Patents

Literature

1025results about How to "Realize secondary use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength polypropylene fiber polymer cement mortar and preparation method thereof

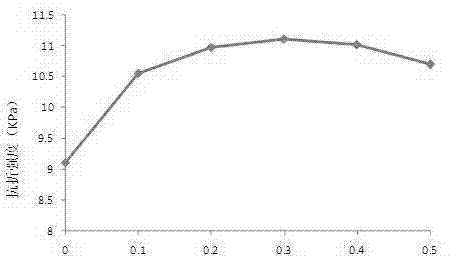

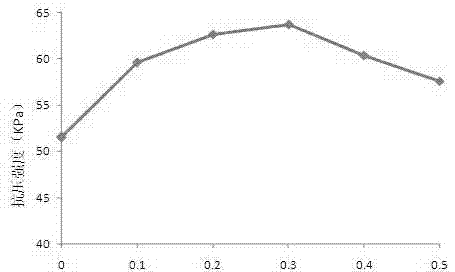

The invention discloses a high-strength polypropylene fiber polymer cement mortar and a preparation method thereof. The mortar is composed of the following components in parts by mass: 0.28-0.3 part of silica fume, 0.68-0.7 part of cement and 1.97-2 part of sand. The SiO3 content in the silica fume is higher than 95%; the water-cement ratio is 0.31; the volume content of the polypropylene fiber is 0.9 kg / m<3>; the water reducer:cementing material ratio is 0.9-1%; the defoaming agent:cementing material ratio is 0.5-0.55%; the coupling agent and diluter:cementing material ratio is 0.3%; the polymer modifier:cementing material ratio is 10-11%; and the reducer:cementing material mass ratio is 3-3.5%. By combining the excellent physical and chemical characteristics of the silica fume, when the silica fume is substituted for cement, the consumption of the cement clinker is saved, and the industrial waste is reutilized, thereby greatly enhancing the pressure resistance and bending resistance of the modified cement mortar.

Owner:ZHENGZHOU UNIV

Method for processing dust with zinc of electric furnace

InactiveCN101092664ARealize comprehensive utilizationRealize secondary useProcess efficiency improvementElectric arc furnaceCooling chamber

This invention discloses a method for treating zinc-containing dust generated in electric furnace. The method comprises: mixing zinc-containing dust with carbon, balling, oven-drying to obtain carbon-containing balls, adding into a converter, calcining at a high temperature to reduce into zinc vapor, introducing into an oxidation chamber, introducing air to oxidize zinc vapor into zinc oxide vapor, introducing into a cooling chamber, cooling to obtain zinc oxide powder, introducing into a dust collection chamber, collecting zinc oxide powder, introducing the carbon-containing balls into a cooler, and cooling to obtain semi-metallized balls. The zinc oxide powder has purity above 90%; the semi-metallized balls have metallization rate above 60%, TFe content above 50%, and zinc content below 2%. The method has such advantages as high utility of zinc-containing dust, low cost and no pollution.

Owner:NANJING NANGANG IND DEV CO LTD

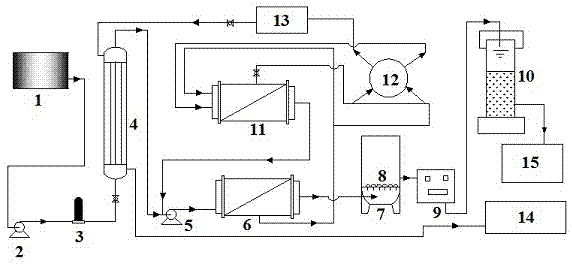

Process for recycling waste mineral oil without hazardous material emission

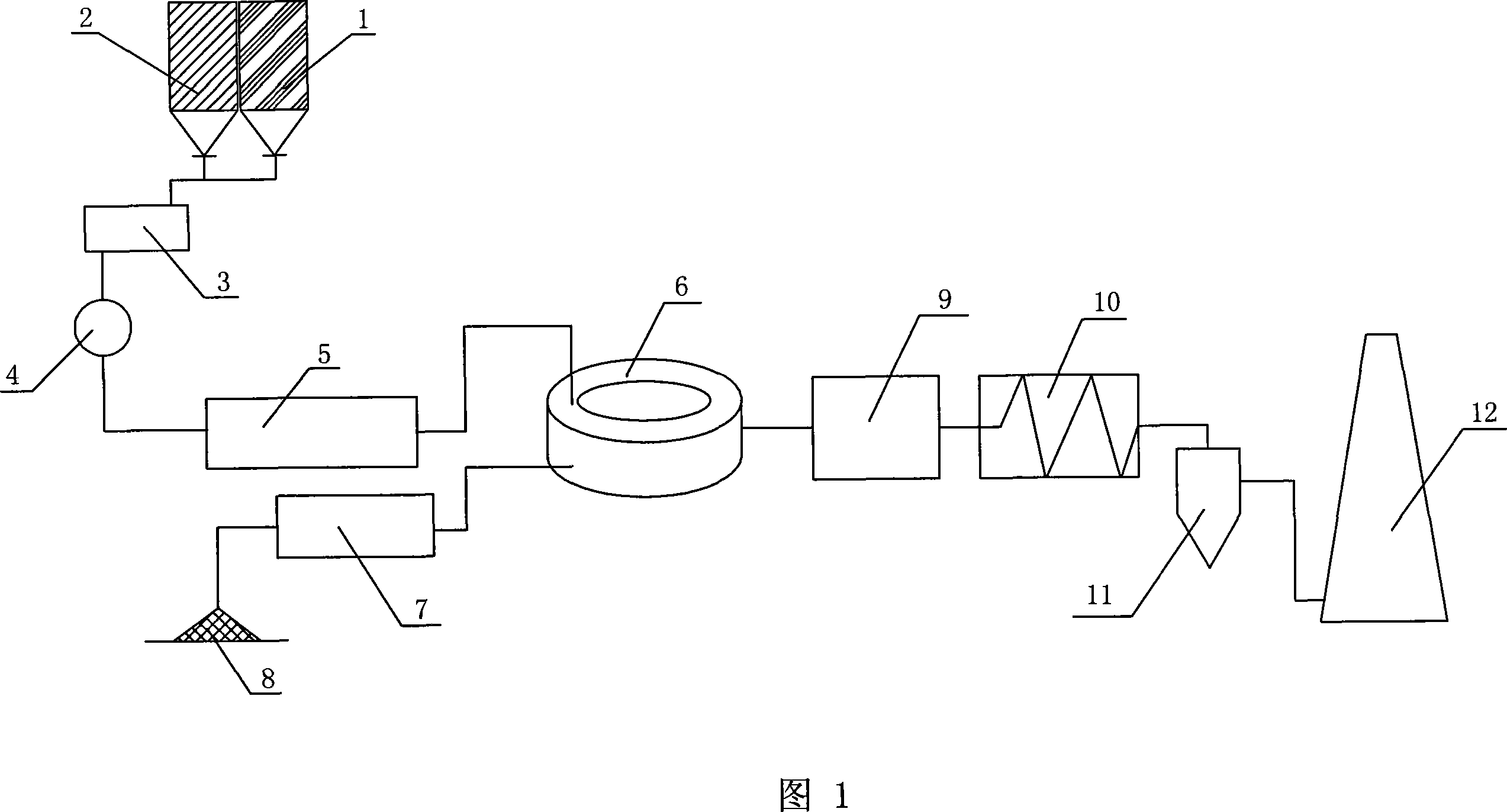

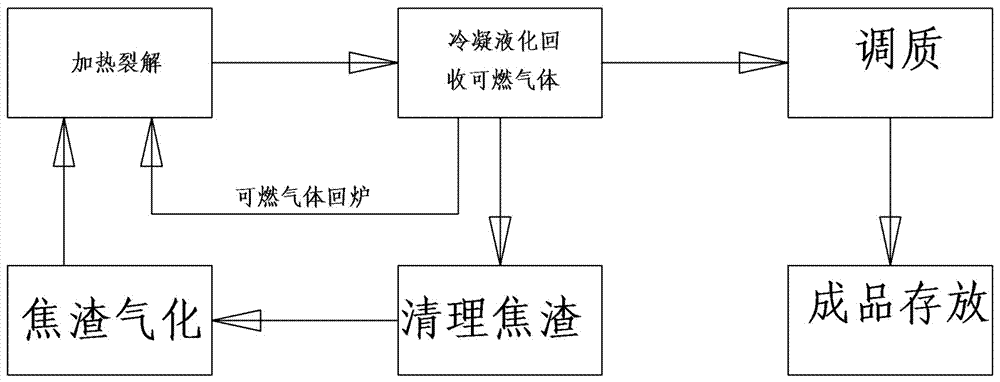

ActiveCN107099328ANo emissionsTake advantage ofTreatment with plural serial stages onlyGasification processes detailsClosed loopCombustible gas

The invention discloses a process for recycling waste mineral oil without hazardous material emission. The process includes steps of 1, carrying out heating pyrolysis; 2, carrying out condensation and liquefaction and simultaneously recycling combustible gas; 3, carrying out conditioning; 4, storing finished products; 5, clearing coke residues, and to be more specific, clearing solid residual substances-coke residues obtained after clearing pyrolysis is carried out in reaction kettles; 6, gasifying the coke residues, to be more specific, crushing the coke residues cleared at the step 5 to obtain granules, then feeding the granules into a coke residue gasification furnace, gasifying the granules by the aid of the gasification furnace to obtain combustible gas, leading the combustible gas into a gas furnace used at the step 1 and combusting the combustible gas in the combustible furnace. The process has the advantages that certain waste gas and waste residues which are generated during pyrolysis on the waste mineral oil can be used as fuel to be fed into heating furnaces for the reaction kettles in closed-loop procedures, and accordingly the process is basically free of emission of toxic waste gas and toxic waste residues; all combustible substances in the waste mineral oil can be comprehensively sufficiently utilized, accordingly, environments can be protected, energy can be saved, and the process is favorable for society and people.

Owner:洛阳德正废弃资源再利用有限公司

Preparation of hydrophobic nature calcium sulphate crystal whisker with liquid phase method of sodium sulfate wastewater in situ

InactiveCN101343773ASimple production processLow costPolycrystalline material growthFrom normal temperature solutionsLiquid wasteSurface-active agents

The invention relates to a normal-pressure low-temperature liquid phase in situ hydrophobic calcium sulfate crystal whisker preparation method, in which sodium sulfate waste water is adopted as a raw material. The preparation method comprises the steps: a certain amount of calcium salt of 0.5 to 1mol / L is added in a three-necked bottle, a surface active agent is added thereto, and after the mixture is evenly blended, a certain amount of sodium sulfate waste water is added, the temperature is increased to 30 to 70 DEG C, the mixture is blended at a constant temperature to cause the crystallizing reaction for 3 to 7 hours, the obtained white product is dried and treated byheat at the temperature of 60 to 200 DEG C after being filtered and cleaned, the calcium sulfate crystal whisker powder with the diameter of 1 to 2 micron, the length of 30 to 50 micron, and the length-diameter ratio of 15 to 50 is obtained, the filtered fluid is a salt solution as much again as the raw material, sodium chloride is produced based thereon, and the secondary utilization of the waste fluid is realized. The invention has the advantages that the sodium sulfate waste water is simply treated during the preparation process, the process is simplified, the energy resources are saved, the cost is reduced, the recycling and utilization of the renewable resources are realized, and the product is provided with higher economic value and social value.

Owner:JILIN UNIV

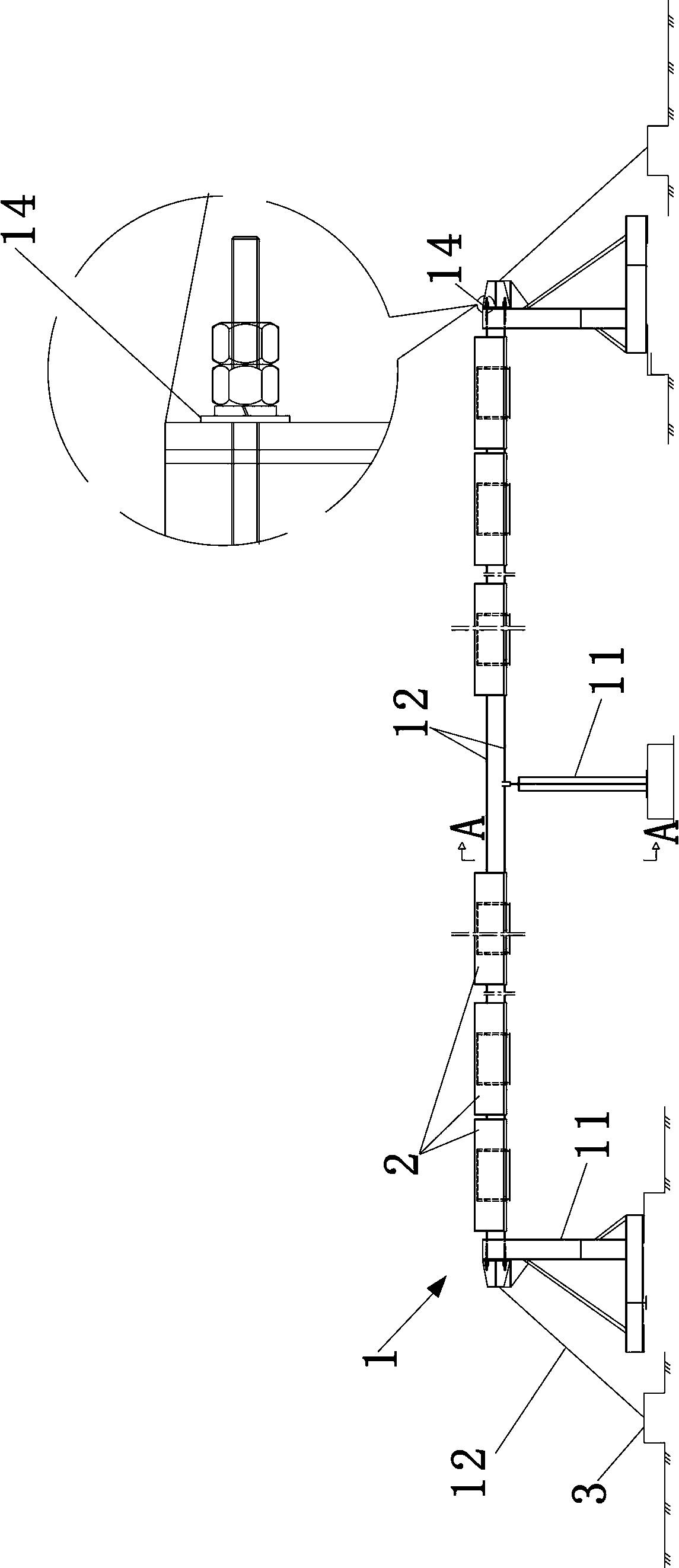

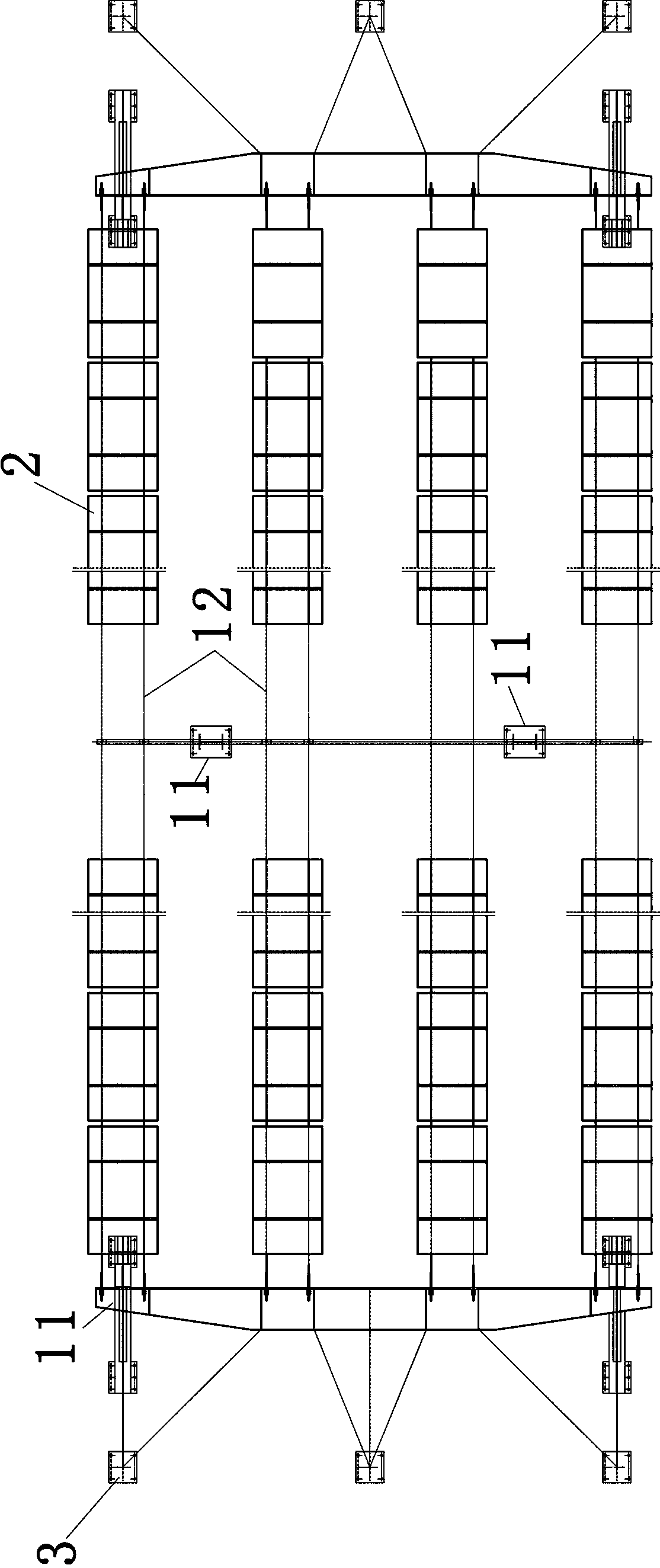

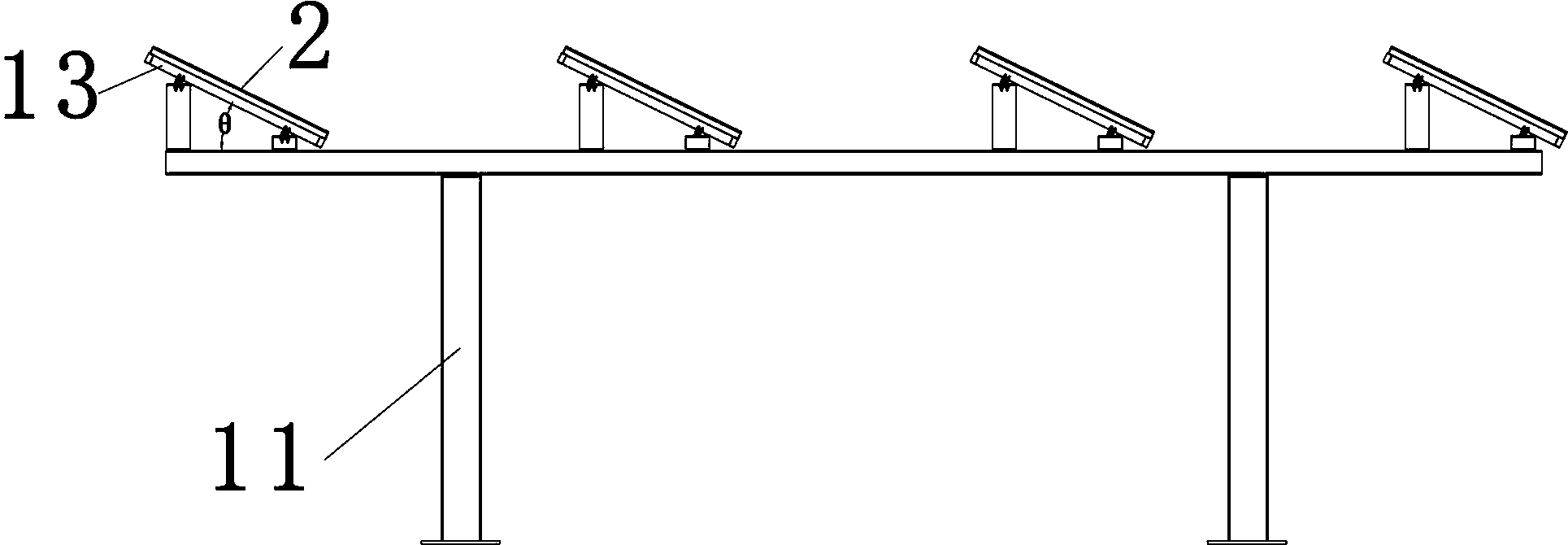

Flexible photovoltaic support

PendingCN104242800ARealize secondary useIncrease flexibilityPhotovoltaic supportsPhotovoltaic energy generationPhotovoltaic power generationElectrical and Electronics engineering

The invention provides a flexible photovoltaic support. The flexible photovoltaic support is used for fixing and supporting photovoltaic modules and comprises two or more supporting pieces and one or more flexible assemblies. The flexible assemblies are connected between the supporting pieces and made of flexible materials, and the photovoltaic modules are fixed to the flexible assemblies. The flexible photovoltaic support has the high adaptability, the use flexibility, the effective safety and the perfect land reutilization economy, is a revolutionary creation in the photovoltaic support field and will promote perfect development of photovoltaic power generation quickly.

