Antifog polypropylene film and preparation method thereof

A polypropylene film and polypropylene resin technology, applied in the polypropylene field, can solve problems such as poor anti-fog effect, achieve good anti-fog and improve the effect of wetting tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

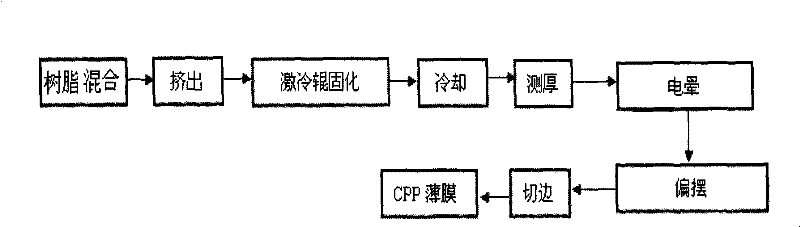

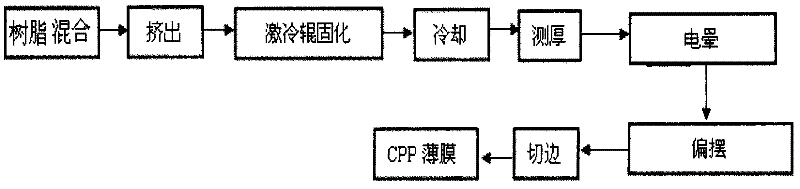

[0026] like figure 1 As shown: the preparation method of the present invention includes the following steps in sequence: extrusion process, chilled roll solidification process, cooling process, thickness measurement process, corona process, deflection process, edge trimming process.

[0027] In the extrusion process: three-stage heating is adopted, the temperature of the first-stage extruder is: 210°C, the temperature of the second-stage extruder: 225°C, the temperature of the third-stage extruder: 230°C; the temperature of the die head: 225°C.

[0028] The corona layer is composed of FC801M.

[0029] The middle layer is composed of FC801 and anti-fog masterbatch, and the weight ratio of FC801:anti-fog masterbatch is 6:1.

[0030] The heat seal layer includes FL7632, ABPP10S, SE07PP;

[0031] The weight ratio of FL7632, ABPP10S, SE07PP is 100:0.5:0.5.

[0032] In the chilling roll solidification process: the hot-melt film is rapidly cooled and shaped by the casting roll und...

Embodiment 2

[0037] The preparation method of the present invention includes the following steps in sequence: extrusion, chilled roll solidification, cooling, thickness measurement, corona, deflection, and edge trimming.

[0038] In the extrusion process: three-stage heating is adopted, the temperature of the first-stage extruder is: 210°C, the temperature of the second-stage extruder: 225°C, the temperature of the third-stage extruder: 230°C; the temperature of the die head: 225°C.

[0039] The corona layer is composed of FC801M.

[0040] The middle layer is composed of FC801 and anti-fog masterbatch, and the weight ratio of FC801:anti-fog masterbatch is 12:1.

[0041] The heat-sealing layer includes FL7632, ABPP10S, SE07PP, and the weight ratio of FL7632, ABPP10S, SE07PP is 100:1:1.

[0042] The thickness ratio of the corona layer, the intermediate layer and the heat-sealing layer is 1:3:1.

[0043] In the chilling roll solidification process: the hot-melt film is rapidly cooled and sh...

Embodiment 3

[0048] The preparation method of the present invention includes the following steps in sequence: extrusion, chilled roll solidification, cooling, thickness measurement, corona, deflection, and edge trimming.

[0049] In the extrusion process: three-stage heating is adopted, the temperature of the first-stage extruder is: 210°C, the temperature of the second-stage extruder: 225°C, the temperature of the third-stage extruder: 230°C; the temperature of the die head: 225°C.

[0050] The corona layer is composed of FC801M.

[0051] The middle layer is composed of FC801 and anti-fog masterbatch, and the weight ratio of FC801:anti-fog masterbatch is 6:1.

[0052] The heat seal layer includes FL7632, ABPP10S, SE07PP,

[0053]The weight ratio of FL7632, ABPP10S, SE07PP is 100:1:0.5.

[0054] The thickness ratio of the corona layer, the intermediate layer and the heat-sealing layer is 1:3:1.

[0055] In the chilling roll solidification process: the hot-melt film is rapidly cooled and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com