Digital painting material with high precision printing used in printer and its production method

An inkjet material and polymer technology, which is applied in the field of polymer material production, can solve problems such as not being able to meet the needs of high-end customer applications, and achieve the effects of improving inkjet printing speed and efficiency, high surface wetting tension, and good reducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

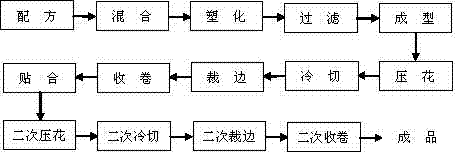

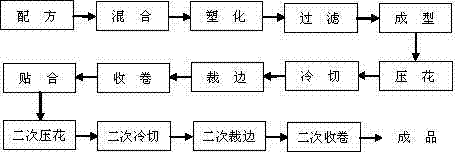

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: a kind of formula of printing inkjet printing material inside finely printed macromolecule digital, in parts by weight:

[0036] 100 parts of PVC with a degree of polymerization of 800,

[0037] Dioctyl phthalate (DOP) 40 parts,

[0038] 3 parts soybean oil,

[0039] 5 parts of barium cadmium zinc stabilizer without adding lubricant,

[0040] Nano calcium 50 parts,

[0041] 0.4 parts of anatase titanium dioxide,

[0042] Ultramarine 0.1 part.

Embodiment 2

[0043] Embodiment 2: another kind of fine printing polymer digital inner print formula of inkjet material, in parts by weight:

[0044] 100 parts of PVC with a degree of polymerization of 900,

[0045] Dioctyl phthalate (DOP) 37 parts,

[0046] 3 parts soybean oil,

[0047] 5 parts of barium cadmium zinc stabilizer without adding lubricant,

[0048] Nano calcium 50 parts,

[0049] 0.4 parts of rutile titanium dioxide,

[0050] Ultramarine 0.1 part.

Embodiment 3

[0051]Embodiment 3: Another kind of formula of precision printing macromolecule digital inner printing inkjet material, in parts by weight:

[0052] 100 parts of PVC with a degree of polymerization of 900,

[0053] Diisononyl phthalate (DINP) 40 parts,

[0054] 3 parts soybean oil,

[0055] 5 parts of barium cadmium zinc stabilizer without adding lubricant,

[0056] Nano calcium 50 parts,

[0057] 0.4 parts of rutile titanium dioxide,

[0058] Ultramarine 0.1 part,

[0059] Everlasting Purple 0.1 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com