Steel-continuous fiber composite bar and preparation method

A technology of continuous fibers and composite bars, applied in structural elements, building components, buildings, etc., can solve problems such as difficult coordination between steel bars and external FRP, threats to structural safety performance, and insufficient bonding force, so as to improve the collaborative work performance , Facilitate infiltration and simplify the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

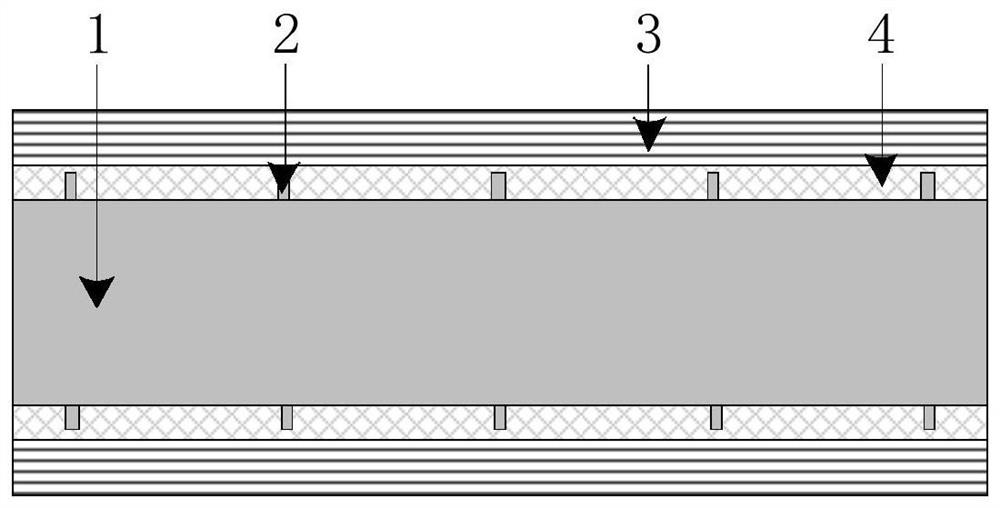

[0034] like figure 1 As shown, the SFCB bar 6 of the present invention includes a steel bar inner core 1, a continuous fiber layer 3 and a bridging layer 4, wherein the bridging layer 4 is wrapped on the steel bar inner core 1, and the steel bar inner core is organically formed by the bridging layer 4 1. The continuous fiber layer 3 forms a stressed whole, and there are reinforcement ribs on the outer surface of the reinforcement.

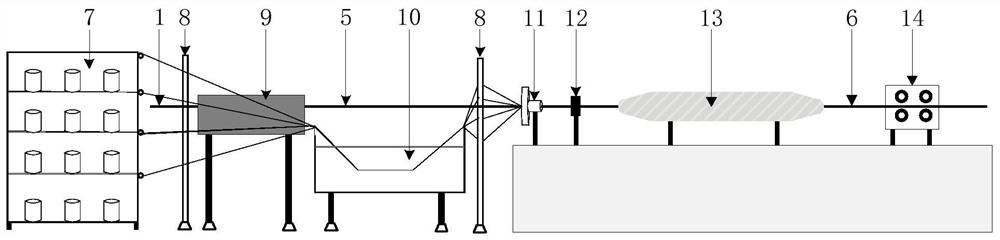

[0035] A total of 6 groups of SFCB bars 6 with different parameters were prepared. The specific parameter design is shown in Table 3. The preparation method of SFCB bars is as follows:

[0036] (1) Grind the threaded steel bar to the height of the ribs to the predetermined height and perform decontamination treatment. After the preliminary treatment, the mechanical properties of the inner core of the steel bar are shown in Table 1. The inner core steel bar is soaked in the silane coupling agent alcohol solution for 30 minutes, and then dried at ro...

Embodiment 2

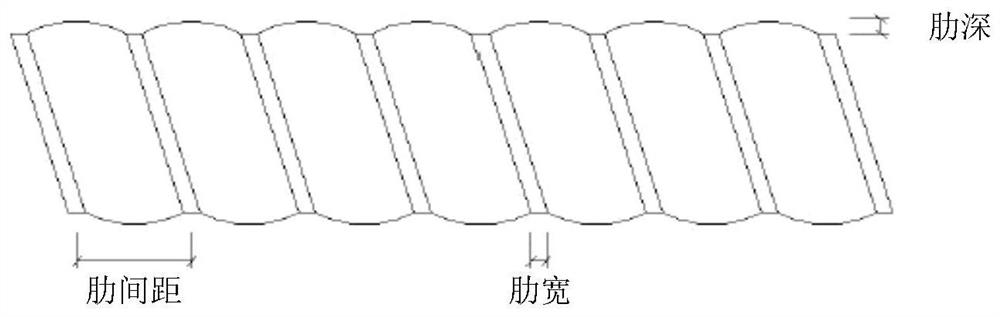

[0052] Adopt the preparation method in Example 1 to prepare 3 groups of steel-continuous fiber composite bars, the preparation parameters of the composite bars are consistent with the sample a in Example 1, that is: the volume ratio of continuous fiber bundles to steel bars is 1:4, and the bridging The layer chopped fiber volume fraction was 45%. The design parameters of the outer surface of the reinforcement are shown in Table 5. Self-mixing concrete was used to pour standard pull-out specimens, and the compressive strength of self-mixing concrete was 41.7MPa.

[0053] table 5

[0054]

[0055] After 28 days of curing, pull-out tests were carried out on the three groups of specimens, and the experimental results are summarized in Figure 4 to Figure 6 ,in Figure 4 is the stress-slip comparison diagram of drawn specimens with different rib depths, Figure 5 is the stress-slip comparison diagram of the drawn specimens with different rib spacings, Image 6 It is the str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com