Patents

Literature

188results about How to "Composite good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

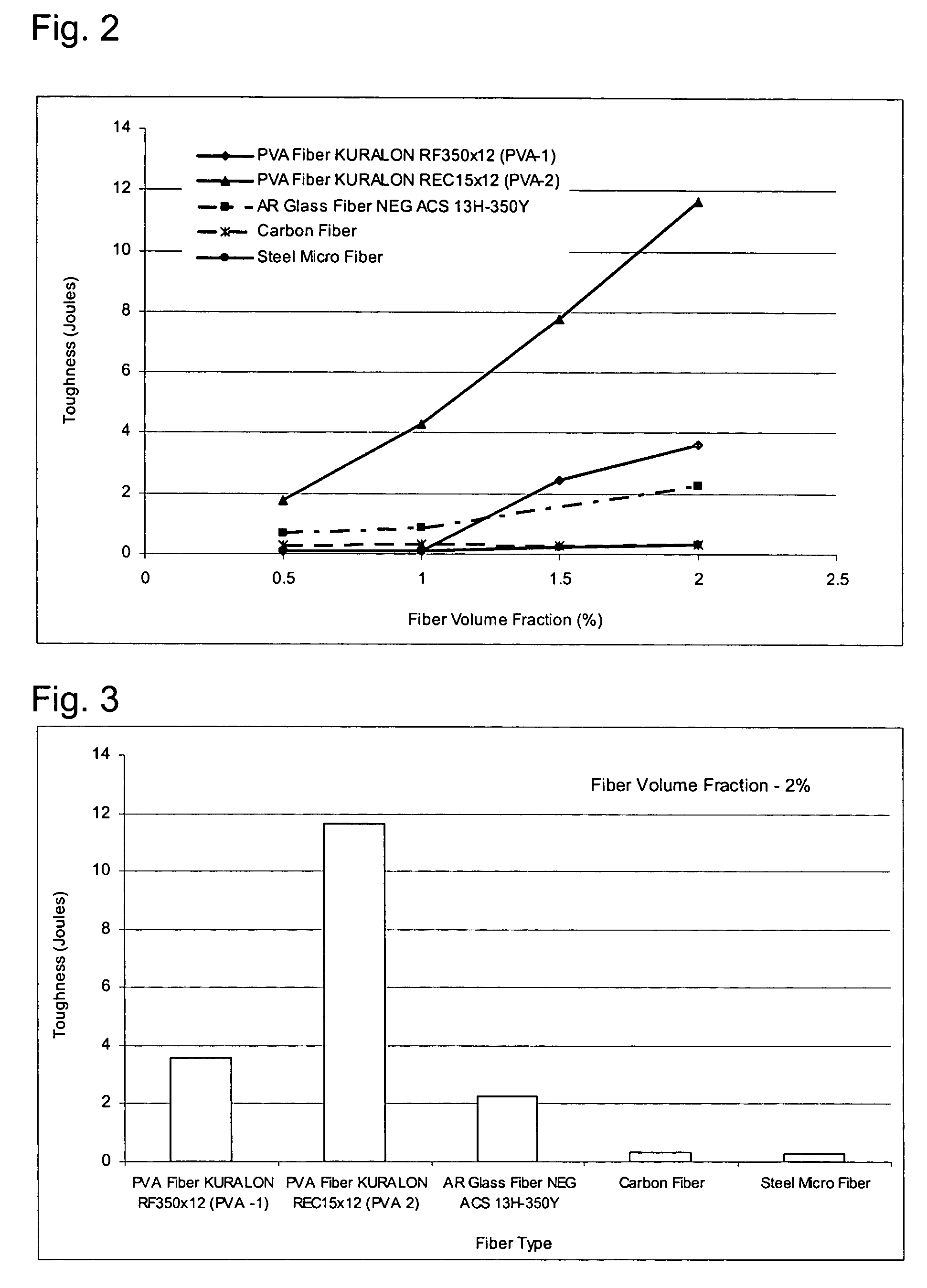

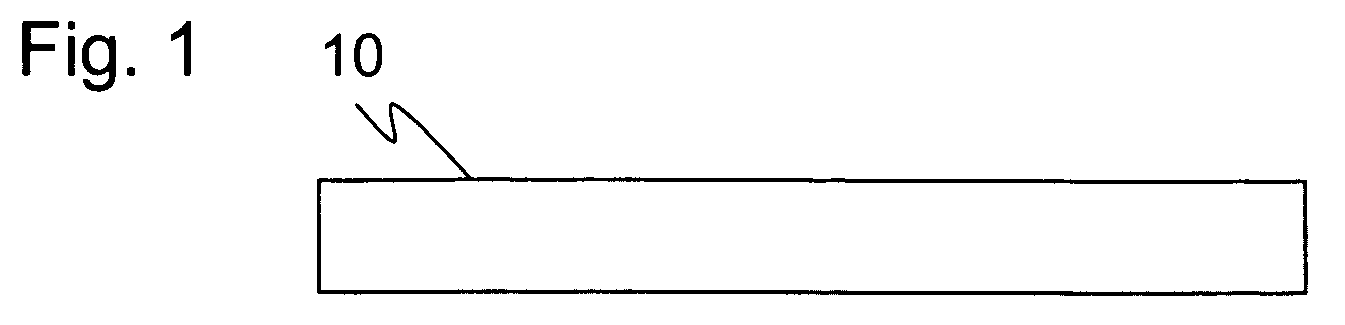

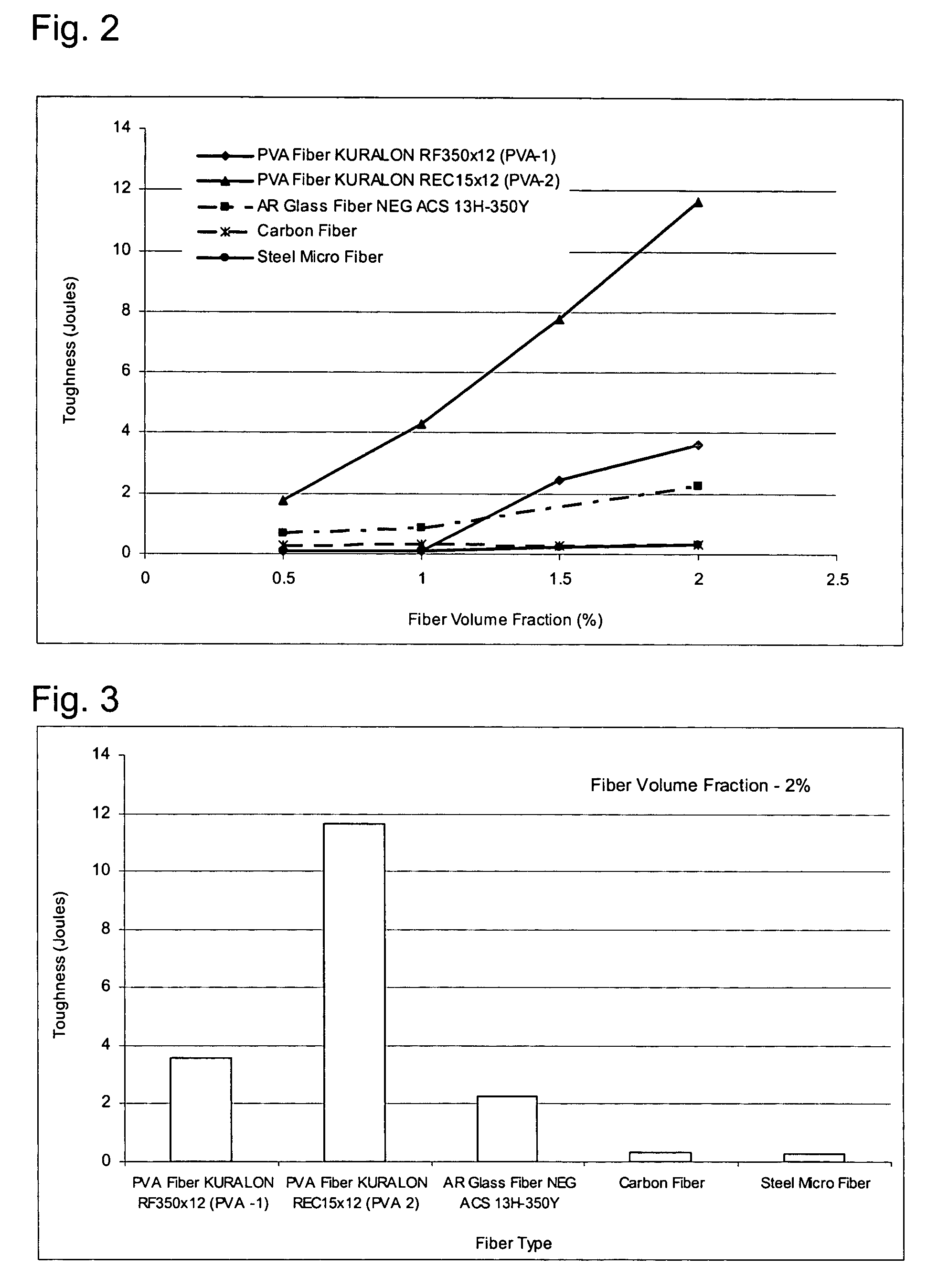

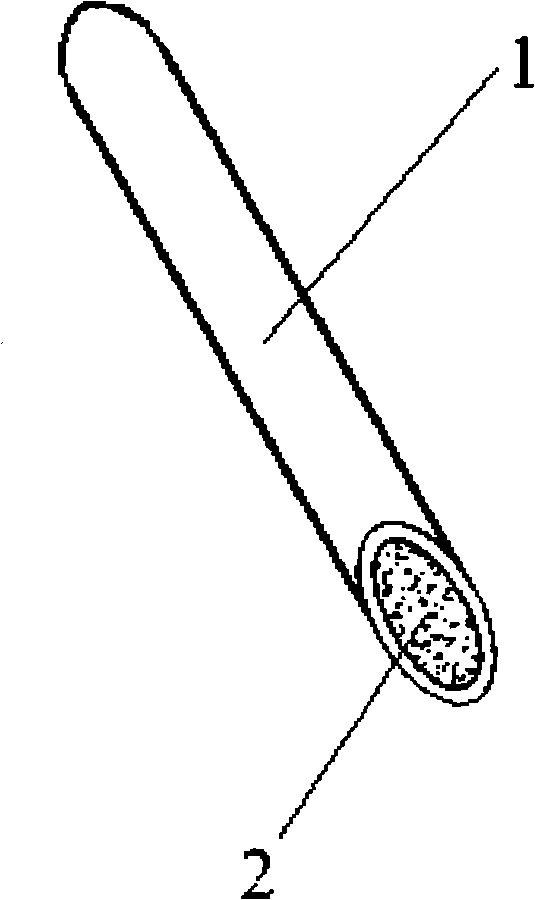

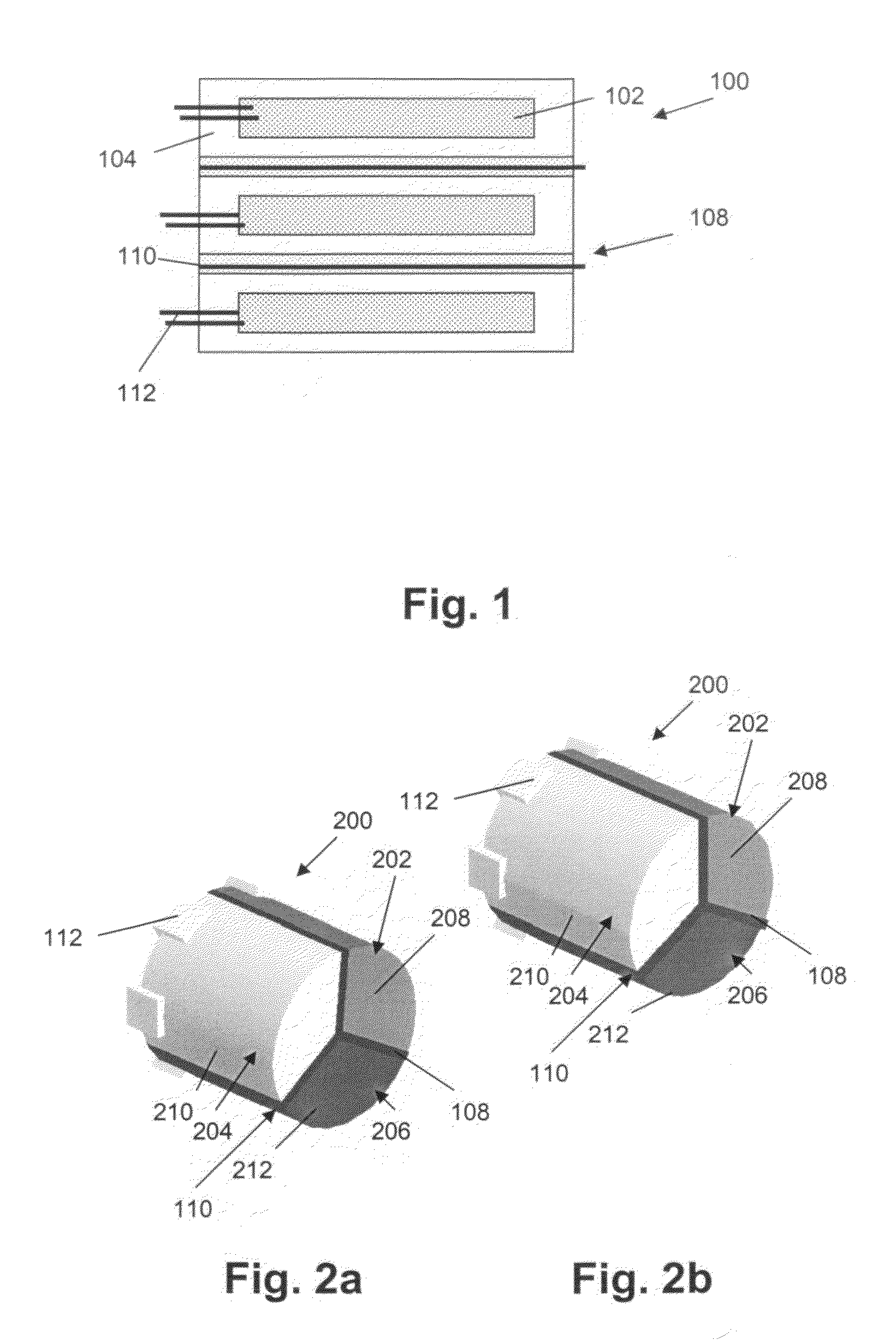

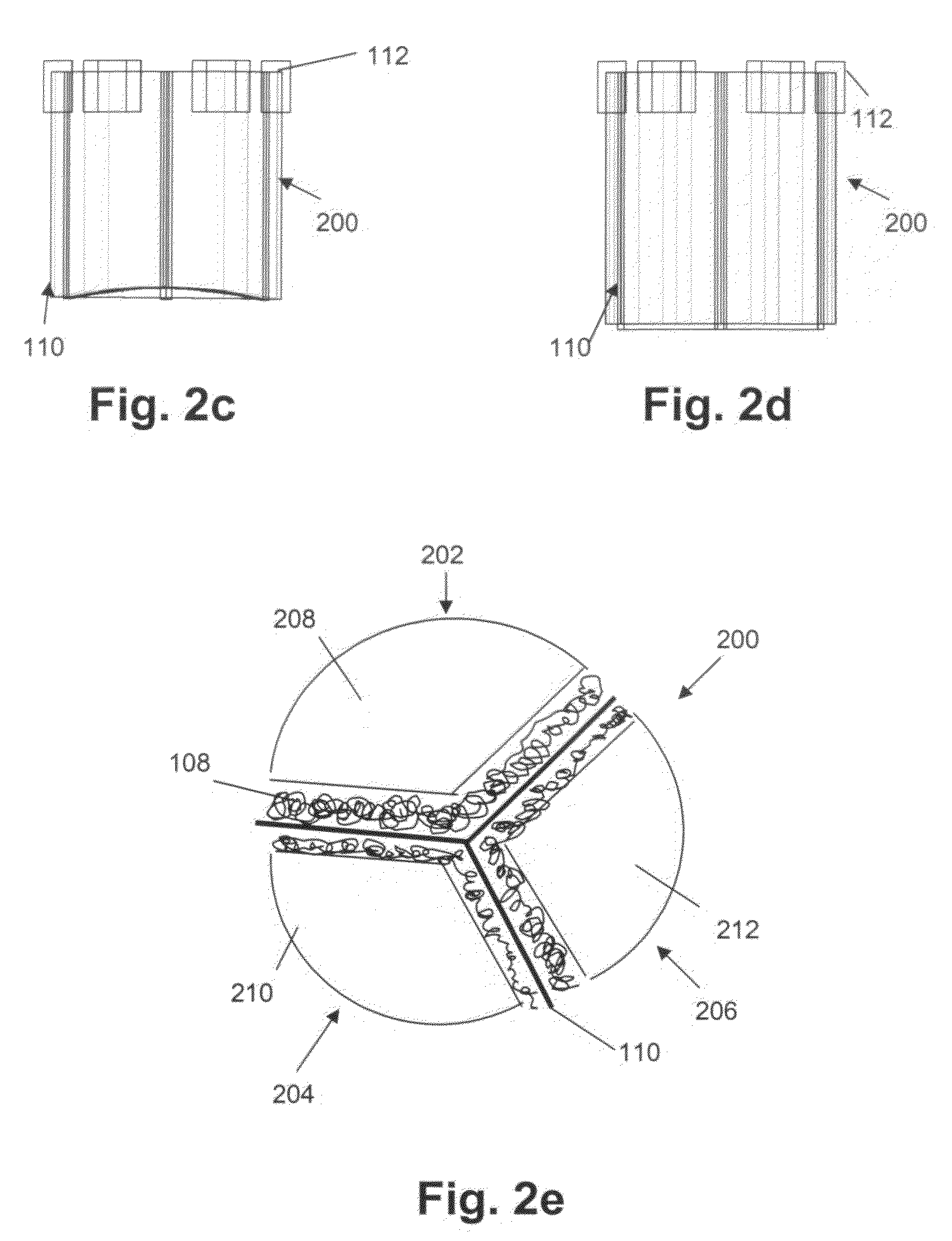

Lightweight, fiber-reinforced cementitious panels

ActiveUS20060147681A1Significant toughnessComposite goodConstruction materialCovering/liningsCement boardToughness

Lightweight, fiber reinforced, cementitious panels possessing exceptional toughness for use as building components in applications such as roofing elements, siding elements, framing and sheathing elements, and substrate elements for installation of floor finishes in residential and other building construction types. The panels employ a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, PVA fibers and lightweight filler. The inorganic binder may be, for example, hydraulic cement alone, or a combination of hydraulic cement and pozzolan / s, or a combination of hydraulic cement, alpha hemihydrate, active pozzolan and optionally lime. The PVA fibers reinforce the continuous phase and are randomly distributed throughout the composite. Typical panels of the invention have a density of 60-85 pcf.

Owner:UNITED STATES GYPSUM CO

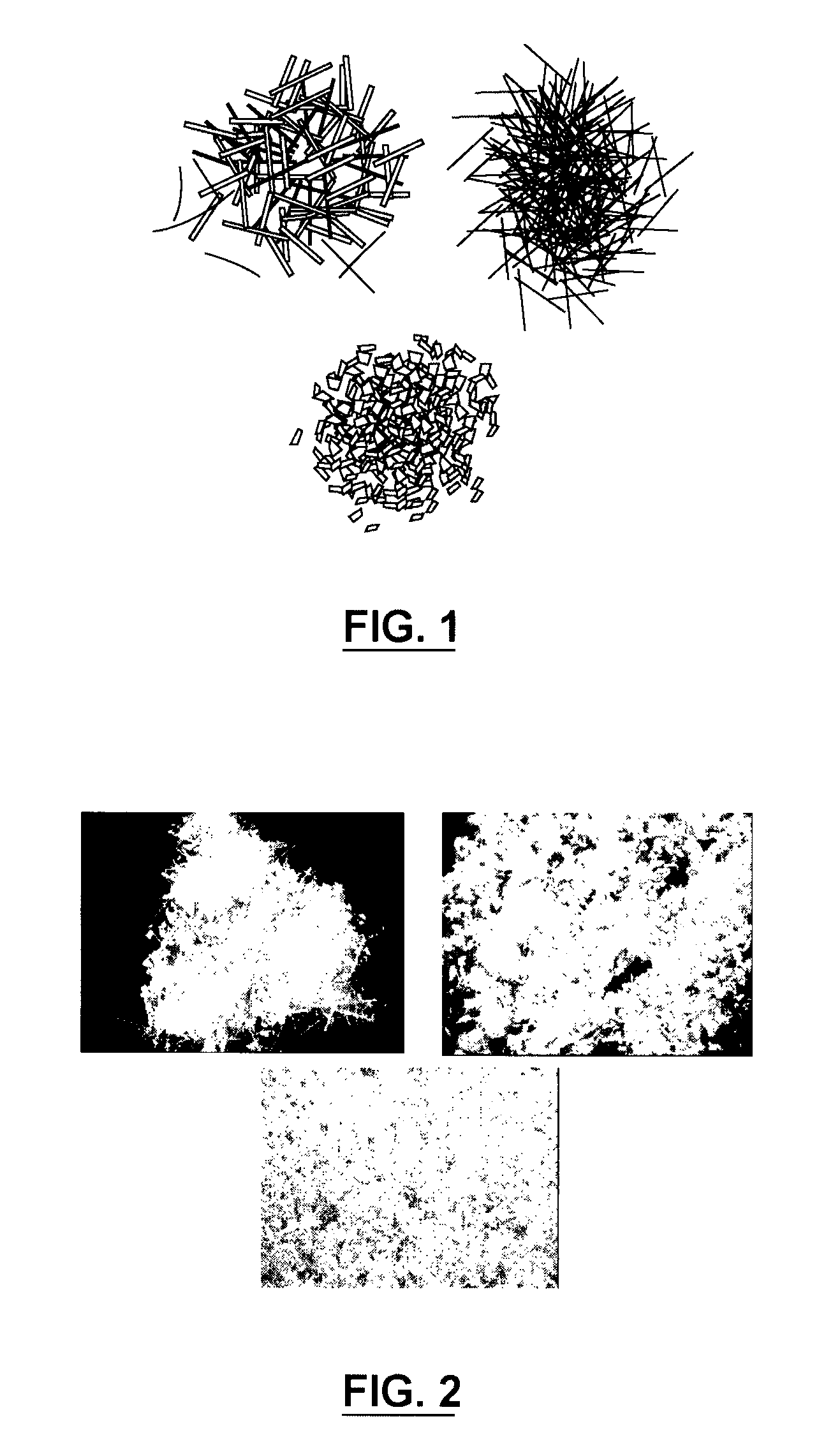

Manufacturing process for high performance short ligno-cellulosic fibre - thermoplastic composite materials

ActiveUS20050225009A1Improve performanceEnhanced interactionCoatingsManufacturing technologyFlexural strength

The present invention relates to a process for the manufacture of short or discontinuous lignocellulosic fibre in combination with synthetic fibre filled thermoplastic composites, in which the process consists of preferably, defiberization and dispersion of the cellulosic fibres in the thermoplastic matrix, further consolidation and dispersion of the blended thermoplastic composition, further blending of the same with inorganic fibres to get the moldable thermoplastic composition and further injection or compression or compression injection molded under high pressure ranging from 100 tones to 1000 tones and a temperature range from 170 to 210 degree centigrade into composite products. The said composites have a tensile strength of at least 75 MPa and a flexural strength of at least 125 MPa. The invention also relates to the use of the said composites in automotive, aerospace, furniture and other structural applications.

