Continuous production method and application of all-cotton spunlace three-resistance non-woven fabric and three-resistance surgical gown

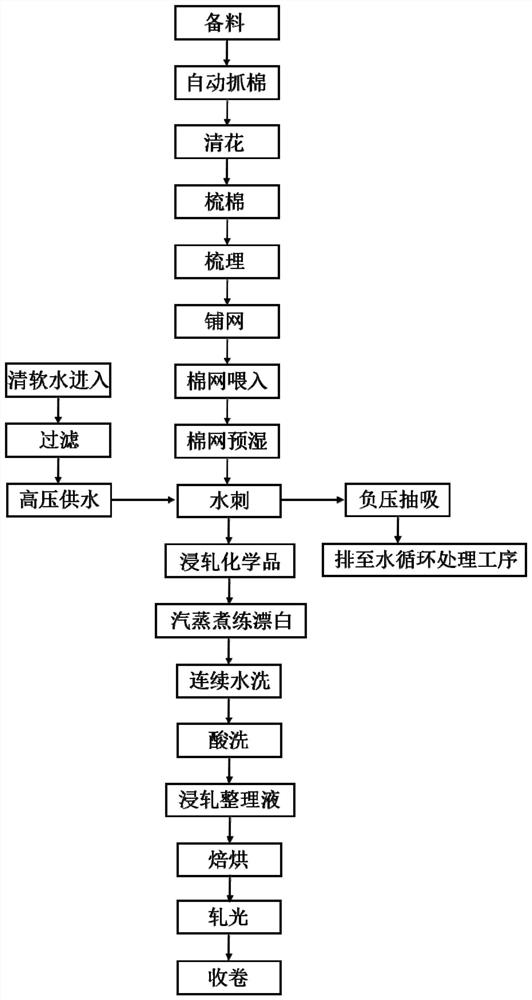

A production method and technology for non-woven fabrics, applied in the field of non-woven fabrics, can solve the problems of low production efficiency, non-continuous production process and long consumption time of cotton spunlace non-woven fabrics, so as to shorten the production process steps and simplify the Production process, good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] After the raw cotton is cleaned, carded, carded and cross-laid, it is fed into the spunlace machine for pre-wetting of the cotton net. The pressure is 55bar, followed by 4 drum spunlace machine spunlace, the pressure of the spunlace head is 57bar, 62bar, 63bar, 65bar in turn;

[0035] The non-woven fabric after spunlace is dipped and squeezed respectively at room temperature. The chemical formula for padding is: refining agent 3g / L, stabilizer 3g / L, caustic soda 15g / L, hydrogen peroxide 20g / L, of which hydrogen peroxide The mass concentration is 27.5%;

[0036] The non-woven fabric after padding chemicals is sent into the steamer for steaming, scouring and bleaching. The steaming temperature is 98°C, and the steaming time is 3 minutes;

[0037] Then perform a normal temperature water wash and a 70°C hot water wash;

[0038] Pickling the washed non-woven fabric, adding concentrated sulfuric acid with a concentration of 98% to the water, and the concentrated sulfuric ac...

Embodiment 2

[0045] After the raw cotton is cleaned, carded, carded and cross-laid, it is fed into the spunlace machine for pre-wetting of the cotton net. The pressure is 50bar, followed by 4 drum spunlace machine spunlace, the pressure of the spunlace head is 52bar, 56bar, 58bar, 60bar;

[0046] The non-woven fabric after spunlace is dipped and squeezed respectively at room temperature. The chemical formula for padding is: refining agent 2.5g / L, stabilizer 2.5g / L, caustic soda 15g / L, hydrogen peroxide 18g / L, Wherein the mass concentration of hydrogen peroxide is 27.5%;

[0047] The non-woven fabric after padding chemicals is sent into the steamer for steaming, scouring and bleaching. The steaming temperature is 98°C, and the steaming time is 3 minutes;

[0048] Then perform a normal temperature water wash and a 70°C hot water wash;

[0049] Pickling the washed non-woven fabric, adding concentrated sulfuric acid with a concentration of 98% to the water, and the concentrated sulfuric acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com