Owner:ZHEJIANG GUOLI YINGHE ENERGY

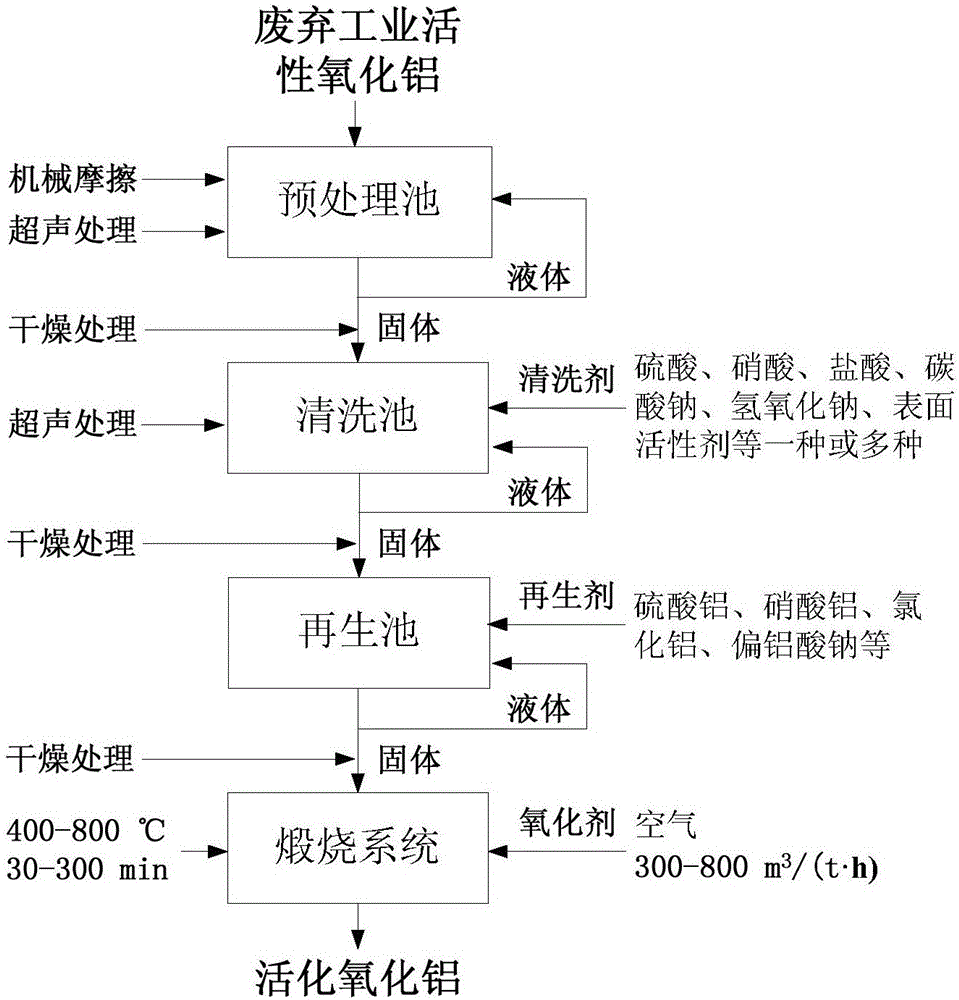

Method for activating and regenerating waste industrial activated aluminum oxide

ActiveCN106629796AHigh pore volumeRealize resource utilizationOther chemical processesAluminates/aluminium-oxide/aluminium-hydroxide purificationAir atmosphereActivated Aluminum Oxide

The invention discloses a method for activating and regenerating waste industrial activated aluminum oxide. The method comprises pretreatment, cleaning liquid impregnation treatment and regeneration treatment; adopted cleaning liquid is selected from at least one of acid liquor and alkali liquor and surfactant solution; the regeneration treatment comprises regenerated liquid impregnation and calcination treatment, and adopted regenerated liquid is selected from aluminum-contained solution; the calcination treatment is performed under air atmosphere, and air inlet amount is 300 to 800 m<3> / (h.t). According to the method for activating and regenerating the waste industrial activated aluminum oxide provided by the invention, an original pore structure channel is dredged through a physical and chemical method, and a new pore structure is regenerated on the basis of the existing pore structure to obtain activated aluminum oxide with high specific surface area and high pore volume.

Owner:杭州贝采催化剂有限公司 +1

Lightweight ceramsite prepared from waste foundry sand and waste ash and preparation method of lightweight ceramsite

ActiveCN107324830ASimple preparation processReduce inputCeramic materials productionCeramicwareFoundryPolyvinyl alcohol

The invention relates to the field of preparation of lightweight ceramsites, in particular to a lightweight ceramsite prepared from waste foundry ash and waste sand, and a preparation method of the lightweight ceramsite. The lightweight ceramsite is prepared from the following components in parts by weight: 95 parts of waste foundry sand and waste ash, 3 to 7 parts of bauxite, 0.1 to 0.5 part of rubber powder and 0.1 to 0.3 part of polyvinyl alcohol, wherein the weight ratio of the waste foundry sand to the waste ash is (8 to 2) to (9 to 1). According to the preparation method disclosed by the invention, the waste foundry sand and the waste ash are directly used for preparing the lightweight ceramsite, and classification treatment of the waste ash and the waste sand are not needed; in addition, special requirements on the granularity of the waste ash and the waste sand are avoided, and all the waste foundry ash and waste sand can be disposed by using a set of equipment, so the preparation method has the advantages of simple preparation technology, small input quantity of the equipment and few hardware requirements on sites and the like; meanwhile, resources are saved and environmental pollution is reduced by secondary utilization of the waste foundry ash and the waste sand.

Owner:LIUZHOU LIUJING TECH CO LTD

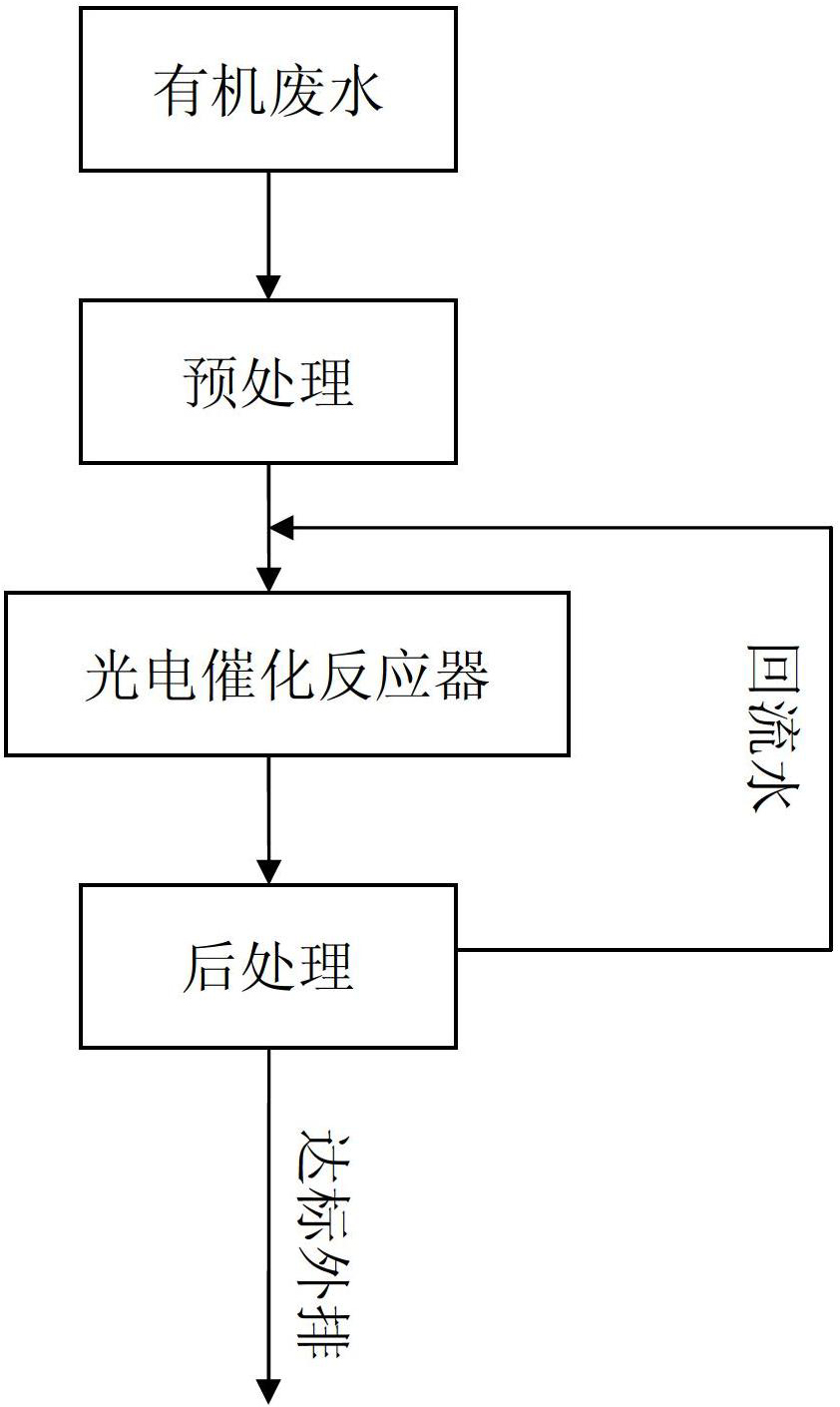

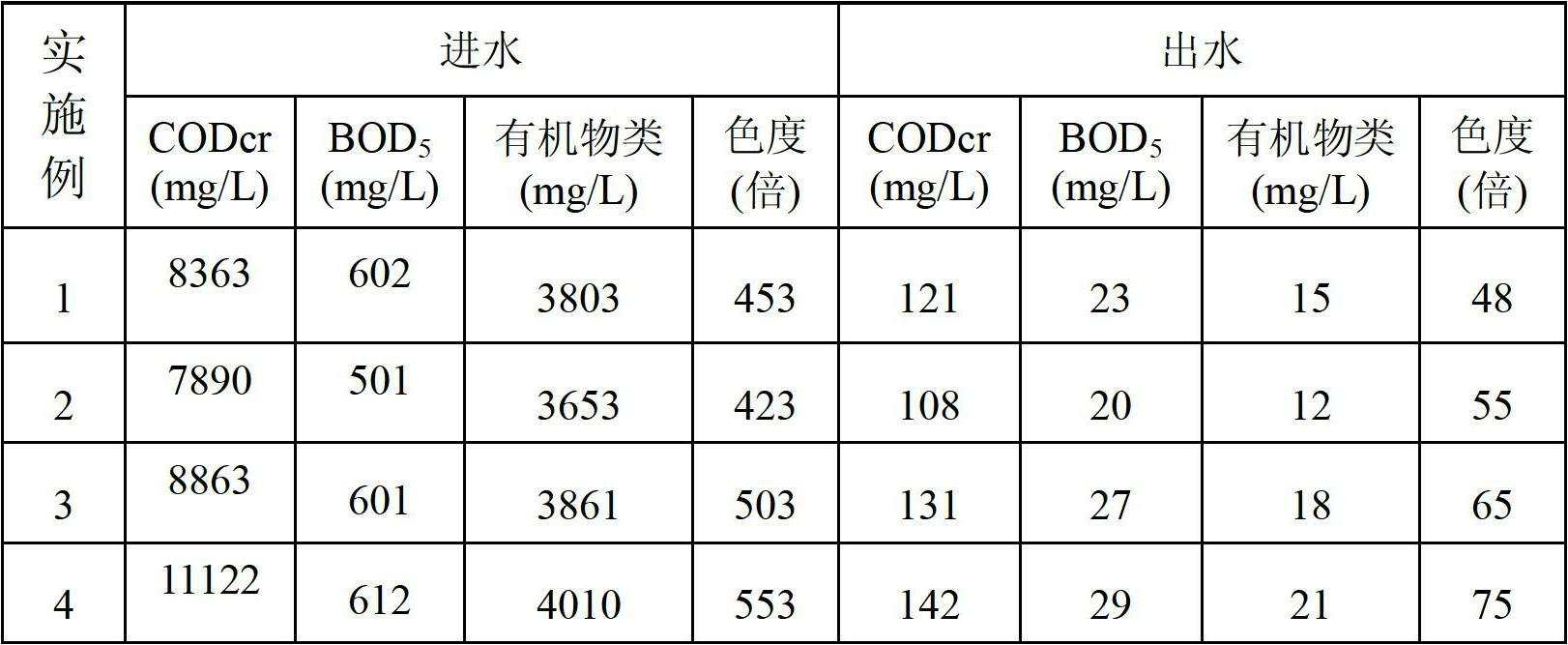

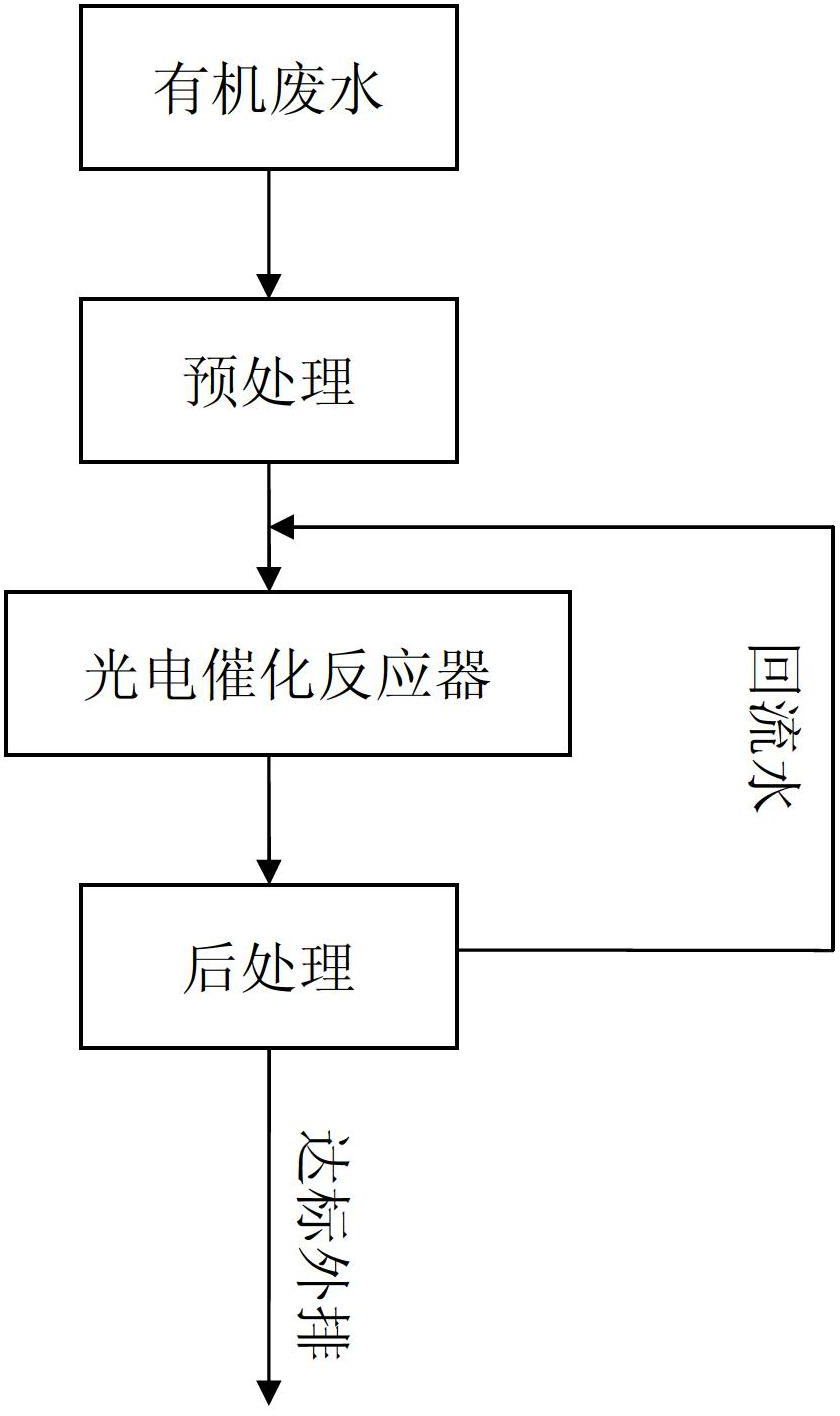

Method for treating organic wastewater through photoelectric catalytic oxidation

InactiveCN102690005ARealize secondary useChange structureMultistage water/sewage treatmentWater/sewage treatment by oxidationUltraviolet lightsCatalytic oxidation

The invention relates to a method for treating organic wastewater through photoelectric catalytic oxidation, comprising the steps of: forming a ferric-carbon microelectrolysis system with waste ferric-carbon or other substances as a raw material; irradiating by using ultraviolet light or other special light sources; adopting modified TiO2 or other oxide and sulfide semiconductors as a photocatalyst; and meanwhile, introducing air or other oxidizing gases to the bottom for aeration, so that wastewater generates a photoelectric catalytic oxidation reaction to oxidize an organic matter into CO2 and H2O, and the treated wastewater can reach the standard to discharge or can be recycled.

Owner:ZIJIN MINING GROUP

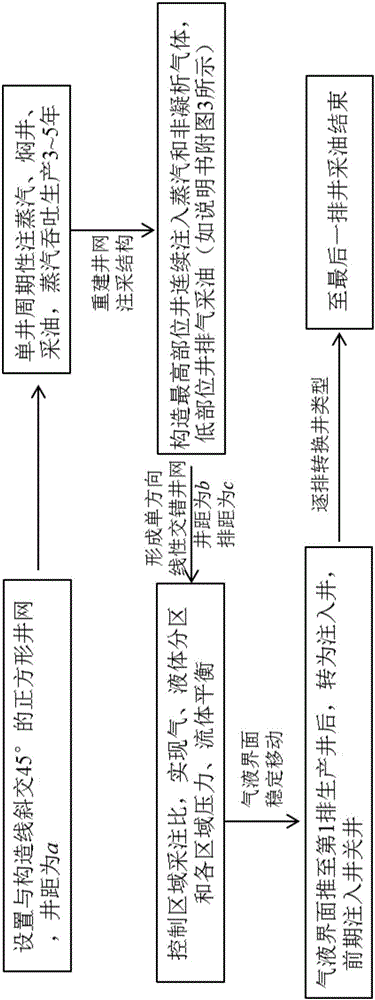

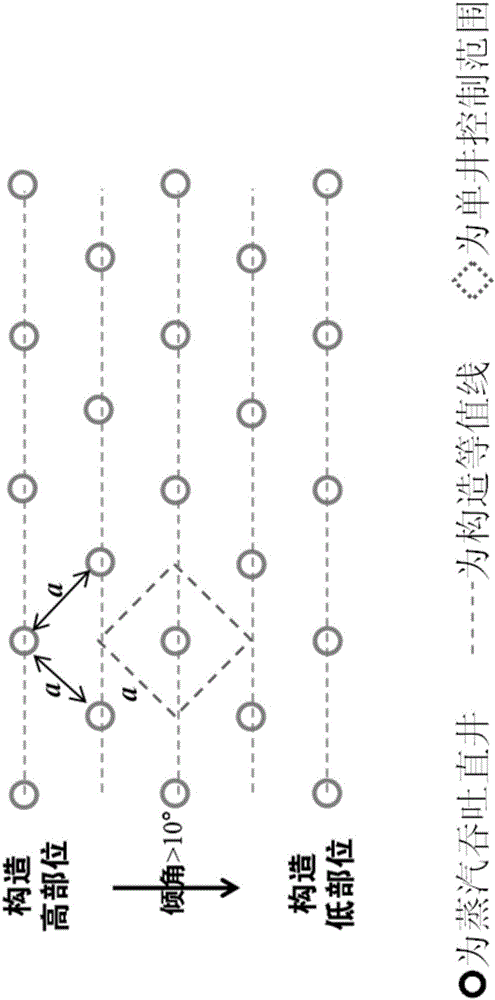

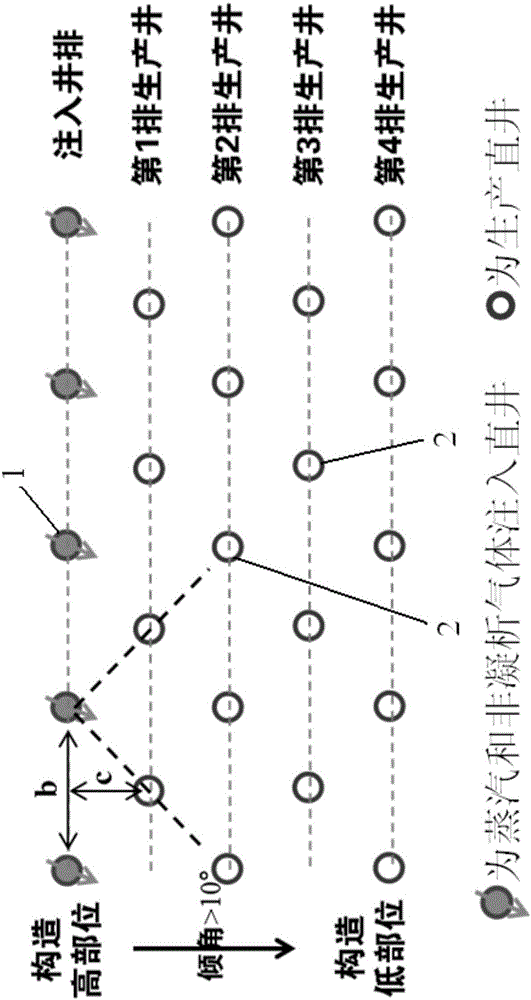

Method for exploiting high-inclined-angle heavy oil reservoir by plane gravity displacement

ActiveCN107435535AGuaranteed one-way advancementImprovement factorFluid removalDensity differenceHot Temperature

