Patents

Literature

41results about How to "Does not affect tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame retardant resin composition

The invention provides a flame-retardant resin composition. The composition comprises hydrogenated styrene-butadiene block copolymers, polypropylene and / or polystyrene, a flame retardant and a compatilizer, wherein the composition also comprises silicone oil. The flame-retardant resin composition has good mechanical property and high stretching strength of 100 percent.

Owner:BYD CO LTD

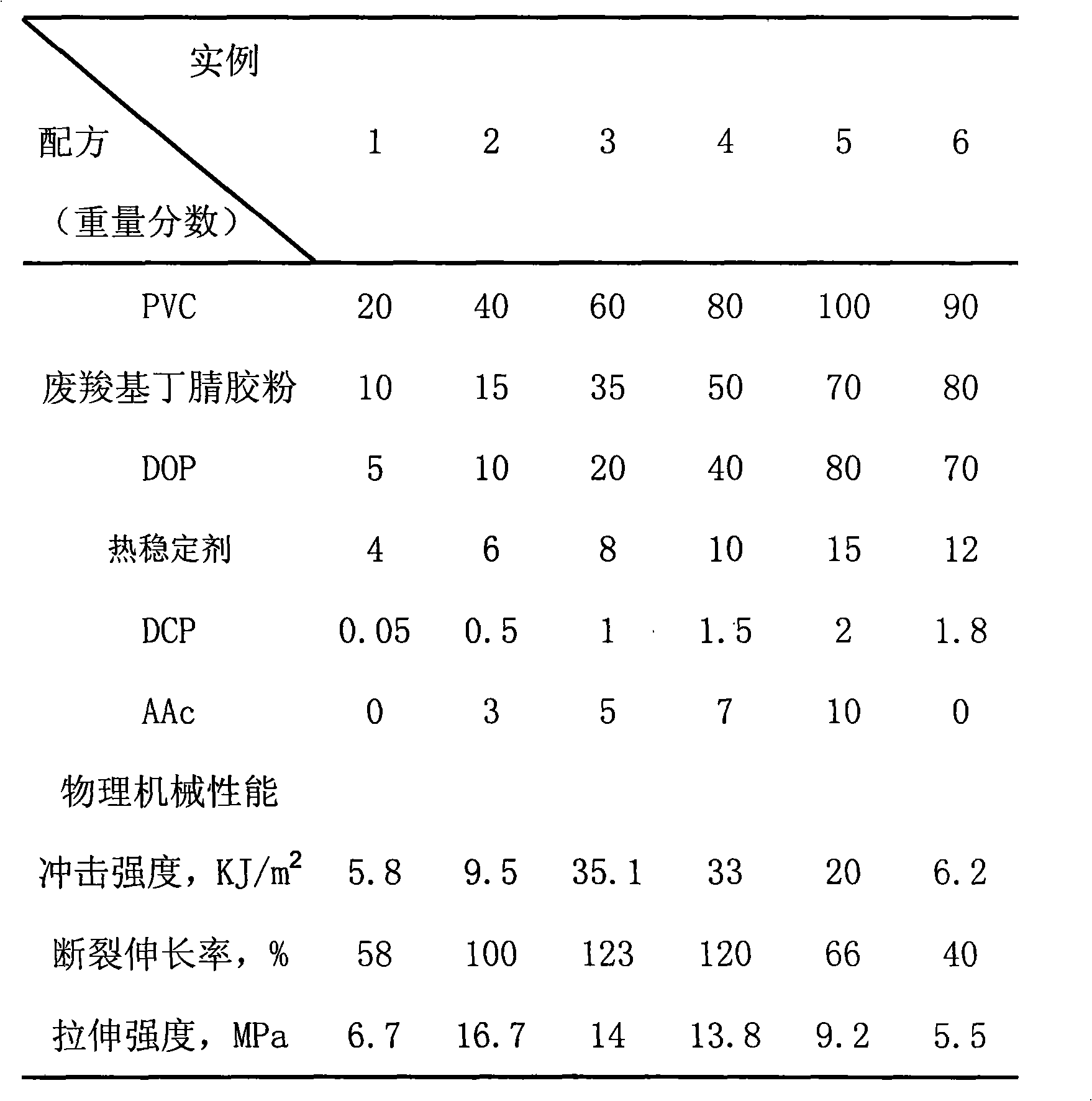

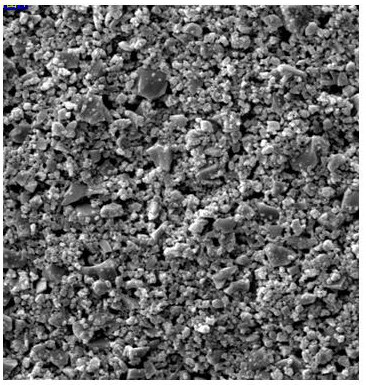

Method for preparing waste carboxylbutyronitrile adhesive powder and PVC mixture

The invention discloses a preparation method for waste carboxyl nitrile gelatine powder and PVC blend. The preparation method comprises the following steps that: plasticizer, heat stabilizer and PVC mixture are added in a double-roller feed mill to carry out preplasticizing, and then initiator, modifier and crushed waste carboxyl nitrile gelatine powder are added in turn to carry out milling; then, after stem pressing is completed inside a flat vulcanizing machine, a test block is quickly moved to a chilling press and demoulding is carried out after the test block is cooled down to room temperature, thereby obtaining the waste carboxyl nitrile gelatine powder / PVC blend. The blend not only has substantially increased impact strength and elongation at break, but also has a compact microstructure; moreover, the blend has wide application, simple manufacturing process, low cost and less environmental pollution.

Owner:SOUTH CHINA UNIV OF TECH

Toughened polylactic acid capable of being used for rapid forming and preparation method thereof

InactiveCN105694401AOvercome the disadvantage of brittlenessDoes not affect transparencyAdditive manufacturing apparatusRapid prototypingToughening

The invention discloses toughened polylactic acid capable of being used for rapid forming and a preparation method thereof. The modified polylactic acid is prepared through the method which includes the steps that polylactic acid and a toughening agent are dried respectively and then fully mixed in proportion, and the toughened modified polylactic acid is obtained after melt blending and extrusion. The modified polylactic acid can overcome the defect that polylactic acid is prone to brittle failure, the transparency and tensile strength of polylactic acid are not affected, the process is simple, implementation is easy, and the toughened polylactic acid is suitable for being used as a 3D printing consumable.

Owner:江苏永盛三维打印新材料有限公司

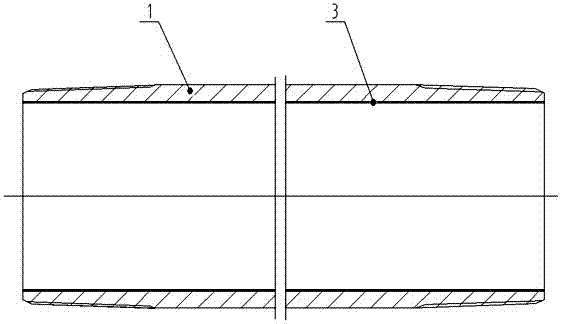

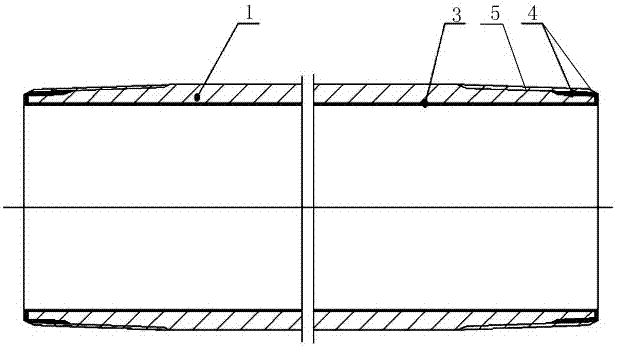

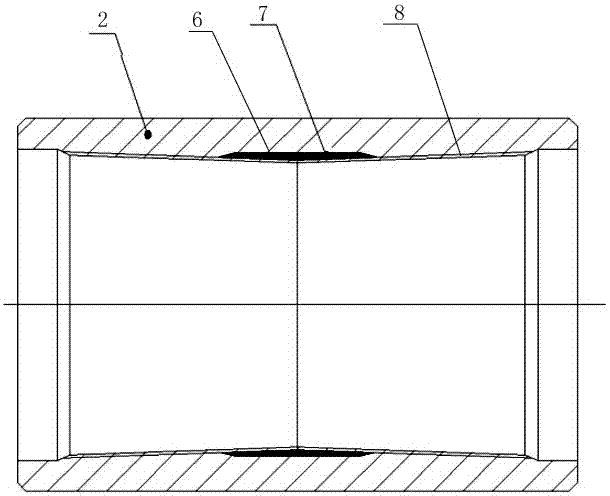

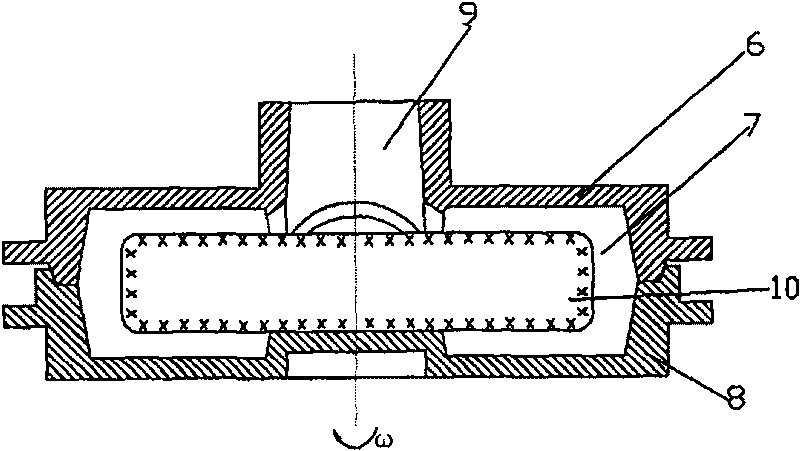

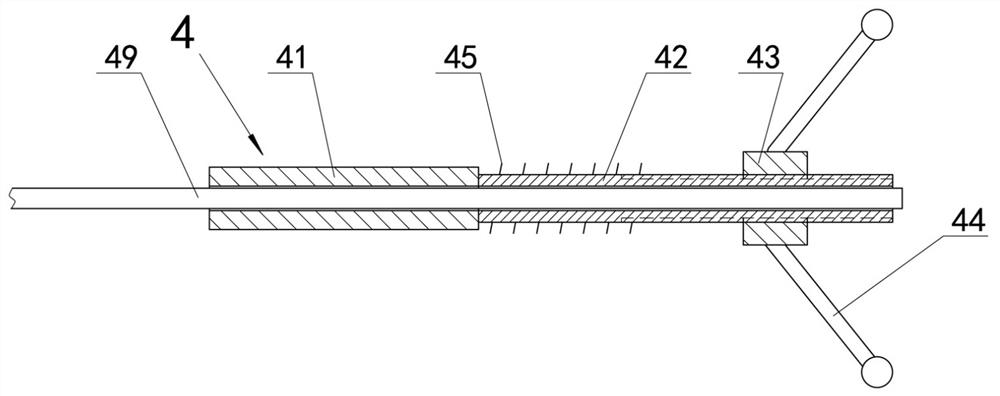

Inner spray welding anticorrosive wear resistant oil pipe and machining method and machining device

The invention discloses an inner spray welding anticorrosive wear resistant oil pipe and a machining method and a machining device. The inner spray welding anticorrosive wear resistant oil pipe comprises a preheating sensing heating ring and a remelting sensing heating ring which are arranged on the outer surface of a pipe body in sequence; a sprayer, a nozzle and supports are arranged in the pipe body, each support is provided with two support rods, the bottoms of the support rods are provided with steel balls capable of freely rolling, and the steel balls are in contact with an inner hole surface of the pipe body; the outer surface of the pipe body is further provided with power idler wheels for pushing the pipe body to rotate and move forwards, the outer end of the pipe body is provided with a spray gun, the spray gun and the sprayer are connected by a powder feeding pipe, a mixed gas pipe and an outer pipe, a cooling water pipe is further arranged in the outer pipe, the outer pipe is filled with cooling water, a cooling water returning pipe is further arranged on the outer pipe, and the spray gun is provided with a hopper, an oxygen pipe, an acetylene pipe and a water inlet. The inner spray welding anticorrosive wear resistant oil pipe is simple in structure, not only the inner surface of an oil pipe but also the end surface and threads of the oil pipe can be subjected to corrosion prevention, a tensile strength of the threads is not affected, the corrosion prevention effect and a connecting strength of a joint are improved, and the corrosion prevention effect is good.

