Production method and production system for vanadium pentoxide

A vanadium pentoxide and production method technology, which is applied in the direction of vanadium oxide, etc., can solve the problems of lower qualified rate and vanadium recovery rate, no deammonization and ammonia recovery device, high melting temperature, etc., so as to improve the vanadium yield and realize large-scale Industrialized production, fast melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

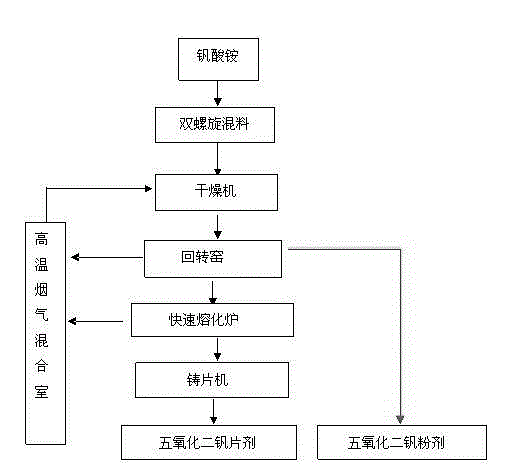

Image

Examples

Embodiment 1

[0024] Embodiment 1: the production method of vanadium pentoxide adopts following processing steps.

[0025] Ammonium polyvanadate with a water content of about 25wt% is measured by a belt scale, and the bulk material is crushed by a double-screw mixer and put into a flash dryer for drying. The drying heat source comes from the heating flue gas of the calcination deamination system and the melting equipment. The mixed gas of high-temperature exhaust gas, the drying temperature is 100-150°C, and the water content of the material is 0.50wt% by sampling at the outlet. Dried ammonium vanadate is put into the calcination deamination system, and calcined for 3 hours at a temperature of 300-360°C and a pressure of -20--30Pa to obtain a mixture of vanadium oxides, the composition of which is: V 2 o 5 : 98.68wt%, V 2 o 4 : 1.97wt%, K 2 O+Na 2 O: 0.49wt%, meeting the requirements of the YB / T5304-2006 standard, is powdery vanadium pentoxide. The obtained powdery vanadium pentoxide ...

Embodiment 2

[0026] Embodiment 2: the production method of vanadium pentoxide adopts following process steps.

[0027] Ammonium metavanadate with a water content of about 50wt% is measured by a belt scale, and the bulk material is crushed by a double-screw mixer and put into a disc dryer for countercurrent drying. The drying heat source comes from the heating flue gas of the calcination deamination system and the melting equipment The mixed gas of the high-temperature exhaust gas, the drying temperature is 200-250 °C, and the water content of the material is 0.35wt% when the material is sampled at the outlet. Dried ammonium vanadate is put into the calcining deamination system, and calcined for 4 hours at a temperature of 430-490°C and a pressure of -10--15pa to obtain a mixture of vanadium oxides, the composition of which is: V 2 o 5 : 99.25wt%; V 2 o 4 : 6.28wt%; K 2 O+Na 2 O: 0.56wt%, continue to put it into the rapid melting casting equipment, heat the converter gas to 710-750 ℃, ...

Embodiment 3

[0028] Embodiment 3: the production method of vanadium pentoxide adopts following process steps.

[0029] Ammonium polyvanadate with a water content of about 35wt% is measured by a belt scale, and the bulk material is crushed by a double-screw mixer and put into a flash dryer for countercurrent drying. The drying heat source comes from the heating flue gas of the calcination deamination system and the melting equipment The mixed gas of high-temperature exhaust gas, the temperature of the drying heat source is 150-200°C, and the water content of the material tested at the outlet is 0.42wt%. Dried ammonium vanadate is put into the calcining deamination system, and calcined for 2 hours at a temperature of 580-650°C and a pressure of -15--20pa to obtain a mixture of vanadium oxides, the composition of which is: V 2 o 5 : 98.87wt%; V 2 o 4 : 2.36wt%; K 2 O+Na 2 O: 0.51wt%, meeting the requirements of the YB / T5304-2006 standard, is powdery vanadium pentoxide. The obtained powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com