The invention provides a method for exploiting a high-inclined-angle heavy oil reservoir by plane gravity displacement. According to the method for exploiting the high-inclined-angle heavy oil reservoir by plane gravity displacement, a plane gravity oil displacement mode using steam injection as a major measure and non-condensable gas injection as an auxiliary measure is designed. Steam and non-condensable gas are proportionally injected; high-temperature hot water and non-condensable gas in the stratum can easily form a secondary gas cap and a secondary water zone with the obvious spatial variation effects due to the density differences; the high-temperature secondary water zone provides a heating resource for a downstream cold oil zone; and the breakthrough of the injection gas towards a production well in a low structure position is prevented. Meanwhile, the oil reservoir integral scaled development is realized; the unidirectional linear staggered well network development is used; and the plane conformance coefficient and the recovery efficiency are improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

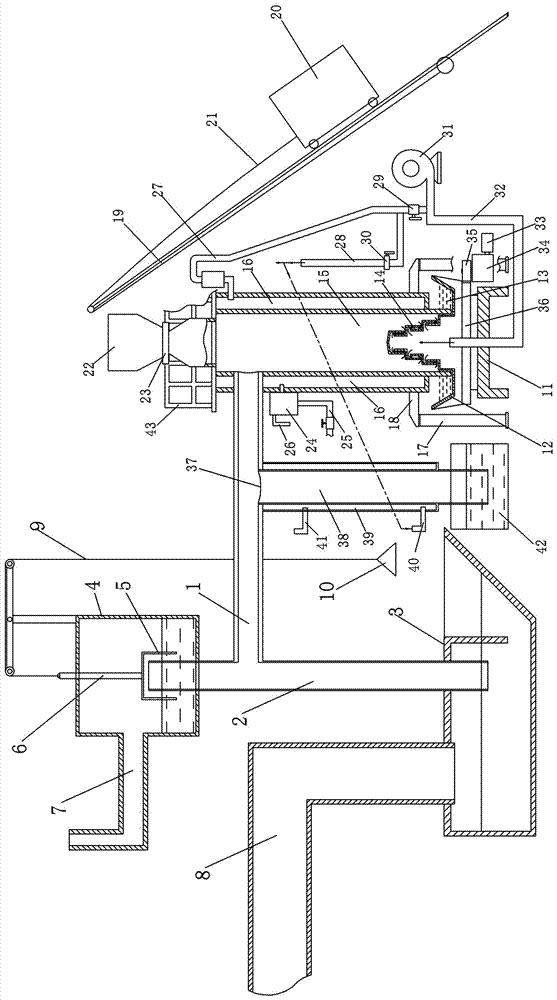

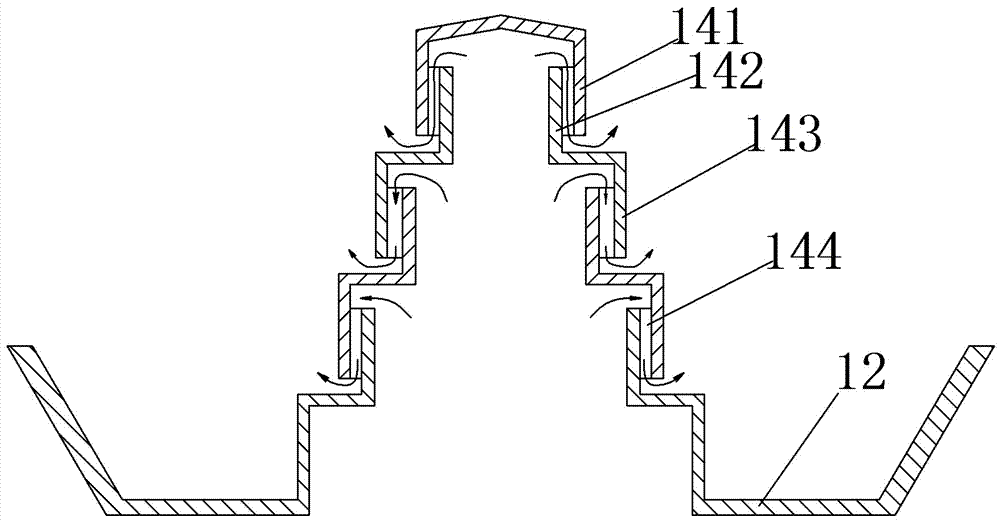

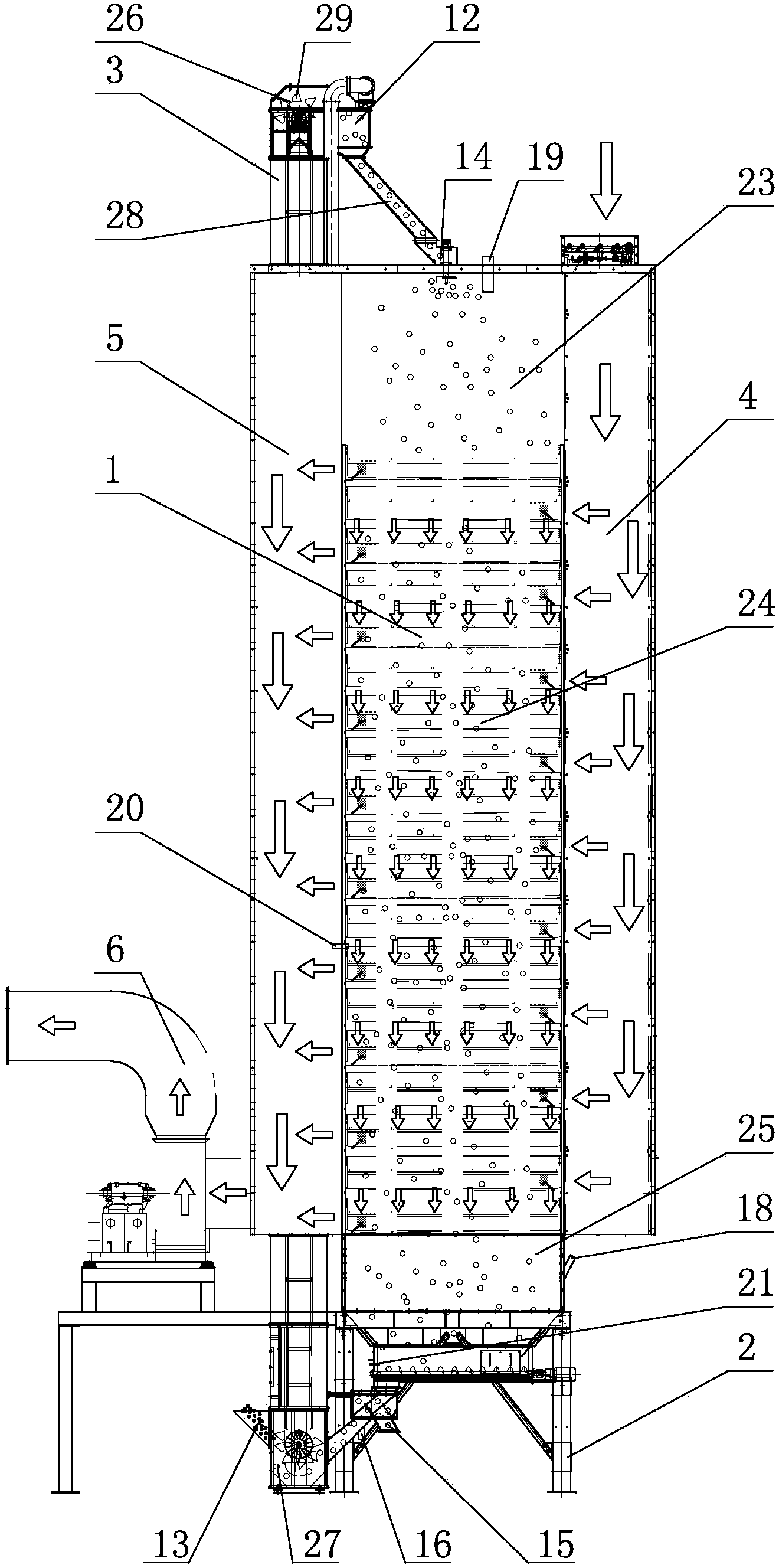

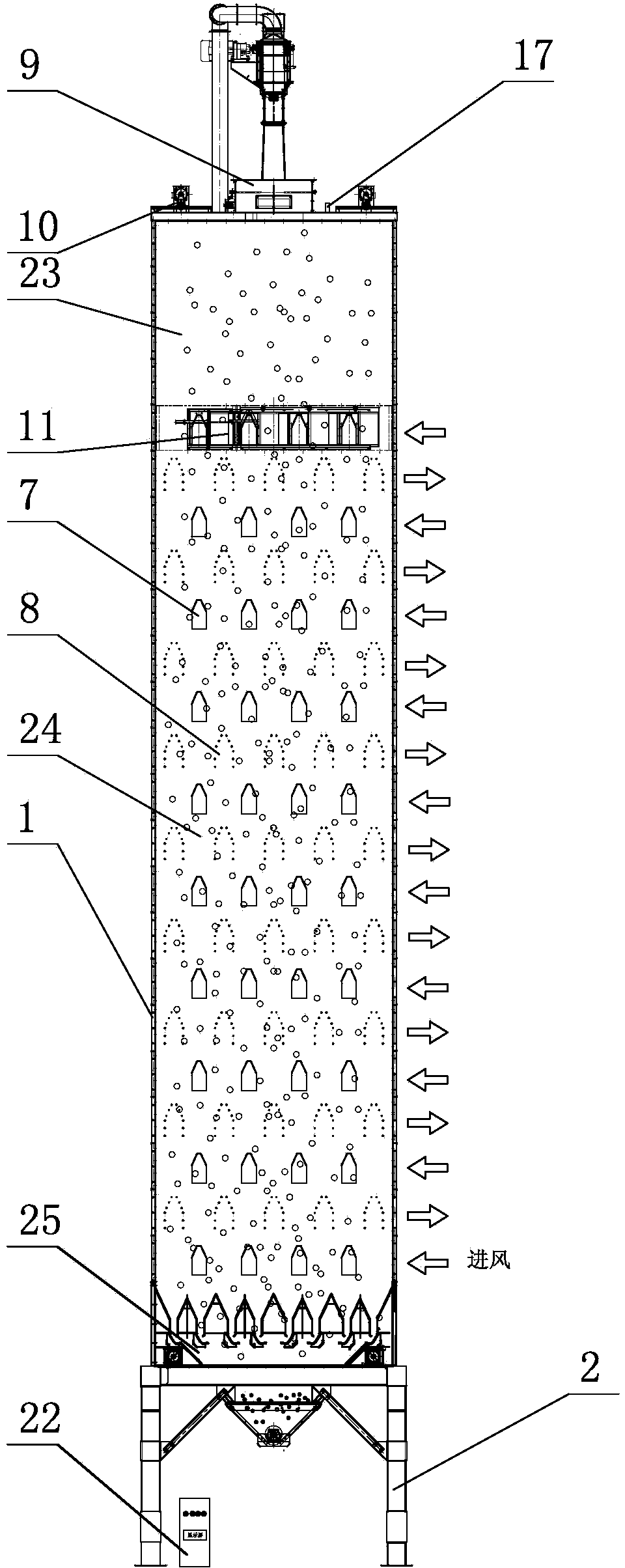

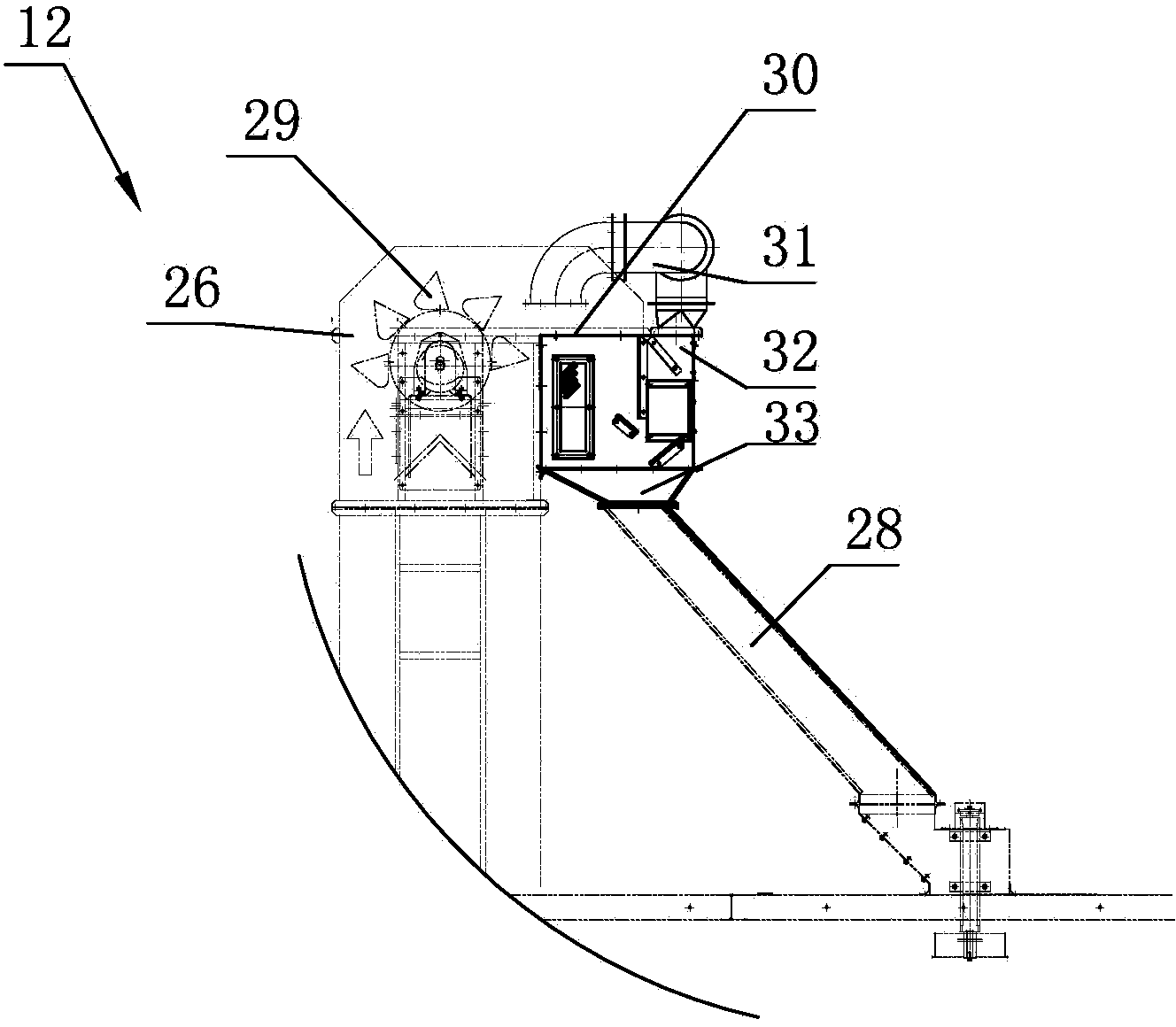

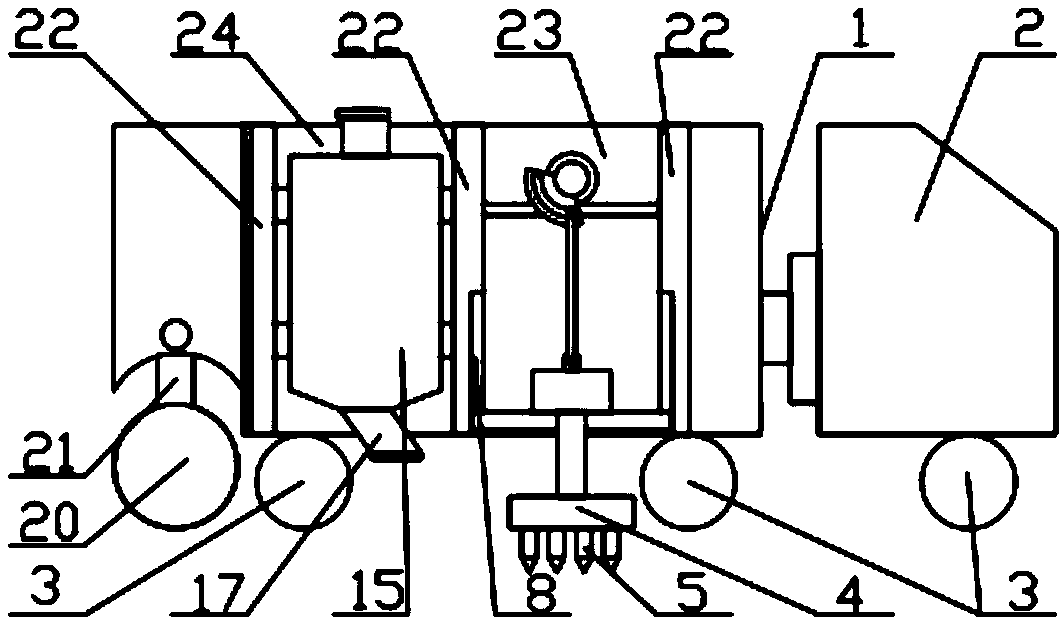

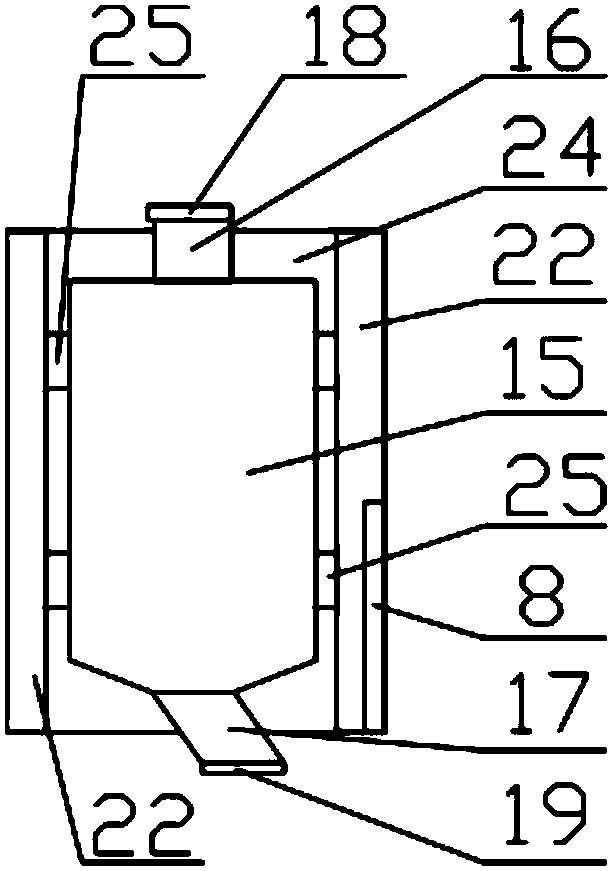

Large-output low-temperature circulating grain drying equipment

ActiveCN103859018ACompact structureIncrease productionSeed preservation by dryingAir separationGrain drying

The invention provides large-output low-temperature circulating grain drying equipment. The drying equipment comprises a lower rack, wherein a drying machine body is installed at the upper part of the lower rack; a retention section is arranged at the upper part of the drying machine body, a drying retention section is arranged at the middle part of the drying machine body, and a grain discharge section is arranged at the lower part of the drying machine body; a hot air passage and an exhaust air passage are arranged on the two sides in the drying machine body respectively; an elevator is installed inside the exhaust air passage and runs through the whole exhaust air passage; an elevator head is installed at the top of the exhaust air passage; an elevator tail is installed at the bottom of the exhaust air passage; the bottom of the drying machine body is connected with a discharge circulating device; an air feeder communicated with the exhaust air passage is also installed outside the exhaust air passage; an air separation device is also installed at the elevator head; a uniform shedding device is connected at the outlet of the air separation device and is arranged at the top of the drying machine body; air inlet vent pipes and air exhaust vent pipes are arranged in the drying retention section of the drying machine body and are alternately arranged up and down at intervals; a control cabinet is installed at the lower part of the lower rack. The drying equipment has high work efficiency.

