Patents

Literature

110 results about "Explosive cladding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

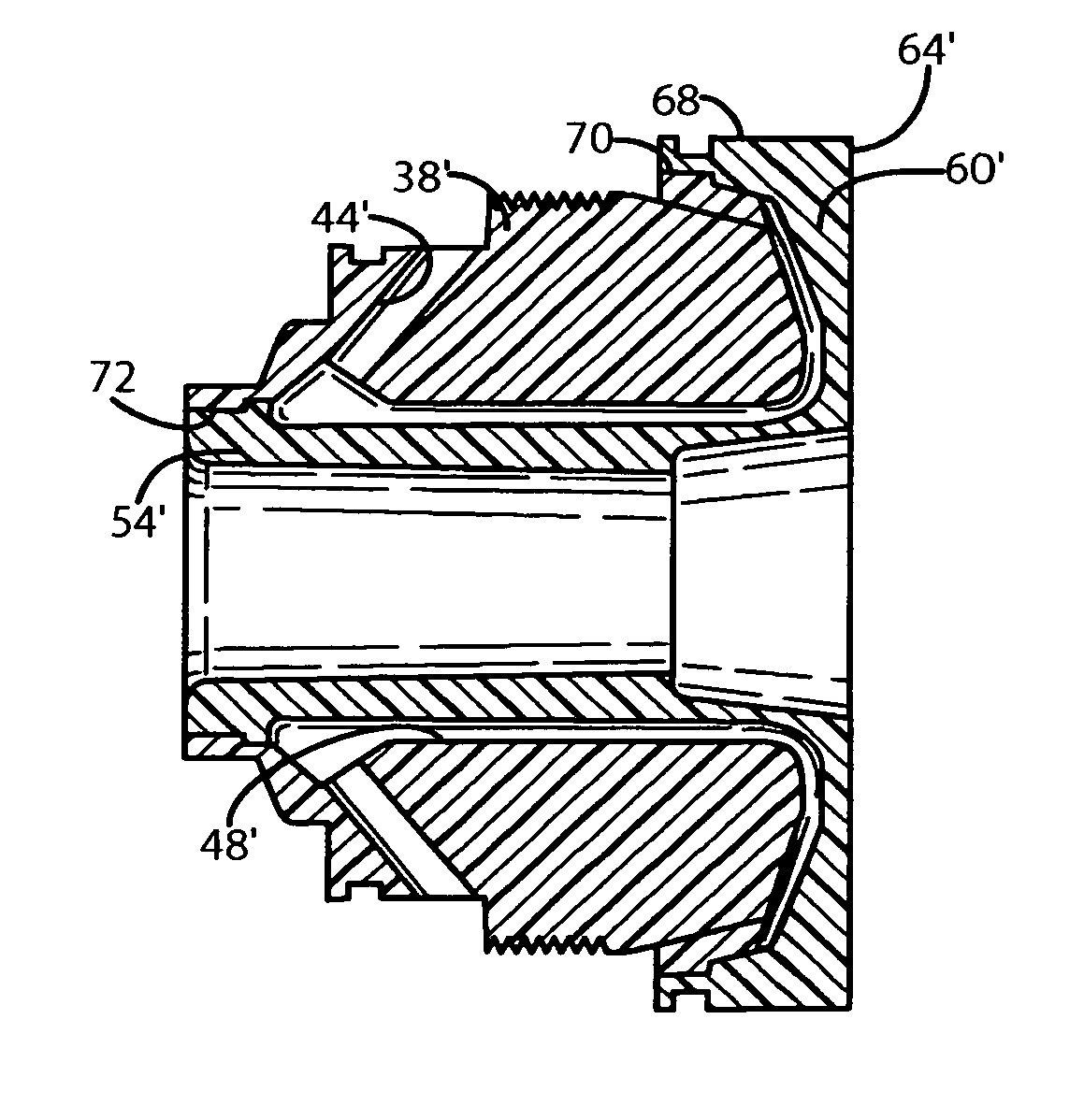

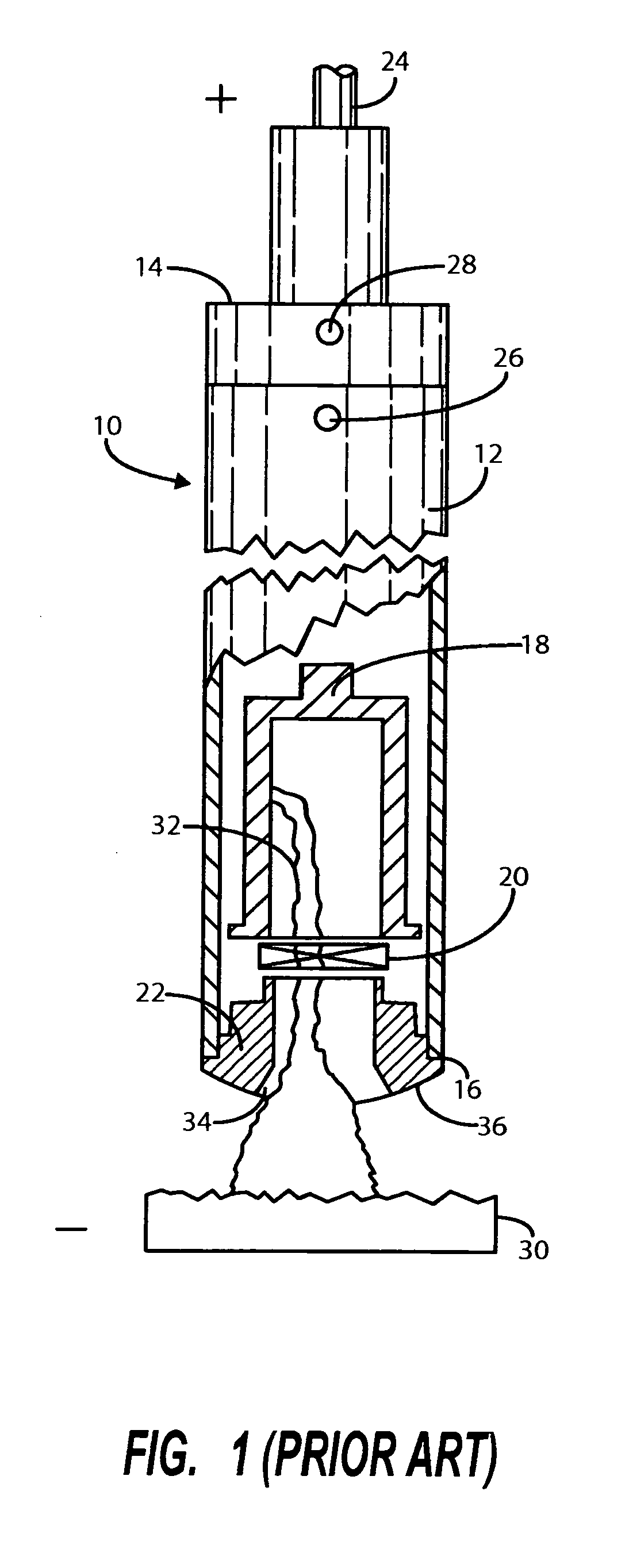

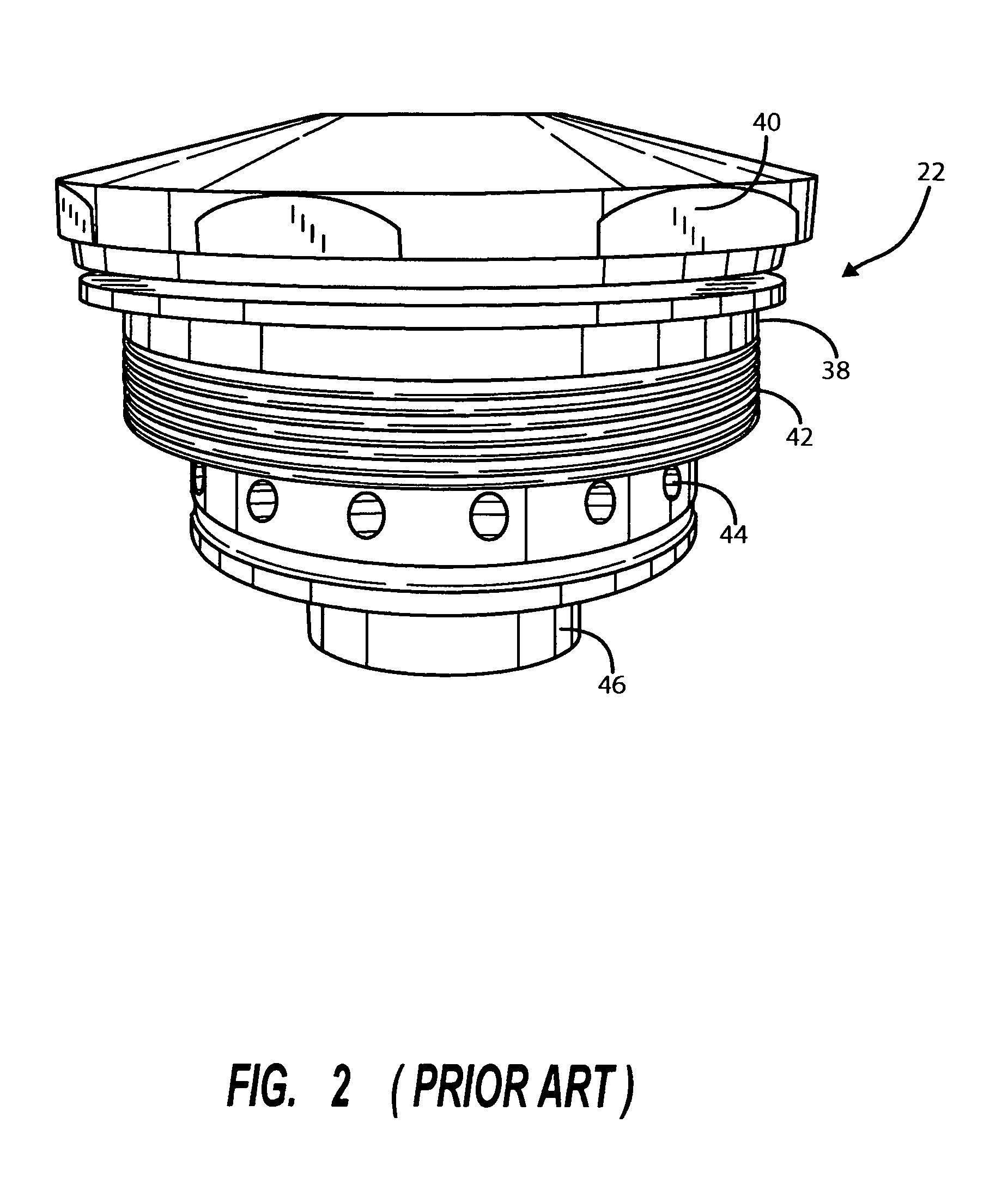

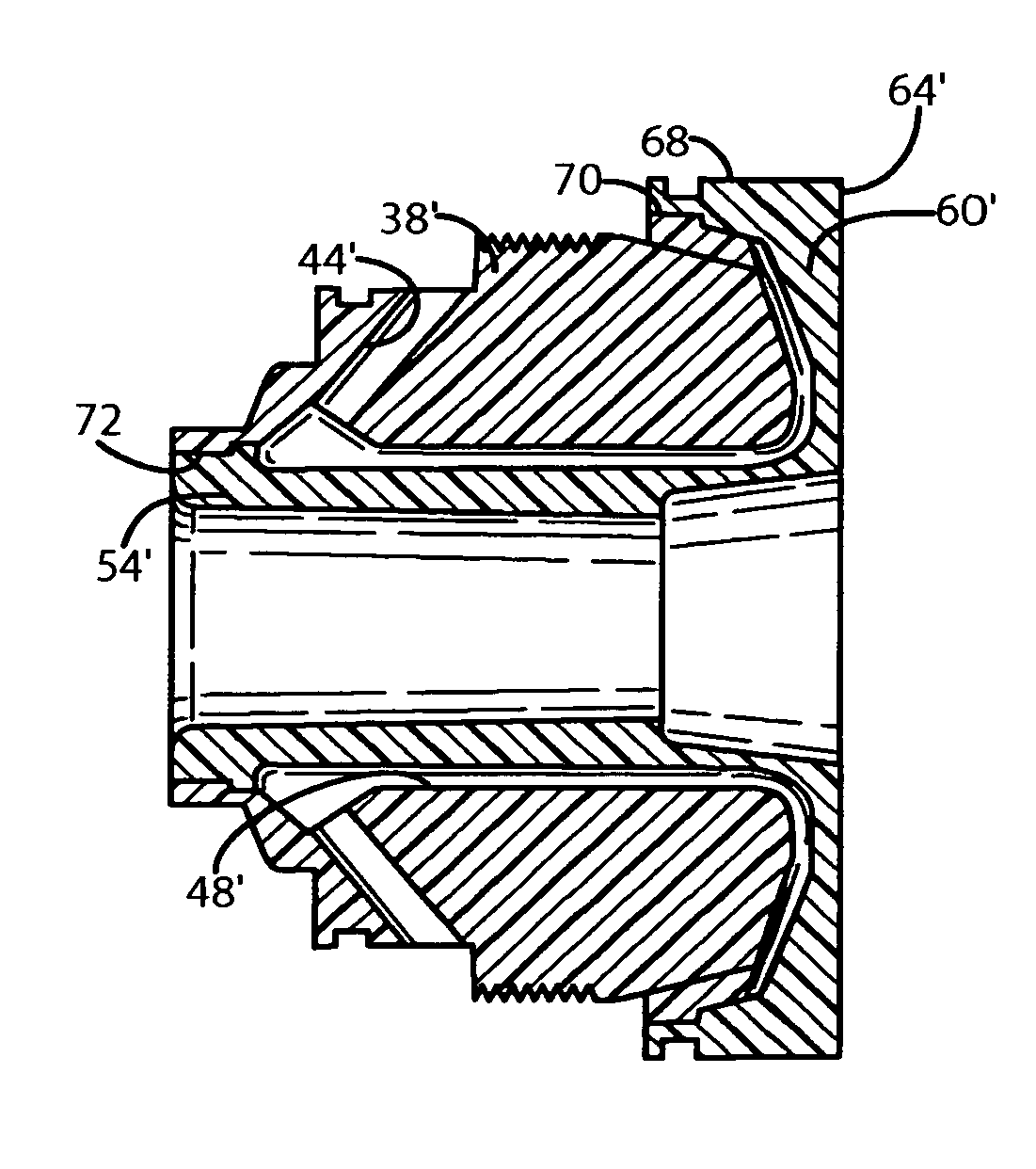

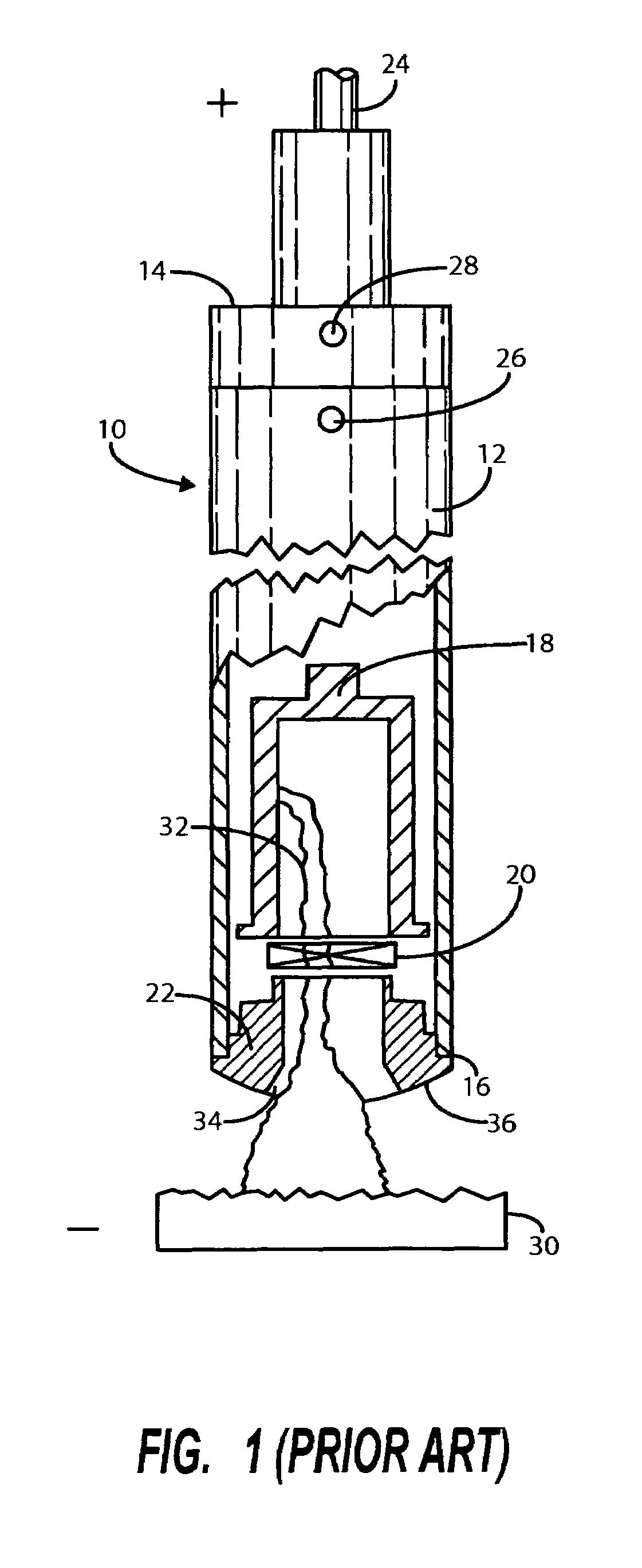

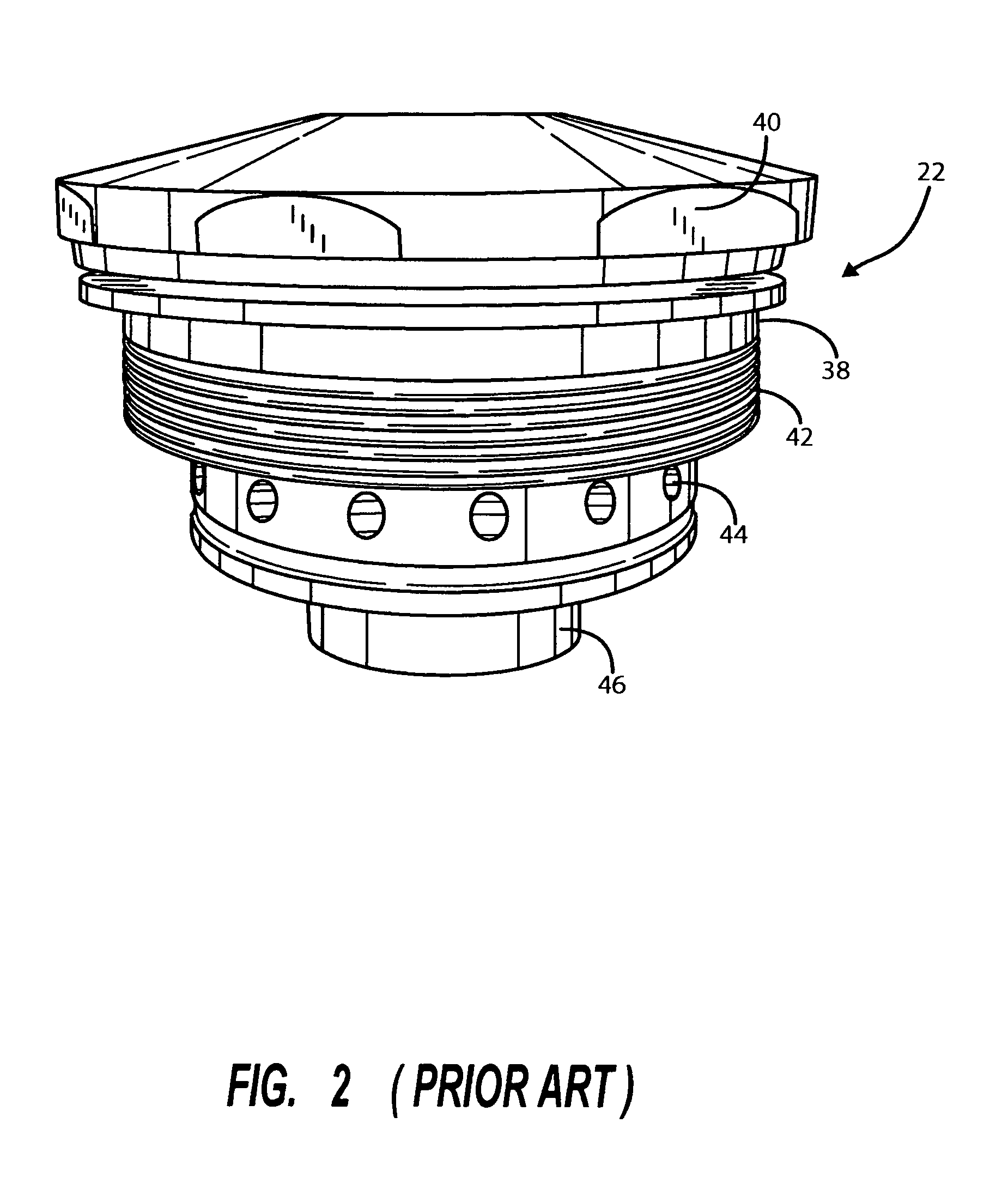

Plasma torch with corrosive protected collimator

ActiveUS20070084834A1Welding/cutting media/materialsWelding electrode featuresTorchPlasma arc welding

To protect the collimator of a transferred plasma arc torch from premature failure due to corrosion, an anti-corrosive covering is applied on the exposed face surface and a portion of the inner exit bore of the collimator. The specification describes several methods for producing the collimator for a plasma torch having an anti-corrosive coating or cladding on the exposed surfaces thereof, including electroplating, electroless plating, flame spraying, plasma spraying, plasma transferred arc, hot isostatic pressing and explosive cladding.

Owner:PHOENIX SOLUTIONS CO

Method for preparing non-brazing seam thin compound layer titanium/steel composite board

InactiveCN101406899AHigh bonding strengthGuaranteed Thickness RequirementsRoll mill control devicesFurnace typesSheet steelExplosive cladding

The invention discloses a method for preparing seamless thin multilayer titanium / steel composite plate and relates to a method for preparing the seamless titanium / steel composite plate with large specifications and a thin multilayer through a combined process of explosive welding plus hot rolling. The method is characterized in that after explosive cladding, a titanium plate and a steel plate form the composite plate through hot rolling. The method adopts a combined process of explosive welding plus hot rolling to prepare the seamless titanium / steel composite plate with the large specifications, an overall length over 10, 000mm and the thin multilayer, thereby not only ensuring the binding property and the specification requirements of the composite plate, but also meeting the demand on the seamless titanium / steel composite plate with the large specifications and the thin multilayer of large-scale pressure equipment.

