Patents

Literature

355results about "Quartz/glass/vitreous enamels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for Removal of Carbon From An Organosilicate Material

Described herein is a method for removing at least a portion of the carbon-containing species within an organosilicate (OSG) film by treating the OSG film with a chemical, such as but not limited to an oxidizer, exposing the OSG film to an energy source comprising ultraviolet light, or treating the OSG film with a chemical and exposing the OSG film to an energy source.

Owner:VERSUM MATERIALS US LLC

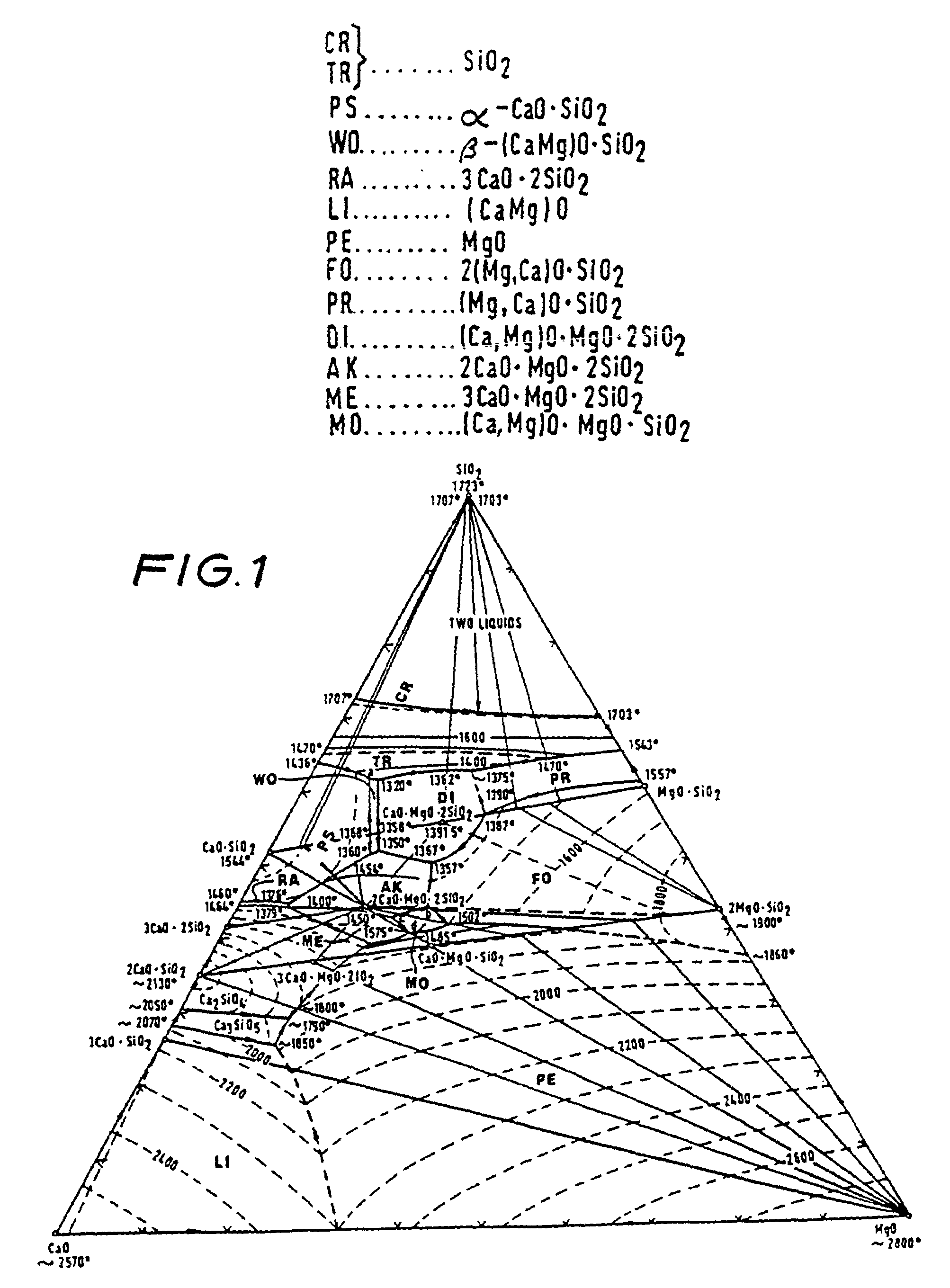

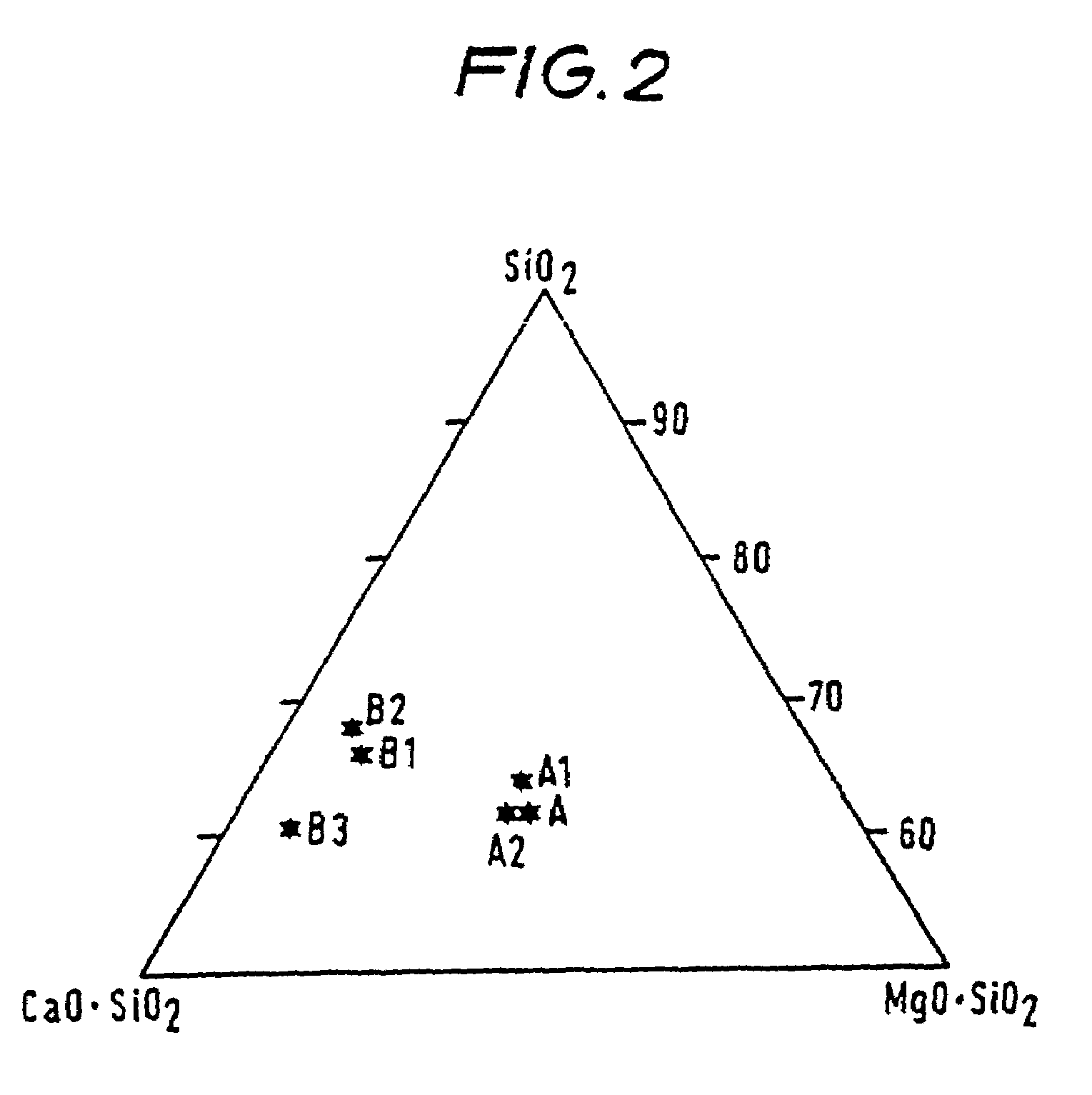

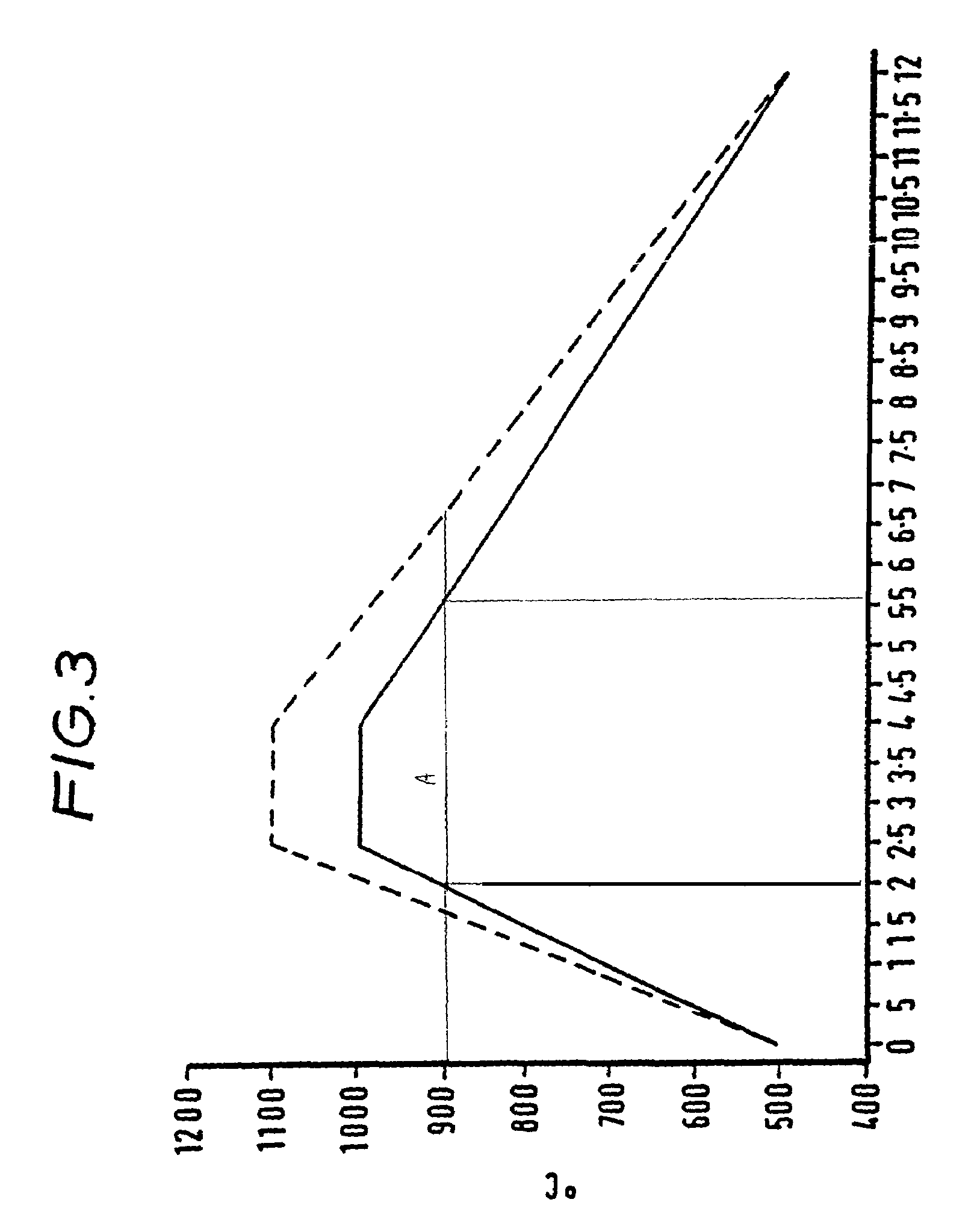

Saline soluble inorganic fibers

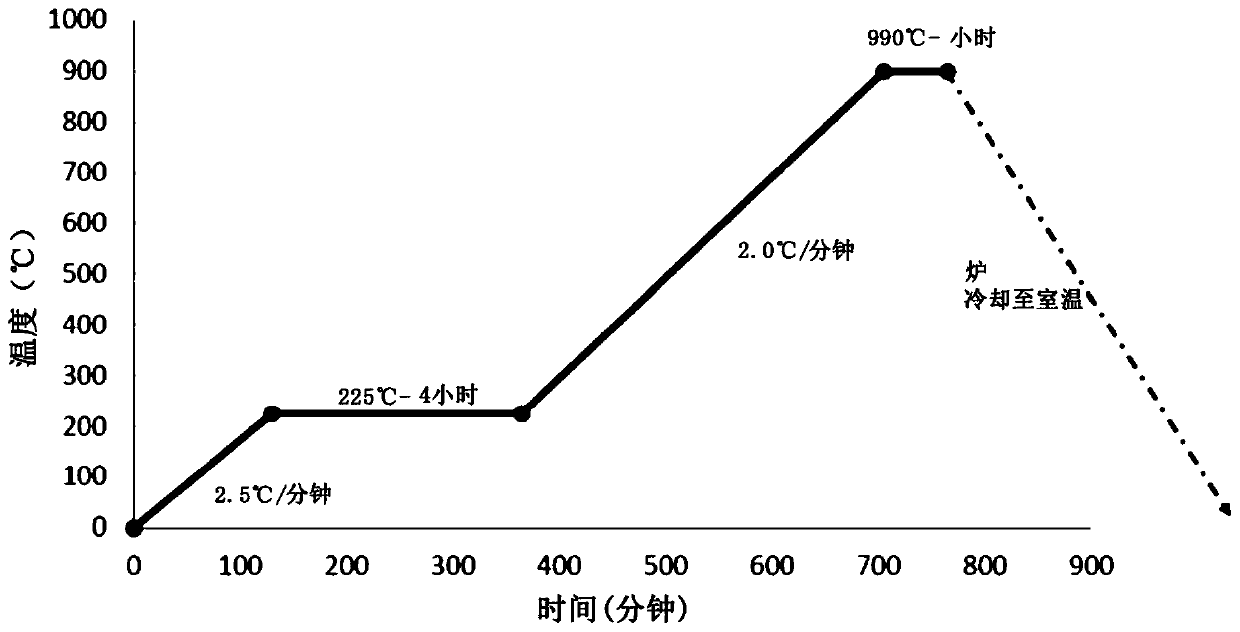

A method for insulating an article requiring resistance against repeated exposure to temperatures exceeding 900° C. uses saline soluble, non-metallic, amorphous, inorganic oxide, refractory fibrous materials as thermal insulation. The compositions that can be used for that purpose include vitreous fibers based on SiO2, CaO, MgO, and optionally, A2O3.

Owner:THE MORGAN CRUCIBLE CO PLC

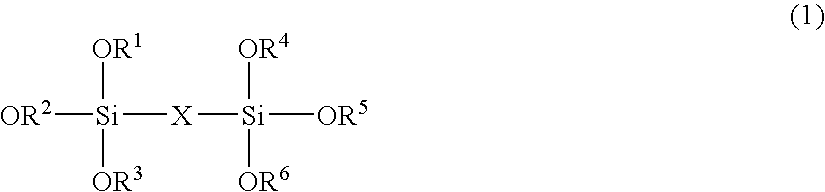

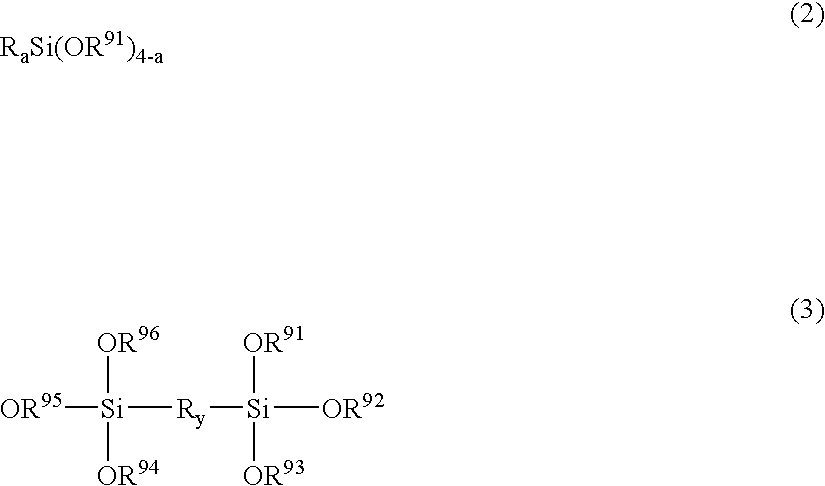

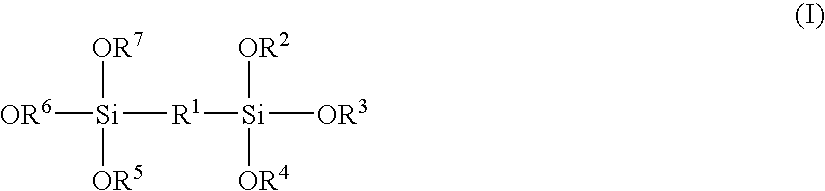

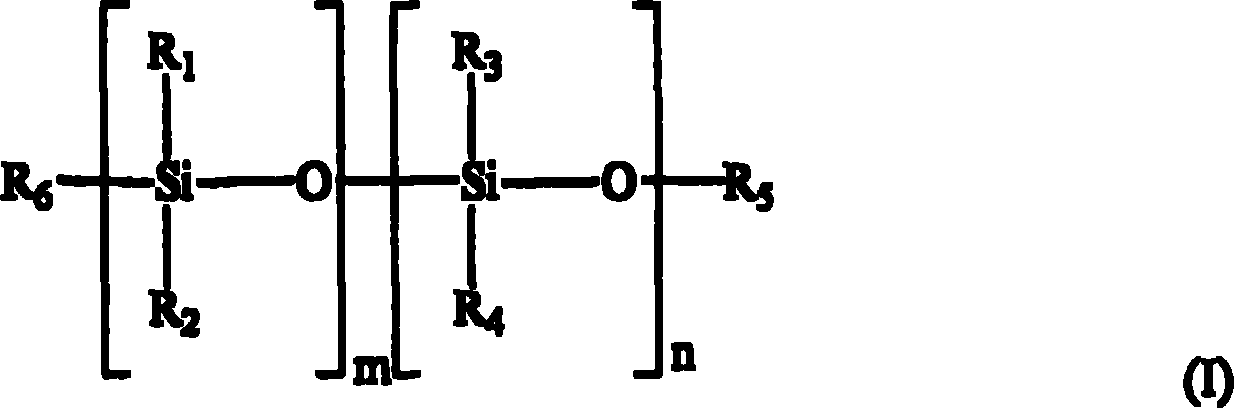

Coating Liquid for Forming Low Dielectric Constant Amorphous Silica-Based Coating Film and the Coating Film Obtained From the Same

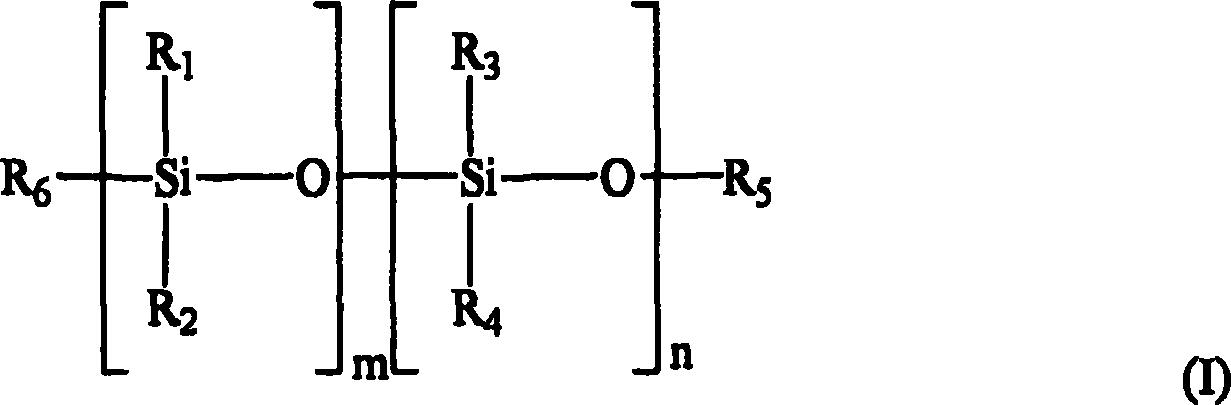

InactiveUS20090025609A1High film strengthImprove hydrophobicitySilicon organic compoundsSilicaAlkaneSilylene

A coating liquid for forming a low dielectric constant amorphous silica-based coating film with a dielectric constant of 3.0 or below and a film strength (Young's modulus) of 3.0 GPa or more, and also having a smooth surface with an excellent hydrophobicity. The coating liquid contains (1) a silicon compound obtained by hydrolyzing bis(trialcoxysilyl)alkane (BTASA) and alcoxysilane (AS) in the presence of tetraalkylammoniumhydroxide (TAAOH), or (2) a silicon compound obtained by hydrolyzing bis(trialcoxysilyl)alkane (BTASA), alcoxysilane (AS) and tetraalkylorthosilicate (TAOS) in the presence of tetraalkylammoniumhydroxide (TAAOH).