Owner:无锡中粮工程科技有限公司

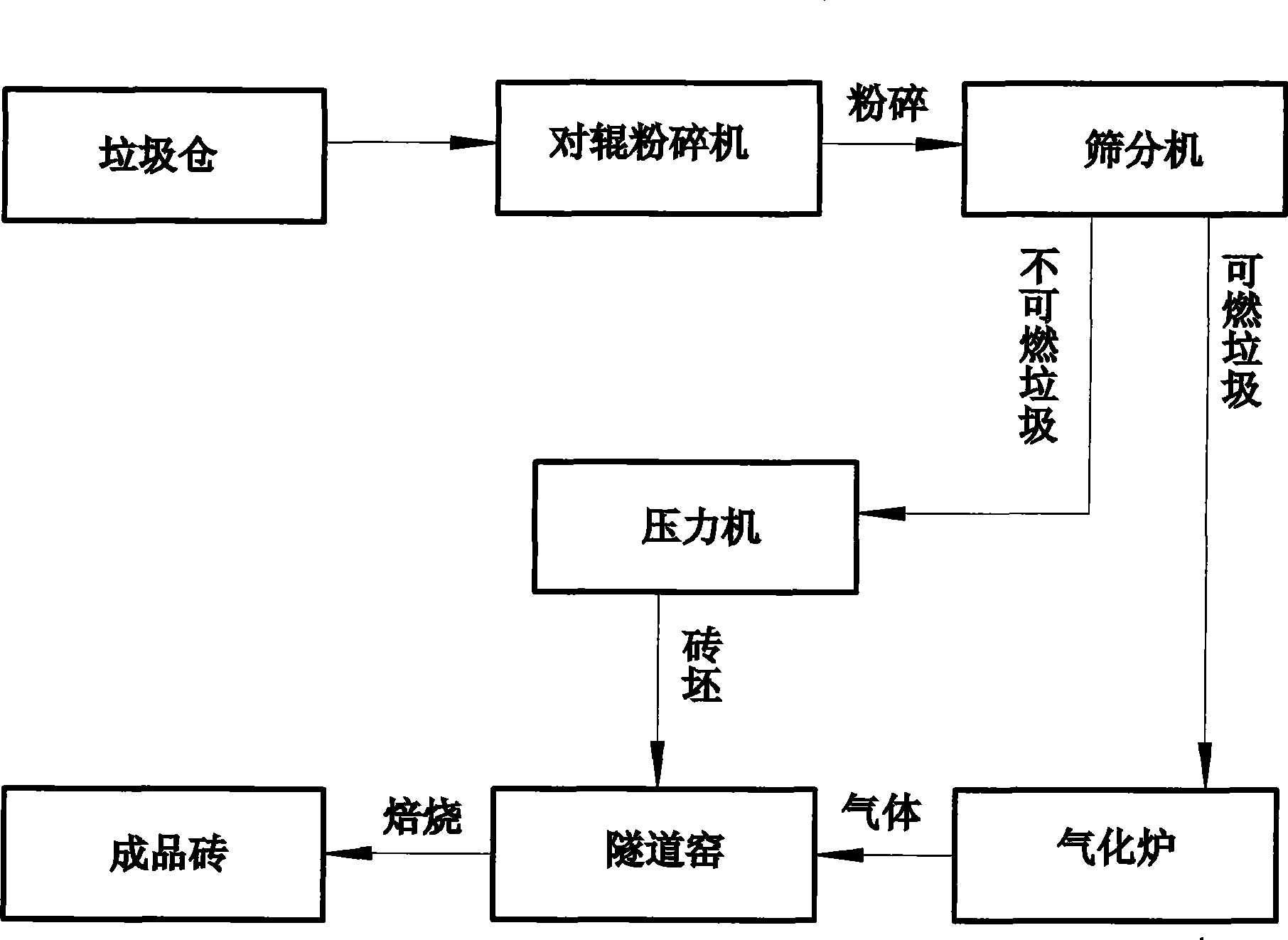

Method for manufacturing bricks by using household garbage

InactiveCN101519300AReduce manufacturing costSolve storage problemsIncinerator apparatusCeramic materials productionTunnel kilnAdobe

The invention relates to a method for manufacturing bricks by using household garbage. The method comprises the following steps of: crushing and mixing 40 portions to 70 portions of non-combustible garbage, 10 portions to 20 portions of coal gangue and 20 portions to 40 portions of clay, adding 20 percent to 30 percent of water into the mixed material, mixing evenly and preparing adobes by dry pressing under the pressure; placing the adobes into a tunnel kiln; introducing the gas generated by the gasified burnable garbage in a gasifying furnace into the tunnel kiln to be as fuel; and obtaining the adobes by roasting at the temperature of 1050 to 1100 DEG C. The method can adopt the gas generated by the burnable garbage after gasification as fuel for high-temperature burning, fully realizes the effective utilization of the household garbage and reduces the production cost of the brick; the material contains the coal gangue which can sinter by self-combustion under high temperature and provide heat; and the method has short production time, simple technique and easy operation, saves energy and is beneficial to environmental protection. By inspection, the pressure resistance of the brick can be up to 8MPa.

Owner:李兴业

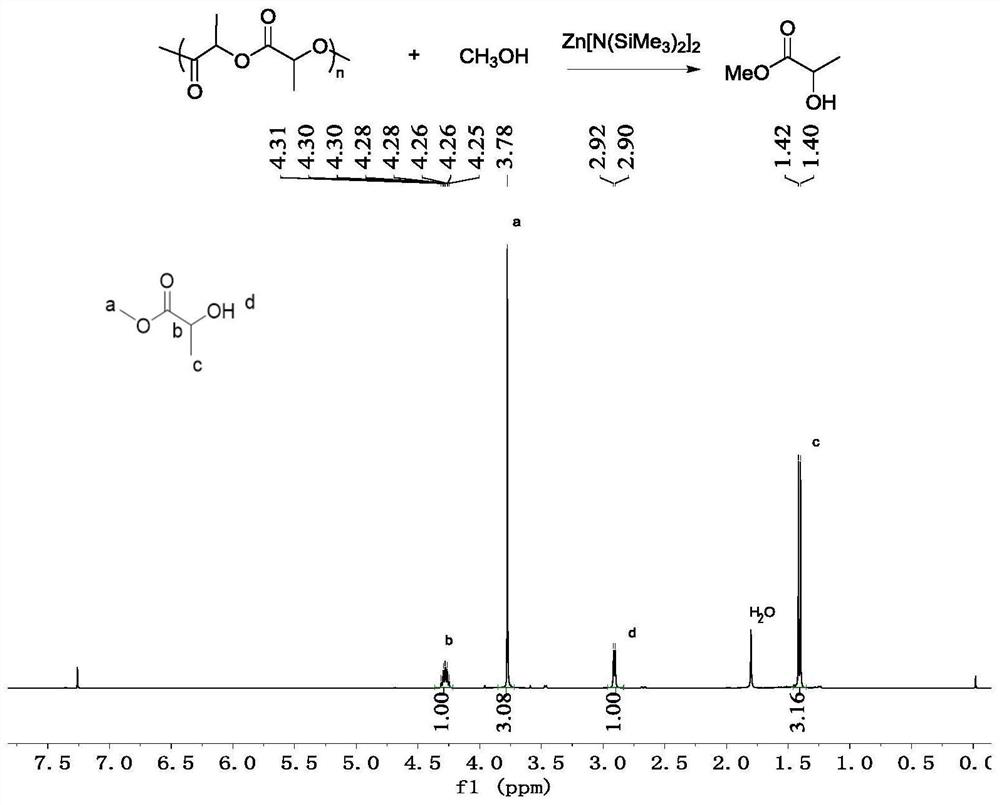

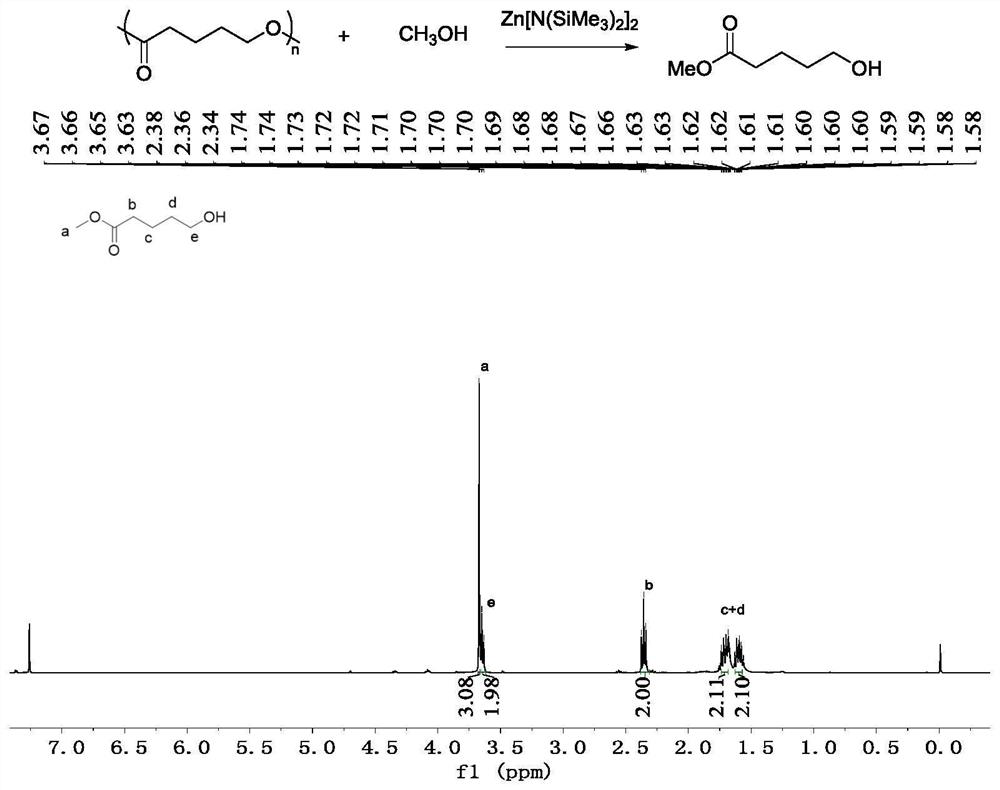

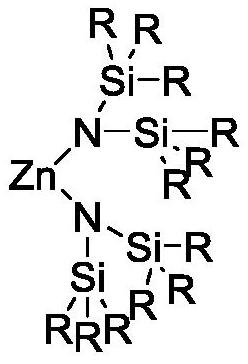

Zinc catalyst applicable to controllable depolymerization of polyester material and catalytic method thereof

ActiveCN112076790AAchieve reuseRealize secondary usePreparation by ester-hydroxy reactionOrganic-compounds/hydrides/coordination-complexes catalystsPolyesterTrans esterification

The invention discloses a zinc catalyst applicable to controllable depolymerization of a polyester material and a catalytic method thereof, and belongs to the technical field of polyester depolymerization. The problems that an existing zinc catalyst used for alcoholysis of waste polyester materials needs to synthesize complex ligands, and the number of synthesis steps is increased are solved. Thecatalyst adopted by the invention is a bis(hexaalkyldisilazane)zinc catalyst with a simple structure, and under the participation of an alcohol compound, the polyester material can be depolymerized into small organic molecules under mild conditions through the transesterification reaction catalyzed by the catalyst, so that the reutilization of waste polyester is realized. The zinc catalyst is adopted to catalyze polyester depolymerization, metal zinc is non-toxic, colorless, cheap and easy to obtain and serves as one of the microelements of a human body, biocompatibility is good, and the production process is more environmentally friendly; the catalyst is simple in structure, few in synthesis steps and more economical in production cost. The catalyst has very good universality, and has a very good depolymerization effect on various polyester materials with different structures.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

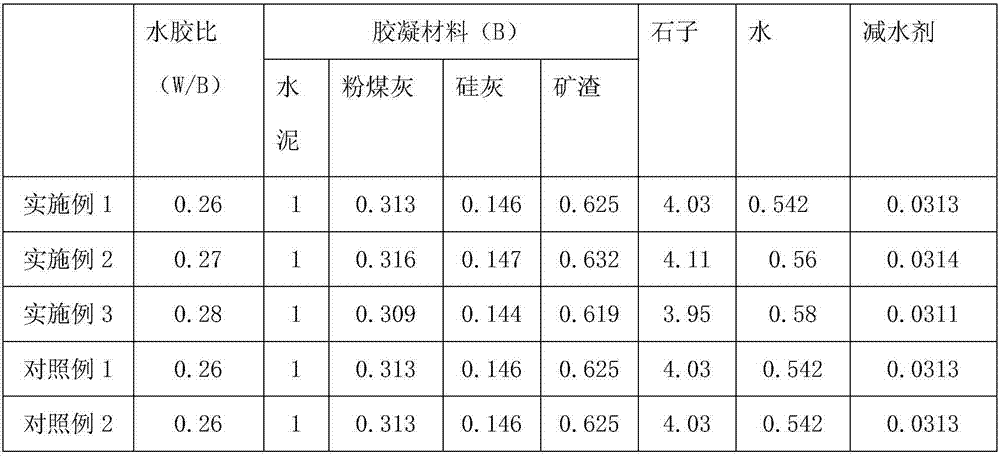

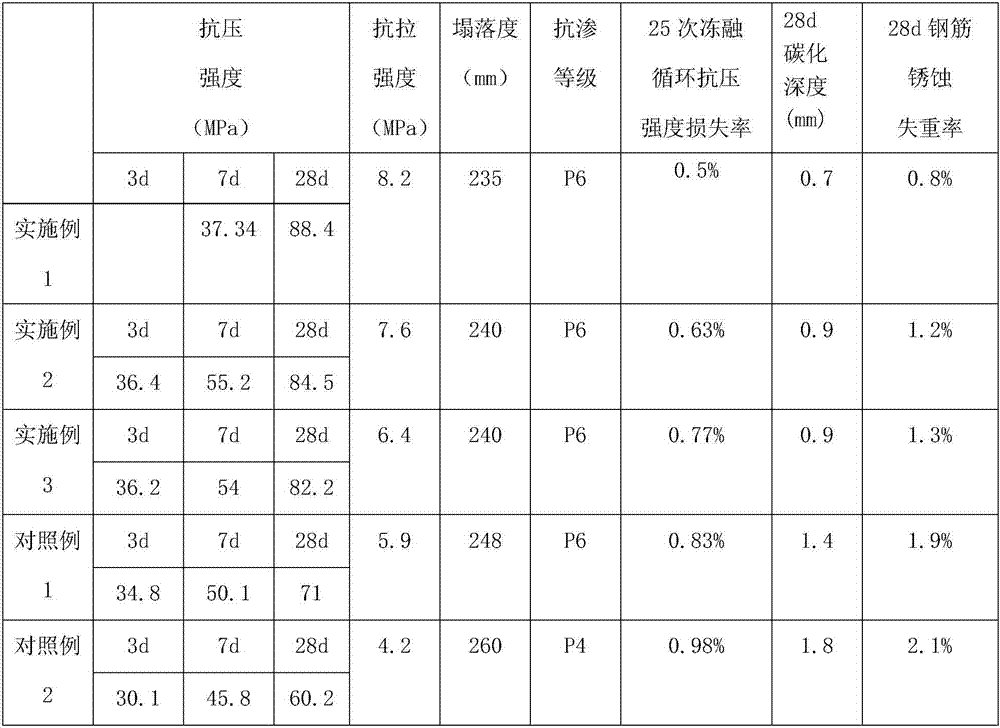

Iron tailing sand doped high-strength concrete, and preparation and applications thereof

The invention discloses an iron tailing sand doped high-strength concrete, and preparation and applications thereof. The iron tailing sand doped high-strength concrete comprises 285 to 291kg of cement, 89 to 91kg of fly ash, 178 to 182kg of mineral slag, 41.5 to 42.4kg of silicon ash, 1149 to 1173kg of cobblestone, 403 to 412kg of iron tailing sand, 154 to 169kg of water, and 8.9 to 9.1kg of a water reducer. The preparation method is simple; iron tailing sand is a mining site discharged waste, and is recycled directly after sieving; waste is changed into valuables via adjusting concrete self structure; requirements on green construction by the states are satisfied; problems such as large iron tailing sand accumulation amount and low utilization rate are solved; the municipal environment and the surrounding environment are improved at the same time; the iron tailing sand doped high-strength concrete can be applied in infrastructure construction, urbanization, and shantytowns transformation.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

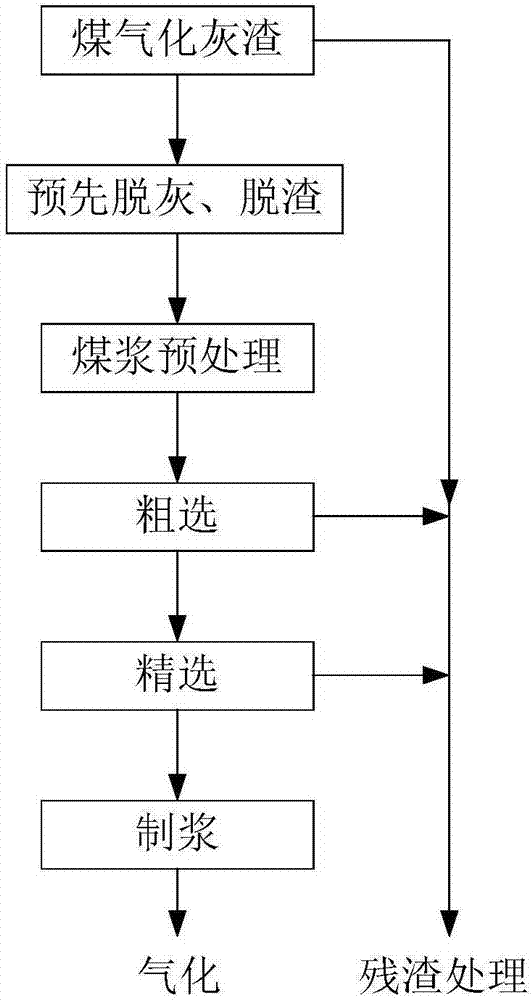

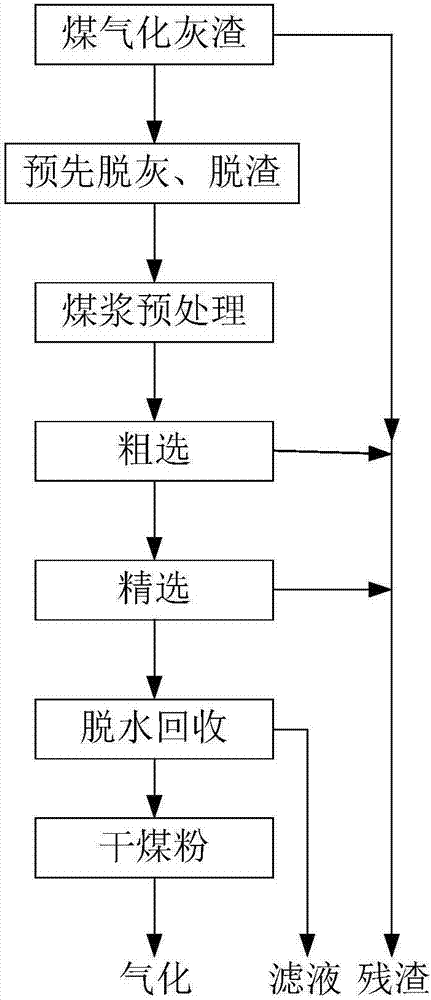

Process for recovering carbon from coal gasification ash residues

InactiveCN107952588AEfficient recyclingEasy to separateSolid fuelsFlotationFurnace temperatureResource utilization

The invention relates to a technical method for recovering carbon from coal gasification ash residues. According to the method, pre-deashing is conducted through a deashing pool, pre-processing is conducted through a coal slurry preprocessor, and rough concentration and fine concentration are conducted through a flotator. The technical method recovers clean coal from the ash residues, thereby being scientific and optimal and achieving energy saving and environment friendliness, and meanwhile, the problems of resource waste and high ash residue utilization difficulty of a coal gasification system caused by overhigh carbon content in the gasification ash residues when operation parameters such as coal types, the oxygen-coal ratio and furnace temperature are changed are effectively solved. Bymeans of the technical method for recovering carbon from the coal gasification ash residues, on the one hand, secondary utilization of residual carbon in the ash residues can be achieved, and on theother hand, the residues can reach the national pulverized ash standards of the level I, the level II and the level III. Coal dust in the ash residues is effectively recovered, the resource utilization rate is increased, resource utilization of low-carbon ash residues is further achieved, and meanwhile environmental pollution caused by stacking of a large amount of unrecycled ash residues can be avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

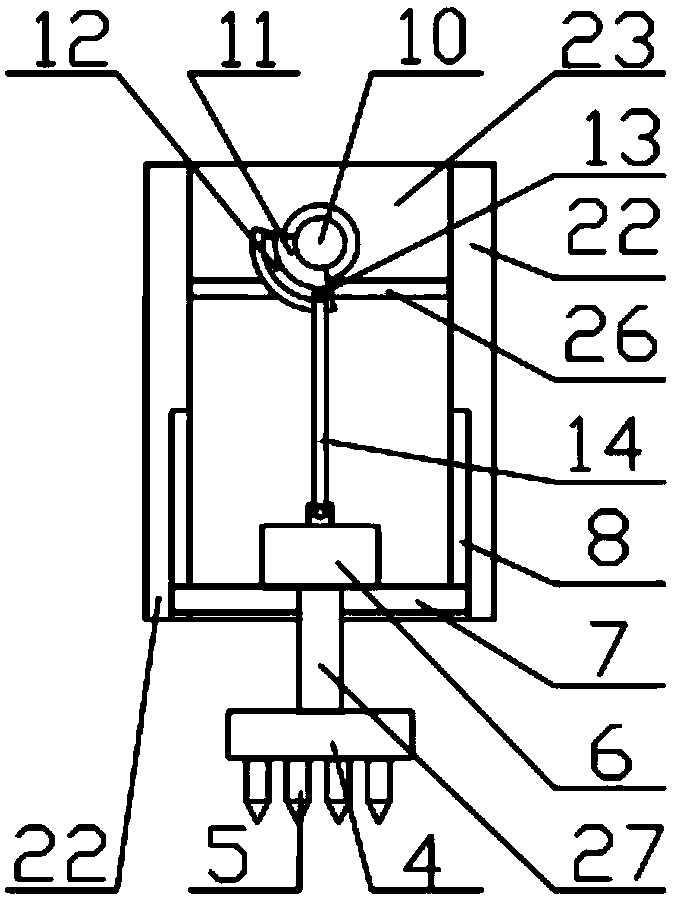

Road repairing device

ActiveCN108842580AVibration crushingGuaranteed to be completely brokenRoads maintainenceElectric machineryRoad surface

The invention discloses a road repairing device, and belongs to the technical field of road repairing. The road repairing device comprises a vehicle body, a breaking and flat ramming mechanism, an asphalt filling mechanism and a compacting roller, wherein the breaking and flat ramming mechanism, the asphalt filling mechanism and the compacting roller are sequentially mounted on the vehicle body from the front end to the rear end in the marching direction of the vehicle body; the breaking and the flat ramming mechanism comprises a flat ramming gravity plate, and a drill bit which is fixed to the lower surface of the flat ramming gravity plate; the upper part of the flat ramming gravity plate is connected to a vibrating motor; a rotating shaft and a sector turntable which is fixed to one side of the rotating plate are arranged right above the vibrating motor; an arc-shaped hole is formed in the sector turntable; a moving rod which vertically passes through the arc-shaped hole is arrangedin the arc-shaped hole; a connecting rod is connected between the moving rod and the vibrating motor; two ends of the connecting rod are correspondingly hinged with the moving rod and the vibrating motor. According to the road repairing device, a broken and old pavement can be hammered and vibrated to realize combined breaking through one mechanism, and the broken pavement can be completely rammed, levelled and compacted; in addition, related acting strength is high; the breaking effect and the flat ramming effect are good.

