Production method of aluminum-plastic plate

A production method and technology of aluminum-plastic panels, applied in chemical instruments and methods, layered products, lamination, etc., can solve problems such as poor oxidation effect of aluminum panels, influence of plastic coating effects, poor tensile strength, etc., and achieve production process steps Fewer steps, simple steps, guaranteed practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

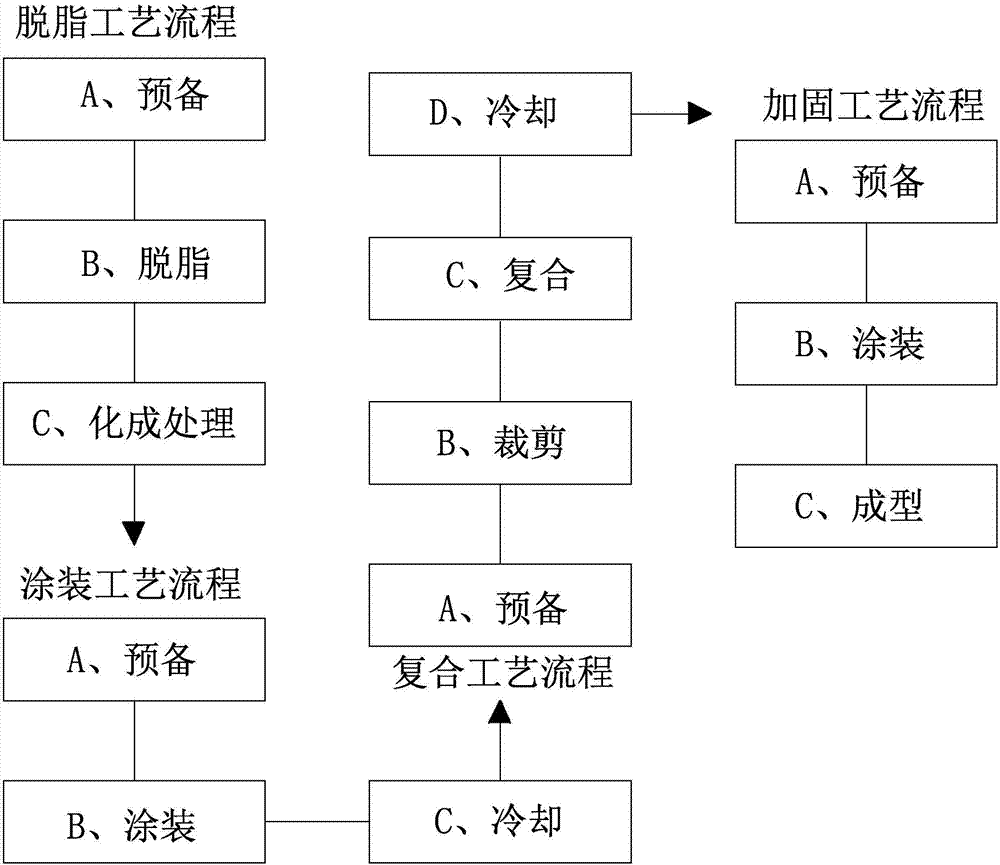

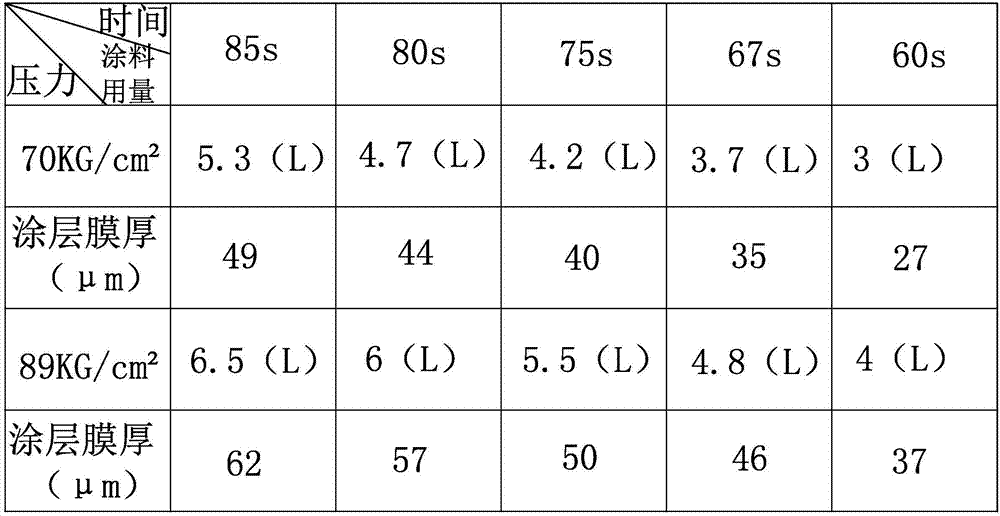

[0034] A production method of an aluminum-plastic panel, the aluminum-plastic panel comprises an upper aluminum alloy layer, a middle layer and a lower aluminum alloy layer connected in sequence, the middle layer adopts a flame-retardant material PE plastic profile, and the upper aluminum alloy layer and the lower aluminum alloy layer The alloy layers are all sprayed with flame-retardant paint, and a filling ring groove is formed between the upper aluminum alloy layer and the lower aluminum alloy layer, which is arranged on the side of the middle layer, and the filling ring groove is filled with thermosetting resin. The production process includes the following steps: ( 1) Degreasing process: A. Preparation: aluminum sheet to be processed, spray chamber, degreasing spray pump, a certain amount of weak alkaline degreasing liquid, brush roller, a certain amount of neutral degreasing liquid, neutralization chamber, washing tank , forming tank, drying box and cooling fan;