Owner:JGC CATALYSTS & CHEM LTD

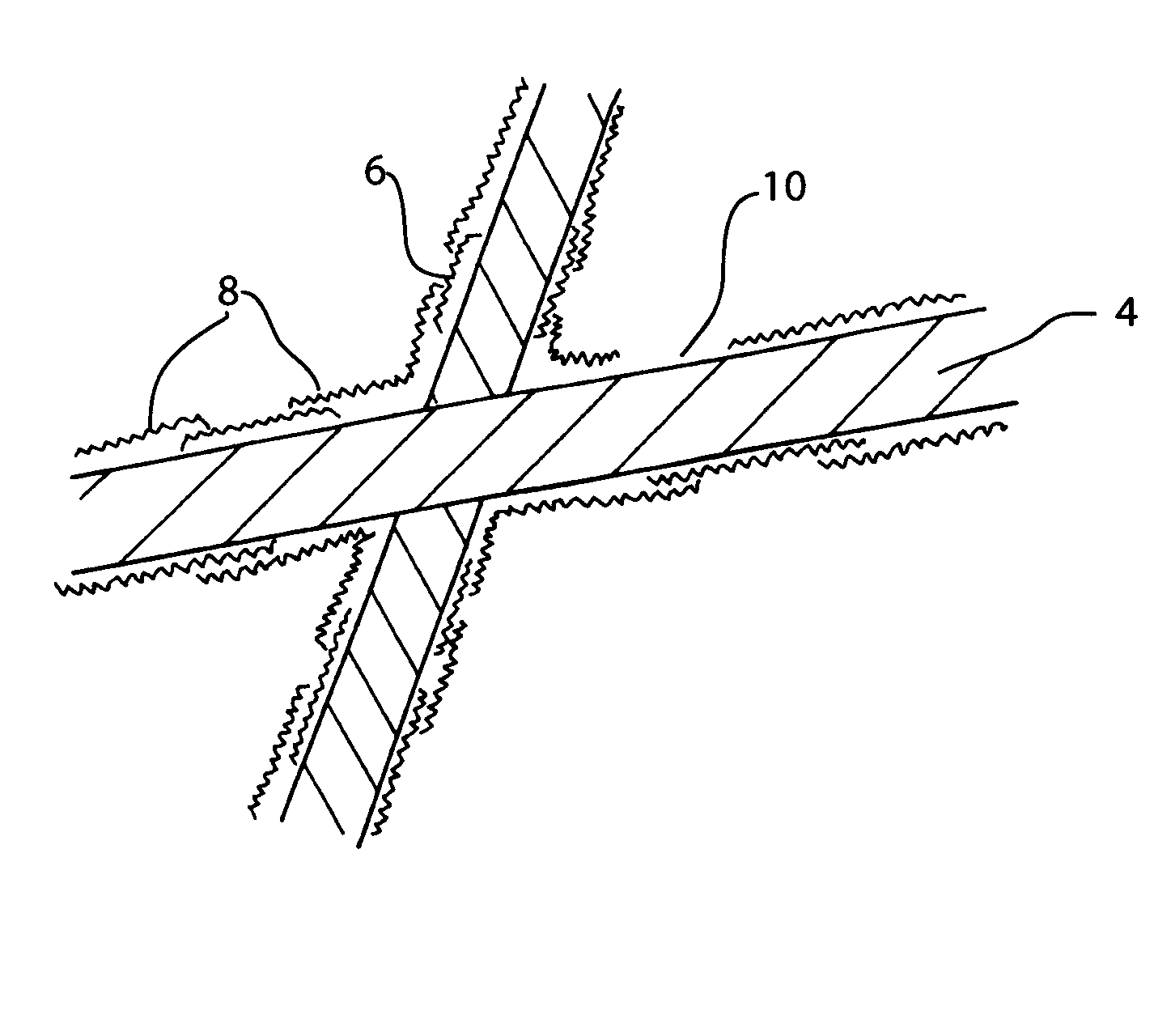

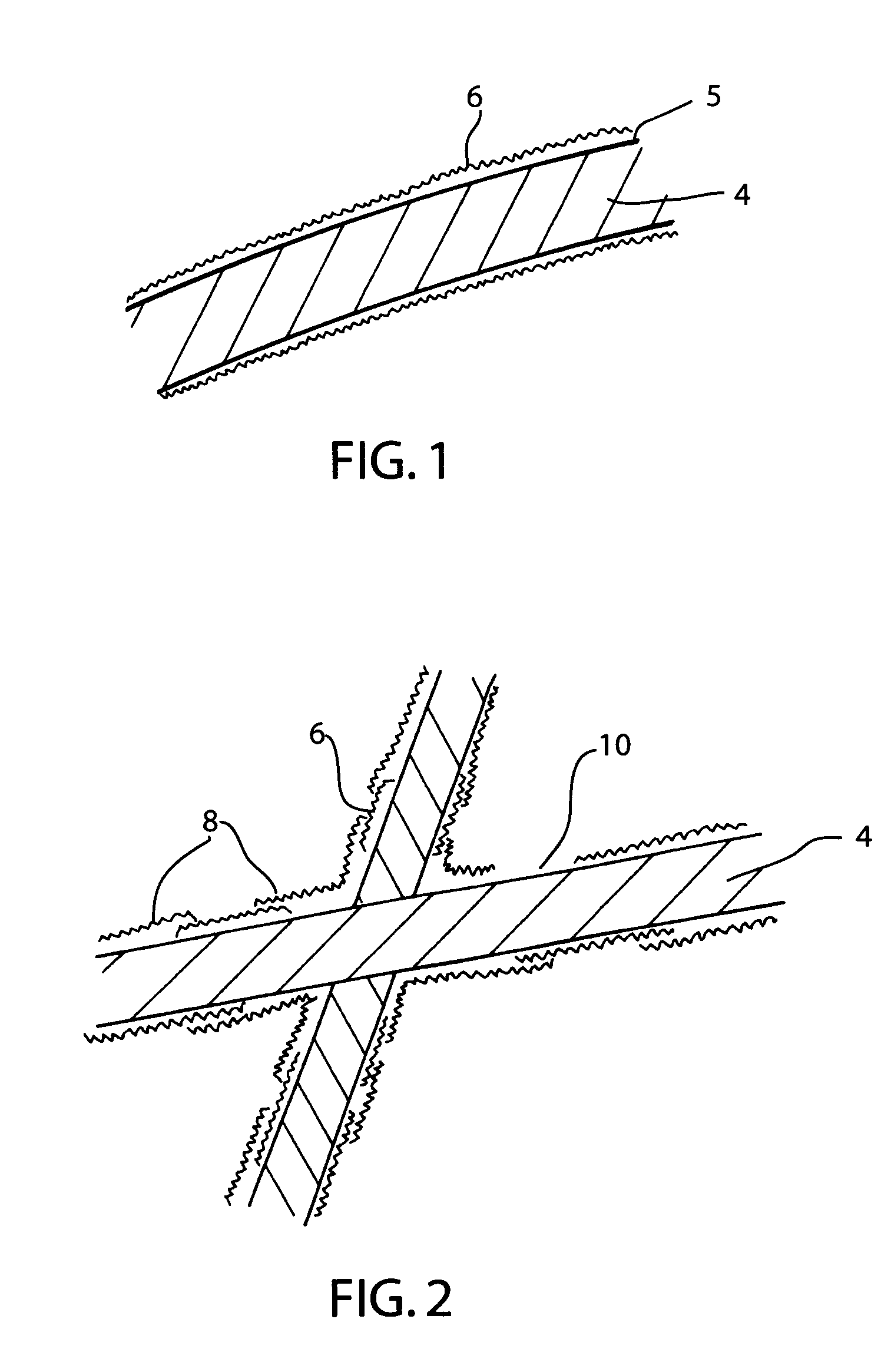

Fabrics with high thermal conductivity coatings

ActiveUS20050277350A1Improve thermal conductivityHigh thermal conductivity materialGlass/slag layered productsNatural mineral layered productsFiberCarbide

The present invention facilitates the thermal conductivity of fabrics by surface coating of the fabrics with high thermal conductivity materials 6. The fabrics may be surface coated when they are individual fibers or strands 4, bundles of strands, formed fabric or combinations therefore. A particular type of fibrous matrix used with the present invention is glass. Some fabrics may be a combination of more than one type of material, or may have different materials in alternating layers. HTC coatings of the present invention include diamond like coatings (DLC) and metal oxides, nitrides, carbides and mixed stoichiometric and non-stoichiometric combinations that can be applied to the host matrix.

Owner:SIEMENS ENERGY INC

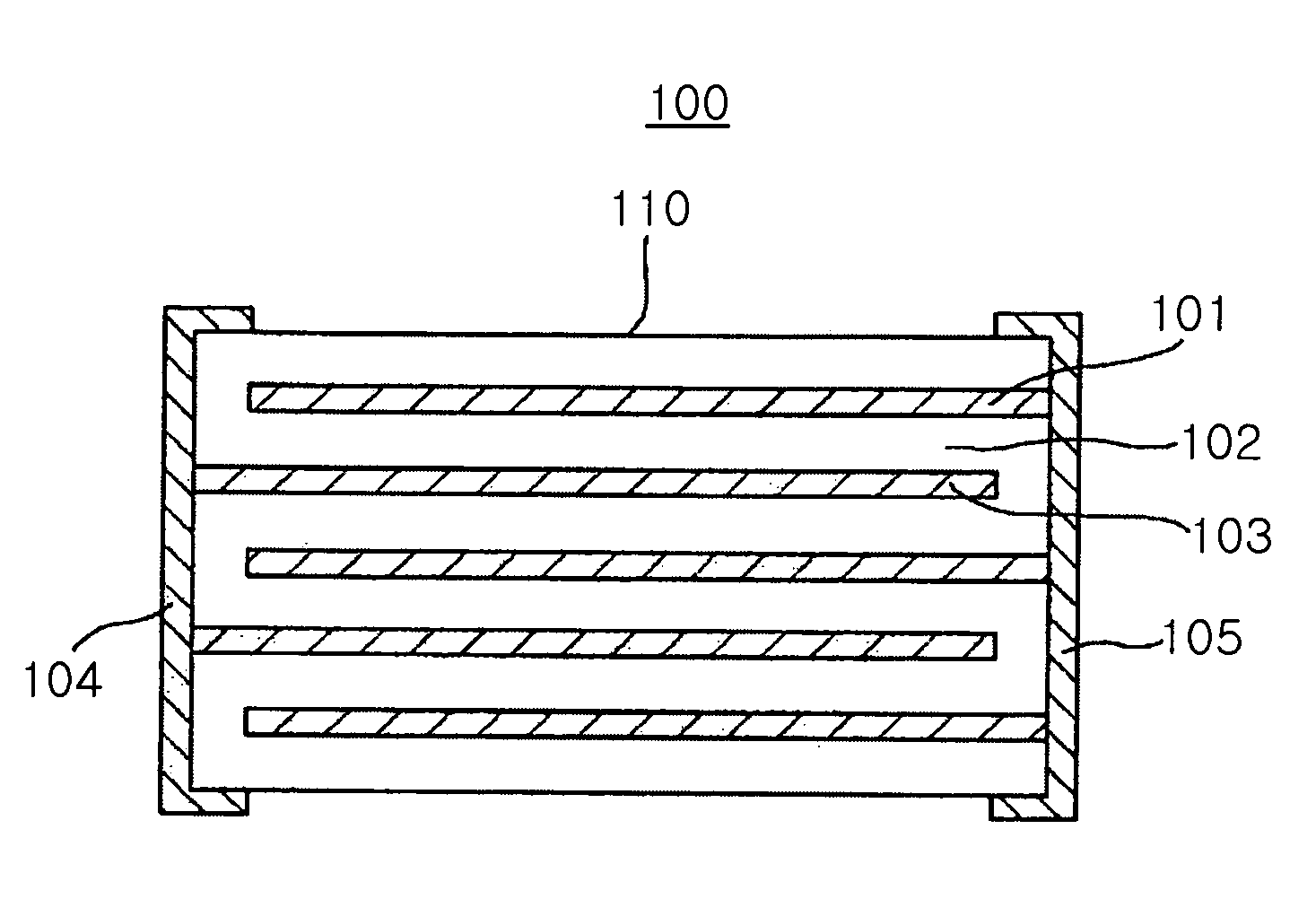

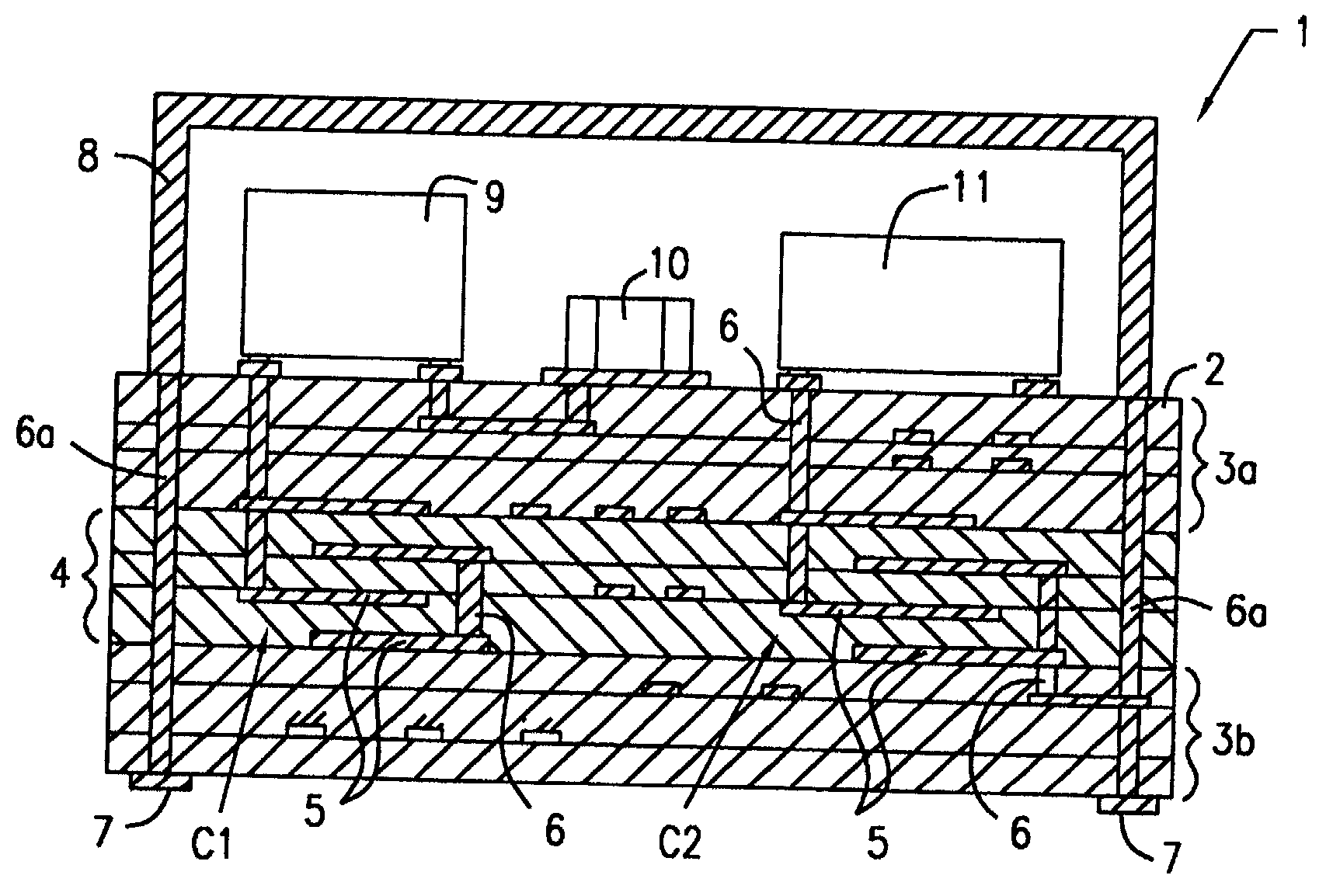

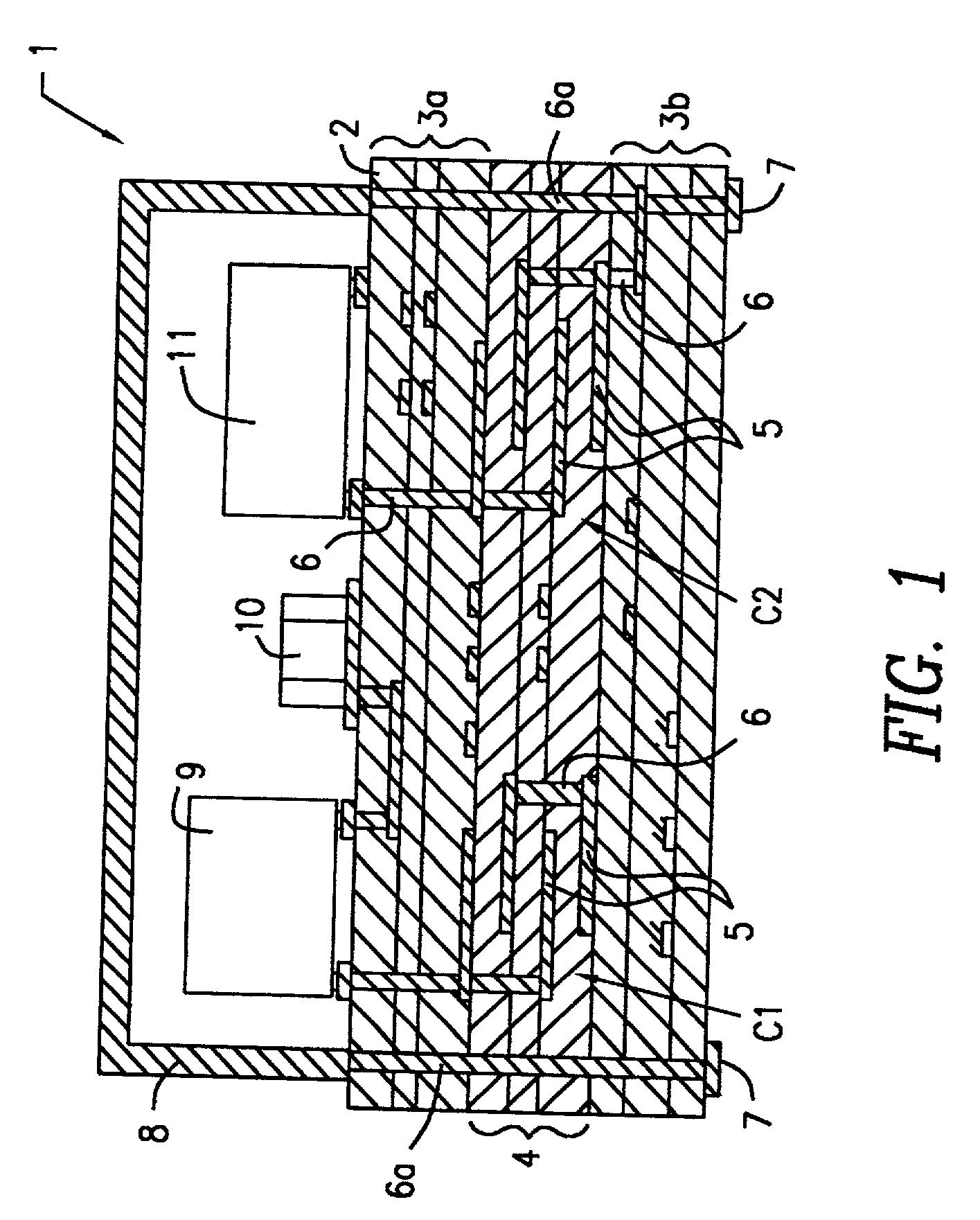

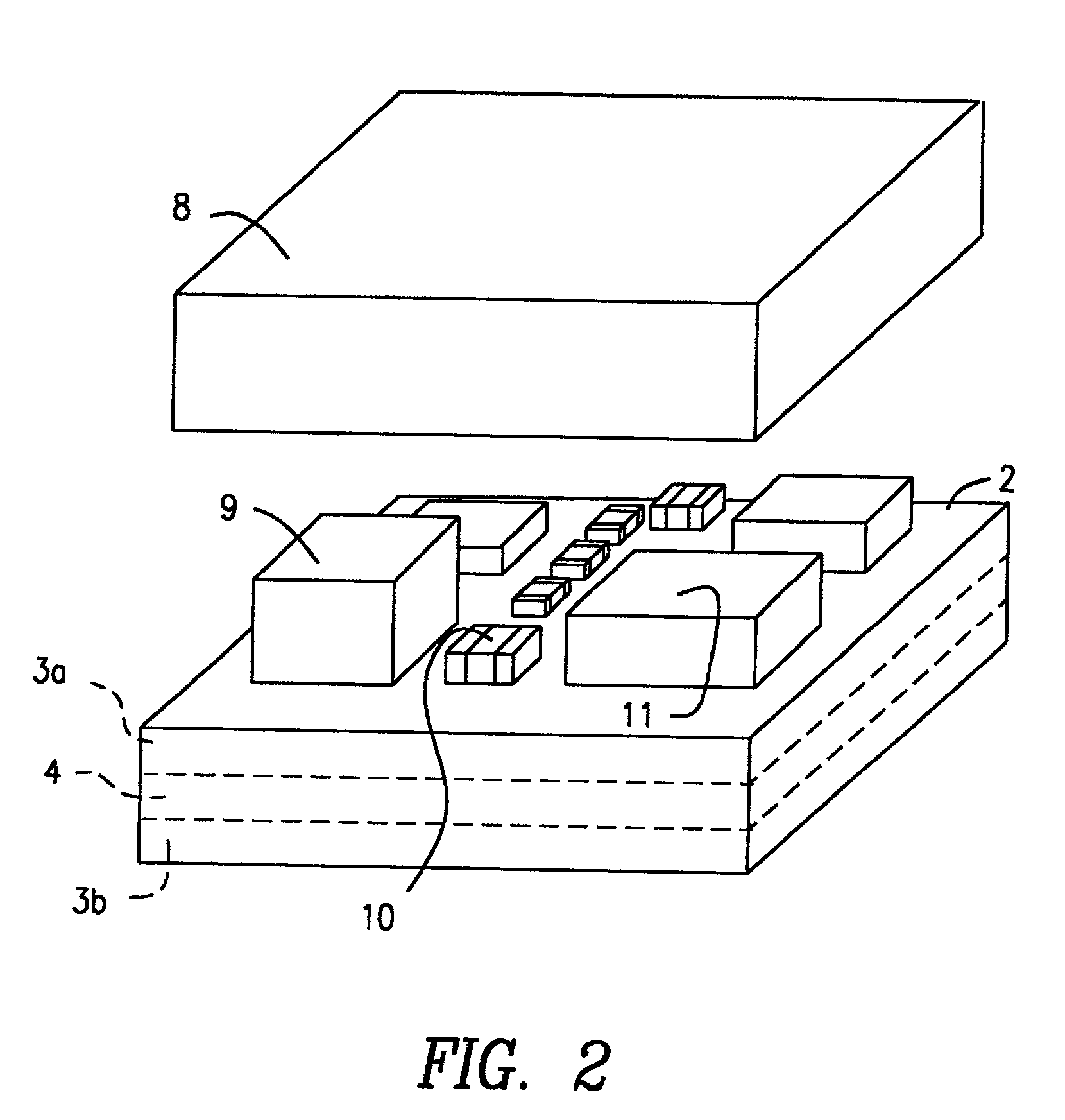

Dielectric ceramic composition for low-temperature sintering and hot insulation resistance and multilayer ceramic capacitor using the same