Owner:DONGYING XINJIA ENVIRONMENTAL PROTECTION TECH DEV CO LTD

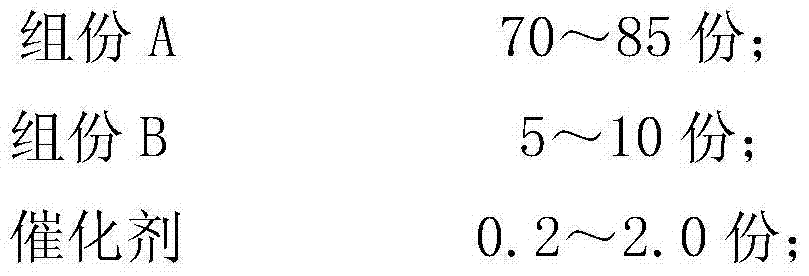

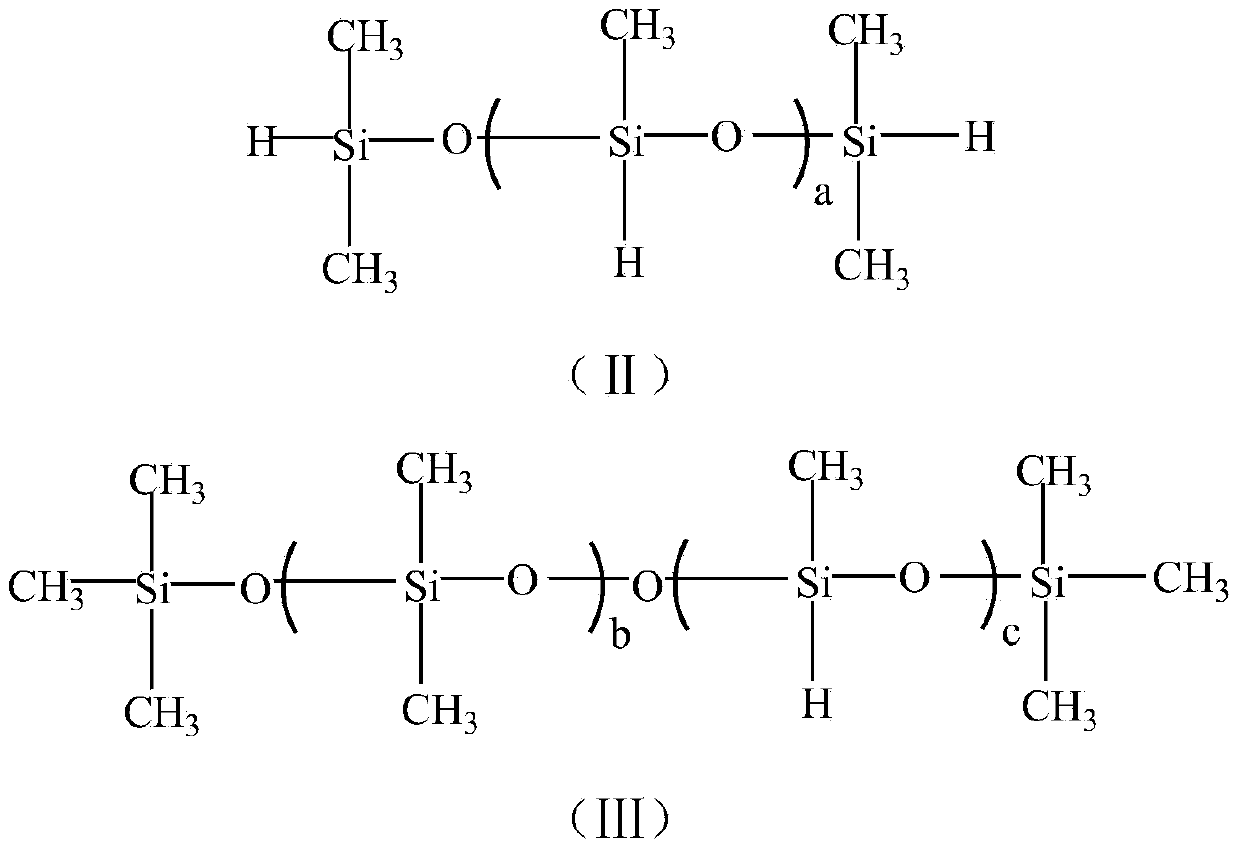

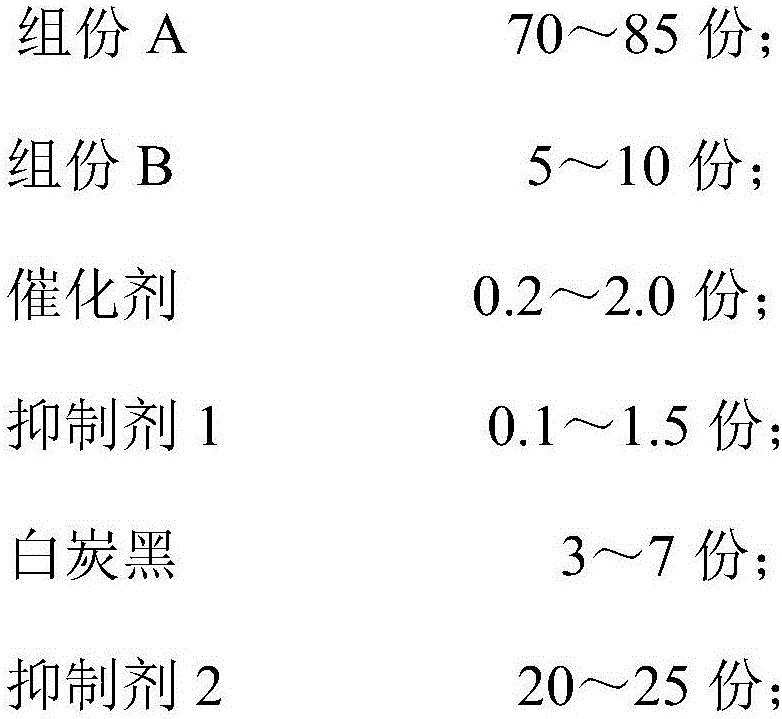

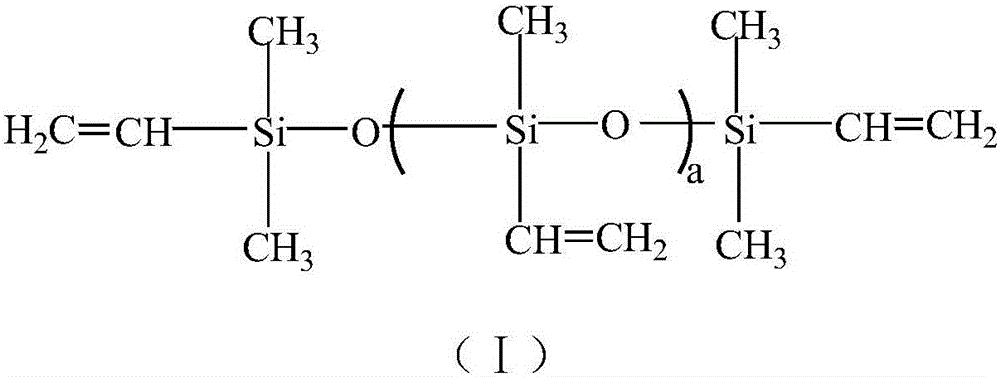

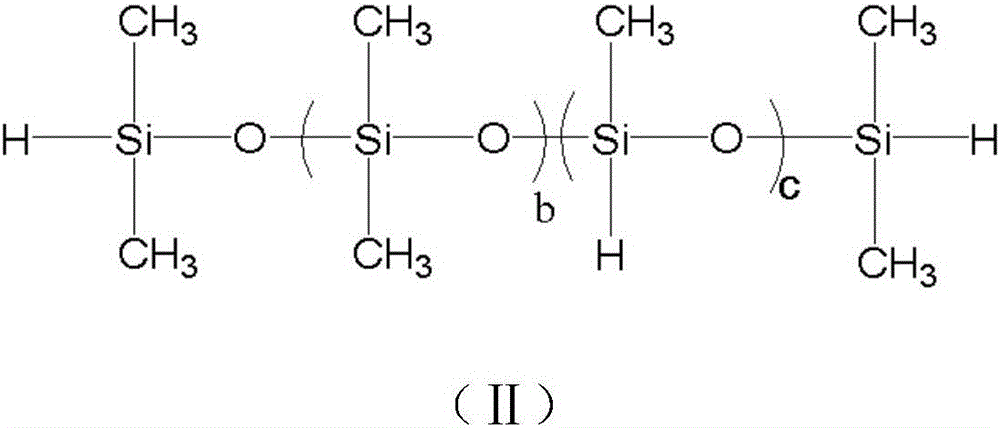

Addition-type mold rubber and preparation method thereof

The invention discloses addition-type mold rubber and a preparation method thereof. The addition-type mold rubber is prepared from the following raw materials in parts by weight: 70-85 parts of component A, 5-10 parts of component B, 0.2-2.0 parts of catalyst, 0.1-1.5 parts of inhibitor 1, 3-7 parts of white carbon black and 20-25 parts of inhibitor 2. The addition-type mold rubber disclosed by the invention has good tensile strength, tear strength and hardness, is very suitable for manufacturing of crystal drills and long in service life, the rolling-over number of times of the addition-type mold rubber reaches up to 35-45 times, and the brightness of the manufactured crystal drills is greatly improved.

