Preparation method for component with Ti/Ti*Al y/Ti multilayer structure

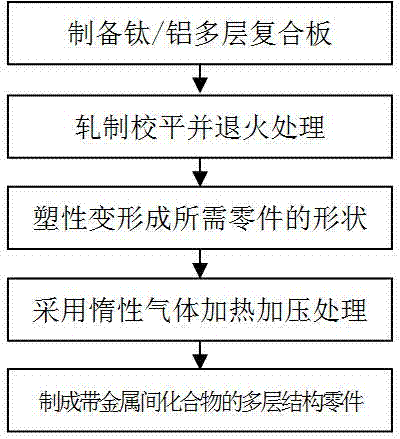

A technology of multi-layer structure and parts, which is applied in the preparation of parts with multi-layer structure, and in the field of parts preparation with Ti/TixAly/Ti multi-layer structure, which can solve the problems of inability to prepare complex parts with multi-layer structures, high cost of preparation methods and parts forming. Single shape and other problems, to achieve the effect of high engineering application value, low preparation cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Select two pure titanium plates and one pure aluminum plate, the size of which is 200 mm long x 250 mm wide x 0.1 mm thick. Use emulsion explosives to perform explosive welding on the plates, control a reasonable detonation velocity, and make a titanium / aluminum / titanium three-layer composite plate, and then perform annealing heat treatment after rolling and leveling to obtain a titanium / aluminum / titanium composite plate with a thickness of 0.2mm;

[0023] Step 2: Bending and deforming the annealed titanium / aluminum / titanium three-layer composite plate with a bending die on the press until the shape becomes V-shaped;

[0024] Step 3. Put the titanium / aluminum / titanium three-layer composite part into the mold, use helium to pressurize the surface of the part, and heat it. The hot pressing temperature is 650°C, the applied pressure is 2MPa, and the temperature is kept for 10h , the reaction of the aluminum layer is completely consumed, and TiAl is generated in the...

Embodiment 2

[0026] Step 1. Select two pure titanium plates and one pure aluminum plate, the size of which is 300 mm long x 350 mm wide x 0.5 mm thick. Use emulsion explosives to perform explosive welding on the plates, control a reasonable detonation velocity, and make a titanium / aluminum / titanium three-layer composite plate, and then perform annealing heat treatment after rolling and leveling to obtain a titanium / aluminum / titanium composite plate with a thickness of 1.2mm;

[0027] Step 2. Perform liquid-filled deep drawing on the annealed titanium / aluminum / titanium three-layer composite plate on the hydraulic equipment until the shape becomes cylindrical, and reasonably control the liquid pressure to avoid the composite plate from breaking;

[0028] Step 3. Put the titanium / aluminum / titanium three-layer composite part into the mold, pressurize the surface of the part with neon gas, and heat it. The hot pressing temperature is 600°C, and the applied pressure is 2.5MPa. 15h, the aluminum ...

Embodiment 3

[0030] Step 1. Select three pure titanium plates and two pure aluminum plates, the size of which is 400mm long x 450mm wide x 0.3mm thick. Use emulsion explosives to explosively weld the plates, control a reasonable detonation velocity, and make a five-layer composite plate of titanium / aluminum / titanium / aluminum / titanium, and then perform annealing heat treatment after rolling and leveling to obtain titanium / aluminum with a total thickness of 0.7mm / titanium / aluminum / titanium five-layer composite board;

[0031] Step 2. Perform liquid-filled deep drawing on the annealed titanium / aluminum / titanium / aluminum / titanium five-layer composite plate on the hydraulic equipment until the shape becomes a box shape, and reasonably control the liquid pressure to avoid the composite plate from breaking;

[0032] Step 3. Put the titanium / aluminum / titanium / aluminum / titanium five-layer composite part into the mold, pressurize the surface of the part with argon gas, and heat it. The hot pressing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com