Owner:SAIN MOHINI M +2

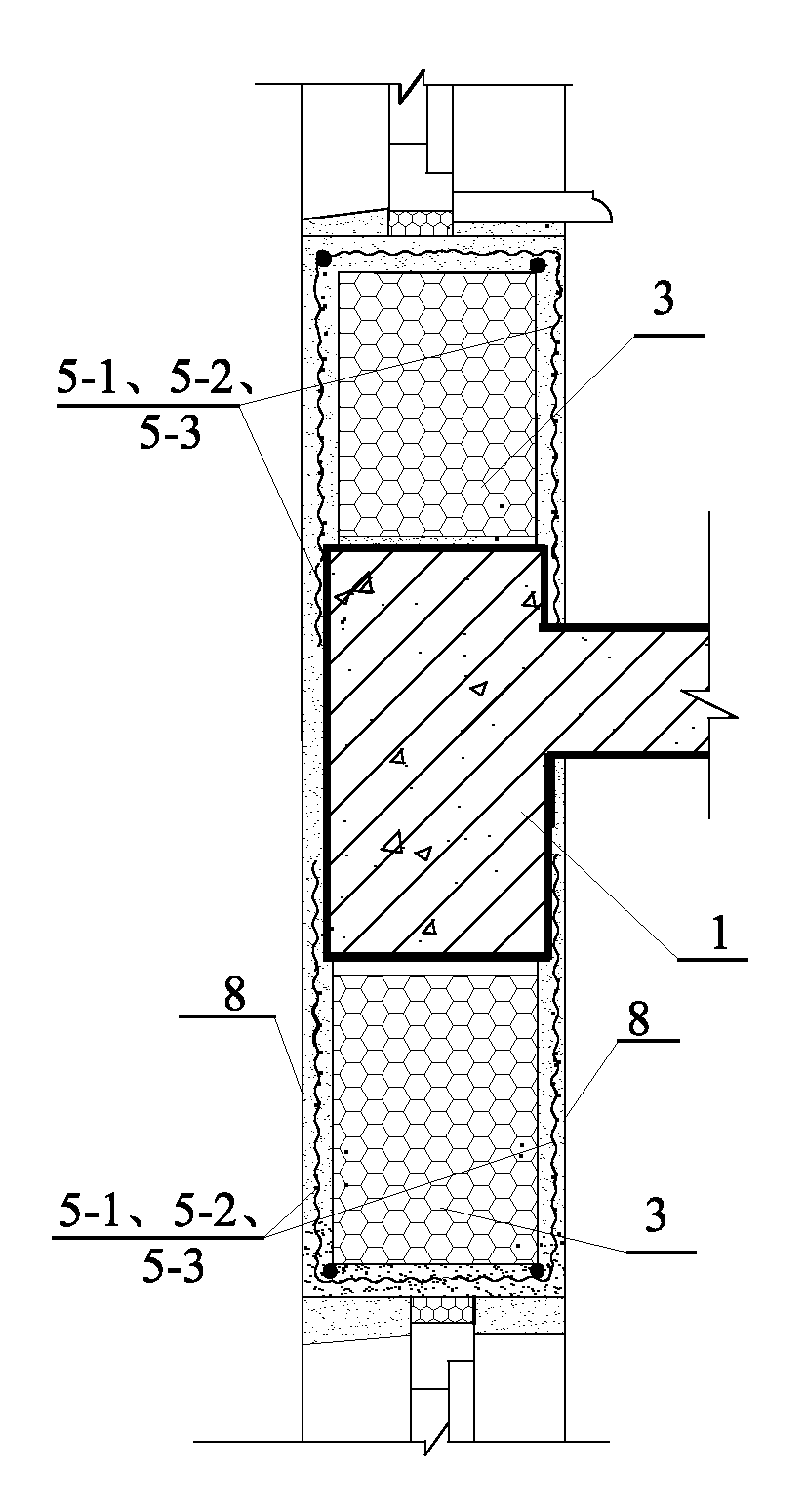

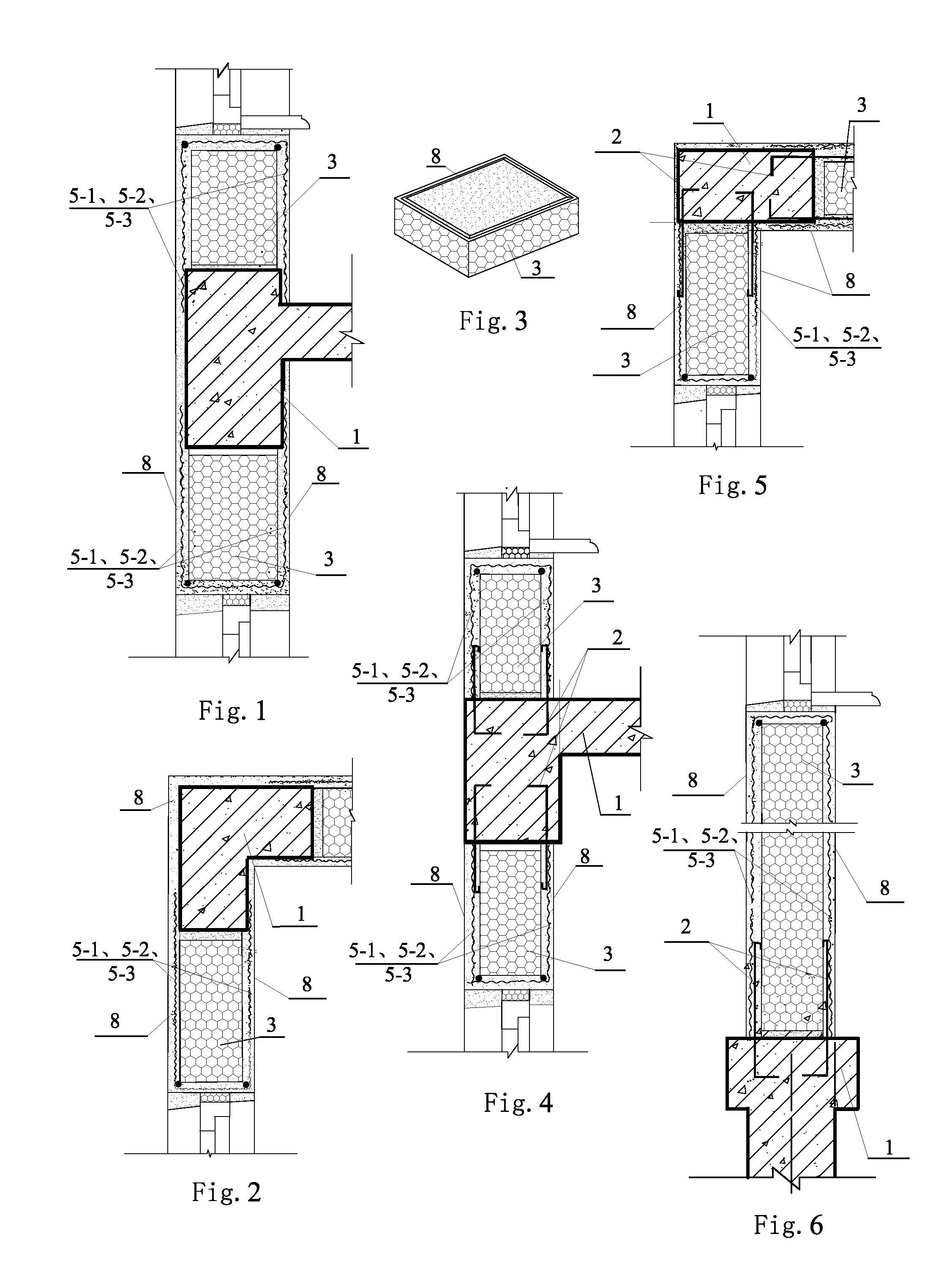

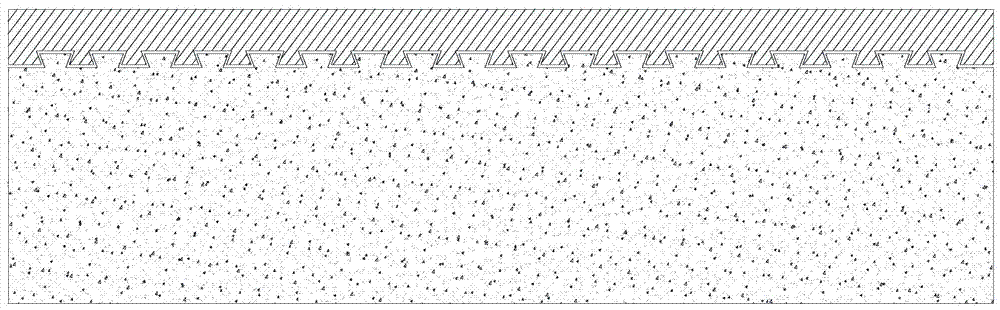

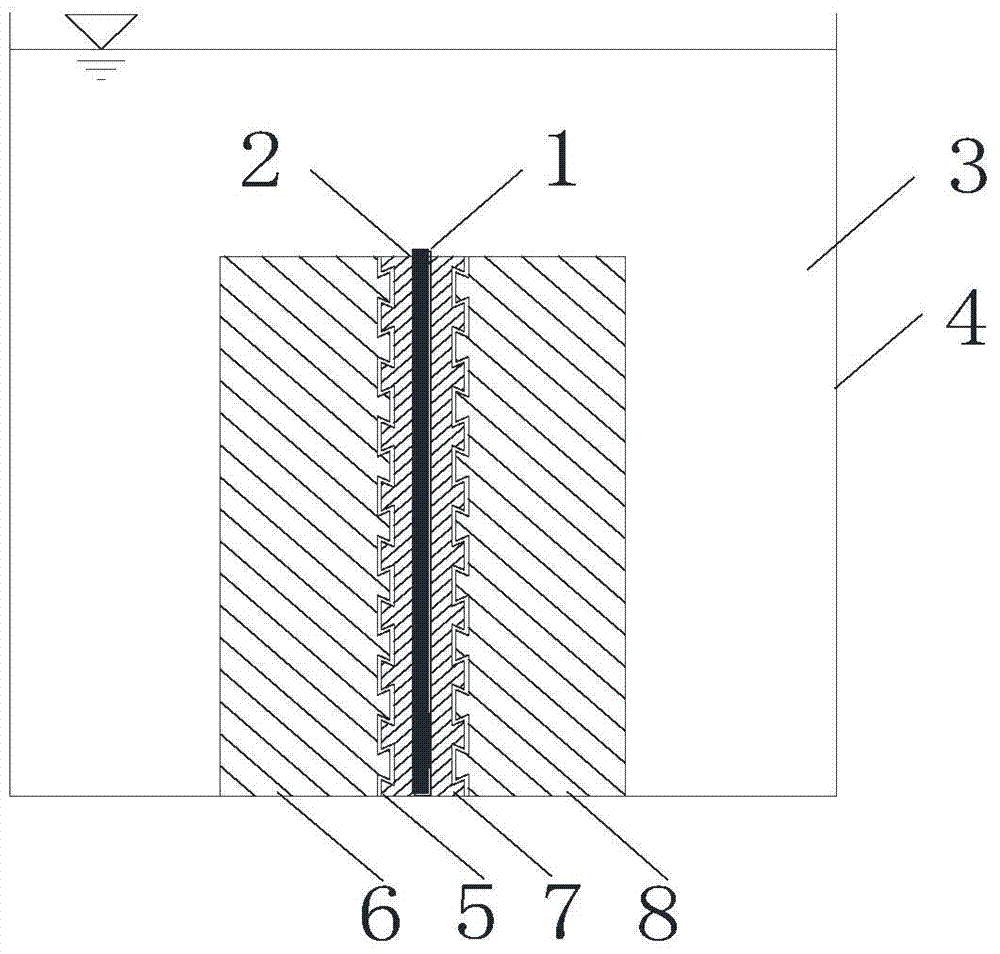

Composite Thermal Insulation Wall Body of a Building

InactiveUS20110258964A1Decreasing total construction weightImprove performanceWallsHeat proofingThermal insulationArchitectural engineering

A composite thermal insulation member of building is provided. It relates to the composite thermal insulation member of the building, especially the composite thermal insulation wall body and the composite roof aimed to solve the problem of high cost of the existing energy-saving wall body and the inconvenience of construction, the first structure is the core layer bonded inside the frame with the outer protecting layer provided on the surface of the core layer and the alkali-resistant netting fabric bonded to the outer protecting layer and the load-carrying component, the second structure is the core layer provided between the indoor and outdoor outer protecting layers and bonded each other, also the steel hoop fixed with the steel bars inside the indoor and outdoor outer protecting layers, the third structure is the outer protecting layer provided on two sides of the core layer and its upper side and bonded to it, also the core layer and the steel bars arranged inside the outer protecting layer as well as the outer protecting layer wrapped and surrounded by the alkali-resistant netting fabric, the fourth structure is the composite pillar anchored to the main structure and the core layer bonded to the main structure and the light composite pillar with the composite girder supported on the composite pillar and the plastered outer protecting layer on the composite pillar, composite girder and the outer side of the core layer, the fifth structure is the core layer provided between the upper and lower outer protecting layers with the lower outer protecting layer fixed to the girder or wall of the main structure, the invention has the advantages of low cost, convenience of construction etc. which is beneficial to the energy-saving of the construction and the reform of the wall body.