Owner:惠州市永卓科技有限公司

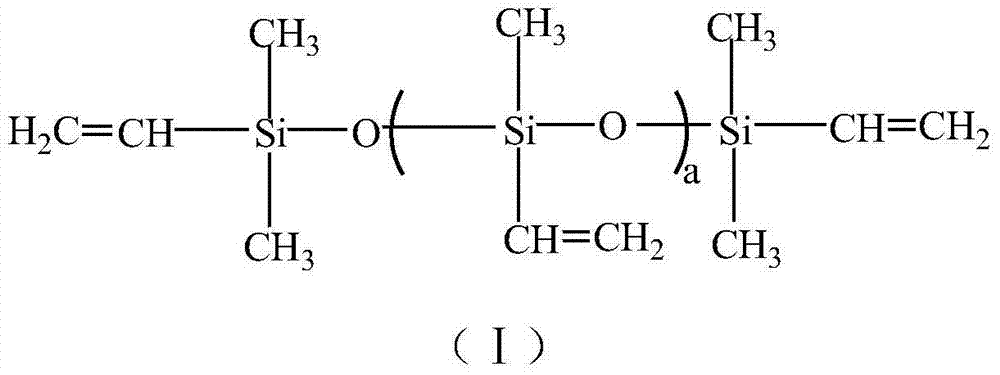

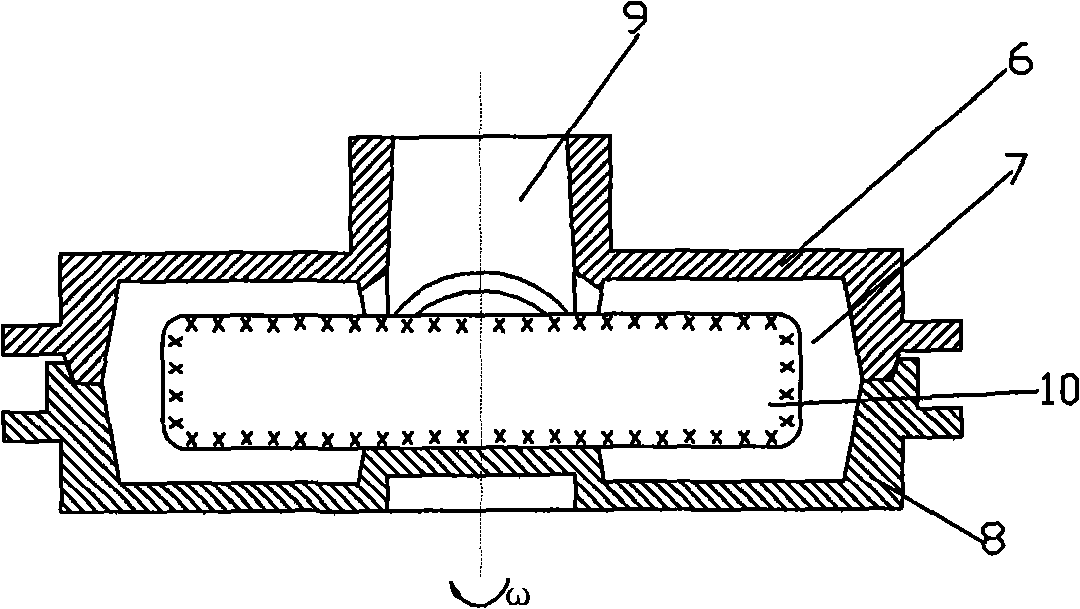

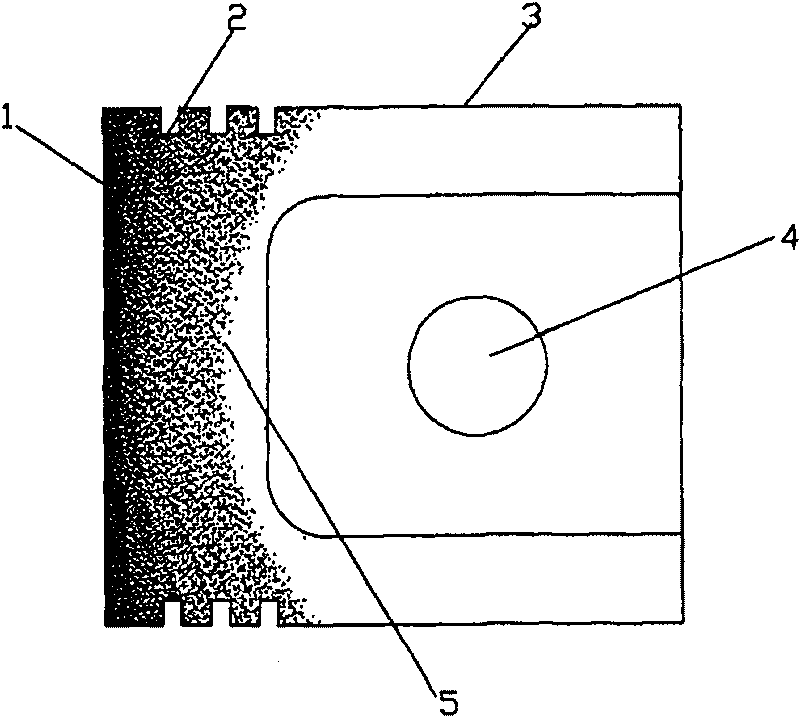

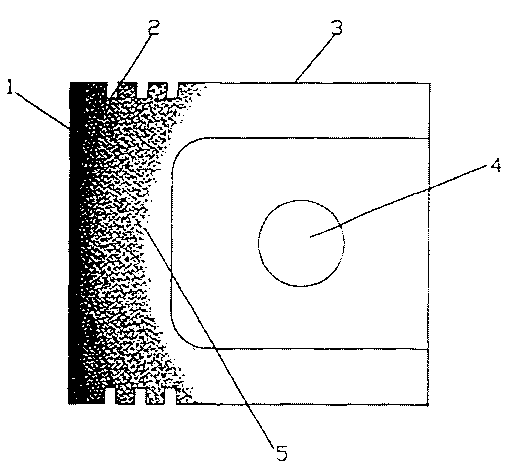

Local granule reinforced piston and its manufacture method

InactiveCN101338708AAchieve local segregationExtended service lifeMachines/enginesPistonsEffective powerEngineering

The present invention discloses a partial reinforced particle piston and a manufacturing method thereof. The partial reinforced particle piston comprises a head, a skirt section and a pin base. The head comprises a piston top and a ring slot part. The piston top and the ring slot part are reinforced areas which are formed by distributing reinforced particles in piston matrix material. The skirt section is an non-reinforced area. The reinforced area and the non-reinforced area are combined by an alloy combination form. The partial reinforced particle piston not only increases the wearing resistance of the head of a piston and reduces the thermal expansion coefficient, but also ensures the good mechanical performance of the skirt section of the piston and realizes the continuous transition of the organization structure and performance of the partial reinforced area and the non-reinforced area; the effective power of an engine is improved; the service life of the piston is prolonged; in order to manufacturing the piston, the present invention uses a centrifugal casting method to assemble the reinforced particles in melted homogenous composite material at the head of the piston, and the manufacturing method has simple technology and low manufacturing cost.

Owner:CHONGQING UNIV

Polystyrene modified plastic and preparation method thereof

The invention discloses a polystyrene modified plastic which comprises the following components in percentage by weight: 70-78% of polystyrene, 7-12% of polycarbonate, 10-12% of inorganic nanoparticle, 0.7-1.5% of coupling agent, 0.7-1.5% of antioxidant, 0.7-1.5% of filler, 0.7-1.5% of lubricant and 0-1% of color master batch, totaling 100%. The polystyrene modified plastic has reasonable formula design. The produced modified polystyrene has the advantages of high impact resistance, favorable heat resistance and frictional resistance.

Owner:SUZHOU RONGCHANG COMPOUND MATERIAL

Rust conversion and rust-proof coating agent for construction steel structure and its usage method

The invention discloses a steel structural rust conversion anti-rust paint used in building. The formulation is that rust conversion agent of polyatomic acid is 300-700 parts, gelling agent is 20-40 parts, atmospheric inhibitor is 1-2 parts, penetrating agent is 0.5-1 parts, organic silicon defoaming agent is 0.1-0.5 parts, and water is 256-678 parts. The steps of usage of the invention include that the components are sequentially added in a reaction tank, mixed and stirred for about 50 minutes under the temperature of 40-60 DEG C, and cooled and filtered to prepare the steel structural rust conversion anti-rust paint. The steel structural rust conversion anti-rust paint is directly brushed on the surface of steel products to remove greasy dirt, mud and sand, and dust which are on the surface of constructional steel structure. The steel products which are coated with the rust conversion anti-rust paint are placed in the air for 1-2 hours, and then are processed via oil paint construction. The rust conversion anti-rust paint has the advantages of thorough rust conversion, simple construction, economy and efficiency, energy-saving, environmental protection and the like, and is capable of strengthening the anti-rust and anti-fire property of the oil paint and increasing the inherent quality of the oil paint.