ActiveUS20090128988A1Improve featuresMinimize short circuit rateMaterial nanotechnologyFixed capacitor dielectricDielectricCeramic capacitor

A dielectric ceramic composition for low-temperature sintering and hot insulation resistance (hot IR) is capable of carrying out low-temperature sintering, improving a hot IR characteristic, and meeting X5R characteristics, and a multilayer ceramic capacitor makes use of the dielectric ceramic composition. The dielectric ceramic composition includes a main component BaTiO3, and sub-components, based on 100 moles of the main component, MgO of 0.5 moles to 2.0 moles, Re2O3 of 0.3 moles to 2.0 moles, MnO of 0.05 moles to 0.5 moles, V2O5 of 0.01 moles to 0.5 moles, BaO of 0.3 moles to 2.0 moles, SiO2 of 0.1 moles to 2.0 moles, and borosilicate glass of 0.5 moles to 3.0 moles, where Re includes at least one selected from the group consisting of Y, Ho and Dy.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

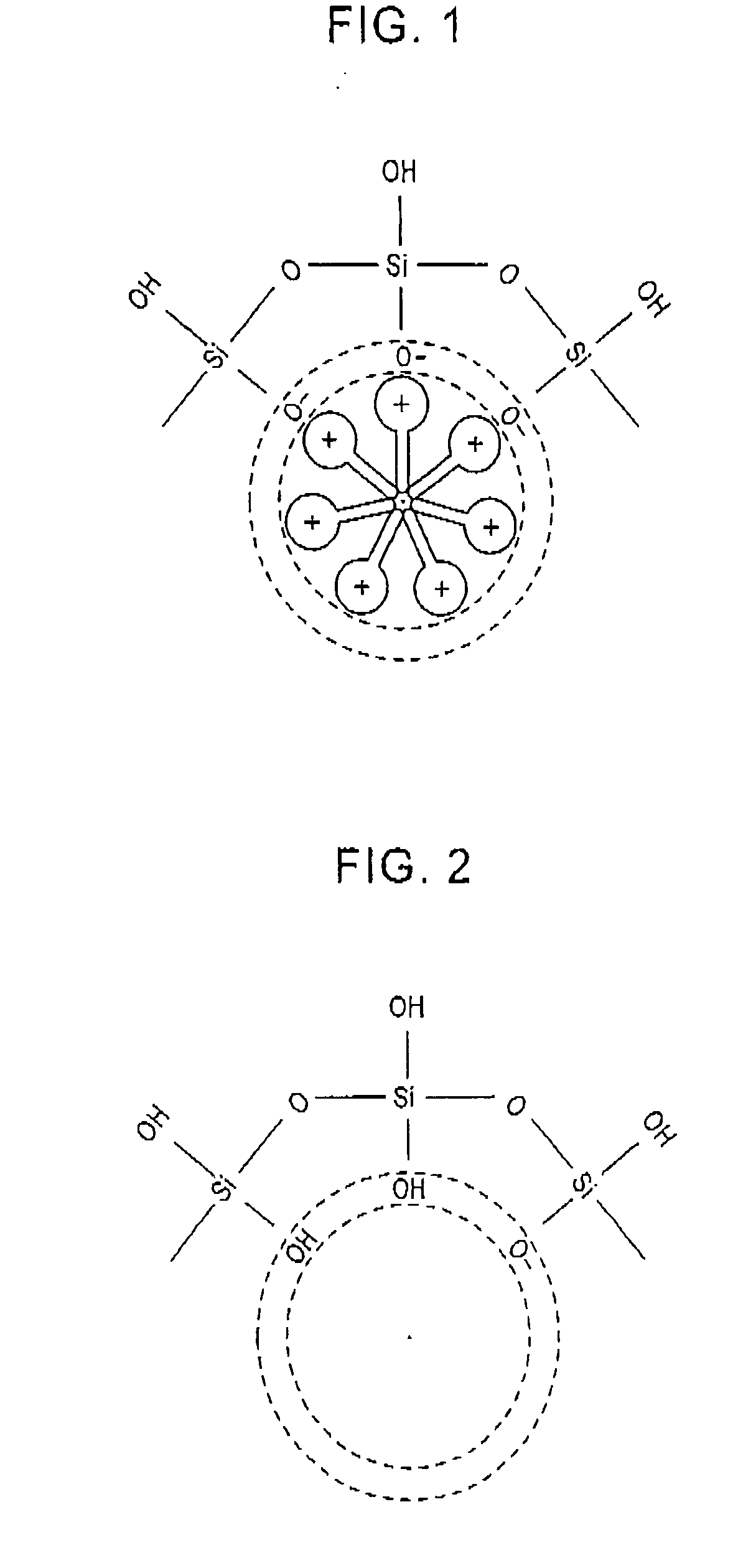

Method for producing porous material

InactiveUS20050119360A1High temporal stabilityGood time stabilitySilicaSemiconductor/solid-state device manufacturingReactive siteMaterials science

A method for producing a porous material exhibiting temporal stability includes the step of forming a primary material containing a matrix precursor for forming the matrix of the porous material and a porogen for forming pores; the step of removing the porogen from the primary material to form reactive sites exposed at the surface of the matrix; and the step of reacting the reactive sites with an inactivation promoter to inactivate the reactive sites. For a porous material hard to shrink even after heat treatment, the method includes the step of forming a primary material including a matrix formed of a matrix precursor and a pore-forming portions formed of a porogen; the step of supplying an additional matrix precursor for growing the matrix, dissolved in a supercritical or subcritical fluid; and the step of removing the porogen from the pore-forming portions.

Owner:KOBE STEEL LTD

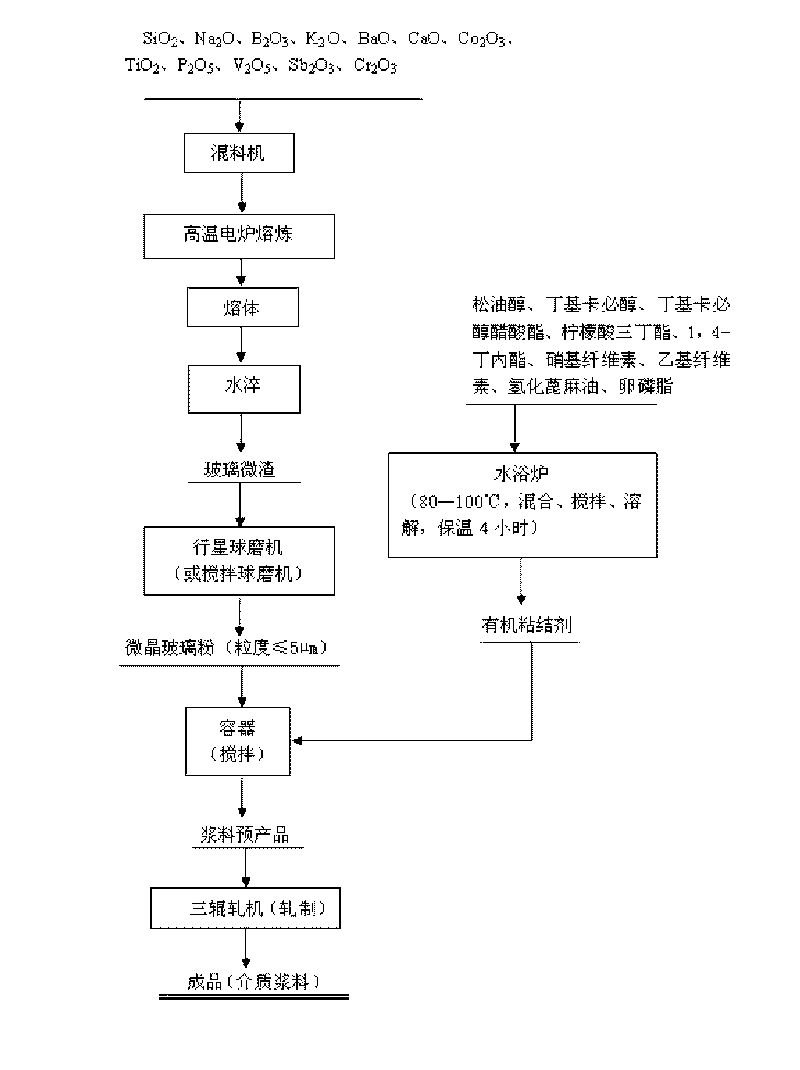

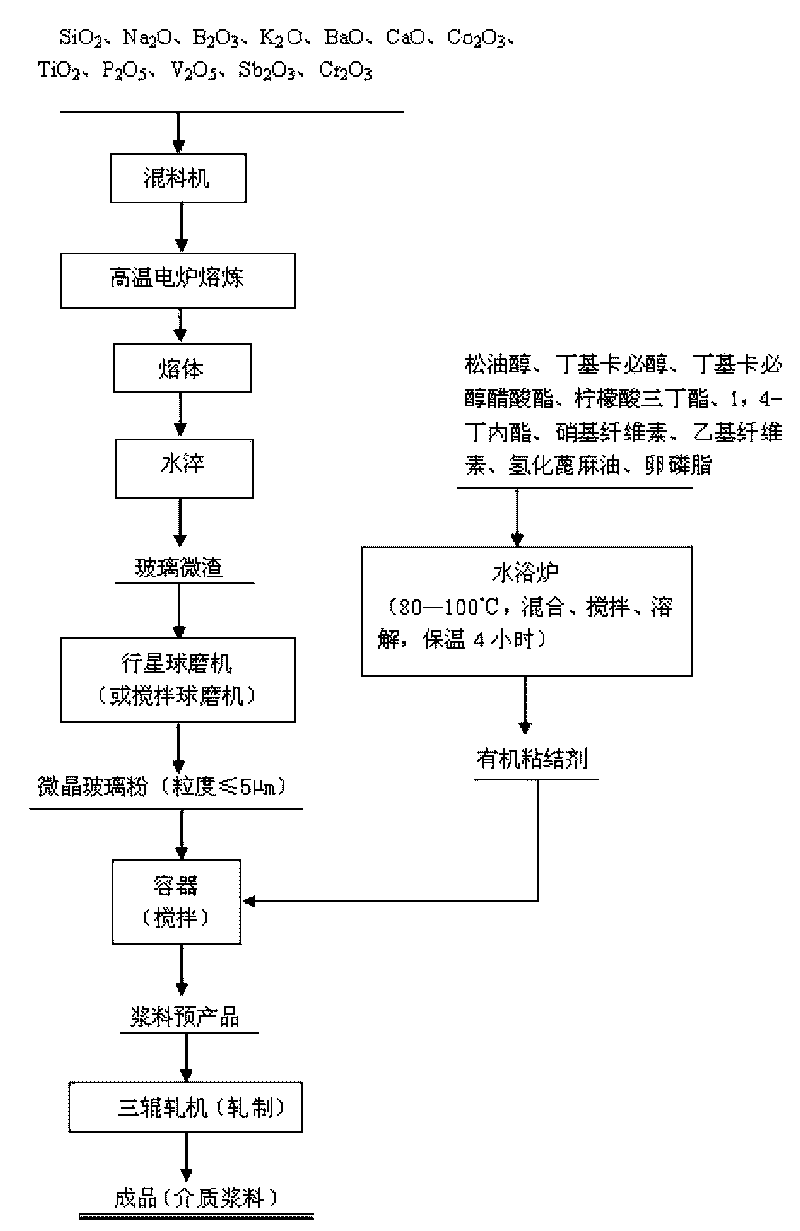

Dielectric paste for metal aluminum substrate thick film circuit and preparation method thereof

InactiveCN101740160AImprove thixotropyGood anti-sinking effectNon-macromolecular adhesive additivesSolid-state devicesDielectricCITRATE ESTER

The invention discloses dielectric paste for a metal aluminum substrate thick film circuit and a preparation method thereof. The invention aims to prepare the dielectric paste matched with a metal aluminum substrate. The dielectric paste is characterized in that SiO2, Na2O, B2O3, K2O, BaO, CaO, Co2O3, TiO2, P2O5, V2O5, Sb2O3 and Cr2O3 are combined to prepare microcrystalline glass powder; and the microcrystalline glass powder and an organic binder which consists of terpinol, butyl carbitol, butyl carbitol acetate, tirbutyl citrate, 1,4-butyrolactone, nitroncellulose, ethyecellulose, hydrogenated castor oil and lecithin are put in a vessel for stirring and rolling by a three-roll roller mill in a weight ratio of the microcrystalline glass powder to the organic binder of 70-90 parts: 30-10 parts so as to prepare the finished product dielectric paste. The dielectric paste is mainly used as the dielectric paste of the thick film circuit formed by being printed on the metal aluminum substrate.

Owner:湖南利德电子浆料股份有限公司

Composite coatings for groundwall insulation, method of manufacture thereof and articles derived therefrom

InactiveCN1992100AWindings insulation materialMaterial nanotechnologyNanoparticleThermosetting polymer

Disclosed herein is an article comprising an electrical component and an electrically insulating layer disposed upon the electrical component, wherein the electrically insulating layer comprises a thermosetting polymer and a nanosized filler, wherein the nanosized filler comprises metal oxide and diamond nanoparticles that have an average largest dimension of less than or equal to about 200 nanometers.

Owner:GENERAL ELECTRIC CO

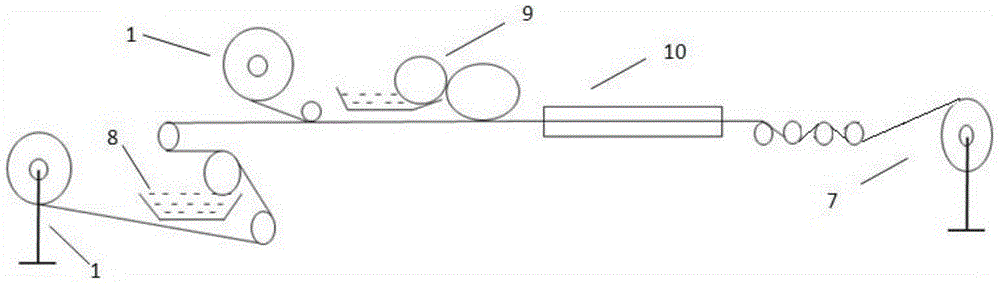

Insulating structure and production for vacuum-pressure immersing process of high-voltage motor

ActiveCN1819408AWindings insulation materialWindings insulation shape/form/constructionProduction lineVacuum pressure

The invention adopts a dry mica tape whole impregnation type VPI (vacuum pressure impregnation) insulation process for stator. It comprises: binding up with dry mica tape; after cog leaves the production line, the whole rotator is impregnated with solventliss epoxy in vacuum pressure condition to form a composite insulation structure of VPI process. It features: the epoxy of the insulation structure contains unsaturated bond, and after adding reactive diluent, the whole impregnation insulation epoxy with low viscosity, hypertonicity and wide adaptation is obtained.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

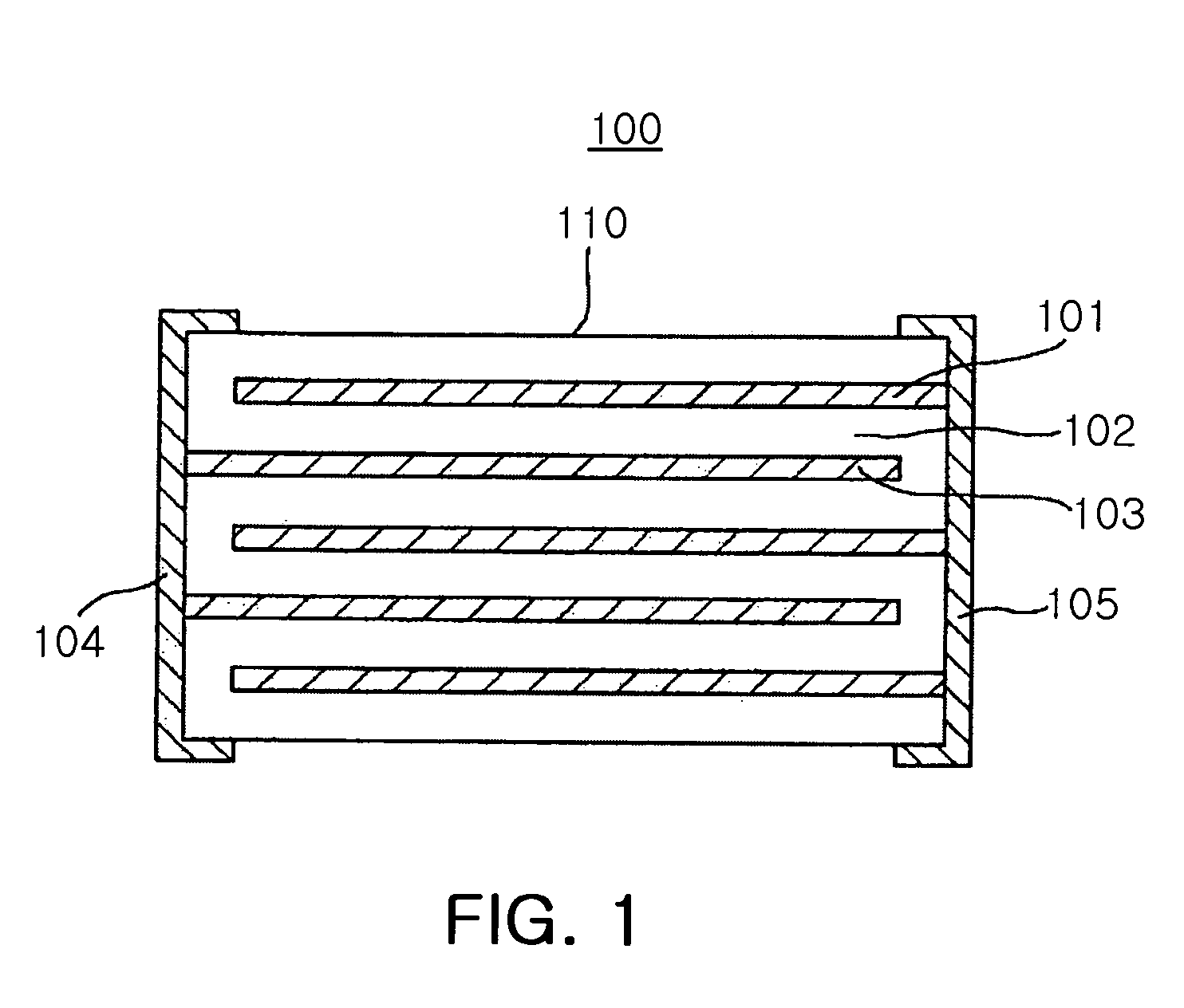

Dielectric ceramic composition, multilayer complex electronic device, multilayer common mode filter, multilayer ceramic coil and multilayer ceramic capacitor

ActiveUS20090278627A1Reduce DC resistanceMaintain good propertiesMultiple-port networksFixed capacitor dielectricCeramic capacitorDielectric permittivity

A dielectric ceramic composition comprises as a main component, Cu oxide, Si oxide and one selected from the group consisting of Zn oxide alone and a combination of Mg oxide and Zn oxide, as a subcomponent, a glass component including B oxide and at least one selected from the group consisting of Si oxide, Ba oxide, Ca oxide, Sr oxide, Li oxide and Zn oxide, and having a glass softening point is 750° C. or less, wherein a content of said glass component is 1.5 to 15 wt % with respect to 100 wt % of said main component.According to the present invention, a dielectric ceramic composition can be provided which is available to be sintered at low temperature (for example, 950° C. or lower) while comparatively decreasing contents of a glass component, which shows good properties (specific permittivity, loss Q value and insulation resistance), and which is available to perform cofiring different materials.

Owner:TDK CORPARATION

Insulative ceramic compact

InactiveUS20020027018A1Satisfactory high-frequency characteristicLow dielectric constantFixed capacitor dielectricCeramicsCeramic moldingSilicon oxide

An insulative ceramic compact is composed of a fired mixture of (A) a MgAl2O4, Mg3B2O6 and / or Mg2B205 ceramic powder, and (3) a glass powder including from about 13 to 50% by weight of silicon oxide in terms of SiO2, from 8 to 60% by weight of boron oxide in terms of B2O3, about 20% by weight or less of aluminum oxide in terms of A12O3, and from about 10 to 55% by weight of magnesium oxide in terms of MgO. The insulative ceramic compact can be obtained by firing at low temperatures of about 1000° C. or less, can be obtained by sintering with Ag or Cu, has a low dielectric constant and a high Q value, and is suitable for use in the high-frequency range.