Owner:WU SHUHUAN

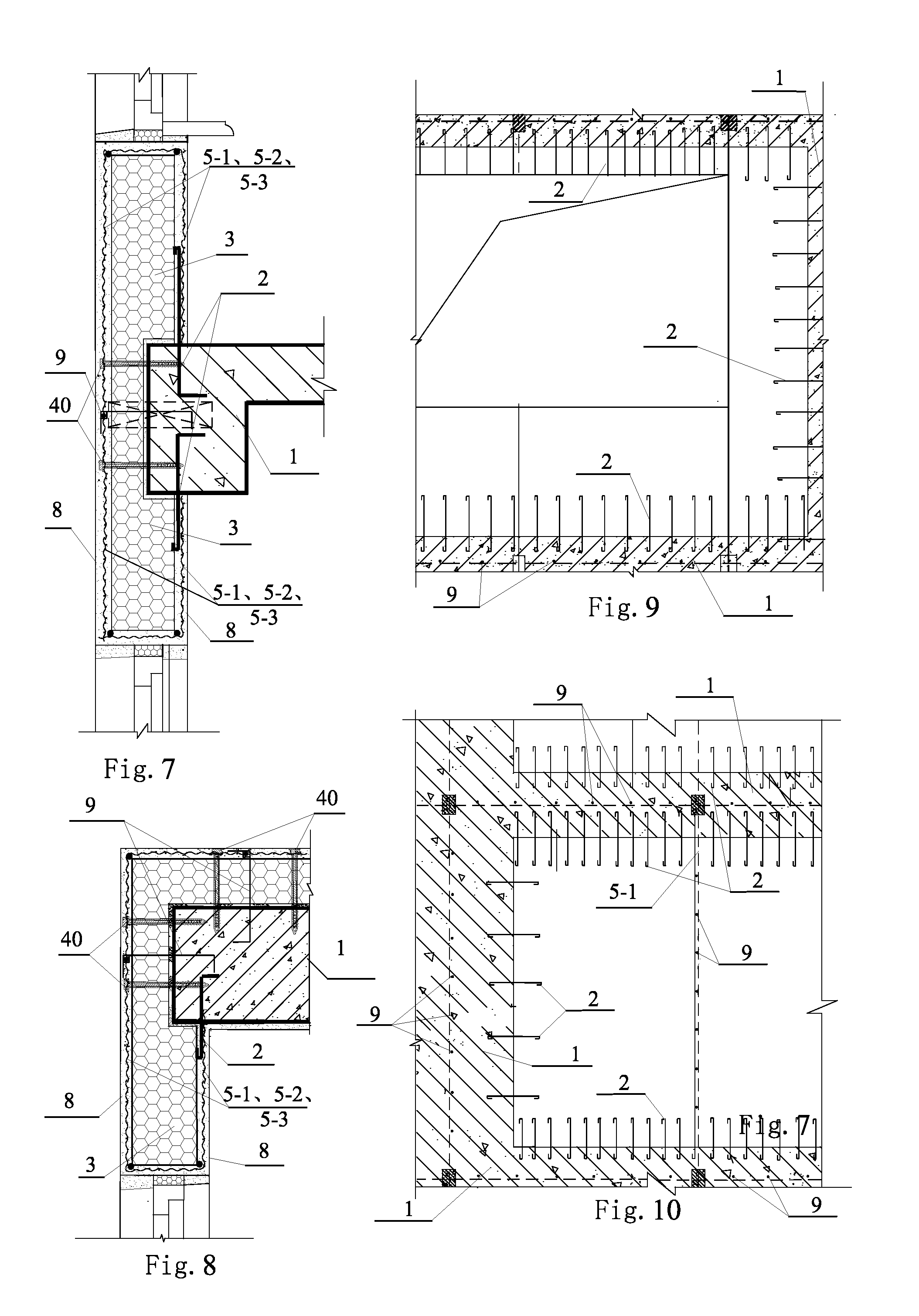

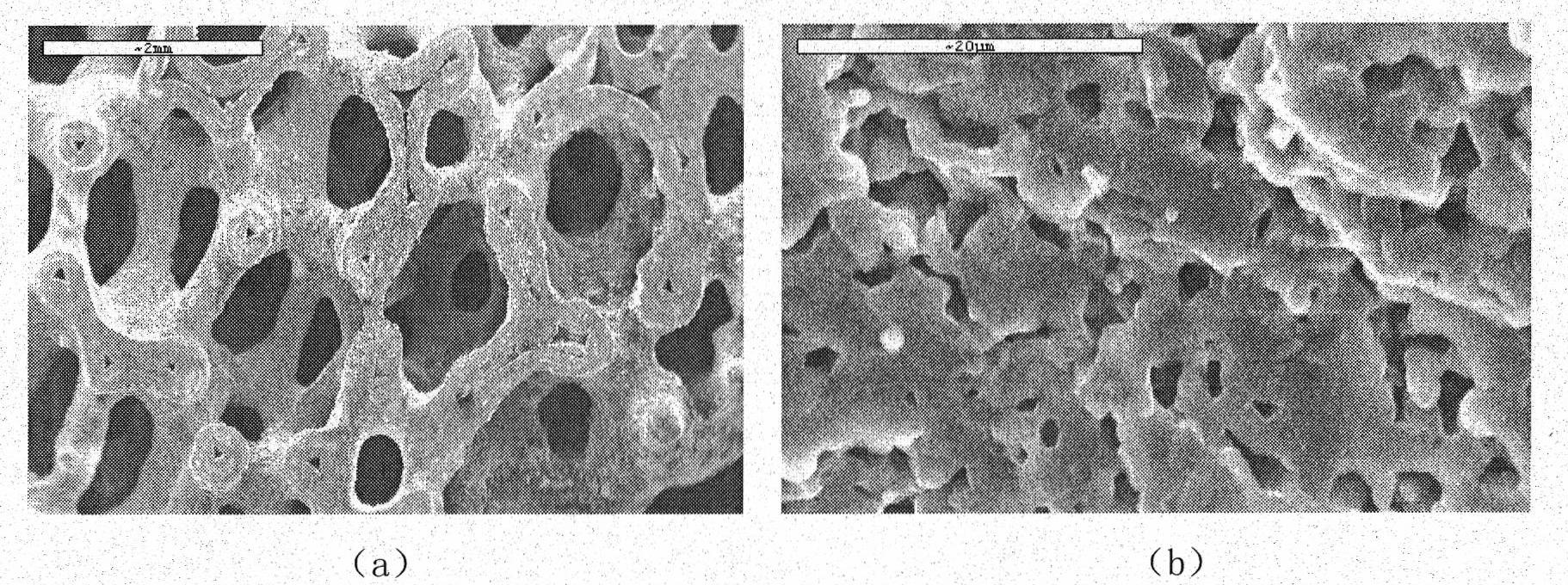

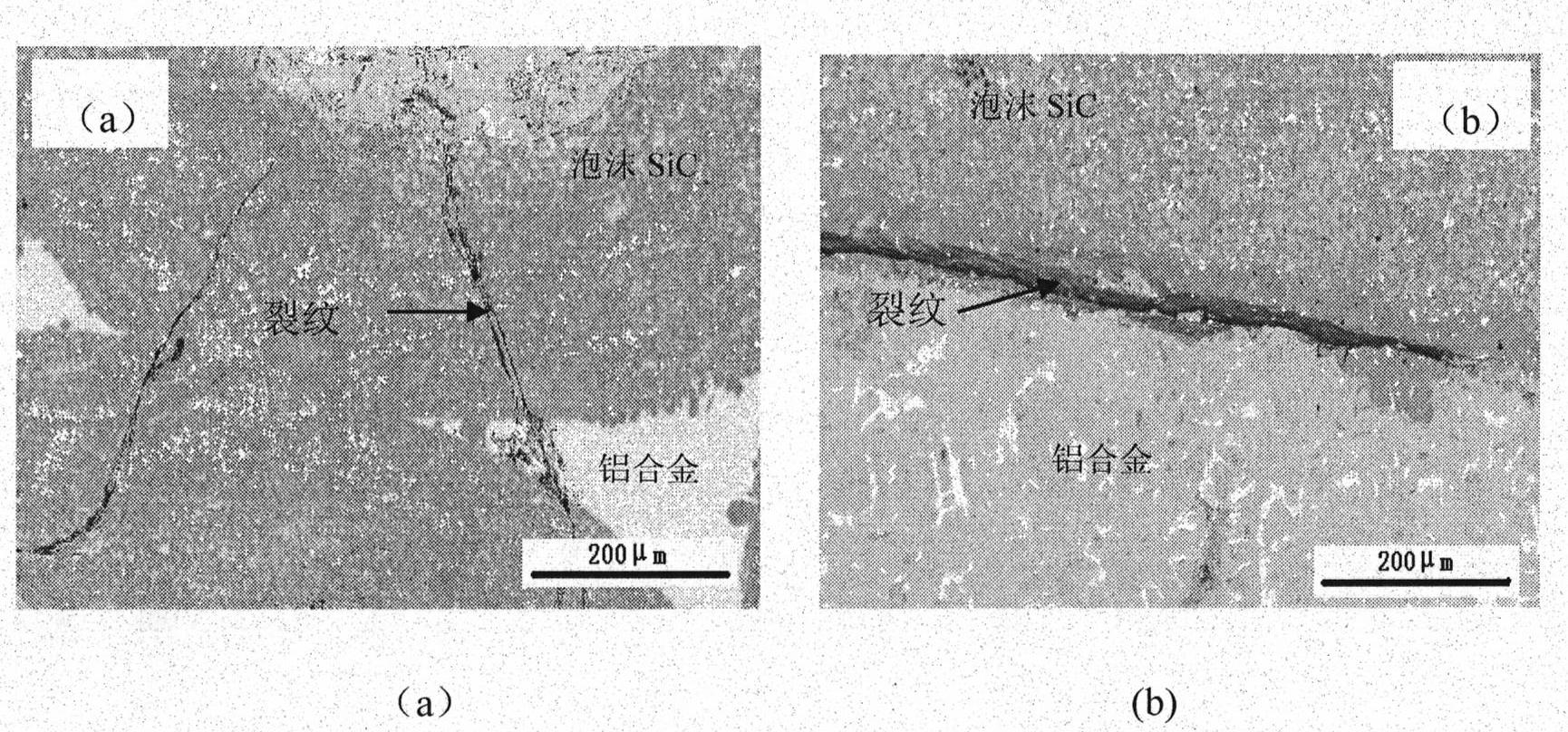

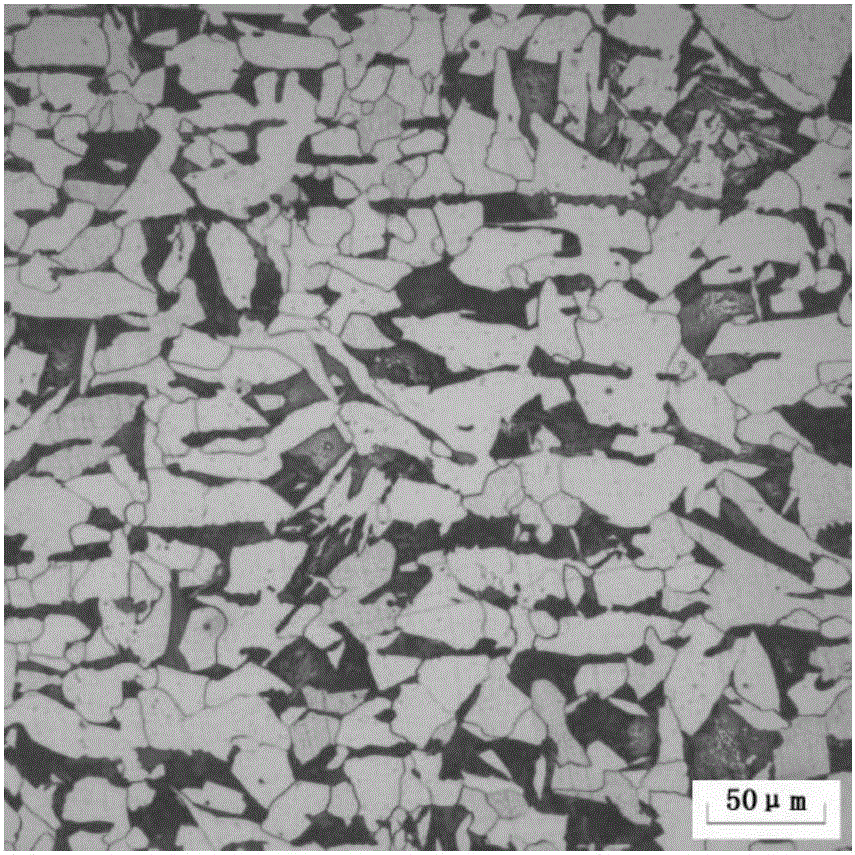

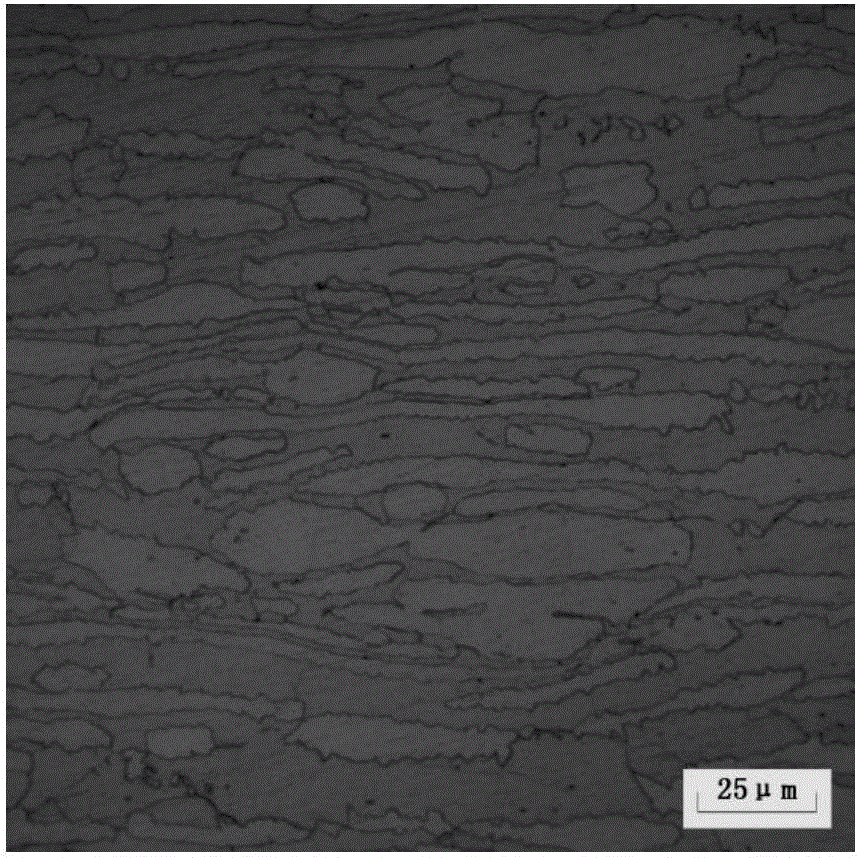

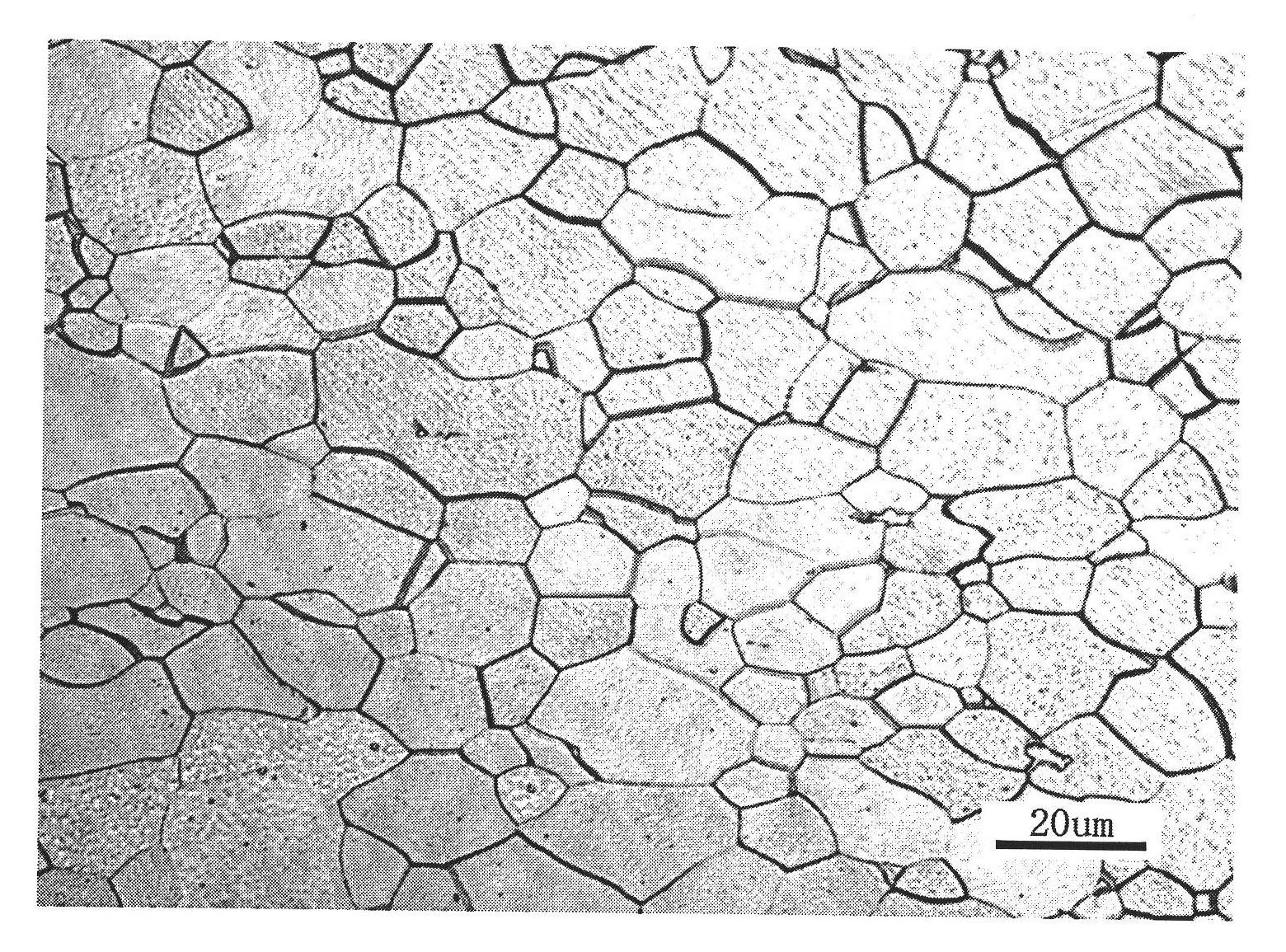

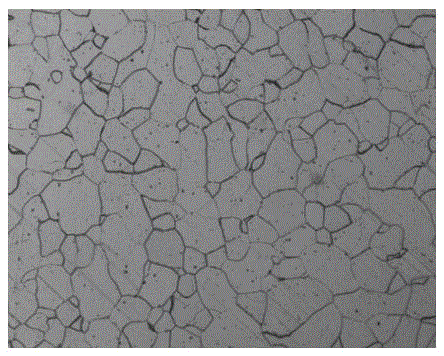

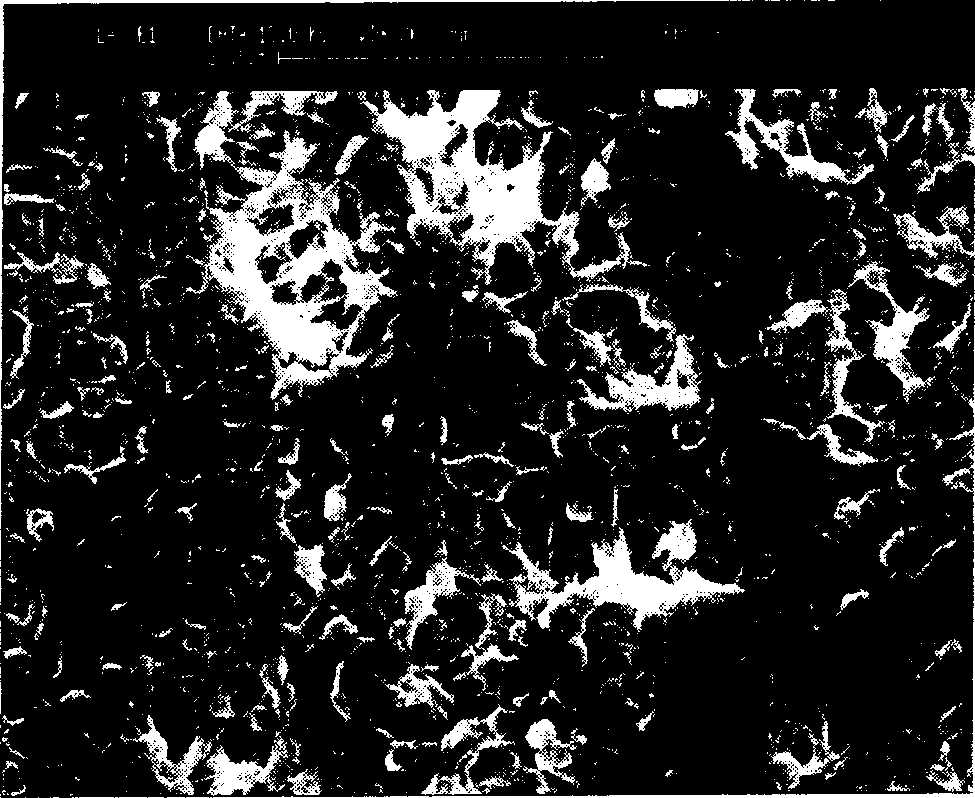

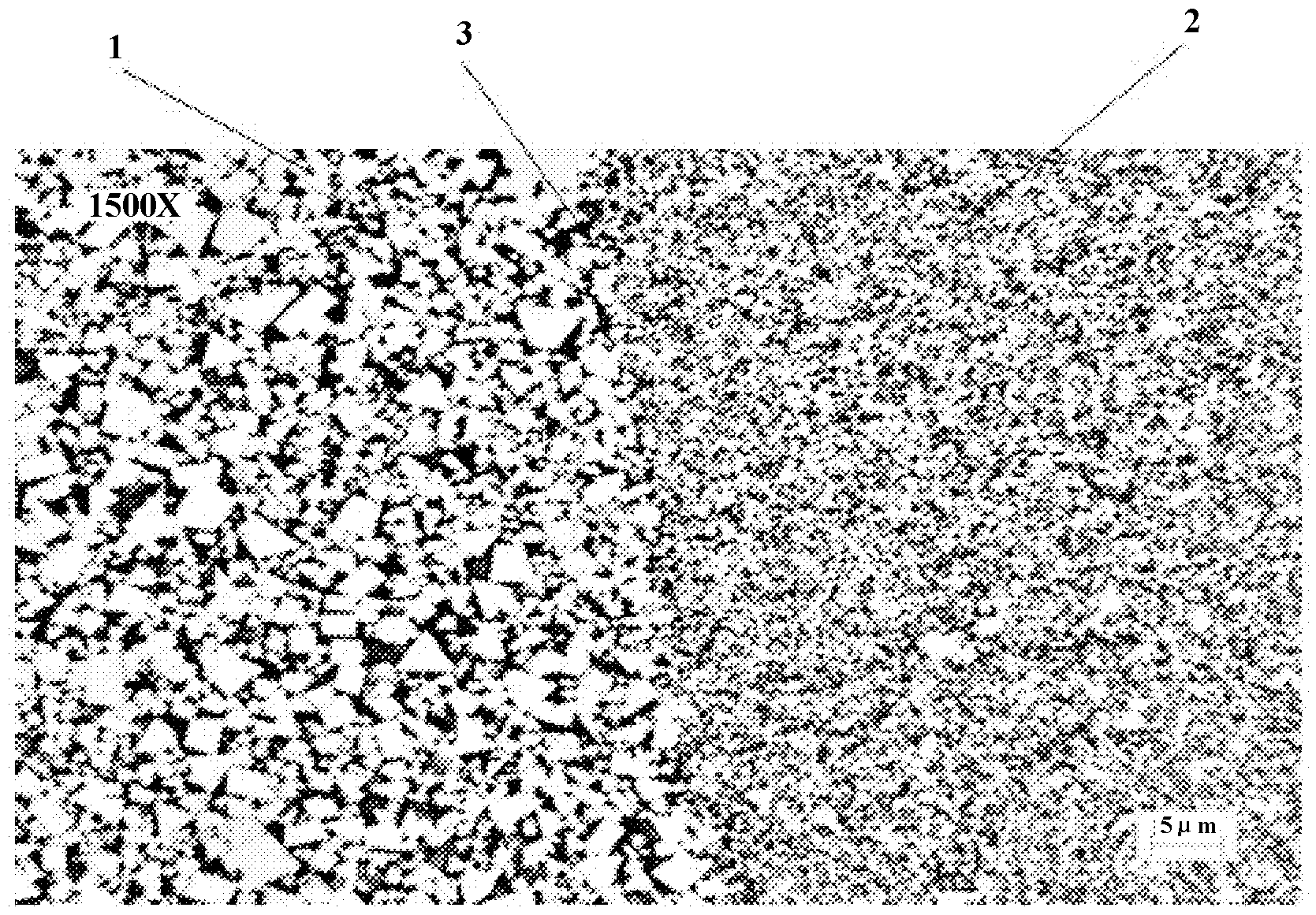

Double-scale silicon carbide foam ceramic material and preparation method thereof

ActiveCN102101785ASimple preparation processAperture controllableCeramicwareMicron scaleNetwork structure

The invention relates to the field of foam ceramics, in particular to double-scale foam ceramics with macro-scale three-dimensional communicated hole diameter and micron-grade three-dimensional communicated hole diameter and a preparation method thereof. The silicon carbide foam ceramics have a three-dimensional communicated network structure; a millimeter-grade hole diameter is expressed in macrography; and a micron-grade mutual communicated mesh is expressed in a ceramic skeleton rib. A hole forming agent is uniformly mixed into silicon carbide slurry in the process of moulding a foal ceramic blank so that the silicon carbide foam ceramics are made into double-scale foam ceramics; and the double-scale silicon carbide foam ceramics are three-dimensional communicated network foam ceramicswhich simultaneously have macro-millimetre scale hole diameter and skeleton rib internal micron scale hole diameter. By being used as a reinforced body of a ceramic / metal double-continuous phase composite material, the double-scale silicon carbide foam ceramic material can eliminate foam skeleton cracks in a composite material, improve composite quality and expand the application of the compositematerial in friction brake, armour protection, electronic packaging, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

