Composite Thermal Insulation Wall Body of a Building

a technology of composite materials and building walls, applied in the direction of walls, building components, construction, etc., can solve the problems of poor earthquake-proofing and wind-proofing ability, large steel consumption, and insufficient material development, so as to reduce the weight of constructions, good thermal insulation and bonding effects of functional materials, and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

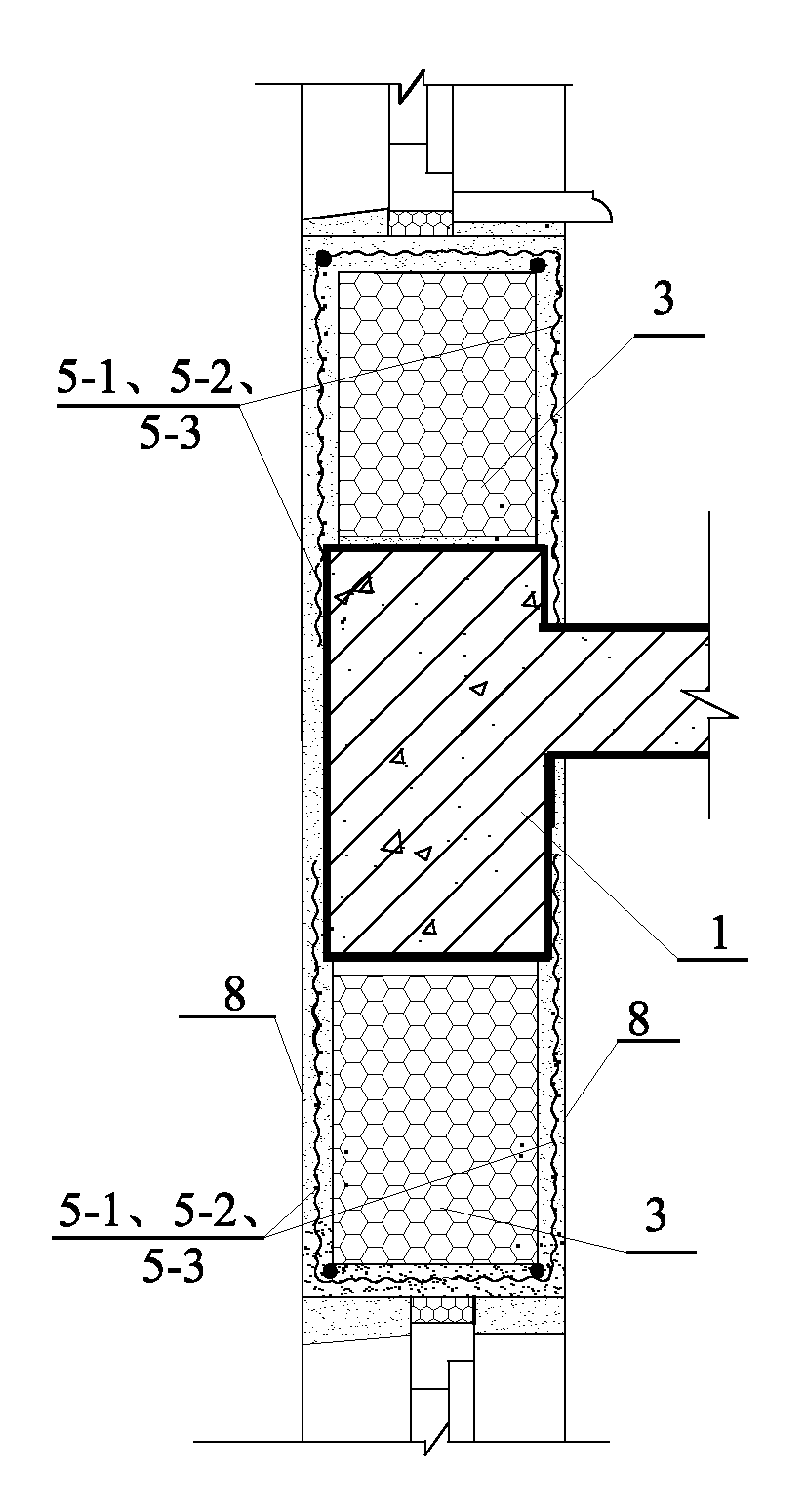

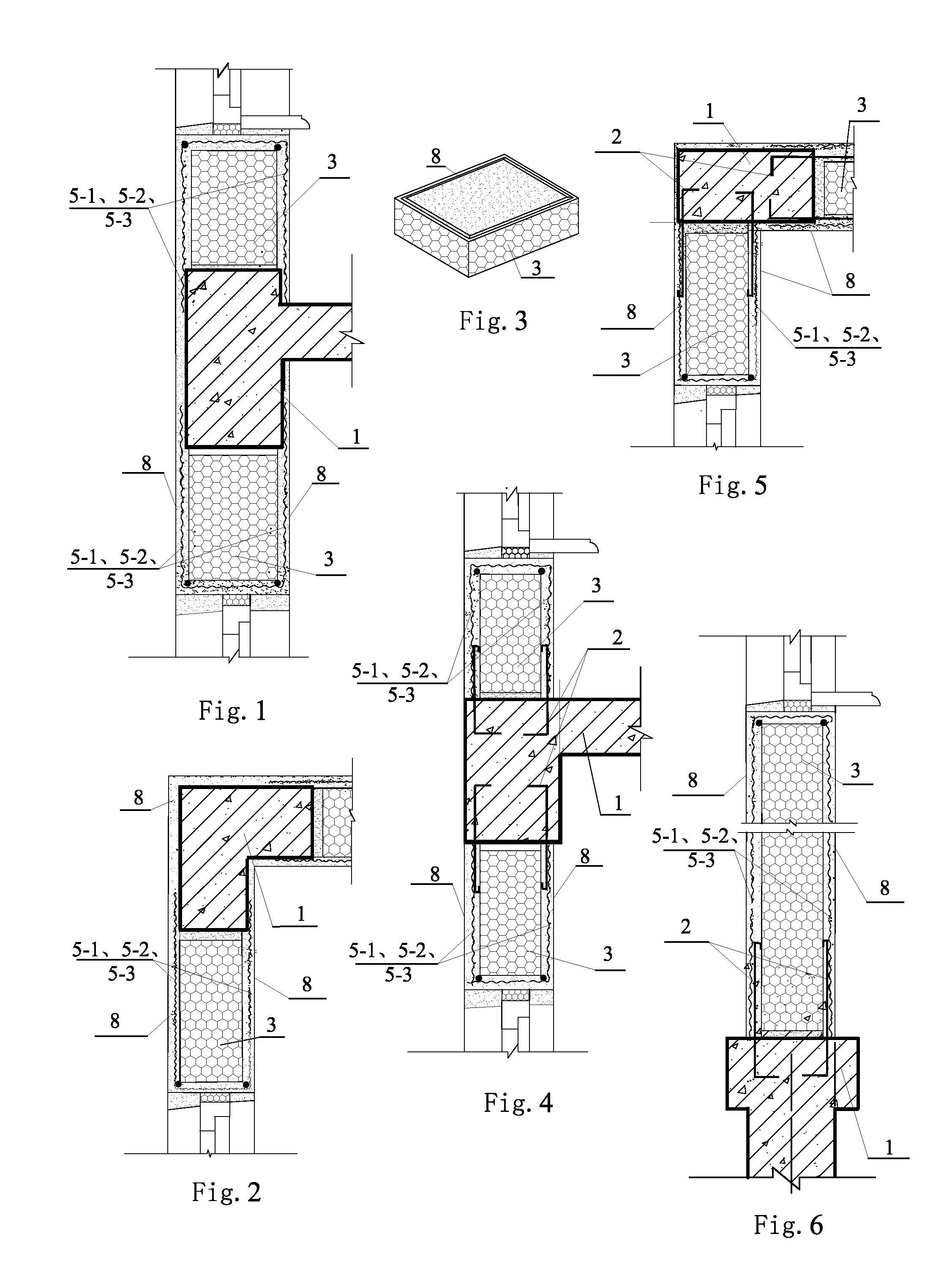

[0073] as shown in FIGS. 1 and 2, a composite thermal insulation component of a building of the embodiment is composed of a load-bearing component 1 of a main structure of the building, a core layer 3, alkali-resistant netting fabric 5-1 or a metal net 5-2 or a bamboo reinforced net 5-3 and an outer protection layer 8. The load-bearing component 1 of the main structure of the building is a girder, a plate, a pillar, a load-bearing wall and a base. The core layer 3 is made of a high molecular thermal insulation material or mineral wool or plant stalks or a paper honeycomb plate. The outer protection layer 8 is a cement mortar, a fine stone concrete plastered layer, a modified cement mortar or a fine stone concrete plastered layer. The said core layer 3 is fixed between the girder or the plate or the pillar of the load-bearing component 1 of the main structure of the building and a interior frame formed by a load-bearing wall, or on the girder or the plate of the load-bearing componen...

embodiment 3

[0079 is suitable for energy-saving buildings. When the composite wall body with outside thermal insulation is constructed, first the core layer is bonded to the outside of the girder-pillar, then the core layer inside the openings of the girder-pillar of the frame is assembled. According to convenience of construction, economic analysis and duration use, the metal net or alkali-resistant netting fabric is determined. The bamboo reinforced net is suitable for simple low-level buildings. Internationally, the results of test of the GRC wall plate used for 25-30 years showed that under the regular condition of indoor use, the strength of the alkali-resistant glass fiber has not been reduced while the strength of that outdoors is reduced. This circumstance becomes more serious at the places more liable to wetting such as windows. Therefore, for the outer wall of design life span over 25 years, besides necessary water-proof measures, it is suitable to provide the steel bars and metal net...

embodiment 8

[0090] the embodiment is different from the preceding embodiment in that the core layer 3 of the composite wall body plastered by the alkali-resistant netting fabric of the embodiment has T-shaped section, which is beneficial to increase the plane rigidity of the composite wall body.