Owner:MURATA MFG CO LTD

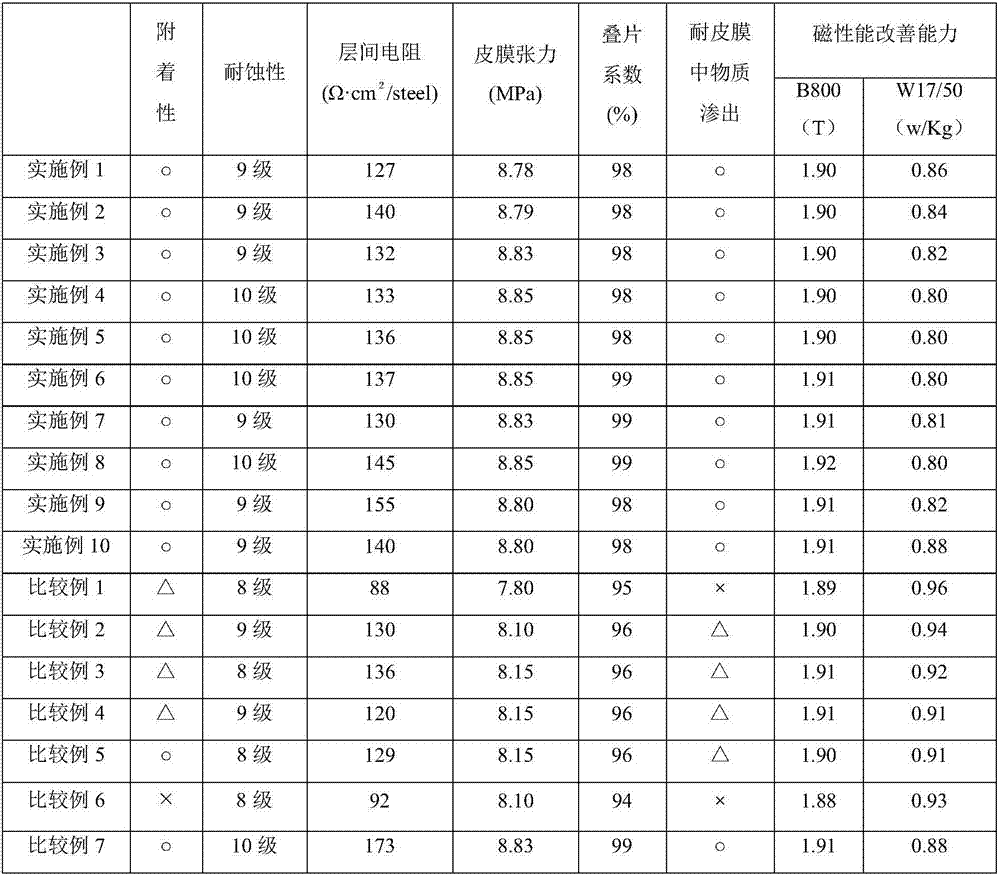

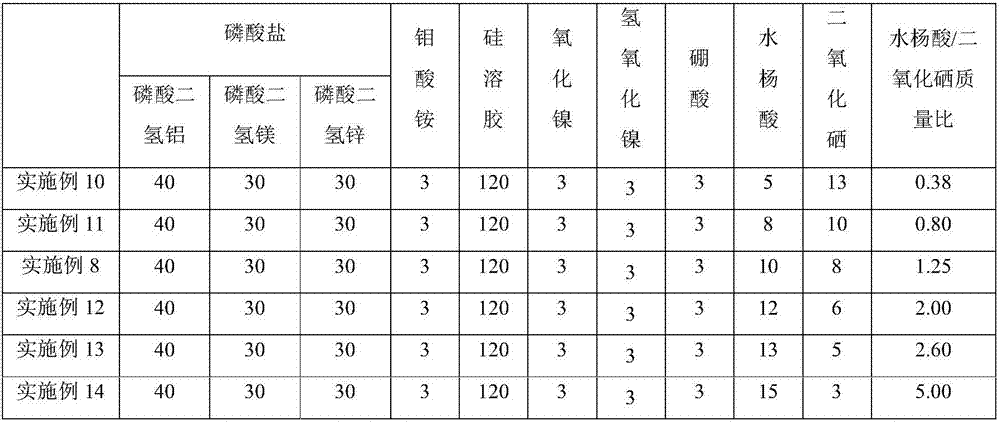

Chrome-free insulating coating composition and preparation method and oriented silicon steel plate

ActiveCN107190252AEasy to recycleImprove the level ofInorganic material magnetismQuartz/glass/vitreous enamelsOrganic acidMolybdate

The invention provides a chrome-free insulating coating composition and a preparation method and an oriented silicon steel plate. The coating composition comprises the following components of, by weight, 100 parts of phosphate solutions, 1-5 parts of molybdate, 50-150 parts of silica sols, 3-13 parts of selenium dioxide, 1-10 parts of metallic oxide and / or metal hydroxide, 5-15 parts of organic acid, 1-6 parts of boric acid and 100-300 parts of water. The preparation method of the composition comprises the steps that the phosphate solutions, the boric acid and the water are added; the selenium dioxide and the organic acid are sequentially added; and the metallic oxide and / or metal hydroxide and the molybdate are added, then the silica sols are added, and the composition is obtained. The oriented silicon steel plate comprises a pedestal and a chrome-free insulating coating formed on the surface of the pedestal, and the chrome-free insulating coating is obtained by coating the chrome-free insulating coating composition on the surface of the pedestal. The chrome-free insulating coating has extremely high interlayer resistance, surface hardness and surface tension and shows the excellent magnetic property improved effect.

Owner:WUHAN YUANRONG TECH CO LTD

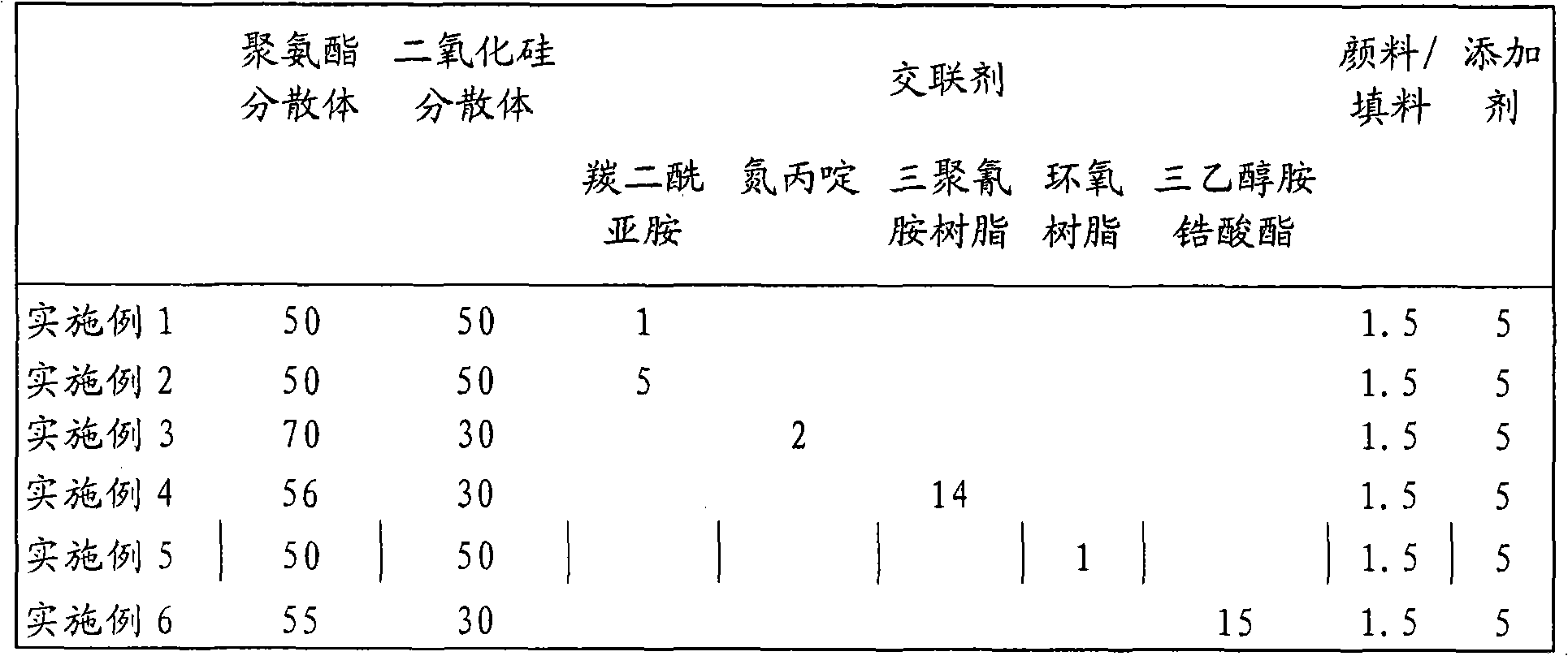

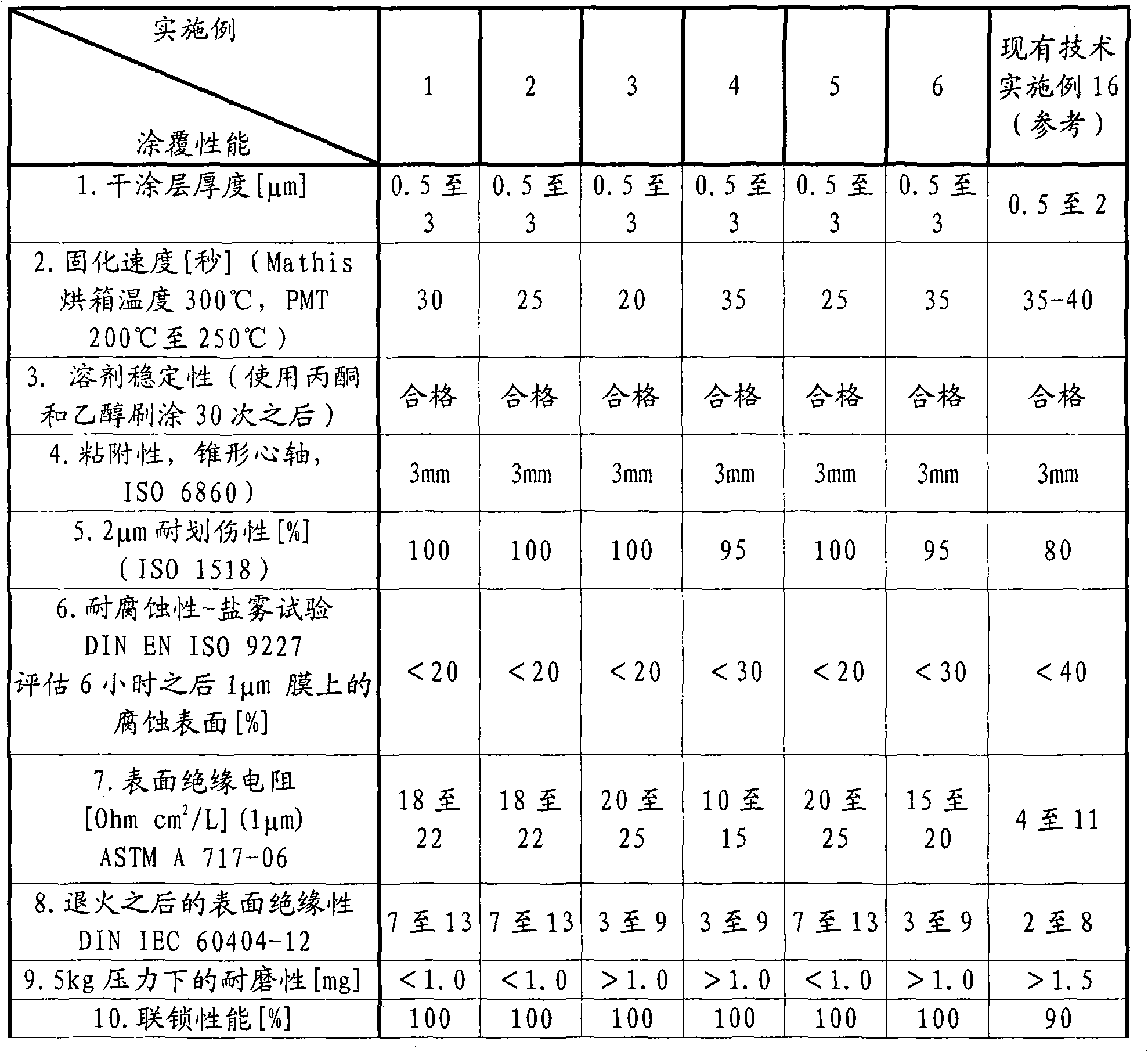

Insulation coating composition for electrical steel

ActiveCN101848964APromote resultsImprove scratch resistanceMaterial nanotechnologyPlastic/resin/waxes insulatorsPolymer scienceElectrical steel

The invention provides a coating composition to coat electrical steel sheets, the composition comprising: A) 5 to 45 weight% of at least one binder resin, B) 0.1 to 40, preferably 1 to 30 weight% of nano scaled particles, the particles having an average radius ranging from 1 to 300 nm, C) at least one cross-linking agent in an amount able to cross-link with the binder resin, preferably 0.1 to 30 weight% of at least one cross-linking agent, D) 0.1 to 60 weight% of at least one additive and / or pigment and / or filler, and E) 5 to 70 weight% of water and / or at least one solvent, the weight% based on the total weight of the composition. The composition according to the invention makes it possible to provide a high property profile standard combining the different technical requirements such as high ability for welding, clamping, interlocking, punching, riveting, high pressure, thermal resistance of electrical steel sheets coated with the composition according to the invention and of cores produced from these coated electrical steel sheets.

Owner:AXALTA COATING SYST GMBH

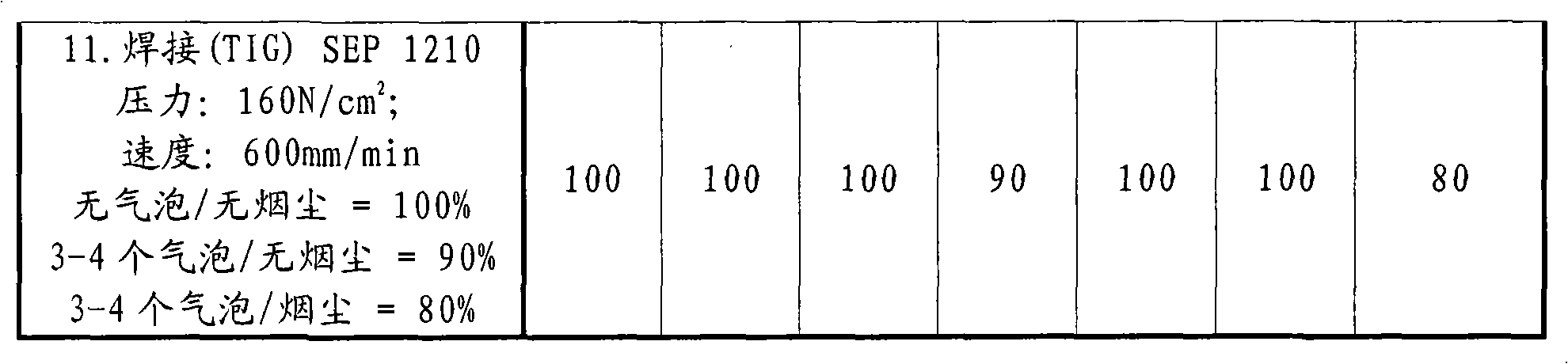

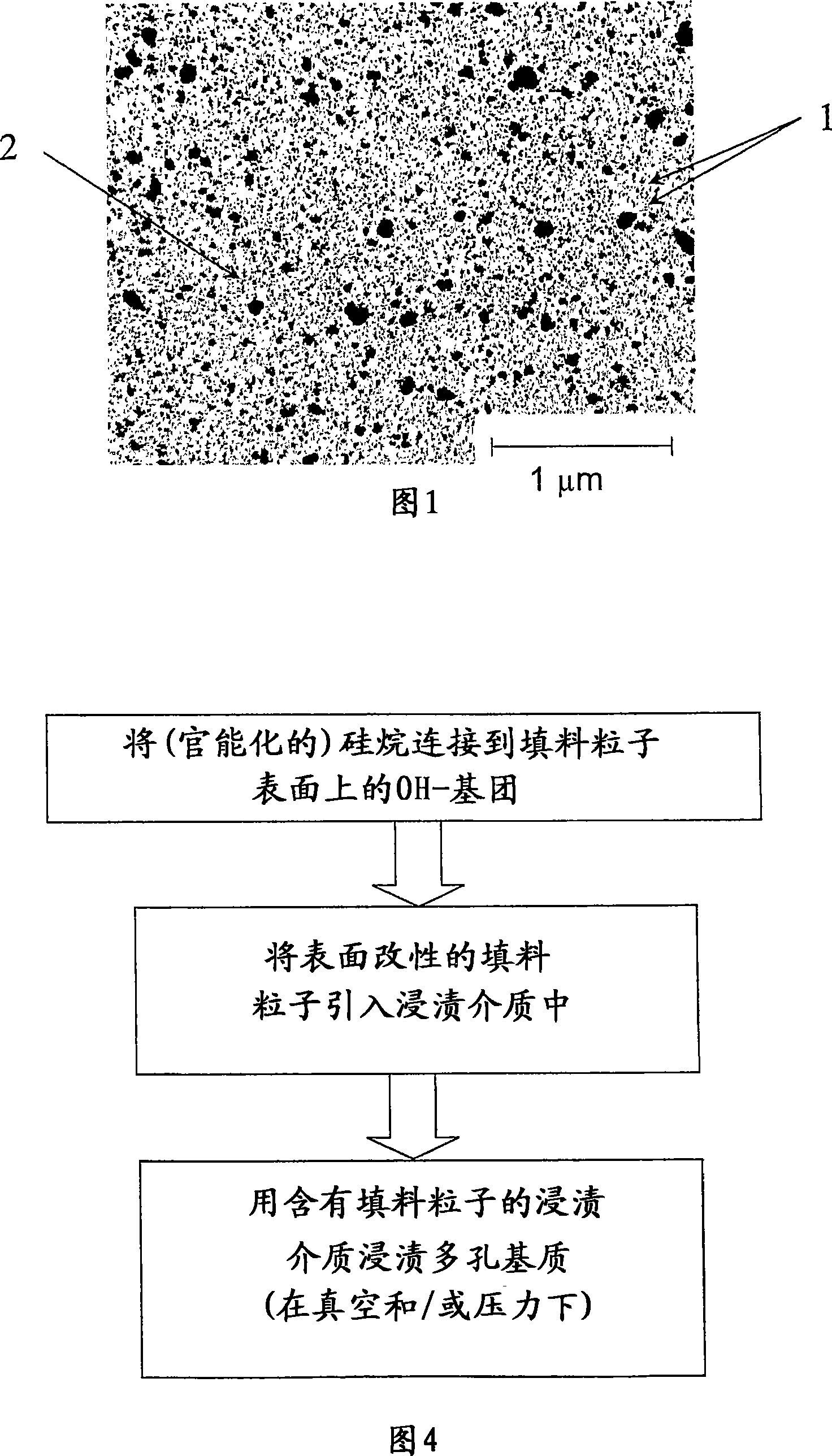

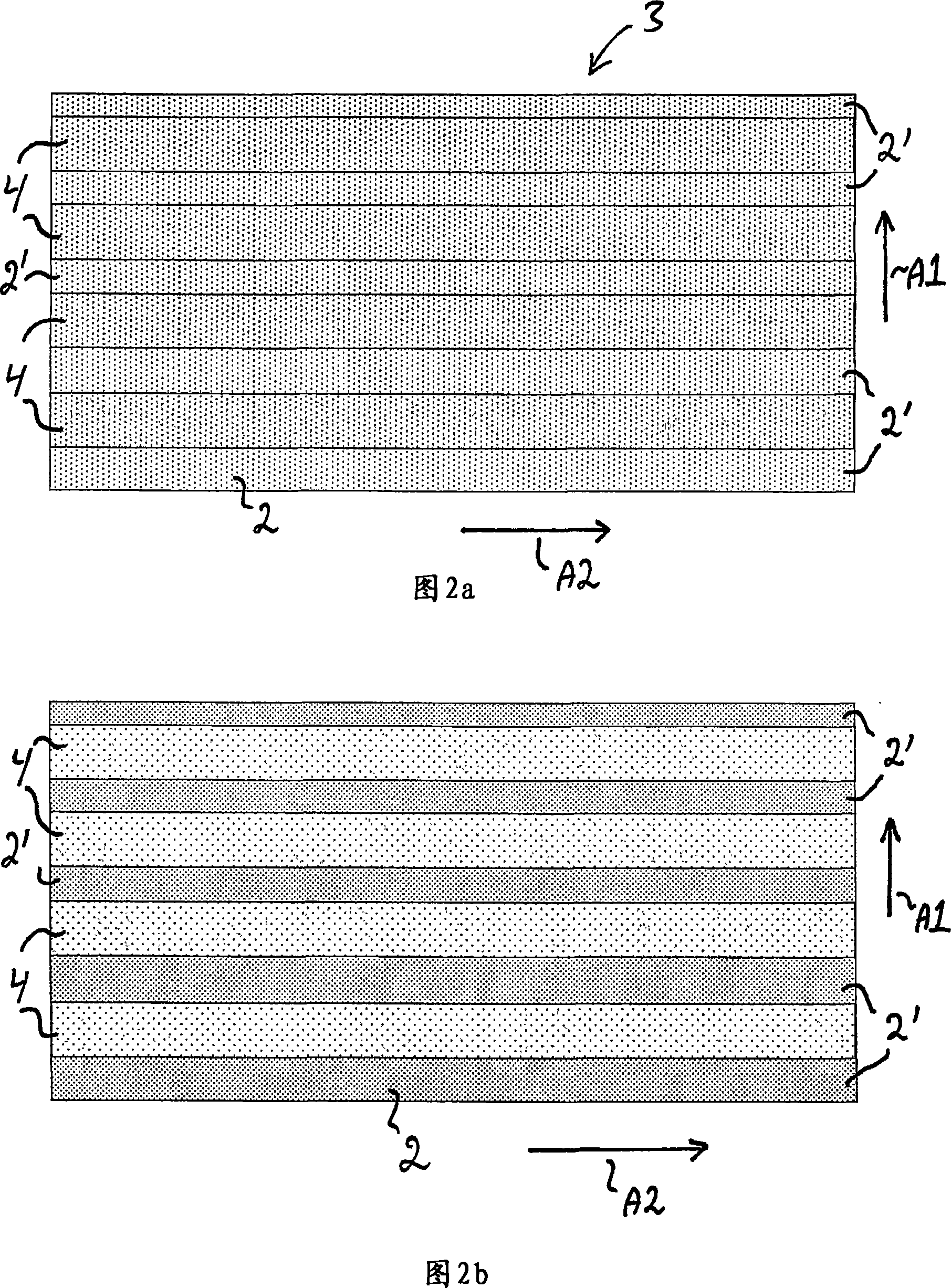

Electric insulation material, an electric device and a method for producing an electric insulation material

The invention relates to an electric insulation material (3) formed by a porous fibrous matrix that is impregnated with an impregnation medium (2) containing filler particles (1) having higher thermal conductivity than the impregnation medium and having at least one dimension smaller than 1m, preferably having at least one dimension smaller than 100 nm, the fibrous matrix (4) being at least partly penetrated by such filler particles (1) of the impregnation medium (2).