Owner:叶云川

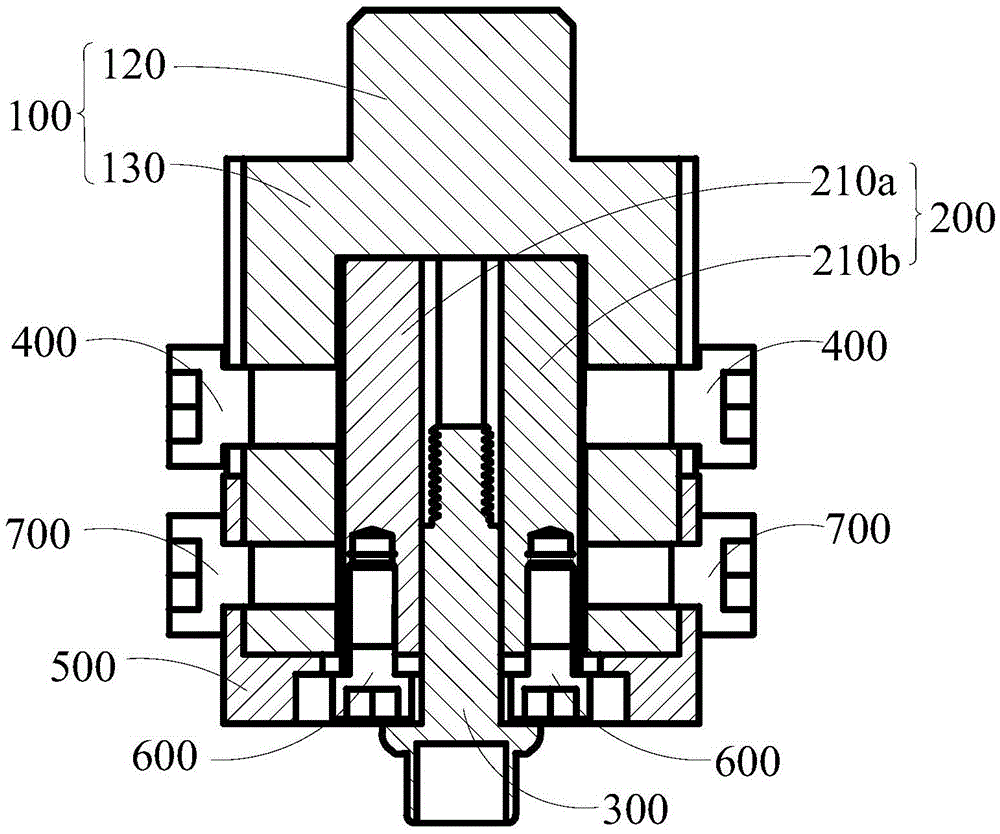

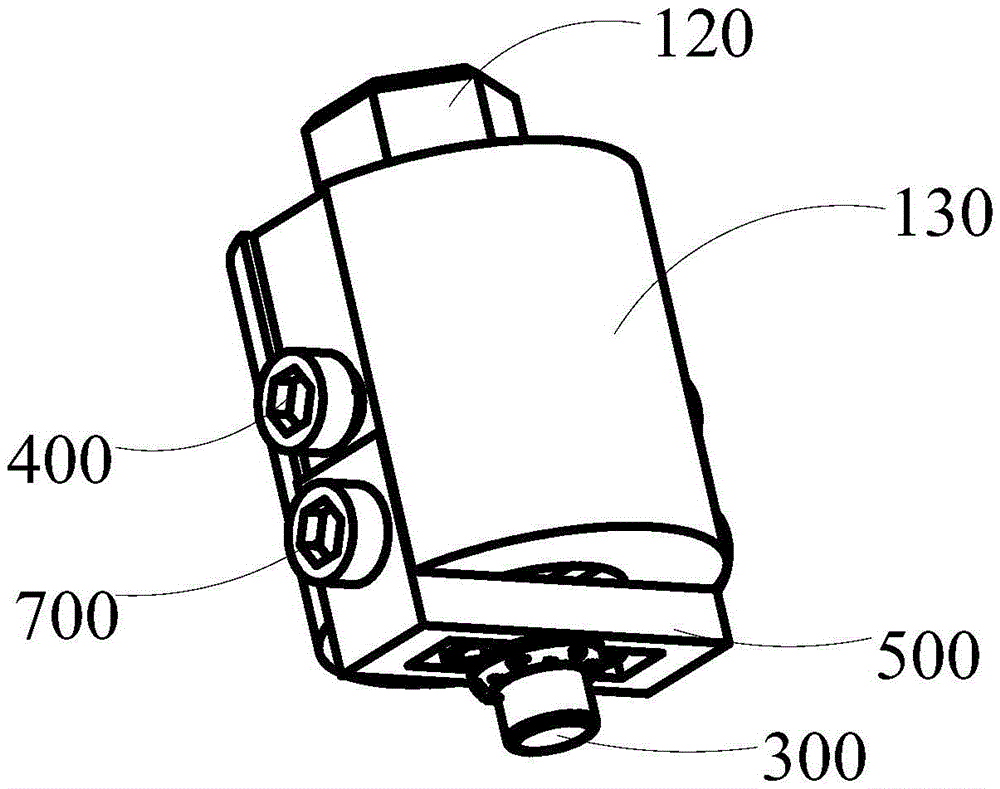

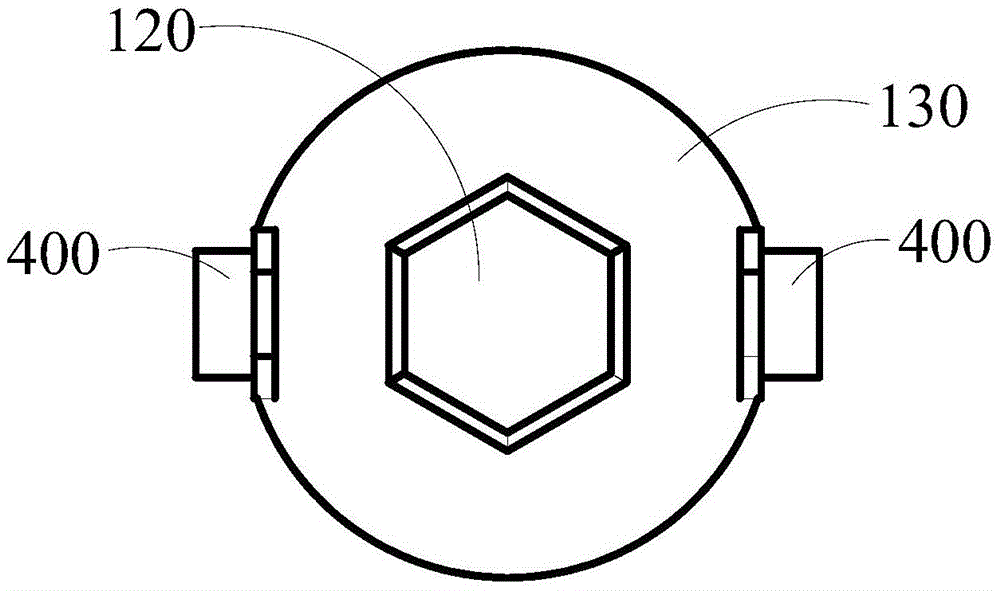

Bolt torque detector

InactiveCN105486444AAchieve fixationAvoid WeldingMeasurement of torque/twisting force while tighteningControl theoryTorque wrench

The invention disclose a bolt torque detector which is used in cooperation with a torque wrench. The bolt torque detector comprises a sleeve and a bolt clamping assembly, the sleeve includes an accommodation cavity with an opening at one end, and can cover a detected bolt; one end of the bolt clamping assembly is arranged in the accommodation cavity, and used to clamp the detected bolt; and the enclosed end of the sleeve is provided with a fixation part, and the fixation part cooperates with the torque wrench. The detector fixes the detected bolt via the bolt clamping assembly, avoids the detected bolt from a welding process, does not influence the original tensile strength of the bolt, ensures the accuracy of a detection result, and effectively solves the problem that the detection result is low in accuracy traditionally due to the fact that the torque of the bolt is damaged.

Owner:GREE ELECTRIC APPLIANCES INC

High-strength high-toughness titanium alloy

The high strength and high toughness titanium alloy has Ti as main component, small amount of Al, V and Zr, and impurity not more than 1 wt%. Owing to Zr capable of forming continuous alpha type and beta type solid solution with Ti, the titanium alloy has excellent refined crystal grain structure, high plasticity and high toughness. The titanium alloy has tensile strength of 980-1180 MPa, elongation of 14-25 % and over 50 % higher than that of Ti-6Al-4V alloy, excellent mechanical performance, good machining performance and long service life. It may be applied in producing plate, rod, wire, pipe, etc used in different fields.

Owner:辽宁峰阁钛业集团有限公司

Nylon with highly hard and abrasion resistant surface and preparation method thereof

ActiveCN104945652ADoes not affect the performance of the bodyDoes not affect tensile strengthNitrogen plasmaAfter treatment

The invention discloses nylon with a highly hard and abrasion resistant surface and a preparation method thereof. The nylon with the highly hard and abrasion resistant surface adopts the technical scheme as follows: a gradient hardening abrasion-resistant layer is arranged on the nylon surface; the gradient hardening abrasion-resistant layer comprises Si-C reticular cross-linking layer and an inorganic carbonized layer from outside to inside; the depth of the gradient hardening abrasion-resistant layer is 1-6 microns; the percentage content of the carbon atoms in the inorganic carbonized layer is not lower than 95%; the depth of the inorganic carbonized layer is 0.5-5 microns. According to the preparation method, nylon is fixed on the target table of an ion implanter, firstly argon plasma is adopted to activate the material surface in a vacuum condition to form the inorganic carbonized layer, and silicon plasma or silicon / nitrogen plasma is injected to form an inorganic compound hardening abrasion-resistant layer; the method is easy to operate, and has no effect on the physical-chemical structure of the nylon body; the obtained nylon after treatment is stable in surface structure, high in surface rigidity and good in abrasion resistance, and can be widely used in structural load-bearing components.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

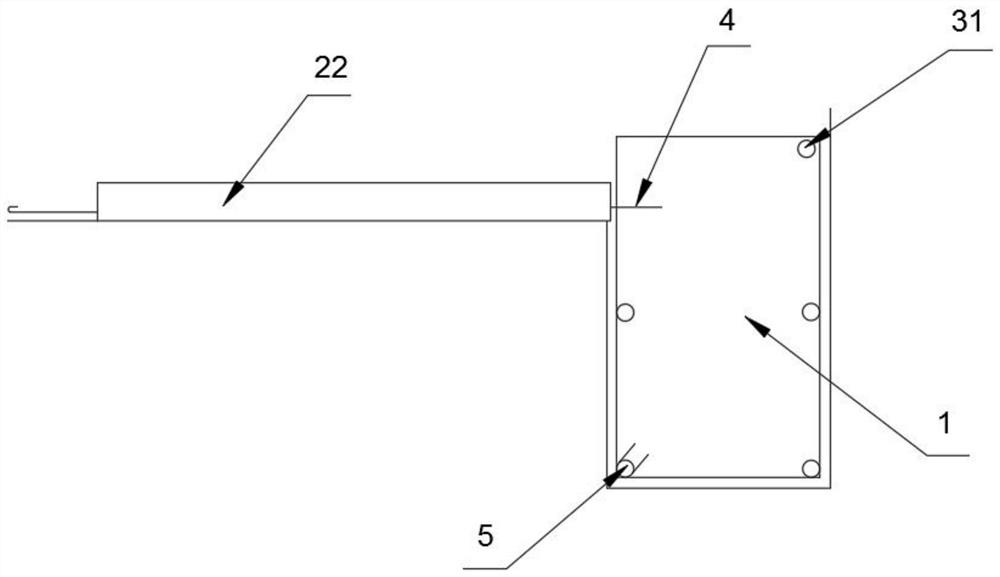

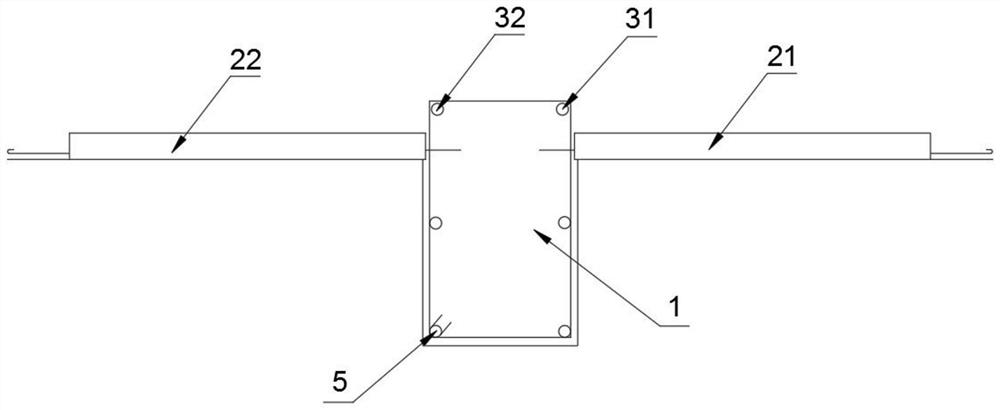

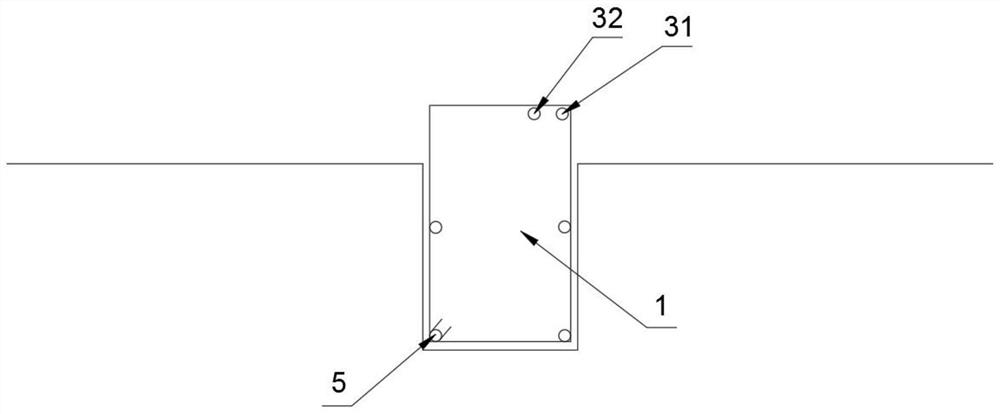

Installation and construction method of assembly type house building composite slabs

InactiveCN111734030ADoes not affect tensile strengthGuaranteed structural qualityFloorsArchitectural engineeringComposite slab

The invention relates to the technical field of house building construction, in particular to an installation and construction method of assembly type house building composite slabs. The method includes the following steps of firstly, binding beams and rebars, and temporarily fixing first upper rebars of the beams to first sides of the upper portions of the beams; secondly, hanging second composite slabs on second sides of the upper portions of the beams, wherein the first sides and the second sides are located on the two sides of the beams correspondingly; and thirdly, fixing and binding thetemporarily-fixed first upper rebars after restoration. Since the first upper rebars and the second composite slabs are located on the different sides of the upper portions of the beams, when the second composite slabs are hung, and no position conflict occurs; anchoring rebars of the second composite slabs do not need to be bent, the tensile strength of the anchoring rebars cannot be affected, and meanwhile the after-installation structure quality is ensured; and since the first upper rebars are disposed for temporary fixation, the beams and the rebars are connected into a whole, the beams and the rebars are prevented from damage when the second composite slabs are installed, construction cost is prevented from being increased, and construction efficiency is improved.