Owner:XIAN TIANLI CLAD METAL MATERIALS

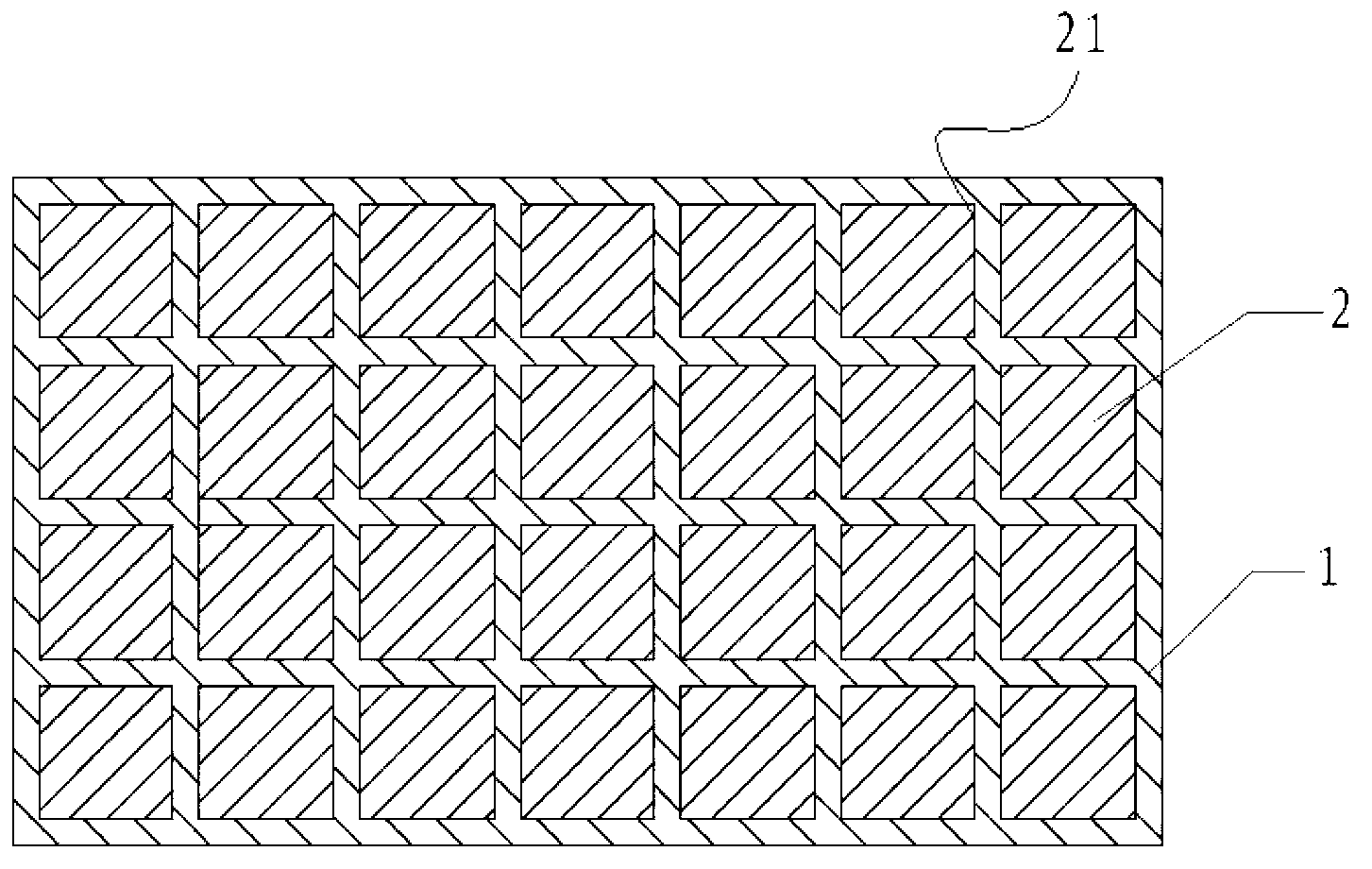

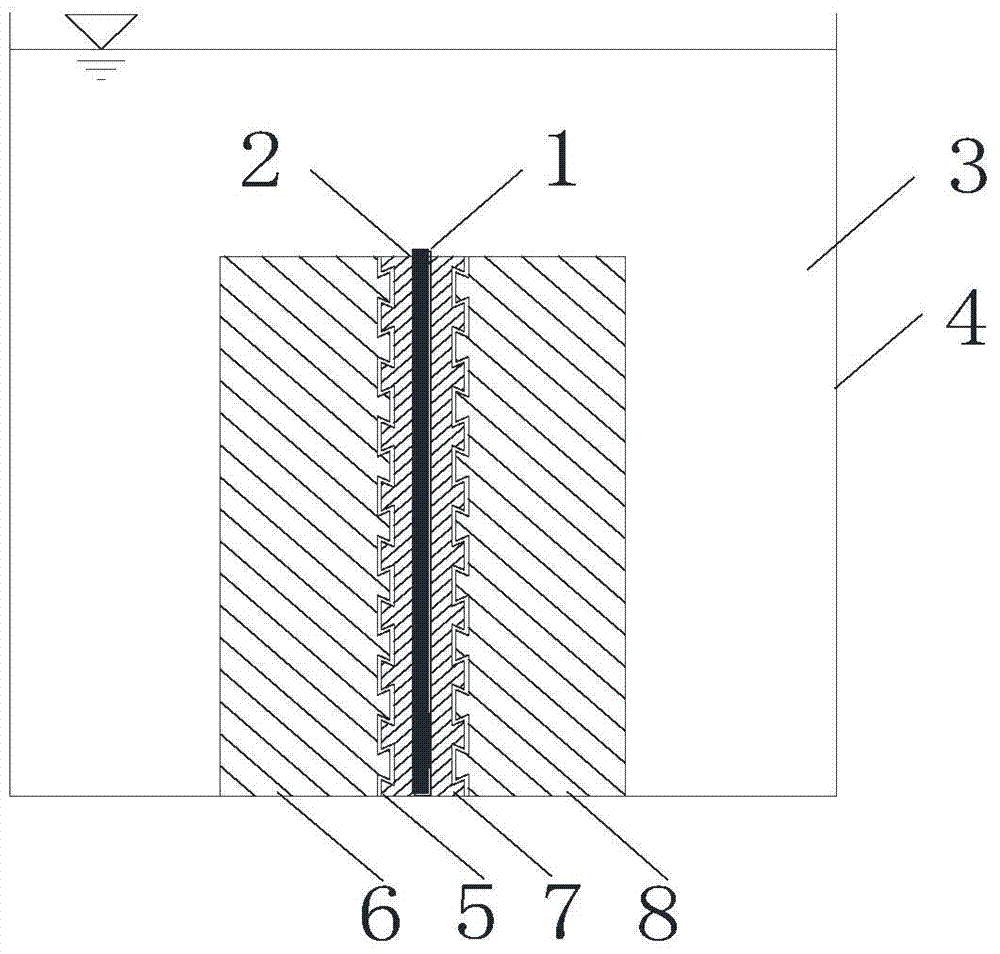

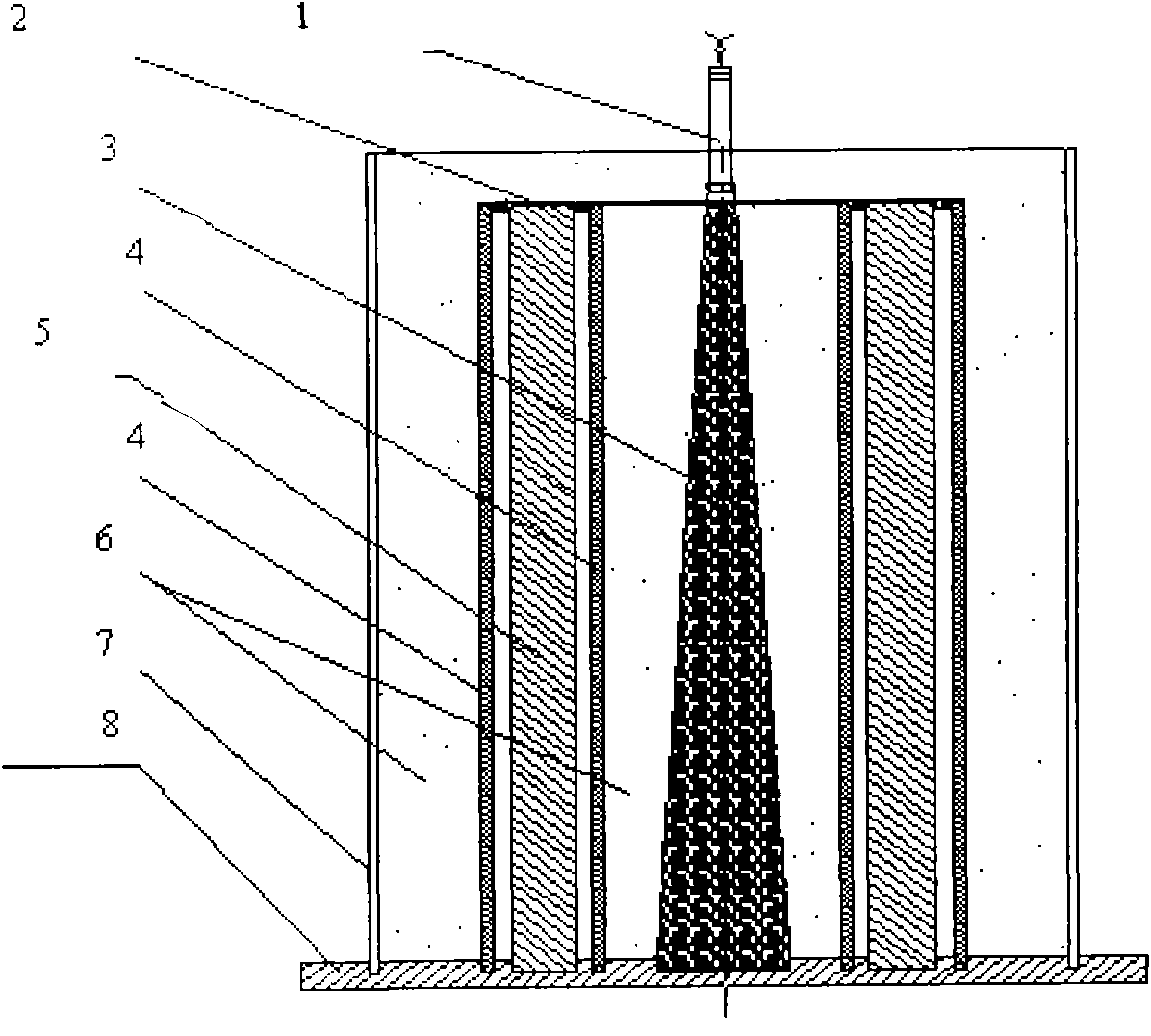

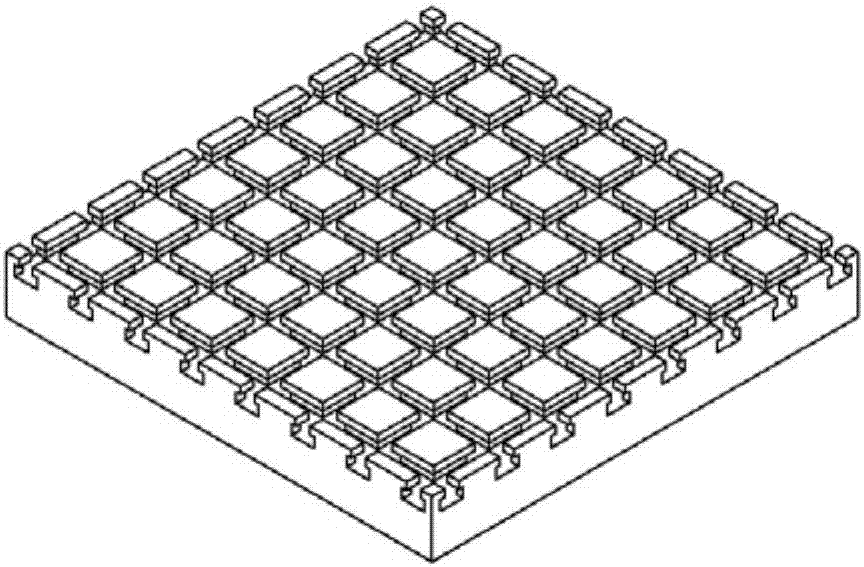

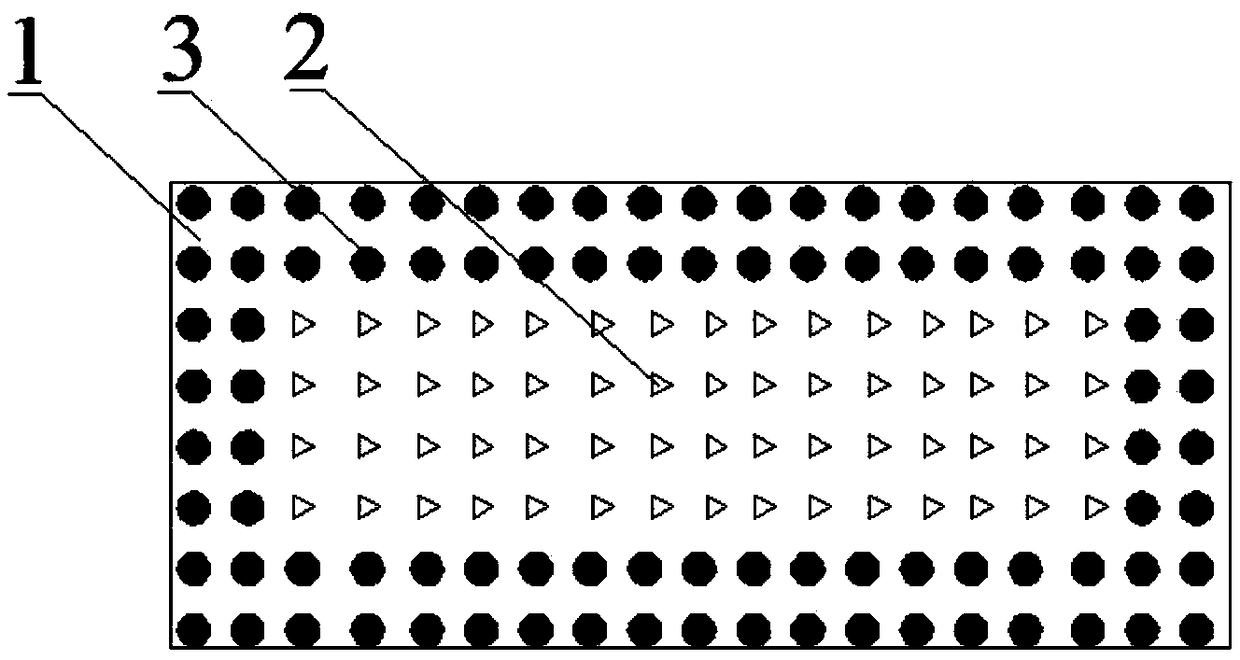

Special structural explosive for explosive cladding, explosive cladding method and explosive cladding device

ActiveCN103317222ASave explosivesReduce critical thicknessNon-electric welding apparatusShock waveExplosive cladding

The invention discloses special structural explosive for explosive cladding, an explosive cladding method and an explosive cladding device. The structural explosive comprises a filling plate, a plurality of cavities filled with the explosive are formed in the filling plate and distributed in a matrix. The special structural explosive for explosive cladding is formed by filling or injecting the explosive in the cavities of the filling plate. A layer of composite plate is mounted on each of two sides of the structural explosive, and the two composite plates are driven to move reversely after explosion to composite with two base plates in reserve directions. By the aid of an explosive filling method, explosive filling quality is guaranteed, critical thickness of stable explosive detonation is reduced, and energy utilization rate of explosive explosion is improved. The special structural explosive is convenient to use, and mechanized batch production can be realized. By the aid of the explosive cladding device, usage amount of the explosive is lowered, production cost is reduced, shock wave and noise pollution are reduced, and working environment of workers is improved.

