High-thermal-conductivity dry mica tape and preparation method therefor

A low-glue mica tape, high thermal conductivity technology, used in mica, insulators, electrical components, etc., can solve the problems of difficult to increase the volume filling of fillers, poor composite performance, etc., to improve design power, excellent electrical performance, and increase service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of above-mentioned high thermal conductivity little glue mica tape, comprises the following steps:

[0034](1) Surface treatment of the selected thermally conductive filler with a surface treatment agent; the selected surface treatment agent is an ethanol solution of silane coupling agent KH-560, and the amount of silane coupling agent is 3% to 5% of the mass of the thermally conductive filler , the amount of ethanol is 1 to 3 times the volume of the thermally conductive filler; the specific operation for surface treatment is: add the thermally conductive filler to the surface treatment agent for ball milling for 2h to 5h, and then put it into the oven after vacuum filtration (the oven temperature is 90°C or so), and finally take it out and seal it for later use;

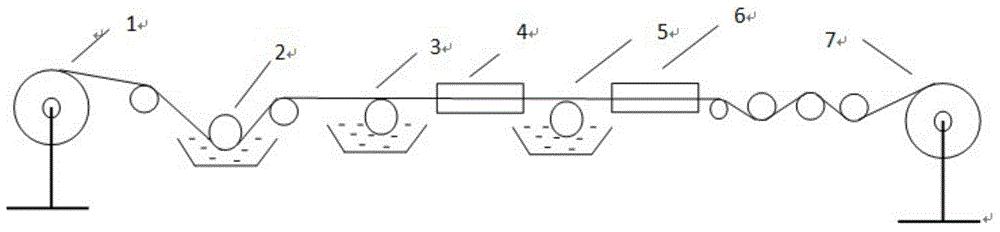

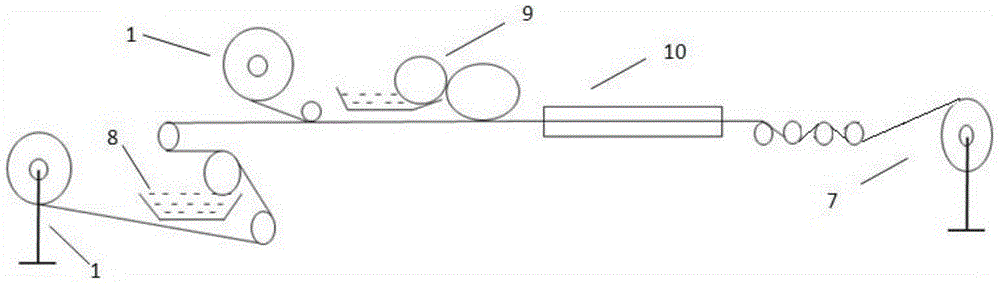

[0035] (2) Evenly disperse the thermally conductive filler after the above-mentioned surface treatment in the binder to obtain a filler-containing glue for subsequent use; the selected ...

Embodiment

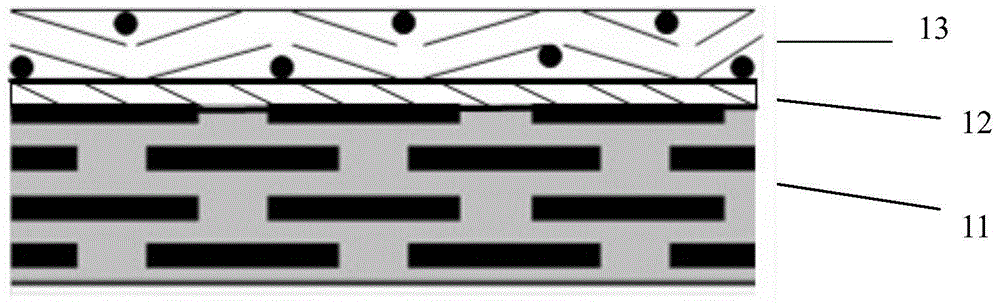

[0042] a kind of like figure 1 The high thermal conductivity mica tape with less glue of the present invention is shown. The mica tape is composed of mica paper 11, adhesive layer 12 and fiber cloth layer 13, and the mica paper 11, adhesive layer 12 and fiber cloth layer 13 are stacked sequentially from bottom to top, and the fibers The surface of the cloth layer 13 is uniformly coated with thermally conductive fillers, and the adhesive layer 12 is superimposed on the fiber cloth layer 13 coated with thermally conductive fillers. The mica paper 11 in this embodiment is non-calcined mica paper, and the thickness of the mica paper 11 is 0.10mm. The adhesive layer 12 is mainly composed of a mixture of polyester resin and epoxy resin. The matrix of the fiber cloth layer 13 is electrical non-alkali glass fiber cloth, and the thickness of the matrix of the fiber cloth layer 13 is 0.04mm.

[0043] The preparation method of the above-mentioned high thermal conductivity less glue mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com