Method for comprehensively utilizing reverse-flotation phosphorite tailings

A phosphate mine tailings and reverse flotation technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of secondary pollution, consumption of large water resources, and ineffective utilization, achieving mild conditions and solving problems. The effect of occupying land resources and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

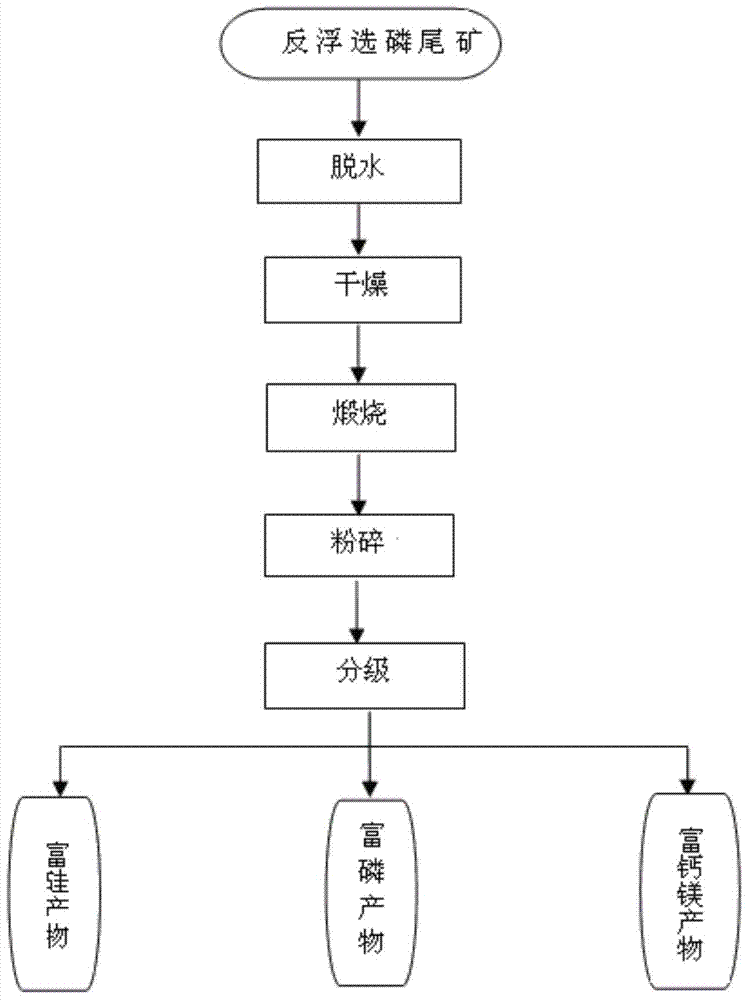

[0029] refer to figure 1 The process flow chart of the above-mentioned reverse flotation phosphate rock tailings is selected. In view of the above-mentioned characteristics of the reverse flotation phosphate rock tailings, the slurry containing the reverse flotation phosphate rock tailings is first formed into a mud cake by means of suction filtration or pressure filtration. , and then the mud cake is dried, and various known drying methods are available. In this embodiment, the mud cake after pressure filtration is selected to be dried at 105 ° C until the moisture content is lower than 2%. After drying, the dried Phosphorus tailings are calcined, the calcining temperature is 800°C, and the calcining time is 1 hour. Of course, it is not necessary to dry the back-selected phosphate rock tailings by adopting a method such as a wet rotary kiln for calcination. The calcination process is mainly for the decomposition of dolomite in phosphorus tailings, so the calcination temperat...

Embodiment 2

[0032] This example is basically the same as Example 1, except that the calcination temperature is 900°C.