Owner:ANHUI NORMAL UNIV

Brackish water desalination method and brackish water desalination device

InactiveCN103936202AGreat tasteAvoid pollutionGeneral water supply conservationMultistage water/sewage treatmentCarbonationChemistry

The invention discloses a brackish water desalination method and a brackish water desalination device. The essential of the technical scheme of the invention is as follows: the brackish water desalination method comprises the steps of cleaning and filtering treatment, ultrafiltration treatment, pressurization treatment, reverse osmosis desalination treatment, reverse osmosis thick-water nanofiltration softening treatment, nanofiltration thick-water energy recovery treatment, nanofiltration thick-water ultrafiltration backwash treatment, ultrafiltration backwash wastewater drainage treatment, product water mineralization and carbonation treatment, product water sterilization and taste improvement treatment, purified water drainage and the like. The invention further discloses a brackish water desalination device. According to the brackish water desalination method and the brackish water desalination device disclosed by the invention, the problems of high production cost brought by addition of lots of chemical agents, low economical efficiency brought by low product water recovery rate, low health drinking performance brought by no deep aftertreatment on product water, and the like in the existing membrane-method brackish water desalination process are effectively solved.

Owner:HENAN NORMAL UNIV

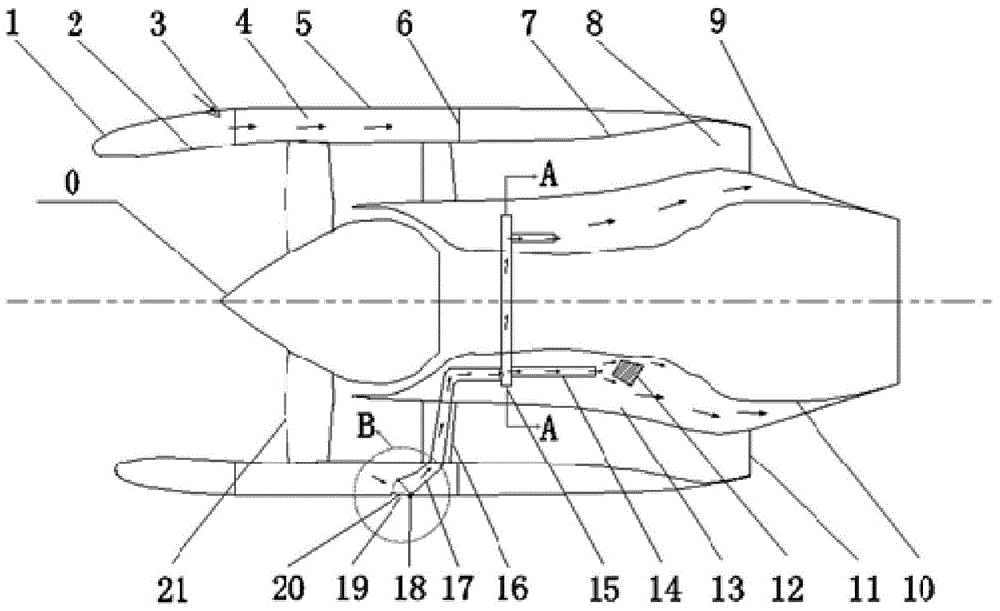

Cooling method and device for engine core module

ActiveCN104948286AAchieve coolingAchieve ventilation and coolingPower plant cooling arrangmentsAir coolingDifferential pressureNatural convection

The invention provides a cooling method and device for an engine core module. According to the method, cooling airflow in a fan cabin is reutilized and introduced into the core module so as to cool the core module. In the ground test state, ambient airflow enters the fan cabin for ventilation cooling through an exhaust port of the fan cabin in a free convection mode and is discharged through an air inlet of the fan cabin finally. In other flying states, ambient airflow enters through the air inlet of the fan cabin under the ram action, is divided into a left stream and a right stream for ventilation cooling of the fan cabin, and then is introduced into the core module through an air guiding pipe under the differential pressure of the fan cabin and the core module to conduct ventilation cooling on the core module, and meanwhile, the ambient airflow can conduct directional concentrated cooling on the local high-temperature region in the cabin under the guiding of the air guiding pipe. In this way, ventilation cooling of the core module is achieved, the air entraining content of an external duct is reduced, entraining loss of the external duct is reduced, and reutilization of ventilation cooling airflow of the fan cabin is achieved.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

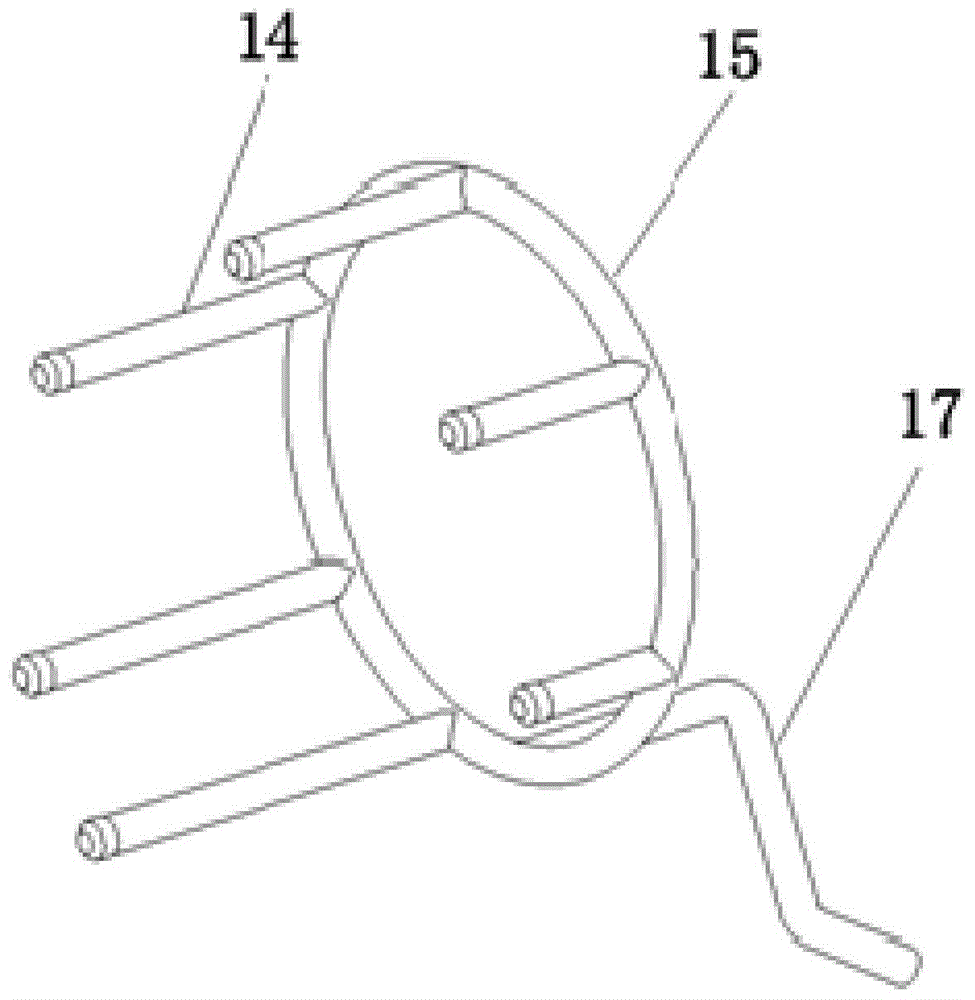

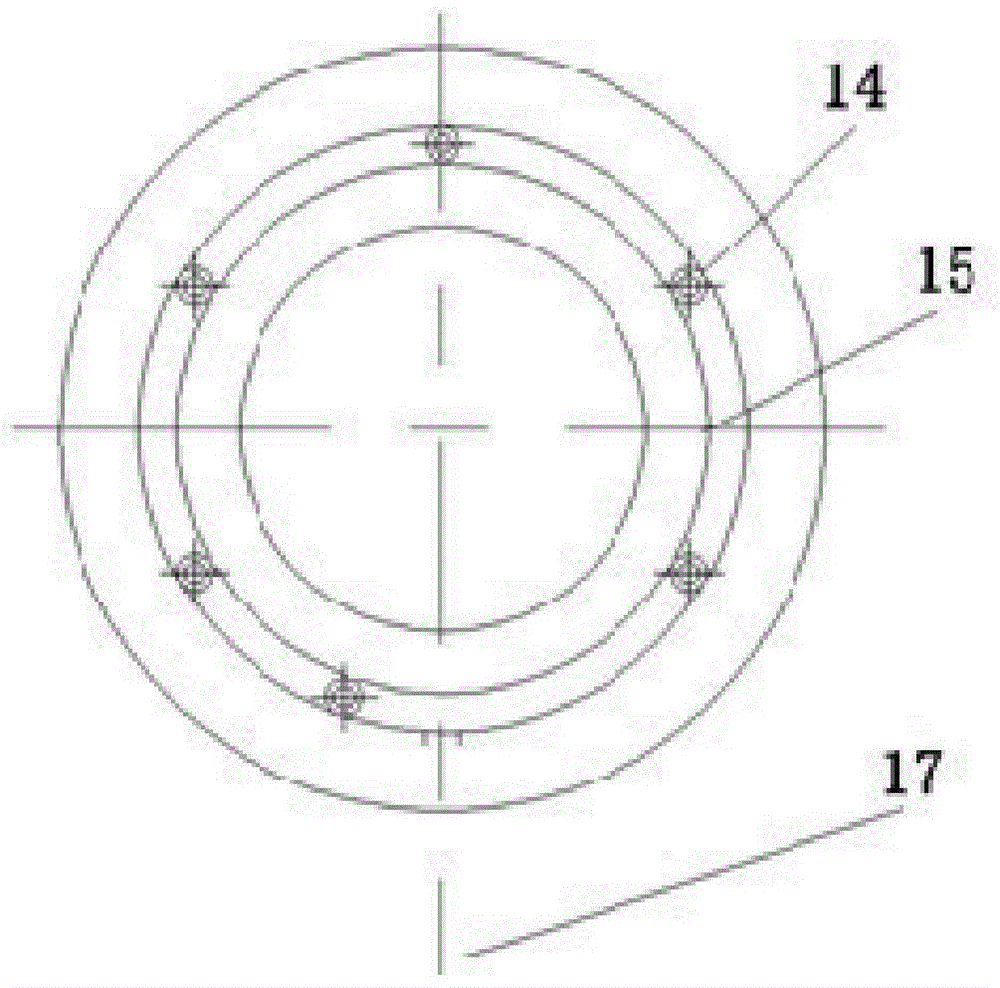

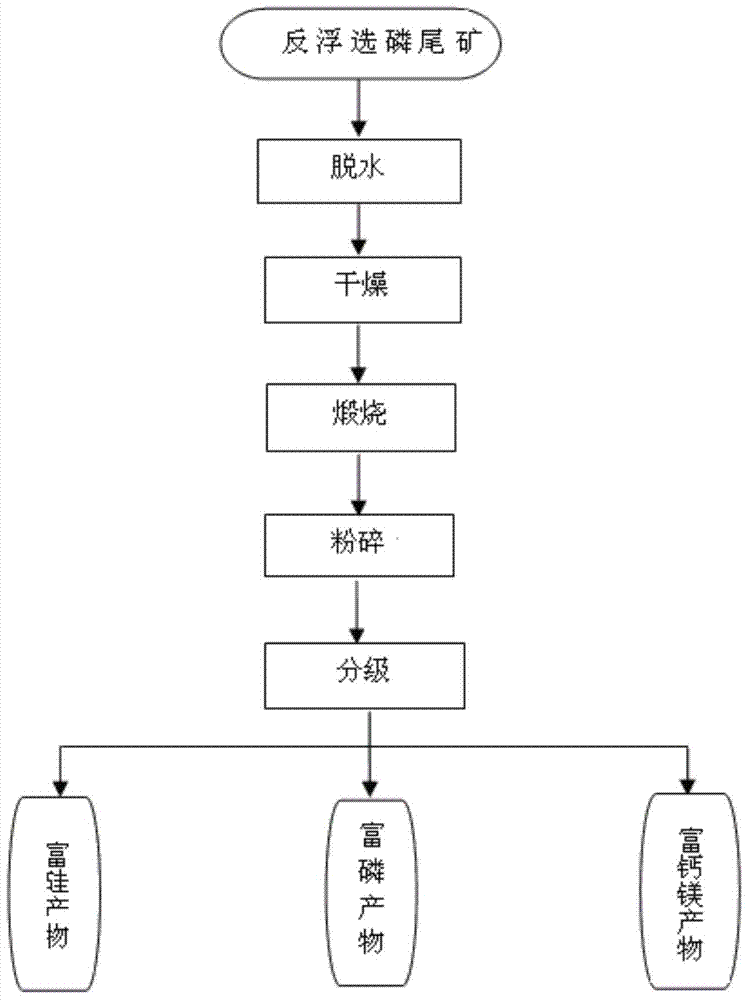

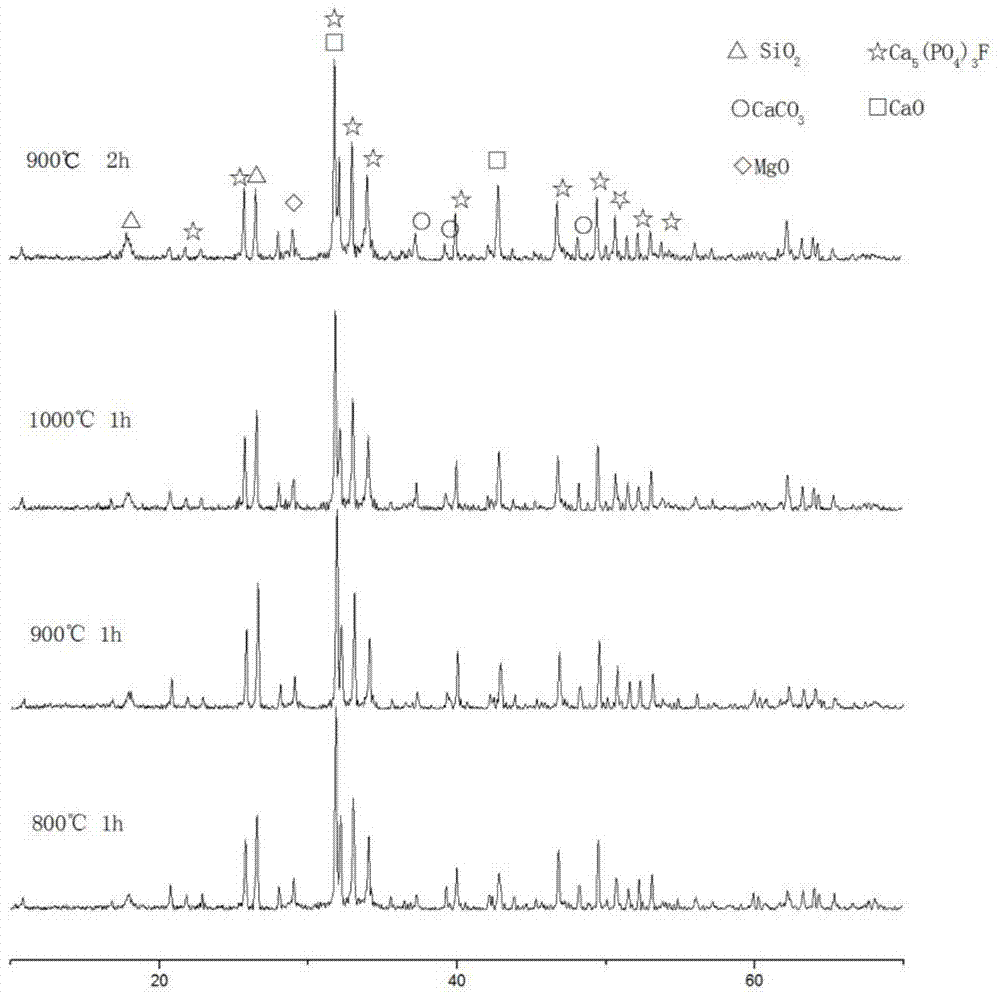

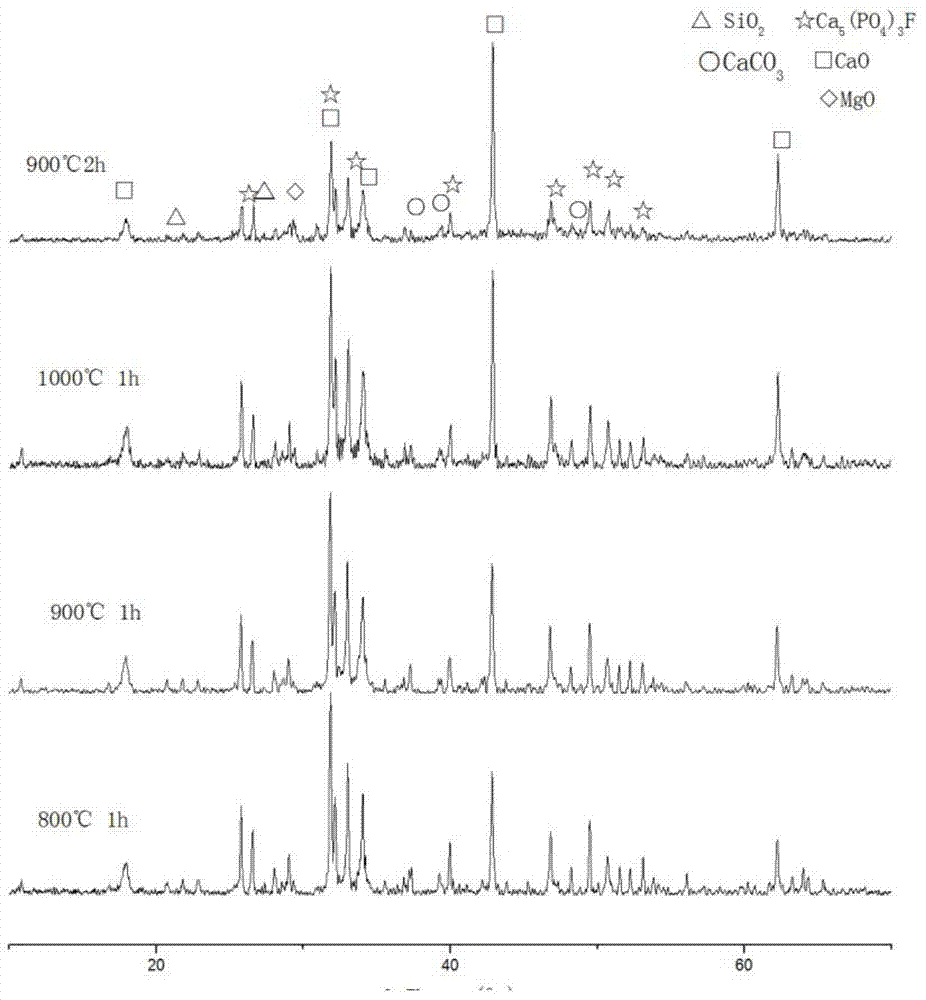

Method for comprehensively utilizing reverse-flotation phosphorite tailings

InactiveCN103569984ARealize secondary useImprove utilizationSolid waste managementCement productionChemical industryMineral Sources

The invention belongs to the field of comprehensive utilization of tailings and particularly relates to a method for comprehensively utilizing reverse-flotation phosphorite tailings. According to the method, the reverse-flotation phosphorite tailings are calcinated at 800-1200 DEG C, then calcinated products are crushed, and finally, the crushed calcinated products are graded according to particle sizes so as to obtain calcium-and-magnesium-rich products, phosphorus-rich products and silicon-rich products, wherein the phosphorus-rich products can be used as raw materials for the phosphorus chemical industry, and the calcium-and-magnesium-rich products and the silicon-rich products can be used as raw materials of building materials. The method is simple in technological process, basically free from emissions of waste water and waste solids and suitable for industrial application; and by the aid of the method, the purpose of efficient utilization of the reverse-flotation phosphorite tailings is achieved, and the method has the positive significance in comprehensive utilization of mineral resources and environmental protection.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

