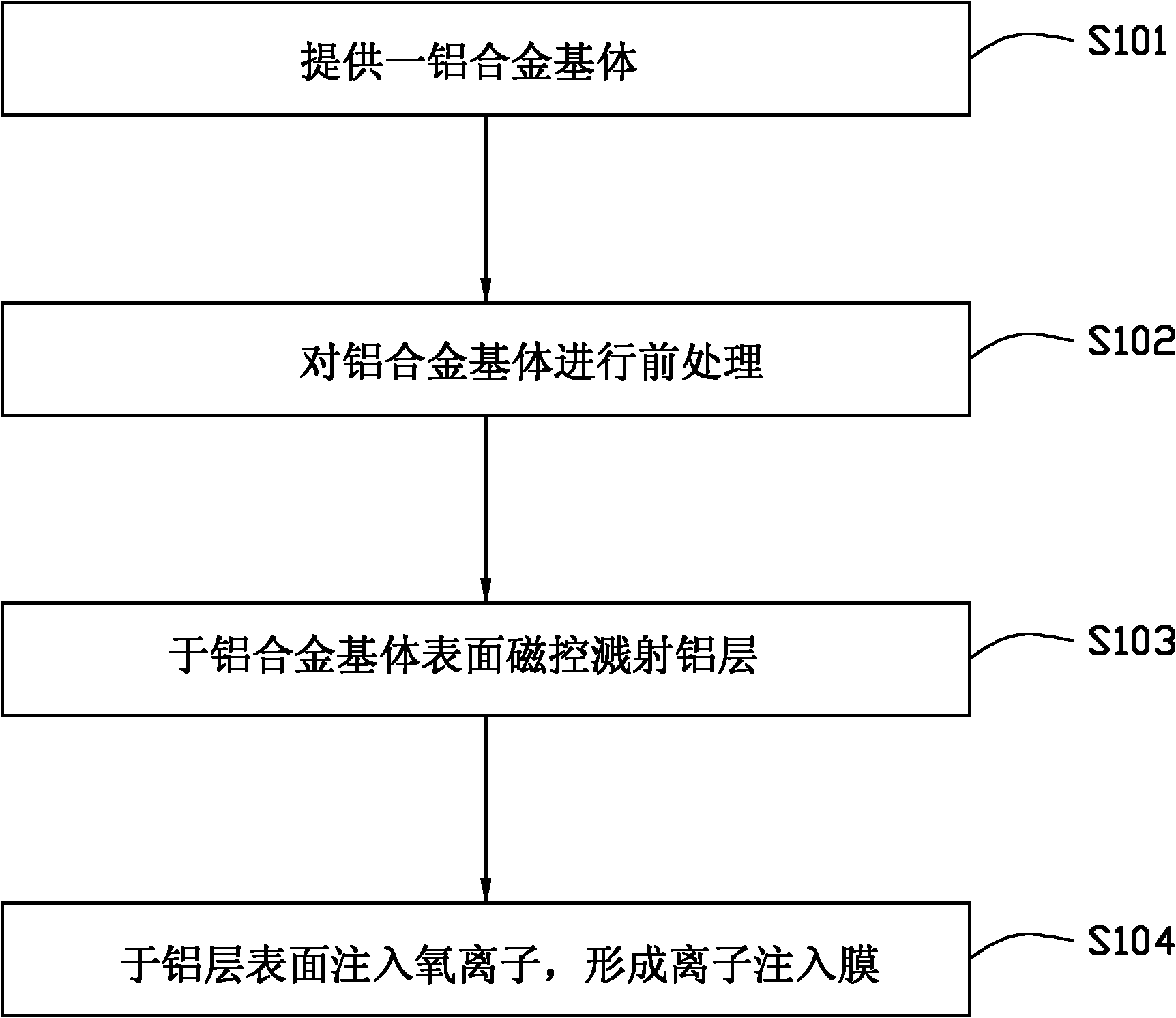

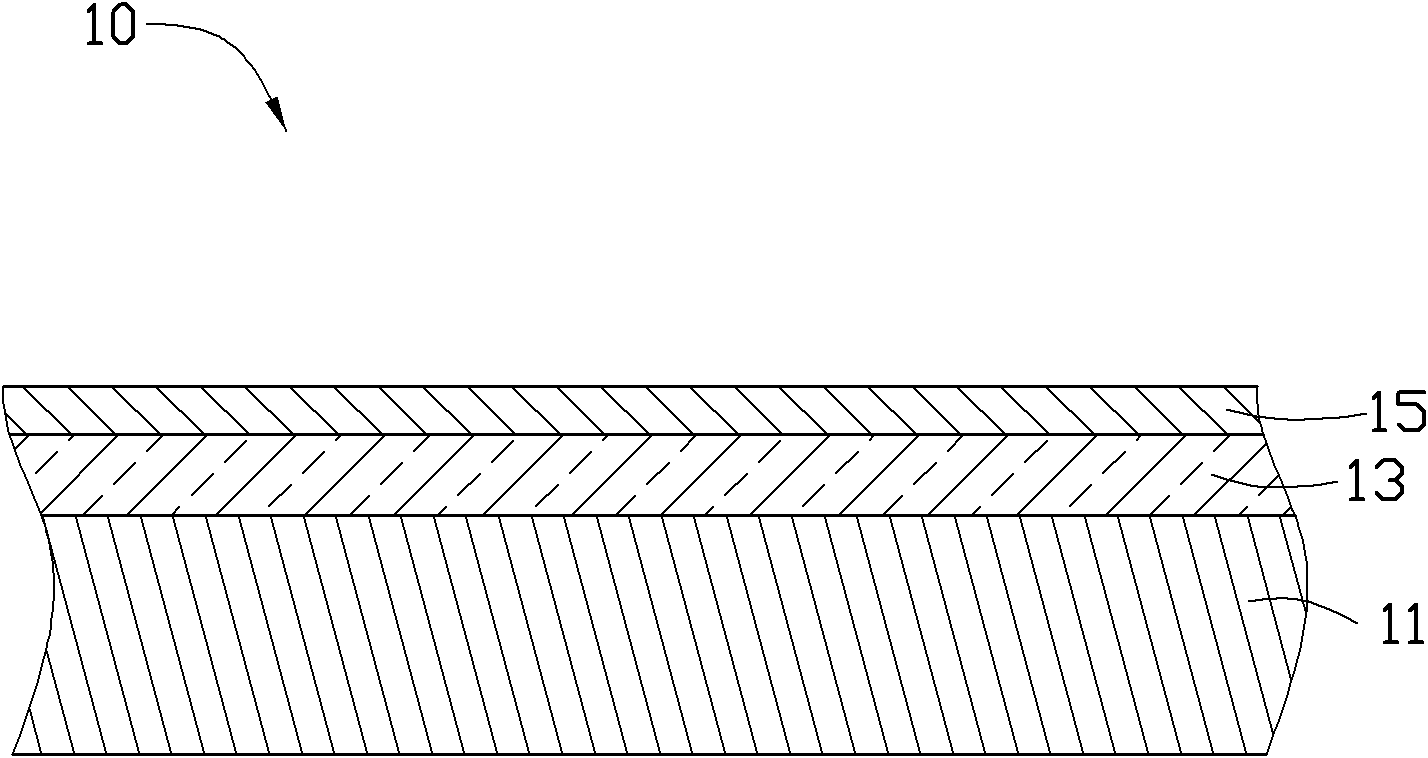

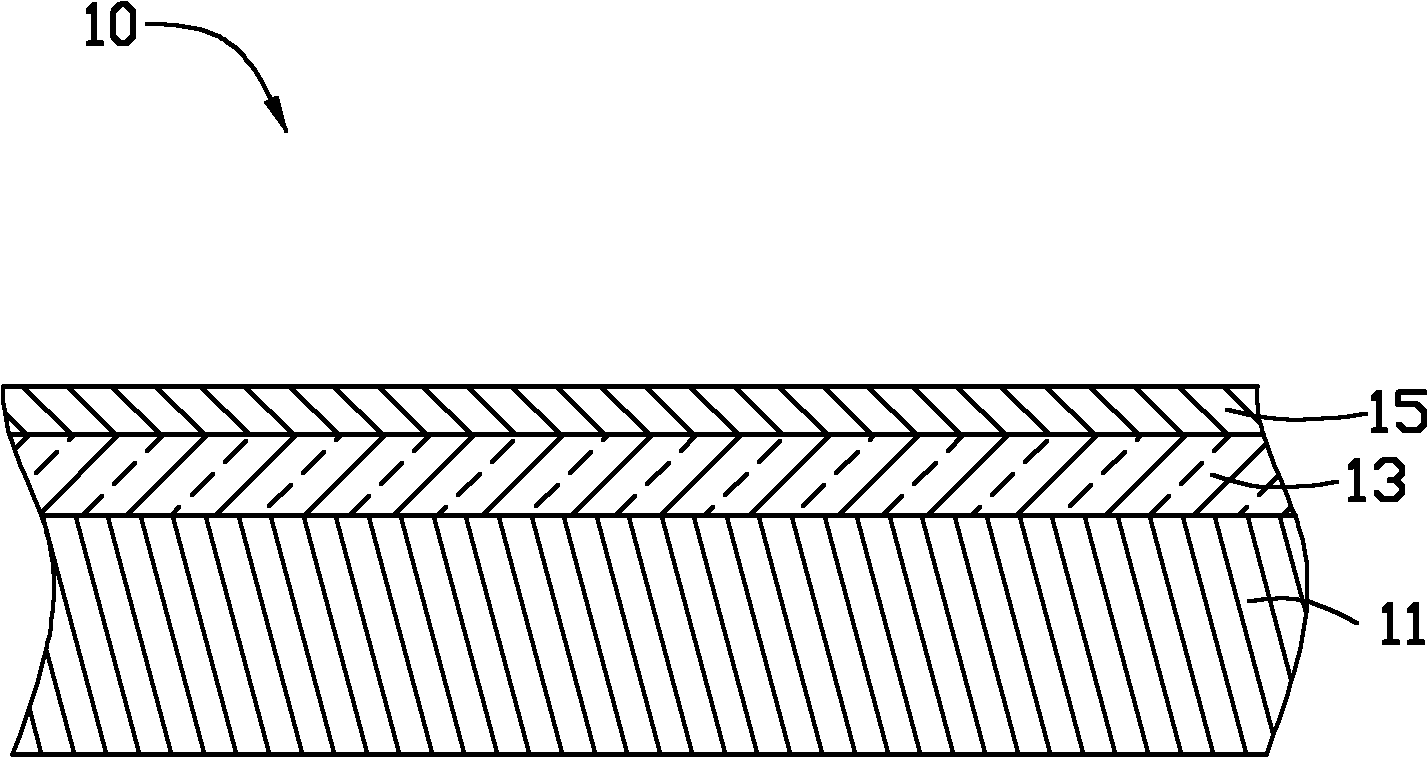

[0020] Please also see figure 1 and figure 2 , the surface treatment method of the aluminum alloy of a preferred embodiment of the present invention comprises the following steps:

[0021] S101: Provide an aluminum alloy base 11 .

[0022] The aluminum alloy base 11 can be obtained by stamping.

[0023] S102: Perform pretreatment on the aluminum alloy substrate 11 . This pretreatment includes:

[0024] The aluminum alloy base 11 is polished to remove the oxide film on the surface of the aluminum alloy base 11 . After polishing, the surface roughness Rz of the aluminum alloy substrate 11 is less than 1.2 μm.

[0025] The polished aluminum alloy substrate 11 is sequentially placed in deionized water and acetone with a purity greater than 99.9% for ultrasonic cleaning to remove oil stains on the surface. After cleaning, the aluminum alloy substrate 11 is dried for future use.

[0026] S103: forming an aluminum layer 13 on the surface of the aluminum alloy substrate 11 by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com