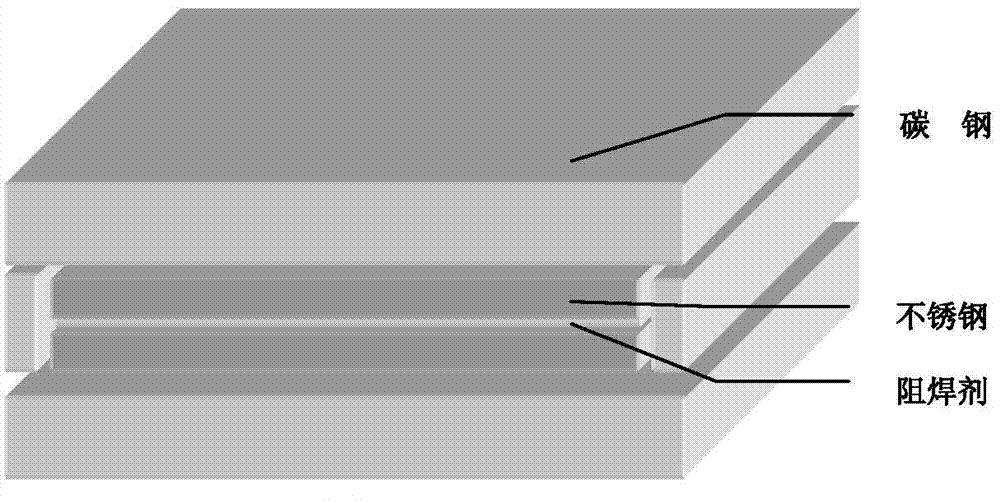

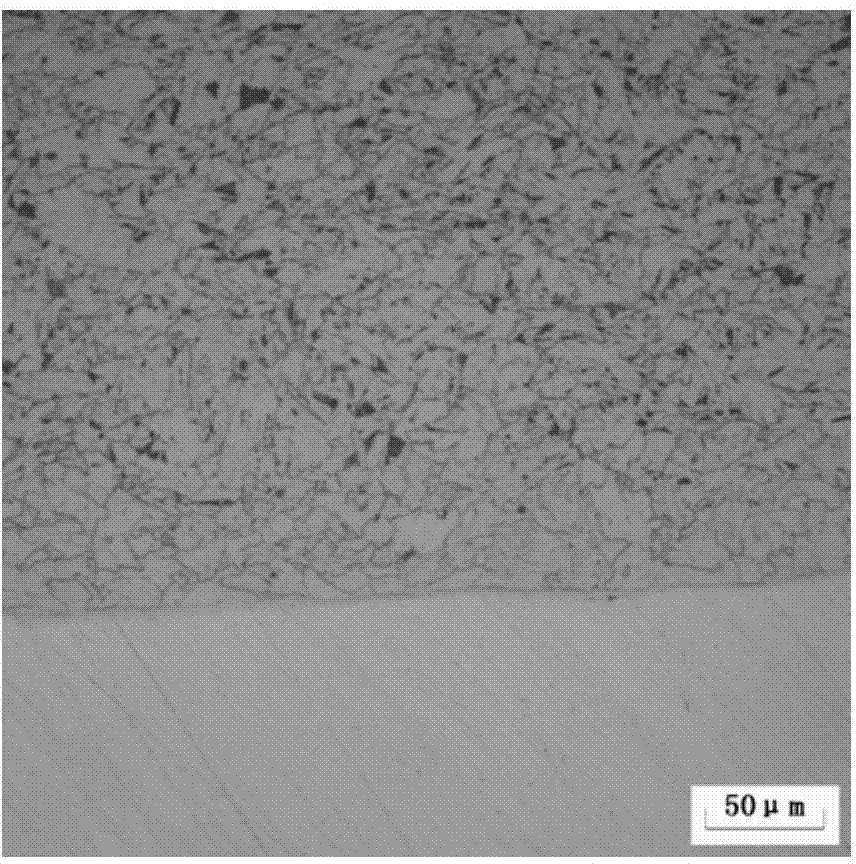

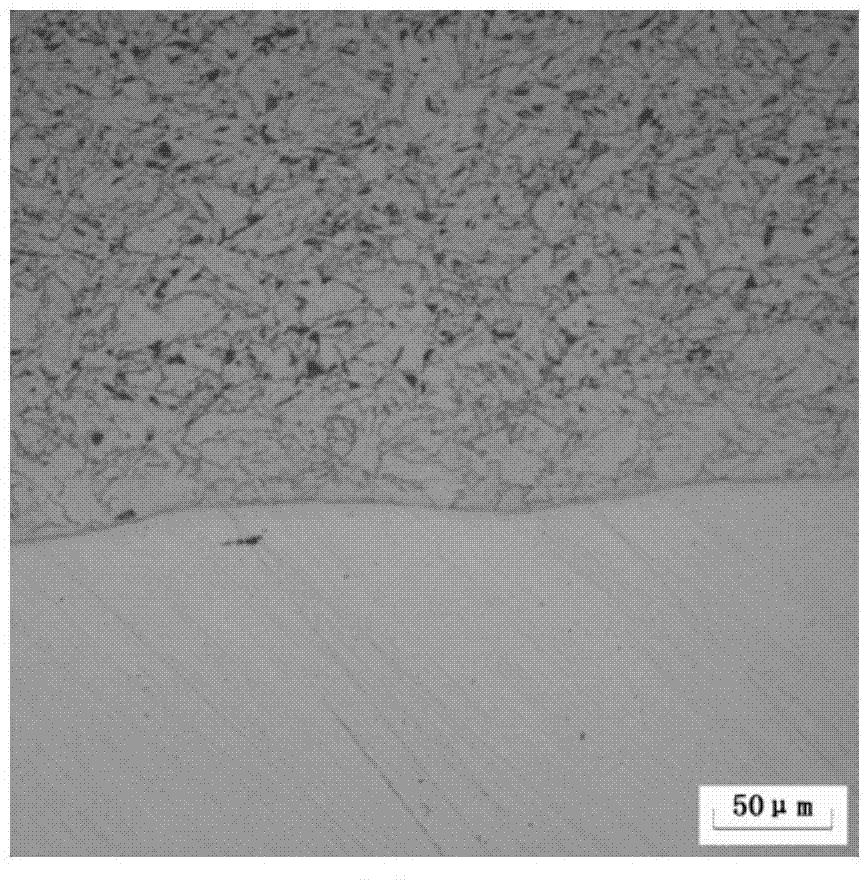

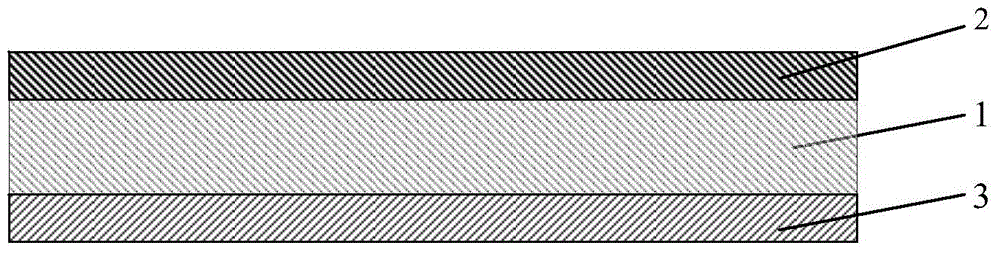

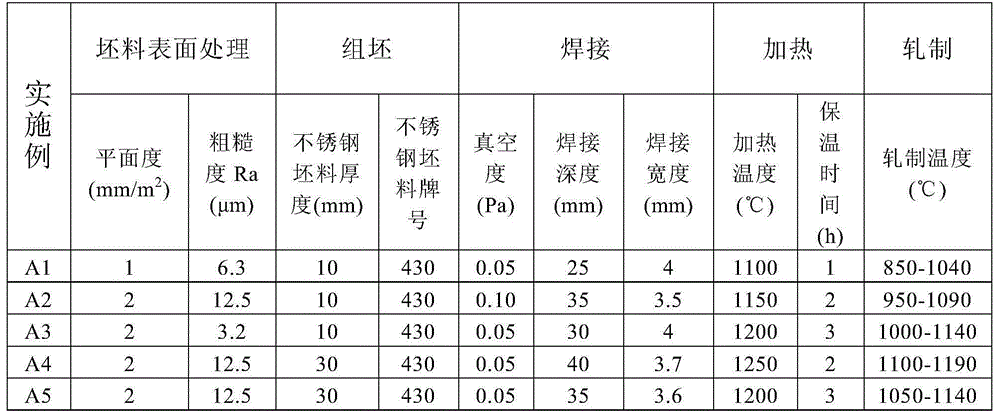

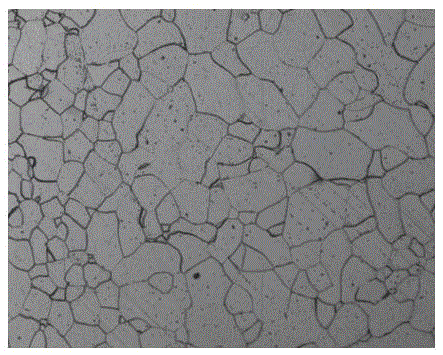

Carbon steel and duplex stainless steel composite steel plate and production method thereof

InactiveCN105772507AComposite goodStrong resistance to intergranular corrosionTemperature control deviceMetal rolling arrangementsWater coolingComposite plate

The invention discloses a carbon steel and duplex stainless steel composite steel plate and a production method of the steel plate, and belongs to the technical field of production of metal composite plates. The steel plate is completed through a steel billet assembly, heating, direct rolling, air cooling or water cooling and tempering process route. Symmetric composite assembly is adopted, the upper layer and the lower layer are Q245R carbon steel, S32205 duplex stainless steel is arranged on the two layers of the middle, scaling powder is not added into the position between the carbon steel and duplex stainless steel, a separant is added to the position between the duplex stainless steel, four-side welding and side sealing are carried out on a steel billet, and vacuumizing treatment is carried out. The carbon steel and duplex stainless steel composite steel plate has the beneficial effects of being good in composite effect and having the higher mechanical property and intergranular corrosion resistance.

Owner:SHOUGANG CORPORATION

Lightweight, fiber-reinforced cementitious panels

ActiveUS7732032B2Significant toughnessComposite goodConstruction materialCovering/liningsCement boardToughness

Lightweight, fiber reinforced, cementitious panels possessing exceptional toughness for use as building components in applications such as roofing elements, siding elements, framing and sheathing elements, and substrate elements for installation of floor finishes in residential and other building construction types. The panels employ a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, PVA fibers and lightweight filler. The inorganic binder may be, for example, hydraulic cement alone, or a combination of hydraulic cement and pozzolan / s, or a combination of hydraulic cement, alpha hemihydrate, active pozzolan and optionally lime. The PVA fibers reinforce the continuous phase and are randomly distributed throughout the composite. Typical panels of the invention have a density of 60-85 pcf.

Owner:UNITED STATES GYPSUM CO

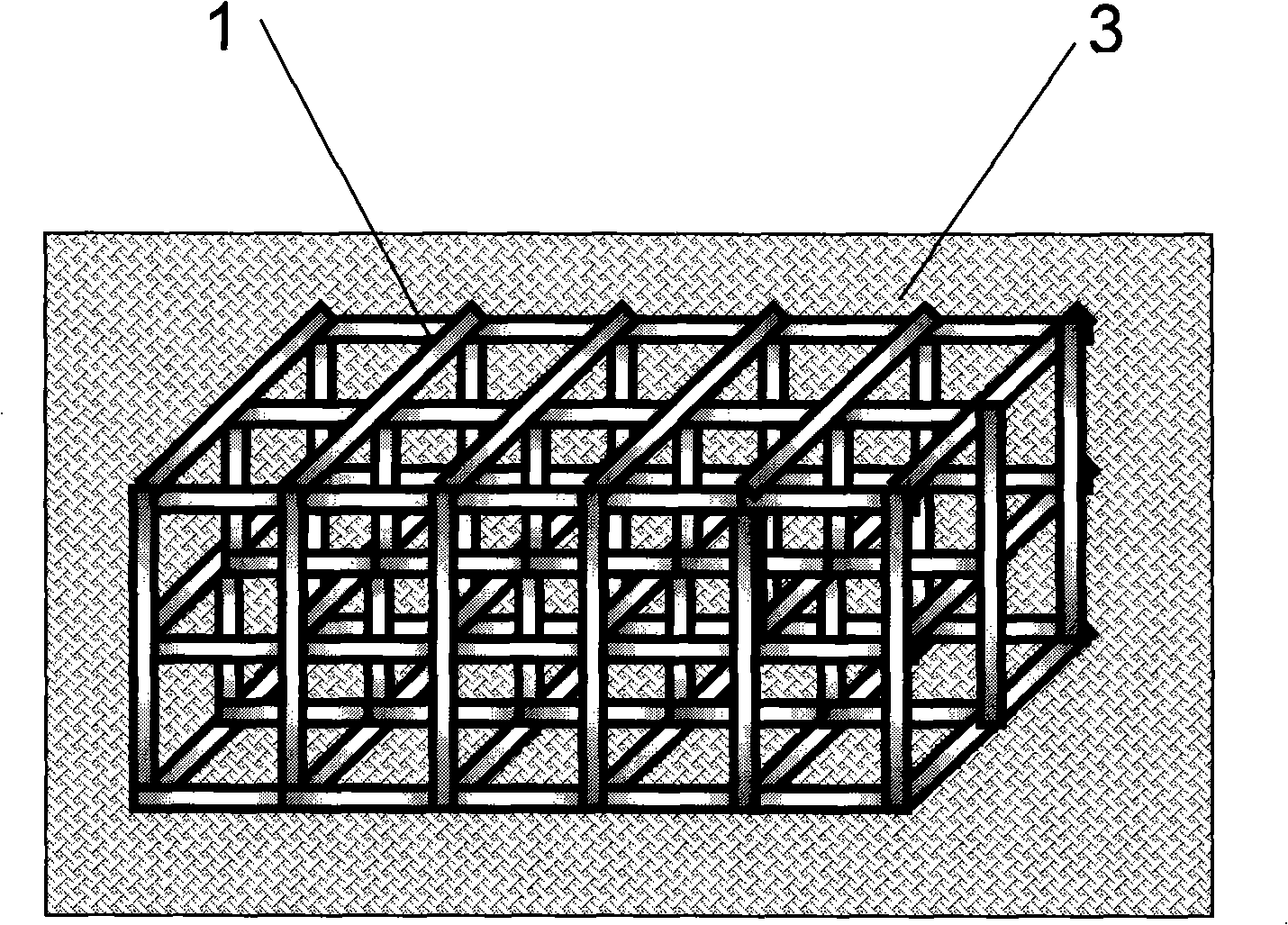

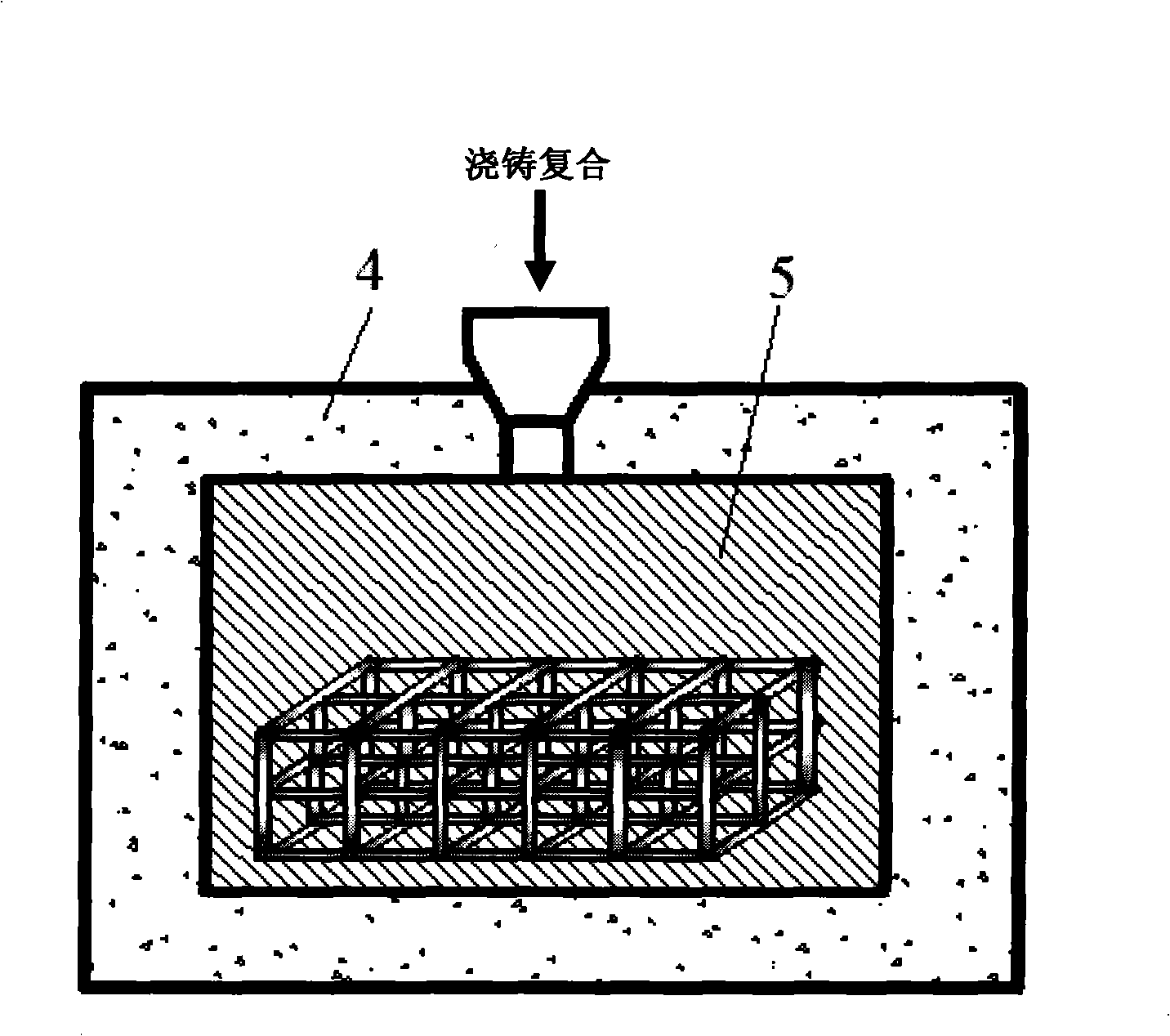

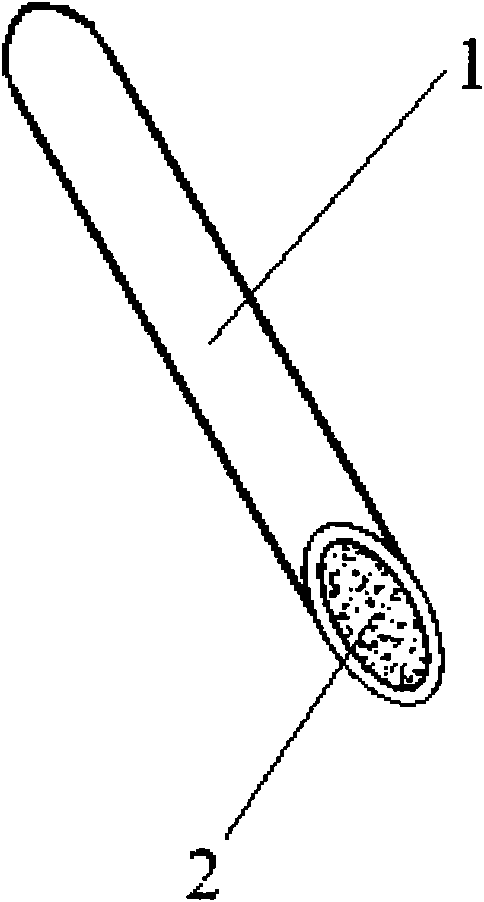

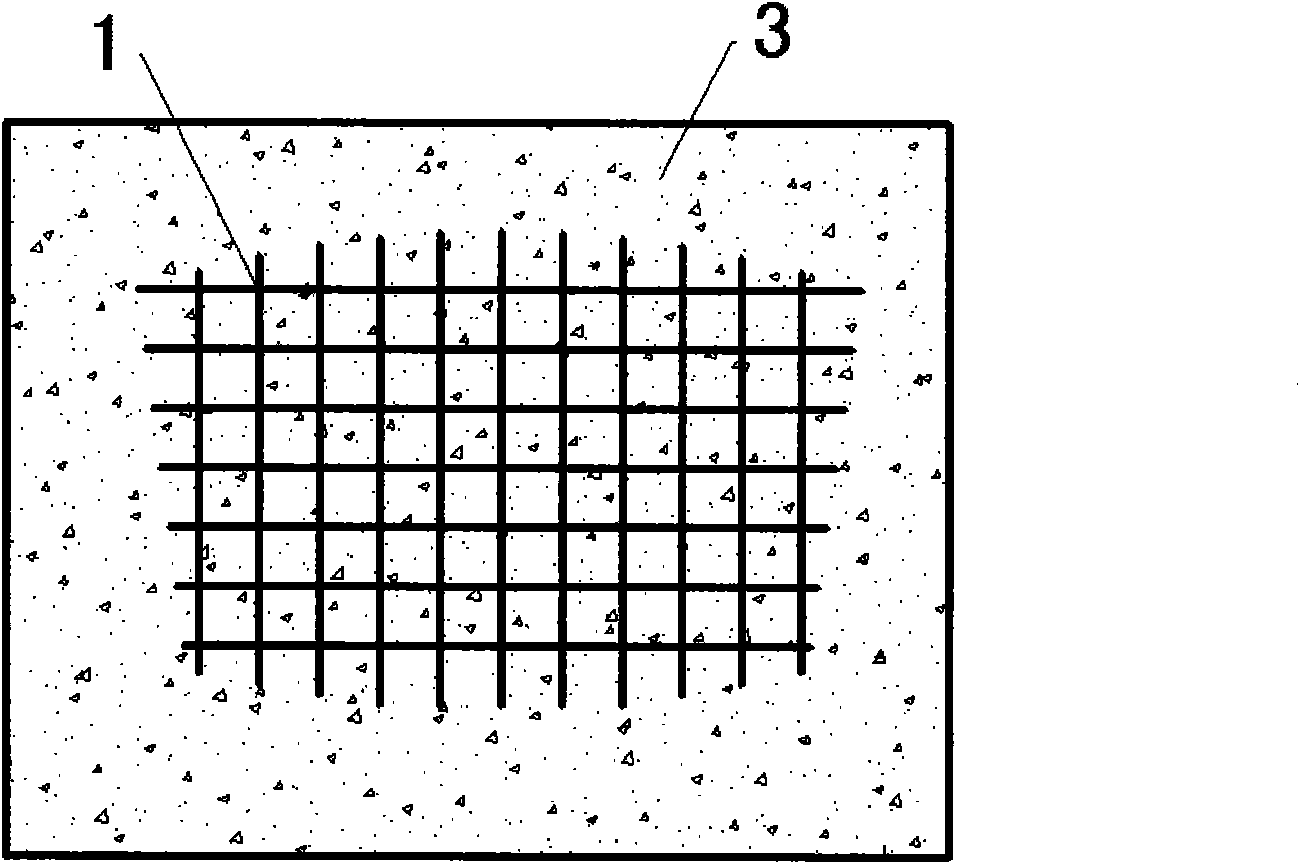

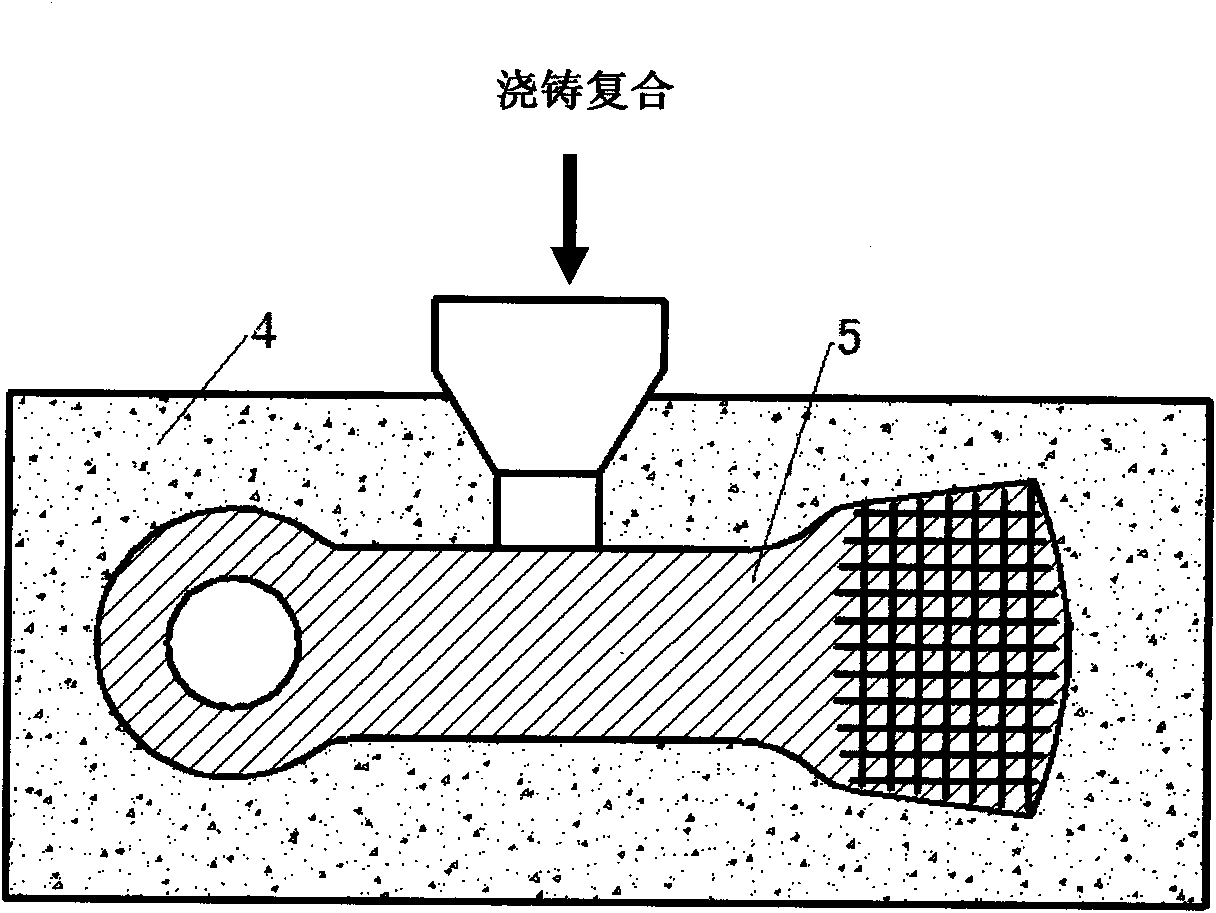

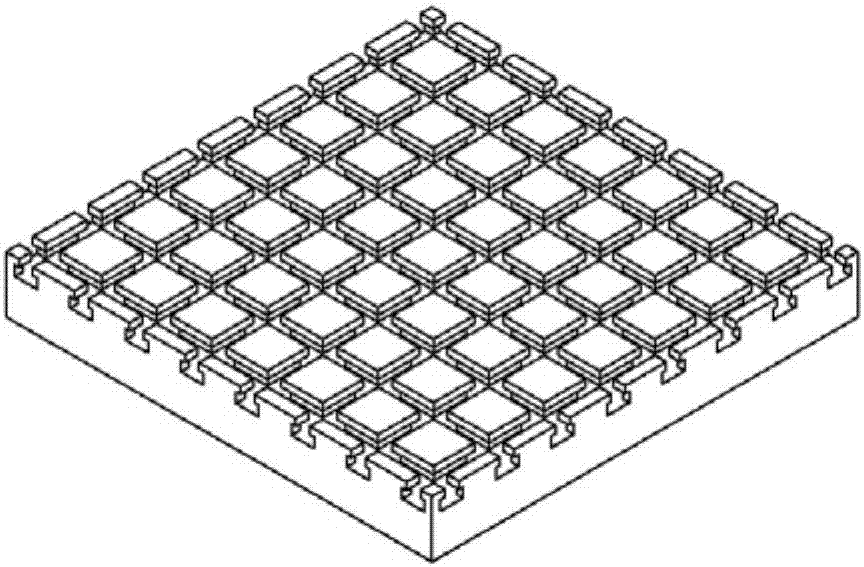

Preparation method of reinforced composite wear-resistant lining board of precast framework