Owner:ABB RES LTD

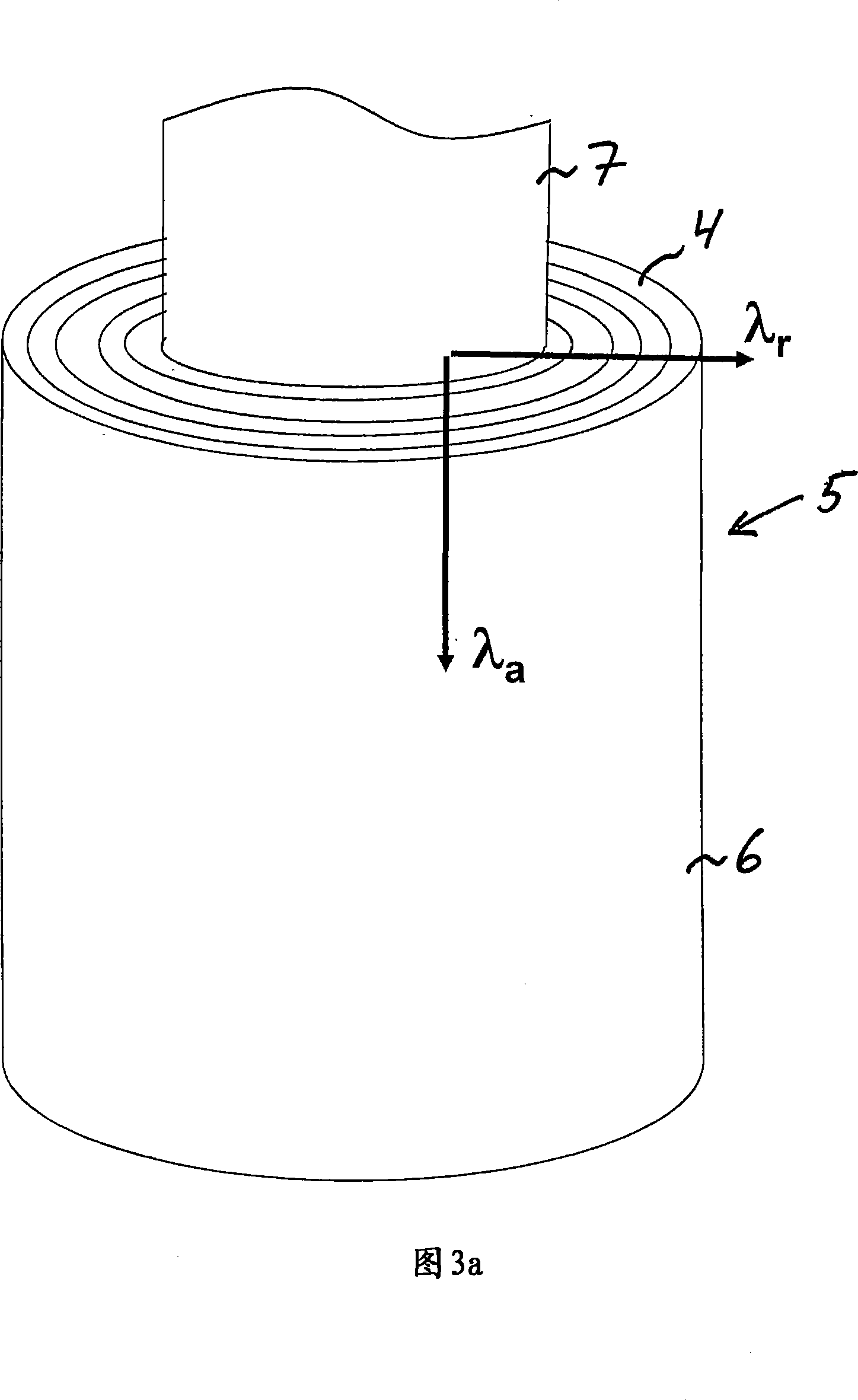

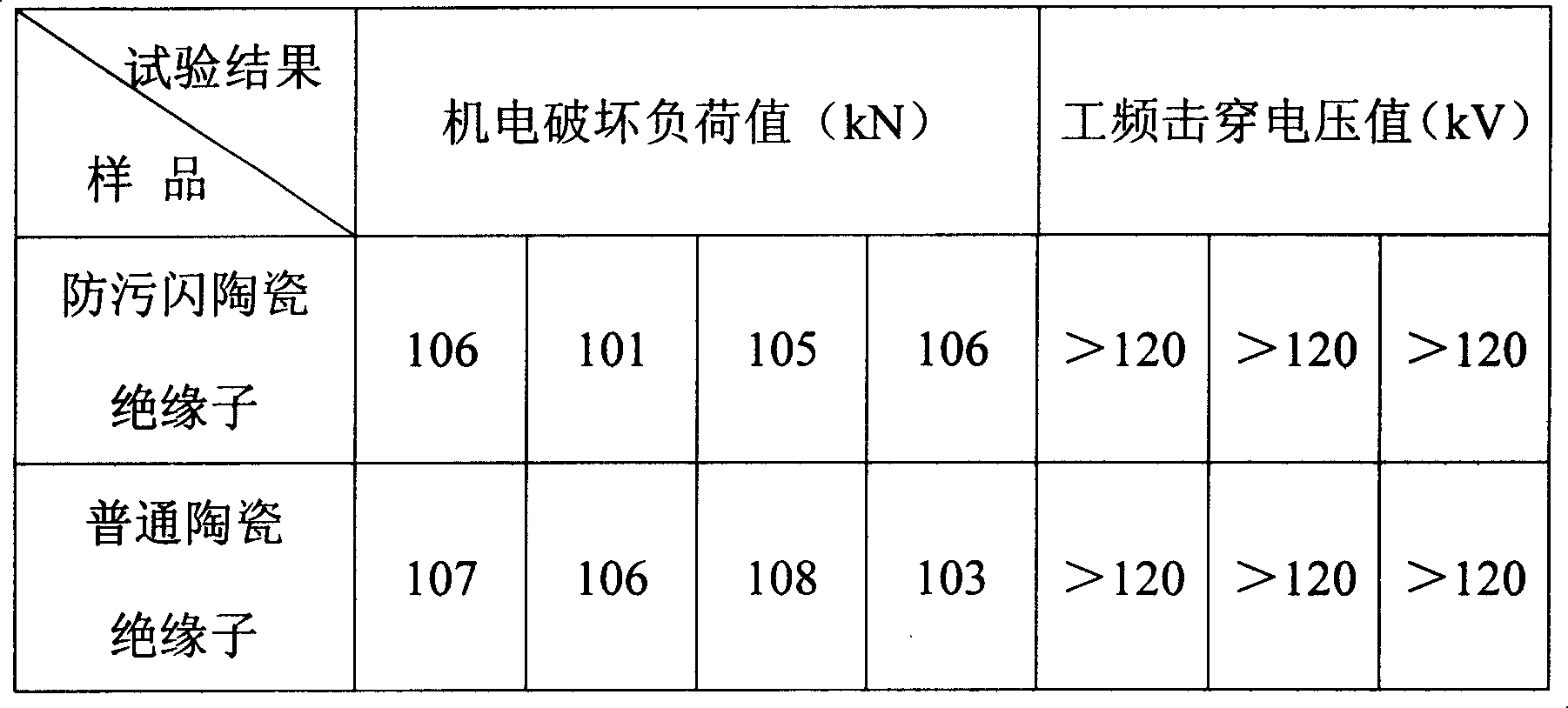

Method for manufacturing anti pollution flashover high tension ceramic and glass insulators

ActiveCN1686951AAnti-agingBest integrated anti-fouling flash functionQuartz/glass/vitreous enamelsHigh pressureSurfactant free

The present invention discloses a high voltage ceramic and glass insulator with the function of resisting pollution flashover and its preparation method. Said method includes the following processes: firstly, preparing titanium dioxide base sol, adding surfactant into the sol, then applying the titanium dioxide sol containing the above-mentioned surfactant or containing no surfactant on the surface of high-voltage ceramic and glass insulator, low-temperature heat treatment to make the titanium dioxide sol be solidified on the insulator surface so as to form a layer of nano inorganic film capable of raising pollution flashover resisting function of genral ceramic insulator.

Owner:FUZHOU UNIV +2

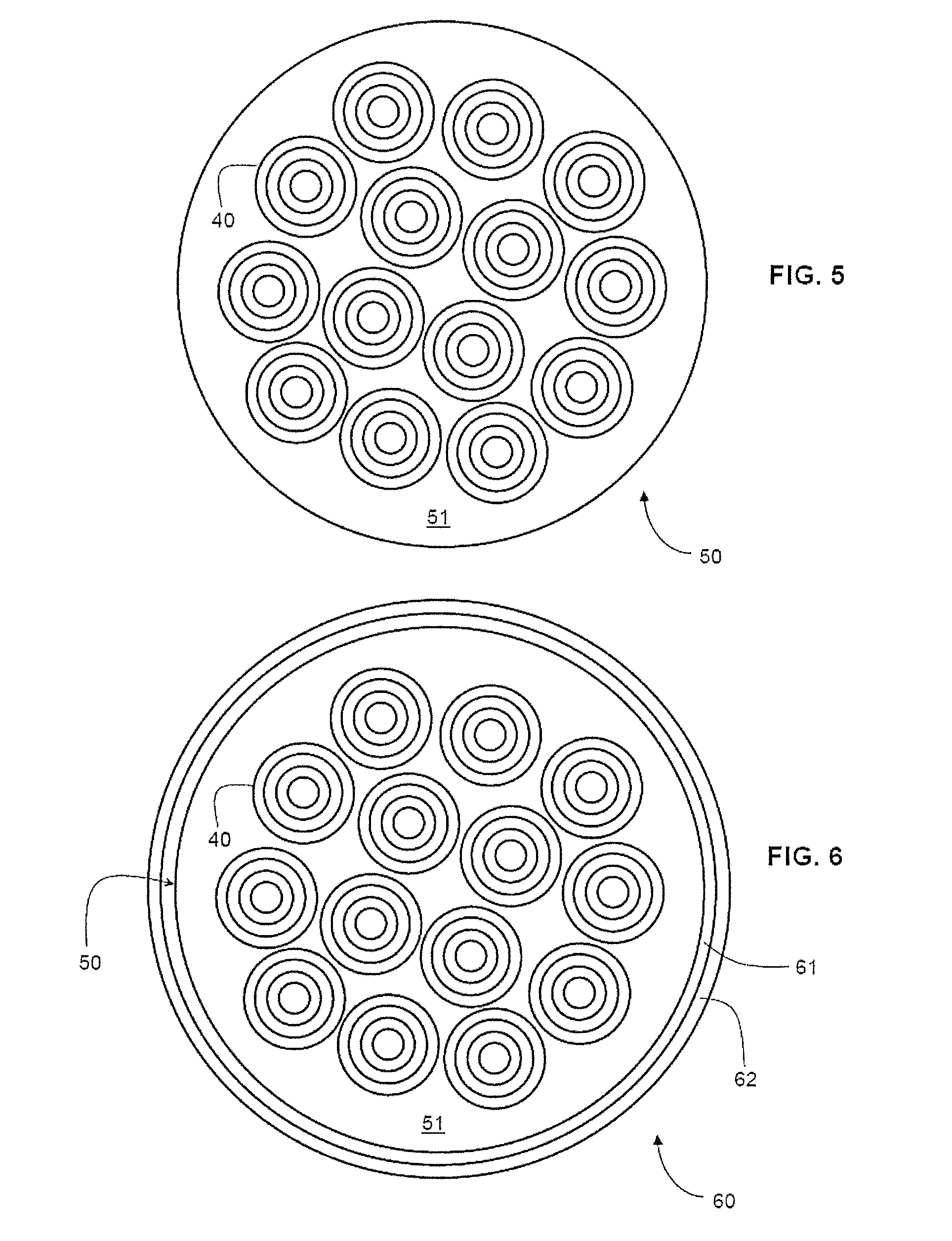

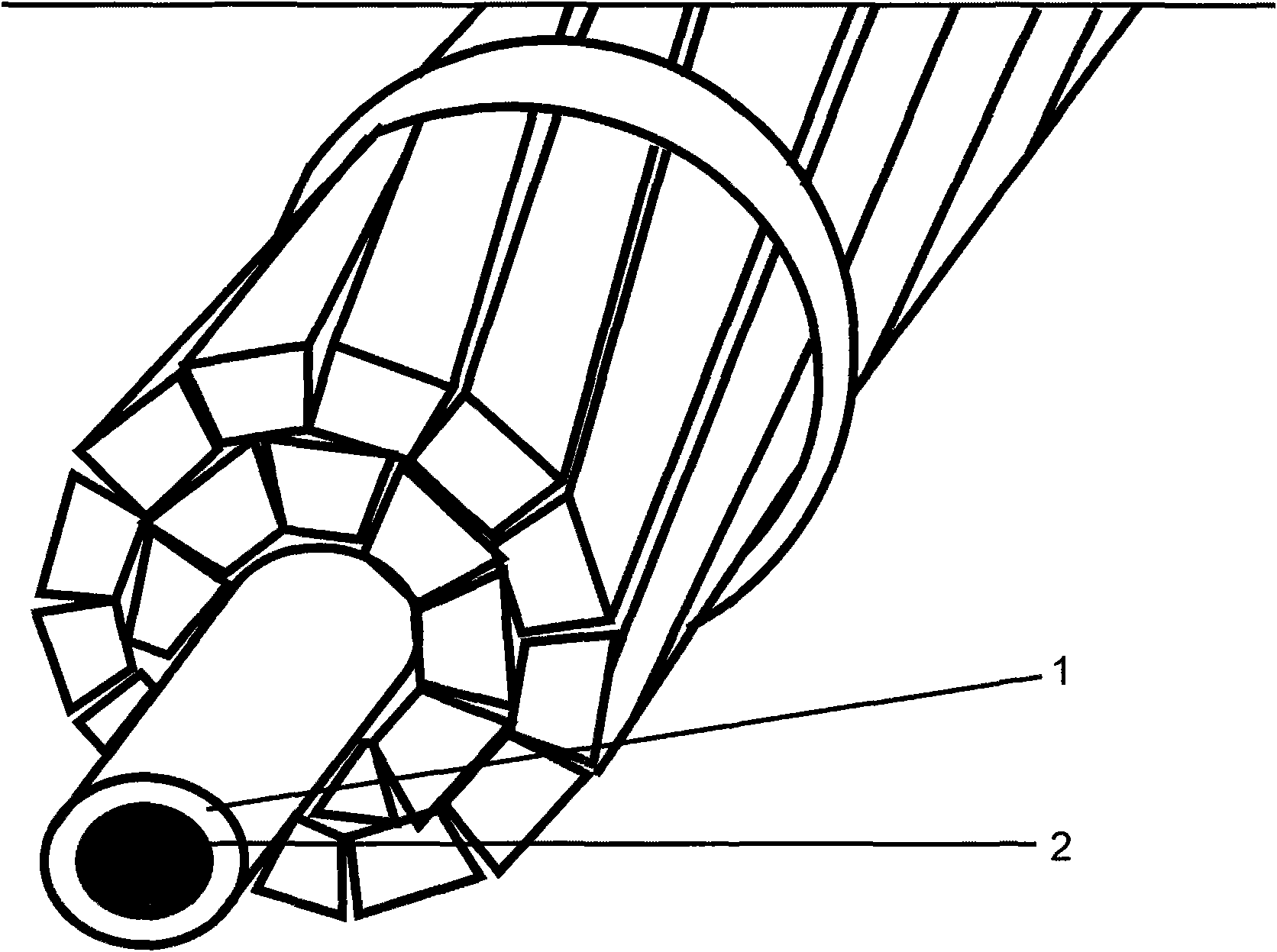

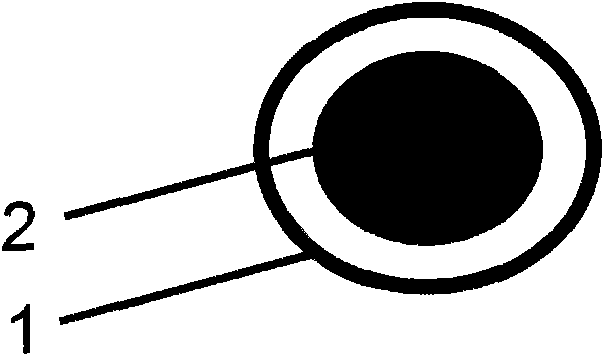

High voltage transmission line cable based on textile composite material

An electric transmission cable having a current conductive element comprising a braided core formed of a plurality of high modulus synthetic armored yarns, each yarn being of at least 53.6 tex and having a tensile strength of at least 200 cN / tex (centiNewton / tex), and the core being of a diameter in the range of 0.7 mm to 4.5 mm and being surrounded by a quartz sleeve covered on an outer surface thereof by a carbon layer.

Owner:SIMENHAUS ZIDKIYAHU +1

Environment-friendly glass frit and preparation method thereof

InactiveCN101794639AAdjust insulationAdjust acid resistanceQuartz/glass/vitreous enamelsNon-adjustable resistorsFritPlasticizer

The invention discloses environment-friendly glass frit and a preparation method thereof. The glass frit comprises the following components in percentage by weight: 55-75% of lead-free glass powder, 10-20% of carriers, 5-20% of pigment mixed liquor, 2-10% of solvents, 1-5% of plasticizers and 0.5-2% of dispersing agents. In the invention, the insulativity, the acid resistance and the printability of the product can be adjusted by changing the addition ratio of the glass powder; the viscosity and the printability of the product can be adjusted by changing the addition ratio of the organic carriers; the plasticity, the leveling property and the printability of the product can be adjusted by changing the addition ratio of the plasticizers; and the pollution-free product with good flatness and insulating property is obtained under the condition of sintering at 530-600 DEG C.