Owner:UNIV OF SCI & TECH OF CHINA

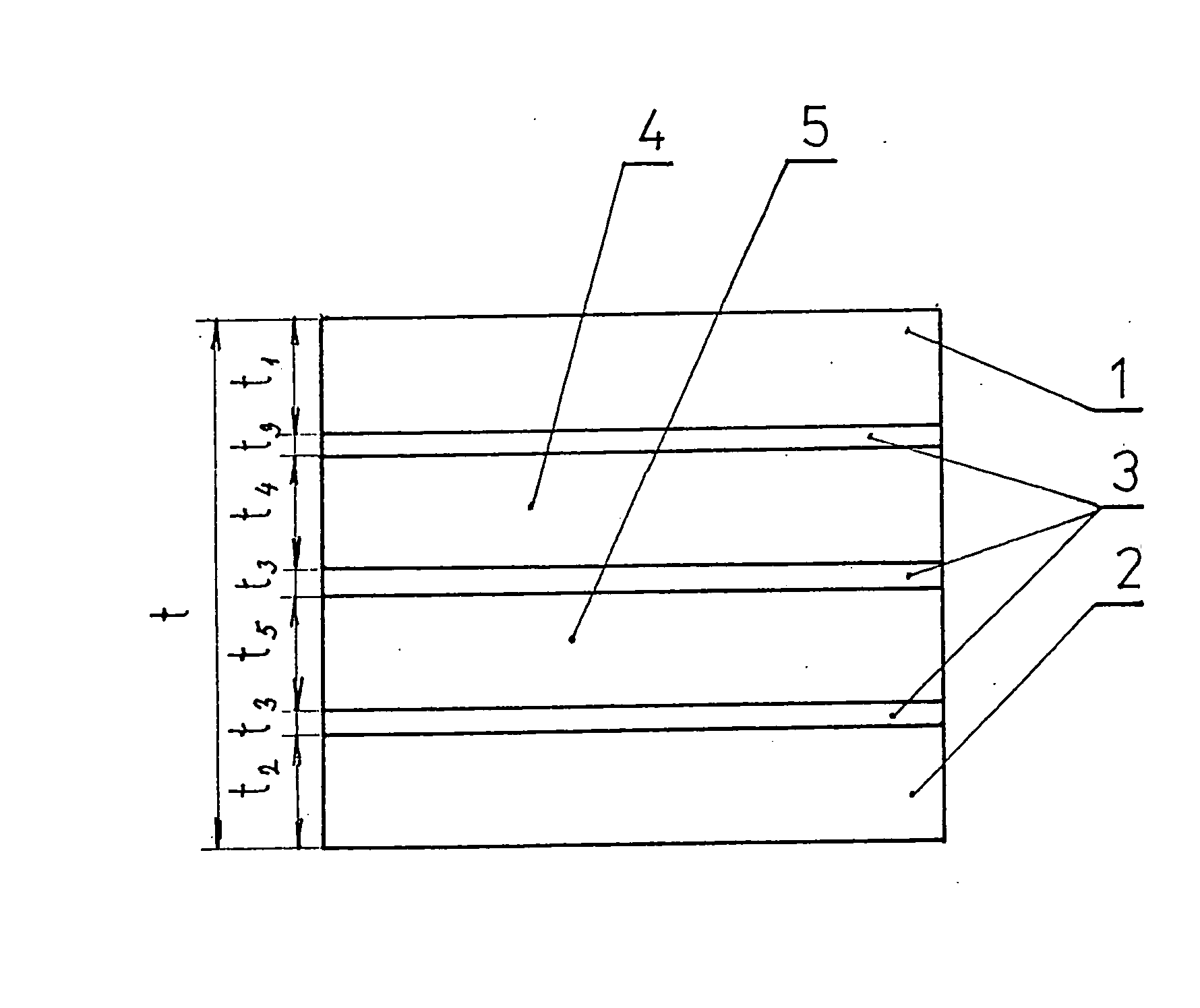

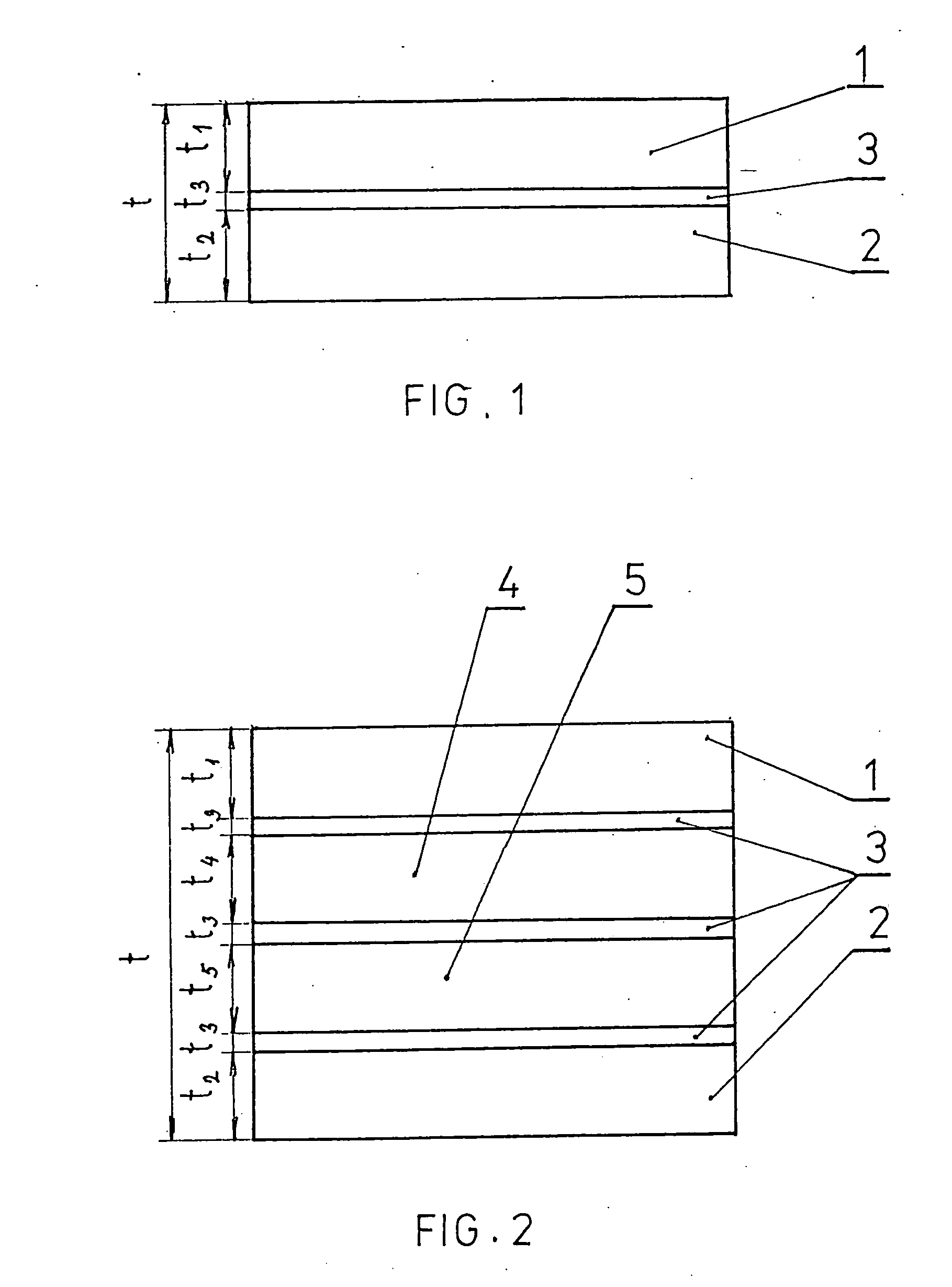

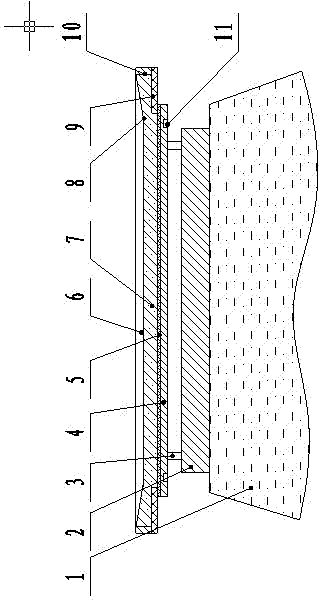

Multilayered steel armour

The multilayered steel armour consisting of the front-face ballistic-resistant armour layer (1) and the backing armour layer (2), which are fully metallurgically bonded by means of at least one joining metallic intermediate layer (3), for example, by casting, wide-area welding techniques, using technology of explosive cladding (high-velocity impact cladding), by roll welding or by a combination of the previous techniques. The joining metallic intermediate layer (3) between the front-face ballistic-resistant armour layer (1) and the backing armour layer (2) is made from the material featuring the face-centered cubic crystalline lattice (FCC lattice), in particular, from the nickel alloy containing maximally 98.0 wt % of nickel and / or from steel.

Owner:SVOS

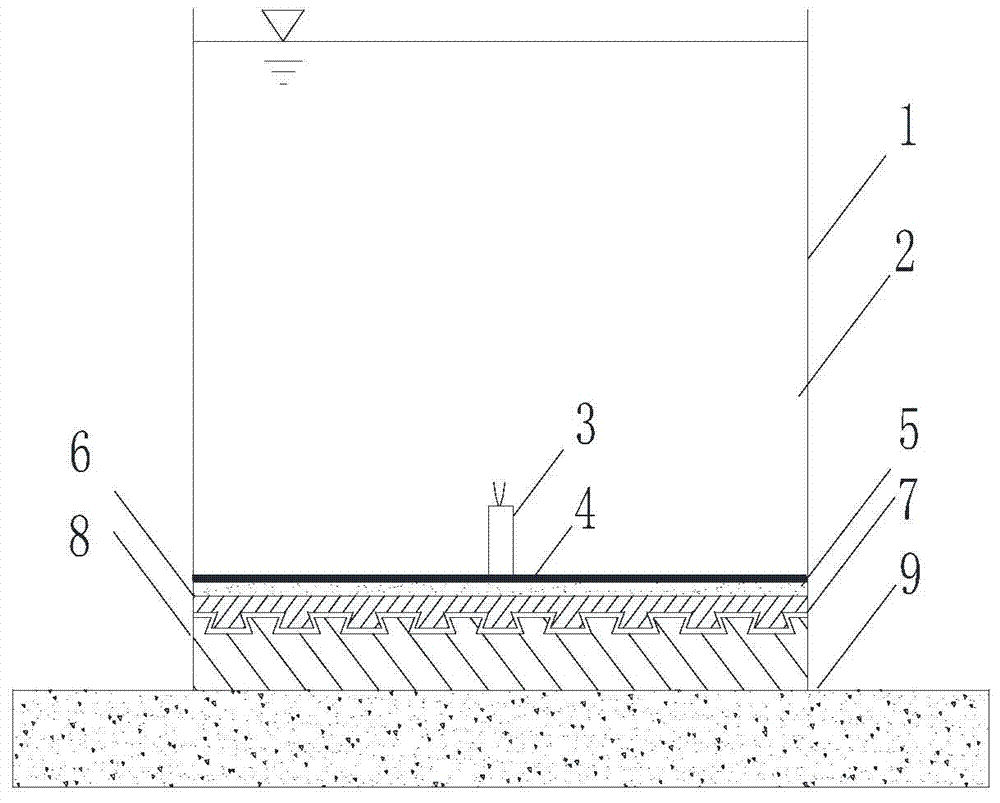

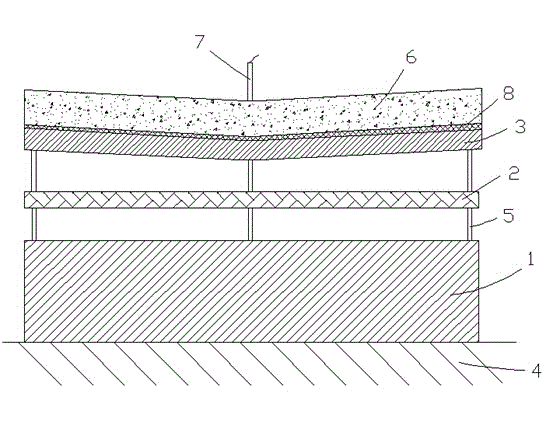

Explosive cladding welding method for titanium-steel composite board soldering joint

InactiveCN101342634AAchieving a complete weldSmooth welding surfaceWelding/soldering/cutting articlesNon-electric welding apparatusDetonatorExplosive cladding