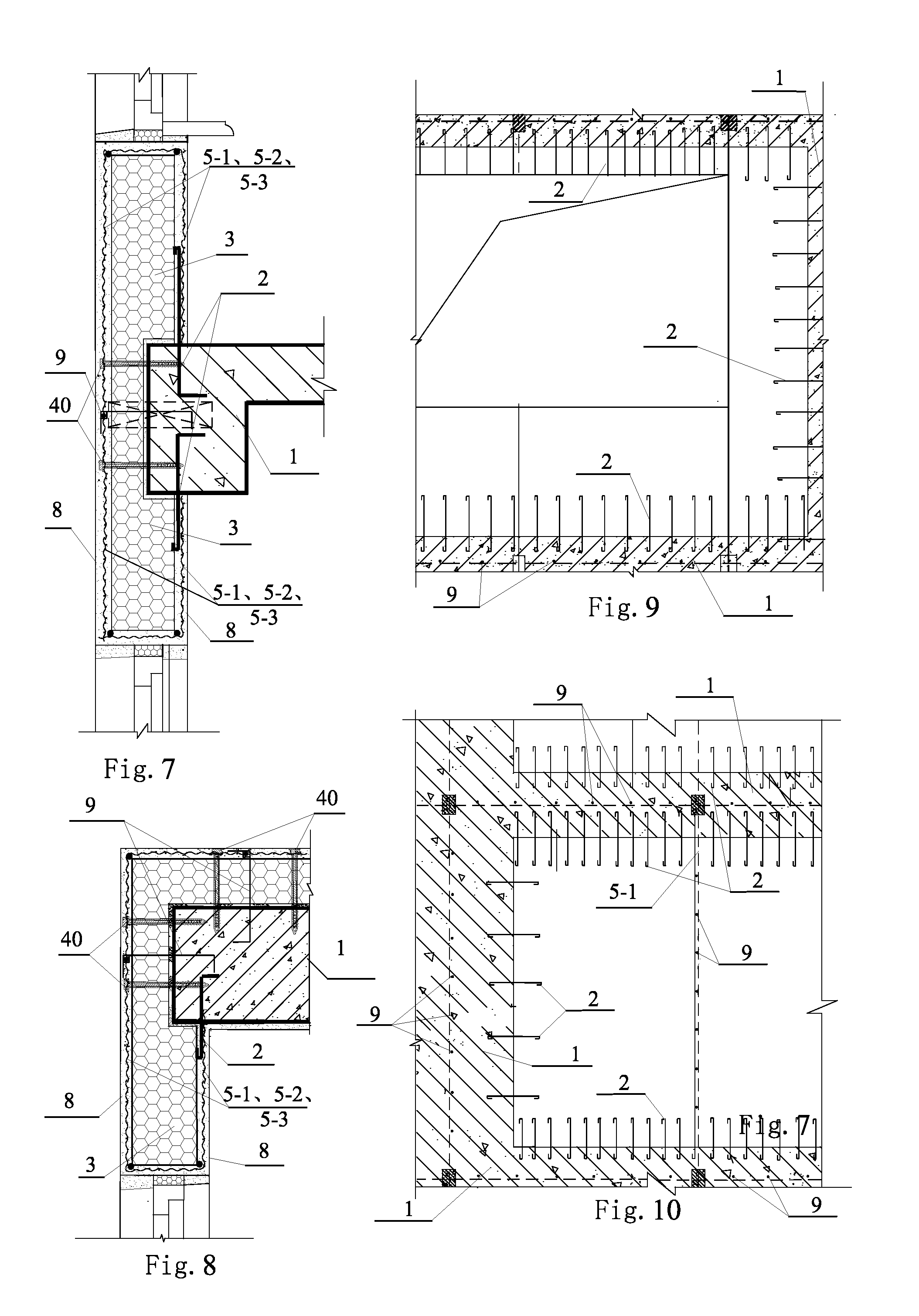

[0091]In the case of using Embodiment 1 or 2 in the load-carrying light composite wall body (the core layer is fixed on the girder or plate of the load-carrying component with the upper part provided with the light roof) sometimes the structures of Embodiment 7 or 8 are needed.

[0092]Embodiment 9: as shown in FIGS. 7 and 8, the embodiment is different from Embodiment 3 in that plastic expansion nails 40 are fixed to the load-carrying component 1 of the main structure of the building through the core layer 3. The iron wires are banded to the outer ends of the tubes of the plastic expansion nails fixing the alkali-resistant netting fabric 5-1 or steel mesh 5-2 or bamboo-reinforced screen 5-3 and the plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com