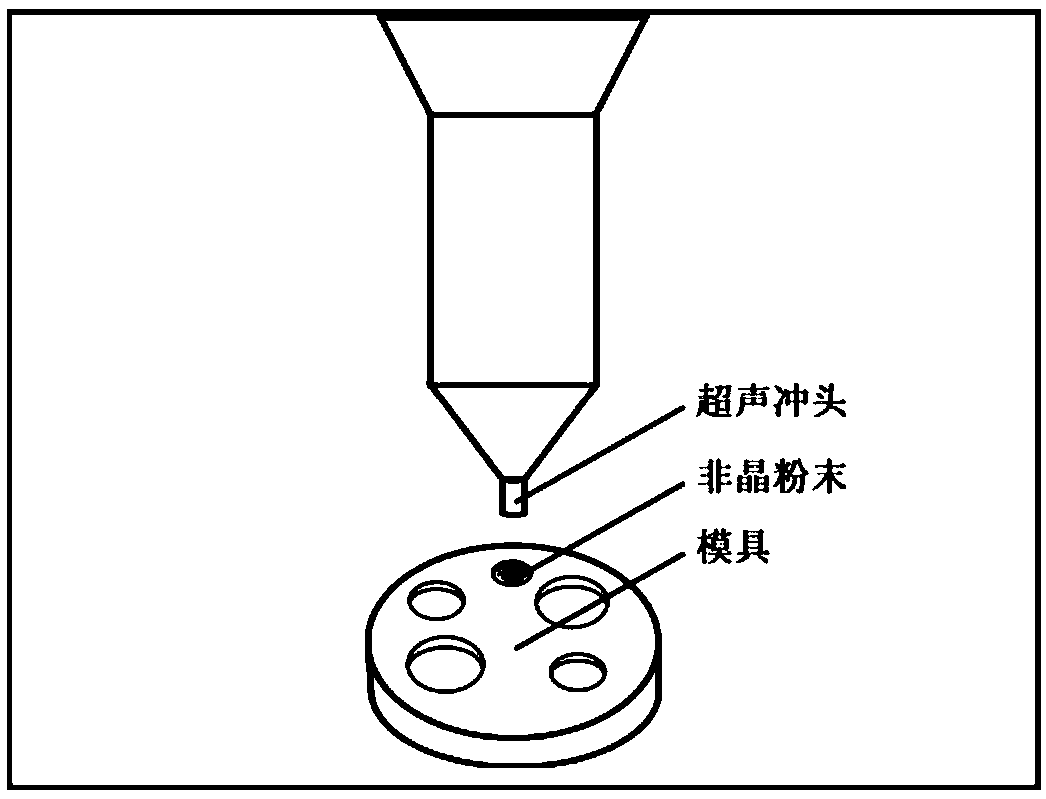

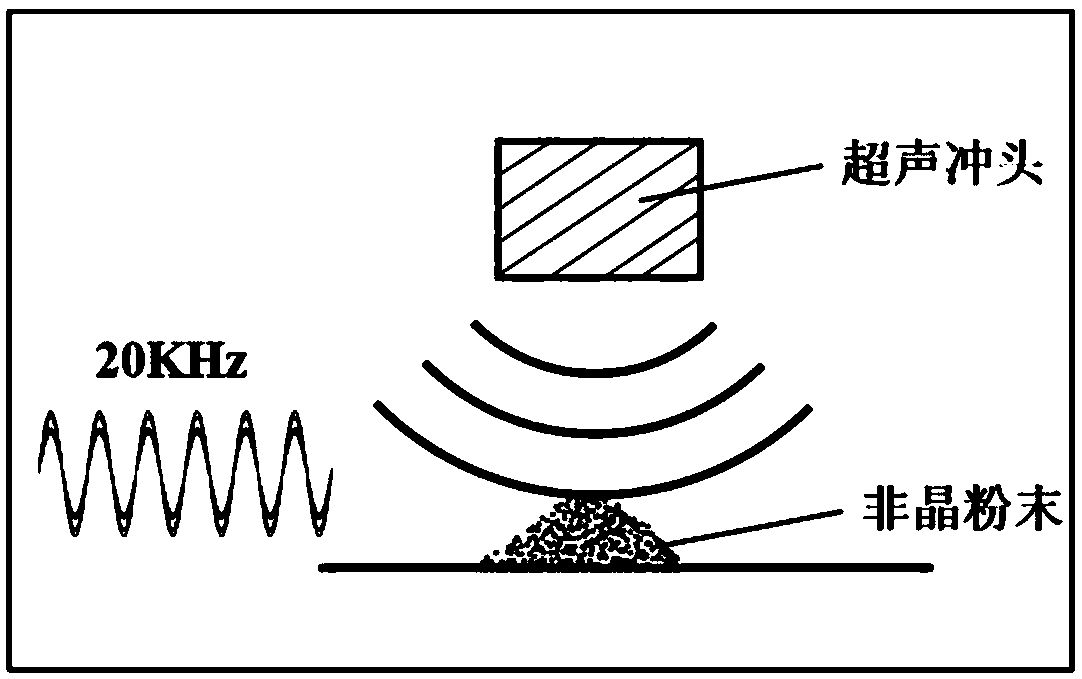

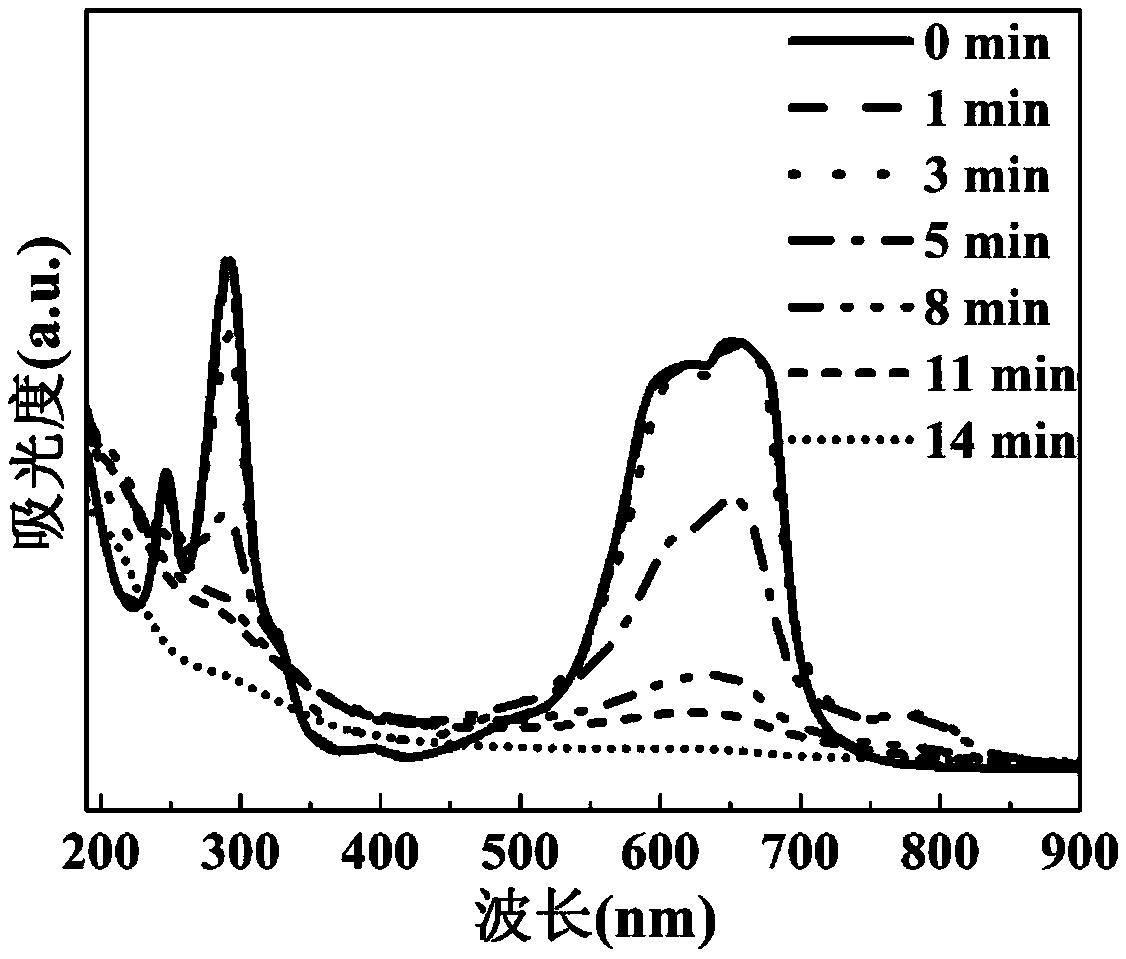

Iron-based amorphous alloy powder for degradation of dye waste liquid and preparation method and application of iron-based amorphous alloy powder

ActiveCN109434120AImprove degradation rateThe preparation method is simple and easy to obtainWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsAlloySewage

The invention discloses a method for preparing iron-based amorphous alloy powder for dye degradation. According to the method, on the premise of meeting the market application requirements, combined with the existing process conditions in actual production, the iron-based amorphous powder is obtained by ultrasonic processing. The invention further discloses application of the amorphous powder after ultrasonic processing used for degrading dye waste liquid. In the process of degradation, different ultrasonic energy and powder dosage are considered specifically and correspondingly, and finally an optimal degradation processing condition is obtained. According to the method for preparing the iron-based amorphous alloy powder for dye degradation, not only is the dye waste liquid degraded, butalso the industrial waste iron-based amorphous powder is effectively utilized, good application prospects in sewage treatment are achieved, and the great significance to environmental protection and sustainable development is achieved.

Owner:SOUTHEAST UNIV +2

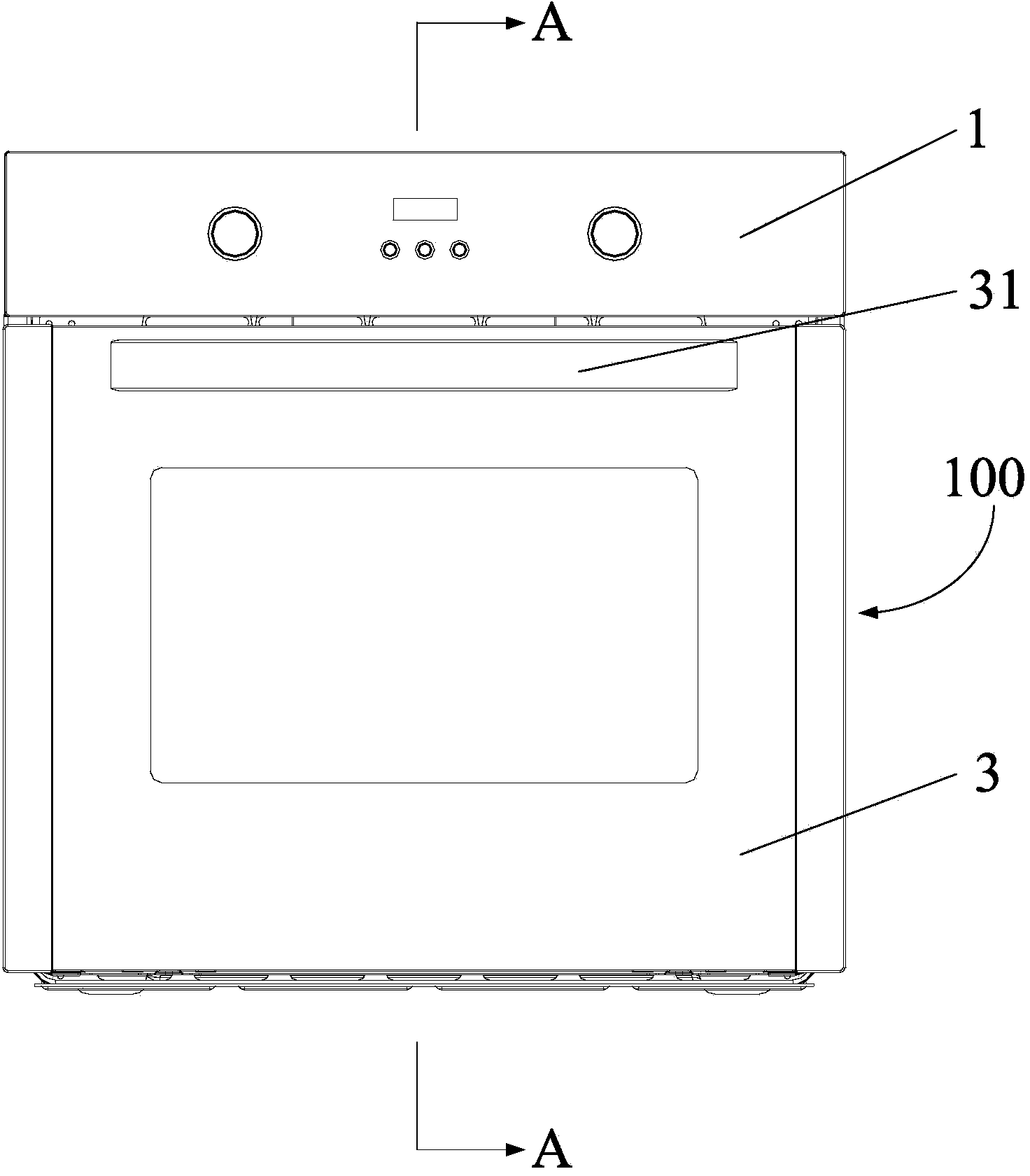

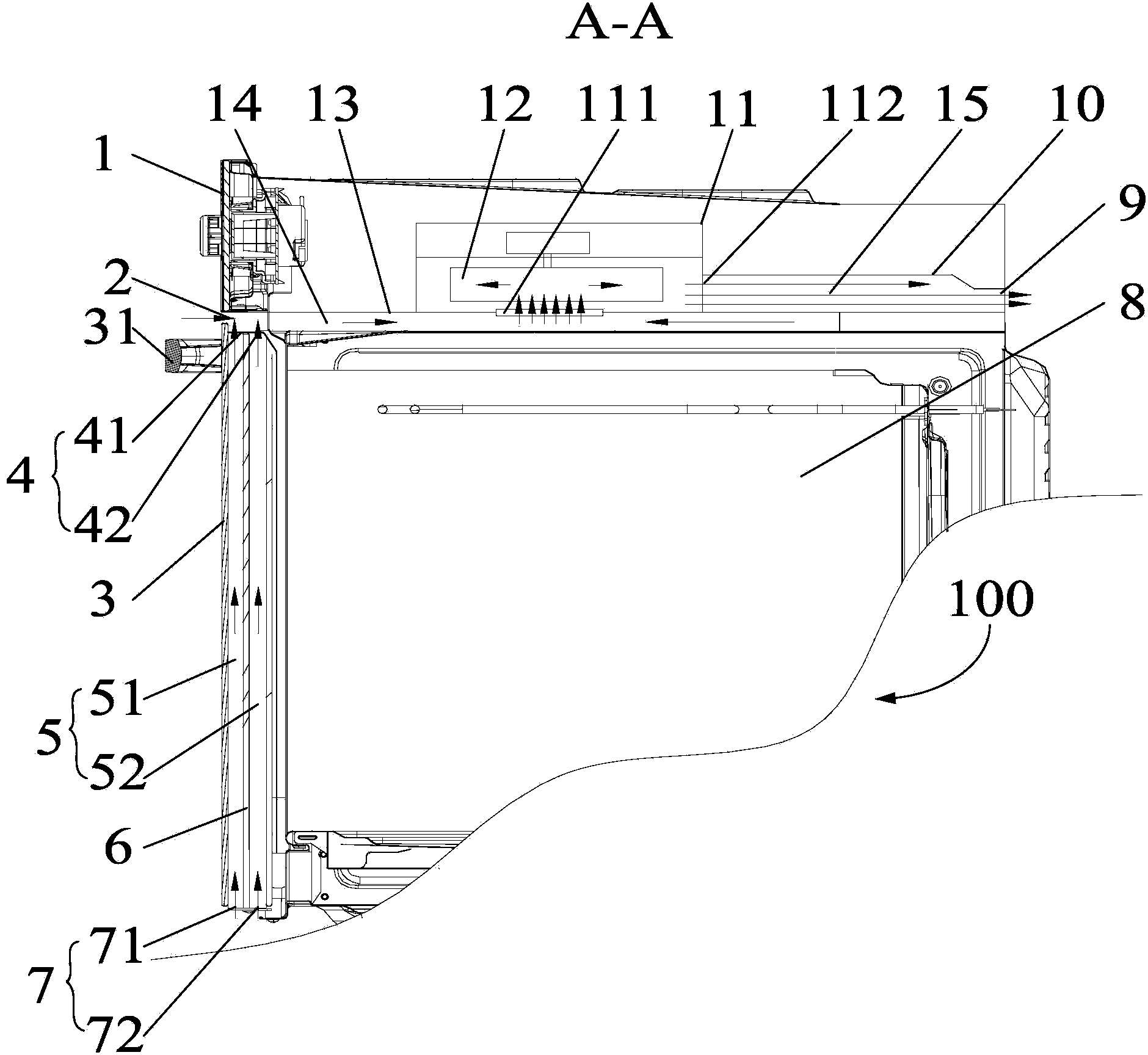

Heat dissipation system for oven and electric oven

The invention provides a heat dissipation system for an oven and the electric oven. The heat dissipation system for the oven comprises an air inlet, an air channel, an air outlet and a fan. The air inlet comprises an oven body air inlet and a door body air inlet, the oven body air inlet is formed in the front portion of the oven, and the door body air inlet is formed in the bottom of an oven door body. The air channel comprises a door body air channel, a first air channel and a second air channel, the door body air channel is communicated with the door body air inlet, and the first air channel is communicated with the oven body air inlet and the door body air channel. The air outlet is formed in the rear portion of the oven and is communicated with the second air channel. A fan exhausts air inside the first air channel into the second air channel. According to the technical scheme, users are effectively prevented from being scalded by the hot air exhausted from the air outlet, and the safety of the oven is improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