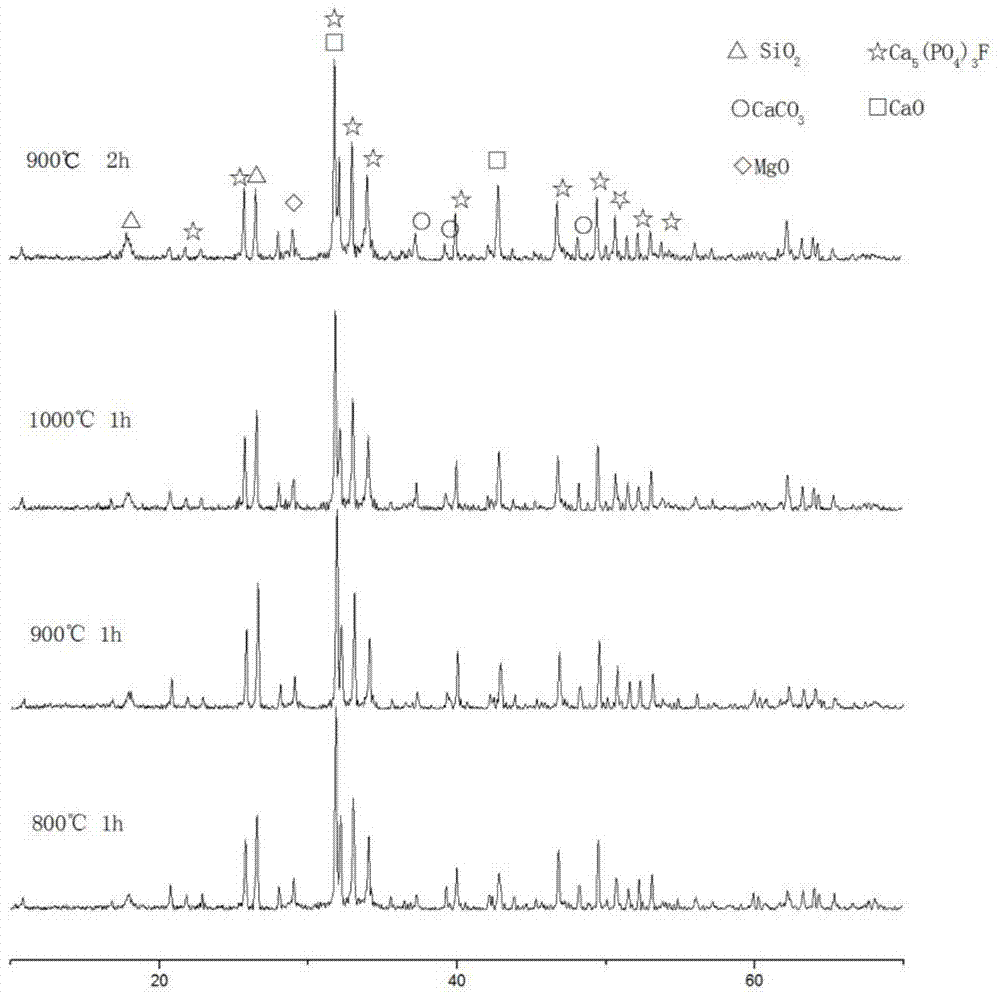

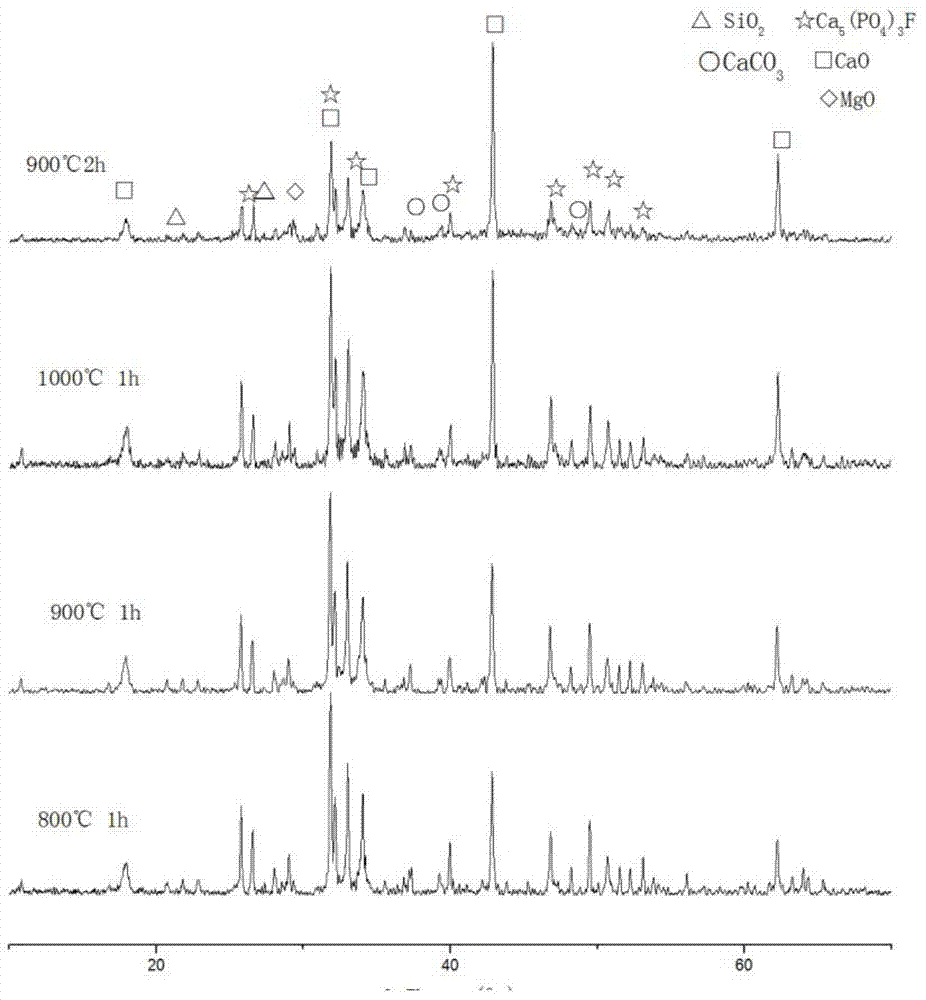

[0033] In order to verify the effectiveness of this method, we tested the graded materials through X-ray diffraction (XRD) analysis, figure 2 The spectrum corresponding to "900, 1h" °C in the middle is the X-ray diffraction spectrum of the phosphorus-rich product in this example, and the apatite is converted into P 2 o 5 , P 2 o 5 Accounting for 30.15% of the total mass of phosphorus-rich products; image 3 The map corresponding to "900, 1h" °C in the middle is the X-ray diffraction pattern of the calcium-magnesium-rich product in this example, and the mass fraction of calcium oxide and magnesium oxide in the calcium-magnesium-rich product is 24.4% after conversion; Figure 4 The spectrum corresponding to "900,1h" °C in the middle is the X-ray diffraction spectrum of the silicon-rich product in this example, and the mass fraction of silicon oxide in the silicon-rich...

Embodiment 3

[0035] This example is basically the same as Example 1, except that the calcination temperature is 1000°C.

[0036] In order to verify the effectiveness of this method, we tested the graded materials through X-ray diffraction (XRD) analysis, figure 2 The spectrum corresponding to "1000°C, 1h" in "1000°C, 1h" is the X-ray diffraction spectrum of the phosphorus-rich product in this example, where apatite is converted into P 2 o 5 , P 2 o 5 Accounting for 31.44% of the total mass of phosphorus-rich products; image 3The spectrum corresponding to "1000°C, 1h" in "1000°C, 1h" is the X-ray diffraction spectrum of the calcium-magnesium-enriched product of this example, and the mass fraction of calcium oxide and magnesium oxide in the calcium-magnesium-enriched product is converted to 25.2%; Figure 4 The pattern corresponding to "1000°C, 1h" in the middle is the X-ray diffraction pattern of the silicon-rich product in this embodiment, and the mass fraction of silicon oxide in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com