Owner:中铁二十三局集团第四工程有限公司

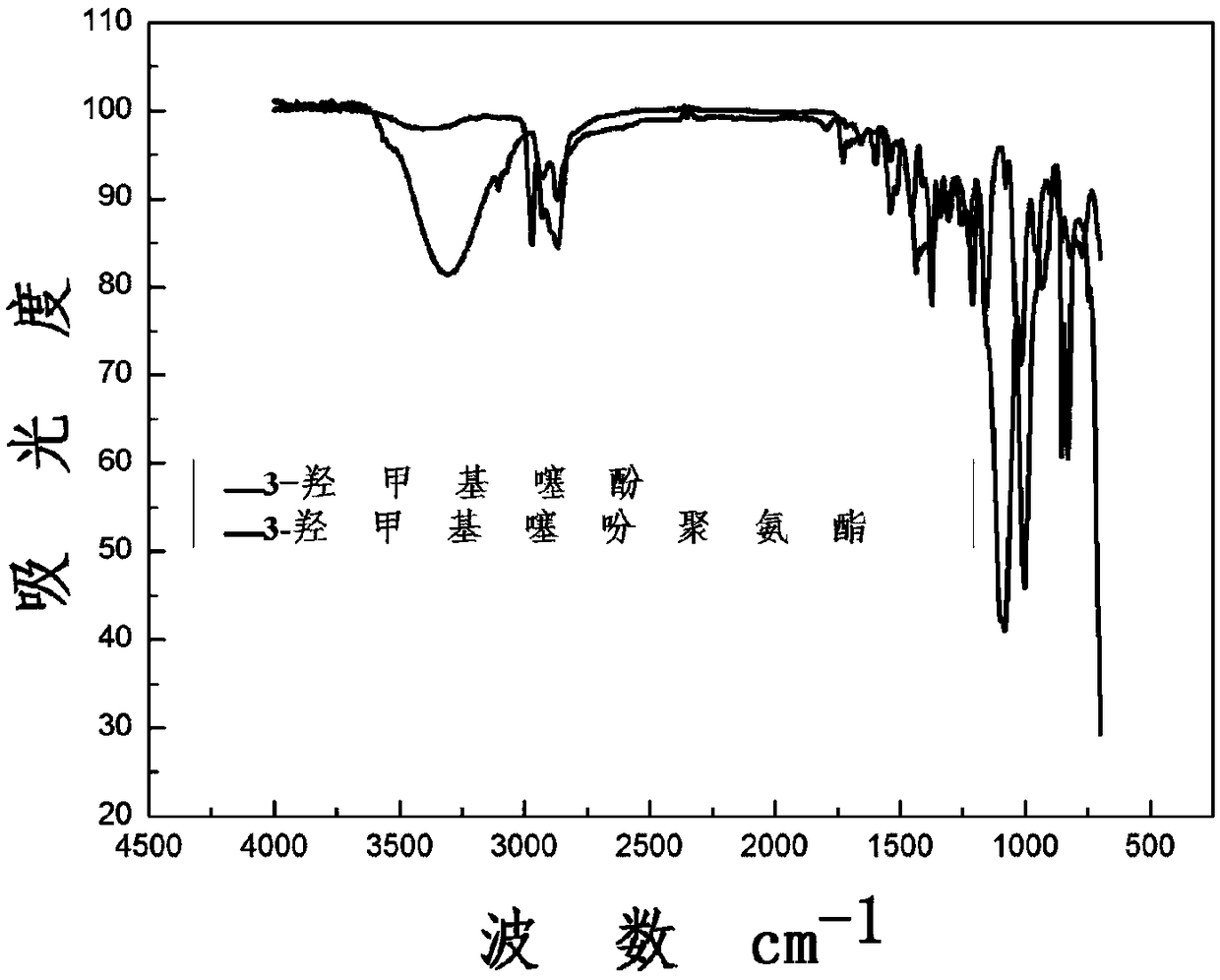

A kind of preparation method of anti-mildew polyurethane prepolymer

The invention discloses a preparation method of a mildew-resistant polyurethane prepolymer. The preparation method comprises the following steps: 1) adding polyether polyol to a reaction vessel, performing vacuum-pumping, controlling the temperature and performing stirring with a stirrer; 2) in the protection of nitrogen, cooling the system, adding diisocyanate and a proper amount of a catalyst, controlling the temperature, and increasing the stirring speed; 4) according the NCO content in the system, slowing adding a silane coupling agent to the reaction system, and continuously performing stirring; 5) adding a certain amount of hydroxyl (or amino) thiophene oligopolymer to the system, and continuously performing stirring; and 6) after the reaction is over, vacuumizing the system to remove bubbles and obtaining a target product. The obtained polyurethane prepolymer is excellent in mildew resistance without mechanical property being affected.

Owner:SOUTH CHINA UNIV OF TECH

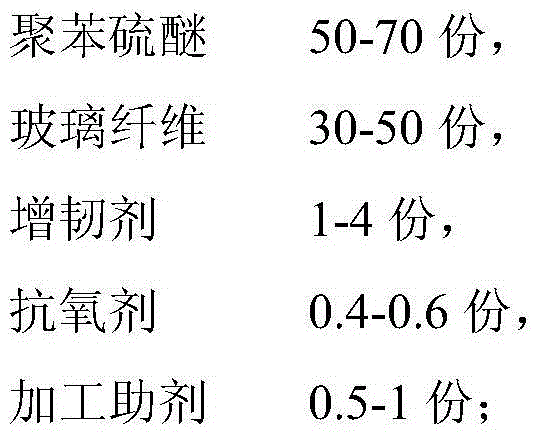

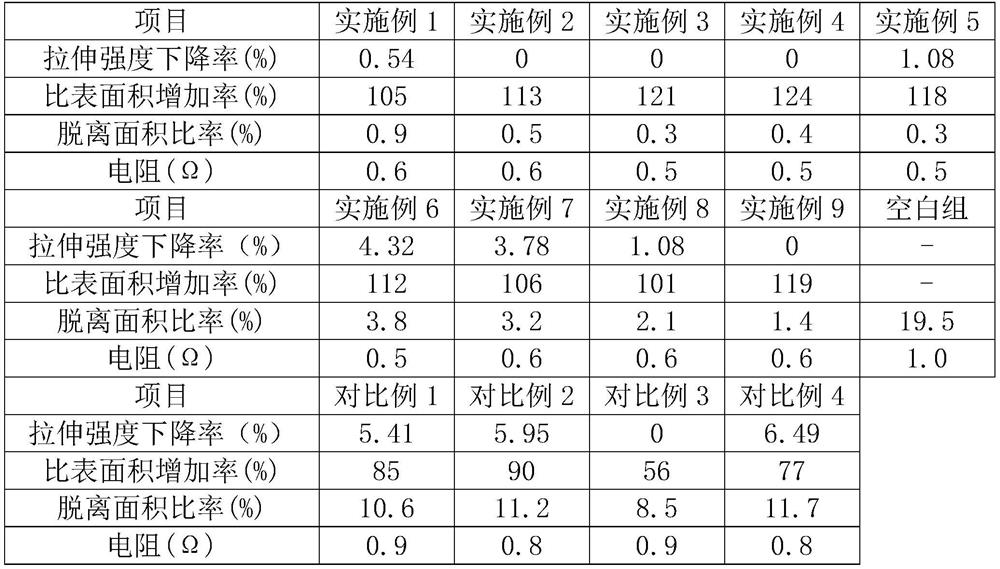

A kind of polyphenylene sulfide composite material and preparation method thereof

The invention belongs to the technical field of high polymer materials and discloses a glass fiber reinforced impact-resistant polyphenylene sulfide composite and a preparation method thereof. The composite is composed of, by weight, 50-70 parts of polyphenylene sulfide, 30-50 parts of glass fibers, 1-4 parts of flexibilizer, 0.4-0.6 part of antioxidant and 0.5-1 part of processing aid. The preparation method of the composite includes the steps: firstly, adding the 50-70 parts of polyphenylene sulfide, 1-4 parts of flexibilizer, 0.4-0.6 part of antioxidant and 0.5-1 part of processing aid into a mixer and mixing for 30min; and secondly, adding the mixture obtained at the step one into an extruding machine through a hopper, adding the 30-50 parts of glass fibers through a glass fiber port, and performing melt extrusion and granulating. The glass fiber reinforced impact-resistant polyphenylene sulfide composite has excellent impact resistance and high mechanical strength.

Owner:HEFEI GENIUS NEW MATERIALS

Current collector etched foil and preparation method thereof, electrode and lithium battery

ActiveCN114744208AIncrease surface wetting tensionDoes not affect tensile strengthElectrode carriers/collectorsSecondary cellsMetallurgyMetal foil

The invention discloses a current collector etched foil and a preparation method thereof, an electrode and a lithium battery, and the preparation method of the etched metal foil comprises the following steps: providing a metal foil; the metal foil is subjected to etching treatment, and the metal foil sequentially enters a pickling tank, an alkaline washing tank, a pickling tank and a cleaning tank; and carrying out drying treatment on the etched metal foil. The preparation method is simple, and the etched metal foil is large in specific surface area, small in resistance and good in adhesive force with an electrode layer.