Owner:IRICO

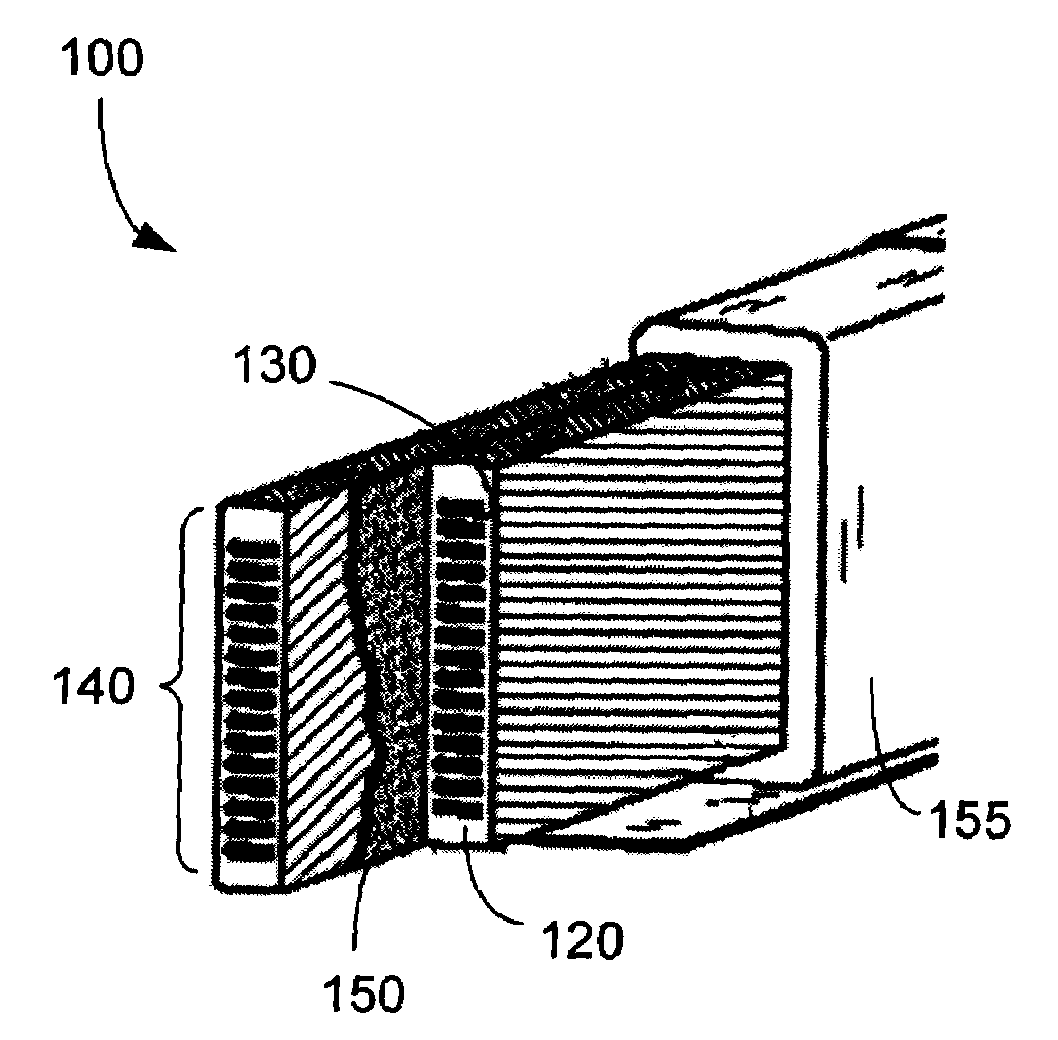

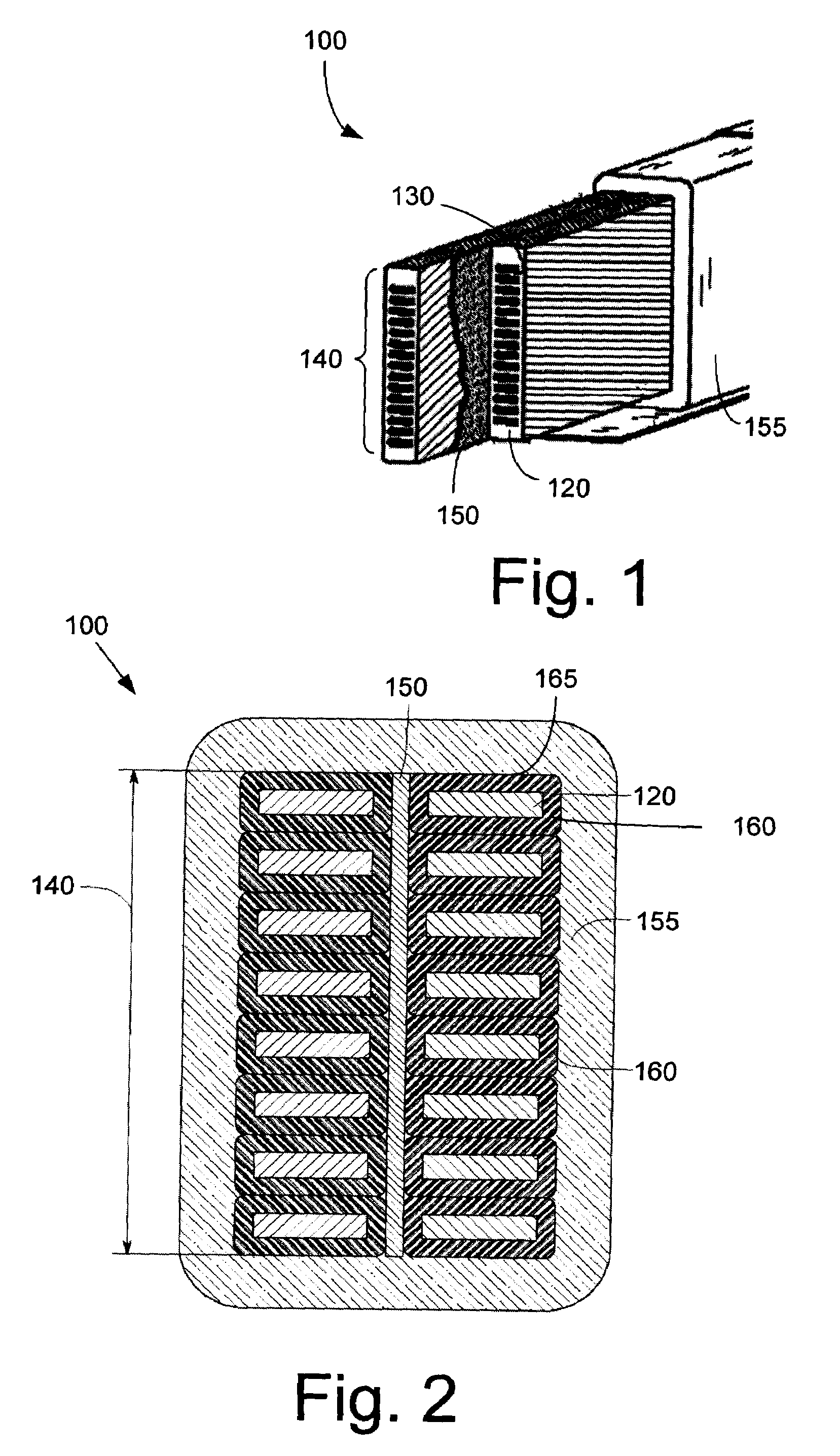

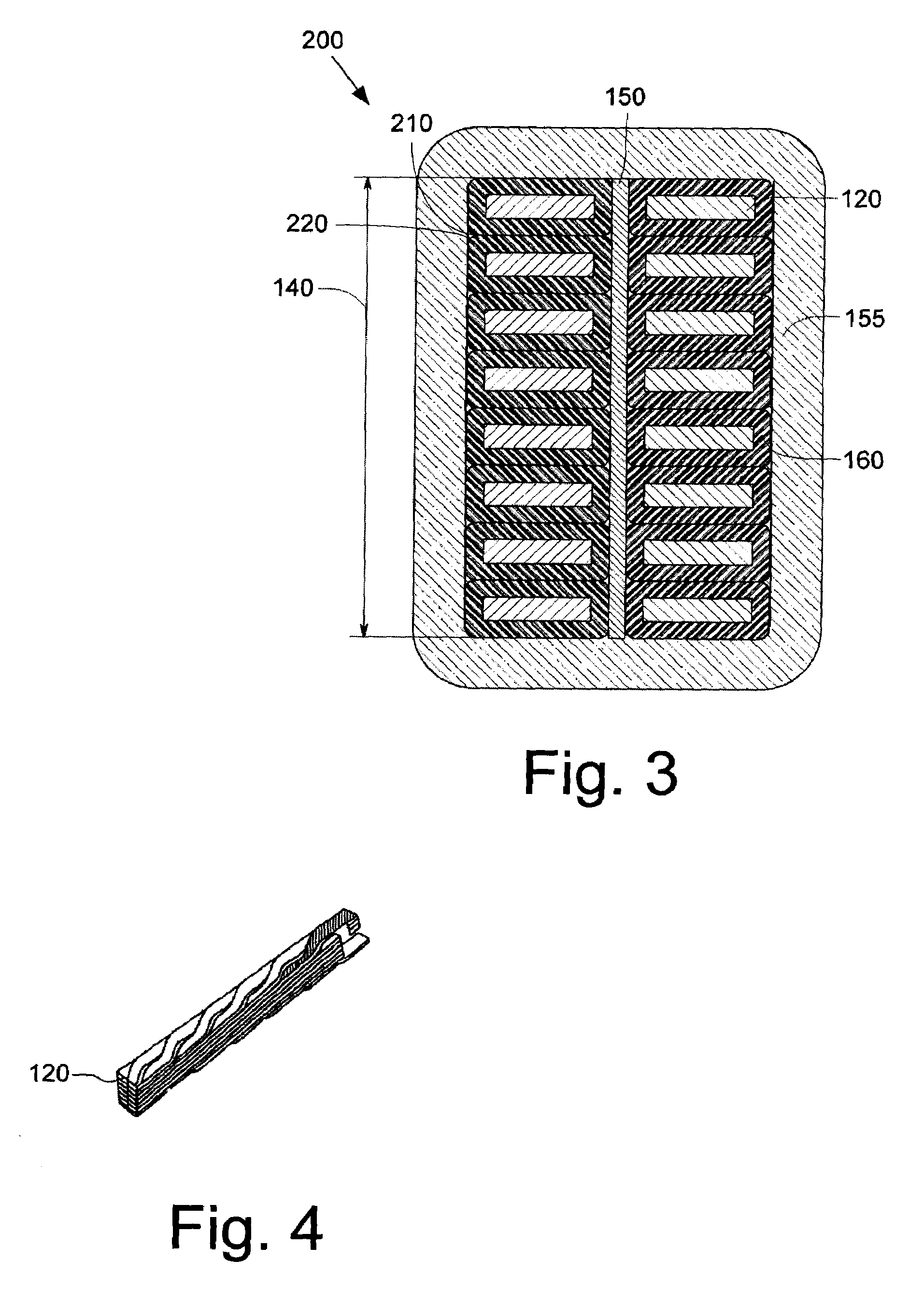

Stator Bar Components with High Thermal Conductivity Resins, Varnishes, and Putties

InactiveUS20090174279A1Improve thermal conductivityWindings insulation materialWindings insulation shape/form/constructionElectrical conductorVarnish

A stator bar. The stator bar may include a conductor, a layer of insulation positioned about the conductor, and a high thermal conductivity varnish to bond the layer of insulation to the conductor.

Owner:GENERAL ELECTRIC CO

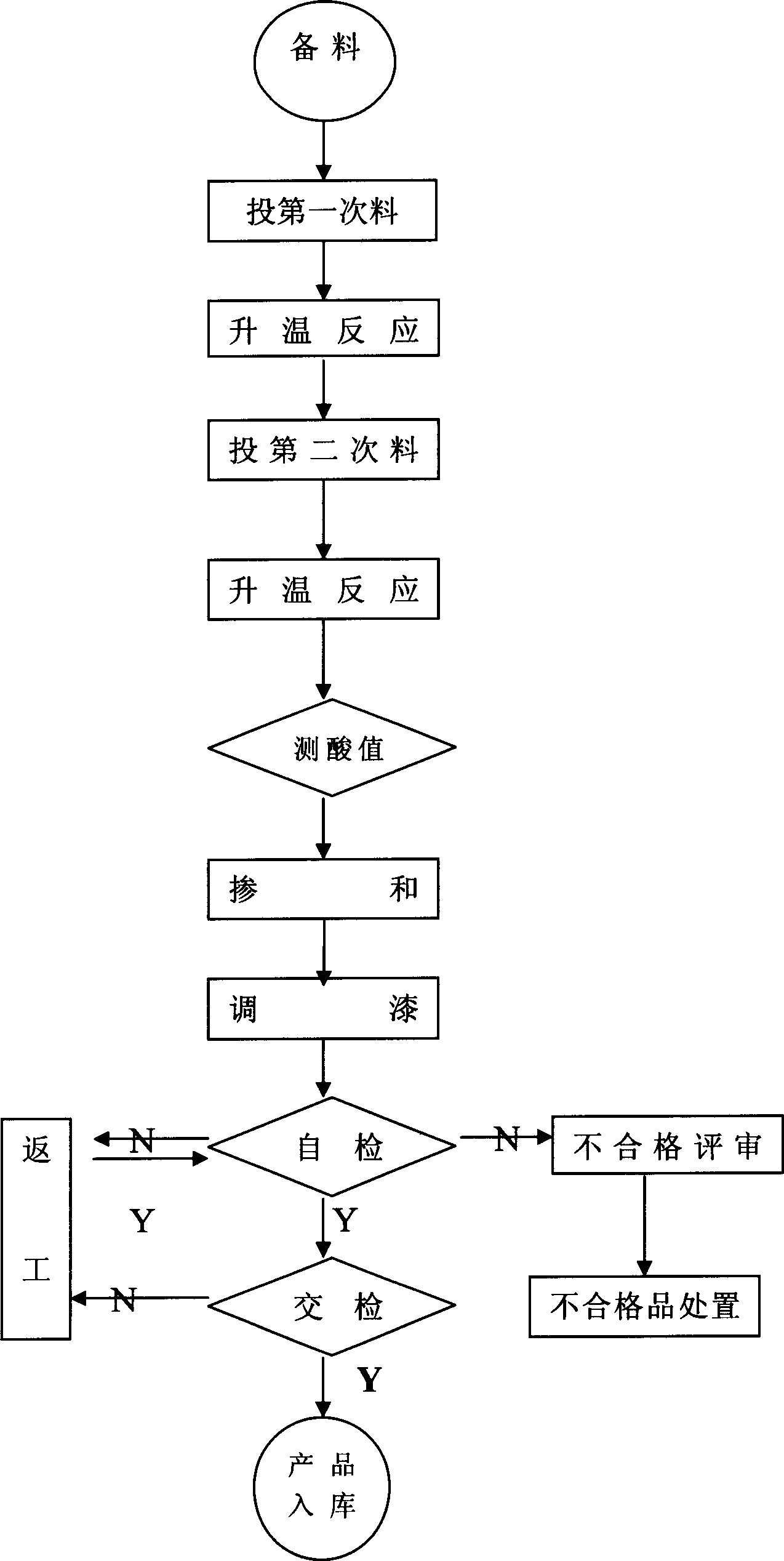

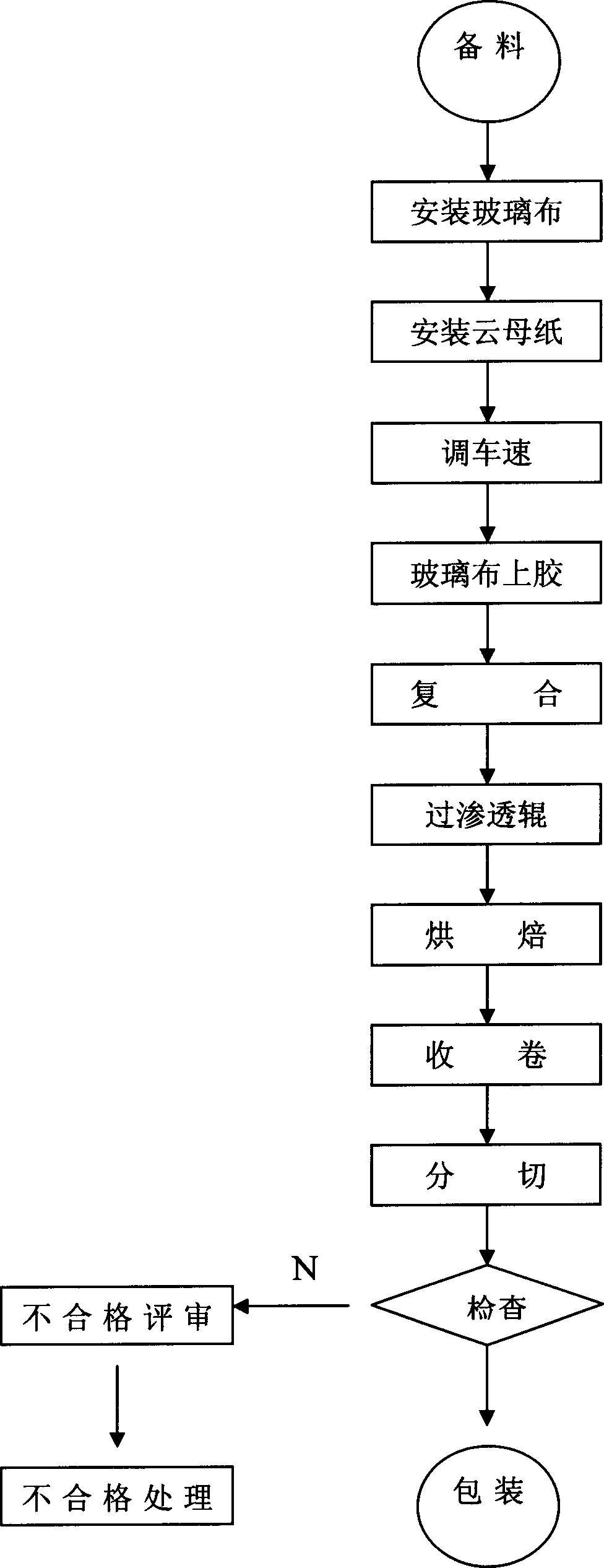

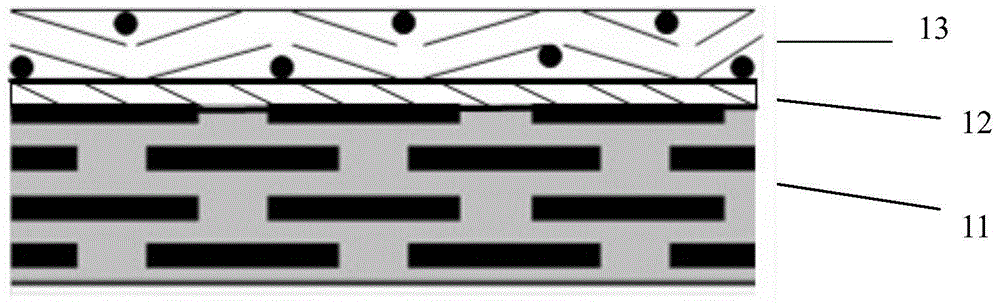

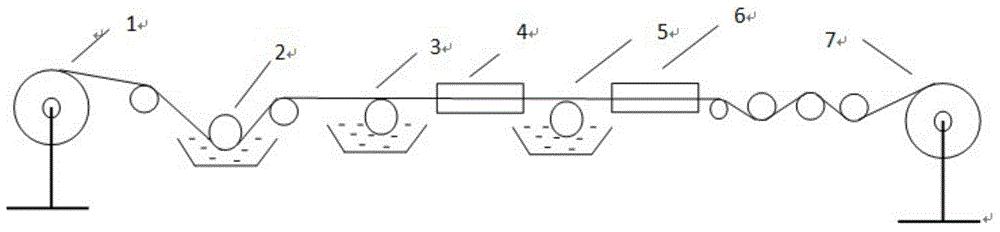

High-thermal-conductivity dry mica tape and preparation method therefor

ActiveCN105632660AReduce temperature riseExtended service lifeQuartz/glass/vitreous enamelsMicaFiberAdhesive

The invention discloses a high-thermal-conductivity dry mica tape, and the dry mica tape consists of mica paper, an adhesive layer, and a fiber cloth layer. Moreover, the mica paper, the adhesive layer and the fiber cloth layer are sequentially overlapped from the bottom to the top. The surface of the fiber cloth layer is uniformly coated with a heat conduction filling material, and the adhesive layer and the fiber cloth layer coated with the heat conduction filling material are overlapped. The preparation method for the mica tape comprises the steps: firstly carrying out the surface treatment of a selected heat conduction filling material through employing a surface treating agent; secondly dispersing the processed heat conduction filling material in an adhesive uniformly, and enabling the obtained adhesive liquid containing the filling material to coat the surface of prepared fiber cloth; thirdly carrying out the baking of the fiber cloth coated with the adhesive liquid, coating one face of the surface with the adhesive, carrying out the surface treatment of the composite mica paper through the adhesive, and obtaining an initial finished product of the mica tape; finally carrying out baking, winding and cutting, and obtaining the finished product of the high-thermal-conductivity dry mica tape. The high-thermal-conductivity dry mica tape is excellent in electrical performances and composite performances, is not layered, does not cause powder to fall, and is stable in quality.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

Laminated toughened glass insulator and preparation method thereof

InactiveCN101409119APrevent self-explosionGuaranteed uptimeQuartz/glass/vitreous enamelsSuspension/strain insulatorsTemperature differenceToughened glass

The invention discloses a laminated toughened glass insulator and a preparation method thereof. The insulator is formed with soda-lime glass or ceramic white porcelain glass as the center and externally coated with aluminosilicate glass or low borosilicate glass. The section structure comprises a first and a third layer of aluminosilicate glass or low borosilicate glass; a middle layer of soda-lime glass or ceramic white porcelain glass. A double layer melting furnace is adopted to melt glass raw materials and form glass material base and then a laminated toughened glass insulator is obtained which has a transparent external layer and a blue middle after forming and annealing. The insulator is characterized by more resistance to external impact, no easy occurrence of unfilled corner, fracture and other phenomenon, no generation of cracking, resistance to temperature difference of over 150 DEG C, hard and fine surface without pores, easy self-cleaning, high strength, is bright (like a new one) after long time of outdoor use and has important significance for ensuring the normal operation of electrical power systems.