The invention discloses a preparation method of a reinforced composite wear-resistant lining board of a precast framework. The prepared reinforced composite wear-resistant lining board is formed by compounding a framework reinforced body containing hard phases and base body metal. The preparation method comprises the following steps: adopting a framework precast body made of tube wires filled with hard materials, performing the vacuum high-temperature sintering, forming the framework reinforced body containing hard phases, and leading the framework reinforced body to perform the metal casting composite molding with the base body metal, so as to form the lining board formed by compounding the framework reinforced body containing hard phases and the base body metal. The framework reinforced body is performed by the vacuum high-temperature sintering to form a complete metallurgical texture structure, which has order arrangement, uniform distribution, stable performance and strong integrity, can always keep complete framework structure after compounding with the base body metal, thereby developing the high wear-resistance of the hard phases in the framework reinforced body, and keeping better flexibility of the base body metal. The reinforced composite wear-resistant lining board can be compounded locally or gradiently, or integrally, and can be widely applied to wear-resistant fields of mine, electricity, metallurgy, coal, building materials, and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

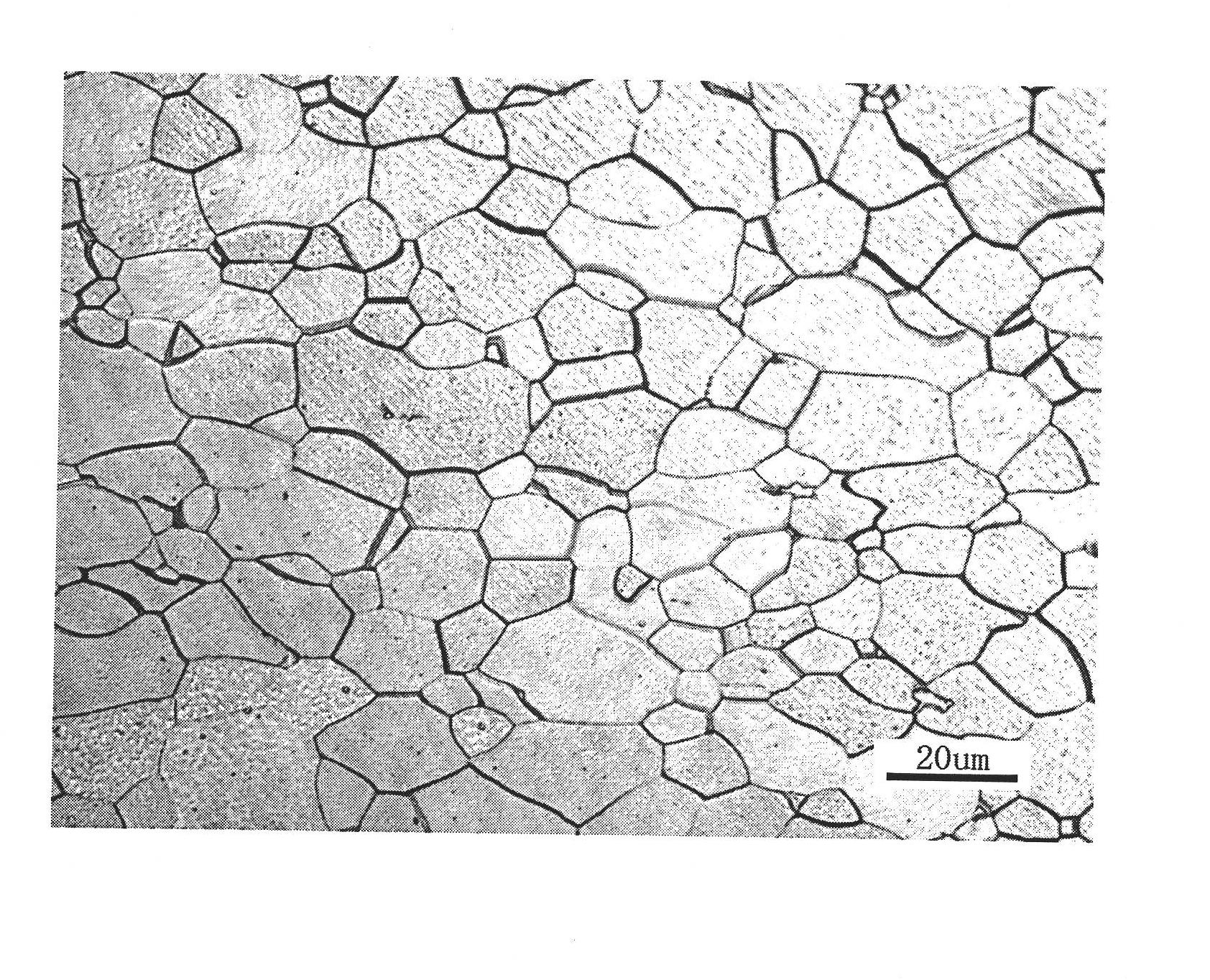

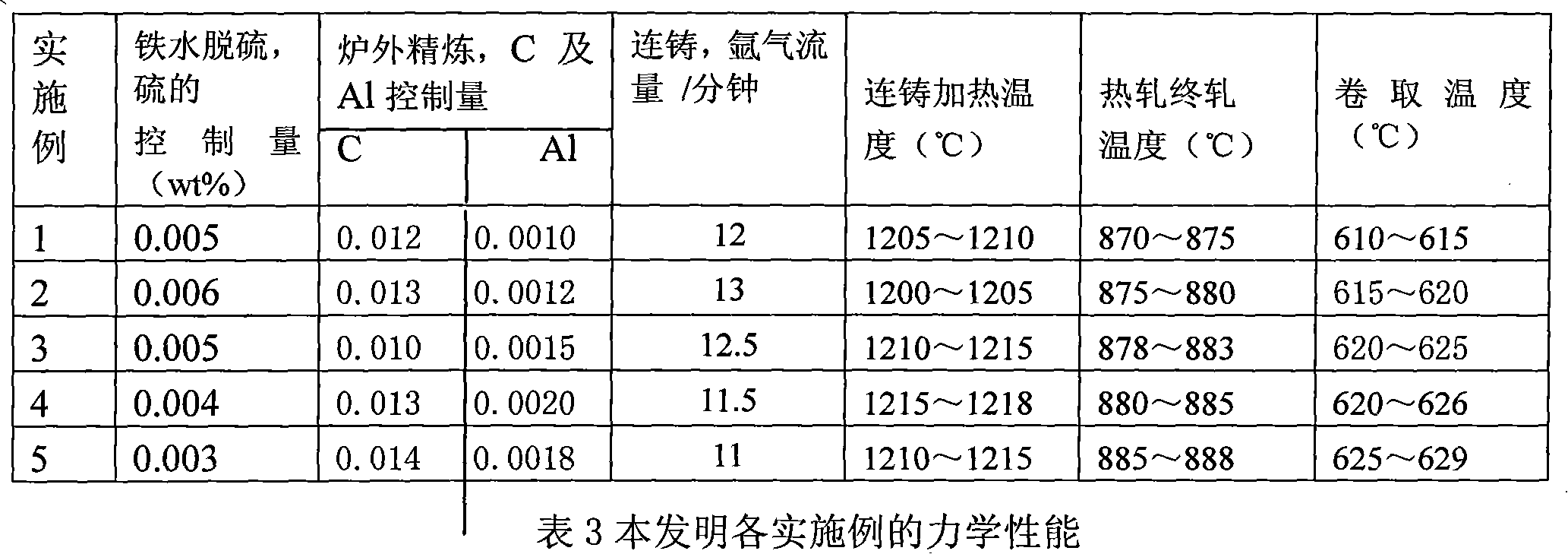

Steel-aluminum compound hot rolled steel with tensile strength of 340MPa and production method thereof

The invention relates to steel for parts with high requirements on thermal conductivity, such as radiators and the like used by power plants of 0.3 million kilowatts and above. The steel comprises the following components by weight percentage: 0.010-0.014% of C, less than 0.018% of Si, 0.30-0.35% of Mn, 0.001-0.002% of Al, not more than 0.02% of P, less than 0.06% of S and not more than 0.003% of O. The steps are as follows: carrying out desulfurization on molten iron; refining outside a furnace; carrying out continuous casting, and adopting a covering agent with 0.5% of C and argon for protecting pouring; heating a continuous casting slab to 1200-1218 DEG C; carrying out hot rolling, and controlling the final rolling temperature to be 870-888 DEG C; and coiling and controlling the temperature to be 610-629 DEG C. The steel can ensure the plasticity of the radiators used by the power plants of 0.3 million kilowatts and above; a compound layer does not form Fe-Al brittle phase and has good compound performance; and the steel can lead the rigidity of the radiator to be high and ensure the stability of the shape and the size of the processed heat exchanger.

Owner:武汉钢铁有限公司

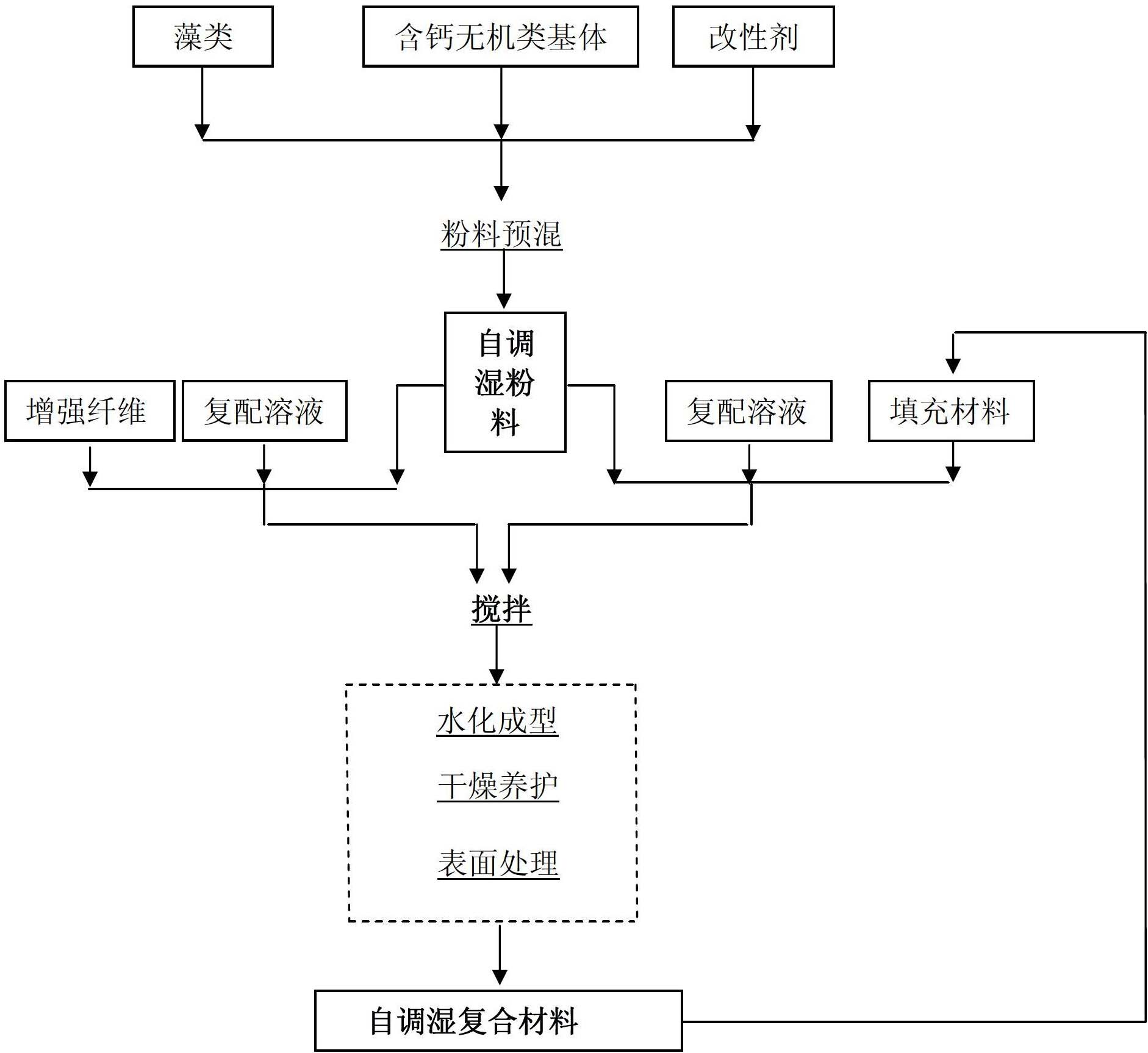

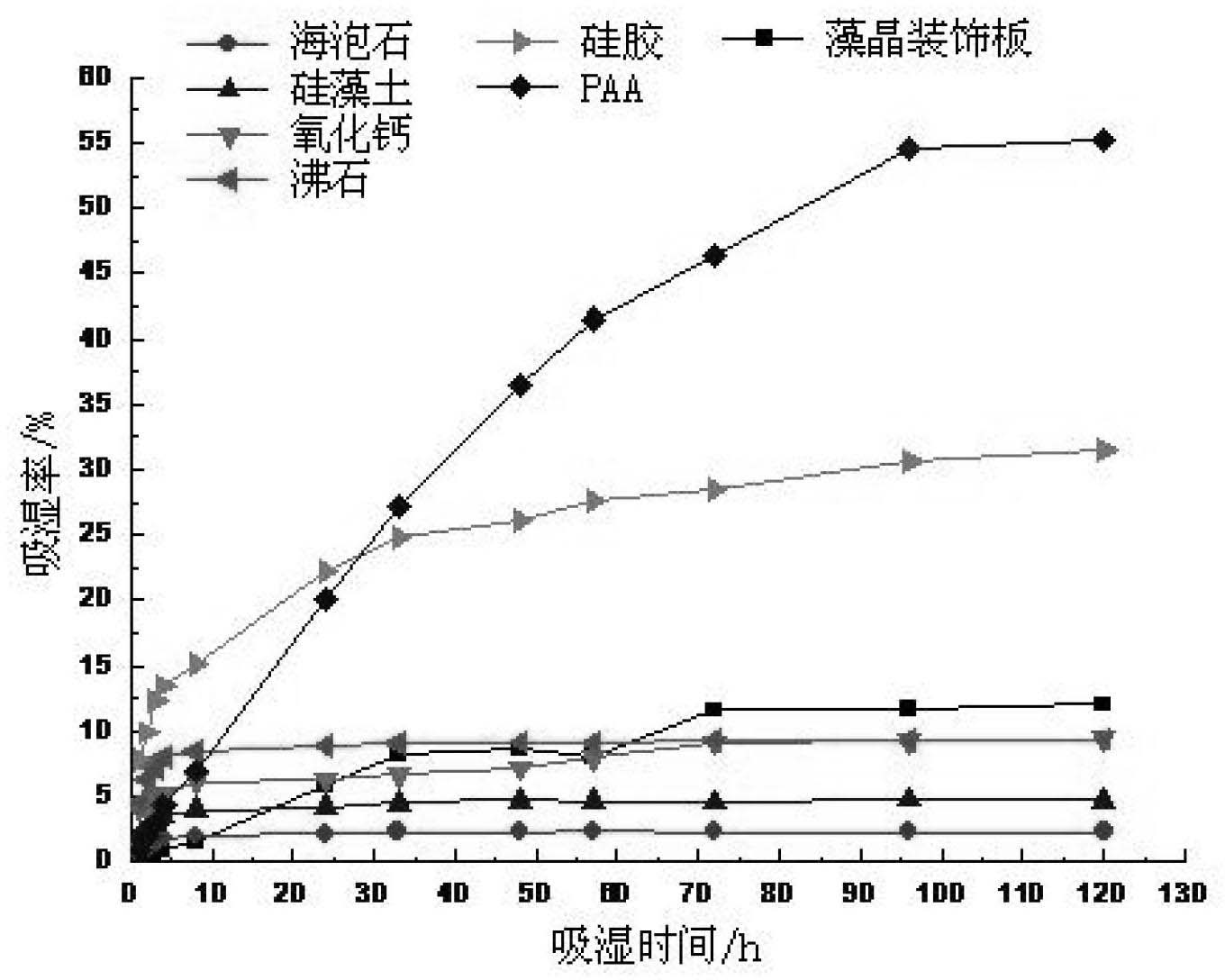

Composite material with self-regulating function and production method thereof

The invention provides a composite material with a self-regulating function. The composite material is prepared by comprising the following components in parts by weight: 45-73 parts of powder with the self-regulating function and one or two of 0.15-1.2 parts of reinforced fibers or 15-20 parts of fillers, which are added into 20-40 parts of combination solution; the powder with the self-regulating function is prepared by the following components: calciferous inorganic matrixes, algae and modifying agent with the weight ratio being 38-55:6-16:3-6; and the combination solution is prepared by compounding the following components in parts by weight: 100 parts of clear water, 1.5-2.0 parts of crystal modifier, 0.4-0.5 part of waterproof agent, and 0.4-0.5 part of defoamer. The moisture absorption of the composite material with the self-regulating function reaches 12 percent, the moisture desorption reaches 8 percent, the combination effect of the self-regulating function and the recombination rate of the self-regulating function of the composite material are better than those of traditional inorganic salt and inorganic porous materials, and the manufacturing cost and the application field of the composite material are better than those of special silica gel and organic polymer. The invention also provides a preparation method of the composite material.

Owner:湖北格林森绿色环保材料股份有限公司

Carbon steel and austenitic stainless steel combined steel plate and production method thereof

InactiveCN104760351AImprove toughnessAccelerated corrosionMetal layered productsSheet steelComposite plate

The invention discloses a carbon steel and austenitic stainless steel combined steel plate and a production method thereof, and belongs to the technical field of metal composite plate production. A steel blank is adopted for symmetrical combination (dual-blank lamination) for the combined steel plate; the upper and lower layers are made from carbon steel made from X70 materials; the two middle layers are made from 316L stainless steel; scaling powder is not added between the carbon steel and the stainless steel; an insulation agent is added between stainless steel; then four edges of the steel blank are welded and sealed, and vacuumization treatment is carried out by using a vacuum dispersion pump. The blank assembling technology of the steel blank is that smelted X70 and 316L steel blanks are respectively subjected to blooming forging to the designed middle size; then the steel blank is subjected to surface polishing treatment; and then welding, edge sealing and vacuumization are carried out. The carbon steel and austenitic stainless steel combined steel plate and the production method thereof have the advantages that the use safety of a petroleum pipeline is improved, and great significance is achieved for the pipeline development of China.

Owner:SHOUGANG CORPORATION

Steel plate for concrete precast element production line mould platform surface and manufacture method of steel plate

ActiveCN104786582AImprove composite effectHigh strengthAuxillary arrangementsMetal rolling arrangementsMechanical propertyAustenitic stainless steel

The invention provides a steel plate for a concrete precast element production line mould platform surface and a manufacture method of the steel plate. The steel plate for the mould platform surface comprises a carbon steel base material layer and a stainless steel composite layer(s) compounded on the upper surface or / and the lower surface of the carbon steel base material layer; the carbon steel base material layer and the stainless steel composite layer(s) are combined through the manner that atoms in the carbon steel base material layer and atoms in the stainless steel composite layer(s) mutually diffuse towards adjacent layers. The steel plate for the mould platform surface is formed by compounding ferritic stainless steel with extremely high magnetic conductivity and an ordinary carbon steel plate, and is good in corrosion resistance, excellent in wear resistance, good in machinability, high in solderability, good in forming property, excellent in both thermal conductivity and magnetic conductivity, high in mechanical strength and excellent in other comprehensive mechanical properties, the manufacture cost of the mould platform is effectively reduced and the service life of the mould platform is prolonged.

