A kind of preparation method of the ltcc medium slurry that is sintered to be transparent after casting

A dielectric slurry and transparent technology, applied in the direction of inorganic insulators, insulators, ceramics, etc., can solve the problems of wasting manpower, material and financial resources, termination, etc., and achieve the effect of dimensional stability guarantee and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

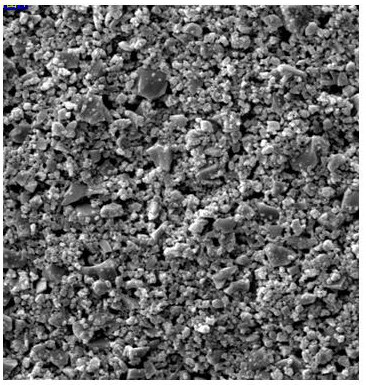

[0029] 1. Add 300g of carbon tetrachloride to the beaker, turn on the magnetic stirrer, then slowly add 500 g of YBS-based glass porcelain powder with particle size D50≤1.0μm into the beaker, stir and mix for 2 hours with a magnetic stirrer, pour it out and put it in Dry in an oven at 74°C for 12 hours, and pass through a 325-mesh nylon screen after drying.

[0030] 2. Put the YBS glass-ceramic powder passed through a 325-mesh nylon screen in step 1 into a polyurethane ball mill tank, add 450g of acetone and 5g of tributyl phosphate, seal the ball mill tank and place it on an eight-roller ball mill for ball milling and dispersion. The duration is 2h.

[0031] 3. Add 15g of polyethylene glycol and 10g of polyvinyl butyral resin after the primary ball mill dispersion, and add 250g of acetone, seal the ball mill tank and place it on an eight-roller ball mill for secondary ball mill dispersion for 16 hours.

[0032] 4. Add 25g of diallyl phthalate and 15g of 1,3-propanediol after...

Embodiment 2

[0035] 1. Add 250g of carbon tetrachloride to the beaker, turn on the magnetic stirrer, then slowly add 500 g of YBS series glass porcelain powder with particle size D50≤1.0μm into the beaker, stir and mix for 2 hours with a magnetic stirrer, pour it out and put it in Dry in an oven at 60°C for 12 hours, and pass through a 325-mesh nylon screen after drying.

[0036] 2. Put the YBS glass-ceramic powder passed through a 325-mesh nylon screen in step 1 into a polyurethane ball mill tank, add 400g of acetone and 3g of tributyl phosphate, seal the ball mill tank and place it on an eight-roller ball mill for ball milling and dispersion. The duration is 1h.

[0037] 3. Add 5g of polyethylene glycol and 5g of polyvinyl butyral resin after the first ball mill dispersion, and add 100g of acetone, seal the ball mill tank and place it on an eight-roller ball mill for secondary ball mill dispersion for 8 hours.

[0038] 4. Add 15g of diallyl phthalate and 5g of 1,3-propanediol after the ...

Embodiment 3

[0041] 1. Add 500g carbon tetrachloride to the beaker, turn on the magnetic stirrer, then slowly add 500 g of YBS glass porcelain powder with a particle size D50≤1.0μm into the beaker, stir and mix for 1 hour with a magnetic stirrer, pour it out and put it in Dry in an oven at 70°C for 10 hours, and pass through a 325-mesh nylon screen after drying.

[0042] 2. Put the YBS glass-ceramic powder passed through a 325-mesh nylon screen in step 1 into a polyurethane ball mill tank, add 500g of acetone and 6g of tributyl phosphate, seal the ball mill tank and place it on an eight-roller ball mill for ball milling and dispersion. The duration is 4 hours.

[0043]3. Add 30g of polyethylene glycol and 25g of polyvinyl butyral resin after the first ball mill dispersion, and add 300g of acetone, seal the ball mill tank and place it on an eight-roller ball mill for the second ball mill dispersion for 24 hours.

[0044] 4. Add 50g of diallyl phthalate and 50g of 1,3-propanediol after the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com