[0035]...

Embodiment 2

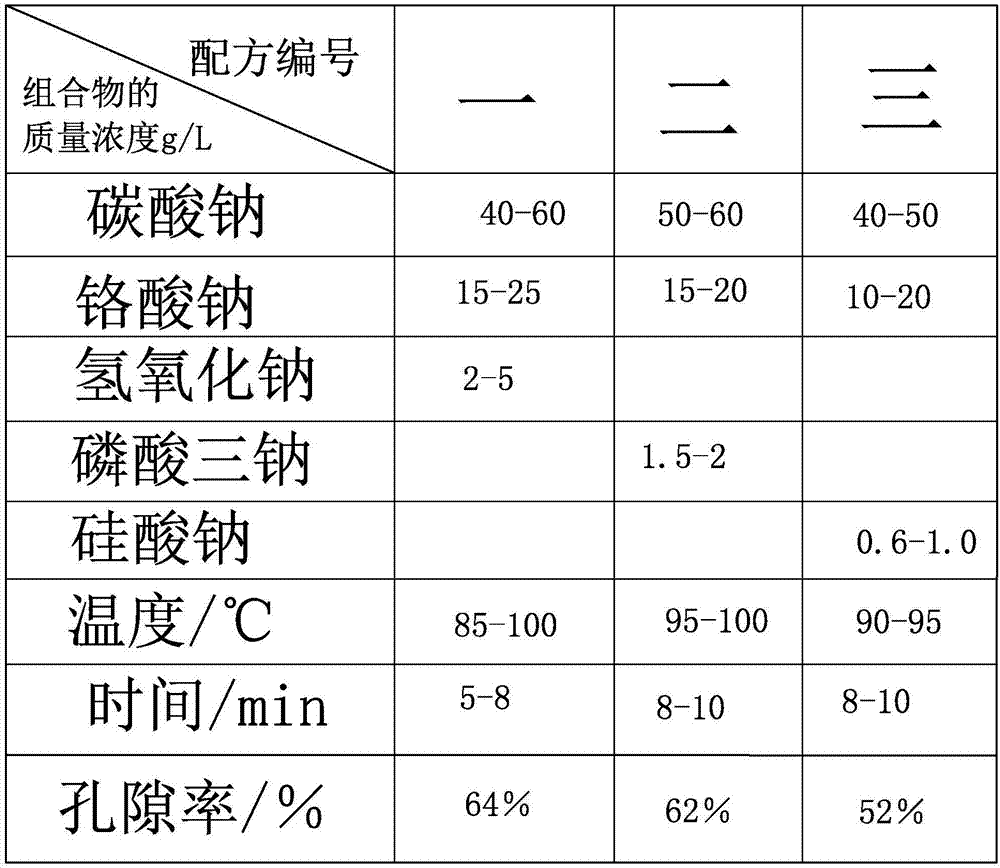

[0053] This embodiment is basically the same as Example 1, the only difference being that the mass concentration of each composition of the alkaline solution in step B in the step (1) degreasing process is sodium carbonate 50-60g / L, sodium chromate 15 -20g / L and trisodium phosphate 1.5-2g / L, and in an environment of 92°C, the duration is between 8min-10min, so that an oxide film is formed on the surface of the aluminum sheet, and the alkaline oxidation solution according to the above ratio is used The film layer obtained in the method is soft, has poor corrosion resistance, high porosity, and good adsorption, which improves the adsorption effect during plastic coating and ensures a good spraying effect.

Embodiment 3

[0055] This embodiment is basically the same as Example 1, the only difference being that the mass concentration of each composition of the alkaline solution in step B in the step (1) degreasing process is sodium carbonate 40-50g / L, sodium chromate 10 -20g / L and sodium silicate 0.6-1g / L, and in the environment of 98°C, the duration is between 8min-10min, so that an oxide film is formed on the surface of the aluminum sheet. The obtained film layer has higher hardness, and the relative adsorption effect will become worse.

[0056] In the step (1) in the embodiment 1,2,3, the aluminum sheet obtained by the basic oxidation method is immersed in 20g / L of CrO 3 In the solution, passivation treatment at room temperature for 5-15 seconds, and then drying at a temperature lower than 50°C can improve the effect of corrosion resistance and ensure good practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com