Owner:FOSHAN SINO SCI NANO TECH MATERIAL CO LTD

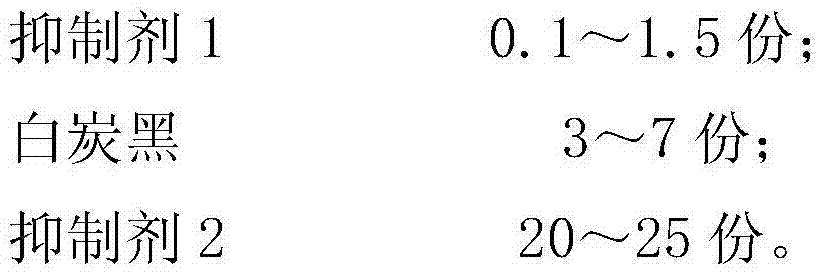

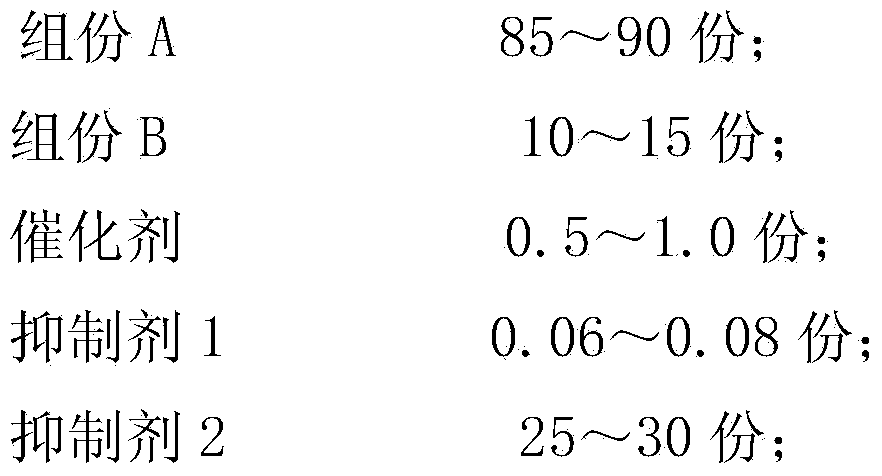

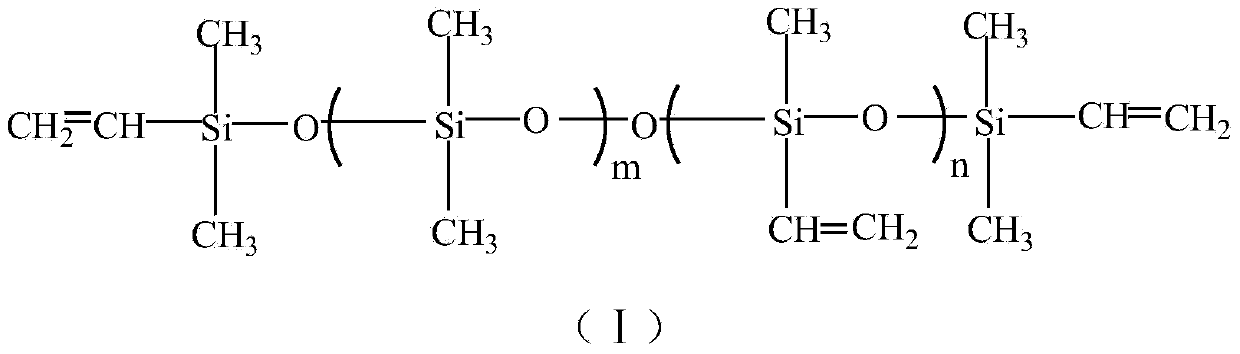

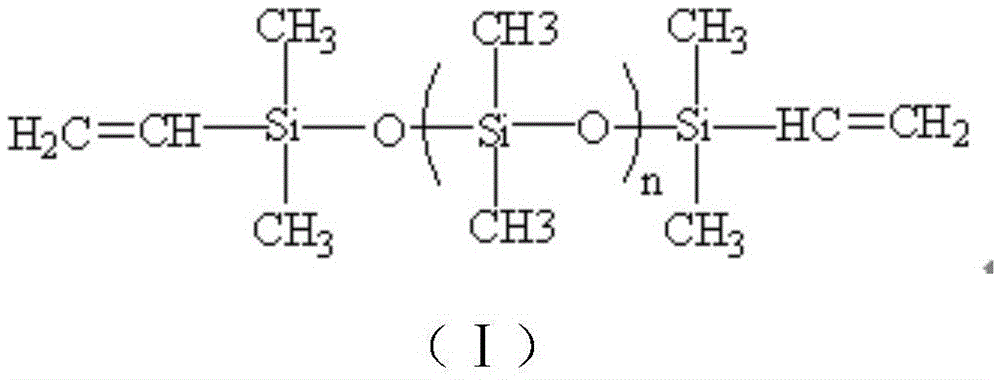

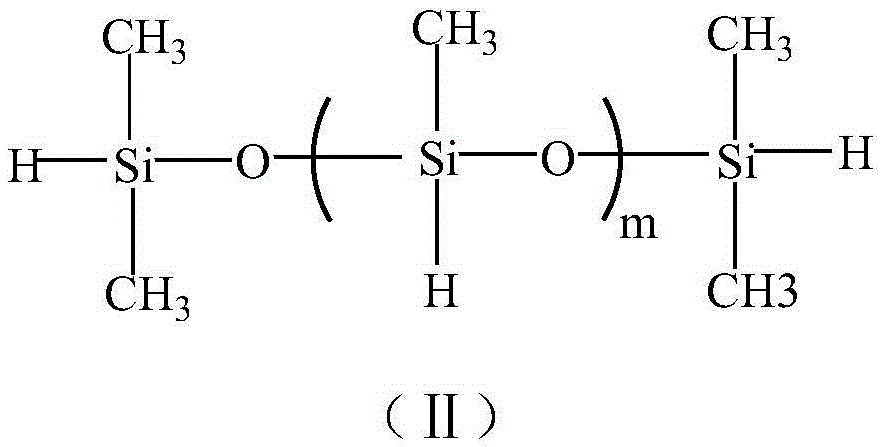

Addition type mold rubber suitable for manufacturing crystal drill and preparation method of mold rubber

ActiveCN103740114AGuaranteed tensile strengthGuaranteed tear strengthHardnessUltimate tensile strength

The invention discloses addition type mold rubber suitable for manufacturing a crystal drill and a preparation method of the addition type mold rubber. The addition type mold rubber is prepared from the following raw materials in parts by weight: 85-90 parts of a component A, 10-15 parts of a component B, 0.5-1.0 part of a catalyst, 0.06-0.08 part of an inhibitor 1 and 25-30 parts of an inhibitor 2. The addition type mold rubber disclosed by the invention has excellent tensile strength, tear strength and hardness, the number of mold rolling-over times is as high as 35-50, and the service life is long.

Owner:惠州市永卓科技有限公司

Local granule reinforced piston and its manufacture method

InactiveCN101338708BAchieve local segregationExtended service lifeMachines/enginesPistonsEffective powerEngineering

The present invention discloses a partial reinforced particle piston and a manufacturing method thereof. The partial reinforced particle piston comprises a head, a skirt section and a pin base. The head comprises a piston top and a ring slot part. The piston top and the ring slot part are reinforced areas which are formed by distributing reinforced particles in piston matrix material. The skirt section is an non-reinforced area. The reinforced area and the non-reinforced area are combined by an alloy combination form. The partial reinforced particle piston not only increases the wearing resistance of the head of a piston and reduces the thermal expansion coefficient, but also ensures the good mechanical performance of the skirt section of the piston and realizes the continuous transition of the organization structure and performance of the partial reinforced area and the non-reinforced area; the effective power of an engine is improved; the service life of the piston is prolonged; in order to manufacturing the piston, the present invention uses a centrifugal casting method to assemble the reinforced particles in melted homogenous composite material at the head of the piston, and the manufacturing method has simple technology and low manufacturing cost.

Owner:CHONGQING UNIV

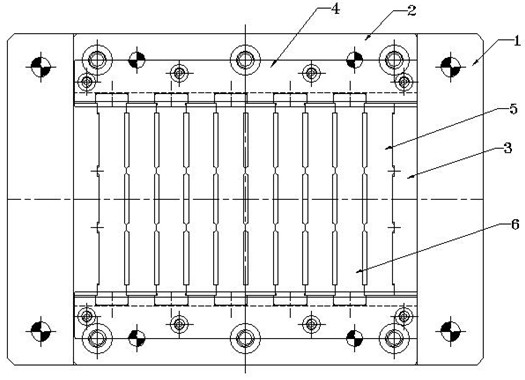

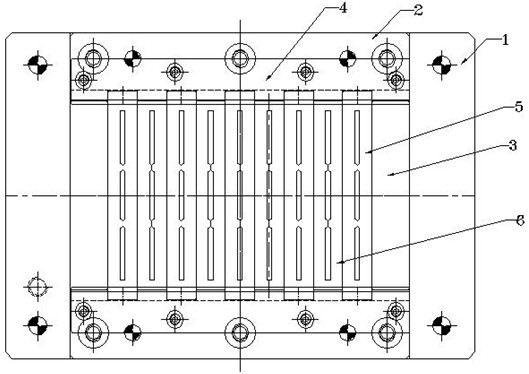

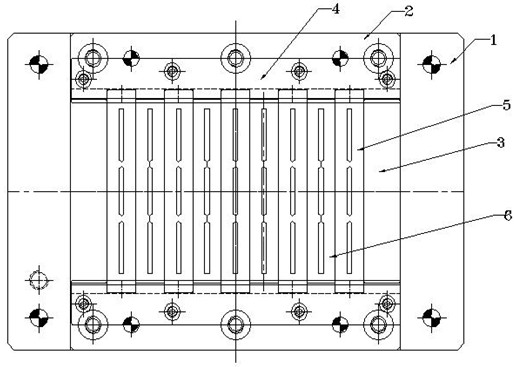

Integral female die with good punching effect

InactiveCN102145364ADoes not affect surface strengthDoes not affect tensile strengthShaping toolsPunchingEngineering

The invention provides an integral female die with a good punching effect, and the integral female die comprises a female die holder and is characterized in that the groove of the die holder is internally provided with at least two first female dies, at least one second female die and at least two female die blocks, wherein the at least two first female dies, the at least one second female die and the at least two female die blocks are arranged side by side, so that the first female dies and the second female die are integrally formed, the second female die is clamped between the two first female dies, two sides of the first female dies and the second female die are fixed by the female die blocks, the tops and bottoms of the first female dies and the second female die are respectively provided with a female die locating block for fixing the positions of the first female dies and the second female die, and the first female dies, the second female die and the female die blocks are pressed by die pressing strips. The integral female die provided by the invention has the advantages of enhancing the tensile strength of steel band products and improving the quality of products.

Owner:NANTONG SHANGMING PRECISION MOLD

Method for relieving stress before plating whole chain

InactiveCN1605635ADoes not affect tensile strengthBeautiful and uniform appearanceFurnace typesHeat treatment furnacesElectroplatingMetal

The stress eliminating process for assembled chain before electroplating includes the following steps: setting assembled chain inside metal basket; tempering the metal basket with chain at 125-150 deg.c for 2 hr; and draining tempering medium. The said stress eliminating process can avoid crack the chain produces during and after electroplating, while making the chain maintaining its tensile strength and being beautiful, durable and superior to chain assembled after electoplating.

Owner:许长荣

Method for relieving stress before plating whole chain

InactiveCN1249255CDoes not affect tensile strengthBeautiful and uniform appearanceFurnace typesHeat treatment furnacesElectroplatingMetal

Owner:许长荣

A kind of addition mold glue and preparation method thereof

The invention discloses addition-type mold rubber and a preparation method thereof. The addition-type mold rubber is prepared from the following raw materials in parts by weight: 70-85 parts of component A, 5-10 parts of component B, 0.2-2.0 parts of catalyst, 0.1-1.5 parts of inhibitor 1, 3-7 parts of white carbon black and 20-25 parts of inhibitor 2. The addition-type mold rubber disclosed by the invention has good tensile strength, tear strength and hardness, is very suitable for manufacturing of crystal drills and long in service life, the rolling-over number of times of the addition-type mold rubber reaches up to 35-45 times, and the brightness of the manufactured crystal drills is greatly improved.

Owner:惠州市永卓科技有限公司

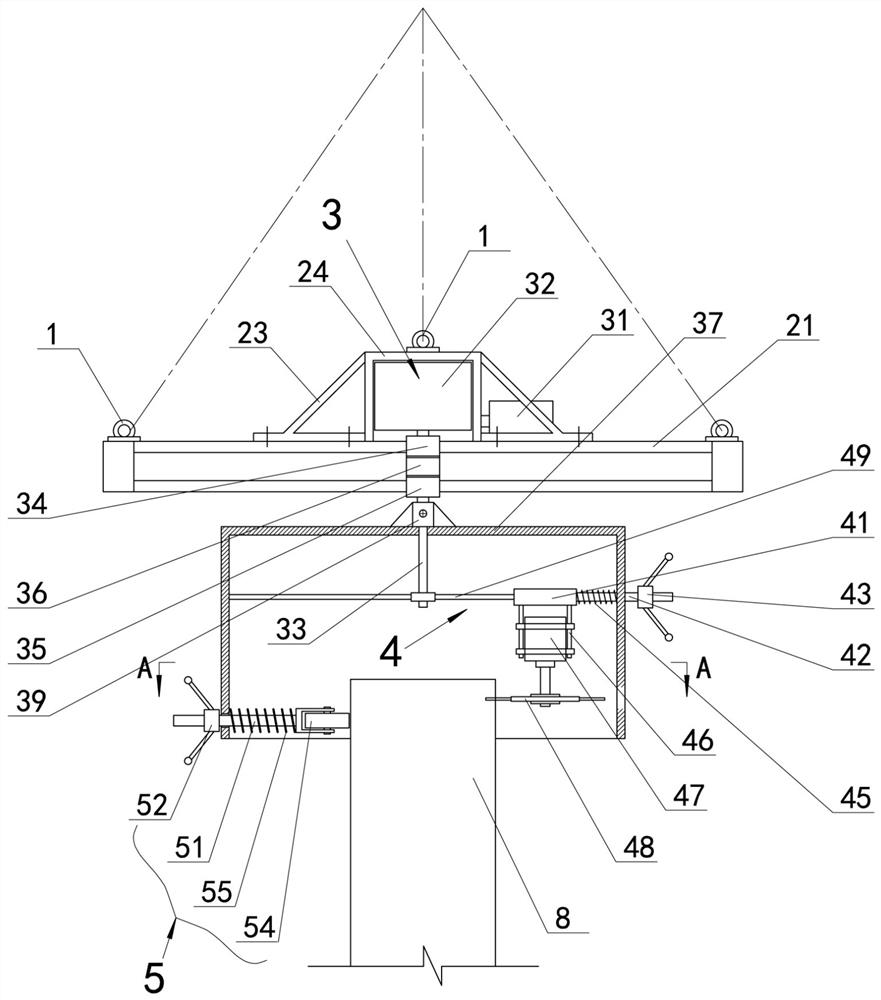

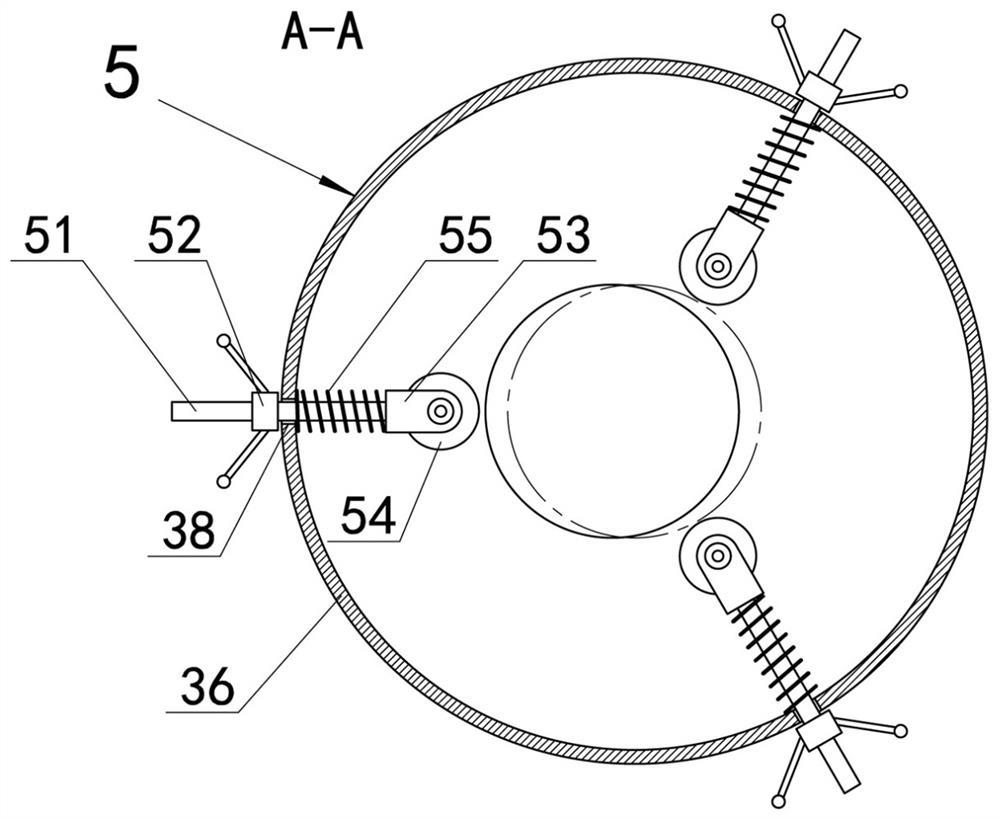

Lifting cast-in-place pile head cutting device

ActiveCN111021355BNo damageWill not cause bending deformationBulkheads/pilesClassical mechanicsThrust bearing