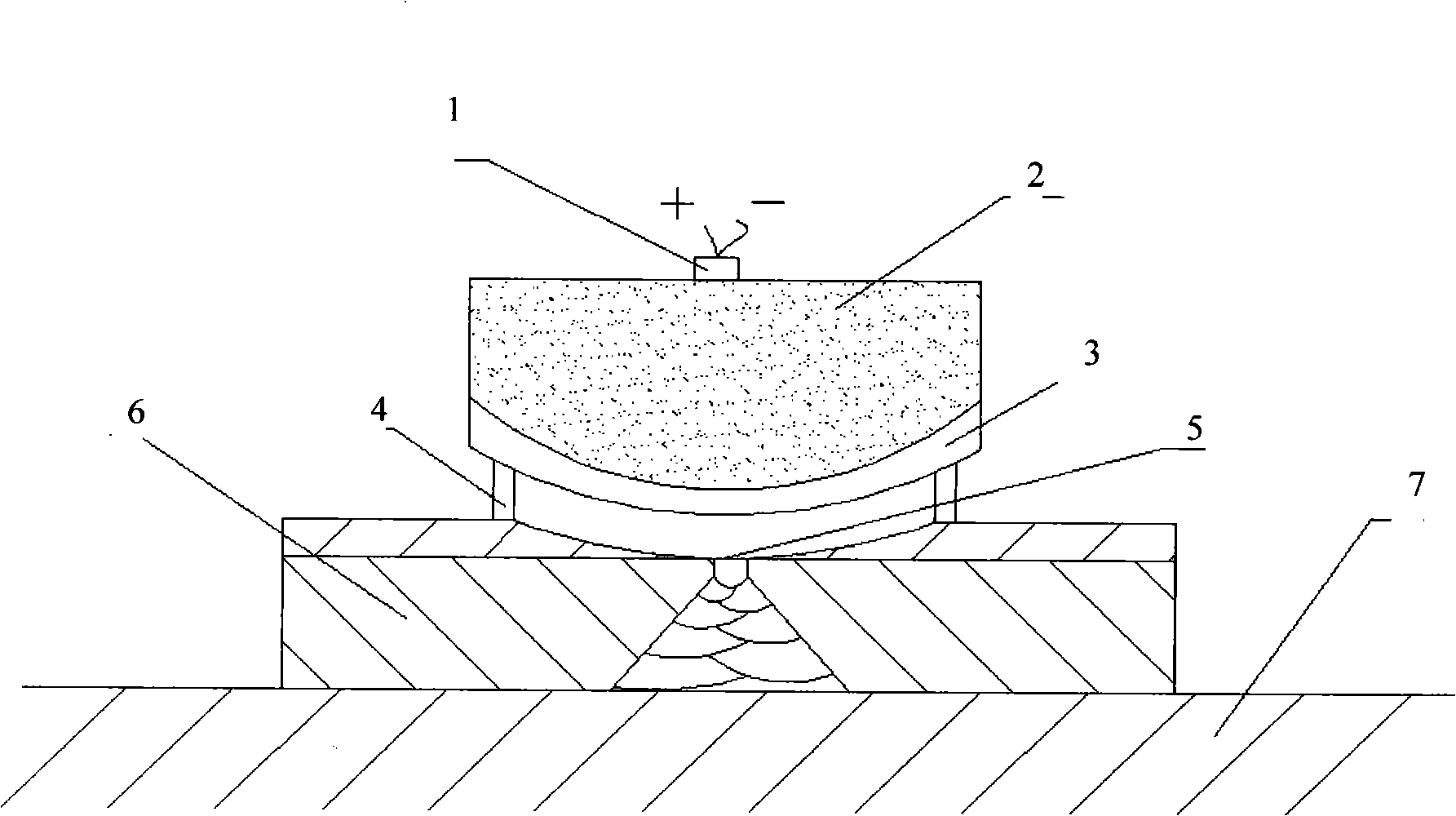

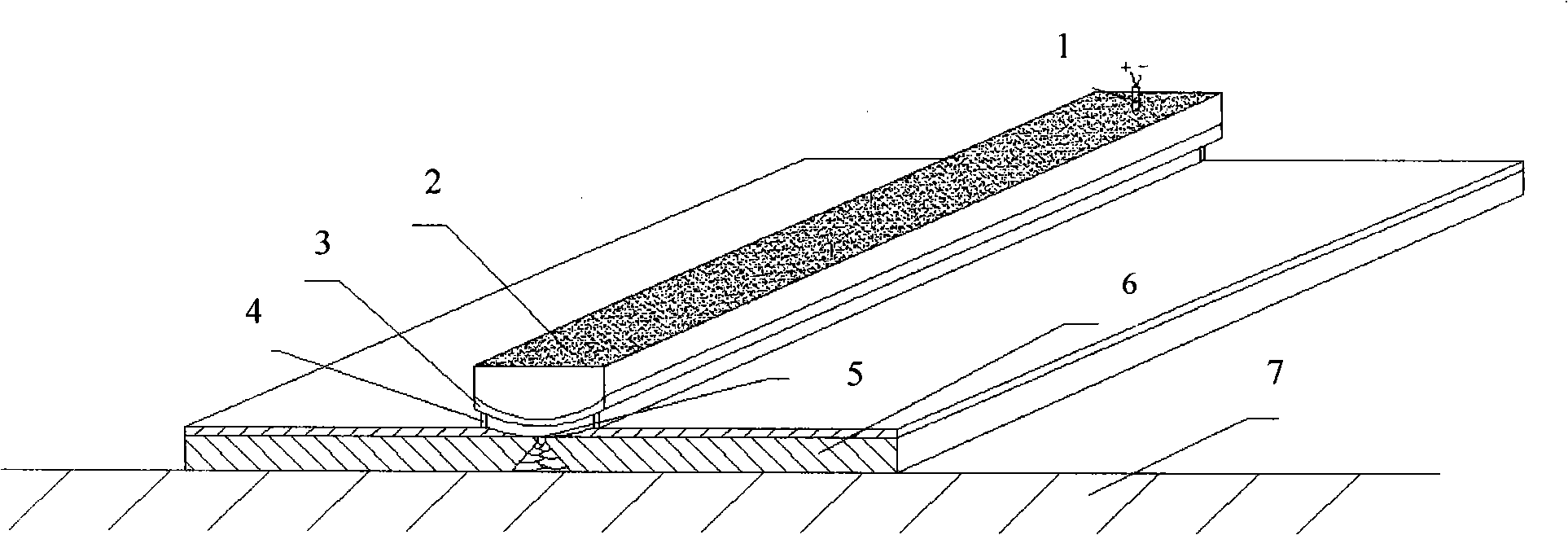

The invention discloses an explosion cladding and welding method of titanium-steel compound plate welding seams. The titanium plate used for cladding is firstly pressed into an arc-shaped titanium plate 3. The base plates of two pre-butt-jointed titanium-steel compound plates are processed into smooth arcs corresponding to the arc-shaped titanium plate 3. A groove is formed on the compound plates. The smooth arcs of the base plates, the groove of the compound plates and the arc-shaped titanium plate are grinded by abrasive paper or buffing wheel to remove the oxides on the surface of the metals and expose metallic luster. Then, the titanium-steel compound plate is arranged on a sand foundation 7, and the arc-shaped titanium plate is arranged over the smooth arcs of the base plate supported by a supporter 4. The height of the supporter is adjustable, ensuring that an arc-shaped welding seam 5 is formed between the smooth arc and the arc-shaped titanium plate. The explosive 2 is arranged on the upper surface of the arc-shaped titanium plate. Explosive charge quantity is determined by the area of explosion cladding unit. The explosive is ignited by 8# industrial electric detonator, ensuring that the arc-shaped titanium plate and the base plate are clad into an integrated body, and a complete welding titanium-steel compound plate with full penetration is gained. The welding seam has a smooth surface, is good-looking and corrosion resistance, and has a long service life.

Owner:LUOYANG SHUANGRUI METAL COMPOSITE MATERIAL

Method for preparing titanium steel cladding board with thin coating

InactiveCN104368600ALow investment costAvoid discountingTemperature control deviceWork treatment devicesProduction lineExplosive cladding

The invention discloses a method for preparing a titanium steel cladding board with a thin coating. The method comprises the steps that (1) an explosive cladding blank with a titanium plate as the upper layer and a steel plate as the lower layer is selected; (2) surfacing cleaning is conducted on the cladding blank; (3)the cleaned cladding blank is put in a stepping type heating furnace to be heated, and steel is loaded at the furnace tail of the stepping type heating furnace; (4) the evenly-heated cladding blank penetrates through a conveying roller table to a rolling mill to be descaled and rolled, the press-down rate of a first gate of rolling is controlled to be 20% or higher, the press-down rate of the rolling of the last gate is controlled to be 10% or lower, and the total press-down rate is 60%-90%. Air cooling is conducted on the cladding board after rolling is completed, and then the rolled cladding board is straightened. According to the method for preparing the titanium steel cladding board with the thin coating, under the premises that other auxiliary devices are not added, the descaling gates and the press-down amount in the rolling process are effectively controlled by using existing equipment of a moderate thickness board production line and by adopting the stepping type heating furnace for heating, and it is ensured that the rolled titanium steel cladding board is good in shape and good in comprehensive performance.

Owner:NANJING IRON & STEEL CO LTD

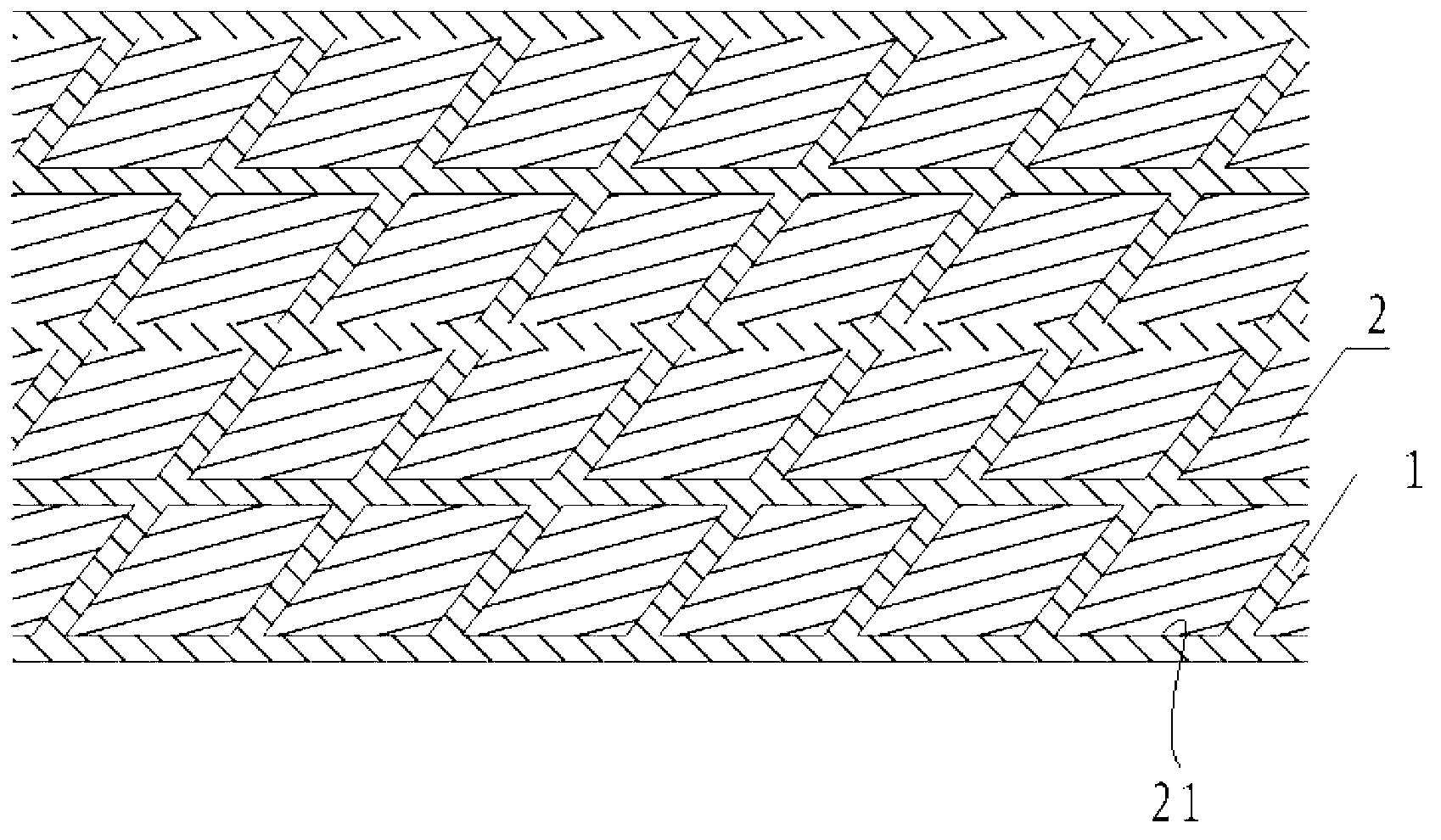

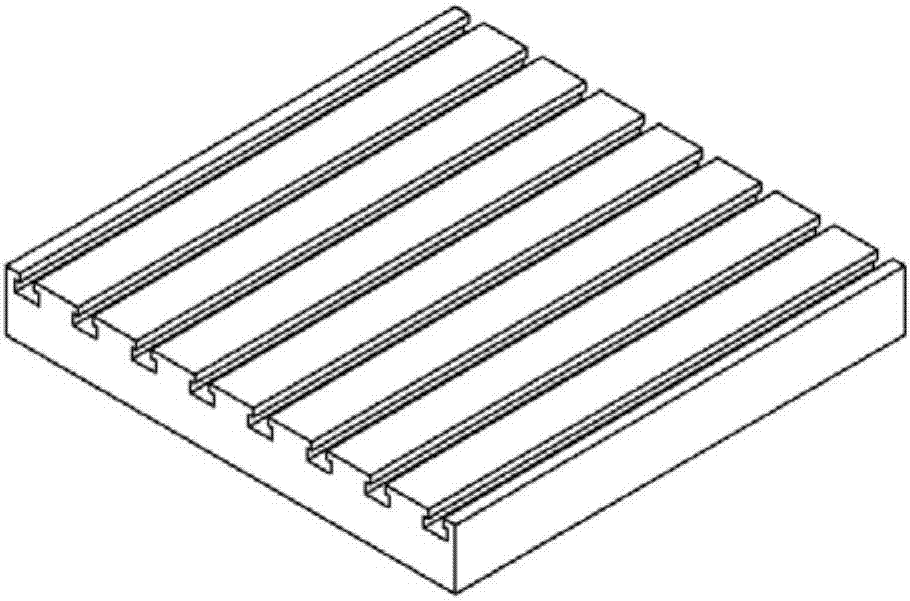

Compositing method of dovetail groove metal plate clearance fit interface

ActiveCN104289810AIncrease profitReduce pollutionMetal working apparatusNon-electric welding apparatusComposite effectInterference fit

The invention discloses a composting method of a dovetail groove metal plate clearance fit interface. The compositing method is realized through the explosive cladding method, the rolling method and the like. According to the method, after a base plate with dovetail grooves and a surface plate with dovetail grooves are in interference fit, the base plate and the surface plate are composited together through combination of a metallurgical bonding mode and a squeezing meshing mode of the dovetail grooves under the actions of energy of explosives or a rolling mechanism. Physical and chemical properties of metal sheets on the two sides of a dovetail groove combination interface are not changed, and large-area metal sheet composition can be conducted; the explosive charge for a unit of compositing area is small, and atmospheric pollution, noise pollution, explosion vibration and overpressure are reduced; during explosive welding of the metal sheets with the dovetail grooves, no boundary effect exists, the compositing effect on the periphery is good, and the lower limit and the upper limit of an explosive welding window are both increased. The compositing technology of the dovetail groove metal plate clearance fit interface can be applied to the fields such as chemical reaction containers and ships so as to meet the requirement for large-area metal composite plates.

Owner:UNIV OF SCI & TECH OF CHINA

Explosive welding method for zirconium-steel-zirconium three layer pipe

ActiveCN101837512ATake advantage of corrosion resistanceTake full advantage of abrasion resistanceNon-electric welding apparatusExplosive claddingPressure reduction

The invention relates to an explosive welding method for a zirconium-steel-zirconium three layer pipe. An outer zirconium pipe in an outer zirconium pipe-steel pipe-inner zirconium pipe has the diameter of 60-505 mm and the thickness of 1-8 mm, and a steel pipe has the diameter of 55-500 mm and the thickness of 8-200 mm; the inner diameter of the steel pipe is 4-6 mm larger than the outer diameter of an inner zirconium pipe, and the inner diameter of the outer zirconium pipe is 4-6 mm larger than the outer diameter of the steel pipe; the inner diameter of the inner zirconium pipe is 10-15 mm larger than the maximal diameter of a buffer cone; the explosive welding method comprises the following steps of carrying out the surface treatment and alignment of a base pipe, treating the zirconium pipe; guaranteeing the straightness of the zirconium pipe; assembling which comprises the steps of matching, vertically mounting the inner zirconium pipe, the outer zirconium pipe and the steel pipe on a technological bottom plate and mounting a pressure reduction cone at the center inside the inner zirconium pipe; carrying out re-explosive-cladding which comprises the steps of horizontally placing the device assembled on an explosive table, additionally mounting a pipe-shaped outer frame at the outer part of an outer steel pipe, and uniformly placing explosives around the pipe-shaped outer frame and the buffer cone of the inner pipe and denotating through detonators placed at the top of the buffer cone; and firmly binding the surfaces of the zirconium pipe and the steel pipe under high braking pressure.