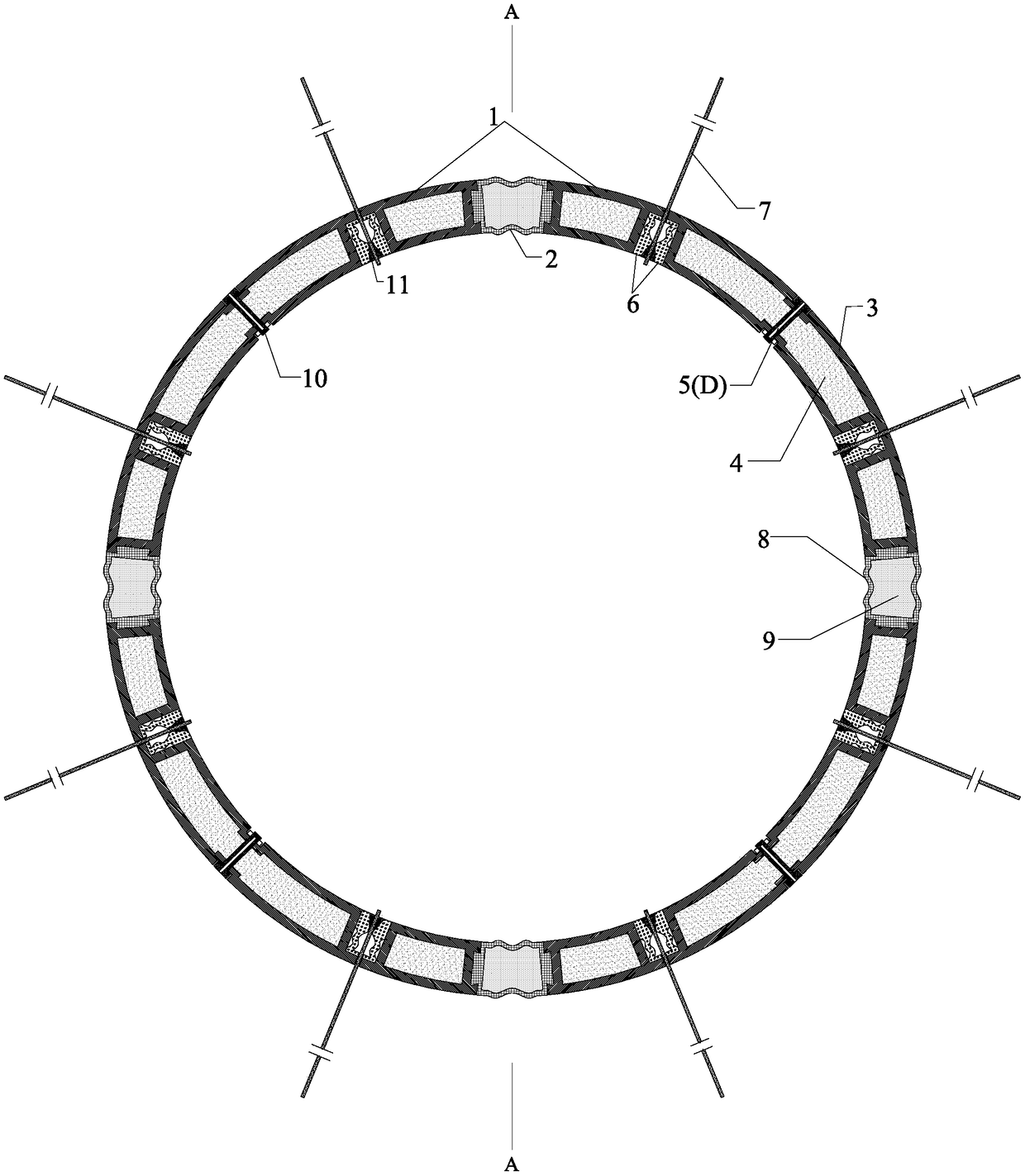

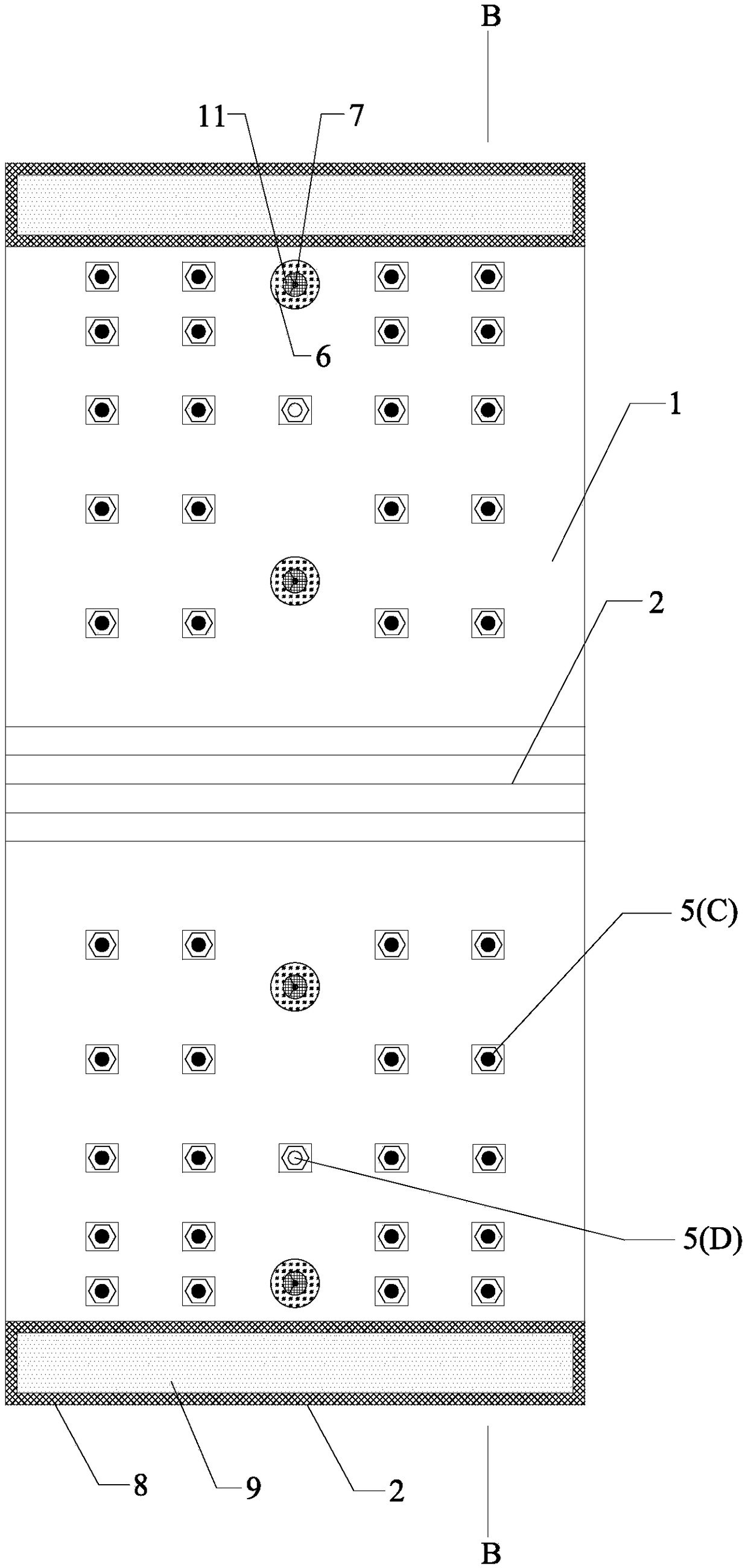

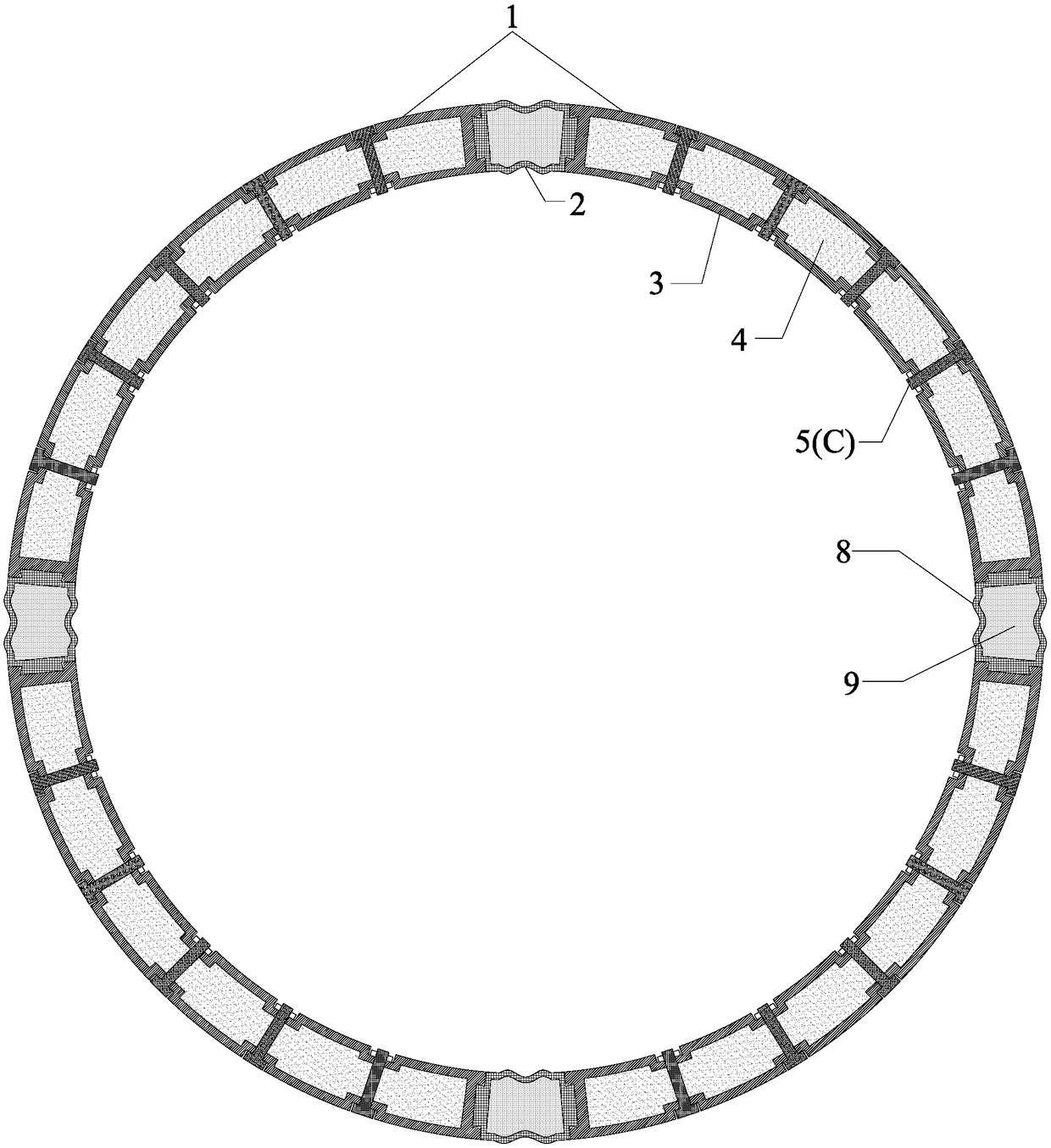

Tunnel pre-stressed restrained filling lining support system with yielding and energy-absorbing functions and technology

PendingCN109184737ASave on-site construction timeImprove construction progressUnderground chambersTunnel liningSupporting systemPre stress

The invention discloses a tunnel pre-stressed restrained filling lining support system with yielding and energy-absorbing functions and a technology. The system includes multiple restrained filling lining bodies arranged along the circumference of a tunnel, and restrained yielding sleeves are connected between the restrained filling lining bodies. Each restrained filling lining body includes a restrained shell which has a filling body inside. Pre-stressed anchor bolts are installed in a penetrating manner along the outer arc surface and the inner arc surface of each restrained shell. A numberof anchor rope holes are arranged in the inner arc surfaces of the restrained shells. The pre-stressed anchor bolts are installed in a penetrating manner in the anchor rope holes by self-locking yielding trays. The pre-stressed anchor bolts are applied with a pre-stress and can produce radial compression on the restrained shells and the inner filling bodies thereof so that the pre-stressed anchorbolts, the restrained shells and the filling bodies constitute a composite bearing shell together. When the pressure on the external surrounding rock of the tunnel exceeds the yielding value set by the restrained yielding sleeves and the self-locking yielding trays, the whole lining support system can realize yielding and energy absorbing along the circumferential and radial directions of the tunnel.

Owner:SHANDONG JIANZHU UNIV

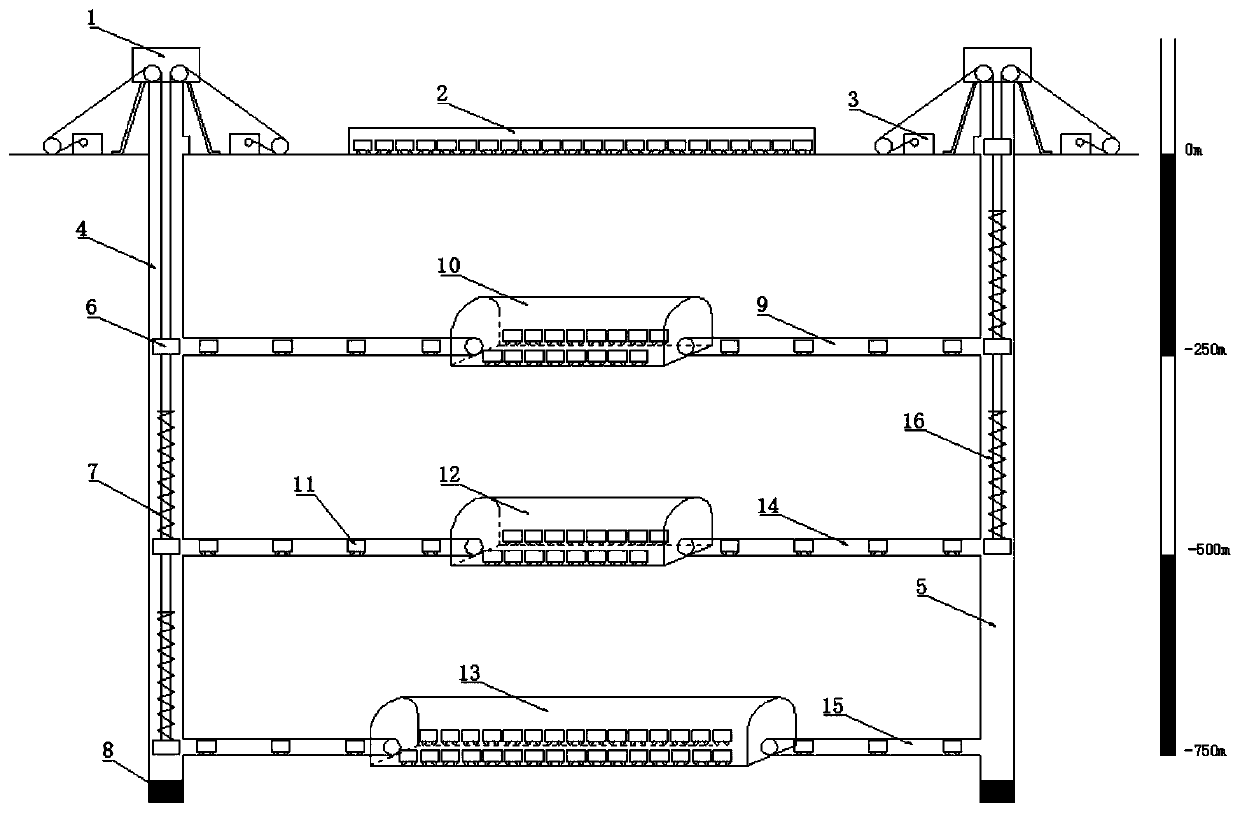

Gradient gravity energy storage system for abandoned mine well shaft and gangue after mining

PendingCN111287918ARealize hierarchical conversionThe principle is simpleMachines/enginesMotorsNew energyMining engineering

The invention discloses a gradient gravity energy storage system for an abandoned mine well shaft and gangue after mining, and provides a more economical new energy storage system and secondary utilization system for the abandoned mine well shaft and the gangue after mining. Based on the specific exploitation situation of an abandoned mine well, abandoned mine well shafts are utilized to serve asenergy storage channels; underground parking lots with different elevations are constructed between a primary well and a secondary well; the number of cage conductors are set according to corresponding elevation difference and the number of parking lots; the number of the cage conductors in a channel on one side is equal to the number of the underground parking lots; and the rising and falling elevation differences between the cage conductors are equal to each other all the time. The system comprises energy storage-release channels transformed by an abandoned primary well and an abandoned secondary well; the upper parts of the channels are out of the ground to connect corresponding equipment; the lower parts are connected with various underground parking lots; various channels are connected to the parking lots by utilizing connecting roadways; when energy is stored, a mine vehicle in a lower-position parking lot is lifted to an upper-position parking lot by a lifting system; and when the energy is released, the mine vehicle in the upper-position parking lot is dropped to the lower-position parking lot. Gradient gravity energy storage and release are realized by controlling the loading capacity of the gangue of the mine vehicle and the transferring amount between the cage conductors in a centralized manner by means of a central control chamber; and in addition, buffering springsare arranged between adjacent cage conductors, so that the energy impact caused by accidental fracture of a steel wire rope is reduced. According to the system, the problem about power energy storageof new energy is solved on the basis of comprehensive utilization of the abandoned mine well shaft and the gangue; and transformation reference is provided for the abandoned well after mining and thewell which is about to be pulled out of production capacity.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

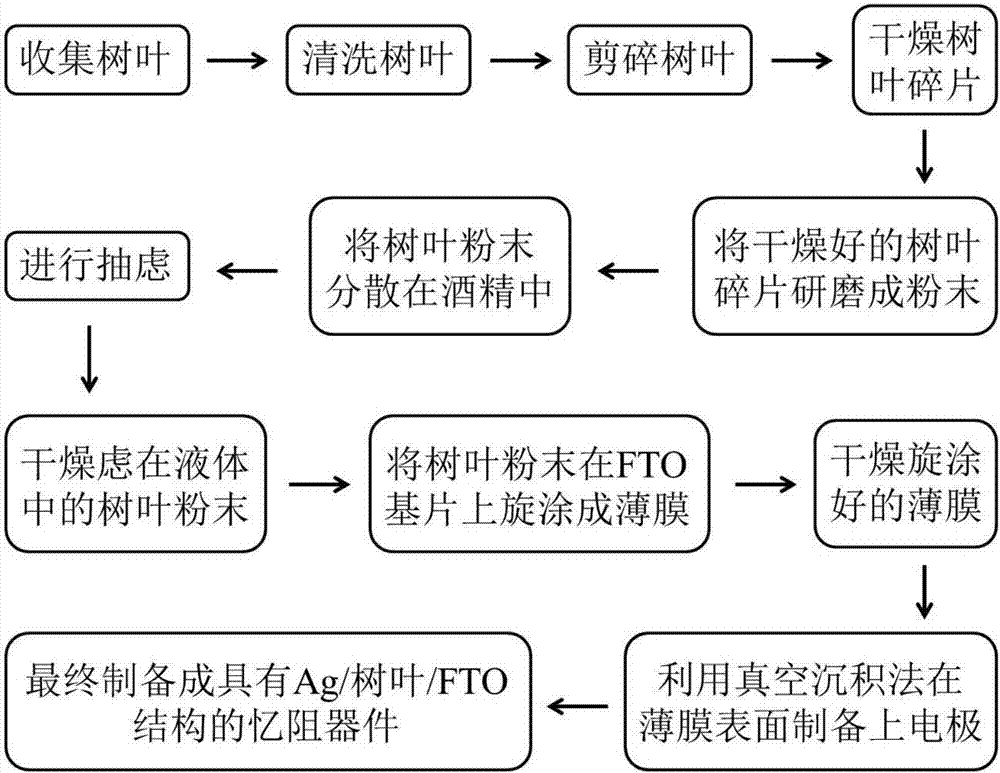

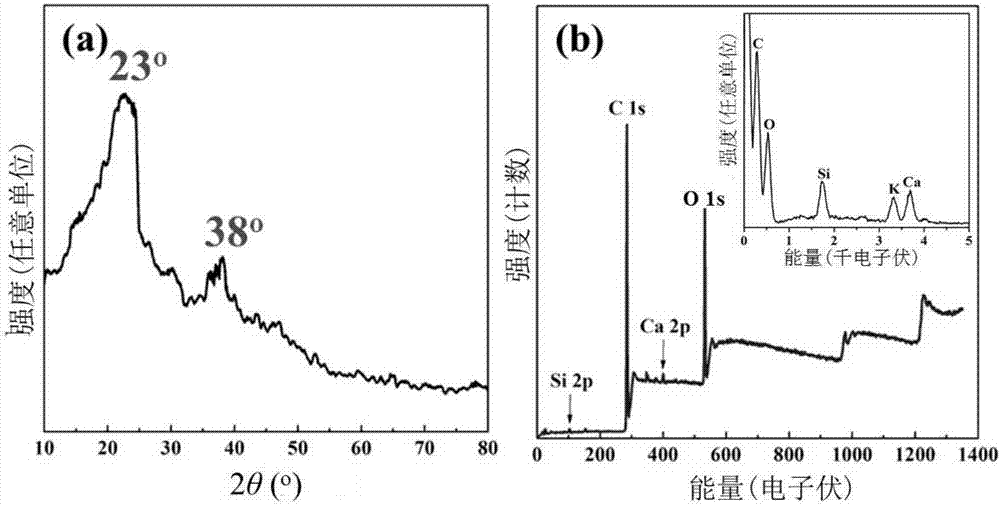

Preparation method of memristor

InactiveCN106953009AImprove utilizationRealize secondary useElectrical apparatusDigital storageCelluloseSemiconductor materials

The present invention provides a preparation method of memristor, and relates to the memory manufacturing technology field. The problem of negative influence of semiconductor materials is effectively solved. The method comprises the steps: the step 1: collecting enough dried leaves; the step 2: obtaining ultrafine leaf powder for standby through adoption of collected leaves in the step 1 by employing the separation method; the step 3: dissolving the ultrafine leaf powder obtained in the step 2 into a ethyecellulose solution, and preparing a colloid; the step 4: taking fluorine doped stannic oxide transparent conducting glass FTO as a substrate, and employing the spin-coating method to perform spin coating of the colloid at one conductive surface of the substrate to form a film as a dielectric layer; the step 5: drying the substrate with the dielectric layer obtained in the step in a drying case with the temperature of 60 DEC G for more than 12 hours; the step 6: putting the substrate dried in the step 5 into a vacuum deposition device; and the step 7: taking the surface deposition metallic silver of the dielectric layer on the substrate as an upper electrode through the vacuum deposition method to obtain a memristor having a silver / leaf / FTO structure.

Owner:SOUTHWEST JIAOTONG UNIV

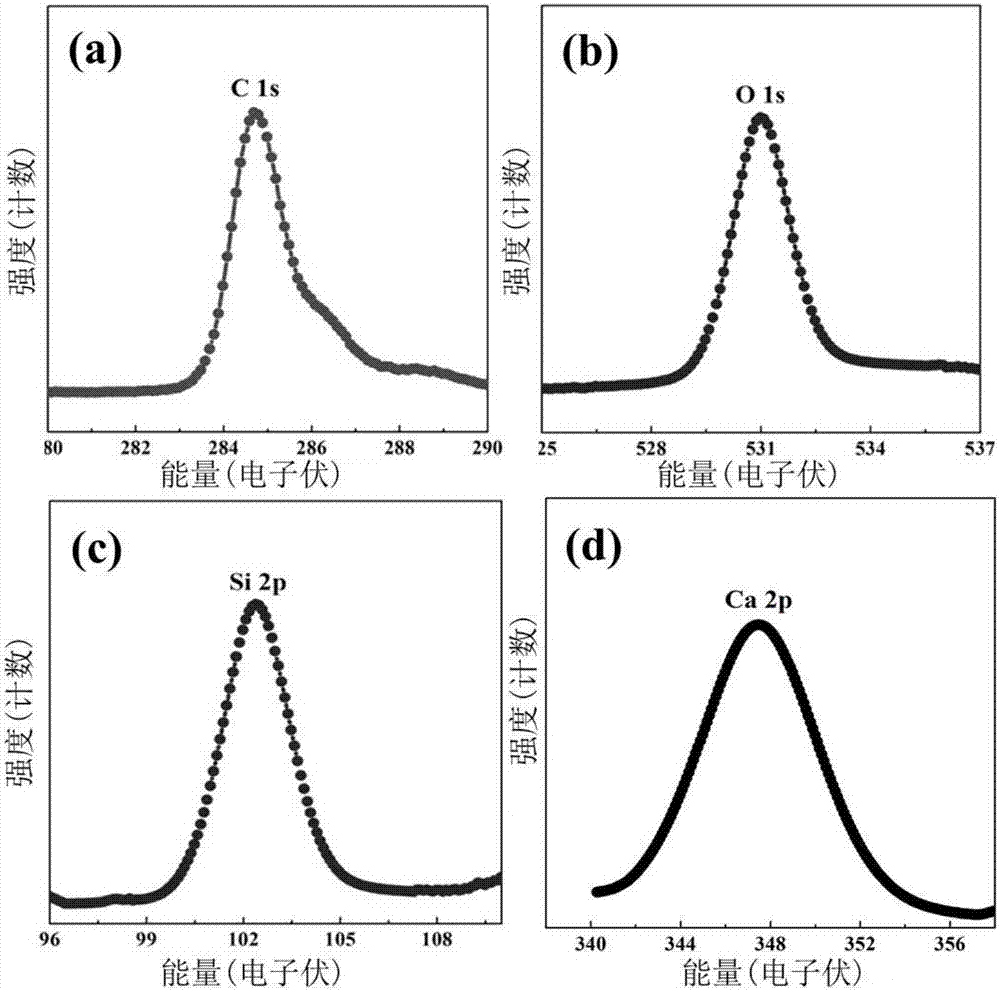

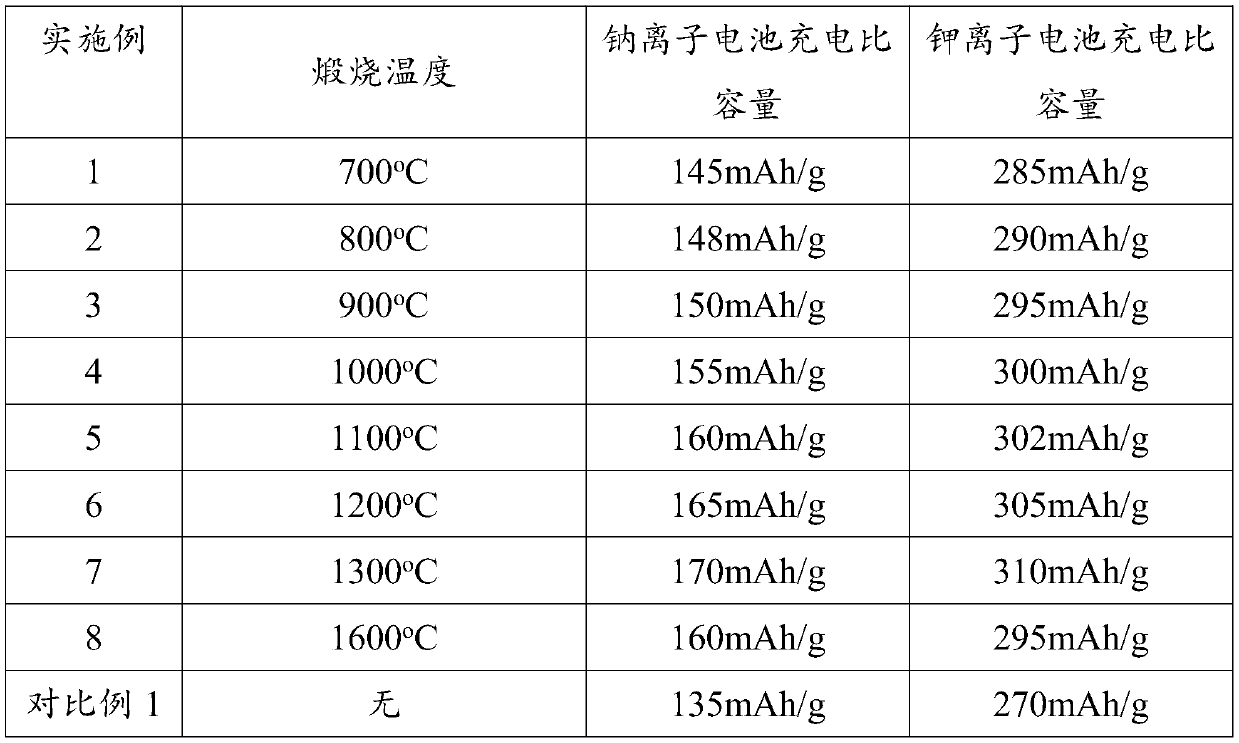

Recycling method of negative electrode material of waste lithium ion battery

ActiveCN109742475ASimple stepsRealize secondary useCarbon compoundsCell electrodesElectrical batteryGraphite

The invention provides a recycling method of negative electrode material of a waste lithium ion battery, and belongs to the technical field of new battery systems. The recycling method comprises the following steps: disassembling and recycling the negative electrode material of the waste lithium ion battery; after that, washing, drying and calcining the negative electrode material to obtain recycled graphite; and taking the recycled graphite as the negative electrode material, and applying the recycled graphite to a sodium ion battery and a potassium ion battery, so as to realize secondary utilization of the recycled graphite. The recycling method provided by the invention has simple steps, saves resources, and the recycled graphite shows superior electrochemical performance. The result ofthe embodiment of the invention shows that the recycled graphite is applied to the sodium ion battery and the potassium ion battery, after that, the sodium ion battery and the potassium ion battery are high in charging specific capacity and good in cycle performance.