The invention discloses a hoisting cast-in-place pile head cutting device, which comprises a support beam, a rotary drive mechanism, a cutting mechanism and a positioning mechanism, wherein the rotary drive mechanism includes a power source, and the output rotating shaft of the power source passes through a thrust bearing and a roller bearing respectively. It is installed in the middle of the supporting beam, and a rotating frame is fixed below the output rotating shaft. The rotating frame is a cylindrical cylinder or a cylindrical frame structure. The cutting mechanism is located on the upper part of the rotating frame, and the positioning mechanism is located on the lower part of the rotating frame. The invention is easy to operate, high in construction efficiency, smooth in cutting section, does not cause damage to steel bars, does not cause bending deformation of steel bars, does not affect the tensile strength of steel bars, and after removing the pile head, the height of the pile top is even , easy to operate and save manpower.

Owner:郑州宏拓电子技术有限公司

Top coat having improved adhesive and soil resistance

InactiveCN100354354CDoes not affect important propertiesDoes not affect tensile strengthCoatingsPolyesterAdhesive

A combination can be made from the following compositions: polymer composition (1) which meets the following conditions: each molecule comprises 0.01 to 3.0 weight percent silicon binding group OR<1> and one or more than one optional polymer composition selected from the following group: (B) vinyl chloride-hydroxypropyl acrylate copolymer, (C) vinyl ester acetate-ethylene polymer, (D) polyvinyl chloride, (E) polyamide, (F) polyester, (G) acrylic ester-polyester polymer, (H) polyamide-polyester polymer, (I) vinyl ester acetate-polyester polymer and (J) monomer (methyl) acrylic ester which meet the following conditions: copolymerization with silicane comprising silicon binding (methyl) acrylate group is completed, (2) silicane of the following general formula: R<3>xSi(OR<2>)4-x, (3) polysiloxane particle which is crosslinked organic polysiloxane particle consisting of a single molecule with the average diameter ranging between 5 nm and 200 nm.

Owner:WACKER CHEM GMBH

A kind of surface high hardness wear-resistant nylon and its preparation method

ActiveCN104945652BDoes not affect the performance of the bodyDoes not affect tensile strengthNitrogen plasmaAfter treatment