Owner:黄山顺钛新材料科技有限公司

Thin-coat metal composite plate and production method thereof

InactiveCN104859218ASimple production processReduce production inputLaminationLamination apparatusMaterials preparationThin metal

The invention discloses a composite plate and a production method thereof, and relates to the field of novel materials. With the method provided by the invention, a composite plate with a coating layer thickness lower than 2mm can be prepared, such that a metallurgically bonded ultra-thin-coat metal composite plate can be obtained. The production method comprises the steps of coating material preparation, composite material preparation and heat treatment. According to the ultra-thin-coat metal composite material, the coating material is prepared through the metal composition methods of rolling composition, explosive cladding, spray coating, electroplating, and the like. The composition of the coating and a substrate is realized with an explosion or rolling method. The thickness of the coating of the ultra-thin metal composite material is lower than 2mm, and the total material thickness of the composite material can be set to any thickness. Therefore, a vacancy of the composite plate with the coating thickness within this range is filled.

Owner:杜双双

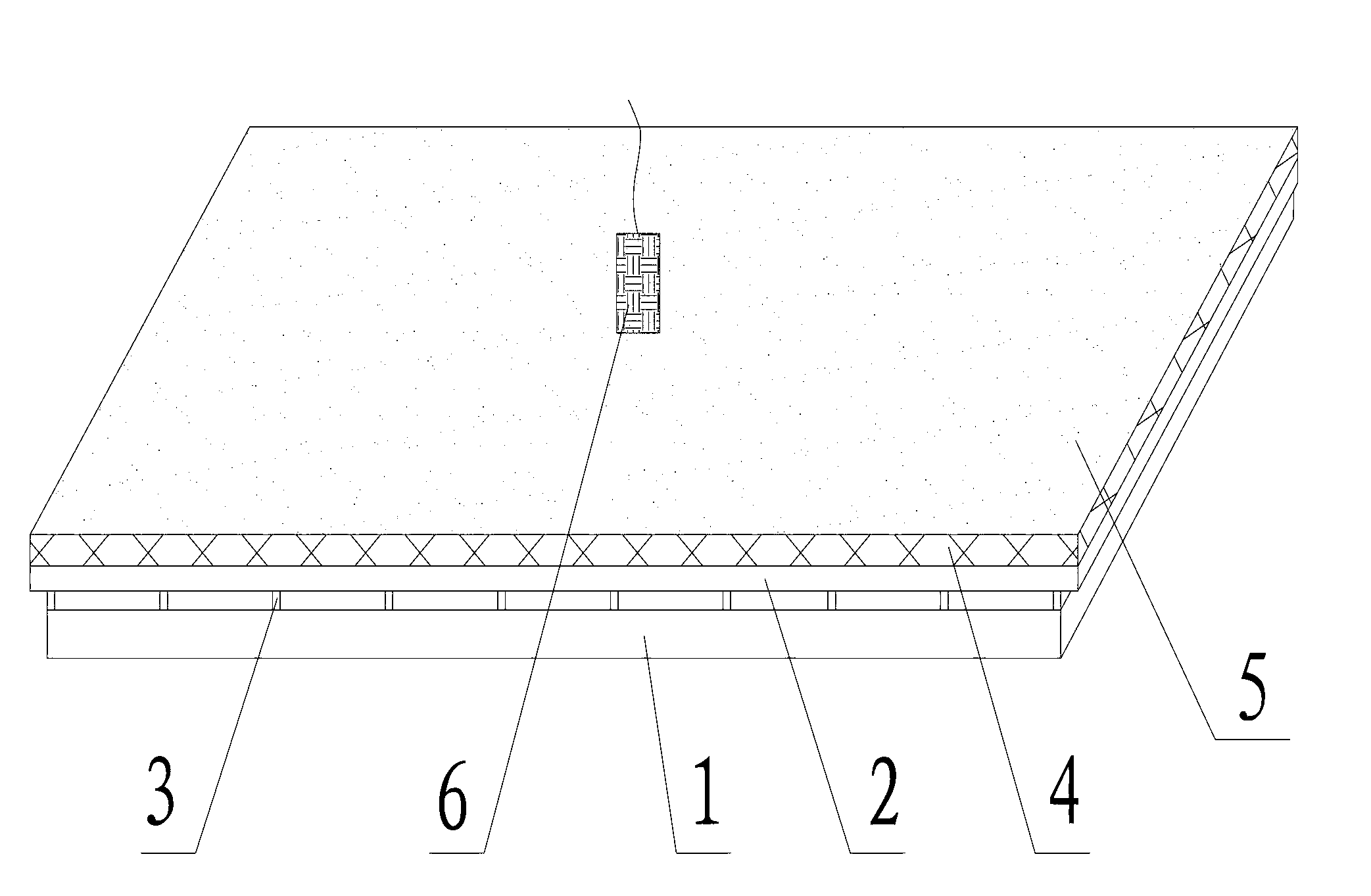

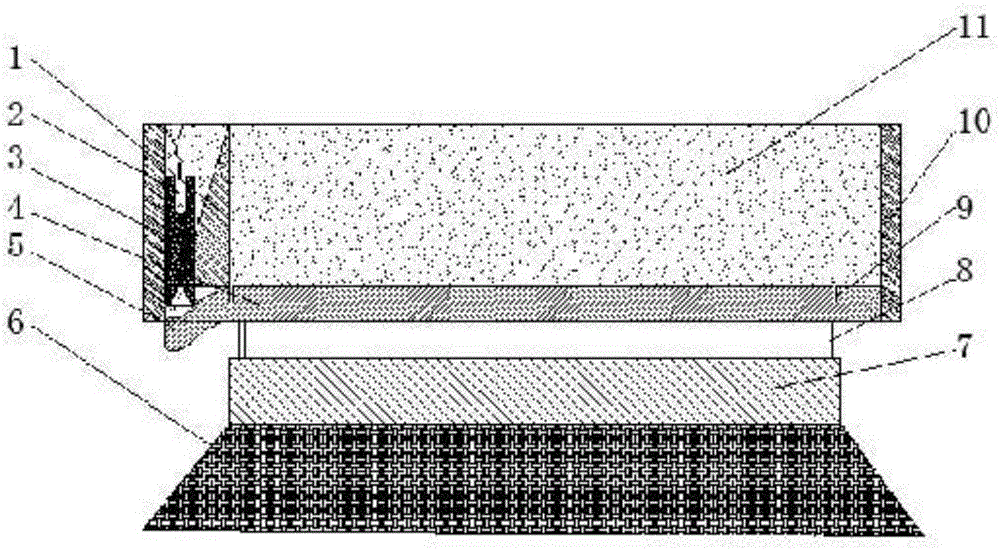

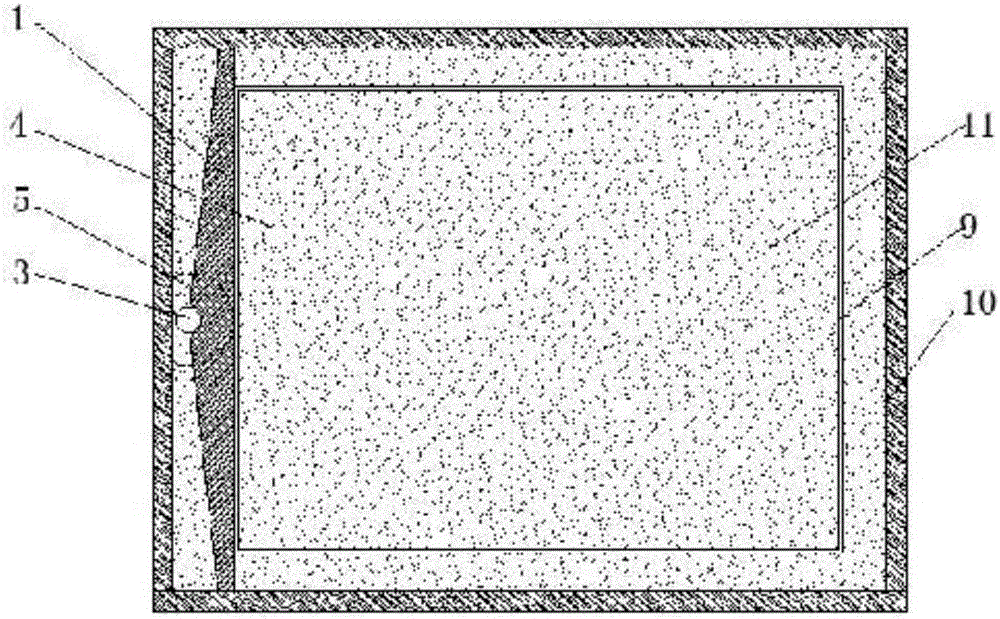

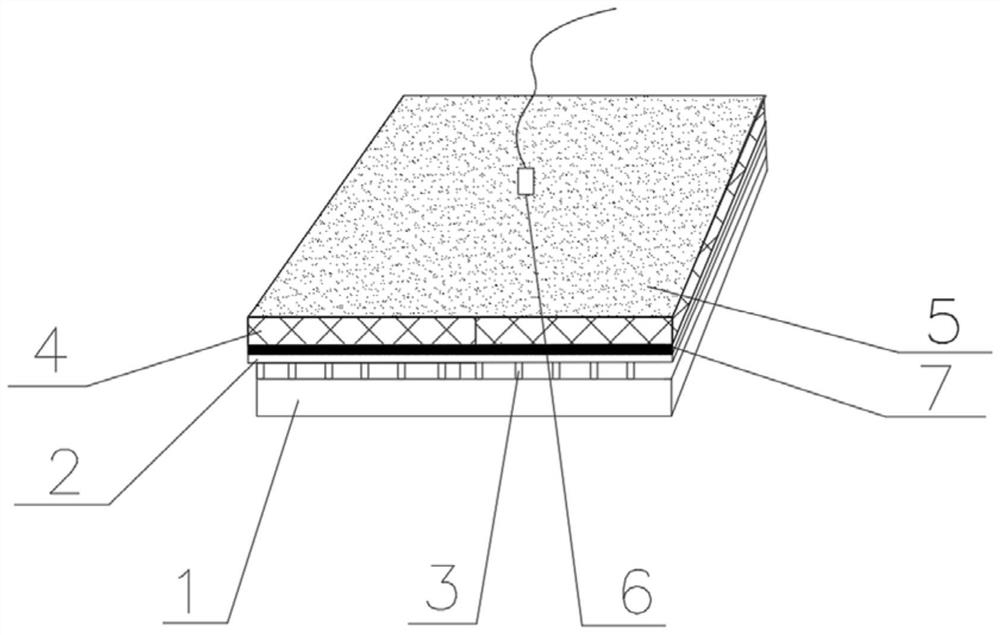

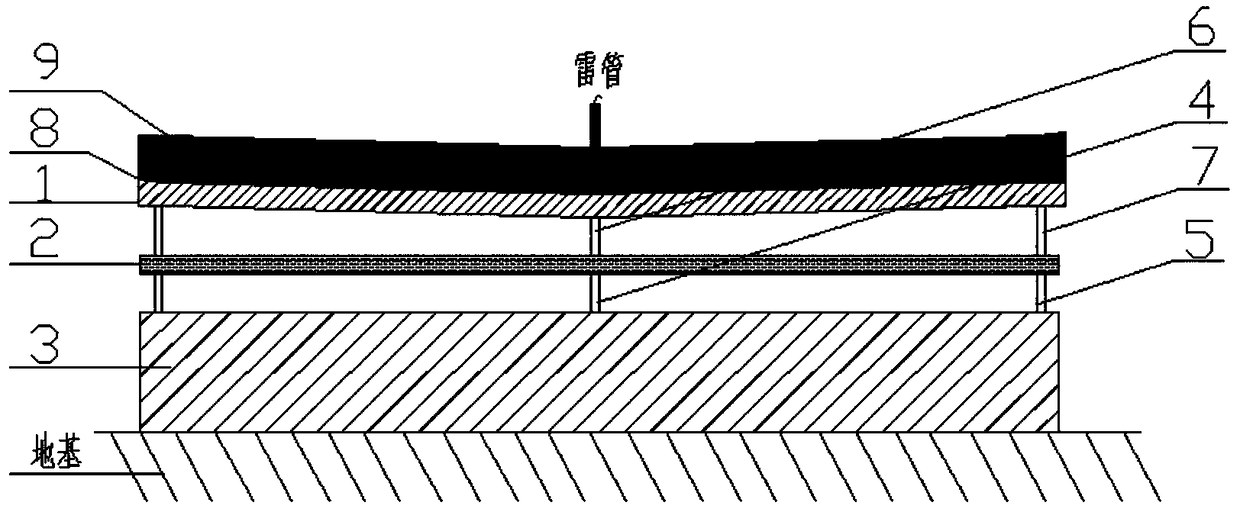

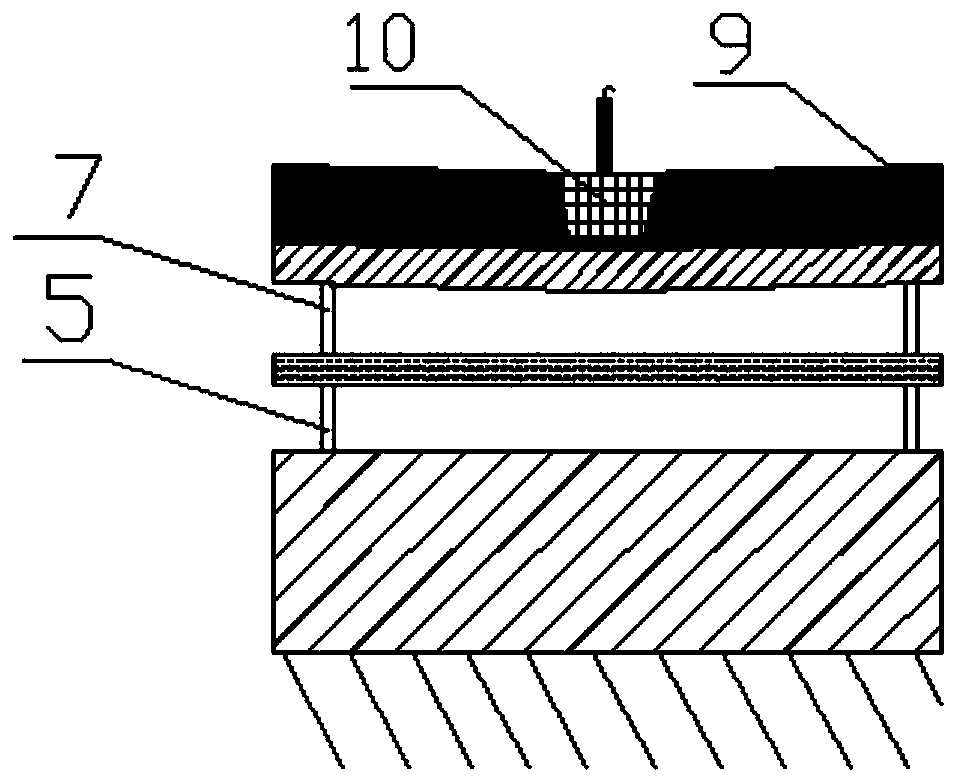

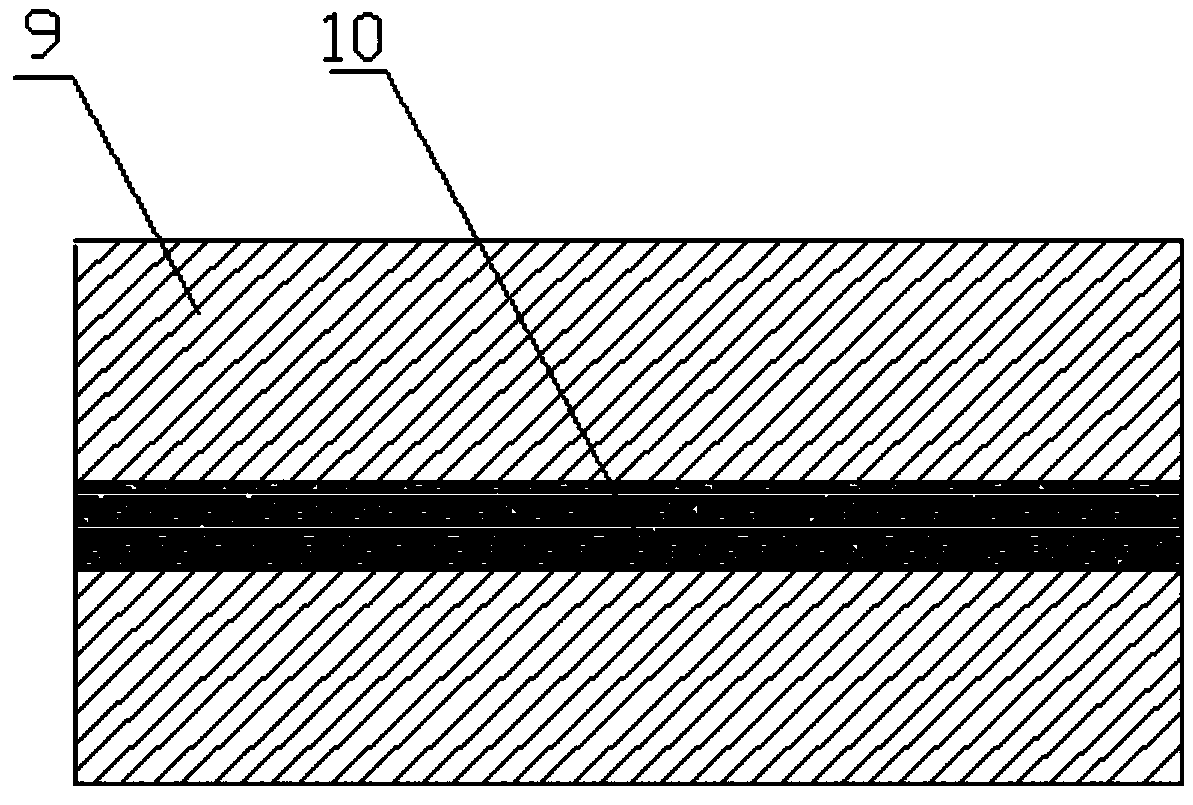

Explosive cladding structure of aluminum-titanium steel composite board and method for preparing aluminum-titanium steel composite board

InactiveCN104690411AReduce distanceAvoid jet restraintMetal layered productsNon-electric welding apparatusSteel qualityExplosive cladding

The invention discloses an explosive cladding structure of an aluminum-titanium steel composite board and a method for preparing the aluminum-titanium steel composite board. The explosive cladding structure of the aluminum-titanium steel composite board comprises a steel substrate board, a titanium board and an aluminum board; the steel substrate board is placed on the foundation; the titanium board is located above the steel substrate board; the aluminum board is located above the titanium board; a support sheet is used for separating between the steel substrate board and the titanium board, and between the titanium board and the aluminum board; an explosive layer is placed on the upper side of the aluminum board, the explosive layer comprises a main explosive and a high explosive velocity drug bar, and the explosive velocity of the high explosive velocity drug bar is higher than that of the main explosive; the main explosive is uniformly placed on the upper side of the aluminum board; the high explosive velocity drug bar is successively placed in the middle of the upper side of the aluminum board along the direction of the long edge; and the middle part of the explosive layer is connected to a detonator. The explosive cladding structure of the aluminum-titanium steel composite board has the advantages of high adhering rate, high bonding strength, and low cost, and has the characters of the good corrosion resistance and abrasive resistance of the aluminum materials and high strength of the steel board.