Owner:BAOSHAN IRON & STEEL CO LTD +1

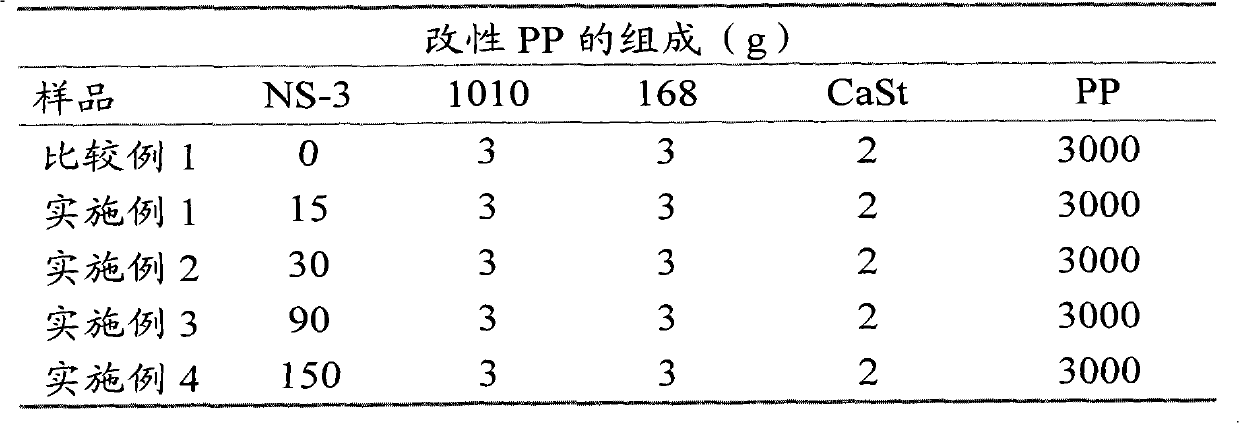

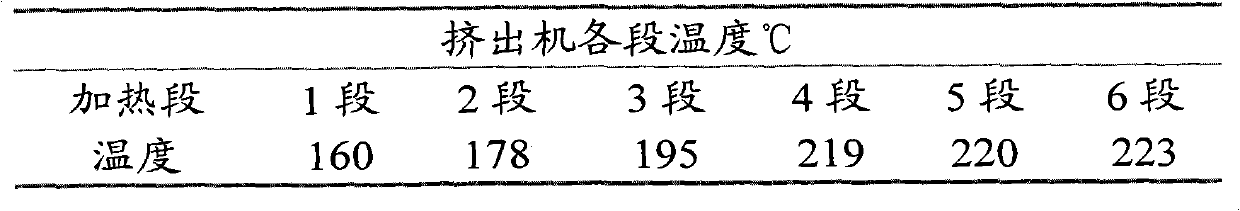

Nano-modified polypropylene soft packaging material

ActiveCN102020796AImprove mechanical propertiesImprove printing effectProcedure AgentsPolymer science

The invention provides a packaging polyolefin processing agent composition which is a mixture of nano silicon dioxide and ethylene-vinyl acetate copolymer, wherein the mass of the nano silicon dioxide accounts for 10-40% of the total mass of the processing agent composition, and the mass of the ethylene-vinyl acetate copolymer accounts for 60-90% of the total mass of the processing agent composition. The invention also provides packaging polyolefin modified by the processing agent composition. The modification of the nano silicon dioxide has greater influences on the mechanical property, the crystallization property, the polarity, the printing property, the composite property, the residue of organic solvent, and other indexes of the polypropylene. A result shows that after the polypropylene soft packaging material is subjected to nano modification, the toughness of the polypropylene soft packaging material is greatly enhanced; meanwhile, the polarity, the printing ink adhesive force and the peel strength of the material are improved; the adsorption of the modified polypropylene on toluene is greatly reduced. After nano modification, the using performance of the polypropylene used as the soft packaging material can be greatly improved.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

LED assembly

InactiveUS7972032B2Increase brightnessComposite goodPlanar light sourcesPoint-like light sourceEngineeringLight emitting device

The present invention relates to a light emitting device assembly. Such a LED assembly comprises a plurality of lamp-type light emitting devices, each of said lamp-type light emitting devices having a light output side and side walls. The plurality of lamp-type light emitting devices are directly or indirectly connected to each other via said side walls. The latter allows to obtain a compact LED assembly with high brightness.

Owner:BARCO NV

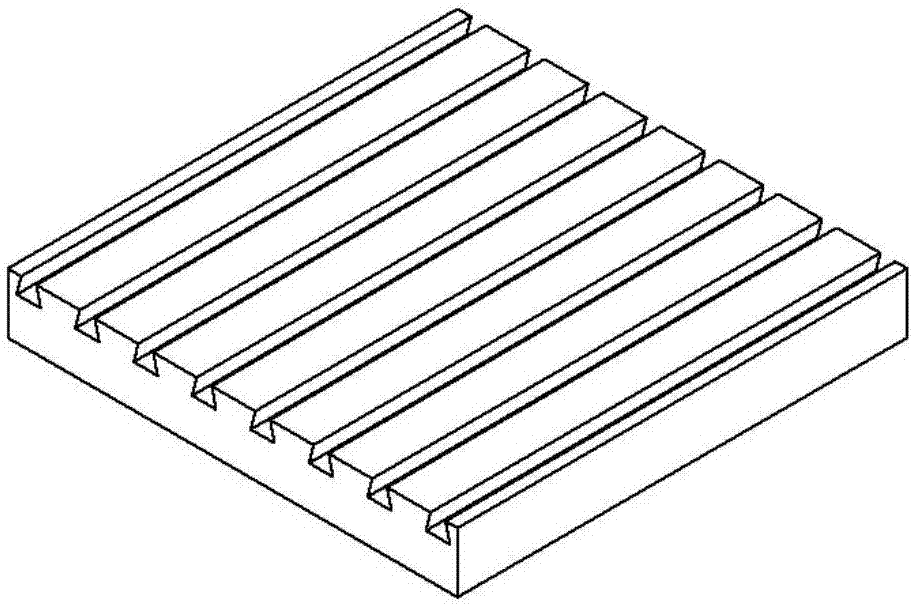

Compositing method of dovetail groove metal plate clearance fit interface

ActiveCN104289810AIncrease profitReduce pollutionMetal working apparatusNon-electric welding apparatusComposite effectInterference fit

The invention discloses a composting method of a dovetail groove metal plate clearance fit interface. The compositing method is realized through the explosive cladding method, the rolling method and the like. According to the method, after a base plate with dovetail grooves and a surface plate with dovetail grooves are in interference fit, the base plate and the surface plate are composited together through combination of a metallurgical bonding mode and a squeezing meshing mode of the dovetail grooves under the actions of energy of explosives or a rolling mechanism. Physical and chemical properties of metal sheets on the two sides of a dovetail groove combination interface are not changed, and large-area metal sheet composition can be conducted; the explosive charge for a unit of compositing area is small, and atmospheric pollution, noise pollution, explosion vibration and overpressure are reduced; during explosive welding of the metal sheets with the dovetail grooves, no boundary effect exists, the compositing effect on the periphery is good, and the lower limit and the upper limit of an explosive welding window are both increased. The compositing technology of the dovetail groove metal plate clearance fit interface can be applied to the fields such as chemical reaction containers and ships so as to meet the requirement for large-area metal composite plates.

Owner:UNIV OF SCI & TECH OF CHINA

Oxygen-bearing steel belt and production method thereof

The invention discloses an oxygen-bearing steel belt and a production method thereof and belongs to the technical field of metallurgy. The oxygen-bearing steel belt comprises, by mass, 0-0.008% of C, 0.15%-0.45% of Mn, 0-0.004% of Si, 0-0.006% of S, 0-0.020% of P, 0.001%-0.003% of Al, 0-0.0040% of N, 0-0.0050% of [O], and the balance iron and inevitable impurities. The production method comprises the specific steps of molten iron desulphurization, converter smelting, external refining, continuous casting, continuous casting slab heating, hot rolling and crimping; the production method is characterized in that the content of the [O] is controlled to be 0-0.0050% through the step of external refining. The oxygen-bearing steel belt produced through the production method is good in steel-aluminum compound property and wide in application range, the tensile strength is 315 MPa or higher, and the yield strength is 246 MPa or higher. According to the oxygen-bearing steel belt and the production method thereof, the production process cost is low, and the production stability is high.

Owner:TANGSHAN IRON & STEEL GROUP

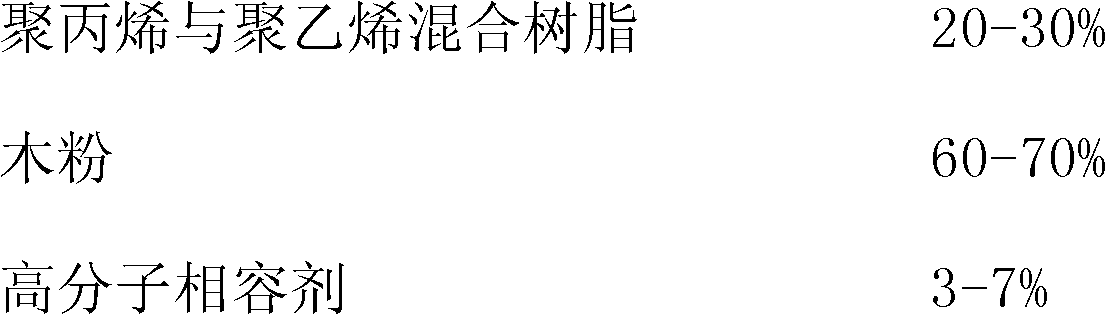

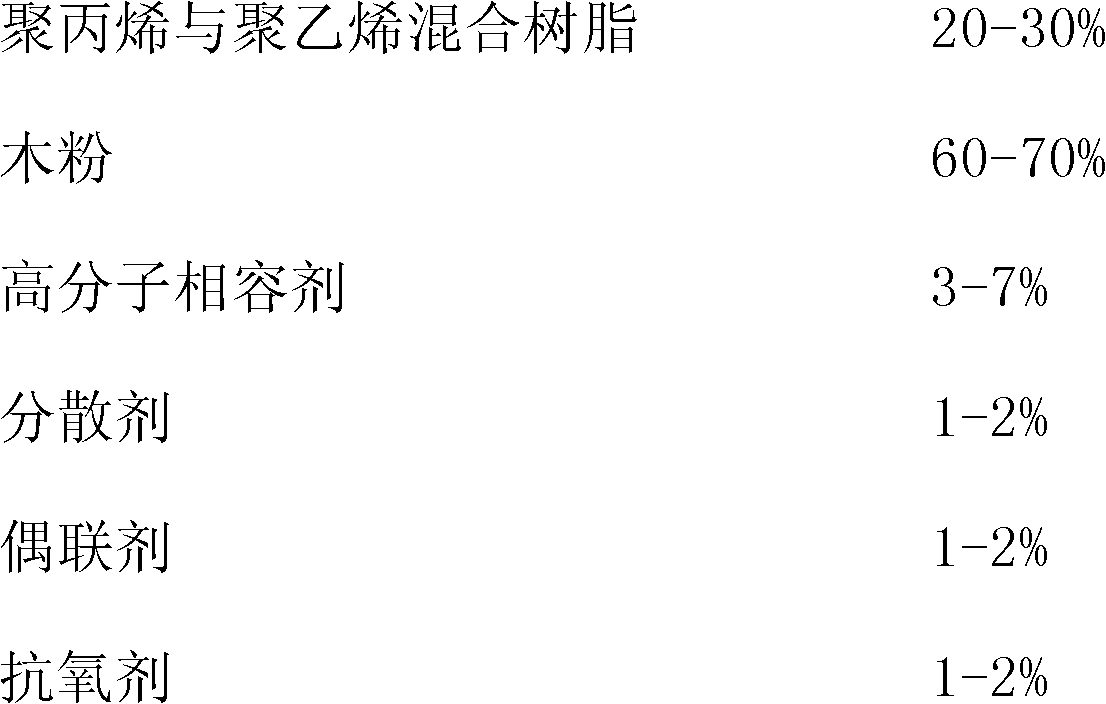

Wood powder filled polypropylene and polyethylene composite material and preparation method for same

The invention discloses a wood powder filled polypropylene and polyethylene composite material and a preparation method for the same. Components of the composite material comprise, by mass, 20-30% of polypropylene and polyethylene mixed resins, 60-70% of wood powder, 3-7% of polymeric compatibilizer, 1-2% of dispersing agent, 1-2% of coupling agent and 1-2% of antioxidant, wherein the polypropylene and polyethylene mixed resins refer to high-flowability mixed reclaimed materials reclaimed on the market and has the melt flow rate higher than 15g / 10min, the wood powder refers to wood materials reclaimed on the market, and the grain size of the wood powder ranges from 80 meshes to 100 meshes. By the aid of the composite material and the preparation method, waste plastics and wood can be reclaimed, so that a great number of wood chips and the mixed PP (polypropylene) and PE (polyethylene) reclaimed materials are consumed, and environmental pollution is avoided. Besides, the wood powder filled polypropylene and polyethylene composite material is excellent in comprehensive performance, and has the advantages of plastics and wood.

Owner:SHENZHEN KEJU NEW MATERIAL

Preparation method of epoxy resin composite material with surface modified spherical SiO2 particles

InactiveCN101250317AImprove hydrophobicityImprove lipophilicityOther chemical processesEpoxyHydrophobic polymer

A preparation process of epoxy resin composite material of surface modified sphere SiO2 particle belongs to the inorganic particle chemical modification and electric appliance encapsulating material field. The process comprises conducting condensation reaction through utilizing silane coupling agent which comprises unsaturated double bond and hydroxyl group on surface of SiO2 under acidic condition, further making unsaturated monomer which is modified to lead in generate free radical copolymerization reaction in situ on the surface of particle under the initiation of free radical initiating agent, preparing modified sphere SiO2 particle whose surface has hydrophobic polymer chain, then dispersing modified sphere SiO2 particle in epoxy resin according to certain proportion, adding stoichiometric curing agent to evenly mix, and preparing epoxy resin composite material which is used as electric appliance encapsulating material. The modified sphere SiO2 particle which is filled in epoxy resin, which can reduce volume shrinking rate in curing process, increase the size ability and heat conductivity property of encapsulating appliances, and significantly increases the mechanical property of epoxy resin composite material.

Owner:JIANGNAN UNIV +1

Preparation method of framework reinforcement compound hammerhead

InactiveCN101658917AImprove wear resistanceImprove toughnessGrain treatmentsCompound aWear resistance

The invention discloses a preparation method of a framework reinforcement compound hammerhead. The made compound hammerhead is formed by compounding a framework reinforcement containing hard phase anda base metal. The method comprises the following processes: making a framework prefabricated part by utilizing a pipe thread filled with hard materials; carrying out vacuum high temperature metallurgy sintering on the framework perform so as to make the framework reinforcement containing the hard phase; and compounding the framework reinforcement with the base metal for molding to form the hammerhead formed by compounding the framework reinforcement containing the hard phase and the base metal. The framework reinforcement forms a sufficient metallurgical structure through vacuum high temperature metallurgy sintering, has orderly arrangement, uniform distribution, stable performance and strong integrity, and can keep complete framework structure when being compounded with the base metal. The invention not only exerts the highly wearable property of the hard phase in the framework reinforcement, but also keeps good toughness of the base metal, and can carry out local compound, graded compound or overall compound, thereby achieving the best use effect and obviously enhancing the comprehensive property.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