Owner:NORTHEAST NORMAL UNIVERSITY

Castable for ladle collector nozzle adopting corundum collector nozzle reclaimed material as aggregate and preparation method of castable

InactiveCN103613398AReduce waste of resourcesImprove utilizationWater resource protectionMicrometerConstruction aggregate

The invention discloses castable for a ladle collector nozzle adopting a corundum collector nozzle reclaimed material as aggregate. The castable is characterized by being prepared from the following raw materials in percentage by weight: 60 to 70 percent of acid-pickled corundum collector nozzle reclaimed material, 10 to 15 percent of corundum fine powder, 10 to 18 percent of corundum micro powder, 5 to 8 percent of binding agent and 0.1 to 1 percent of dispersion agent. The preparation method comprises the following steps: recovering the corundum collector nozzle from a steel factory, and packaging the corundum collector nozzle reclaimed material for standby use after the treatment of the sorting, iron removing, crushing and acid pickling process; weighing the raw materials according to the weight percentage; uniformly mixing the weighed materials, and uniformly mixing the materials with water; pouring the mixture into a designed ladle collector nozzle mold, and vibrating, pouring, drying and molding the castable. The corundum fine powder adopts the mixture of plate-type sintered corundum fine powder with the granularity of 20 to 45 micrometers and the granularity of 0 to 20 micrometers, and the mixing ratio is optimized, so that not only can the mobility of the castable be improved, but also the gap of the castable can be effectively filled, the dense of the castable can be enhanced, and the strength is remarkably improved.

Owner:WUHAN IRON & STEEL (GROUP) CORP

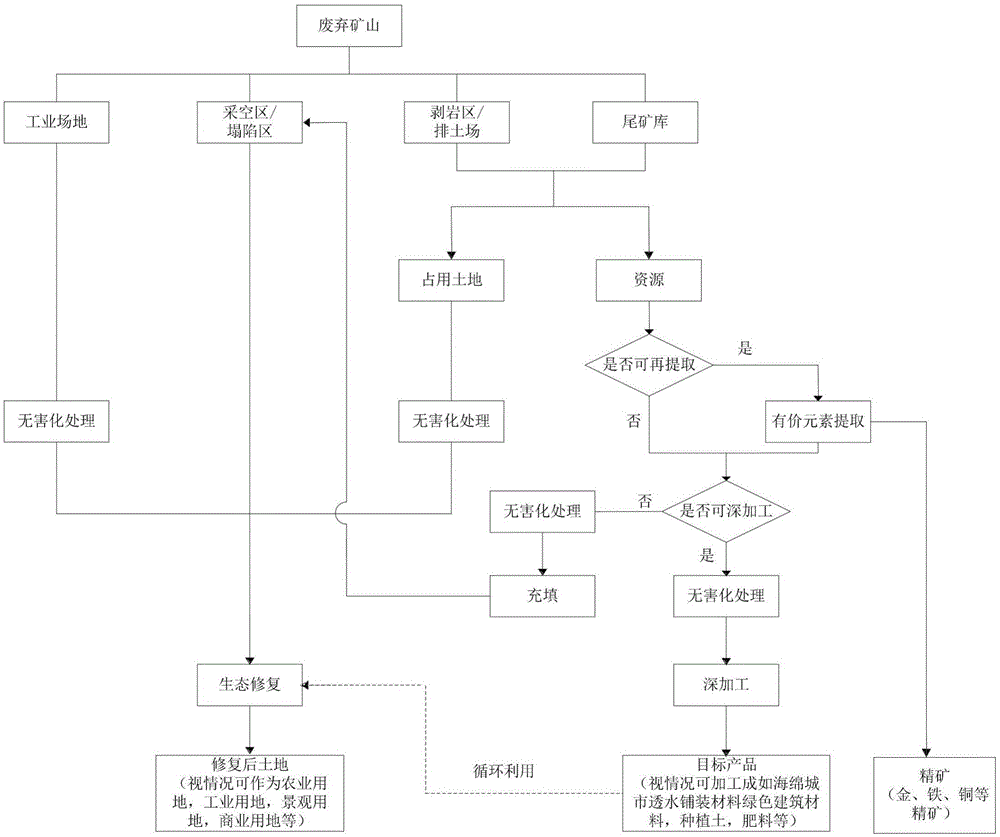

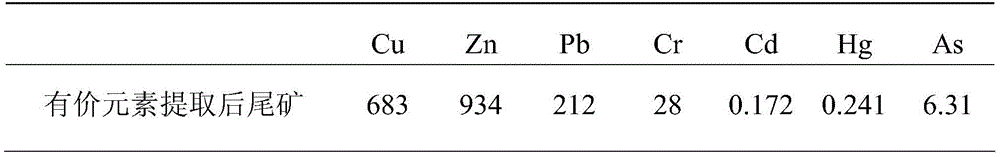

Resource mine repairing method

ActiveCN105598143AEliminate heavy metal and chemical pollutionEliminate potential safety hazardsContaminated soil reclamationIndustrial siteSubsidence

The invention provides a resource mine repairing method. The method comprises the steps that a tailing resource in a tailing pond and / or a mineral resource of a rock stripping area or a dumping site are subjected to valuable element extraction; if tailings produced from the valuable element extraction procedure of the tailing resource and / or the mineral resource without the extracting value are suitable for deep processing, deep processing is conducted, and a target product is obtained; if the tailings are not suitable for deep processing, and a goaf or a subsidence area is filled with the tailings; harmless processing is conducted on occupied land of the rock stripping area or the dumping site and / or an industrial site; ecological restoration is conducted on the occupied land of the rock stripping area or the dumping site and / or the industrial site which is subjected to harmless processing and the goaf or the subsidence area subjected to filling. According to the resource mine repairing method, maximization of repaired land value is achieved, tailing-free, harm-free, hidden danger-free and all green repairing effects of a mine are achieved, the processing cost is low, and the economic benefit is good.

Owner:DALIAN DEETOP ENVIRONMENTAL TECH CO LTD

DC energy storage backup power supply with peak-clipping and valley-filling function and control method thereof

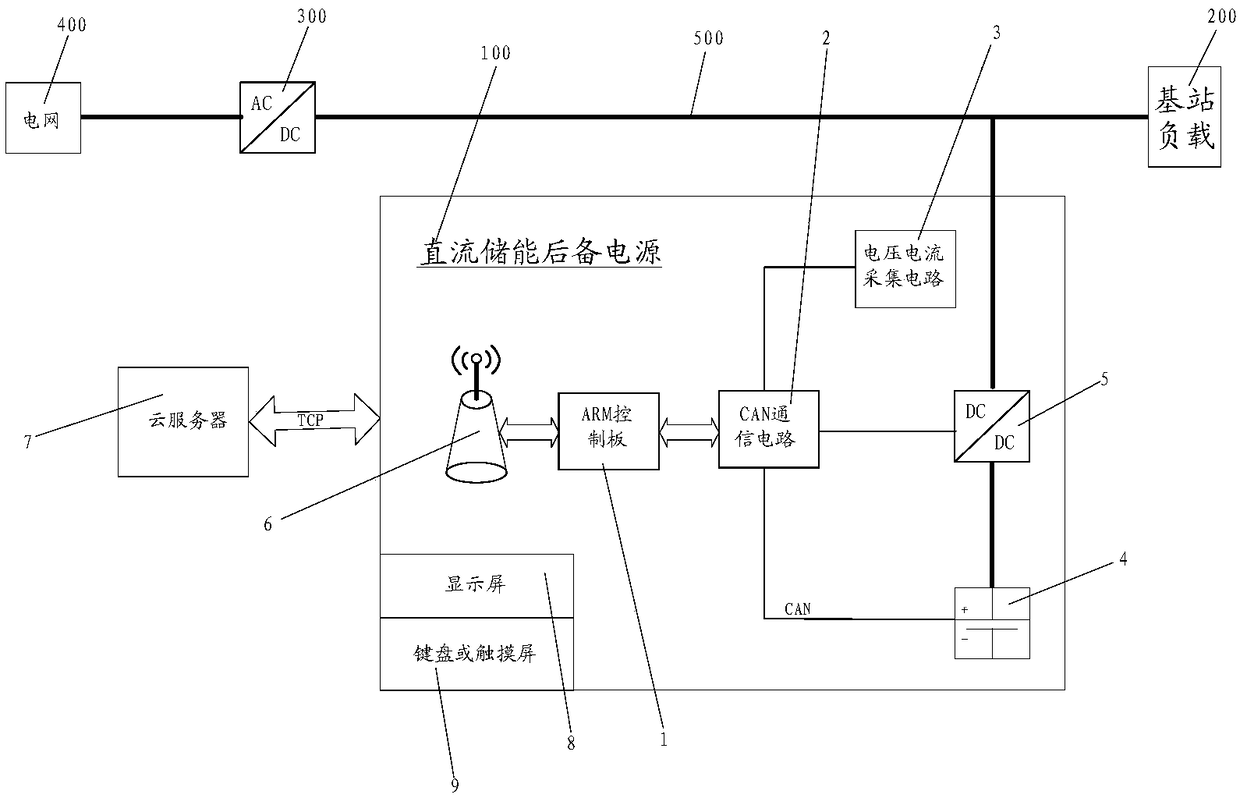

PendingCN109245085AReduce power consumptionReduce loadElectrical storage systemLoad balancing in dc networkDc dc converterPower grid

The invention provides a DC energy storage backup power supply witha peak clipping and valley filling function, which comprises a control main board, a CAN communication circuit, a voltage and currentacquisition circuit, a battery, a DC-DC converter, a DTU communication module and a cloud server; The control motherboard is connected with the cloud server through the DTU communication module; Thevoltage and current collecting circuit, the battery and the DC-DC converter are connected with that control motherboard through the CAN communication circuit; The battery and the DC-DC converter are connected, and that DC-DC convert is connected with a base station load. The invention also provides a control method of the DC energy storage backup power supply witha peak clipping and valley fillingfunction. The invention can greatly lighten the load of the power network in the period of the peak power price, and can create enormous economic value by utilizing the difference between the peak power price and the valley power price.

Owner:FUJIAN NEBULA ELECTRONICS CO LTD

Method for carrying out secondary equipment whole life cycle management by electronic label

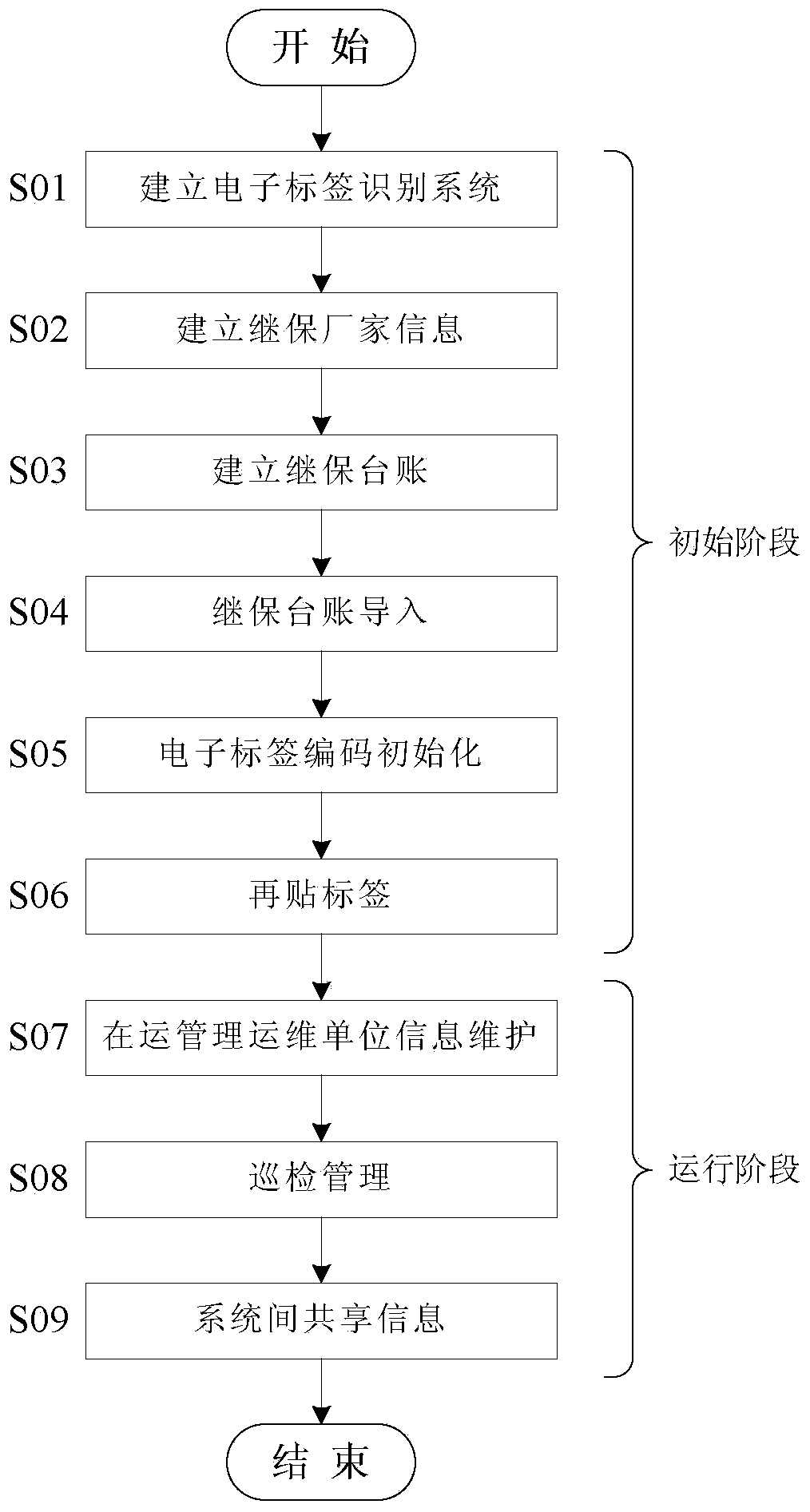

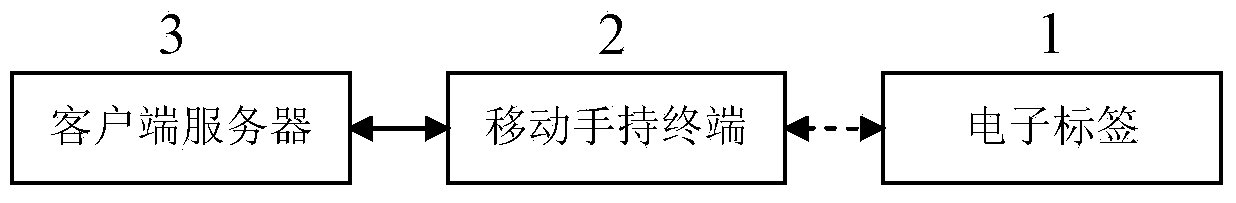

InactiveCN104182828AAccurate collectionImprove the level of standardizationCo-operative working arrangementsResourcesElectronic taggingManagement system

The invention provides a method for carrying out secondary equipment whole life cycle management by an electronic label. The method comprises the following stages of: building an electronic label recognition system; building relay protection factory information; building a relay protection standing book; importing the relay protection standing book; initializing electronic label codes; pasting labels; carrying out operation maintenance information maintenance an in operation maintenance management unit; carrying out patrol and examination management; and sharing information among systems, and the like. The method for carrying out the secondary equipment whole life cycle management by the electronic label provided by the invention has the advantages that the unified management of the standing book-card-object standing book and operation and transformation information of relay protection equipment is realized through building a relay protection equipment management system on the basis of RFID (Radio Frequency Identification) label unique marks; the information fine management to equipment plug-ins is realized; and the effective management of the whole life cycle including equipment installation, commissioning, operation and maintenance, unusual action and return is realized.

Owner:STATE GRID CORP OF CHINA +1

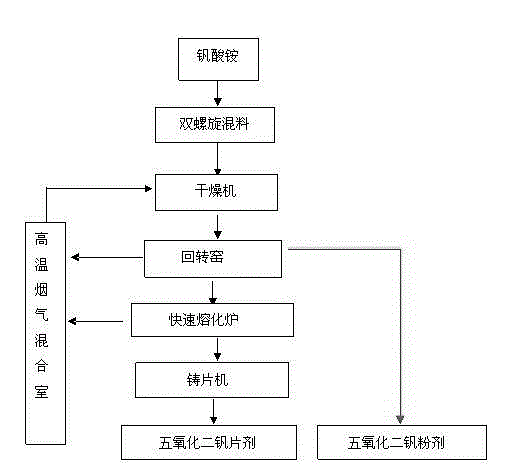

Production method and production system for vanadium pentoxide

The invention discloses a production method and a production system for vanadium pentoxide. The production method comprises the following steps of breaking industrial ammonium vanadate filter cakes and then continuously adding the industrial ammonium vanadate filter cakes into drying equipment and drying by using high-temperature gas; enabling the dried ammonium vanadate to enter calcinating equipment for deaminizing oxidation to obtain mixer of powder vanadium pentoxide or vanadium oxide; and enabling the mixer of the powder vanadium pentoxide or vanadium oxide to enter melting equipment for melting and casting pieces to obtain flaky vanadium pentoxide. According to the production method, drying for dehydration, calcinating for deaminizing and melting and piece casing processes of ammonium polyvanadate or ammonium metavanadate are respectively operated in three sets of equipment; the temperature, the furnace charge stay time and oxidation supply atmosphere (hot air) can be effectively controlled according to different function phases of drying, deaminizing and oxidizing and optimal conditions, and thus each function phase is operated under the optimal condition and further stability, high quality and high yield are achieved. The production method can be used for producing flaky and powder vanadium pentoxide and the yield of metal vanadium is respectively greater than 99 percent.

Owner:HEBEI IRON AND STEEL

3004 aluminum foil and preparing method and application thereof

The invention discloses 3004 aluminum foil and a preparing method and application thereof. The aluminum foil comprises chemical elements: by mass, 0.15-0.25% of Si, smaller than or equal to 0.55% of Fe, 0.14-0.2% of Cu, 1.02-1.15% of Mn, 0.95-1.1% of Mg, smaller than or equal to 0.05% of Cr, smaller than or equal to 0.15% of Zn, 0.015-0.025% of Ti, smaller than 0.1% of other chemical elements andthe balance Al. The 3004 aluminum foil is obtained by performing 3004 aluminum alloy smelting, refining, standing, online degassing and deslagging, casting, face-milling, uniform heating treatment, hot rolling, cold rolling, intermediate annealing, cold foil rolling and finished product annealing. With the combination of the various elements and the preparing process, the prepared aluminum foil has high strength and toughness, the thickness is greatly reduced when the aluminum foil is used as a container, use is convenient, and the consumption of the raw materials is reduced; and waste ring-pull cans can be adopted as a raw material, the consumption of the raw material is reduced, resources are reutilized, the source of the raw materials for preparing the aluminum foil is widened, meanwhile the burdens on the environment are avoided, the production cost is reduced, and the 3004 aluminum foil has quite good social economic benefits.

Owner:河南明泰科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com