Owner:迷你仓(上海)储物设备有限公司

Preparation method of glass fibre fabric conductive material

InactiveCN1444234AImprove shielding effectReduce surface resistanceBraided wire conductorsGlass making apparatusGlass fiberMilitary installation

A method for preparing glass fiber fabric conduction material includes vacuum coating with Ni or Cu, then continuously coated with Ni, Cu, Ag or Mu metal layer on glass fiber cloth, net and felt matrix. This invented material can be retardant, fire resistant, suitable for screening materials of space and military installations or screening materials of electronic and precision instruments.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

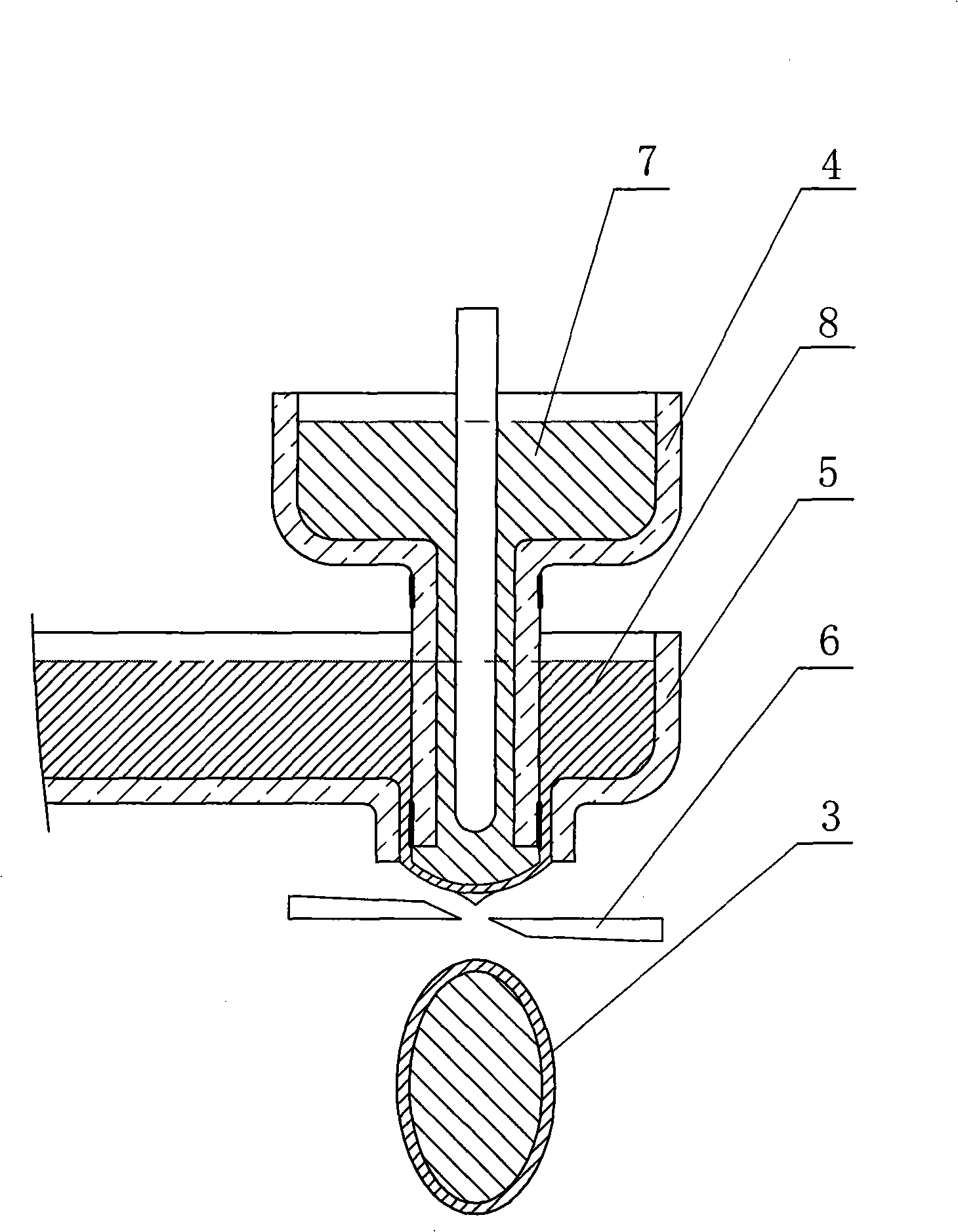

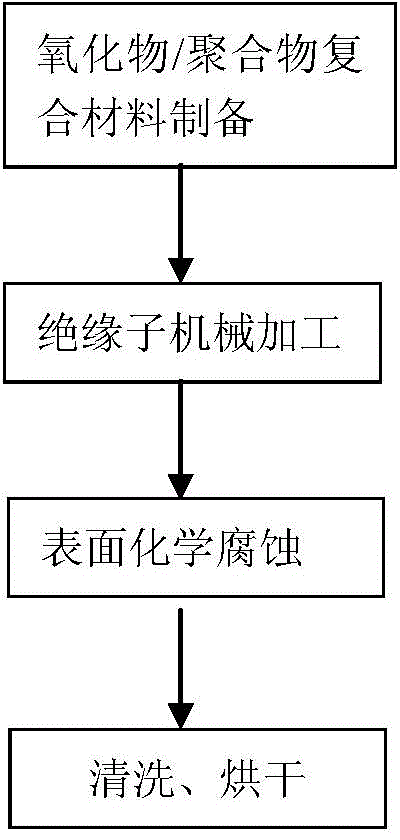

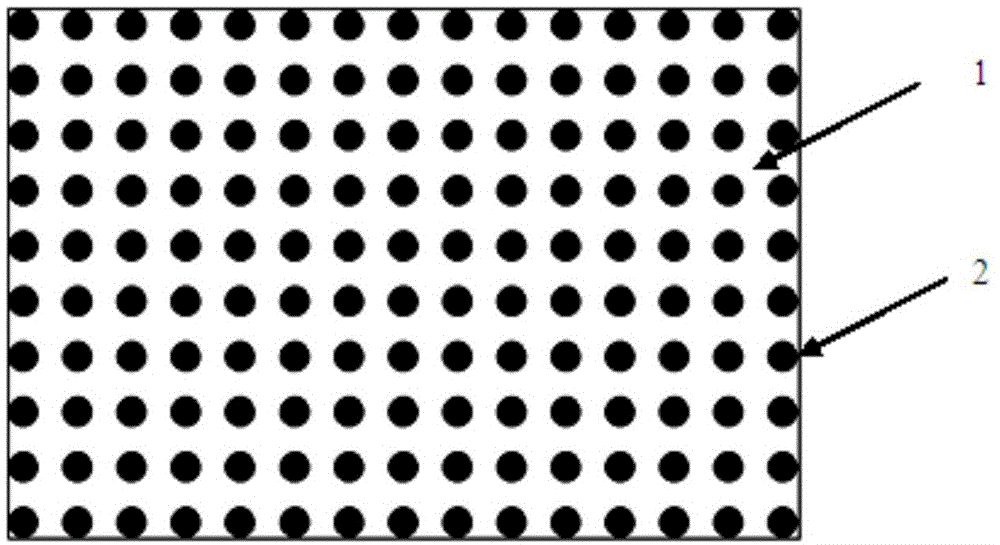

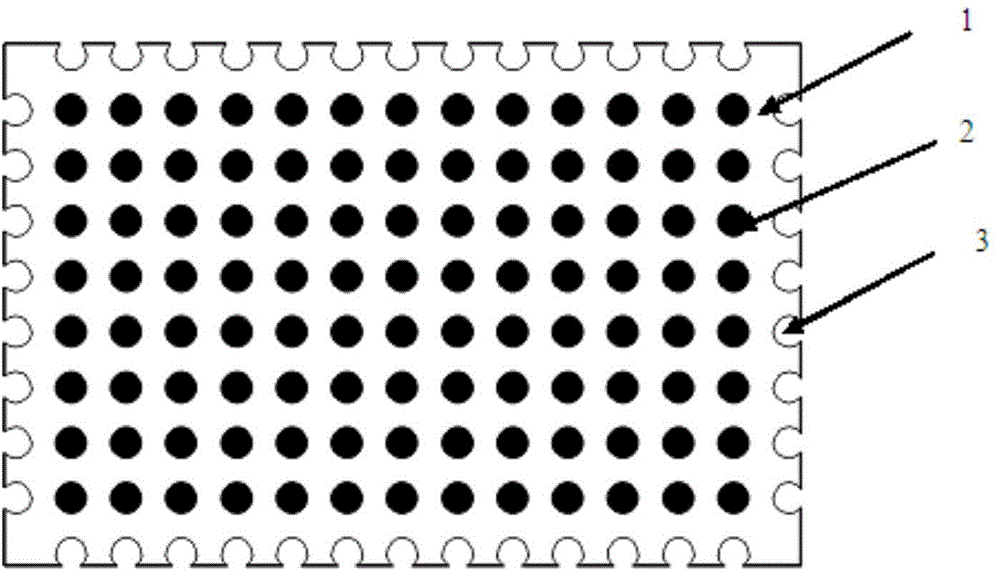

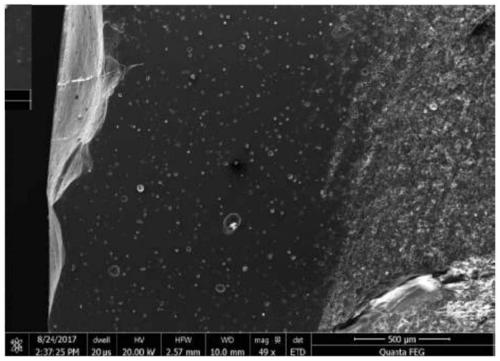

Polymer insulator with uniform hole distribution on surface and preparation method thereof

ActiveCN104900299AImprove mechanical propertiesUniform distribution of holesPlastic/resin/waxes insulatorsQuartz/glass/vitreous enamelsPolymer scienceGas phase

The invention relates to a polymer insulator with uniform hole distribution on the surface and a preparation method thereof. The method mainly includes the following steps: a composite material with uniform oxide particle distribution is obtained through a polymerization reaction by taking fumed silica as a thixotropic agent and oxide particles ranging from tens of nanometers to several microns as a surface pore-forming agent in polymer monomer solution; and after the composite material is machined into a polymer insulator, the oxide particles on the surface are etched and removed by a chemical etching method to obtain a polymer insulator with uniform hole distribution on the surface. By adjusting the size and mass ratio of the oxide particles, control on the hole size and hole density distribution on the surface of the polymer insulation material is realized, the vacuum surface flashover characteristic of the insulator is improved, and the surface breakdown voltage of the insulator is improved. The vacuum surface flashover field strength of an insulator with a special surface structure is improved by 20-50% compared with a pure polymer insulator.

Owner:NORTHWEST INST OF NUCLEAR TECH

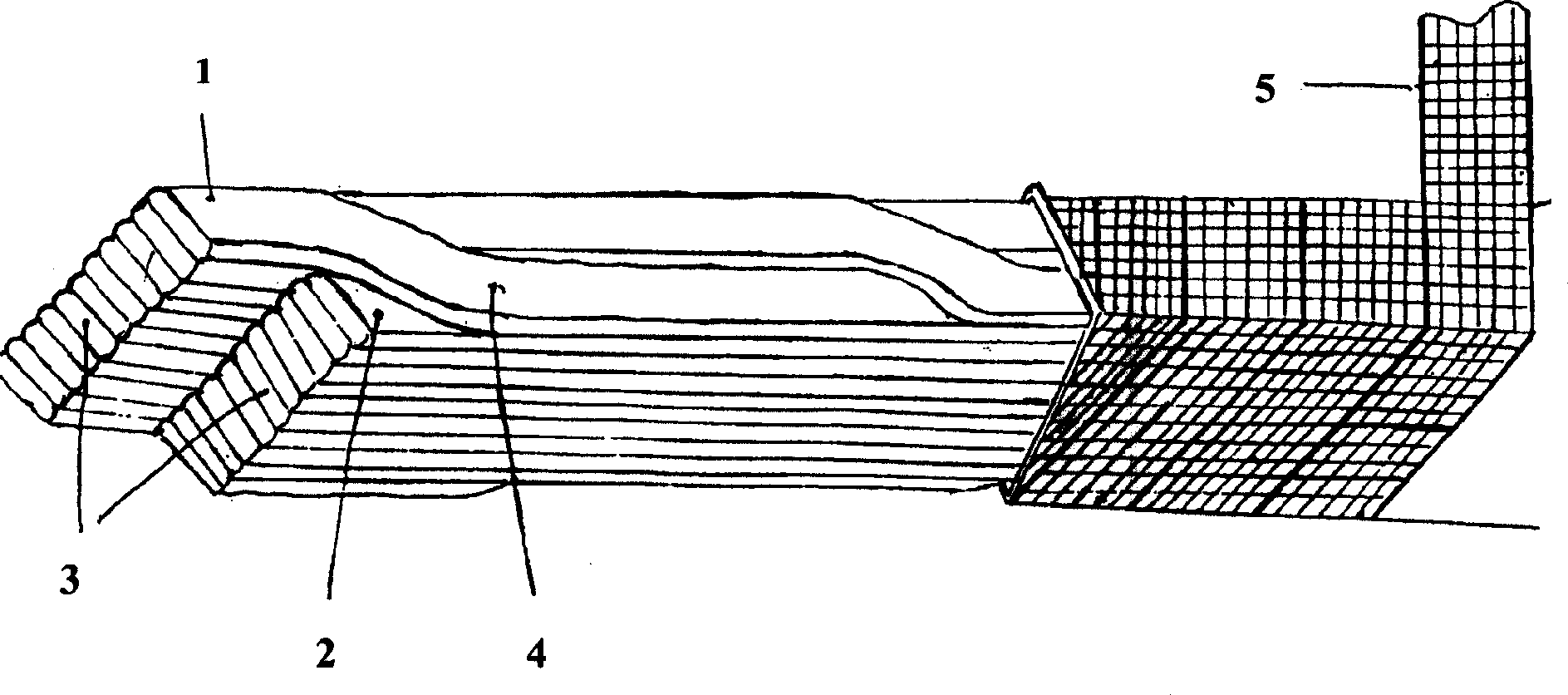

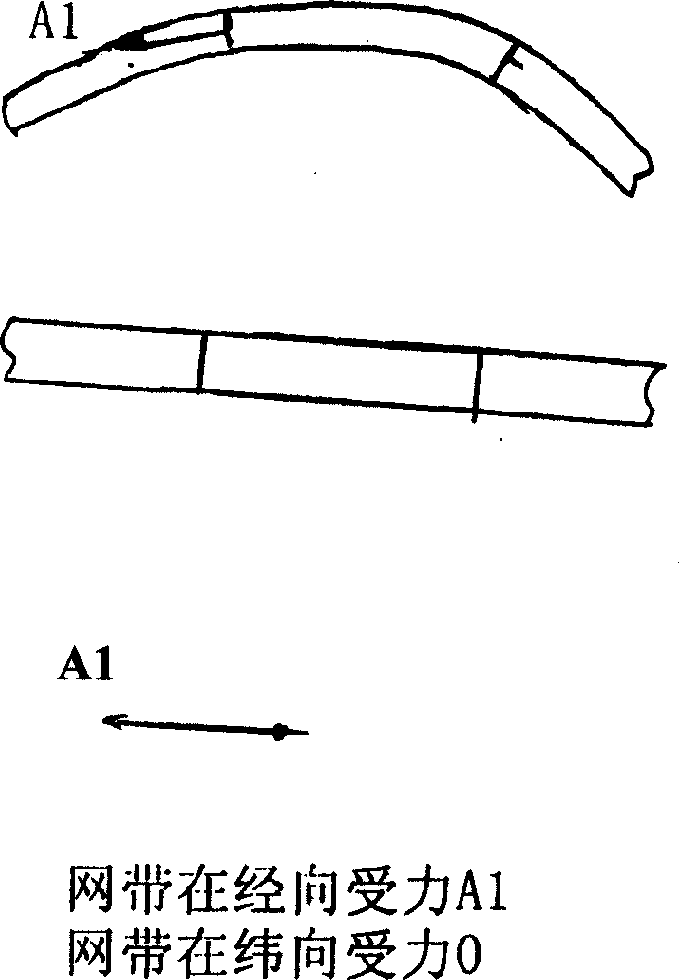

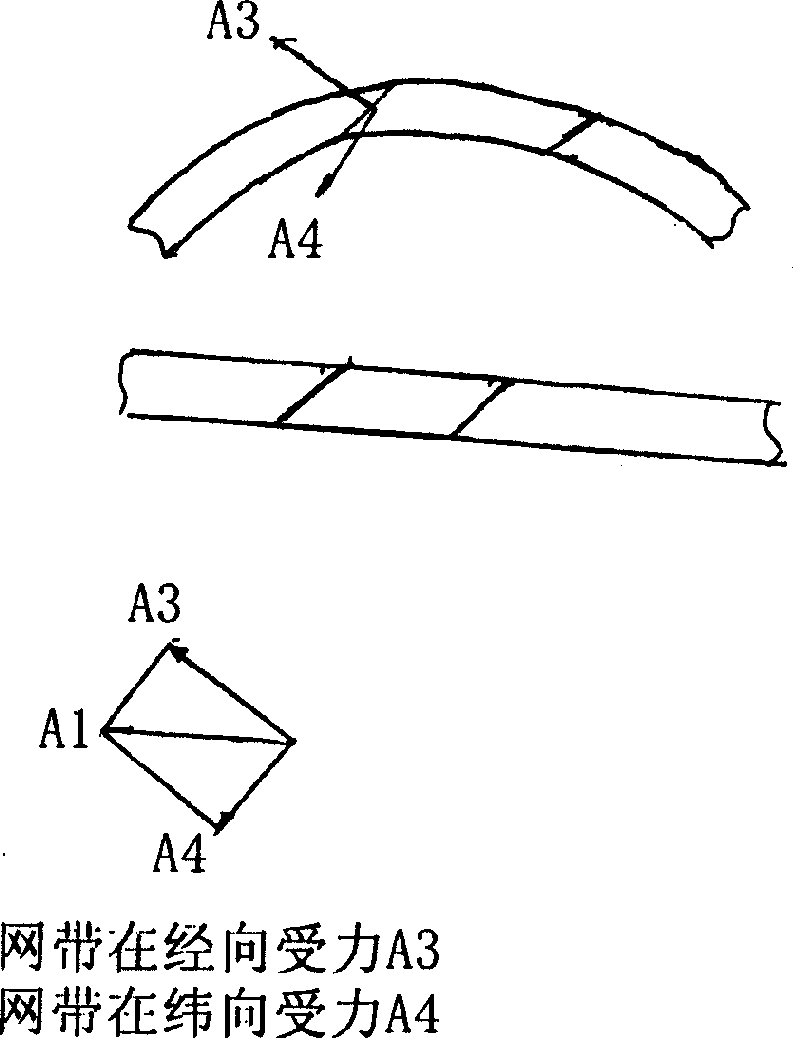

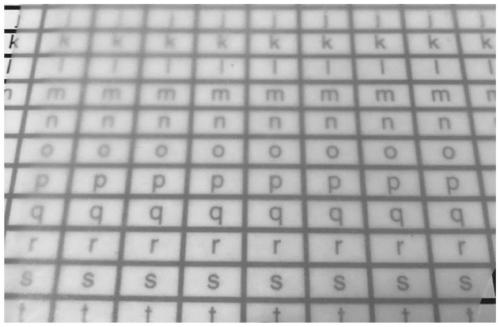

Glass fiber silk screen tape commutating conducting wire, and its manufacture and use method

InactiveCN1581380AWindings insulation materialWindings insulation shape/form/constructionFiberglass meshGlass fiber

Transposed conducting wire includes first column of enameled conducting wire and second column of enameled conducting wire. There are several pieces of enameled conducting wire in each column. Each piece of enameled conducting wire in first column through a bend and passes through second column of enameled conducting wire. Each piece of enameled conducting wire in second column through a bend and passes through first column of enameled conducting wire so as to realize transposition between first column of enameled conducting wire and second column of enameled conducting wire. In the invention, the transposed conducting wire is covered by fiberglass web. Thus, the conducting wires keep their structure and performance all the time to prevent hydrolysis.

Owner:NEXANS

Low-k dielectric composition for high frequency applications

ActiveCN109928617ANon-insulated conductorsSemiconductor/solid-state device detailsSilicon dioxideCrystallization

The present invention provides a low-K dielectric composition for high frequency applications. The invention relates to a low-K, high-Q, low fired dielectric materials and a method of forming a fireddielectric material. The dielectric material can be fired at 950 DEG C or below or 1,100 DEG C or below, the K value is less than about 8 at 10GHz to 30GHz, and the Q value is greater than 500 or greater than 1,000 at 10GHz to 30GHz. Before firing, the dielectric material comprises a solid portion comprising a silica powder and a glass component. The glass component contains SiO2, B2O3, Al2O3, K2O, Na2O, Li2O and F; the total amount of Li2O + Na2O + K2O is from 0.1 mol% to 30 mol% of the glass component. The silica powder may be amorphous or crystalline.

Owner:FELLOWES INC

Moistureproof insulation material for electrical engineering

InactiveCN104592704AHigh strengthImprove insulation performancePlastic/resin/waxes insulatorsPolyureas/polyurethane adhesivesEpoxyElectrical engineering technology

The invention discloses a moistureproof insulation material for electrical engineering. The material comprises an inner layer and an outer layer. The inner layer is prepared from the following raw materials in parts by weight: 10-16 parts of quartz sand, 16-22 parts of aluminum oxide, 16-22 parts of polyallylamine resin, 3-9 parts of dimethylformamide, 1-4 parts of butyl rubber and 3-9 parts of nano silicon dioxide. The outer layer is prepared from the following raw materials in parts by weight: 15-22 parts of epoxy resin, 10-17 parts of polyamide resin, 20-28 parts of glass fiber, 2-6 parts of ethylene propylene diene monomer rubber, 0.5-1.2 parts of 2-mercaptobenzimidazole, 1-4 parts of nano zinc oxide, 10-18 parts of silicon nitride, 2-9 parts of hydrogenated nitrile-butadiene rubber, 5-11 parts of aluminum nitride and 5-11 parts of polyethylene. The moistureproof insulation material is composed of the inner layer and outer layer; the outer layer achieves the moistureproof effect under the combined actions of the components; and the material has steady insulating property under the combined actions of the components of the inner layer.