Owner:安徽宝泰特种材料有限公司

Explosive welding method of NO8825 nickel-based alloy clad steel plate

InactiveCN101559527AReduce usageEffective compoundWelding/soldering/cutting articlesMetal working apparatusExplosive claddingSheet steel

The invention relates to an explosive cladding process of metals. The process is characterized by comprising the following steps: substrate treatment, composite treatment, applying and pairing, explosive cladding, repair welding, heat treatment and post-treatment. The process can help clad NO8825 nickel-based alloy plates with general steel plates effectively so that the clad steel plates can have the required strength on the premise of owning all the advantages of the NO8825 nickel-based alloys, thus saving consumption of expensive metals. The clad steel plates have high welding quality, and can certainly remain stable in long-term use without sealing off.

Owner:SICHUAN JINGLEI SCI & TECH CO LED

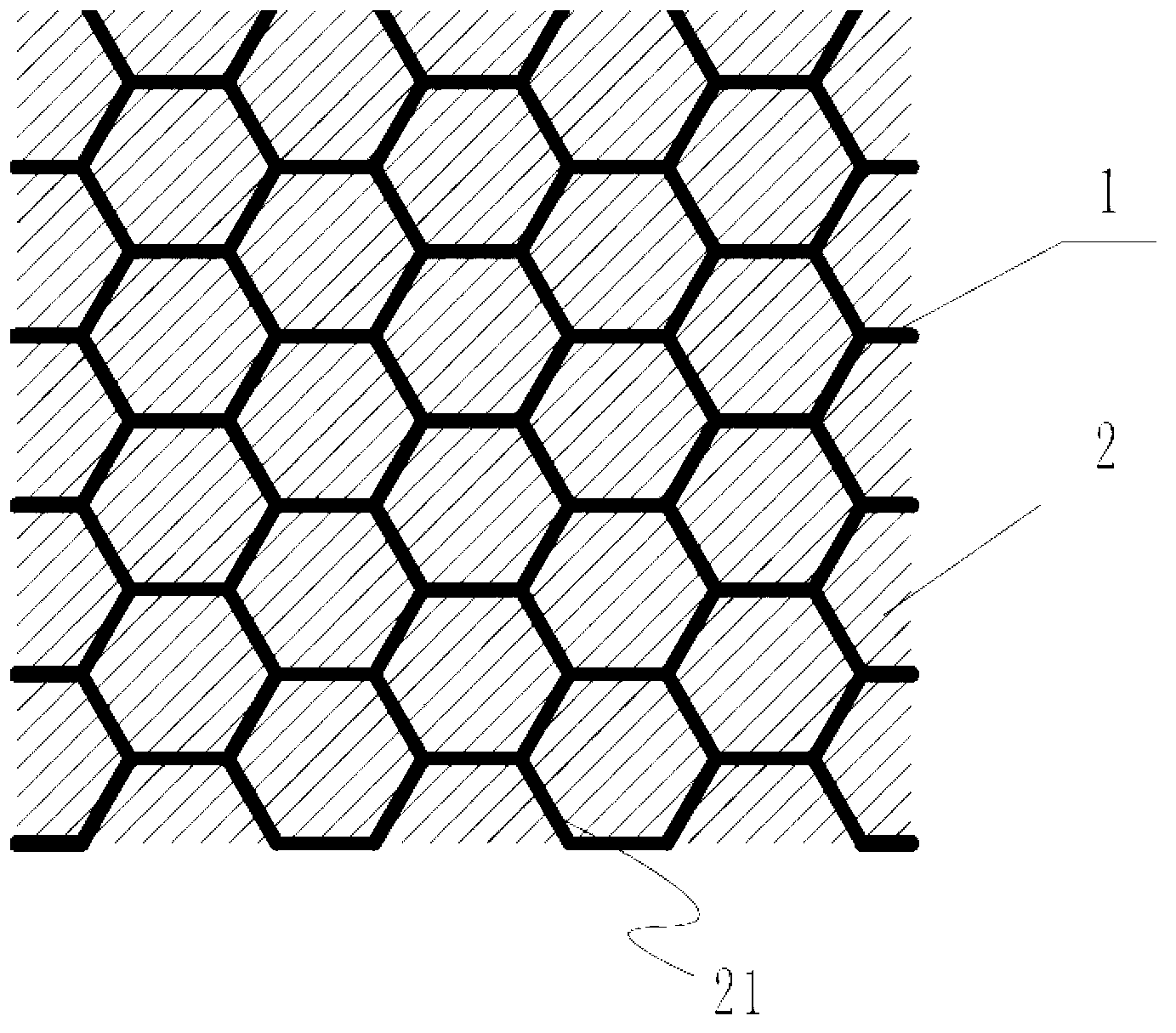

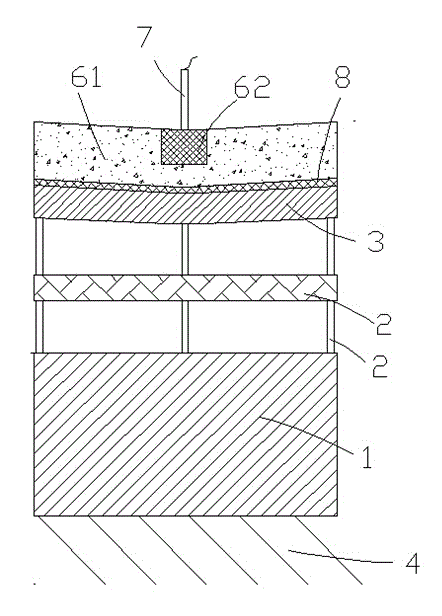

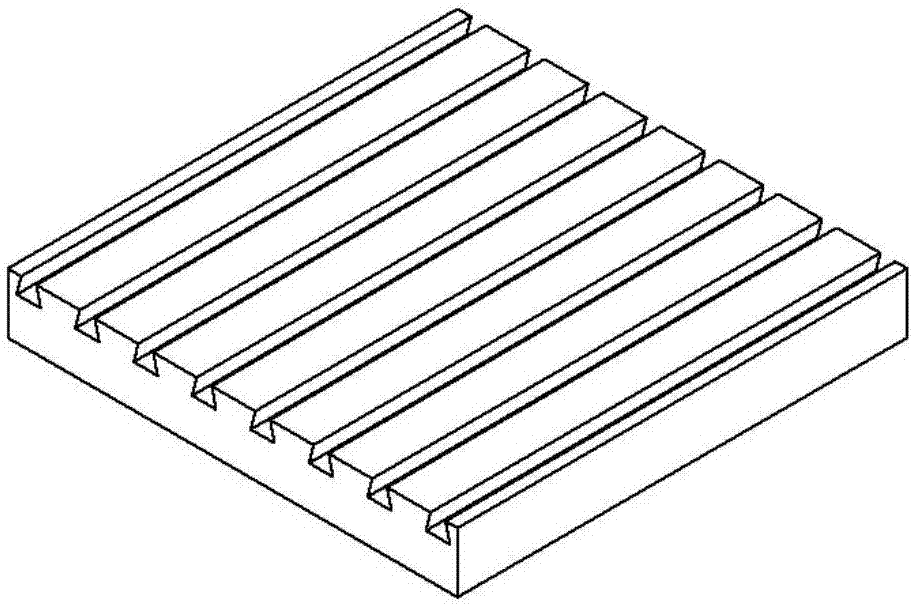

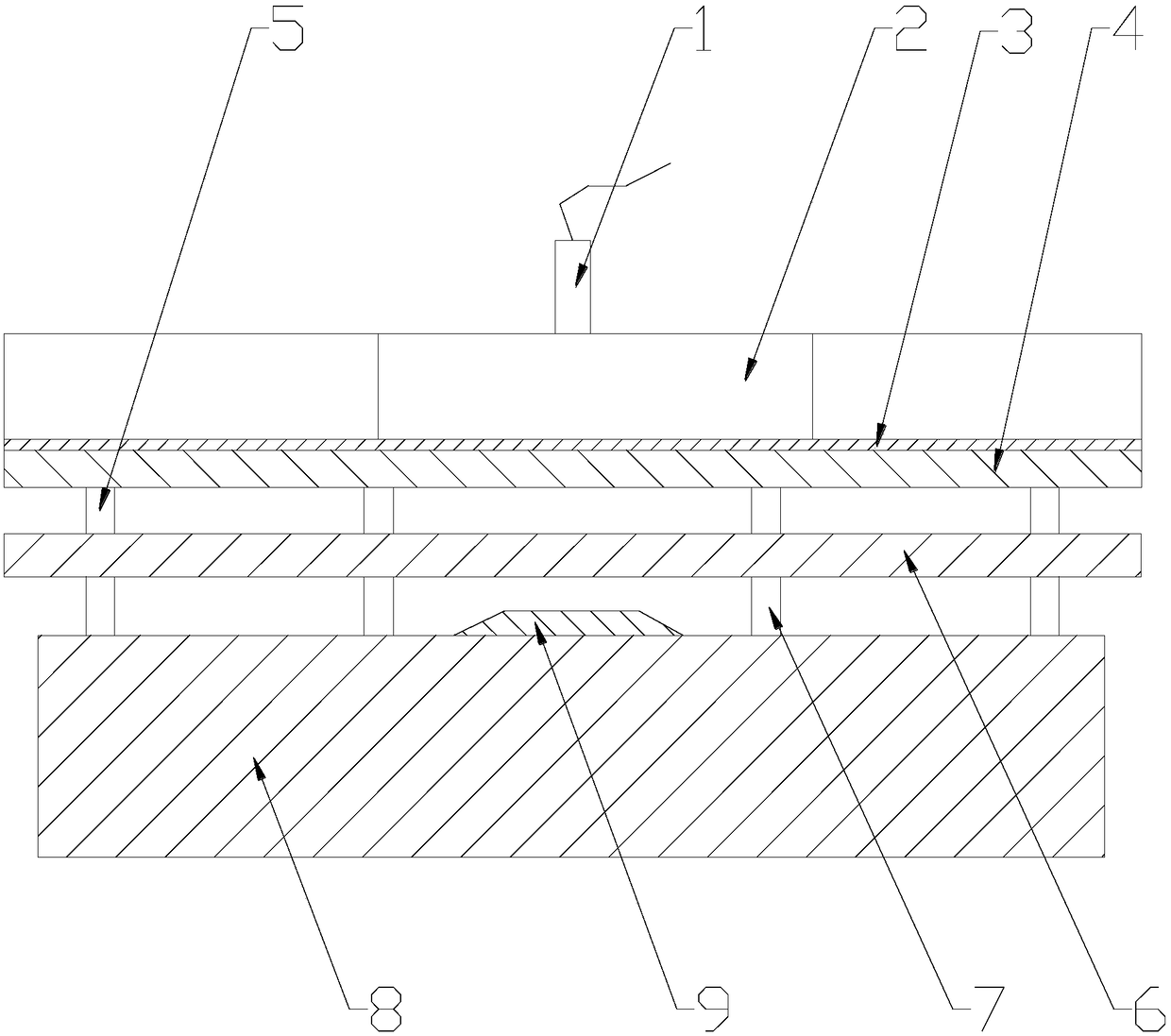

Explosive cladding method for groove type hot melt interface of metal plate and explosive device

PendingCN106956073AReduce pollutionSmall amount of explosiveNon-electric welding apparatusExplosive claddingExplosive Agents

The invention provides an explosive cladding method for a groove type hot melt interface of a metal plate and an explosive device. According to the method, grooves are formed in the surface of a metal base plate at first, the grooved interface is cleaned up, raw materials of a covering plate are melted in a high-temperature furnace, a part of melted liquid flows into groove cavities, under the thermal action of the high-temperature liquid and the mechanical action of the grooves, primary combining of the covering plate and the base plate is achieved, then the covering plate is further squeezed into the grooves through an explosive method, the base plate and the covering plate squeeze each other and are combined closely, and tight combining force is achieved on the interface of the two metal plates. According to the explosive cladding method and the explosive device, the amount of explosives in unit area is small, a honeycomb aluminum explosive loading structure is adopted, the explosive amount and the cladding time can be saved, and meanwhile, atmospheric pollution, noise pollution, vibration and overpressure are reduced.

Owner:UNIV OF SCI & TECH OF CHINA

Explosive cladding explosive and preparation method and applications thereof

ActiveCN103058800ALow costExcellent caking resistanceExplosivesNon-electric welding apparatusExplosive claddingExplosive Agents

The present invention provides an explosive cladding explosive prepared from expanded ammonium nitrate explosive, calcium nitrate, graphite and magnesium stearate according to a certain ratio. The present invention also provides a method for preparing the explosive, and the method comprises weighing all raw materials and placing the raw materials in an automatic drug mixing machine to mix uniformly to obtain an explosive cladding explosive. Further, the present invention also provides a method for preparing explosive clad plates by using the explosive, and the method comprises: laying a clad plate on the top of a baseplate, and laying support columns between the clad plate and the baseplate; positioning an explosive frame on the clad plate, overlying the explosive inside the explosive frame, and placing a detonating primer on the explosive; and detonating the explosive by using the detonating primer to obtain the explosive clad plate. The explosive cladding explosive of the invention is good in formula design, simple in a blending method, low in cost, excellent in performance and anti-caking performance; and the explosive clad plate prepared by using the explosive cladding explosive of the invention has a high interlaminar bonding rate and high combination strength, and is for large-scale industrial production.

