Silicon carbon negative electrode material of lithium ion battery and preparation method of silicon carbon negative electrode material

A technology for lithium-ion batteries and negative electrode materials, which can be used in battery electrodes, secondary batteries, circuits, etc., and can solve the problems of poor composite effect of silicon-carbon negative electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

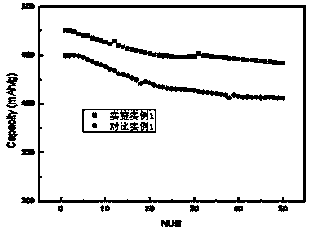

Examples

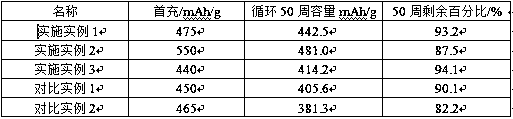

Embodiment 1

[0021] Add 10g of PVA into 1000g of silicon oxide aqueous solution (solid content 15%), stir evenly for 0.5h, then spray dry to obtain surface-coated silicon oxide particles, and then roast them at 1000°C by mechanical crushing Depolymerize to obtain modified silica particles; mix the modified silica with artificial graphite and asphalt according to the ratio of 20:50:30, and then heat it to 400°C at 2°C / min in the reactor, and the stirring speed is 50rpm. Fusion coating is carried out; then the fusion coating material is carbonized in a nitrogen atmosphere at a rate of 2°C / min to 1000°C, and then sieved to obtain a modified silicon-carbon negative electrode material.

Embodiment 2

[0023] Add 5g of phenolic resin to 1000g of silicon alcohol solution (solid content 10%), stir evenly for 0.5h, then perform low-temperature vacuum drying treatment to obtain surface-coated silicon particles, and then roast them at 1100°C in airflow mode Depolymerize to obtain modified silicon particles; mix modified silicon with natural graphite and phenolic resin at a ratio of 10:70:20VC, and then heat to 700°C at 5°C / min in the reactor, stirring at 30rpm, for fusion coating Then, the fused coating material is carbonized in an argon atmosphere at a rate of 1 °C / min to 1100 °C, and then sieved to obtain a modified silicon-carbon negative electrode material.

Embodiment 3

[0025] Add 5g of sucrose to 1000g of silicon oxide aqueous solution (solid content 15%), stir evenly for 0.5h, then perform low-temperature vacuum drying to obtain surface-coated silicon oxide particles, and then roast them at 600°C, using airflow Depolymerization is carried out to obtain modified silicon oxide particles; the modified silicon oxide is mixed with artificial graphite, carbon fiber, and pitch according to 15:55:5::20 ball milling, and then the fusion coating material is mixed in an argon atmosphere with 1 °C / min is raised to 1100 °C for carbonization treatment, followed by sieving treatment to obtain the modified silicon carbon negative electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com