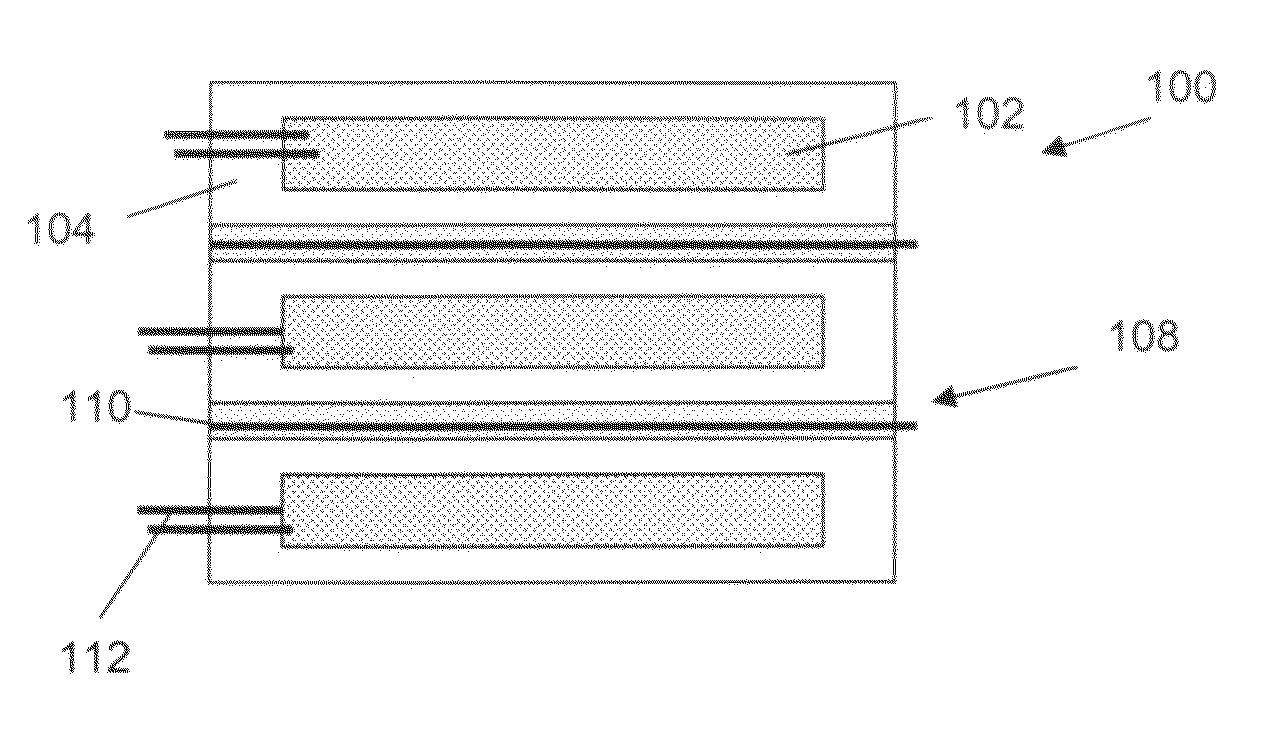

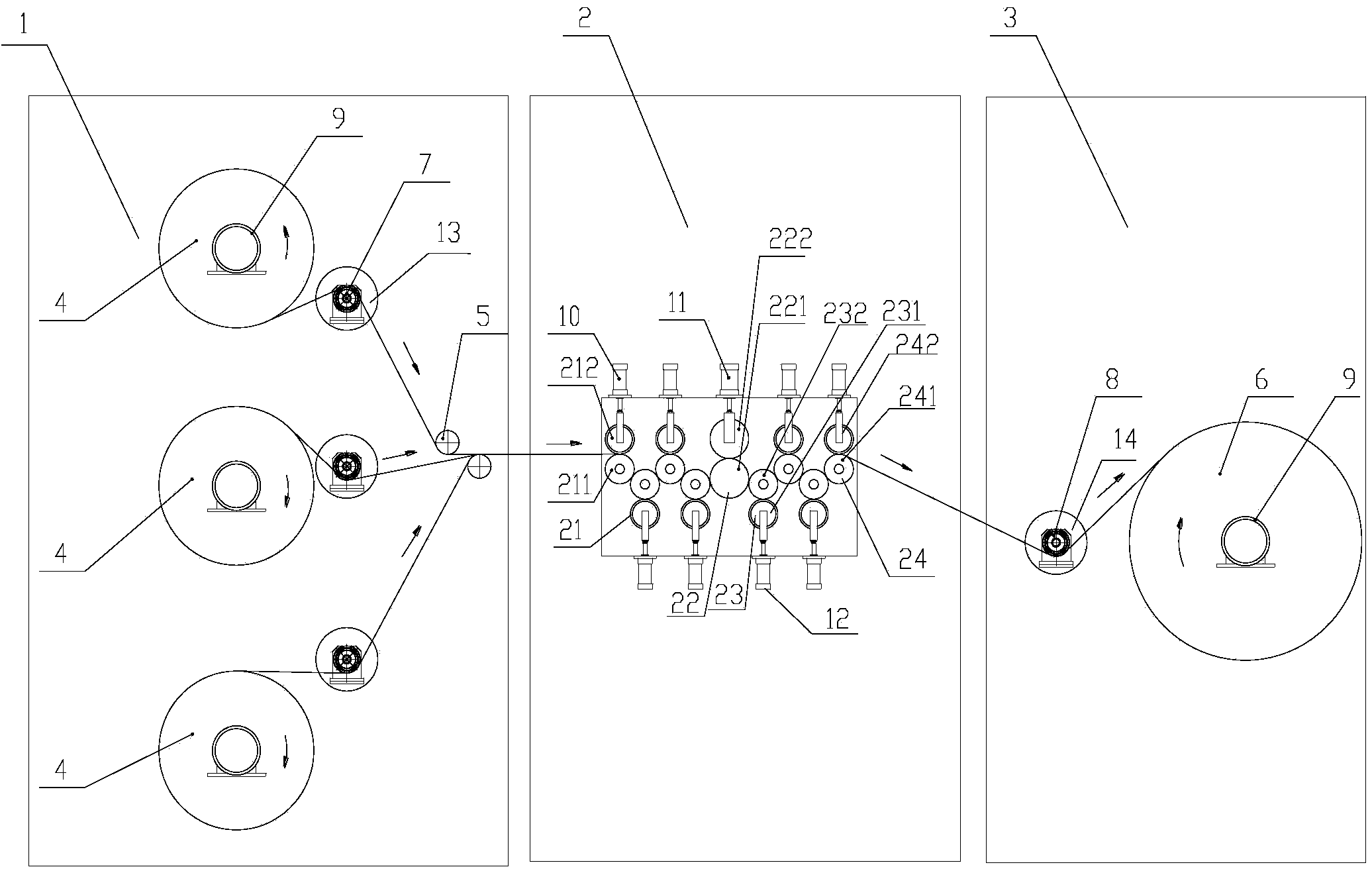

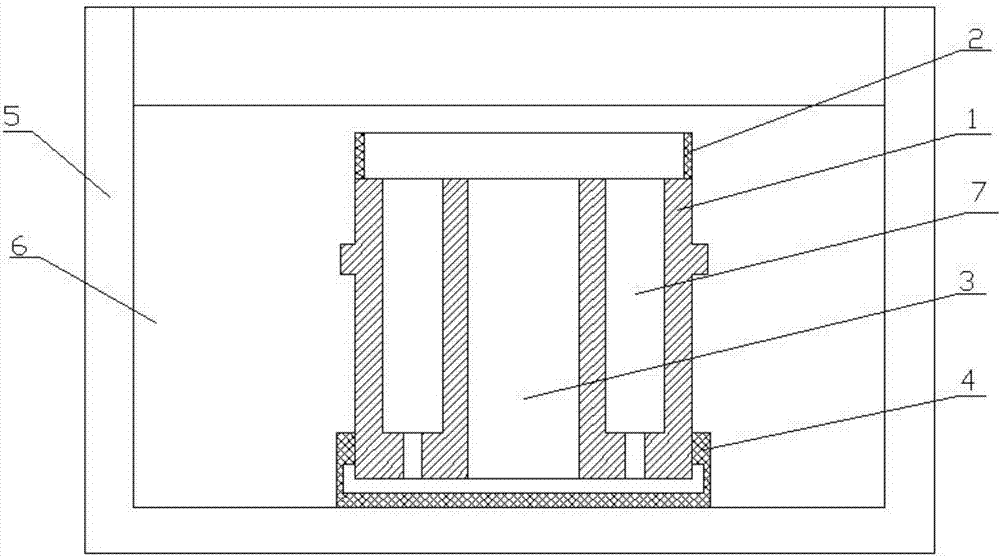

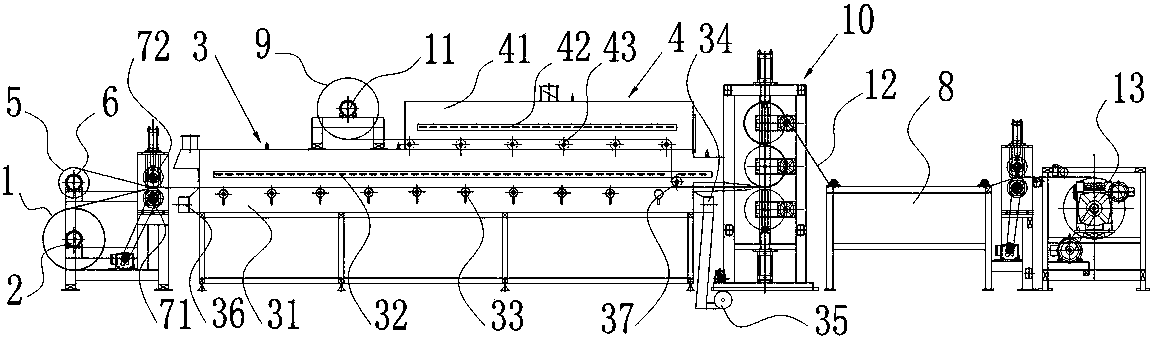

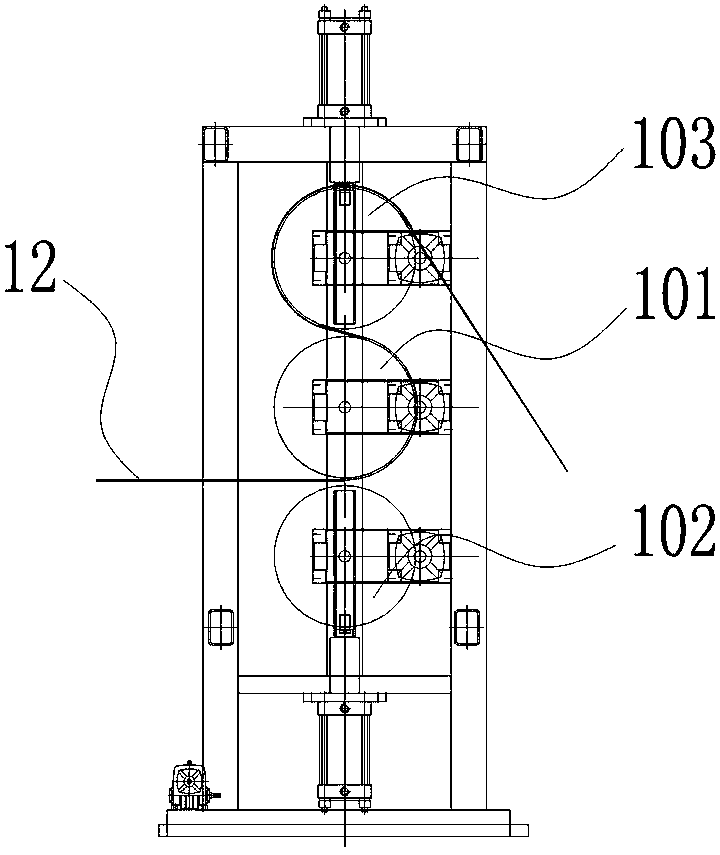

Lithium battery diaphragm compound device and compound method thereof

InactiveCN103753936AUniform Roll LaminationGood adhesionLaminationLamination apparatusPulp and paper industryLithium battery

The invention discloses a lithium battery diaphragm compound device and a compound method thereof. The device comprises an unwinding device, a rolling device and a winding device, wherein the unwinding device comprises at least two unwinding rollers, an unwinding guide roller and a direction guide roller; the unwinding guide roller is used for guiding a lithium battery diaphragm to the rolling device; the direction guide roller is used for changing the diaphragm guide direction; the rolling device comprises a preheating roller, a hot pressing roller, a heat setting roller and a cooling roller; the preheating roller, the hot pressing roller, the heat setting roller and the cooling roller are orderly arranged in parallel; the preheating roller, the hot pressing roller, the heat setting roller and the cooling roller are arranged inside the rolling device of the device, so that uniform rolling and compounding of a plurality of layers of films can be well achieved, the adhesion between the films can be enhanced, and the compound effect is better.

Owner:成都芝田高分子材料有限公司

Method for preparing electrolyte of porous compound polymer doped by titanium dioxide through hydrolysis method in situ

InactiveCN1916069AImprove the porous network structureImprove uniformitySecondary cellsComposite electrolyteN-Butanol

This invention relates to an in-situ hydrolysis method for preparing TiO2-doped porous composite polymer electrolyte for Li-ion batteries. The method comprises: (1) dropping diluted tetrabutyl titanate (TBT) solution into mixed acetone solution under stirring to obtain white TiO2 sol; (2) adding PVDF-HFP and n-butanol into white TiO2 sol, heating to 40-60 deg.C and stirring for 2-4 h; (3) preparing TiO2-doped porous composite polymer membrane, and immersing in Li-ion battery electrolytic solution to obtain ion-conductive electrolyte membrane. The method improves the porous network strcture of the electrolyte membrane, and TiO2 is uniformly distributed without forming aggregates. Besides, TiO2 is closely linked with the polymer matrix, thus improving the electrochemical and mechanical properties of the electrolyte membrane.

Owner:UNIV OF SCI & TECH BEIJING

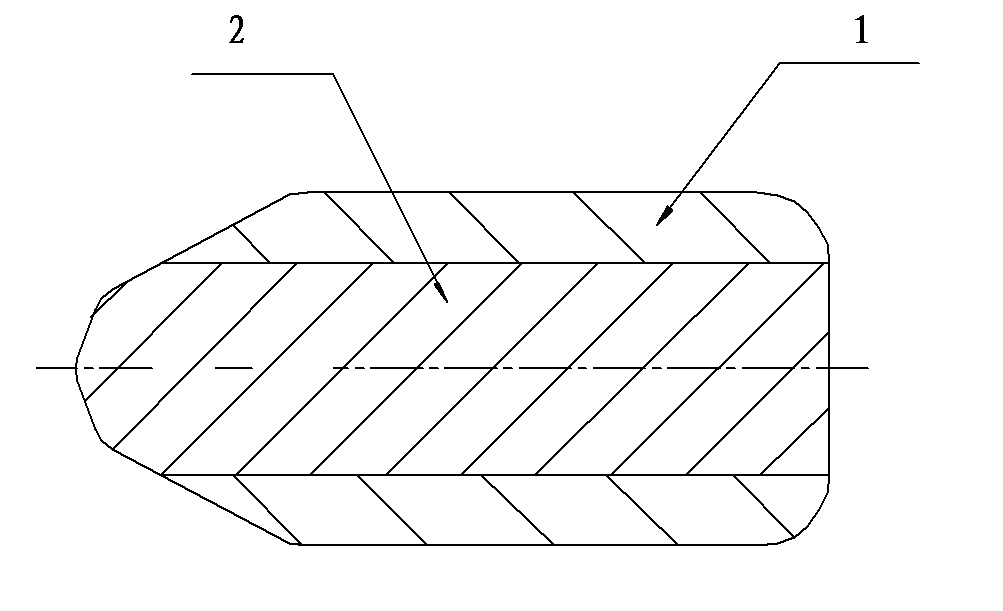

Multilayer composite hard alloy product and manufacturing method thereof

InactiveCN102653002AComposite goodImprove the bonding strength of the interfaceAlloyMechanical property

The invention relates to a multilayer composite hard alloy product and a manufacturing method of the multilayer composite hard alloy product. Specifically, the invention discloses a multilayer composite hard alloy product, at least comprising a first layer of hard alloy (1) and a second layer of hard alloy (2) which is bonded with the first layer of hard alloy (1), wherein the combination between the first layer of hard alloy (1) and the second layer of hard alloy (2) is metallurgical bonding; and an apparent interface exists between the first layer of hard alloy (1) and the second layer of hard alloy (2). The invention also relates to a method for manufacturing the multilayer composite hard alloy product. The multilayer composite hard alloy product manufactured according to the invention has the advantages of simple, rapid and controllable manufacturing process, high reliability and high product property repeatability, and is capable of satisfying the specific working condition of having different requirements for the mechanical properties of different parts of the product.

Owner:HUNAN BOYUN DONGFANG POWDER METALLURGY

Casting method for steel-copper composite cylinder body

InactiveCN107096905AImprove corrosion resistanceImprove wear resistanceInternal combustion piston enginesCylindersCopper cylinderComposite cylinder

The invention discloses a casting method for a steel-copper composite cylinder body. The casting method comprises the steps of performing three-dimensional modeling, designing a casting technology and performing technology simulation and optimization, performing base steel heat treatment, performing machining, tool machining and welding, performing base steel surface treatment, performing pre-heating treatment before base steel production, smelting copper alloy, dipping the copper alloy, melting anhydrous borax, putting base steel into a borax solution, pouring the copper alloy into the base steel, putting the base steel into a water tank and cooling and solidifying the base steel to room temperature to obtain the steel-copper composite cylinder body. According to the casting method, the problems of the composite casting technology and the composite material composition of the steel-copper cylinder body can be solved; and the composite strength of the thermometal cylinder body can be high, the yield can be high, the cost can be low, the size of the cylinder body can not be limited, the forming process can be controlled easily, and the quality can be stable.

Owner:安徽恒利增材制造科技有限公司

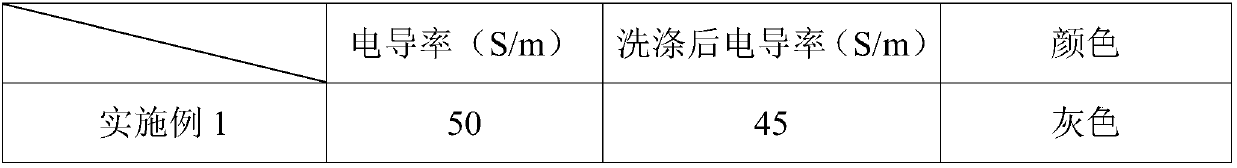

Graphene modified inorganic material, preparation method and application

The invention relates to a method for preparing a graphene material composited inorganic material. The method comprises steps as follows: an inorganic material and a graphene material are dispersed inan aqueous solution and / or a hydrophilic solution and modified at the temperature of 90 DEG C or higher, and a dispersion liquid containing the graphene material composited inorganic material is obtained. According to the method, the use temperature is lower, expensive production equipment with high energy consumption is not needed, the method is environmentally friendly and energy saving and realizes environmental protection, electric conductivity and heat conductivity of produced multi-batch products have no fluctuation, and the inorganic material can be supported with the graphene materialrapidly, efficiently and stably. The graphene supported composite material obtained after treatment has excellent electric conductivity and heat conductivity, and besides, a graphene loading layer isstable, has lighter color and lower cost and is suitable for most occasions utilizing inorganic conductive materials.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Wall decoration board, UV transfer printing and coating technology thereof, and applications thereof

InactiveCN105298059AImprove protectionGood for healthCovering/liningsLayered productsWeather resistanceAdhesive

The invention discloses a wall decoration board, a UV transfer printing and coating technology thereof, and applications thereof. The wall decoration board is characterized in that the back surface of a substrate is coated with a UV back coating layer; the front surface of the substrate is sequentially coated with a UV penetration primer; the UV penetration primer is coated with UV filling putty; the UV filling putty is coated with a UV roller coat sanding primer; the UV roller coat sanding primer is coated with a UV rolling coat before-sprinkling roller; the UV rolling coat before-sprinkling roller is coated with a UV covering white primer; the UV covering white primer is coated with UV transfer printing glue; a transfer printing film is subjected to UV solidification and transfer printing on the UV transfer printing glue; the transfer printing film is coated with an adhesive; the adhesive is coated with a UV primer or a UV outdoor varnish layer; and the UV outdoor varnish layer is coated with a film covering layer. The wall decoration board is highly environment-friendly, is good in compound effect, water boiling resistance, water resistance, yellowing resistance and weather resistance, has multiple kinds of patterns, and is high in coating efficiency.

Owner:HUNAN BANFERT NEW MATERIALS TECH

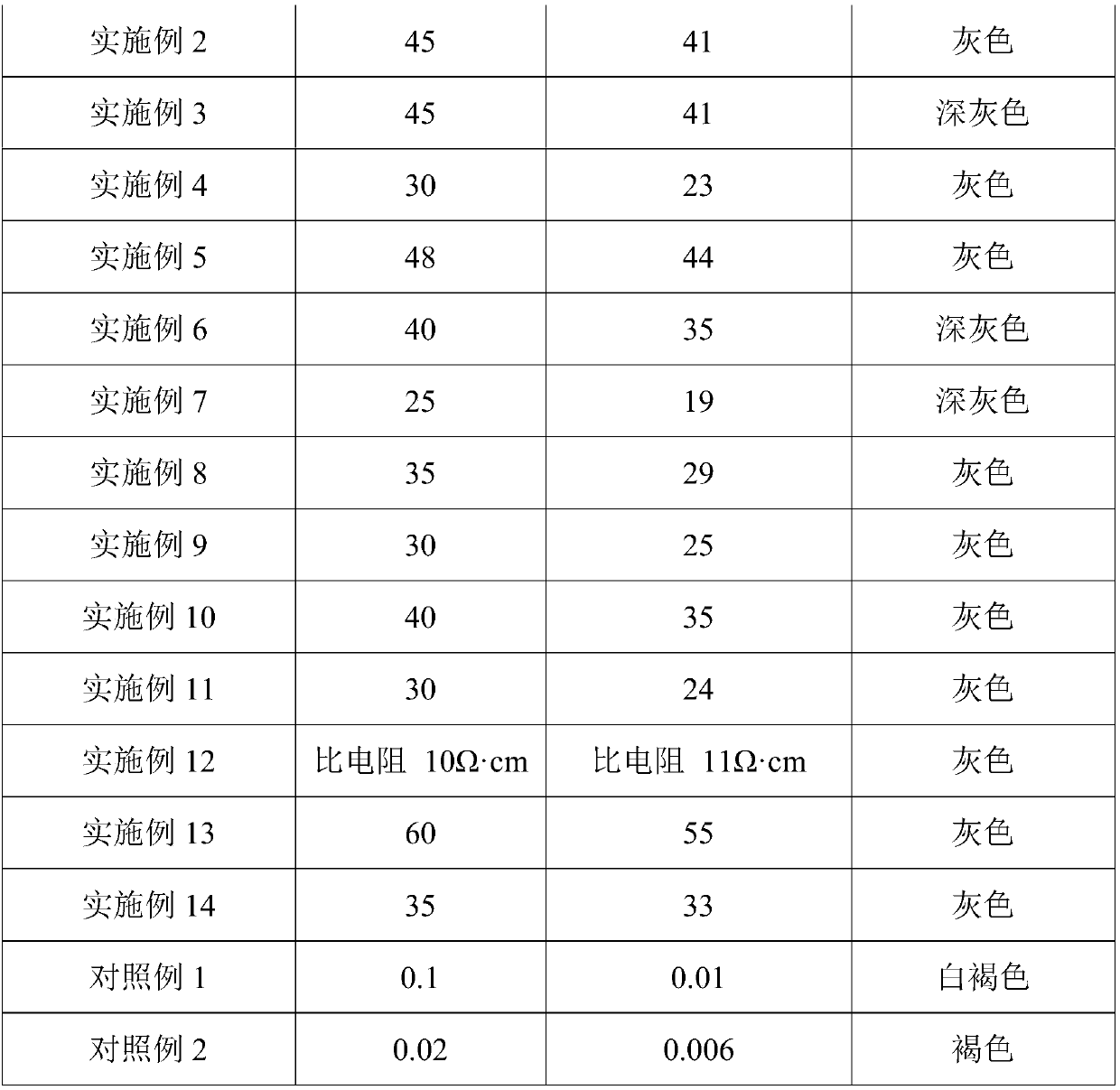

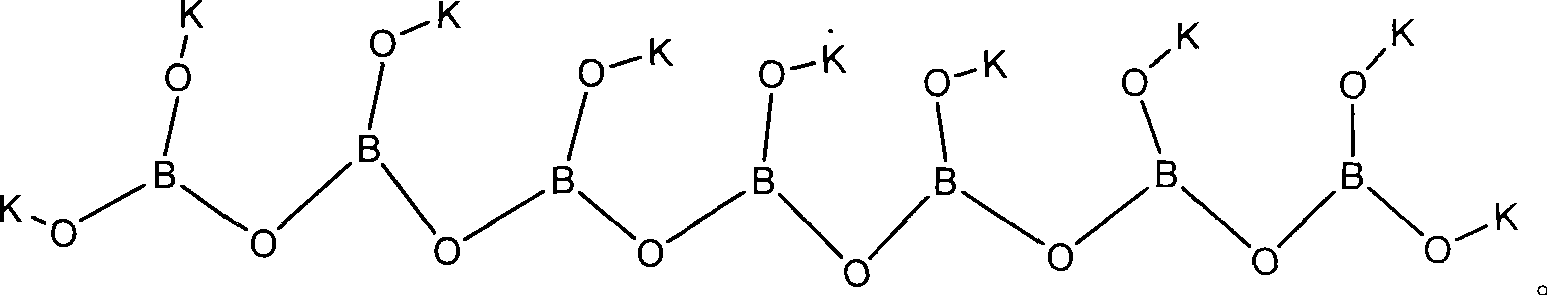

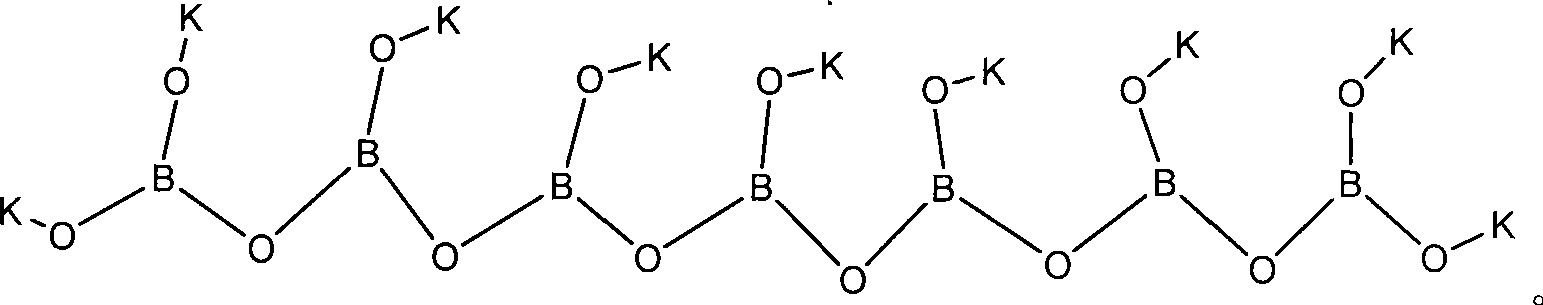

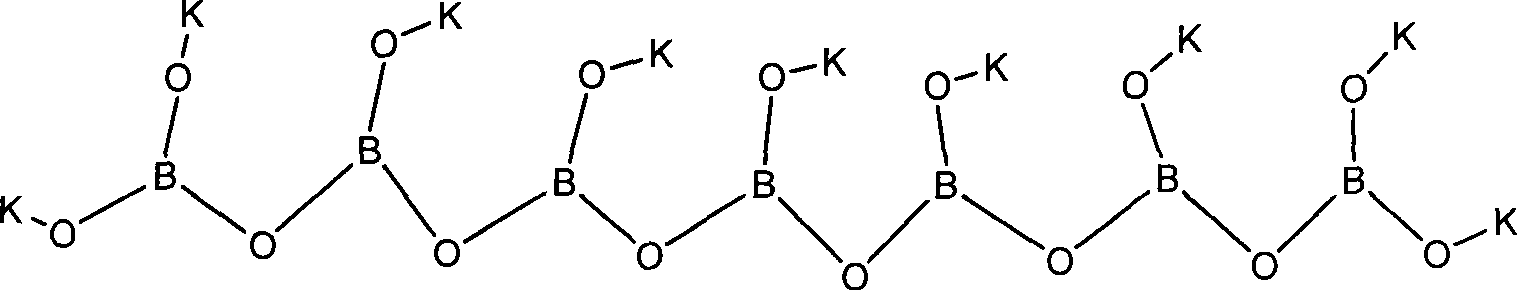

Abrasion resistant extreme-pressure additive of borate and preparation method thereof

The invention relates to borate antiwear and extreme pressure additive and a preparation method thereof. The additive mainly comprises oil media, dispersant and macromolecule polymerization borate, and the weight percentage is as follows: 10 to 50 percent of oil media, 1-5 percent of dispersant and 50 to 90 percent of macromolecule polymerization borate; the oil media is the mixture of mineral base oil, synthetic base oil, mineral oil and synthetic oil; the dispersant adopts C12-C22 fatty acid metallic soap or C12-C22 hydroxyl fatty acid metallic soap; the preparation method is, firstly, according to the molar ratio of 1:1 to 0.2:1, caustic potash and boric acid are added in a certain amount of water in sequence, and heated to 70 to 90 DEG C and react for a certain time; secondly, one or several types of the above base oil is added, and heated to 100 to 200 DEG C, the water is evaporated, and then heated to 200 to 230 DEG C, and polymerization reaction lasts for 0.5 to 1h; thirdly, the mixture is cooled down to approximate 180 DEG C, one or several types of the above dispersant is added, and continuously cooled down to approximate 110 DEG C, took out of the reaction vessel, homogenized under high pressure with a homogenization pump, and the finished product is obtained; the invention has the advantages that the technology is simple; the operation is easy; the water resistance is good; the steadiness is good; the antiwear and extreme pressure property is excellent; and the application range of the borate is widened.