Owner:XIAN TIANLI CLAD METAL MATERIALS

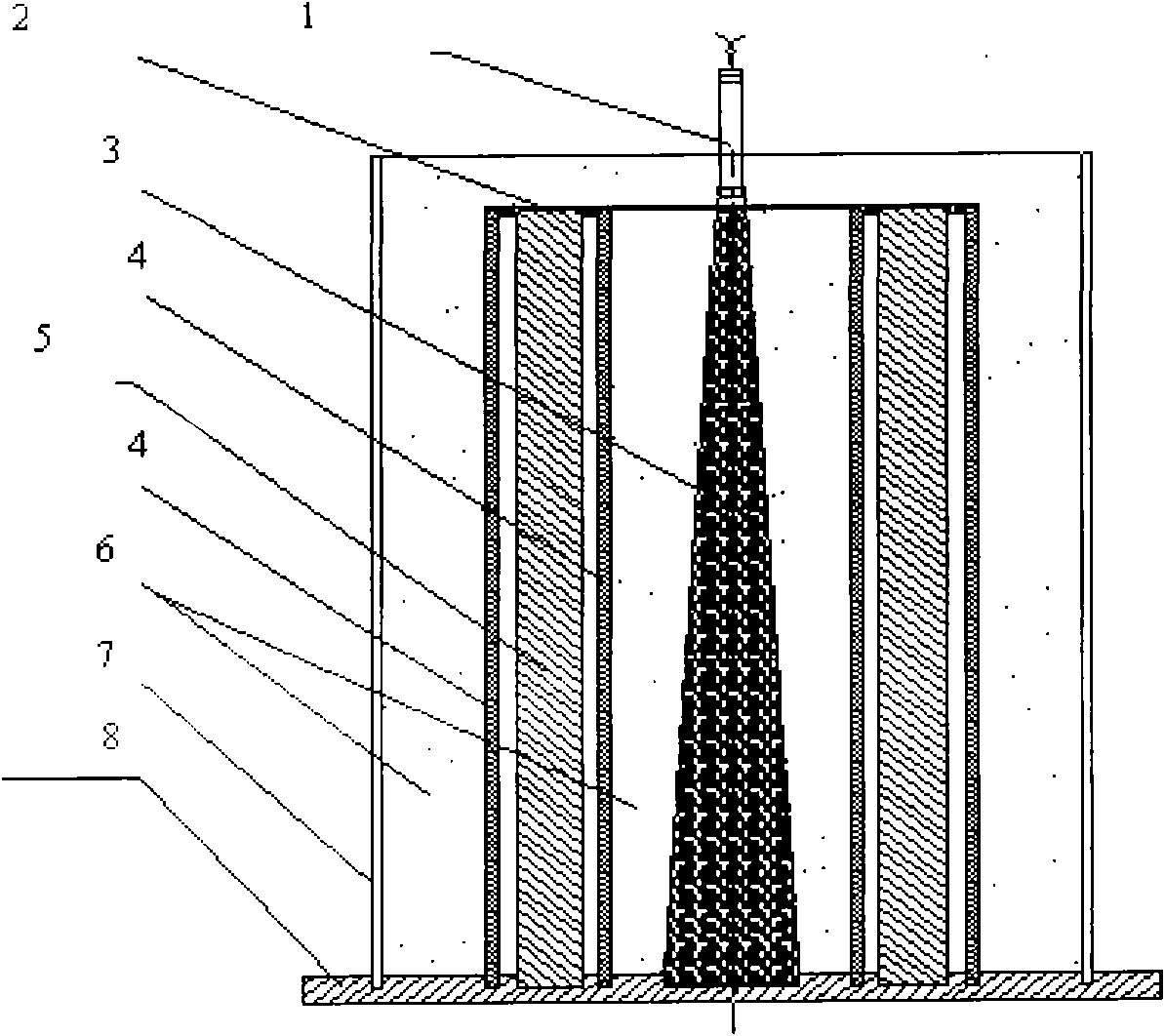

Explosive cladding method for stainless steel clad plate

ActiveCN102873452AIncreased Explosive Bonding RateReduce the unbound areaNon-electric welding apparatusDetonatorExplosive cladding

The invention relates to an explosive cladding method for a stainless steel clad plate, successively comprising the steps of: I, matching, assembling a base plate with the stainless steel clad plate according to the demands of final finished products; II, polishing surfaces, eliminating oxides and sundries on an explosive cladding surface of the base plate and the clad plate; III, laying explosive, clearing up explosive cladding foundation by using river sand; laying the base plate; supporting the clad plate on the base plate by using a strut made of copper sheets; placing a medicine frame for preventing the explosive scattering around the clad plate; IV, manufacturing an energy-gathered aperture with a cone in the explosive; taking the centre of the clad plate as the initiation explosion position; forming the conical energy-gathered aperture at the initiation explosion position; V, vertically standing an electric detonator for explosion on the cone; adding the explosive with high detonation velocity around the conical energy-gathered aperture lightly; vertically standing the electric detonator on the cone; and VI, igniting explosive welding of the electric detonator. The cladding rate of the explosive cladding stainless steel clad plate of the clad plate reaches to 96%.

Owner:太原钢铁(集团)有限公司

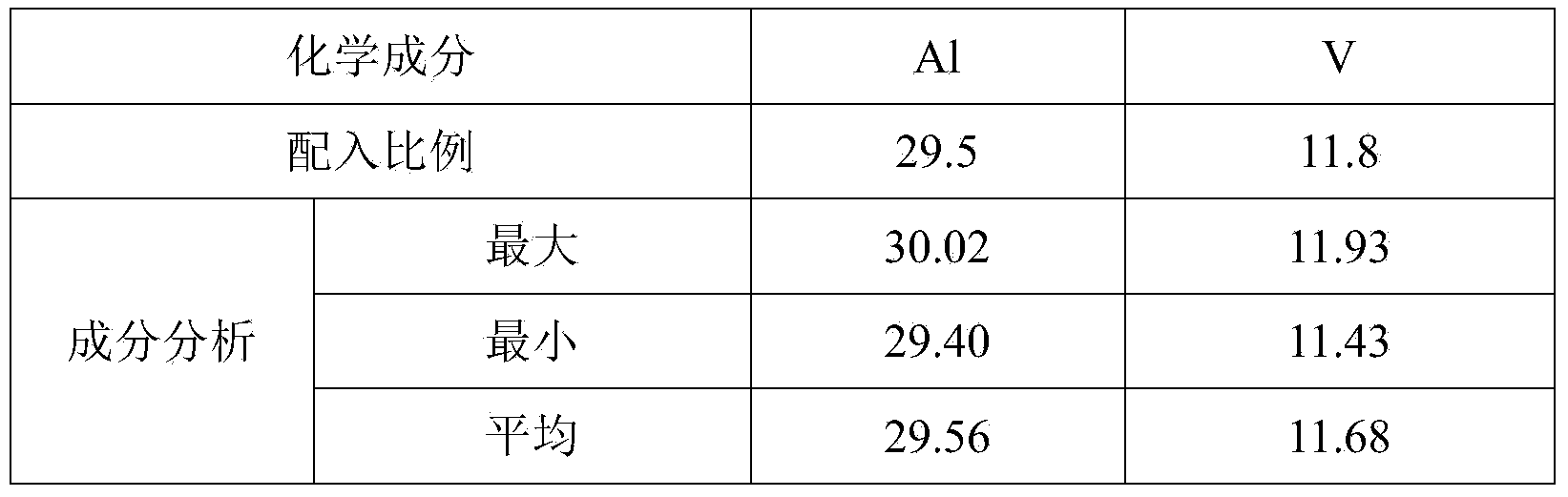

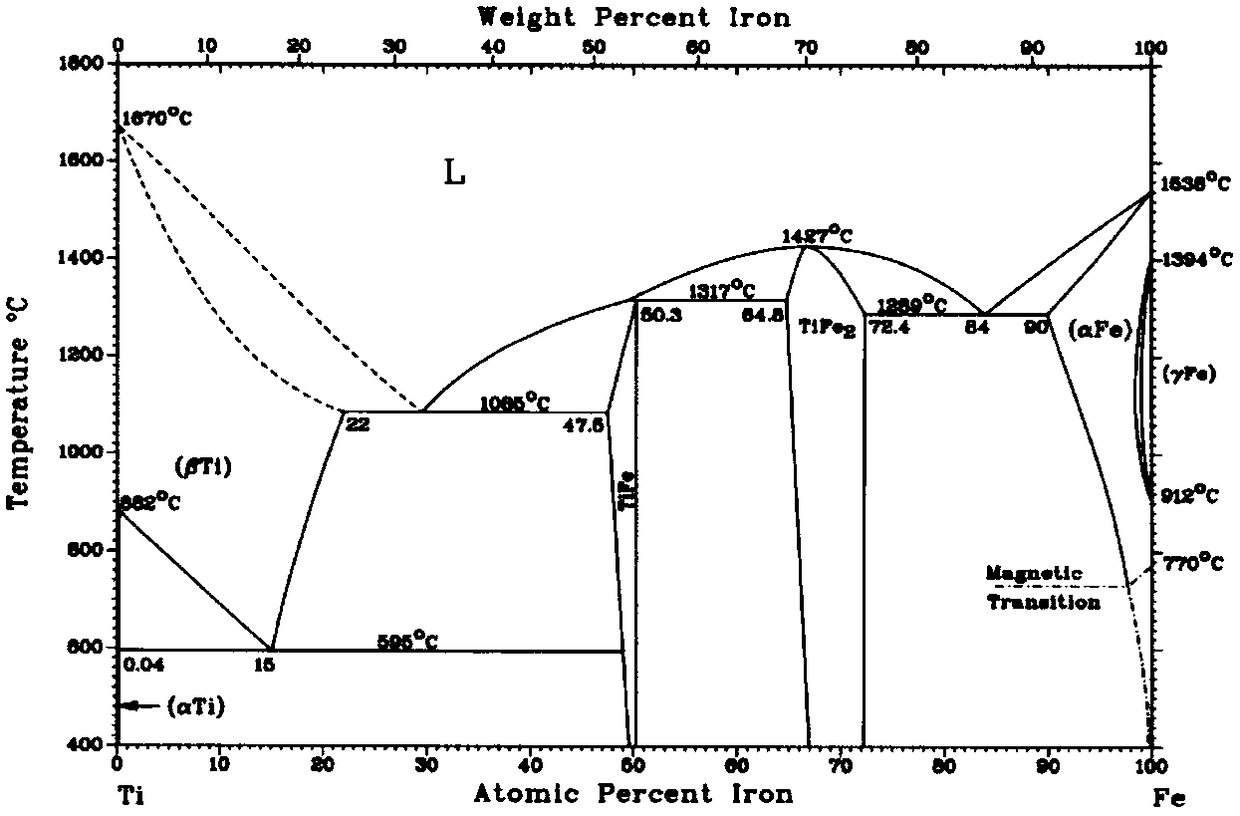

Vacuum melting and slab casting method of titanium-aluminum alloy

The invention provides a vacuum melting and slab casting method of a titanium-aluminum alloy, wherein titanium and aluminum metal raw materials are formed into a rectangular slab by a method of multiple vacuum consumable melting and centrifugal casting; the melt is solidified into an ingot in a metal composite material crucible; the crucible is fabricated from a composite material of a special metal and pure copper formed after explosive cladding; the outer layer is cooled by pure copper liquid so that a slow cooling speed is obtained during the melting of the TiAl alloy.

Owner:安徽宝泰特种材料有限公司 +1

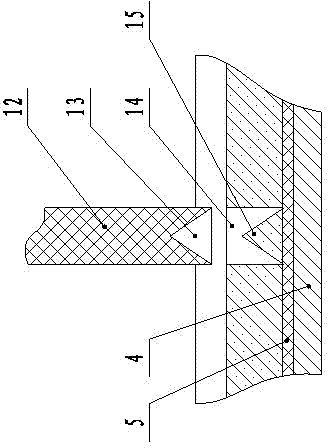

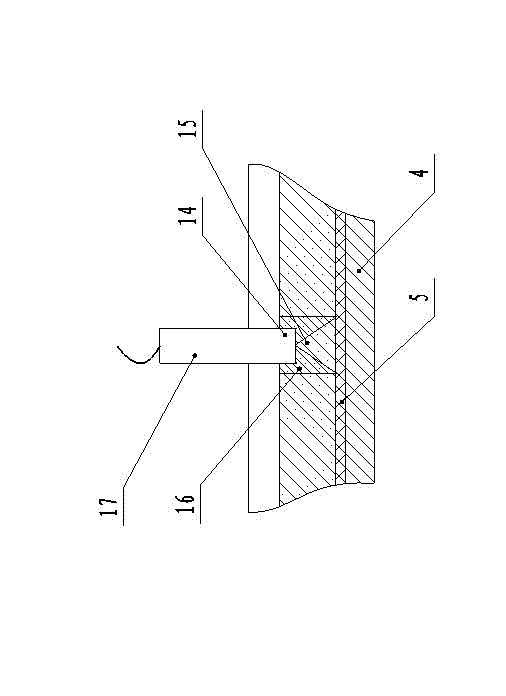

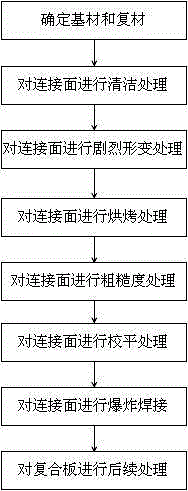

Explosive welding method for pre-processing rare and precious metal composite plate through severe surface deformation

ActiveCN105397266AReduce defects such as cracksFew defects such as cracksWelding/soldering/cutting articlesNon-electric welding apparatusComposite plateMicrostructure

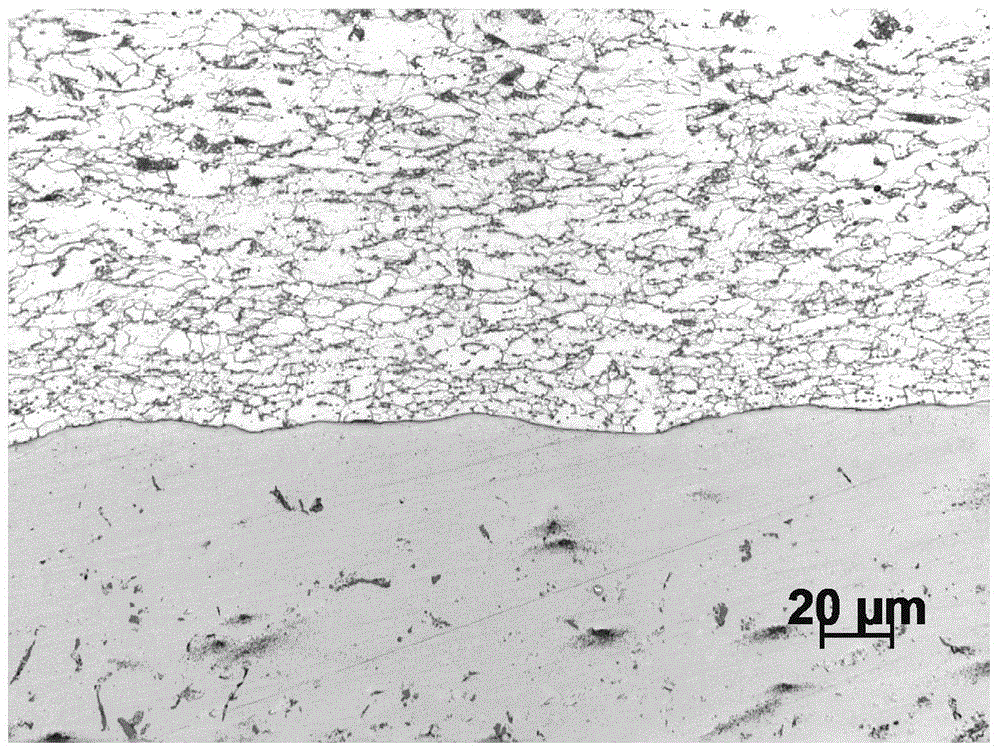

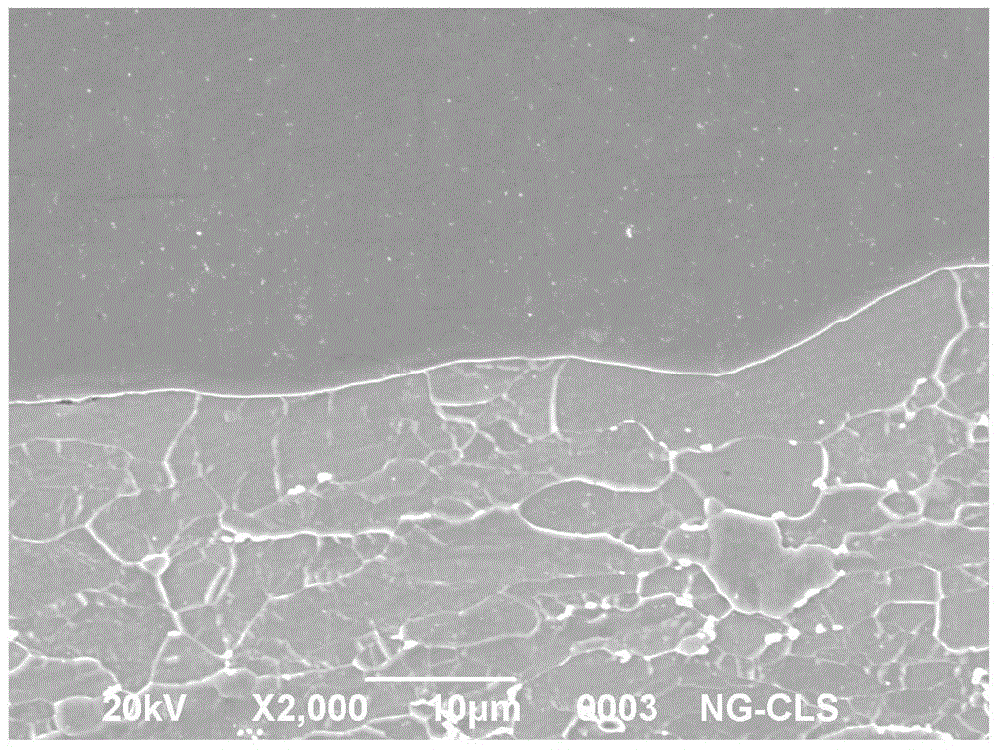

The invention provides an explosive welding method for pre-processing a rare and precious metal composite plate through severe surface deformation. The method includes the following steps that a base material and a composite material are determined, a connecting face of the base material and the composite material is cleaned and processed, severe deformation processing is performed on the connecting face, the connecting face is baked, roughness processing is performed on the connecting face, leveling processing of the connecting face is performed, and explosion welding and cladding and follow-up repair welding, leveling, edge cutting and mechanical polishing are performed, wherein a severe deformation processing method includes rolling, mechanical grinding, mechanical impacting, shot blasting or sand blasting. Before explosive cladding, the severe surface deformation processing is performed on the base material and the composite material, the connecting face can be of a multi-stage micro structure in different sizes, and the defect that cracks and the like happen easily in the explosive cladding process of rare and precious metal can be reduced; and besides, the severe surface deformation induces a large number of crystal structure defects, intermetallic compounds can be reduced, and the interface binding strength is remarkably improved.