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

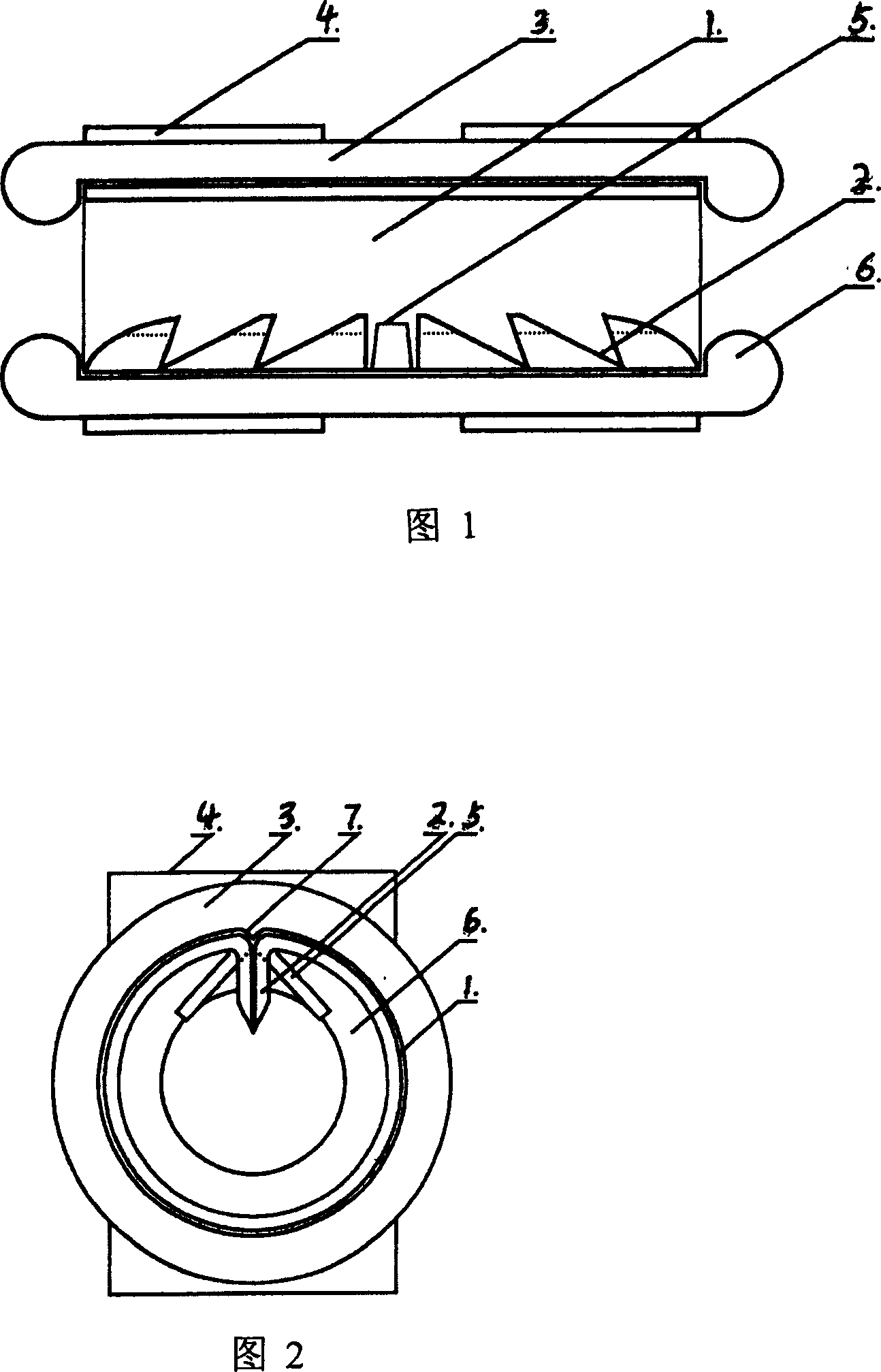

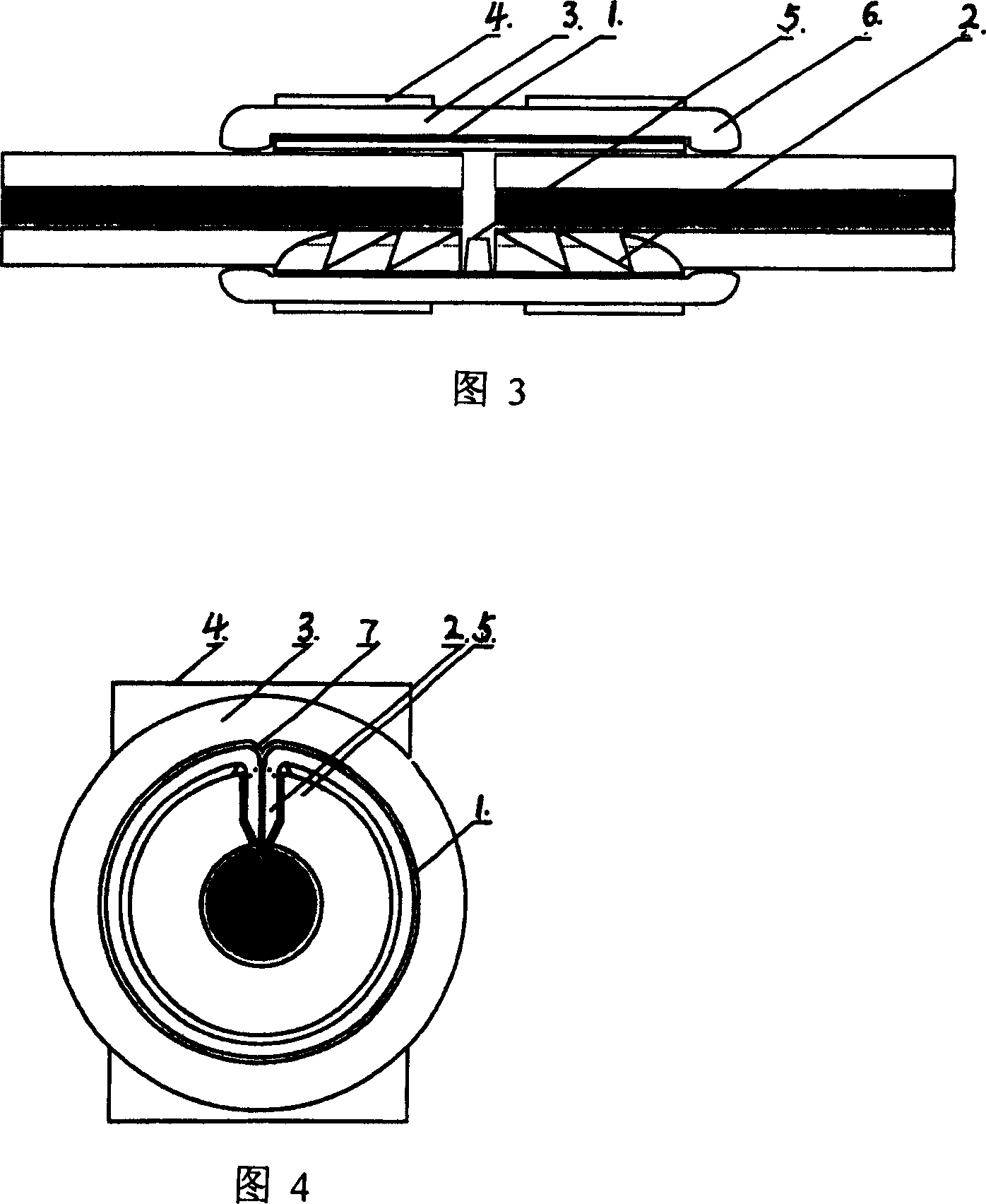

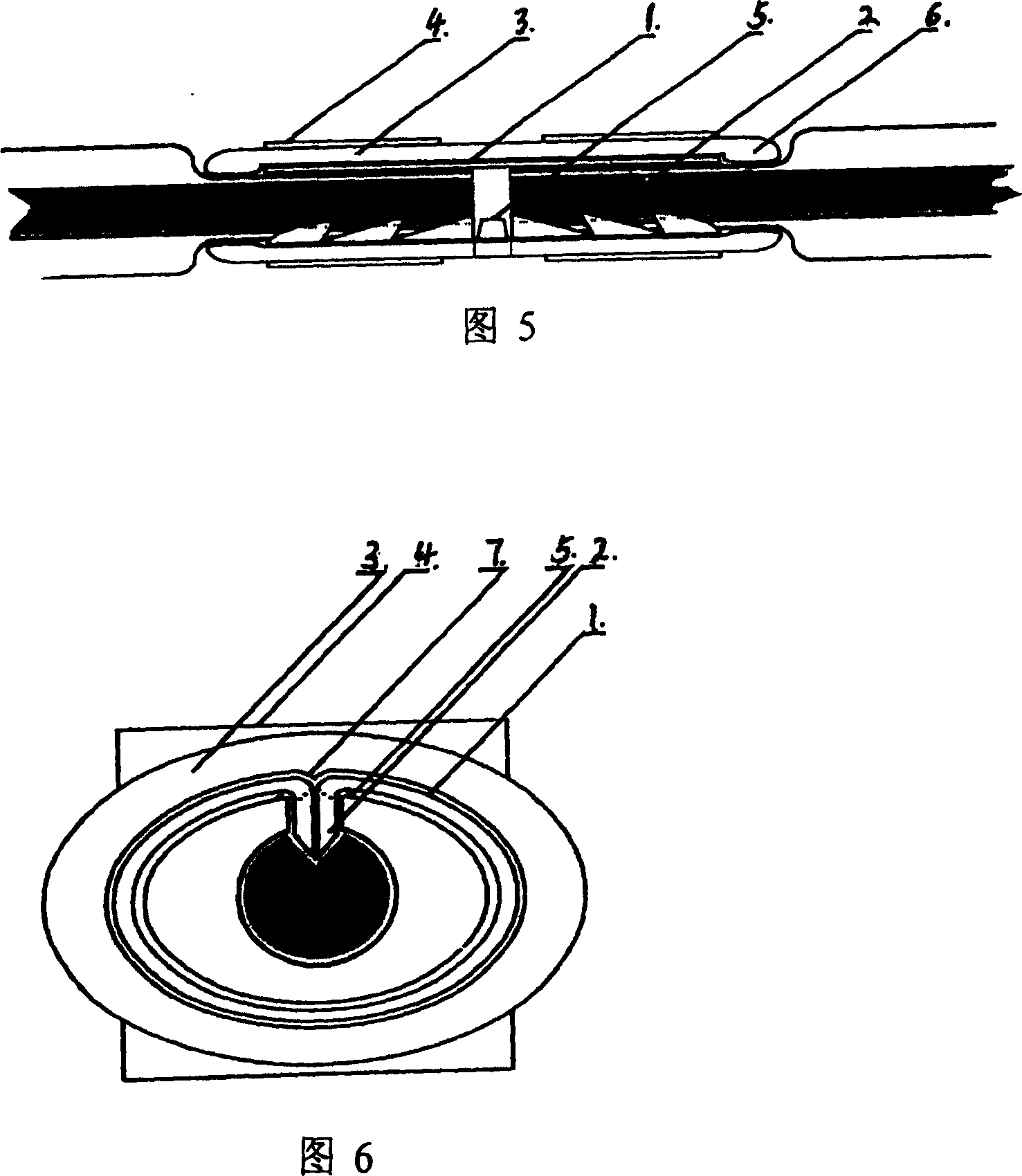

Wire continuous connector

InactiveCN1319212CNo shortening lengthSimplify the next stepConnections effected by permanent deformationCable junctionsElectricityEngineering

This invention is discloses a connector of electric wire, which mainly composed of the metal ring cover. The characteristic is that the metal ring cover has the portrait crimp teeth, and the ends of the crimp teeth are the blade; the metal ring cover is in the insulating sleeve. It can fast finish the connection of the electric leads, the connection of the leads is firm and stable, the insulation performance is fine. The adapting connection and packaging are finished for once time, so the process is simple and the maneuverability is strong. It saves the time and the energy, and has high efficiency and simplifies the adapting processes of the electric wires.

Owner:齐俊曌

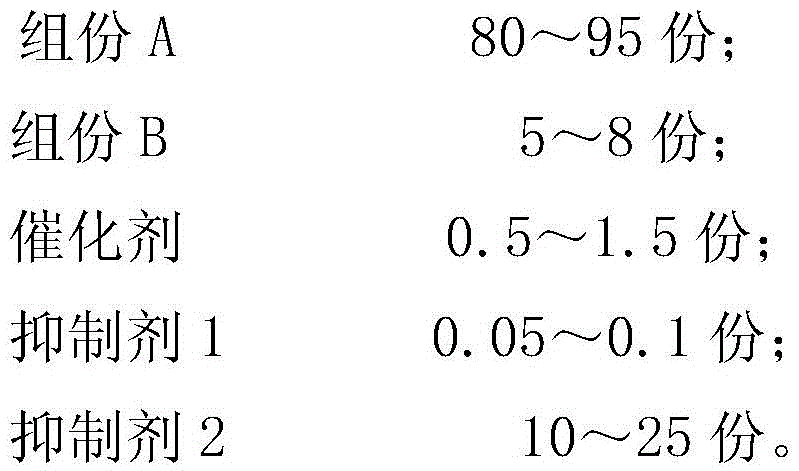

A kind of addition mold glue for making crystal drill and preparation method thereof

The invention discloses an addition type mould gel for making a crystal drill and a preparation method of the addition type mould gel. The addition type mould gel comprises the following raw materials in parts by weight: 80-95 parts of a component A, 5-9 parts of a component B, 0.5-1.5 parts of a catalyst, 0.05-0.1 part of an inhibitor 1 and 10-25 parts of an inhibitor 2. The addition type mould gel disclosed by the invention is very suitable for making the crystal drill by means of tensile strength, tearing strength and hardness, and is long in service life, simple in preparation method, low in cost and very high in economic value; the mould turnover times reaches 35-40 times.

Owner:惠州市永卓科技有限公司

A kind of preparation method of the ltcc medium slurry that is sintered to be transparent after casting

ActiveCN113436783BPromote environmental protectionDoes not affect tensile strengthCeramicsQuartz/glass/vitreous enamelsSlurryElectric properties

The invention discloses a preparation method of LTCC medium slurry which is sintered to be transparent after casting. During the dispersion process of YBS series glass porcelain powder, carbon tetrachloride is used to replace conventional isopropanol, and at the same time, it is dispersed after secondary ball milling. Diallyl phthalate and 1,3-propylene glycol are then added to prepare media slurry. The LTCC dielectric slurry prepared by the method of the present invention is cast and sintered into a colorless and transparent porcelain ribbon, and the ceramic substrate can be obtained after the ceramic ribbon is processed, so that the defects of the sintered substrate can be intuitively judged, and occurrence Defects such as bumps, fractures, and bubbles can be terminated in time, without the need for further electrical performance, adhesion, and durability tests, which avoids cost waste and can effectively stop damage without affecting the tensile strength and bending strength of the ceramic tape. And dielectric properties, while also ensuring low dielectric loss, dimensional stability is also guaranteed.

Owner:西安宏星电子浆料科技股份有限公司

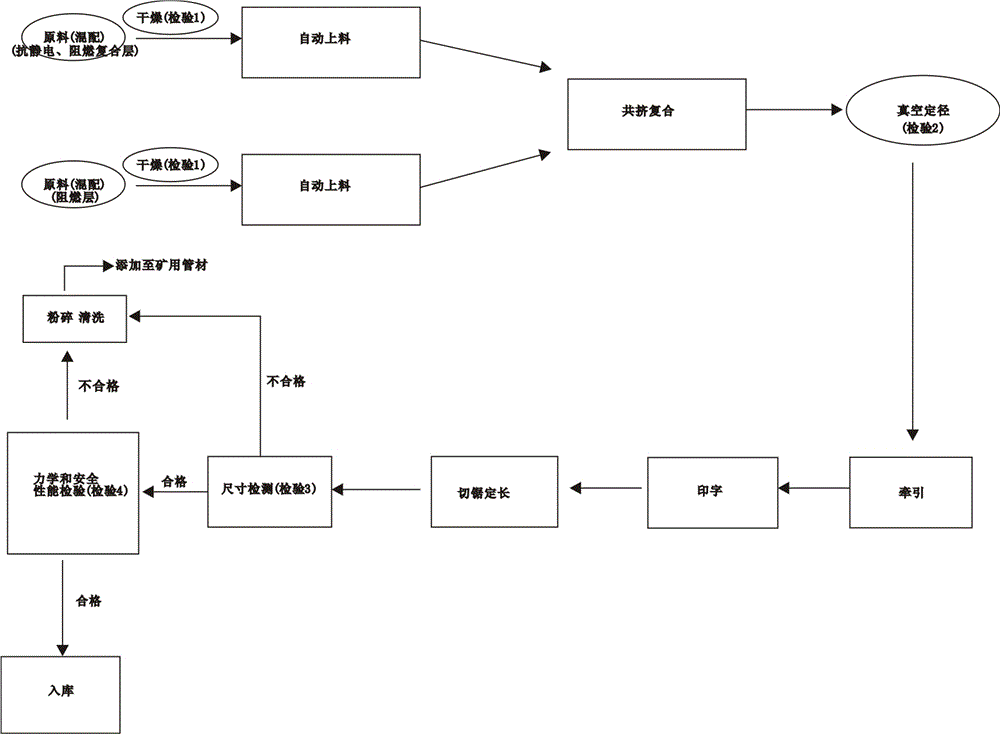

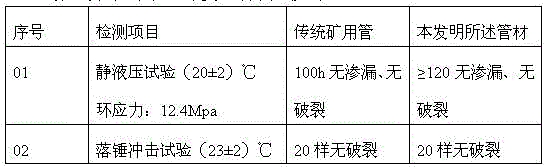

Coal mine underground polyethylene composite pipe

ActiveCN103267178BEasy to transportImprove anti-agingRigid pipesPipe protection against damage/wearNational standardFire retardant

The invention discloses a polyethylene composite tube for an underground coal mine. The polyethylene composite tube is characterized in that the composite tube is divided into three layers, the middle portion of the composite tube is an inflaming retarding layer, the inner surface and the outer surface of the inflaming retarding layer are an antistatic layer and an inflaming retarding composite layer respectively, and the inflaming retarding layer, the antistatic layer and the inflaming retarding composite layer form an integral structure. The inflaming retarding layer is prepared, by mass percent, by 80-85% polyethylene resin and 15-20% environment-friendly inflaming retarding components. The inner surface and the outer surface of the inflaming retarding layer are the antistatic layer and the inflaming retarding composite layer, wherein the antistatic layer and the inflaming retarding composite layer are prepared, by mass percent, by 7-10% superconducting antistatic carbon black, 10-15% environment-friendly fire retardant and 78-83% polyethylene resin. Antistatic and flame retardant properties accord with national standards, so the polyethylene composite tube is applied to inflammable and explosive specific places in a pit. The polyethylene composite tube serves as a dedicated tube stock, so inflaming retarding and antistatic characteristics are particularly highlighted. The polyethylene composite tube is light in weight, convenient to install, good in anti-aging and rapid cracking resistance, corrosion-resistant, and free of scaling at the same time.

Owner:CHENGDU SANHUAN METAL PROD

A kind of heat treatment method of medium carbon low alloy steel

ActiveCN111154956BHigh elongationImprove mechanical propertiesProcess efficiency improvementTemperingHardness

Owner:HUSN CASTING ANHUI YINGLIU GROUP

Peel-off lip gloss without damage to lip

InactiveCN105832599AGood flexibilitySoftness helpsCosmetic preparationsMake-upPolyvinyl alcoholEngineering

The invention discloses peel-off lip gloss without the damage to the lip, and relates to the technical fields of beauty treatment and beauty makeup. The peel-off lip gloss is manufactured from the following raw materials including polyvinyl alcohol, glycerin, tween 80, allantoin, dimethicone, and natural plant pigment. Through the peel-off lip gloss, the problems that dermatitis is caused, for the lip is hurt when a lip gloss membrane formed on the lip is peeled and the lip gloss membrane is difficult to remove cleanly are solved.

Owner:覃碧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com