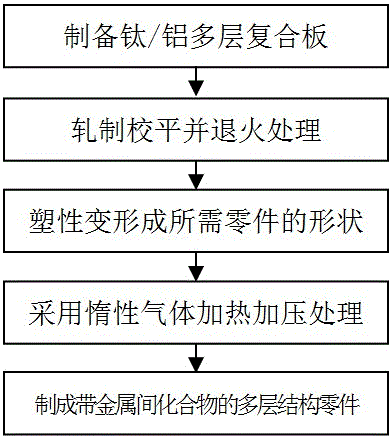

Part preparation method with ti/tixaly/ti multilayer structure

A technology of multi-layer structure and parts, which is applied in the preparation of parts with multi-layer structure, and the field of parts preparation with Ti/TixAly/Ti multi-layer structure, can solve the problem of single part forming shape, high cost of preparation method, and inability to prepare multi-layer structure Complex parts and other problems, to achieve the effect of high production efficiency, low preparation cost, and high engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Select two pure titanium plates and one pure aluminum plate, the size of which is 200 mm long x 250 mm wide x 0.1 mm thick. Use emulsion explosives to perform explosive welding on the plates, control a reasonable detonation velocity, and make a titanium / aluminum / titanium three-layer composite plate, and then perform annealing heat treatment after rolling and leveling to obtain a titanium / aluminum / titanium composite plate with a thickness of 0.2mm;

[0023] Step 2: Bending and deforming the annealed titanium / aluminum / titanium three-layer composite plate with a bending die on the press until the shape becomes V-shaped;

[0024] Step 3. Put the titanium / aluminum / titanium three-layer composite part into the mold, use helium to pressurize the surface of the part, and heat it. The hot pressing temperature is 650°C, the applied pressure is 2MPa, and the temperature is kept for 10h , the reaction of the aluminum layer is completely consumed, and TiAl is generated in the...

Embodiment 2

[0026] Step 1. Select two pure titanium plates and one pure aluminum plate, the size of which is 300 mm long x 350 mm wide x 0.5 mm thick. Use emulsion explosives to perform explosive welding on the plates, control a reasonable detonation velocity, and make a titanium / aluminum / titanium three-layer composite plate, and then perform annealing heat treatment after rolling and leveling to obtain a titanium / aluminum / titanium composite plate with a thickness of 1.2mm;

[0027] Step 2. Perform liquid-filled deep drawing on the annealed titanium / aluminum / titanium three-layer composite plate on the hydraulic equipment until the shape becomes cylindrical, and reasonably control the liquid pressure to avoid the composite plate from breaking;

[0028] Step 3. Put the titanium / aluminum / titanium three-layer composite part into the mold, pressurize the surface of the part with neon gas, and heat it. The hot pressing temperature is 600°C, and the applied pressure is 2.5MPa. 15h, the aluminum ...

Embodiment 3

[0030] Step 1. Select three pure titanium plates and two pure aluminum plates, the size of which is 400mm long x 450mm wide x 0.3mm thick. Use emulsion explosives to explosively weld the plates, control a reasonable detonation velocity, and make a five-layer composite plate of titanium / aluminum / titanium / aluminum / titanium, and then perform annealing heat treatment after rolling and leveling to obtain titanium / aluminum with a total thickness of 0.7mm / titanium / aluminum / titanium five-layer composite board;

[0031] Step 2. Perform liquid-filled deep drawing on the annealed titanium / aluminum / titanium / aluminum / titanium five-layer composite plate on the hydraulic equipment until the shape becomes a box shape, and reasonably control the liquid pressure to avoid the composite plate from breaking;

[0032] Step 3. Put the titanium / aluminum / titanium / aluminum / titanium five-layer composite part into the mold, pressurize the surface of the part with argon gas, and heat it. The hot pressing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com