Owner:NANJING INST OF TECH +2

Method for producing steel composite Ti (titanium) plate for chimney

InactiveCN108906898AReduce temperature dropThe difference between the same plate is smallAuxillary arrangementsMetal rolling arrangementsSheet steelExplosive cladding

The invention discloses a method for producing a steel composite Ti (titanium) plate for chimney. The method for producing the steel composite Ti plate for the chimney includes the steps of making steel billets through explosive cladding of Ti and Q235 or Q345 substrates, and then making he steel billets into the steel composite Ti plate for the chimney by heating, high-pressure phosphorus removal, rolling and straightening, wherein the thickness of the steel billets is 58-100 millimeters, the thickness of Ti 5-7 millimeters and the thickness of the Ti composite plate for the chimney 10-20 millimeters. The method for producing the steel composite Ti plate for the chimney has the advantages that the surface quality of the steel composite Ti plate for the chimney meets the requirements of GB / T 14977 Class B, and the steel plate is zero-grinding delivery; Ti plate thickness precision control is high, and when thickness of the Ti plate h is no more than 15 millimeters, same plate difference is controlled within 0.3 millimeter, and when the thickness of the Ti plate h is more than 15 millimeters and no more than 20 millimeters, same plate difference is controlled with 0.4 millimeter; after the Ti plate is rolled, the plate is flat, the straightness of the same meets the requirements of the European standard of 6 millimeters to 2 meters, and no cracking at the head and tail exists, which fully meets the needs of users.

Owner:WUYANG IRON & STEEL

Plasma torch with corrosive protected collimator

To protect the collimator of a transferred plasma arc torch from premature failure due to corrosion, an anti-corrosive covering is applied on the exposed face surface and a portion of the inner exit bore of the collimator. The specification describes several methods for producing the collimator for a plasma torch having an anti-corrosive coating or cladding on the exposed surfaces thereof, including electroplating, electroless plating, flame spraying, plasma spraying, plasma transferred arc, hot isostatic pressing and explosive cladding.

Owner:PHOENIX SOLUTIONS CO

Explosive welding method of C276 nickel-based alloy clad steel plate

InactiveCN101559517AReduce usageEffective compoundWelding/soldering/cutting articlesMetal working apparatusSheet steelExplosive cladding

The invention relates to an explosive cladding process for metals. The process is characterized by comprising the following steps: substrate treatment, composite treatment, applying and pairing, explosive cladding, repair welding, heat treatment and post-treatment. The process can help clad C276 nickel-based alloys with general steel plates effectively so that the clad steel plates can have the required strength on the premise of owning all the advantages of the C276 nickel-based alloys, thus saving consumption of expensive metals. The clad steel plates have high welding quality, and can certainly remain stable in long-term use without sealing off.

Owner:SICHUAN JINGLEI SCI & TECH CO LED

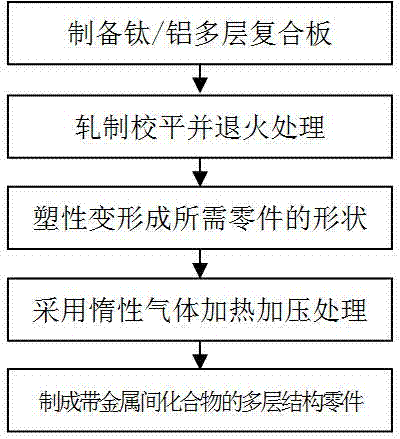

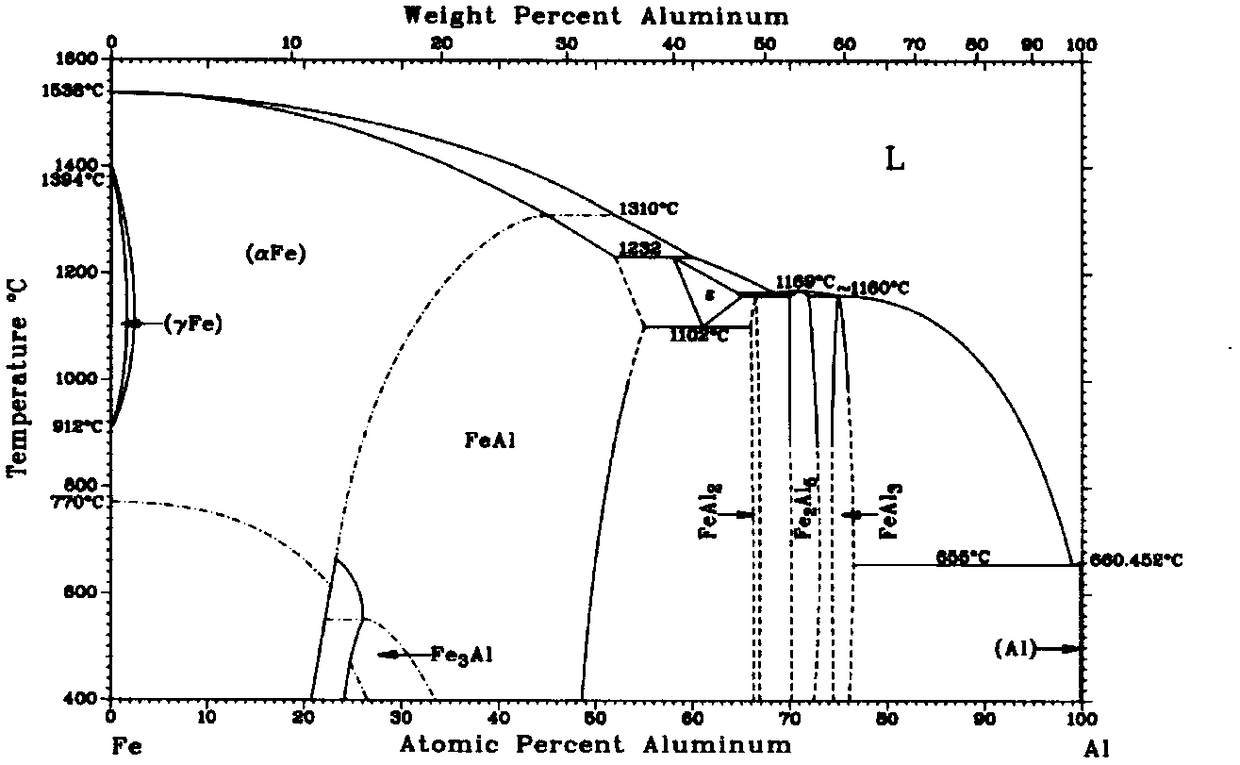

Preparation method for component with Ti/Ti*Al y/Ti multilayer structure

InactiveCN103753132AOvercome the defect of single shapeReduce manufacturing costExplosive claddingComposite laminates

The invention discloses a preparation method for a component with a Ti / Ti*Al y / Ti multilayer structure and belongs to the technical field of the preparation and forming of metal-based composite materials. The preparation method includes: firstly, using an explosive cladding method to prepare titanium / aluminum multilayer composite material, rolling, leveling, annealing and carrying out heat treatment; secondly, molding the metal composite laminate through a plastic forming method to obtain a component with complex shape; thirdly, putting the component in a die, pressurizing the surface of the component by means of inert gas, heating the component to react and consume the aluminum layer completely to generate a titanium-aluminum intermetallic compound layer, and obtaining the complex component with Ti / Ti*Al y / Ti multilayer structure finally. The preparation method for the component with the Ti / Ti*Al y / Ti multilayer structure overcomes the disadvantage that the traditional method is difficult to prepare the titanium-aluminum intermetallic compound component with complex structure and expands the application field of the titanium-aluminum intermetallic compound; the preparation cost is low, the production efficiency is high, and the engineering application value is very high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Explosive welding method for extra-thick plate

InactiveCN106141413AWelding/soldering/cutting articlesMetal working apparatusEmulsion explosiveEngineering

The invention provides an explosive welding method for an extra-thick plate. The explosive welding method for the extra-thick plate is applied to a steel plate with the thickness of a coating plate being 25-30 mm and the thickness of a substrate being 30-115 mm. The explosive welding method for the extra-thick plate is characterized by comprising the following steps that a coating prefabricated crack is formed; detonating points are prefabricated; the coating plate is arranged on the upper portion, the steel plate serves as the substrate on the lower portion, the coating plate and the substrate are installed and arranged in parallel through supporting pads at four corners at the edges, and the height of a supporting gap is 1.2-1.8 times the thickness of the coating plate; the coating prefabricated crack is aligned with the edge of the substrate; the requirement for even application and distribution of high voltage pulse loads of the whole plate is met; emulsion explosives are evenly arranged on the surface of the coating plate, the explosion speed is 2200-3200 mm / s, a plane wave generator is arranged along the prefabricated detonating points, the explosion speed is 4000-4500 mm / s, and an energy-gathered igniting primer is located in the middle of the edge of the coating plate; and after explosive cladding, through heat treatment and flattening, by means of explosive cladding primary forming, the attaching rate reaches 100%, and the minimum shear strength [tau]b>=210 Mpa.

Owner:南京三邦新材料科技有限公司

Explosive welding method of NO6059 nickel-based alloy clad steel plate for flue gas desulfurization

InactiveCN101559528AReduce usageEffective compoundWelding/soldering/cutting articlesMetal working apparatusSheet steelExplosive cladding

The invention relates to an explosive cladding process of metals. The process is characterized by comprising the following steps: substrate treatment, composite treatment, applying and pairing, explosive cladding, repair welding, heat treatment and post-treatment. The process can help clad NO6059 nickel-based alloy plates with general steel plates effectively so that the clad steel plates can have the required strength on the premise of owning all the advantages of the NO6059 nickel-based alloys, thus saving consumption of expensive metals. The clad steel plates have high welding quality, and can certainly remain stable in long-term use without sealing off.

Owner:SICHUAN JINGLEI SCI & TECH CO LED

Explosive welding method for manufacturing composite plate from C-276 alloy

InactiveCN109434267AAchieve explosive recombinationNon-electric welding apparatusDetonatorExplosive cladding

The invention discloses an explosive welding method for manufacturing a composite plate from a C-276 alloy. According to the explosive welding method, a steel plate and a C-276 alloy plate are included. The explosive welding method of the composite plate comprises the following steps of (1) making preparation for the steel plate and the C-276 alloy plate subjected to grinding and primary treatmentbefore explosion; (2) selecting a plurality of satisfactory conventional supporting blocks and a plurality of satisfactory auxiliary supporting blocks; (3) selecting powder emulsion explosive as mainexplosive; (4) arranging the C-276 alloy plate on the auxiliary supporting blocks; (5) arranging and fastening a detonator at the center of the C-276 alloy plate; and (6) detecting the attachment ratio and the shear strength. According to the explosive welding method, the C-276 alloy / steel composite plate is produced with the explosive as energy through explosive cladding so as to realize nationalization, and the requirements for development of the chemical engineering industry and other industries in China are met.

Owner:安徽宝泰特种材料有限公司

Novel metal compounding process

InactiveCN102717551AHarm reductionHigh strengthLamination ancillary operationsLaminationExplosive claddingMetal

The invention discloses a novel metal compounding process. The process comprises the following steps of: (1) performing surface roughening treatment to ensure that the surfaces of bonding layers are dissolved and roughened; (2) preparing a complex, namely adding an interlayer metal material with low melting point and high electric conductivity between substrate-layer metal and composite-layer metal so as to ensure that the interlayer metal material is permeated between the substrate-layer metal and the composite-layer metal to form metallurgical bonding; and (3) rolling the complex on a roller mill so as to closely bond the substrate-layer metal and the composite-layer metal. According to the process, an explosive cladding link is eliminated in a production environment, so that the harm of explosive cladding to the environment is reduced; the production cost is saved, and the production cycle is shortened; and moreover, the welding and rolling of all bonding surfaces are combined, so that the bonding compactness is relatively high.

Owner:常荣波

Explosive welding method of super austenitic stainless steel 904L clad steel plate

InactiveCN101559521AReduce usageEffective compoundWelding/soldering/cutting articlesMetal working apparatusExplosive claddingSheet steel

The invention relates to an explosive cladding process of metals. The process is characterized by comprising the following steps: substrate treatment, composite treatment, applying and pairing, explosive cladding, repair welding, heat treatment and post-treatment. The process can help clad 904L super austenitic stainless steel plates with general steel plates effectively so that the clad steel plates can have the required strength on the premise of owning all the advantages of the 904L super austenitic stainless steel, thus saving consumption of expensive metals. The clad steel plates have high welding quality, and can certainly remain stable in long-term use without sealing off.

Owner:SICHUAN JINGLEI SCI & TECH CO LED

Explosive welding method for C-22 nickel-based alloy composite steel plates

InactiveCN101564792AReduce usageEffective compoundWelding/soldering/cutting articlesMetal working apparatusExplosive claddingSheet steel

Owner:SICHUAN JINGLEI SCI & TECH CO LED

Preparation method of large-area all-joint-rate zirconium/titanium/steel explosive clad plate

InactiveCN108145303ARealize localizationMeet the needs of the development of the chemical industryWelding/soldering/cutting articlesNon-electric welding apparatusChemical industryExplosive cladding

The invention discloses a preparation method of a large-area all-joint-rate zirconium / titanium / steel explosive clad plate. A current general explosive clad process with titanium metal as a transitionlayer is adopted, a detonating point position is selected before explosive cladding, one titanium layer with the diameter being 280-320 mm and the thickness being 2 mm is subjected to explosive cladding on a base board to serve as the transition layer, then the transition layer serves as a detonating point, large-area zirconium and titanium one-time continuous welding is conducted, the plate is made to fit in all area, the smallest shearing strength tau b is greater than or equal to 137.9 Mpa, and the large-area all-joint explosive cladding welding is achieved accordingly. The method can produce the large-area zirconium and steel clad plate with the area being 6-15 m<2> and the joint rate being 100%, domestication of the large-area zirconium and steel clad plate is achieved, and the requirement of chemical industry development in China is met.

Owner:安徽宝泰特种材料有限公司

Explosive welding method for hard and brittle materials

PendingCN113601000AAchieve explosive weldingIncrease binding rateNon-electric welding apparatusExplosive claddingExplosive Agents

The invention relates to an explosive welding method for hard and brittle materials, and belongs to the technical field of material processing. The technical problem to be solved by the invention is to provide an explosive welding method for a hard and brittle material, which can obviously reduce cracks. The explosive welding method for the hard and brittle material comprises the following steps: a, selecting a compound plate and a base plate according to needs, then laying the compound plate on the top of the base plate, and arranging a plurality of supporting columns between the base plate and the compound plate; b, laying a water layer on the upper surface of the compound plate laid on the base plate in the step a, then placing an explosive frame on the top of the compound plate covered with the water layer, and then evenly laying explosive for explosive cladding in the explosive frame, wherein the laying area of the explosive for explosive cladding is not smaller than the surface area of a substrate; and c, detonating to obtain the explosive composite board. The composite board obtained through the method is high in binding rate and binding strength, uniform and consistent in performance and good in board shape.

Owner:BAOJI TAICHENG METAL CO LTD

Explosive cladding method used for transition base plate of helicopter deck of drilling platform

InactiveCN109290671AReduce distanceAvoid restraintWelding/soldering/cutting articlesNon-electric welding apparatusDetonatorInitiation point

The invention discloses an explosive cladding method used for a transition base plate of a helicopter deck of a drilling platform. An explosive welding formation method of a composite plate includingan aluminum plate, a titanium plate and a steel plate comprises the following steps that first, the surface of the aluminum plate, the surface of the titanium plate and the surface of the steel plateare cleaned; second, the aluminum plate is used as a first layer in contact with a corrosive medium, the titanium plate is used as a second layer used for transition, and the steel plate is used as athird layer for bearing a load; third, a rock emulsion explosive 1# with the detonation velocity equal to or higher than 2000mm / s is continuously laid on the surface of the aluminum plate, a detonation groove with the width of 20mm is laid on the rock emulsion explosive 1#, and an ammonium oil explosive having the detonation velocity equal to or higher than 2600mm / s is continuously laid in the detonation groove; and fourth, an initiation point is arranged at the center of the aluminum plate, and a detonator is arranged on the initiation point. By adoption of the explosive cladding method, therequirements for the cladding joint rate, the shearing strength and the tensile strength of large-area aluminum plate, titanium plate and steel plate explosion for development of the well-drilling petroleum industry can be met.

Owner:安徽宝泰特种材料有限公司

High corrosion-resistant steel-aluminum composite material for ships and warships and preparation method thereof

InactiveCN108838506AHigh strengthImprove corrosion resistanceWelding/soldering/cutting articlesNon-electric welding apparatusEmulsion explosiveComposite plate

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com