Owner:WUJIANG HUACHENG COMPOSITE MATERIAL SCI & TECH

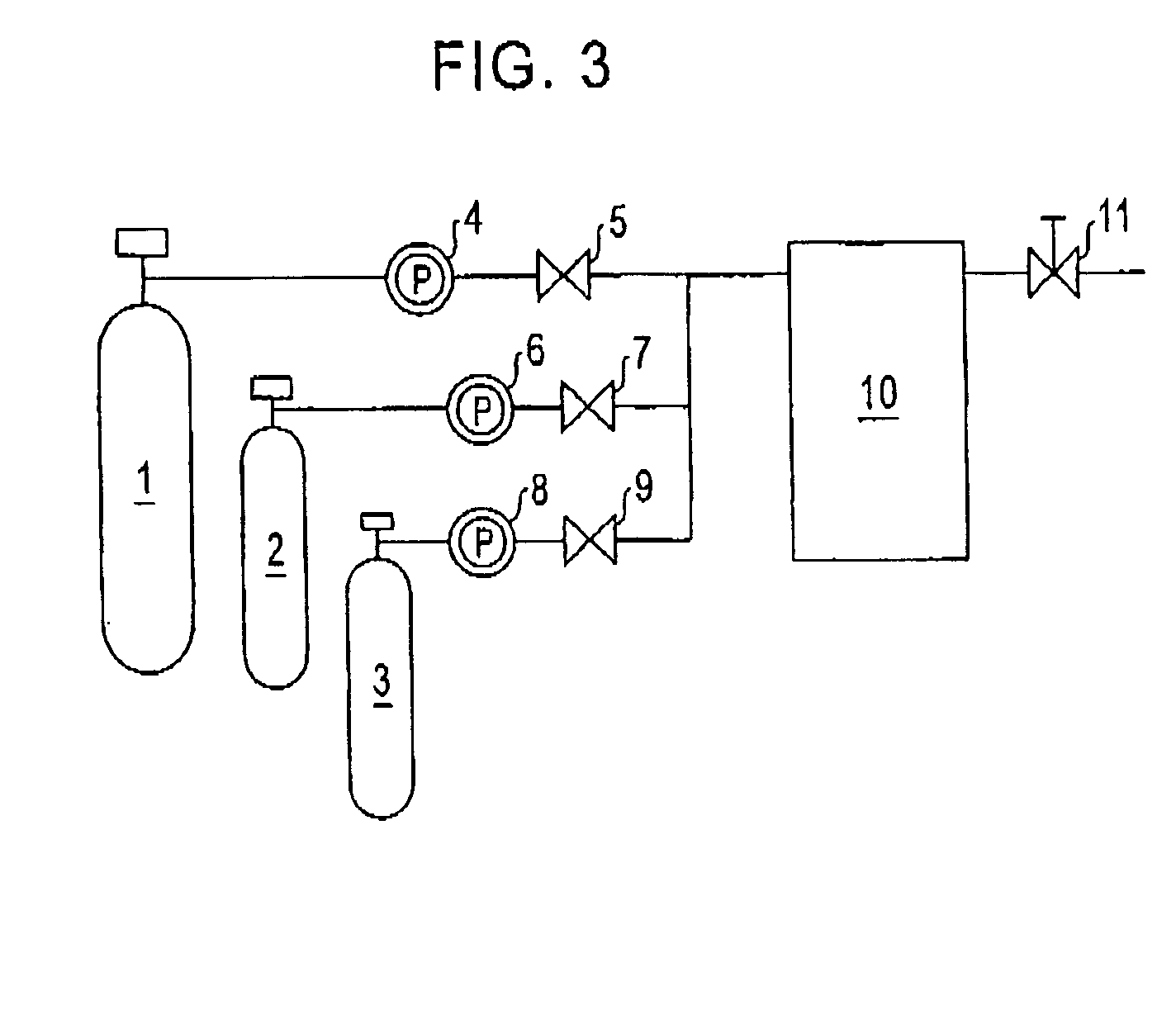

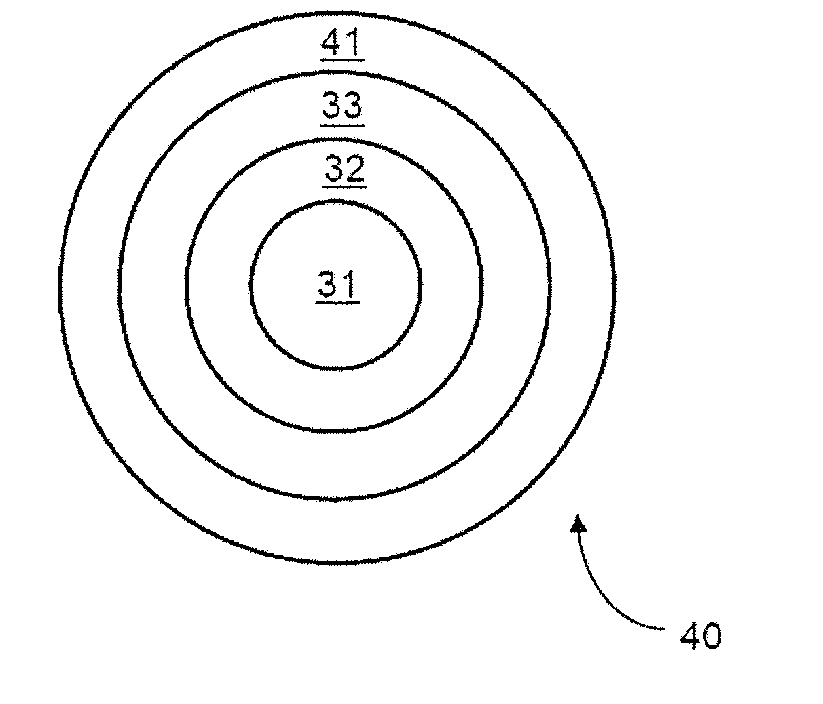

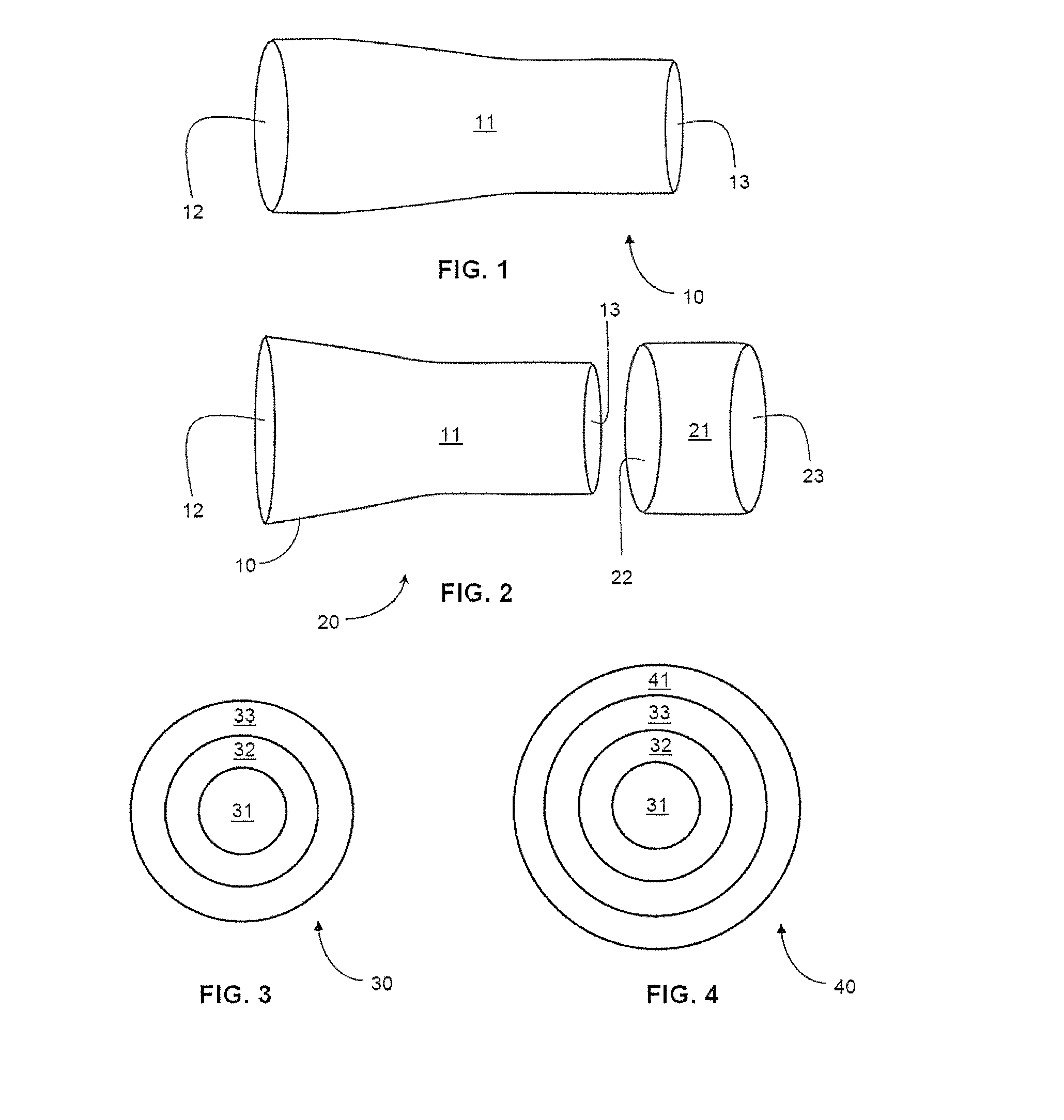

Glass fiber and carbon fiber composite core for wire of transmission line

InactiveCN101572132AHigh strengthImprove practicalityPlastic/resin/waxes insulatorsConductive materialFiberYarn

The invention discloses a glass fiber and carbon fiber composite core for a wire of a transmission line, which is characterized by consisting of 50 to 55 percent of carbon fibers, 10 to 15 percent of glass fibers and 30 to 40 percent of resin and auxiliary materials. Carbon fiber yarns pass through fibers-converging stander to be converged into a rounded body to be drawn outward; glass fibers cover the carbon fiber rounded body from a plurality of layers of creels and are drawn outward; and the carbon fiber rounded body covered by glass fiber yearns is synchronously drawn outward to pass through a mould. A well-stirred resin raw material can be poured into a resin storage tank 5 after being sieved by an 80 mesh sieve. The temperatures of a curing region and a forming region in the heating mould are set to be 200+ / -10 DEG C and 140+ / -10 DEG C respectively, and the heating mould is electrically heated. A heating system of an extruder is started, and the temperatures of heating areas are adjusted according to process requirements. The class fiber and carbon fiber composite core can well solve the problem of the combination of a thermosetting process and a thermoplastic process, thereby achieving excellent product quality and fulfilling a preset technical solution target.

Owner:程显军

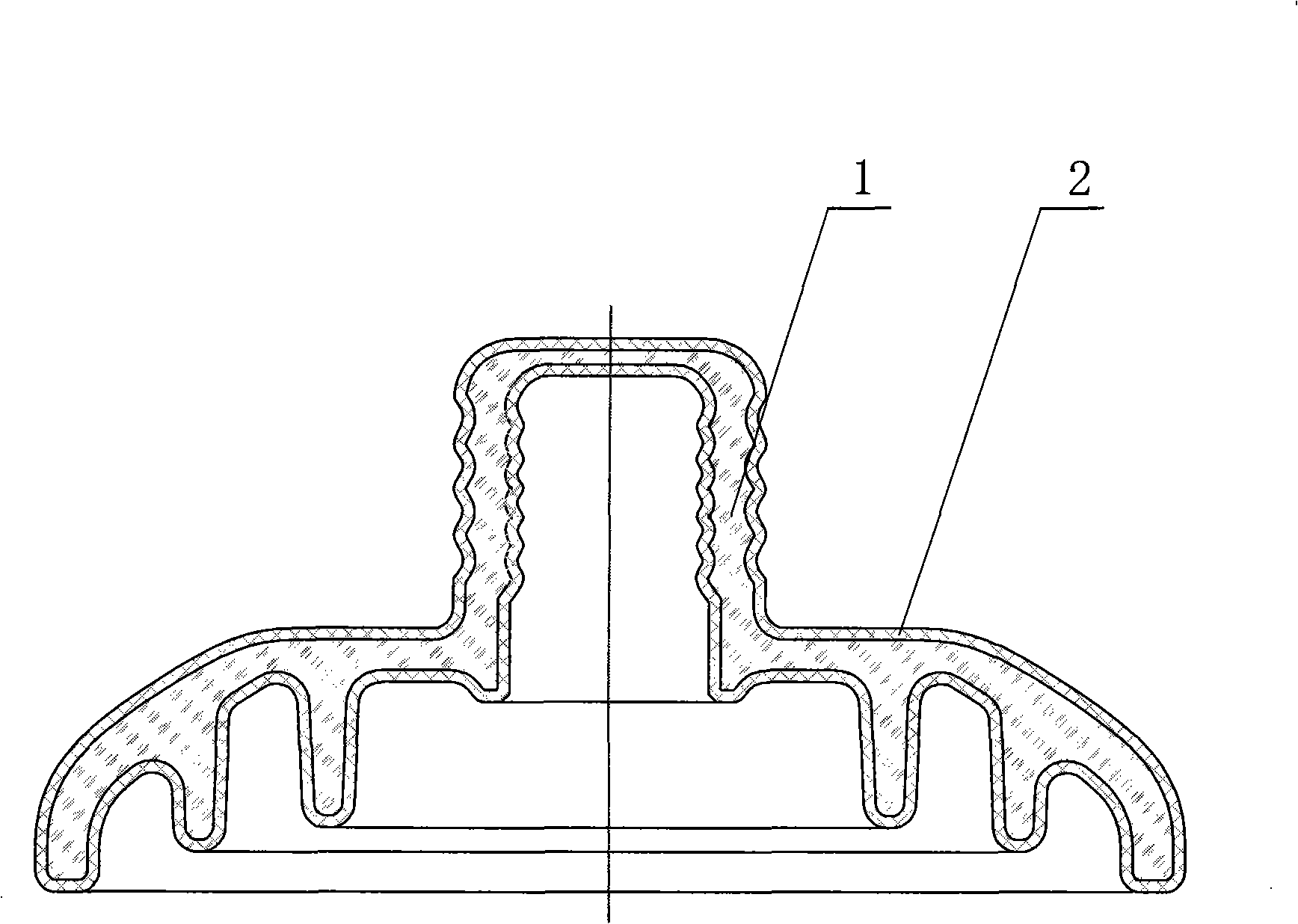

Electric machine stator component and electric machine

InactiveCN101752928AIncrease creepage distanceImprove insulation performanceWindings insulation shape/form/constructionPlastic/resin/waxes insulatorsSlot insulationElectric machinery

The invention relates to the electric machine technology and provides an electric machine stator component. The component comprises a stator core and a stator winding wound on the stator core, wherein the stator core comprises a plurality of stator poles which are distributed along the circumference at intervals and extend along the radial direction and yokes used for connecting all stator poles together, the adjacent two stator poles and a yoke used for connecting the two stator poles constitute an iron core groove; and the stator winding is placed in the iron core grooves, groove insulation parts are lined between the stator core and the stator winding for electric insulation, an opening corresponding to the notch of one iron core groove is formed between the two end parts of each groove insulation part, and a flange is formed on the side with the opening of the end parts of the groove insulation part. The embodiment of the invention can increase the insulation performance between the stator core and the stator winding while the overall dimension of the stator component is not increased.

Owner:JOHNSON ELECTRIC SHENZHEN

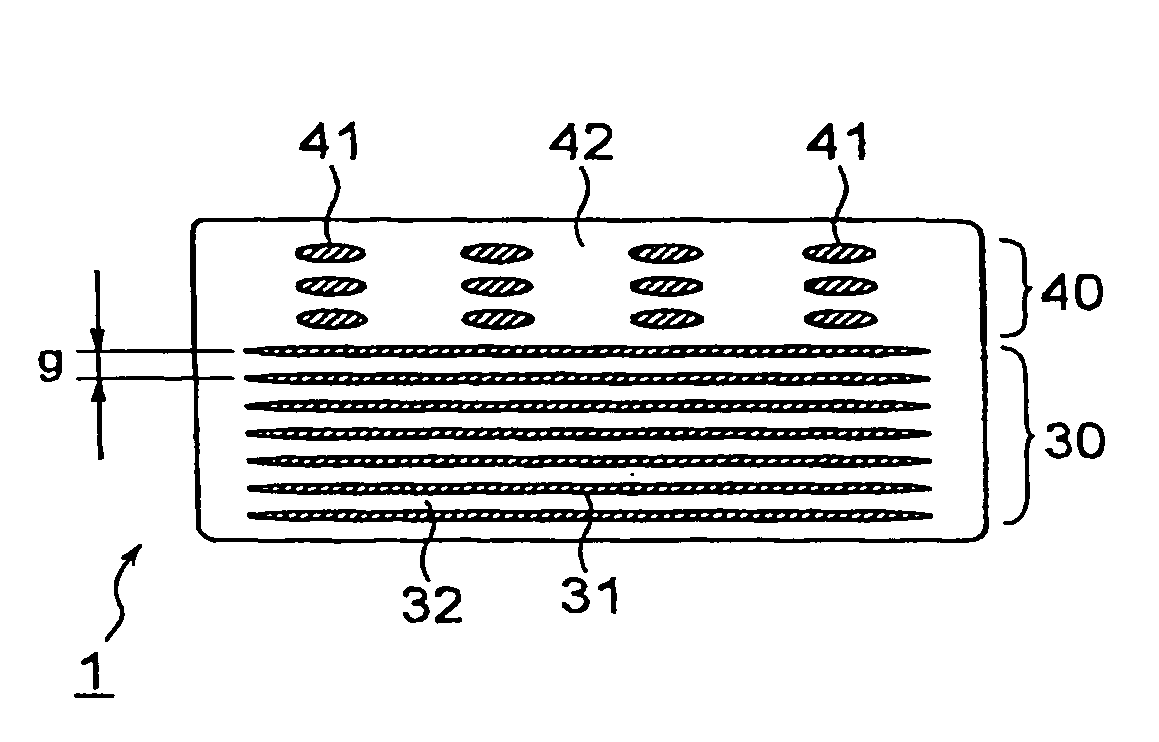

Nano-enhanced rich resin mica tape with high thermal conductivity and applications thereof

ActiveCN103400665AReduce temperature riseLow costWindings insulation materialQuartz/glass/vitreous enamelsElectrical field strengthAlkali free

The invention discloses a nano-enhanced rich resin mica tape with high thermal conductivity and applications thereof. The nano-enhanced rich resin mica tape with high thermal conductivity is formed by compounding a layer of mica paper, a layer of alkali-free glass cloth or two layers of alkali-free glass cloth, adhesive resin and inorganic nano powder, wherein the weight per unit area of each component is as follows: 70-140g / m<2> of mica paper, 15-70 g / m<2> of alkali-free glass cloth, 60-100 g / m<2> of adhesive resin and 1-15 g / m<2> of inorganic nano powder. The nano-enhanced rich resin mica tape with high thermal conductivity is applied to prepare main insulation of a high-voltage motor. With the adoption of the main insulation prepared by the nano-enhanced rich resin mica tape with high thermal conductivity, the heat conductivity coefficient is not lower than 0.35W.m-1.K-1, the bending strength is not lower than 120MPa at the temperature of 155 DEG C, and the electrical service life is not lower than 1200 hours under 10kV / mm electric field intensity, so that the nano-enhanced rich resin mica tape with high thermal conductivity and applications thereof are beneficial for lowering the temperature rising of a generator and the manufacturing cost of the whole generator, and improving the running reliability of the unit.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Dielectric paste for aluminium alloy substrate thick film circuit, and preparation technology for dielectric paste

InactiveCN107358991AWon't hurtLower melting temperatureQuartz/glass/vitreous enamelsWorking environmentHardness

The invention discloses a dielectric slurry for aluminum alloy substrate thick-film circuits and a preparation process thereof. The slurry is composed of the following components: 60-75% of glass-ceramic powder and 25-40% of binder; wherein, Glass-ceramic powder is composed of SiO2, Bi2O3, B2O3, BaO, CaO, ZnO, Al2O3, V2O5, TiO2, Co2O3. The glass-ceramic powder prepared by using the above raw materials has a low melting temperature, so that the sintering temperature is lower than the melting temperature of the aluminum alloy substrate when the dielectric layer is prepared, and the substrate will not be damaged when the dielectric layer is prepared. In addition, the raw materials do not contain lead, which meets environmental protection requirements. . The thermal expansion coefficient of the obtained dielectric layer matches the aluminum alloy substrate, has good bonding performance, and can form a solid network structure, making the composite glass-ceramic insulating medium have excellent hardness and flexibility, which can meet the requirements of high-power aluminum alloy substrate thick film Special requirements when the circuit is in a harsh working environment. At the same time, the preparation process of the slurry is simple and easy to produce, and the obtained medium slurry has excellent performance.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

Dielectric material for plasma display plate

InactiveCN1572747AExcellent chemical durabilityNot easy to produceGas discharge electrodesStatic indicating devicesSilver electrodeMetallurgy

PURPOSE: A dielectric material used for a plasma display panel is provided to easily remove bubbles from a dielectric layer during a burning process, obtain excellent chemical resistance of the dielectric layer and prevent a silver electrode from being browned. CONSTITUTION: A dielectric material used for a plasma display panel has glass powder that contains PbO of 25 to 55%, B2O3 of 10 to 40%, SiO2 of 1 to 15%, ZnO of 3 to 35%, BaO+CaO+MgO+SrO+Bi2O3 of 2 to 30%, Al2O3 of 0 to 10%, and TiO2+ZrO2 of 0.01 to 10%. The content of TiO2 is 0.01 to 10%. The content of BaO is 1 to 30%. The dielectric material further contains ceramic powder. In this case, the content of the glass powder is 90 to 100weight% and the content of the ceramic powder is 0 to 10weight%.

Owner:NIPPON ELECTRIC GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com