Owner:杭州得润宝油脂股份有限公司

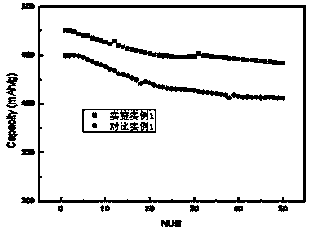

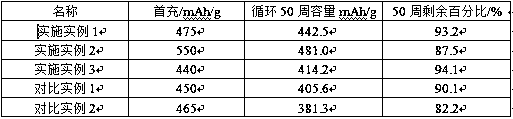

Silicon carbon negative electrode material of lithium ion battery and preparation method of silicon carbon negative electrode material

InactiveCN107611369AImprove cycle performanceImprove practicalityCell electrodesSecondary cellsCarbonizationSodium-ion battery

The invention discloses a silicon carbon negative electrode material of a lithium ion battery and a preparation method of the silicon carbon negative electrode material, and mainly aims to improve thecomposite effect between silicon or oxide thereof and graphite by solving the technical problems so as to lower material polarization and improve material cycle performance. The negative electrode material is obtained by the steps of performing surface treatment and roasting and dispersing on silicon or oxide thereof, next, mixing with carbon micro powder and an organic carbon source, and performing coating, and finally carrying out carbonization treatment. Compared with the prior art, the silicon carbon negative electrode material prepared in the invention has relatively high cycling performance, excellent processability and easy batch production.

Owner:天津爱敏特电池材料有限公司

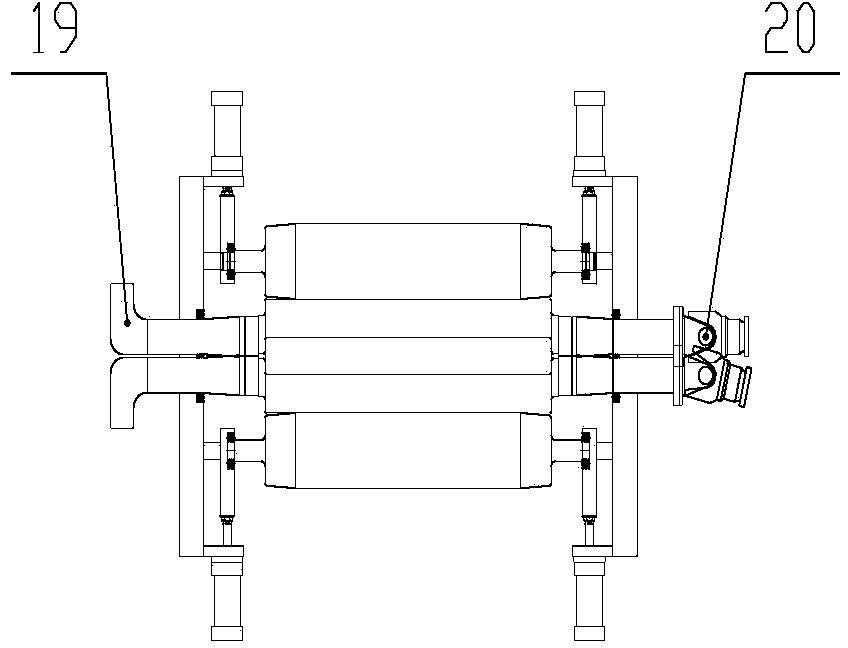

Combining device and method of composite PTFE (polytetrafluoroethylene) plate

ActiveCN103612463ANo reduction in composite strengthComposite goodLaminationLamination apparatusGlass fiberFluoroplast

The invention discloses a fluoroplastic combining device and method and provides a combining device and method of a composite PTFE plate, which are capable of completely changing the non-sticky property of fluoroplastic and endowing the PTFE plate with excellent corrosion resistance and enable the PTFE plate to be spliced and combined with other materials. The technical problems that the PTFE plate treatment technology is only limited to surface treatment, and a lining layer is peeled and bulged and even worse, severe safety accidents are resulted because a surface activation layer easily loses effectiveness are solved. The combining device comprises a first drying tunnel and a second drying tunnel which are arranged side by side, wherein a PTFE plate unwinding machine and a composite film unwinding machine are arranged at the inlet end of the first drying tunnel side by side; the PTFE plate and a composite film are synchronously introduced into the first drying tunnel through a fixed-speed base material conveying mechanism after being superposed; a glass fiber cloth unwinding machine is arranged at the inlet end of the second drying tunnel; a plating press is arranged between the outlet ends of the first drying tunnel and the second drying tunnel; the PTFE plate and the composite film, which go out of the first drying tunnel, and glass fiber cloth going out of the second drying tunnel are superposed and then are extruded and combined through the plating press to form the composite PTFE plate; the composite PTFE plate winds a winding roller through a cooling mechanism.

Owner:ZHEJIANG DONGFU PLASTIC SCI & TECH

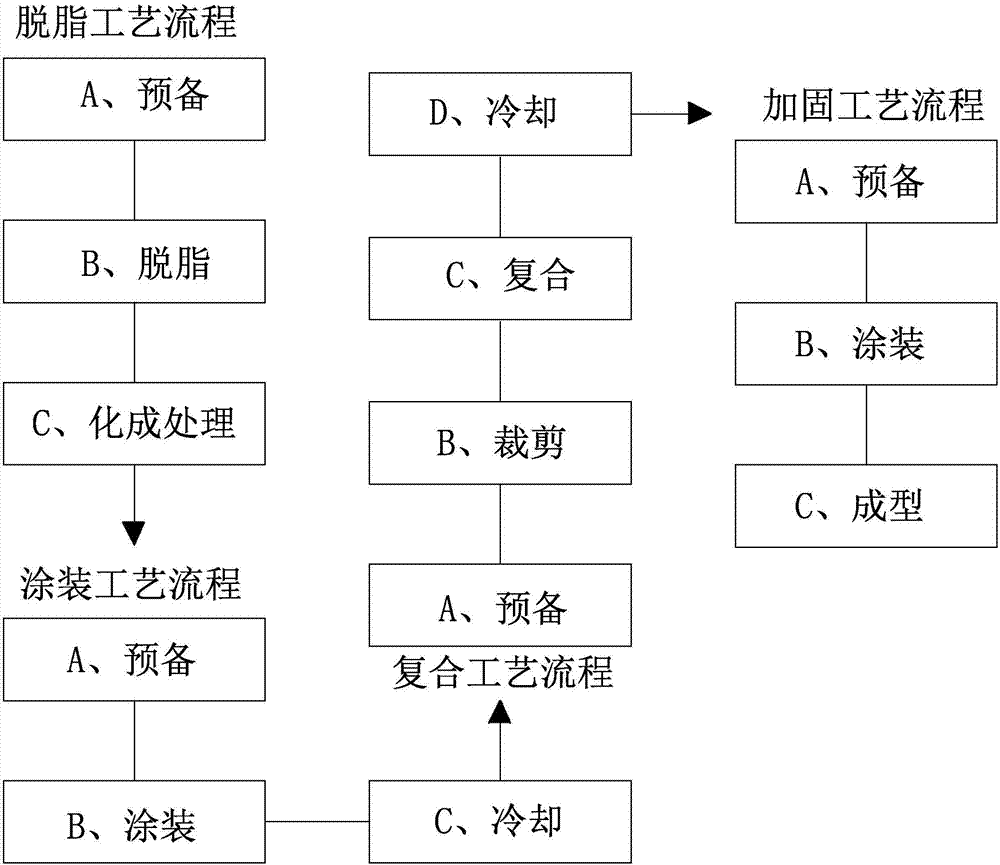

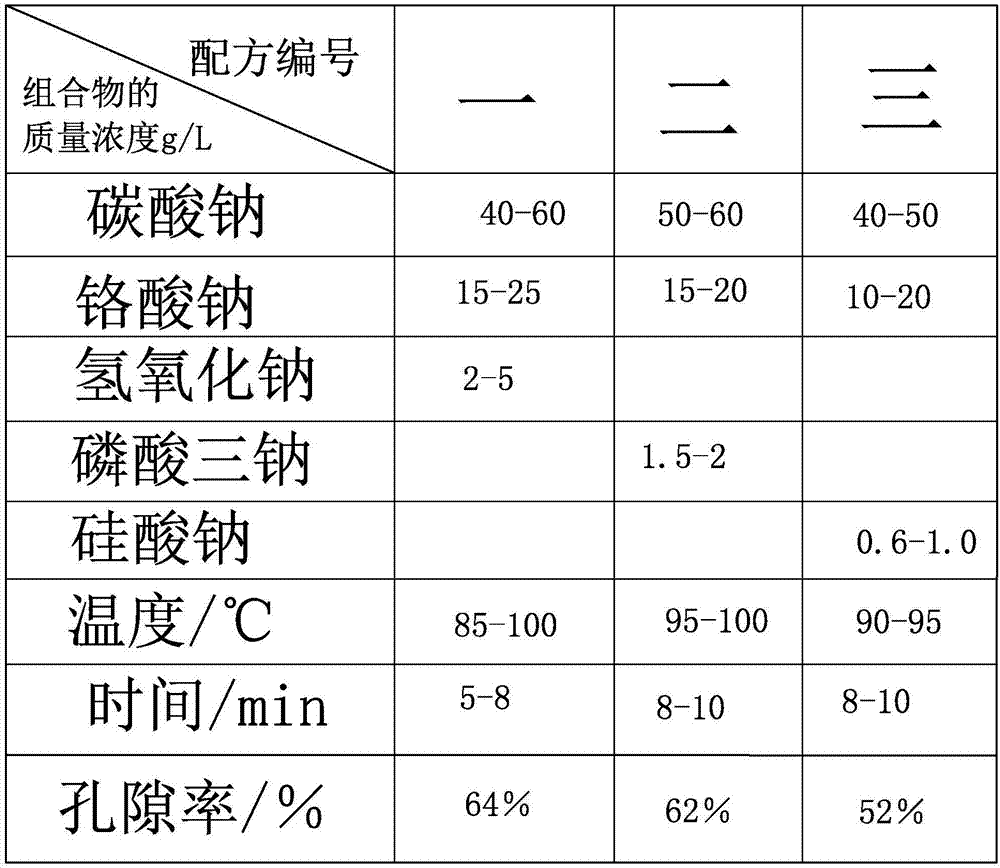

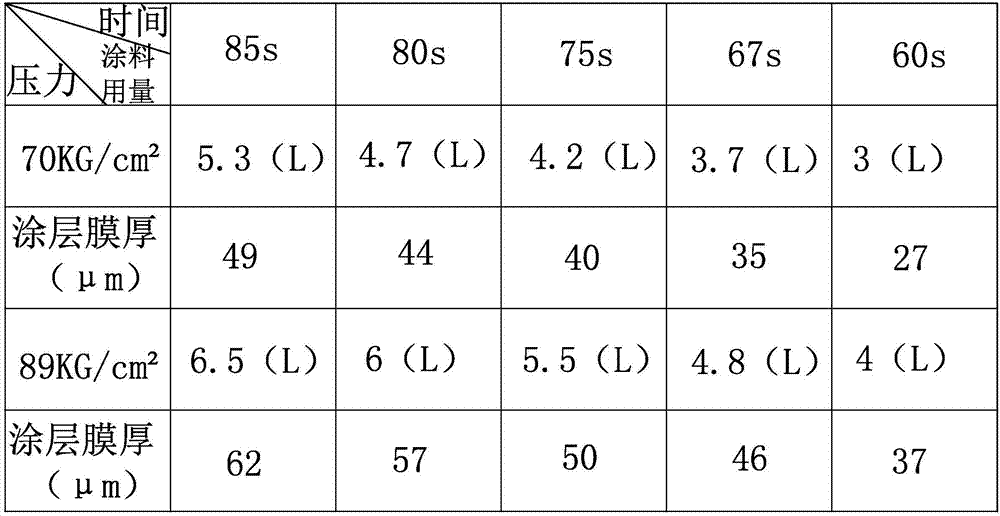

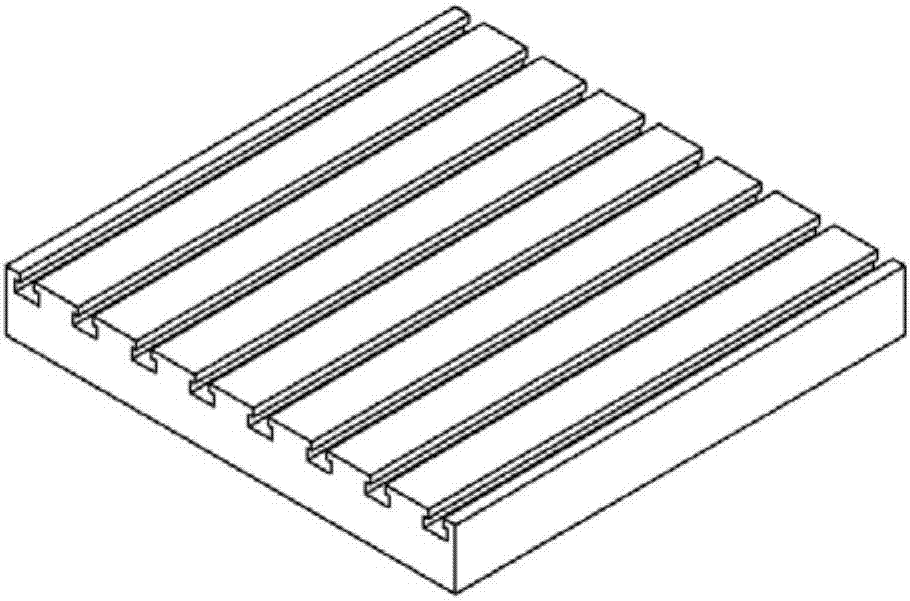

Production method of aluminum-plastic plate

InactiveCN107471807AReduce production process stepsSimple stepsCovering/liningsLamination ancillary operationsCorrosionMaterials science

The invention discloses a production method of an aluminum-plastic plate. The aluminum-plastic plate produced by the method has the effects of being good in corrosion resistance effect and plastic coating effect, and high in tensile strength. The aluminum-plastic plate is characterized by comprising an upper aluminum alloy layer, a middle layer and a lower aluminum alloy layer which are sequentially connected with one another, wherein the middle layer is prepared from flame-retardant material polyethylene (PE) plastic profiles; the upper aluminum alloy layer and the lower aluminum alloy layer are respectively sprayed with a flame-retardant coating; a filling ring groove is formed at the peripheral side of the middle layer and is positioned between the upper aluminum alloy layer and the lower aluminum alloy layer; the filling ring groove is internally filled with thermosetting resin. The production process comprises the following steps: (1) a degreasing process; (2) coating process; (3) compounding process; (4) strengthening process. The production method of the aluminum-plastic plate is suitable for the technical field of aluminum-plastic plate production.

Owner:台州港邦建材有限公司

Explosive cladding method for groove type hot melt interface of metal plate and explosive device

PendingCN106956073AReduce pollutionSmall amount of explosiveNon-electric welding apparatusExplosive claddingExplosive Agents

The invention provides an explosive cladding method for a groove type hot melt interface of a metal plate and an explosive device. According to the method, grooves are formed in the surface of a metal base plate at first, the grooved interface is cleaned up, raw materials of a covering plate are melted in a high-temperature furnace, a part of melted liquid flows into groove cavities, under the thermal action of the high-temperature liquid and the mechanical action of the grooves, primary combining of the covering plate and the base plate is achieved, then the covering plate is further squeezed into the grooves through an explosive method, the base plate and the covering plate squeeze each other and are combined closely, and tight combining force is achieved on the interface of the two metal plates. According to the explosive cladding method and the explosive device, the amount of explosives in unit area is small, a honeycomb aluminum explosive loading structure is adopted, the explosive amount and the cladding time can be saved, and meanwhile, atmospheric pollution, noise pollution, vibration and overpressure are reduced.

Owner:UNIV OF SCI & TECH OF CHINA

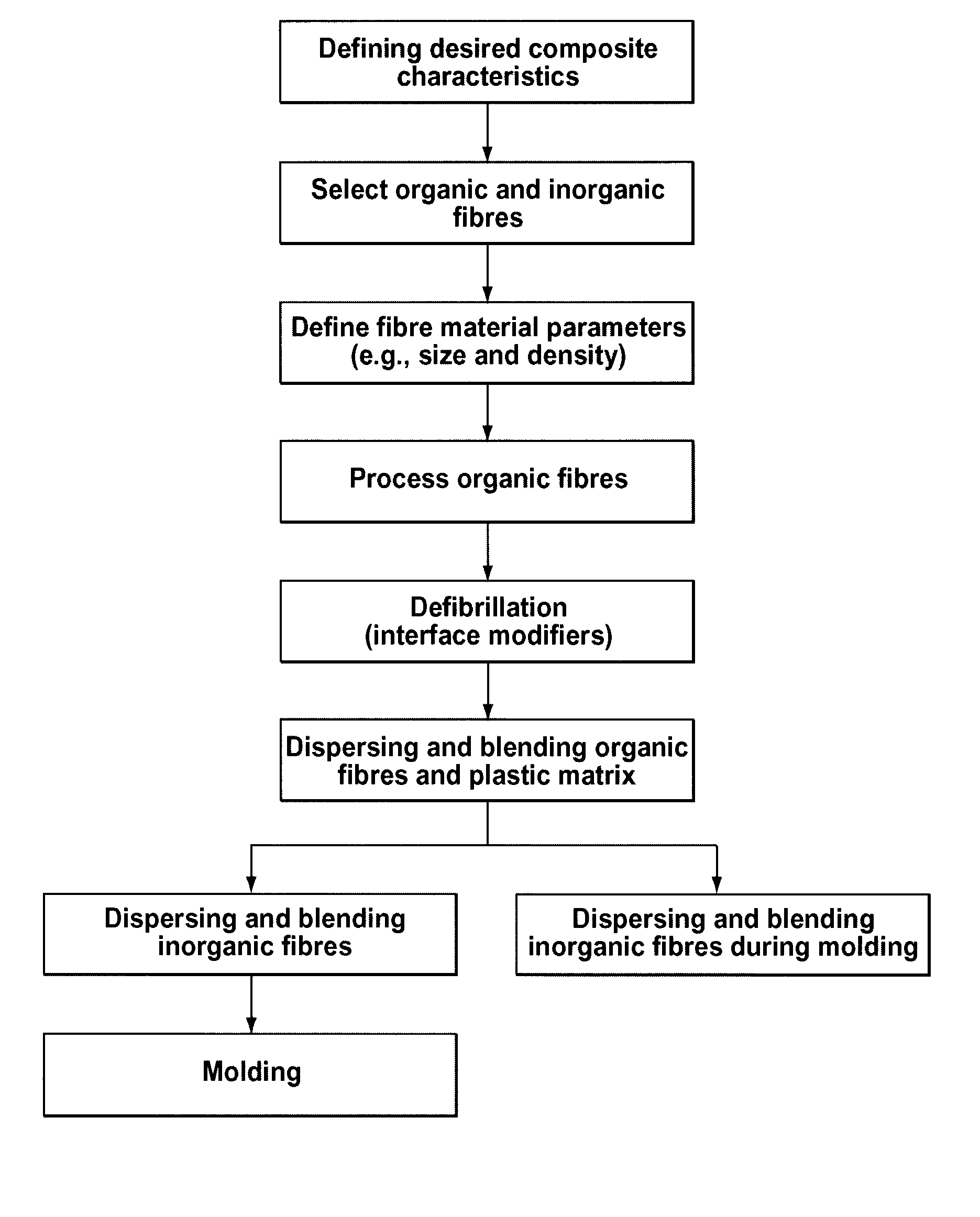

Manufacturing process for hybrid organic and inorganic fibre-filled composite materials

InactiveUS8940132B2Improve performanceComposite goodCellulosic pulp after-treatmentFibreboardPolymer scienceHydrogen

The present invention relates to a process for the manufacture of structural hybrid thermoplastic composites where organic and inorganic fibers are well dispersed in a thermoplastic matrix. The process comprises defibrillating the organic fibers with or without the presence of surface active agents using a mixer at a high shear and at a temperature lower than the decomposition temperature of organic fibers and melting point of the surface active agents to separate the hydrogen bonded fibers and generate microfibers, followed by blending and dispersion of the organic fibers in the thermoplastic matrix to produce a fiber composite, followed by further blending and dispersion of the fiber composite with inorganic fibers at a low shear to get the moldable hybrid composite, followed by extrusion, injection or compression-injection molding. Low shear mixing maintains the inorganic fiber length. The process produces high performance composite materials having excellent performance properties and are ideally suited for automotive, aerospace, furniture, sports articles, upholstery and other structural and semi-structural applications.

Owner:SAIN MOHINI M +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com